sensor NISSAN PICK-UP 2001 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 753 of 1306

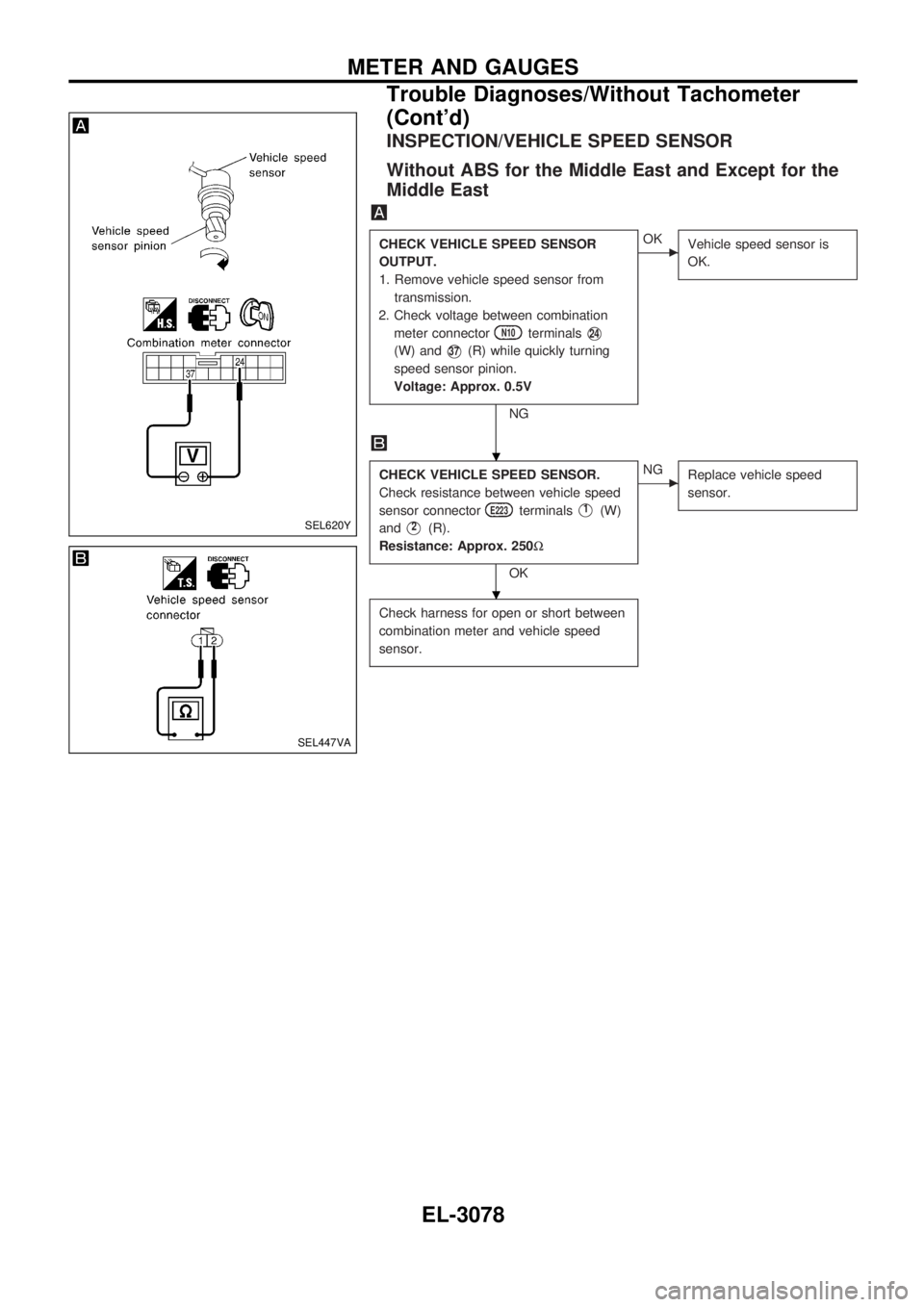

INSPECTION/VEHICLE SPEED SENSOR

Without ABS for the Middle East and Except for the

Middle East

CHECK VEHICLE SPEED SENSOR

OUTPUT.

1. Remove vehicle speed sensor from

transmission.

2. Check voltage between combination

meter connector

N10terminalsV24

(W) andV37(R) while quickly turning

speed sensor pinion.

Voltage: Approx. 0.5V

NG

cOK

Vehicle speed sensor is

OK.

CHECK VEHICLE SPEED SENSOR.

Check resistance between vehicle speed

sensor connector

E223terminalsV1(W)

and

V2(R).

Resistance: Approx. 250W

OK

cNG

Replace vehicle speed

sensor.

Check harness for open or short between

combination meter and vehicle speed

sensor.

SEL620Y

SEL447VA

.

.

METER AND GAUGES

Trouble Diagnoses/Without Tachometer

(Cont'd)

