width NISSAN PRIMERA 1999 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 824 of 2267

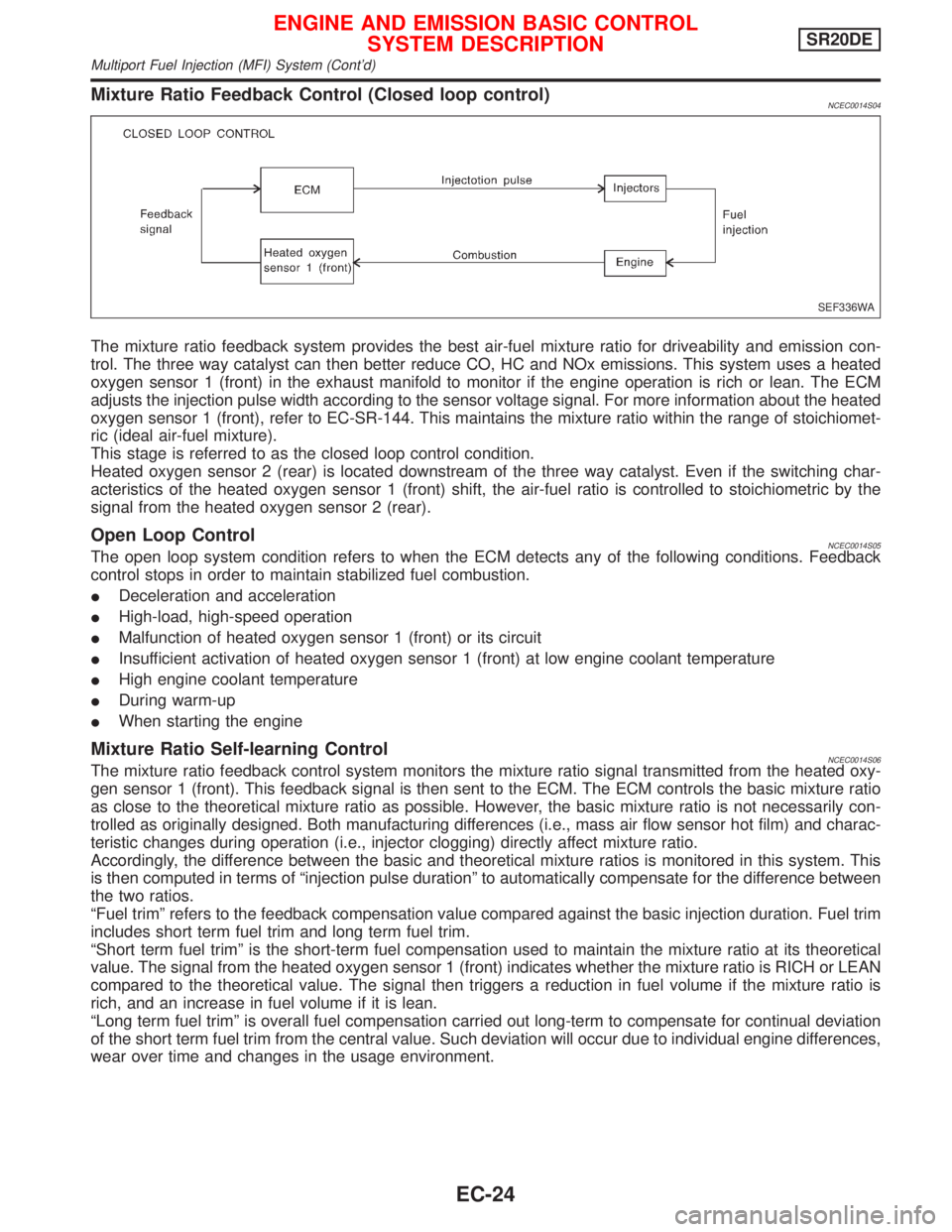

Mixture Ratio Feedback Control (Closed loop control)NCEC0014S04

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission con-

trol. The three way catalyst can then better reduce CO, HC and NOx emissions. This system uses a heated

oxygen sensor 1 (front) in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about the heated

oxygen sensor 1 (front), refer to EC-SR-144. This maintains the mixture ratio within the range of stoichiomet-

ric (ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 (rear) is located downstream of the three way catalyst. Even if the switching char-

acteristics of the heated oxygen sensor 1 (front) shift, the air-fuel ratio is controlled to stoichiometric by the

signal from the heated oxygen sensor 2 (rear).