EL-3078

Page 754 of 1306

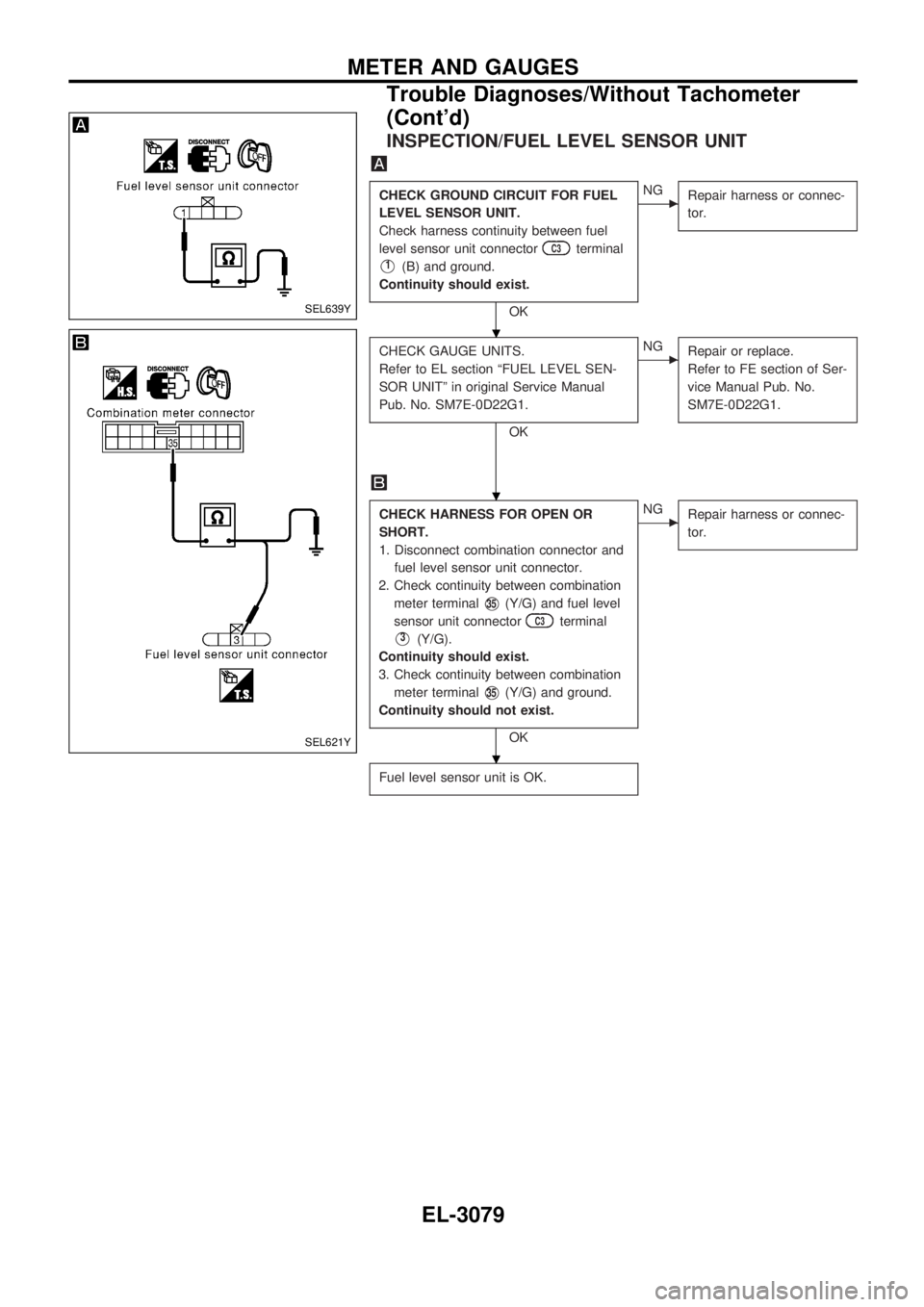

INSPECTION/FUEL LEVEL SENSOR UNIT

CHECK GROUND CIRCUIT FOR FUEL

LEVEL SENSOR UNIT.

Check harness continuity between fuel

level sensor unit connector

C3terminal

V1(B) and ground.

Continuity should exist.

OK

cNG

Repair harness or connec-

tor.

CHECK GAUGE UNITS.

Refer to EL section ªFUEL LEVEL SEN-

SOR UNITº in original Service Manual

Pub. No. SM7E-0D22G1.

OK

cNG

Repair or replace.

Refer to FE section of Ser-

vice Manual Pub. No.

SM7E-0D22G1.

CHECK HARNESS FOR OPEN OR

SHORT.

1. Disconnect combination connector and

fuel level sensor unit connector.

2. Check continuity between combination

meter terminal

V35(Y/G) and fuel level

sensor unit connector

C3terminal

V3(Y/G).

Continuity should exist.

3. Check continuity between combination

meter terminal

V35(Y/G) and ground.

Continuity should not exist.

OK

cNG

Repair harness or connec-

tor.

Fuel level sensor unit is OK.

SEL639Y

SEL621Y

.

.

.

METER AND GAUGES

Trouble Diagnoses/Without Tachometer

(Cont'd)

EL-3079

Page 810 of 1306

System Description

FUNCTION

Multi-remote control system has the following function.

+Door lock

+Door unlock

+Hazard reminder

LOCK OPERATION

When the LOCK signal is input to multi-remote control unit (the antenna of the system is combined with

multi-remote control unit), ground is supplied

+through multi-remote control unit terminal

V5

+to smart entrance control unit terminalV4.

Then smart entrance control unit supplies power and ground to each door lock actuator.

UNLOCK OPERATION

When the UNLOCK signal is input to multi-remote control unit (the antenna of the system is combined with

multi-remote control unit), ground is supplied

+through multi-remote control unit terminal

V6

+to smart entrance control unit terminalV5.

Then smart entrance control unit supplies power and ground to each door lock actuator.

HAZARD REMINDER

When the doors are locked or unlocked (signal from driver's door unlock sensor) by multi-remote controller,

power is supplied

+through multi-remote control unit terminals

V3andV8

+to the hazard warning lamps

Then hazard warning lamp flash as follows.

+Lock operation: Flash once

+Unlock operation: Flash twice

MULTI-REMOTE CONTROLLER ID CODE ENTRY

A maximum of four remote controllers can be entered. Any attempt to enter a remote controller will erase

all ID codes previously entered. Therefore, be sure to receive all remote controllers from the vehicle owner

when any ID code entry is performed.

To enter ID code entry, the following signals must be input to the multi-remote control unit.

+Ignition switch ON signal

+Battery power supply

+Signal from remote controller

For detailed procedure, refer to ªID Code Entry Procedureº in EL-3139.