Open Loop ControlNCEC0014S05The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

IDeceleration and acceleration

IHigh-load, high-speed operation

IMalfunction of heated oxygen sensor 1 (front) or its circuit

IInsufficient activation of heated oxygen sensor 1 (front) at low engine coolant temperature

IHigh engine coolant temperature

IDuring warm-up

IWhen starting the engine

Mixture Ratio Self-learning ControlNCEC0014S06The mixture ratio feedback control system monitors the mixture ratio signal transmitted from the heated oxy-

gen sensor 1 (front). This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio

as close to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily con-

trolled as originally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and charac-

teristic changes during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This

is then computed in terms of ªinjection pulse durationº to automatically compensate for the difference between

the two ratios.

ªFuel trimº refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

ªShort term fuel trimº is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from the heated oxygen sensor 1 (front) indicates whether the mixture ratio is RICH or LEAN

compared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is

rich, and an increase in fuel volume if it is lean.

ªLong term fuel trimº is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

SEF336WA

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-24

Page 825 of 2267

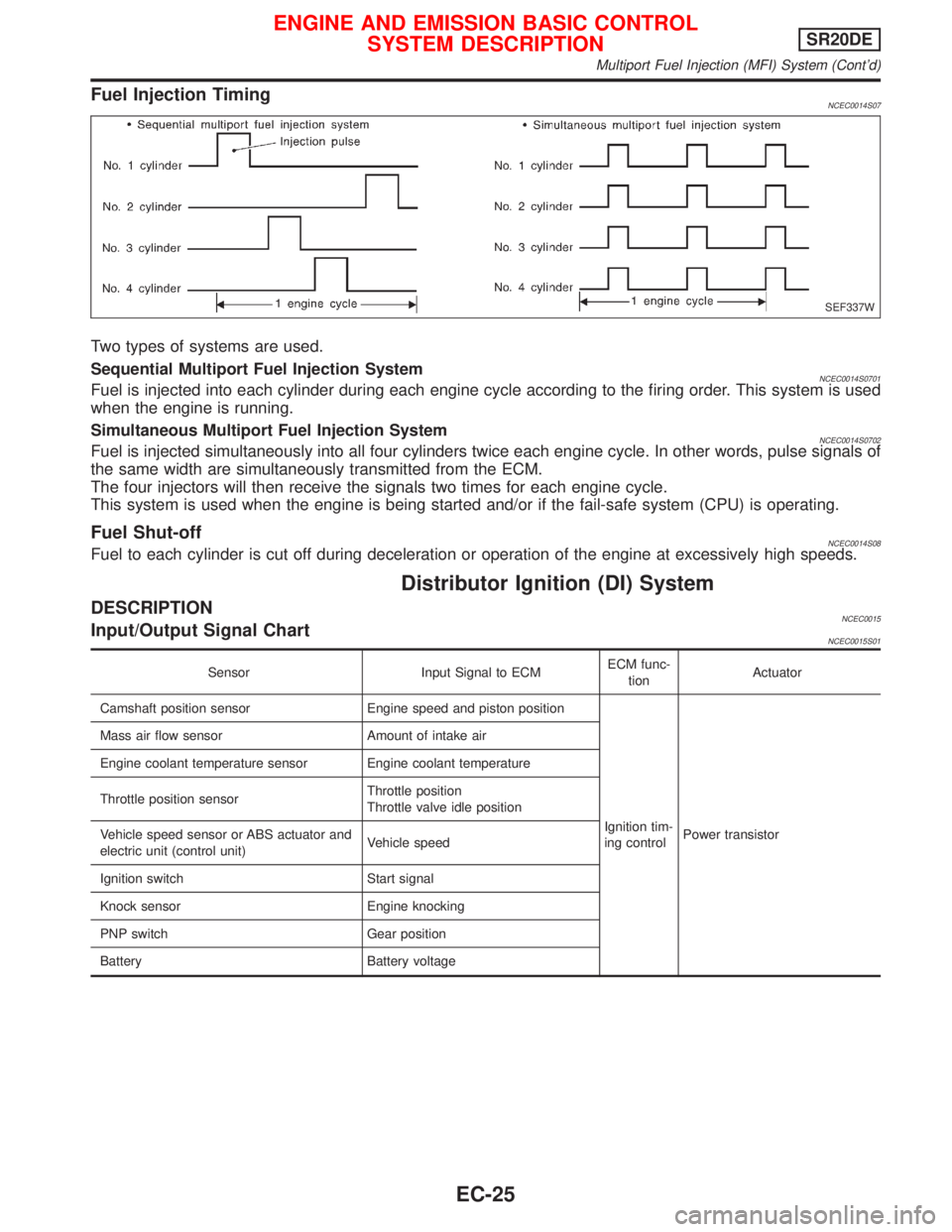

Fuel Injection TimingNCEC0014S07

Two types of systems are used.