MULTI-REMOTE CONTROL SYSTEM

EL-3135

Page 812 of 1306

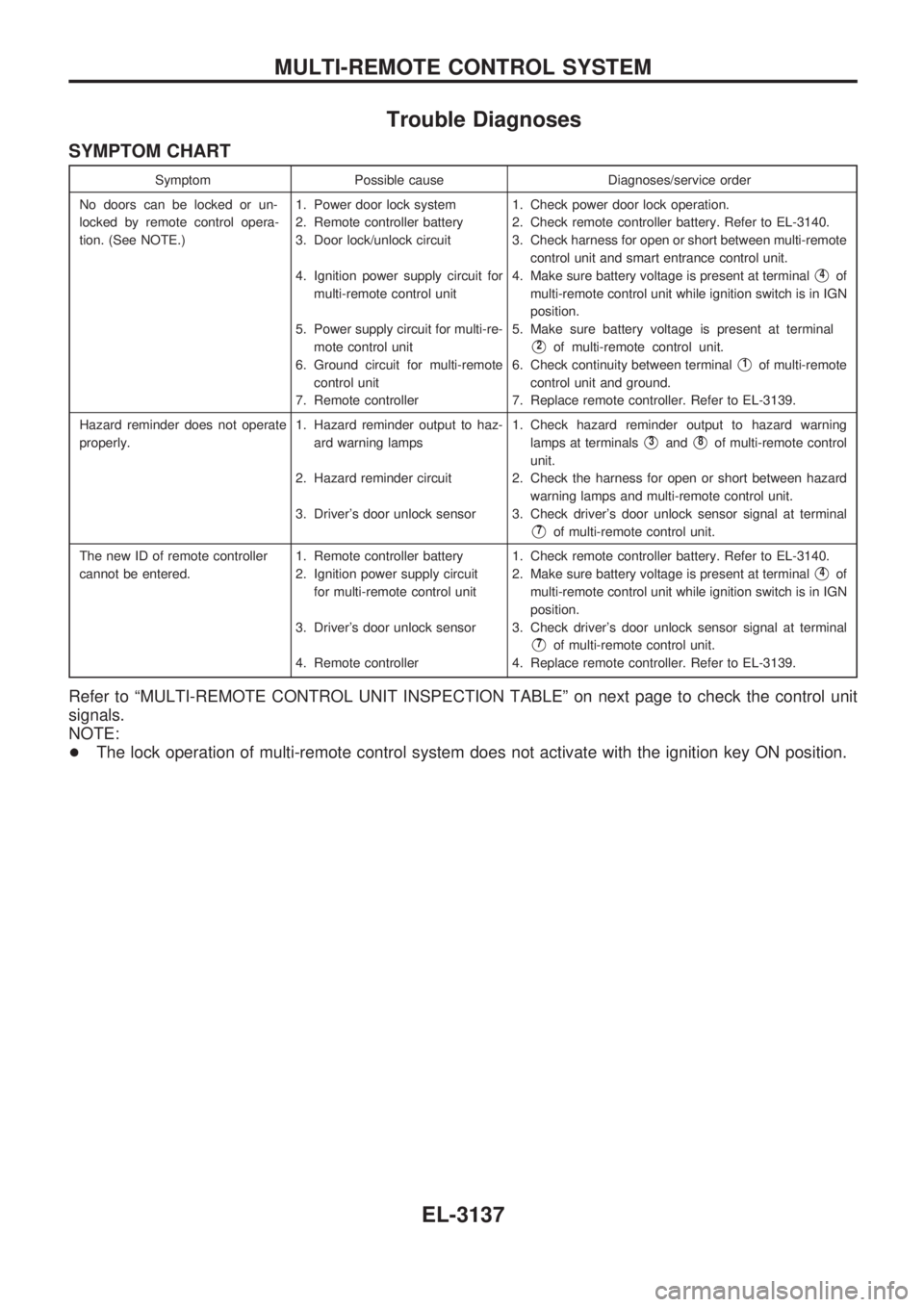

Trouble Diagnoses

SYMPTOM CHART

Symptom Possible cause Diagnoses/service order

No doors can be locked or un-

locked by remote control opera-

tion. (See NOTE.)1. Power door lock system

2. Remote controller battery

3. Door lock/unlock circuit

4. Ignition power supply circuit for

multi-remote control unit

5. Power supply circuit for multi-re-

mote control unit

6. Ground circuit for multi-remote

control unit

7. Remote controller1. Check power door lock operation.

2. Check remote controller battery. Refer to EL-3140.

3. Check harness for open or short between multi-remote

control unit and smart entrance control unit.

4. Make sure battery voltage is present at terminal

V4of

multi-remote control unit while ignition switch is in IGN

position.

5. Make sure battery voltage is present at terminal

V2of multi-remote control unit.

6. Check continuity between terminal

V1of multi-remote

control unit and ground.

7. Replace remote controller. Refer to EL-3139.

Hazard reminder does not operate

properly.1. Hazard reminder output to haz-

ard warning lamps

2. Hazard reminder circuit

3. Driver's door unlock sensor1. Check hazard reminder output to hazard warning

lamps at terminals

V3andV8of multi-remote control

unit.

2. Check the harness for open or short between hazard

warning lamps and multi-remote control unit.

3. Check driver's door unlock sensor signal at terminal

V7of multi-remote control unit.

The new ID of remote controller

cannot be entered.1. Remote controller battery

2. Ignition power supply circuit

for multi-remote control unit

3. Driver's door unlock sensor

4. Remote controller1. Check remote controller battery. Refer to EL-3140.

2. Make sure battery voltage is present at terminal

V4of

multi-remote control unit while ignition switch is in IGN

position.

3. Check driver's door unlock sensor signal at terminal

V7of multi-remote control unit.

4. Replace remote controller. Refer to EL-3139.

Refer to ªMULTI-REMOTE CONTROL UNIT INSPECTION TABLEº on next page to check the control unit

signals.

NOTE:

+The lock operation of multi-remote control system does not activate with the ignition key ON position.

MULTI-REMOTE CONTROL SYSTEM

EL-3137

Page 813 of 1306

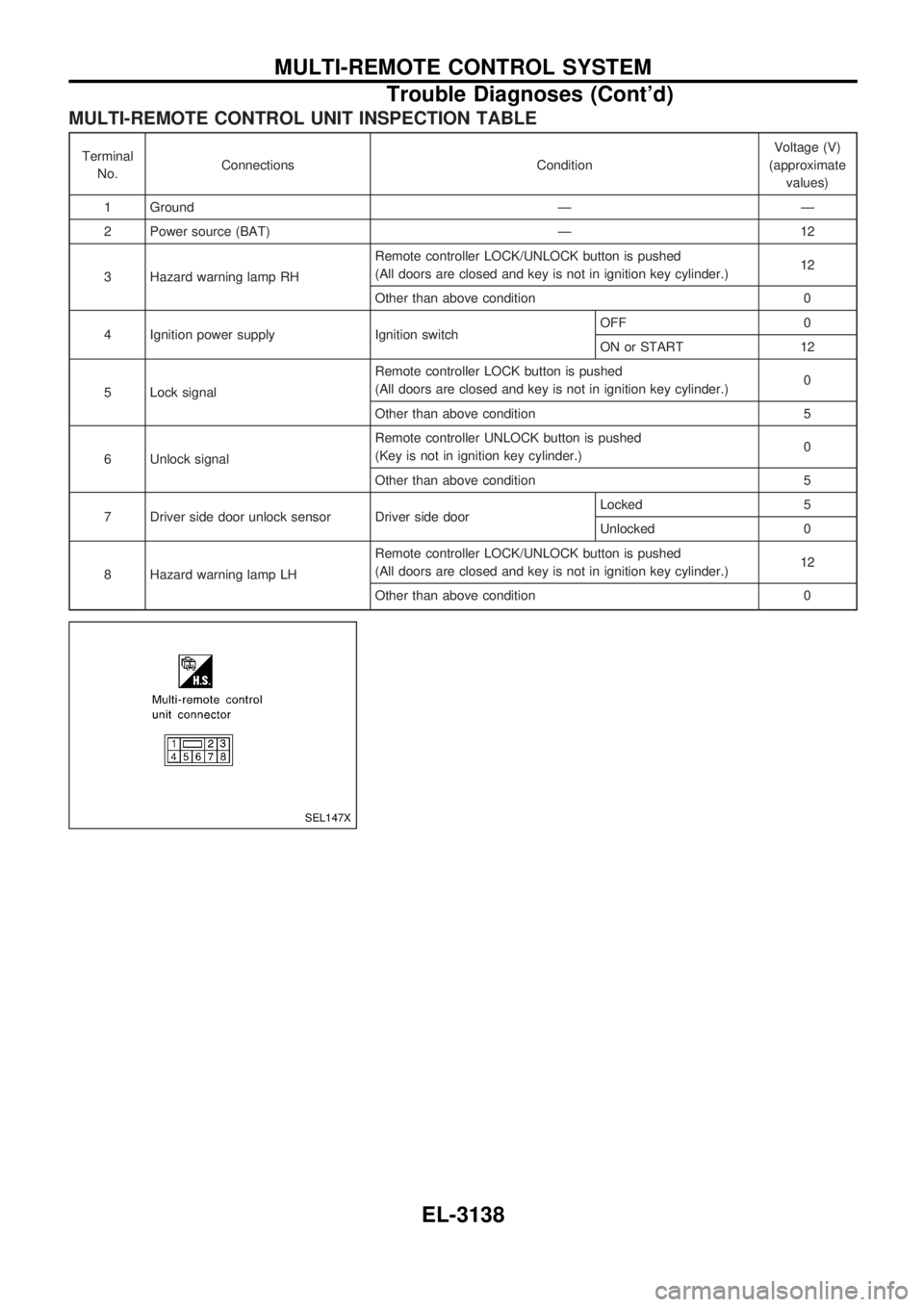

MULTI-REMOTE CONTROL UNIT INSPECTION TABLE

Terminal

No.Connections ConditionVoltage (V)

(approximate

values)

1 Ground Ð Ð

2 Power source (BAT) Ð 12

3 Hazard warning lamp RHRemote controller LOCK/UNLOCK button is pushed

(All doors are closed and key is not in ignition key cylinder.)12

Other than above condition 0

4 Ignition power supply Ignition switchOFF 0

ON or START 12

5 Lock signalRemote controller LOCK button is pushed

(All doors are closed and key is not in ignition key cylinder.)0

Other than above condition 5

6 Unlock signalRemote controller UNLOCK button is pushed

(Key is not in ignition key cylinder.)0

Other than above condition 5

7 Driver side door unlock sensor Driver side doorLocked 5

Unlocked 0

8 Hazard warning lamp LHRemote controller LOCK/UNLOCK button is pushed

(All doors are closed and key is not in ignition key cylinder.)12

Other than above condition 0

SEL147X

MULTI-REMOTE CONTROL SYSTEM

Trouble Diagnoses (Cont'd)