Sequential Multiport Fuel Injection System

NCEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NCEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNCEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Distributor Ignition (DI) System

DESCRIPTIONNCEC0015Input/Output Signal ChartNCEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor Engine speed and piston position

Ignition tim-

ing controlPower transistor Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

SEF337W

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Multiport Fuel Injection (MFI) System (Cont'd)

EC-25

Page 826 of 2267

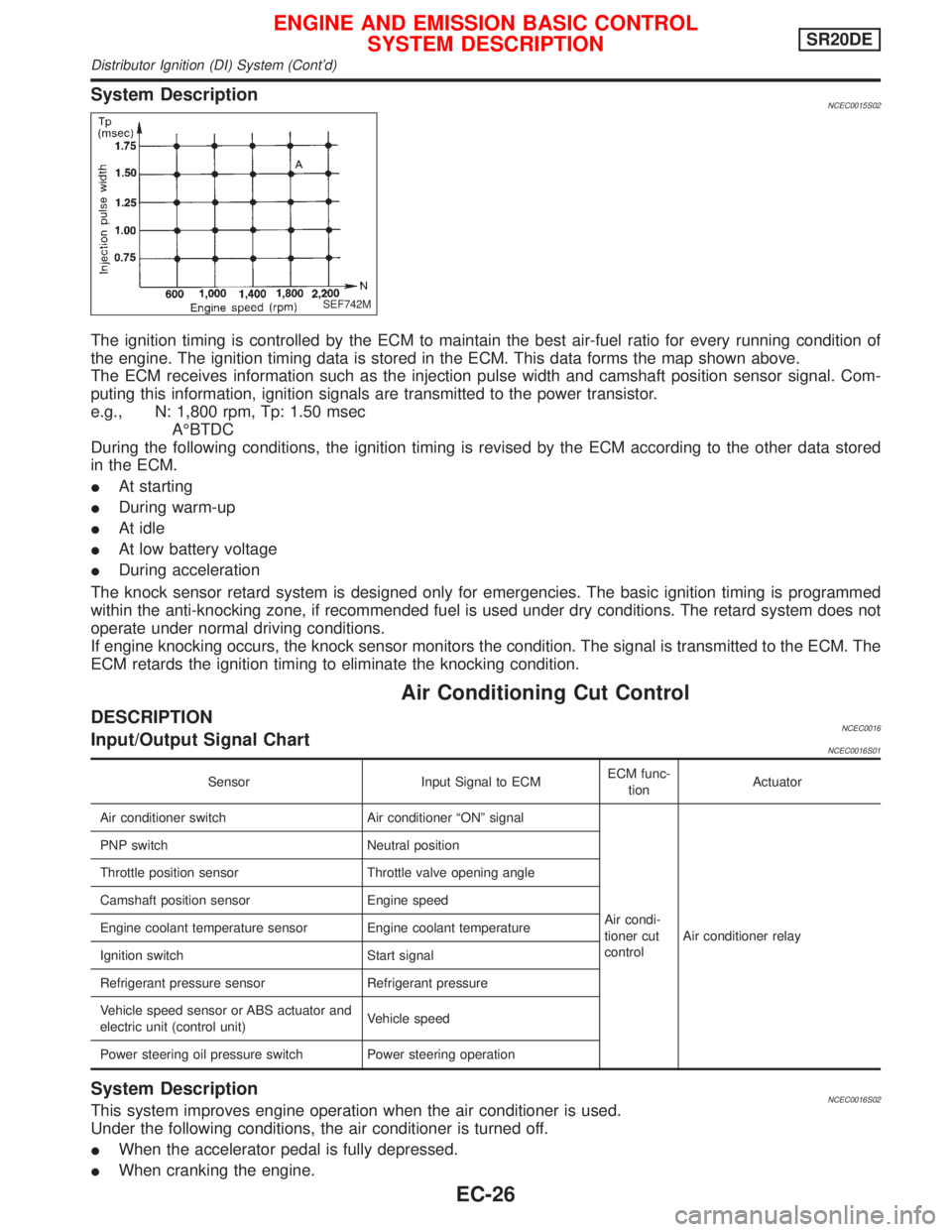

System DescriptionNCEC0015S02

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of

the engine. The ignition timing data is stored in the ECM. This data forms the map shown above.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Com-

puting this information, ignition signals are transmitted to the power transistor.

e.g., N: 1,800 rpm, Tp: 1.50 msec

AÉBTDC

During the following conditions, the ignition timing is revised by the ECM according to the other data stored

in the ECM.

IAt starting

IDuring warm-up

IAt idle

IAt low battery voltage

IDuring acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions.

If engine knocking occurs, the knock sensor monitors the condition. The signal is transmitted to the ECM. The

ECM retards the ignition timing to eliminate the knocking condition.

Air Conditioning Cut Control

DESCRIPTIONNCEC0016Input/Output Signal ChartNCEC0016S01

Sensor Input Signal to ECMECM func-

tionActuator

Air conditioner switch Air conditioner ªONº signal

Air condi-

tioner cut

controlAir conditioner relay PNP switch Neutral position

Throttle position sensor Throttle valve opening angle

Camshaft position sensor Engine speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Refrigerant pressure sensor Refrigerant pressure

Vehicle speed sensor or ABS actuator and

electric unit (control unit)Vehicle speed

Power steering oil pressure switch Power steering operation

System DescriptionNCEC0016S02This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned off.

IWhen the accelerator pedal is fully depressed.

IWhen cranking the engine.

SEF742M

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTIONSR20DE

Distributor Ignition (DI) System (Cont'd)

EC-26

Page 873 of 2267

![NISSAN PRIMERA 1999 Electronic User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioning signal.

P NISSAN PRIMERA 1999 Electronic User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioning signal.

P](/img/5/57377/w960_57377-872.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioning signal.

P/N POSI SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

PNP switch signal.

PW/ST SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition of the

power steering oil pressure switch deter-

mined by the power steering oil pressure

switch signal.

LOAD SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

electrical load signal and/or lighting

switch.

ON ... rear defogger is operating and/or

lighting switch is on.

OFF ... rear defogger is not operating

and lighting switch is not on.

IGNITION SW

[ON/OFF]qIIndicates [ON/OFF] condition from igni-

tion switch.

HEATER FAN SW

[ON/OFF]qIIndicates [ON/OFF] condition from the

heater fan switch.

INJ PULSE -B1

[msec]qIIndicates the actual fuel injection pulse

width compensated by ECM according to

the input signals.IWhen the engine is stopped, a cer-

tain computed value is indicated.

B/FUEL SCHDL

[msec]IªBase fuel scheduleº indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board cor-

rection.

IGN TIMING [BTDC]qIIndicates the ignition timing computed by

ECM according to the input signals.

IACV-AAC/V [step]qIIndicates the IACV-AAC valve control

value computed by ECM according to

the input signals.

A/F ALPHA -B1 [%]qIIndicates the mean value of the air-fuel

ratio feedback correction factor per

cycle.IWhen the engine is stopped, a cer-

tain value is indicated.

IThis data also includes the data for

the air-fuel ratio learning control.

AIR COND RLY

[ON/OFF]qIIndicates the air conditioner relay control

condition determined by ECM according

to the input signals.

FUEL PUMP RLY

[ON/OFF]qIIndicates the fuel pump relay control

condition determined by ECM according

to the input signals.

COOLING FAN

[HI/LOW/OFF]qIIndicates the control condition of the

cooling fan determined by ECM accord-

ing to the input signals.

HI ... High speed operation

LOW ... Low speed operation

OFF ... Stop

HO2S1 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of heated

oxygen sensor 1 (front) heater deter-

mined by ECM according to the input

signals.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

CONSULT-II (Cont'd)

EC-73

Page 874 of 2267

![NISSAN PRIMERA 1999 Electronic User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of heated

oxygen sensor 2 (rear) heater deter-

mined by ECM according to the NISSAN PRIMERA 1999 Electronic User Guide Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of heated

oxygen sensor 2 (rear) heater deter-

mined by ECM according to the](/img/5/57377/w960_57377-873.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

HO2S2 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of heated

oxygen sensor 2 (rear) heater deter-

mined by ECM according to the input

signals.