EL-3138

Page 869 of 1306

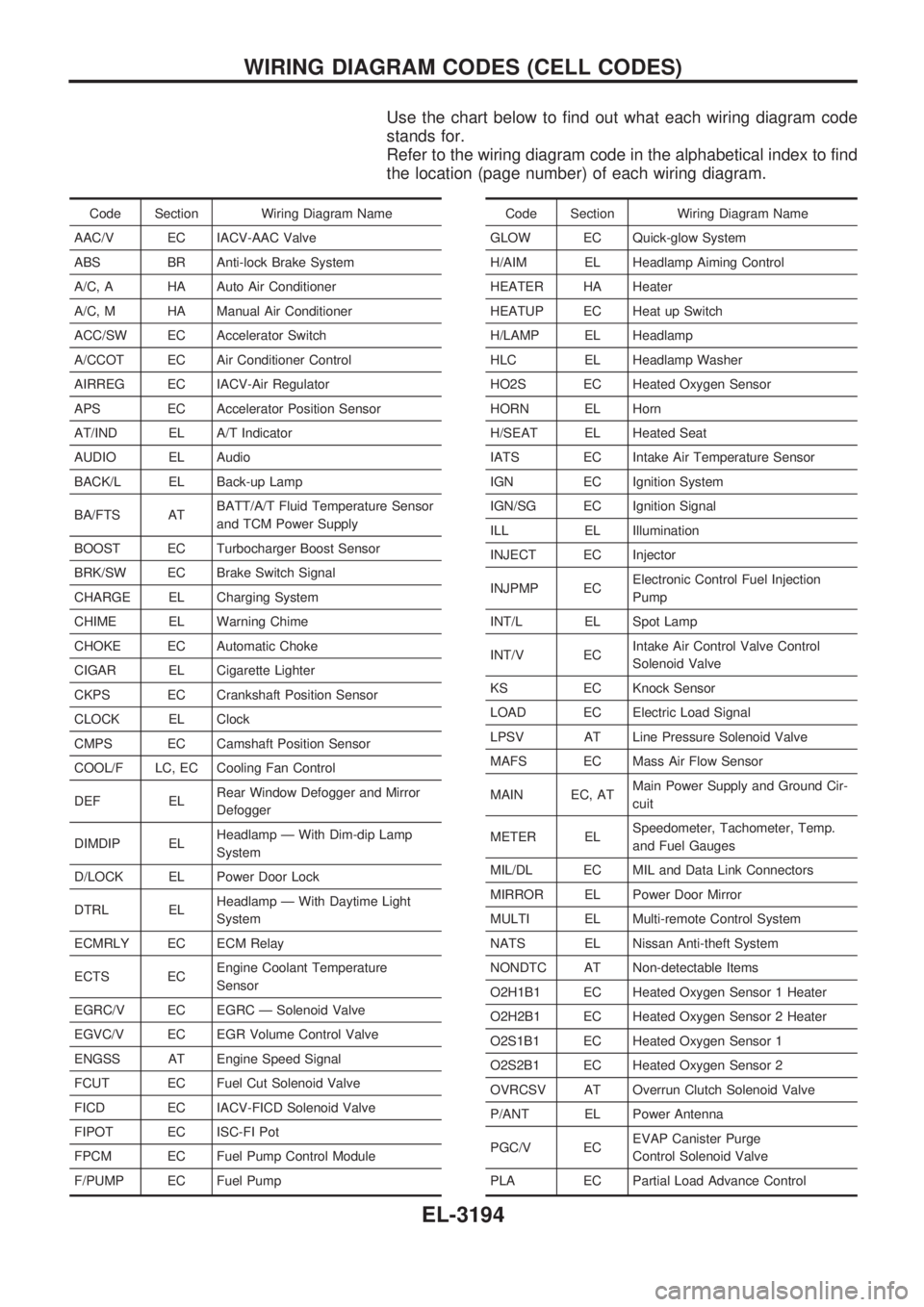

Use the chart below to find out what each wiring diagram code

stands for.

Refer to the wiring diagram code in the alphabetical index to find

the location (page number) of each wiring diagram.

Code Section Wiring Diagram Name

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

A/C, A HA Auto Air Conditioner

A/C, M HA Manual Air Conditioner

ACC/SW EC Accelerator Switch

A/CCOT EC Air Conditioner Control

AIRREG EC IACV-Air Regulator

APS EC Accelerator Position Sensor

AT/IND EL A/T Indicator

AUDIO EL Audio

BACK/L EL Back-up Lamp

BA/FTS ATBATT/A/T Fluid Temperature Sensor

and TCM Power Supply

BOOST EC Turbocharger Boost Sensor

BRK/SW EC Brake Switch Signal

CHARGE EL Charging System

CHIME EL Warning Chime

CHOKE EC Automatic Choke

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor

CLOCK EL Clock

CMPS EC Camshaft Position Sensor

COOL/F LC, EC Cooling Fan Control

DEF ELRear Window Defogger and Mirror

Defogger

DIMDIP ELHeadlamp Ð With Dim-dip Lamp

System

D/LOCK EL Power Door Lock

DTRL ELHeadlamp Ð With Daytime Light

System

ECMRLY EC ECM Relay

ECTS ECEngine Coolant Temperature

Sensor

EGRC/V EC EGRC Ð Solenoid Valve

EGVC/V EC EGR Volume Control Valve

ENGSS AT Engine Speed Signal

FCUT EC Fuel Cut Solenoid Valve

FICD EC IACV-FICD Solenoid Valve

FIPOT EC ISC-FI Pot

FPCM EC Fuel Pump Control Module

F/PUMP EC Fuel PumpCode Section Wiring Diagram Name

GLOW EC Quick-glow System

H/AIM EL Headlamp Aiming Control

HEATER HA Heater

HEATUP EC Heat up Switch

H/LAMP EL Headlamp

HLC EL Headlamp Washer

HO2S EC Heated Oxygen Sensor

HORN EL Horn

H/SEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IGN EC Ignition System

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP ECElectronic Control Fuel Injection

Pump

INT/L EL Spot Lamp

INT/V ECIntake Air Control Valve Control

Solenoid Valve

KS EC Knock Sensor

LOAD EC Electric Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN EC, ATMain Power Supply and Ground Cir-

cuit

METER ELSpeedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Power Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-theft System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

O2H2B1 EC Heated Oxygen Sensor 2 Heater

O2S1B1 EC Heated Oxygen Sensor 1

O2S2B1 EC Heated Oxygen Sensor 2

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V ECEVAP Canister Purge

Control Solenoid Valve

PLA EC Partial Load Advance Control

WIRING DIAGRAM CODES (CELL CODES)