PURG VOL C/V [%]IIndicates the EVAP canister purge vol-

ume control solenoid valve computed by

the ECM according to the input signals.

IThe opening becomes larger as the

value increases.

CAL/LD VALUE [%]IªCalculated load valueº indicates the

value of the current airflow divided by

peak airflow.

ABSOL TH×P/S [%]IªAbsolute throttle position sensorº indi-

cates the throttle opening computed by

ECM according to the signal voltage of

the throttle position sensor.

MASS AIRFLOW

[gm/s]IIndicates the mass airflow computed by

ECM according to the signal voltage of

the mass air flow sensor.

IDL A/V LEANIDisplay the condition of idle air volume

learning

YET...Idle air volume learning has not

been performed yet.

CMPLT...Idle air volume learning has

already been performed successfully.

INCMP...Idle air volume learning has not

been performed successfully.

TRVL AFTER MIL

[km] or [Mile]IDistance traveled while MI is activated

VOLTAGE [V]IVoltage measured by the voltage probe.

PULSE

[msec] or [Hz] or [%]IPulse width, frequency or duty cycle

measured by the pulse probe.IOnly ª#º is displayed if item is unable

to be measured.

IFigures with ª#ºs are temporary ones.

They are the same figures as an

actual piece of data which was just

previously measured.

DATA MONITOR (SPEC) MODENLEC1365S07

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sen-

sor specification is displayed.IWhen the engine is running, specifi-

cation range is indicated.

B/FUEL SCHDL

[msec]IªBase fuel scheduleº indicates the fuel injec-

tion pulse width programmed into ECM,

prior to any learned on board correction.IWhen the engine is running, specifi-

cation range is indicated.

A/F ALPHA-B1 [%]qIIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONSR20DE

CONSULT-II (Cont'd)