EL-3194

Page 870 of 1306

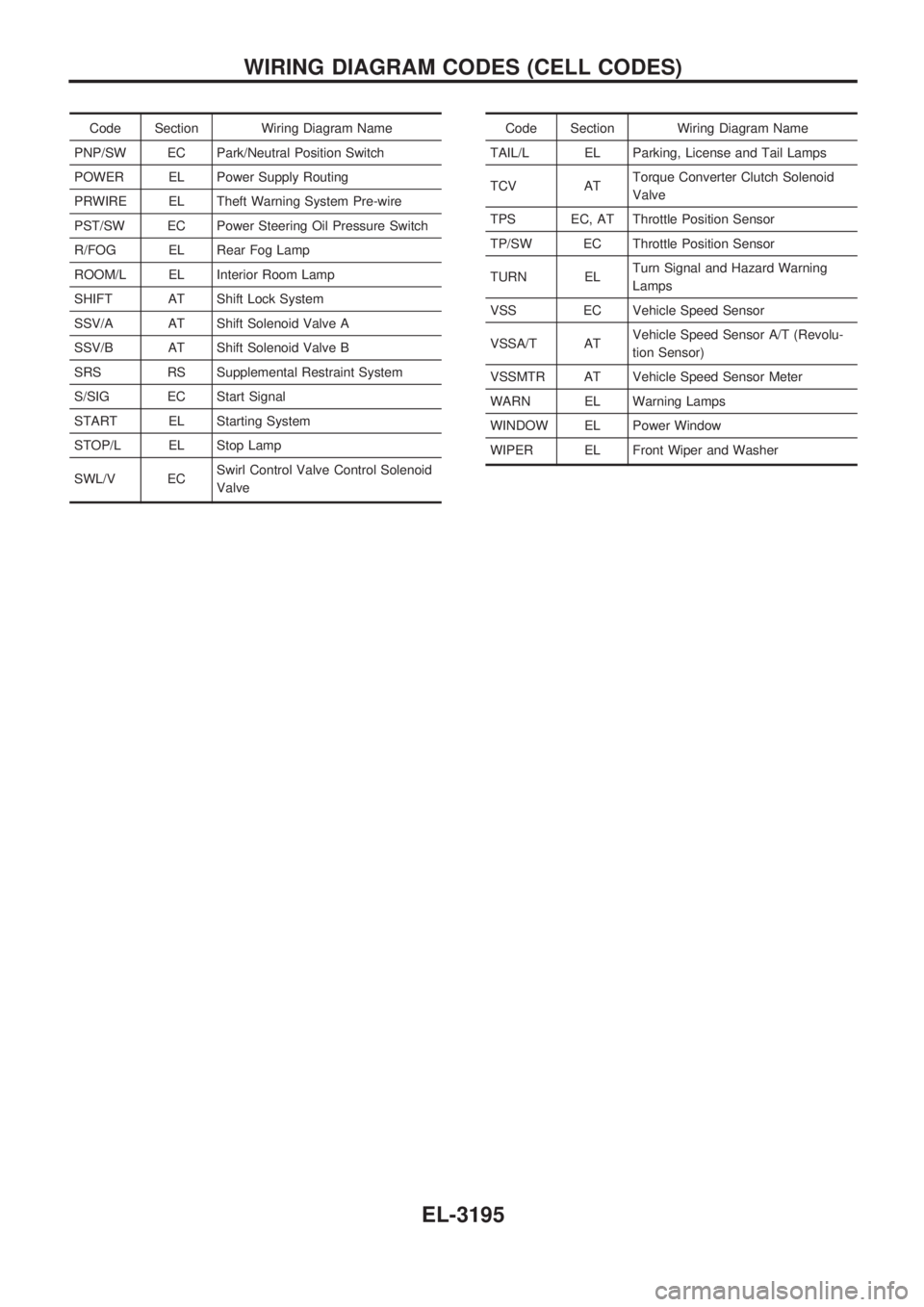

Code Section Wiring Diagram Name

PNP/SW EC Park/Neutral Position Switch

POWER EL Power Supply Routing

PRWIRE EL Theft Warning System Pre-wire

PST/SW EC Power Steering Oil Pressure Switch

R/FOG EL Rear Fog Lamp

ROOM/L EL Interior Room Lamp

SHIFT AT Shift Lock System

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

SRS RS Supplemental Restraint System

S/SIG EC Start Signal

START EL Starting System

STOP/L EL Stop Lamp

SWL/V ECSwirl Control Valve Control Solenoid

ValveCode Section Wiring Diagram Name

TAIL/L EL Parking, License and Tail Lamps

TCV ATTorque Converter Clutch Solenoid

Valve

TPS EC, AT Throttle Position Sensor

TP/SW EC Throttle Position Sensor

TURN ELTurn Signal and Hazard Warning

Lamps

VSS EC Vehicle Speed Sensor

VSSA/T ATVehicle Speed Sensor A/T (Revolu-

tion Sensor)