EC-74

Page 910 of 2267

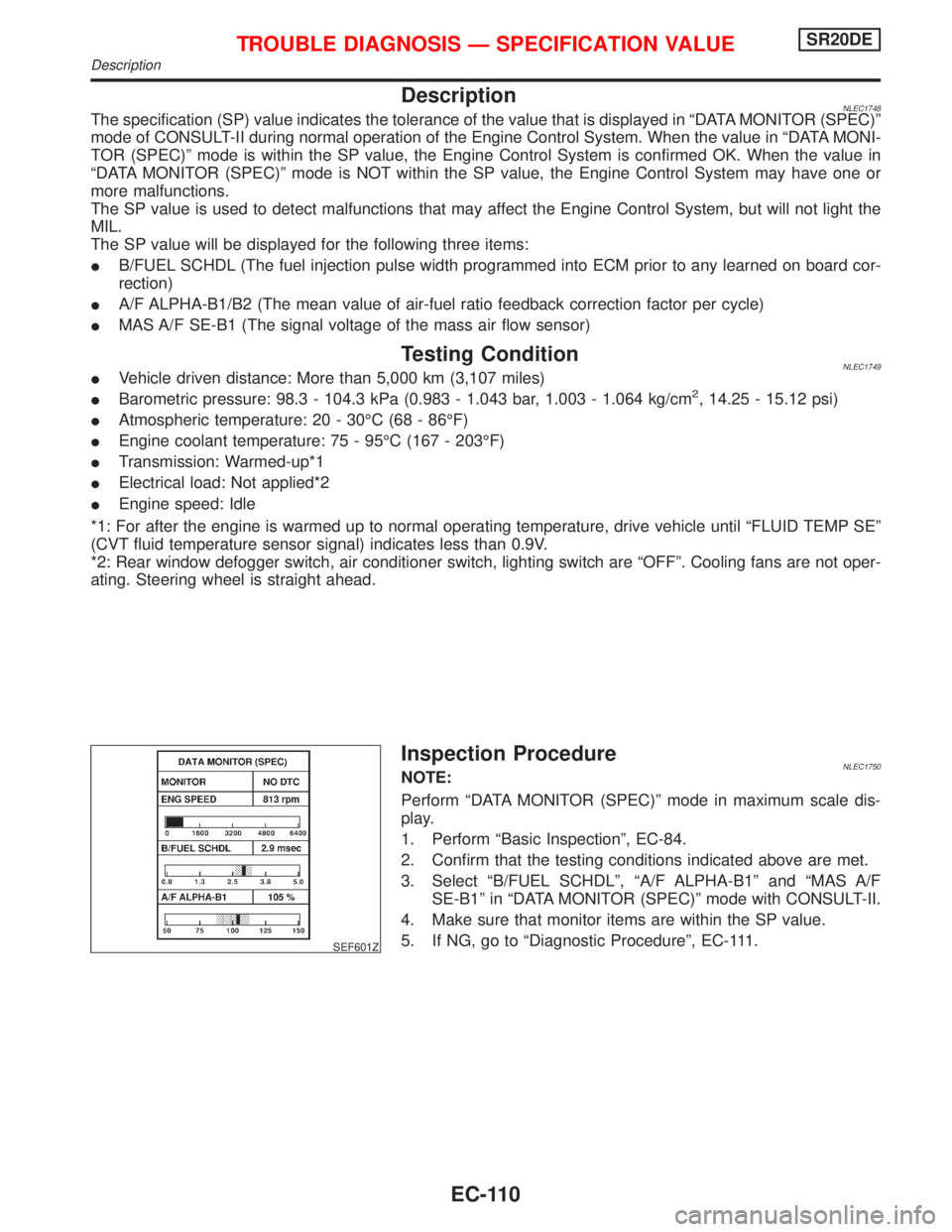

DescriptionNLEC1748The specification (SP) value indicates the tolerance of the value that is displayed in ªDATA MONITOR (SPEC)º

mode of CONSULT-II during normal operation of the Engine Control System. When the value in ªDATA MONI-

TOR (SPEC)º mode is within the SP value, the Engine Control System is confirmed OK. When the value in

ªDATA MONITOR (SPEC)º mode is NOT within the SP value, the Engine Control System may have one or

more malfunctions.

The SP value is used to detect malfunctions that may affect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

IB/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board cor-

rection)

IA/F ALPHA-B1/B2 (The mean value of air-fuel ratio feedback correction factor per cycle)

IMAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Testing ConditionNLEC1749IVehicle driven distance: More than 5,000 km (3,107 miles)

IBarometric pressure: 98.3 - 104.3 kPa (0.983 - 1.043 bar, 1.003 - 1.064 kg/cm2, 14.25 - 15.12 psi)

IAtmospheric temperature: 20 - 30ÉC (68 - 86ÉF)

IEngine coolant temperature: 75 - 95ÉC (167 - 203ÉF)

ITransmission: Warmed-up*1

IElectrical load: Not applied*2

IEngine speed: Idle

*1: For after the engine is warmed up to normal operating temperature, drive vehicle until ªFLUID TEMP SEº

(CVT fluid temperature sensor signal) indicates less than 0.9V.

*2: Rear window defogger switch, air conditioner switch, lighting switch are ªOFFº. Cooling fans are not oper-

ating. Steering wheel is straight ahead.

SEF601Z

Inspection ProcedureNLEC1750NOTE:

Perform ªDATA MONITOR (SPEC)º mode in maximum scale dis-

play.

1. Perform ªBasic Inspectionº, EC-84.

2. Confirm that the testing conditions indicated above are met.

3. Select ªB/FUEL SCHDLº, ªA/F ALPHA-B1º and ªMAS A/F

SE-B1º in ªDATA MONITOR (SPEC)º mode with CONSULT-II.