VSSMTR AT Vehicle Speed Sensor Meter

WARN EL Warning Lamps

WINDOW EL Power Window

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-3195

Page 872 of 1306

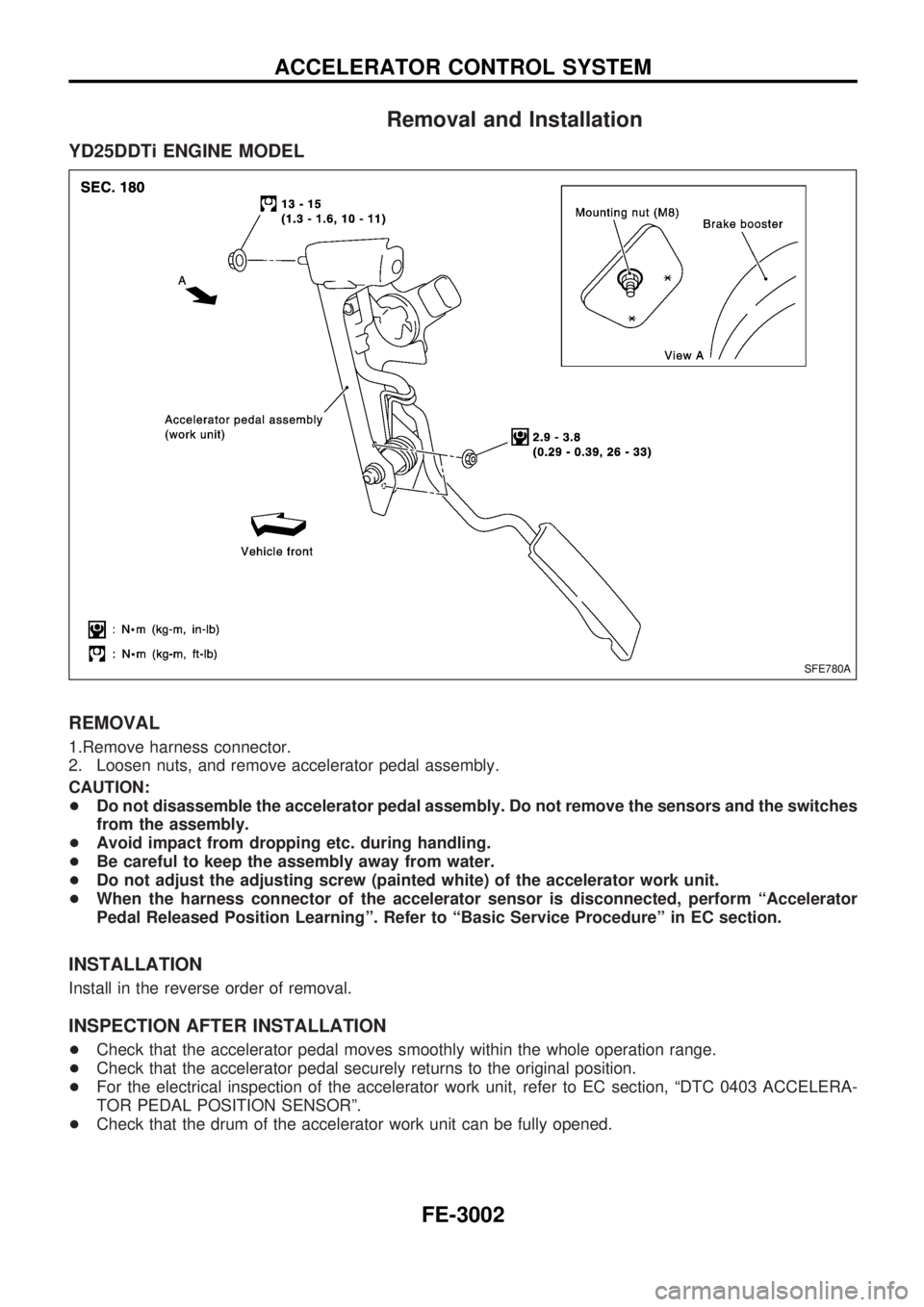

Removal and Installation

YD25DDTi ENGINE MODEL

REMOVAL

1.Remove harness connector.

2. Loosen nuts, and remove accelerator pedal assembly.

CAUTION:

+Do not disassemble the accelerator pedal assembly. Do not remove the sensors and the switches

from the assembly.

+Avoid impact from dropping etc. during handling.

+Be careful to keep the assembly away from water.

+Do not adjust the adjusting screw (painted white) of the accelerator work unit.

+When the harness connector of the accelerator sensor is disconnected, perform ªAccelerator

Pedal Released Position Learningº. Refer to ªBasic Service Procedureº in EC section.

INSTALLATION

Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

+Check that the accelerator pedal moves smoothly within the whole operation range.

+Check that the accelerator pedal securely returns to the original position.

+For the electrical inspection of the accelerator work unit, refer to EC section, ªDTC 0403 ACCELERA-

TOR PEDAL POSITION SENSORº.

+Check that the drum of the accelerator work unit can be fully opened.

SFE780A

ACCELERATOR CONTROL SYSTEM

FE-3002

Page 886 of 1306

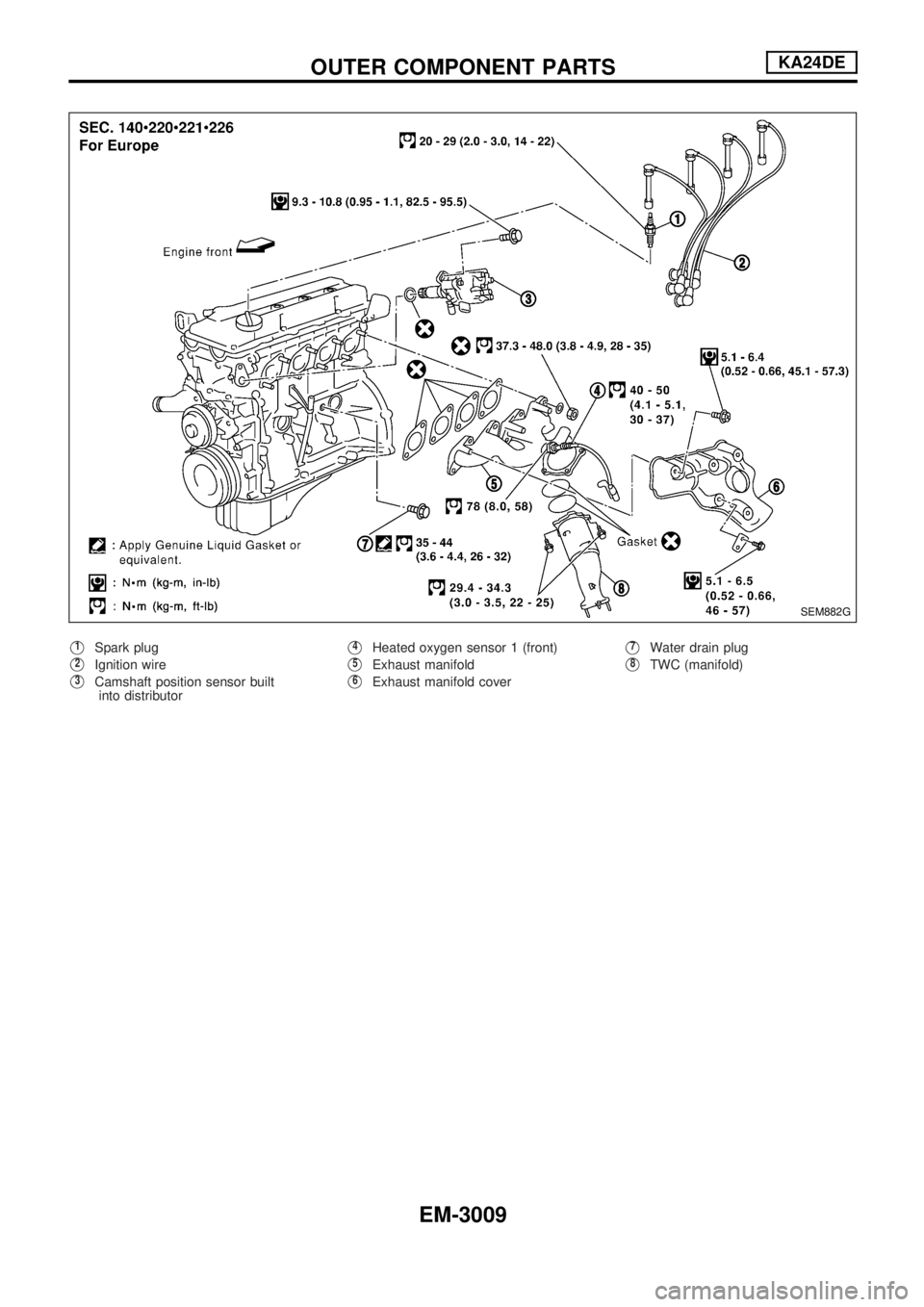

V1Spark plug

V2Ignition wire

V3Camshaft position sensor built

into distributor

V4Heated oxygen sensor 1 (front)

V5Exhaust manifold

V6Exhaust manifold cover

V7Water drain plug

V8TWC (manifold)

SEM882G

OUTER COMPONENT PARTSKA24DE

EM-3009

Page 894 of 1306

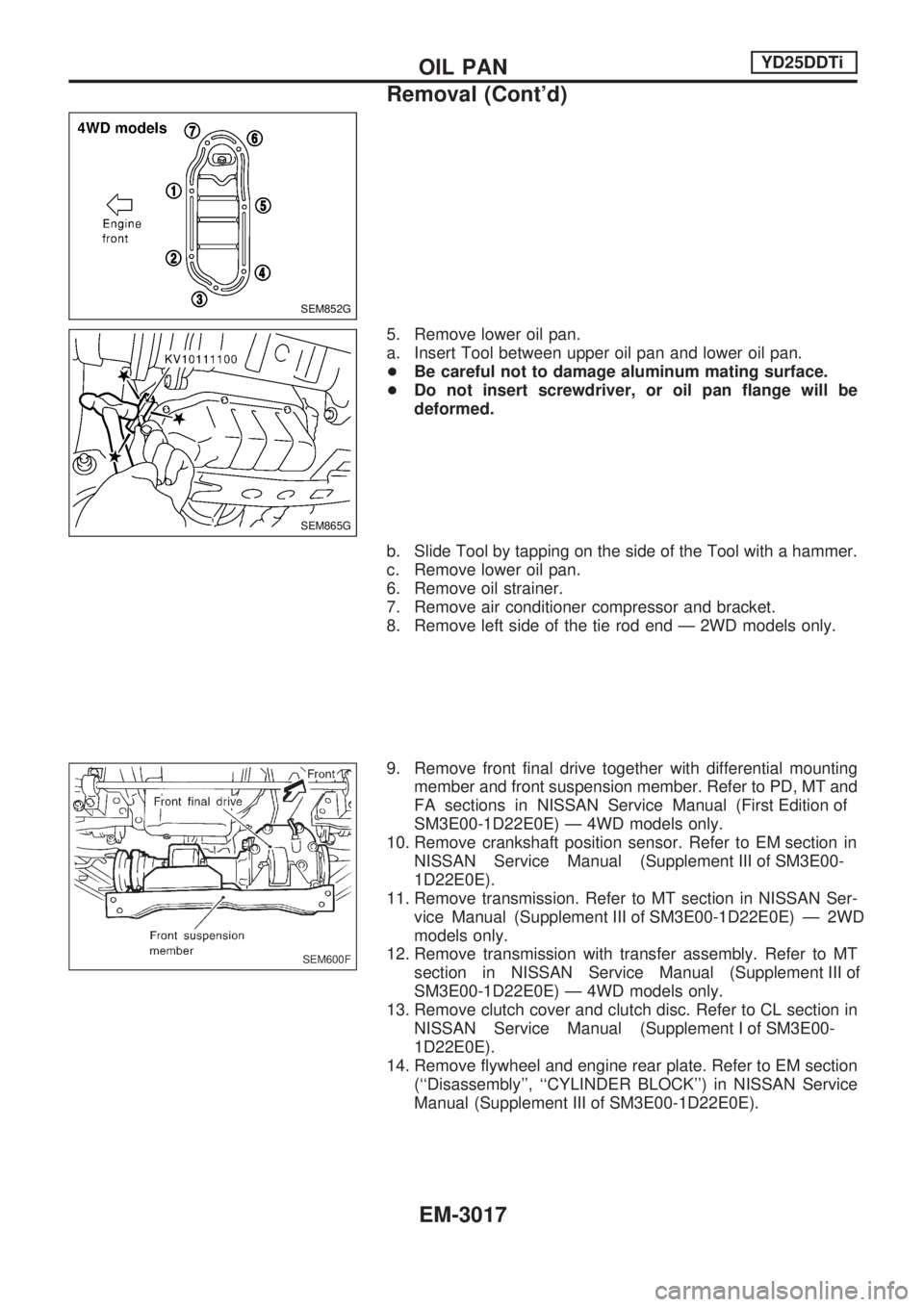

5. Remove lower oil pan.

a. Insert Tool between upper oil pan and lower oil pan.

+Be careful not to damage aluminum mating surface.

+ Do not insert screwdriver, or oil pan flange will be

deformed.

b. Slide Tool by tapping on the side of the Tool with a hammer.

c. Remove lower oil pan.

6. Remove oil strainer.

7. Remove air conditioner compressor and bracket.

8. Remove left side of the tie rod end Ð 2WD models only.

9. Remove front final drive together with differential mounting member and front suspension member. Refer to PD, MT and

FAsectionsinNISSANServiceManual(First Edition of

SM3E00-1D22E0E) Ð 4WD models only.

10.Removecrankshaftpositionsensor.RefertoEM sectionin NISSANServiceManual(Supplement III of SM3E00-

1D22E0E).

11. Remove transmission. Refer to MT section in NISSAN Ser- viceManual(Supplement III of SM3E00-1D22E0E)Ð2WD

models only.

12. Remove transmission with transfer assembly. Refer to MT sectioninNISSANServiceManual(Supplement III of

SM3E00-1D22E0E) Ð 4WD models only.

13. Remove clutch cover and clutch disc. Refer to CL section in NISSANServiceManual(Supplement I of SM3E00-

1D22E0E).

14. Remove flywheel and engine rear plate. Refer to EM section (``Disassembly'', ``CYLINDER BLOCK'') in NISSAN Service

Manual(Supplement III of SM3E00-1D22E0E).

SEM852G

SEM865G

SEM600F

OILPAN YD25DDTi

Removal (Cont'd)

EM-3017