4. Make sure that monitor items are within the SP value.

5. If NG, go to ªDiagnostic Procedureº, EC-111.

TROUBLE DIAGNOSIS Ð SPECIFICATION VALUESR20DE

Description

EC-110

Page 1579 of 2267

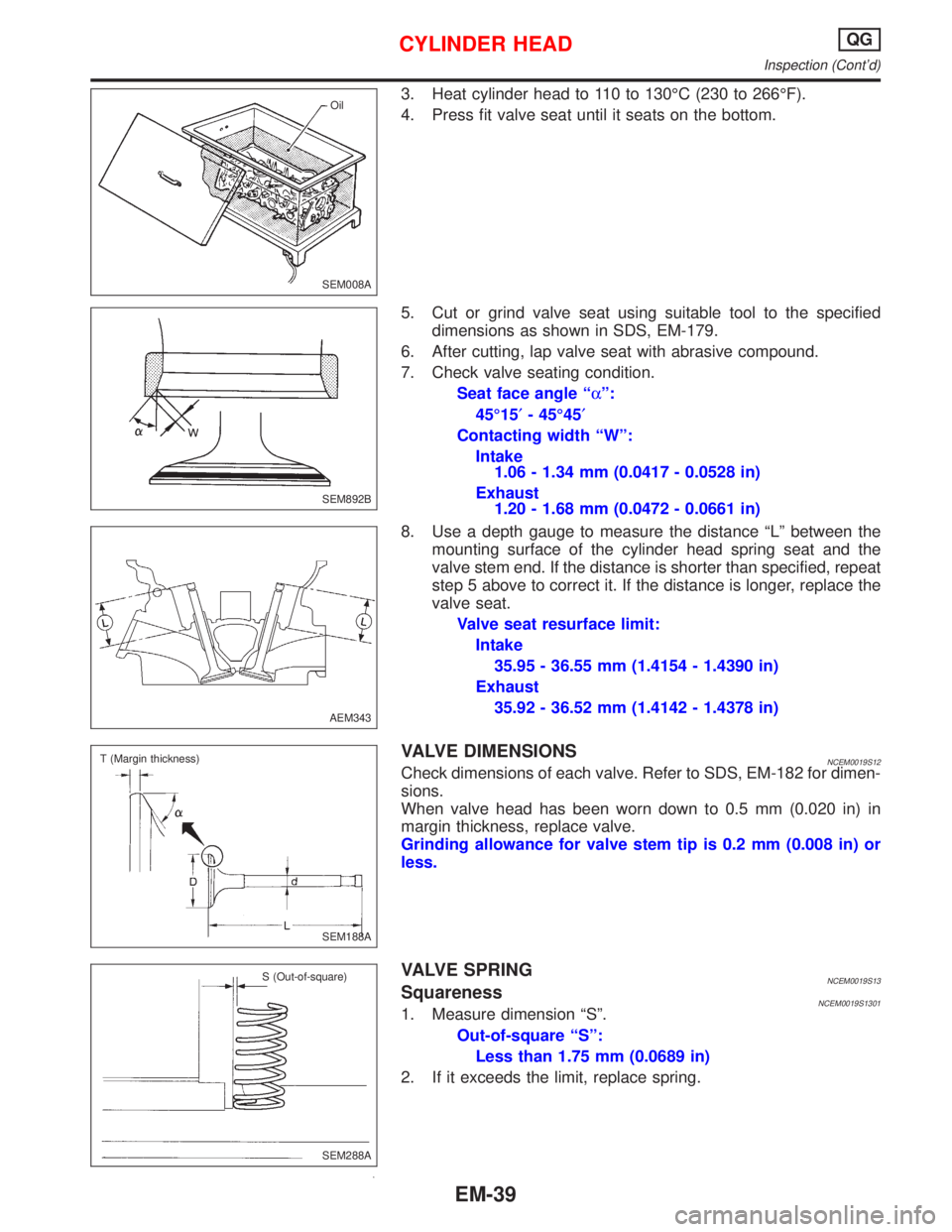

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool to the specified

dimensions as shown in SDS, EM-179.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ªaº:

45É15¢- 45É45¢

Contacting width ªWº:

Intake

1.06 - 1.34 mm (0.0417 - 0.0528 in)

Exhaust

1.20 - 1.68 mm (0.0472 - 0.0661 in)

8. Use a depth gauge to measure the distance ªLº between the

mounting surface of the cylinder head spring seat and the

valve stem end. If the distance is shorter than specified, repeat

step 5 above to correct it. If the distance is longer, replace the

valve seat.

Valve seat resurface limit:

Intake

35.95 - 36.55 mm (1.4154 - 1.4390 in)

Exhaust

35.92 - 36.52 mm (1.4142 - 1.4378 in)

VALVE DIMENSIONSNCEM0019S12Check dimensions of each valve. Refer to SDS, EM-182 for dimen-

sions.

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

VALVE SPRINGNCEM0019S13SquarenessNCEM0019S13011. Measure dimension ªSº.

Out-of-square ªSº:

Less than 1.75 mm (0.0689 in)

2. If it exceeds the limit, replace spring.

SEM008AOil

SEM892B

AEM343

SEM188A T (Margin thickness)

SEM288A S (Out-of-square)

CYLINDER HEADQG

Inspection (Cont'd)

EM-39

Page 1635 of 2267

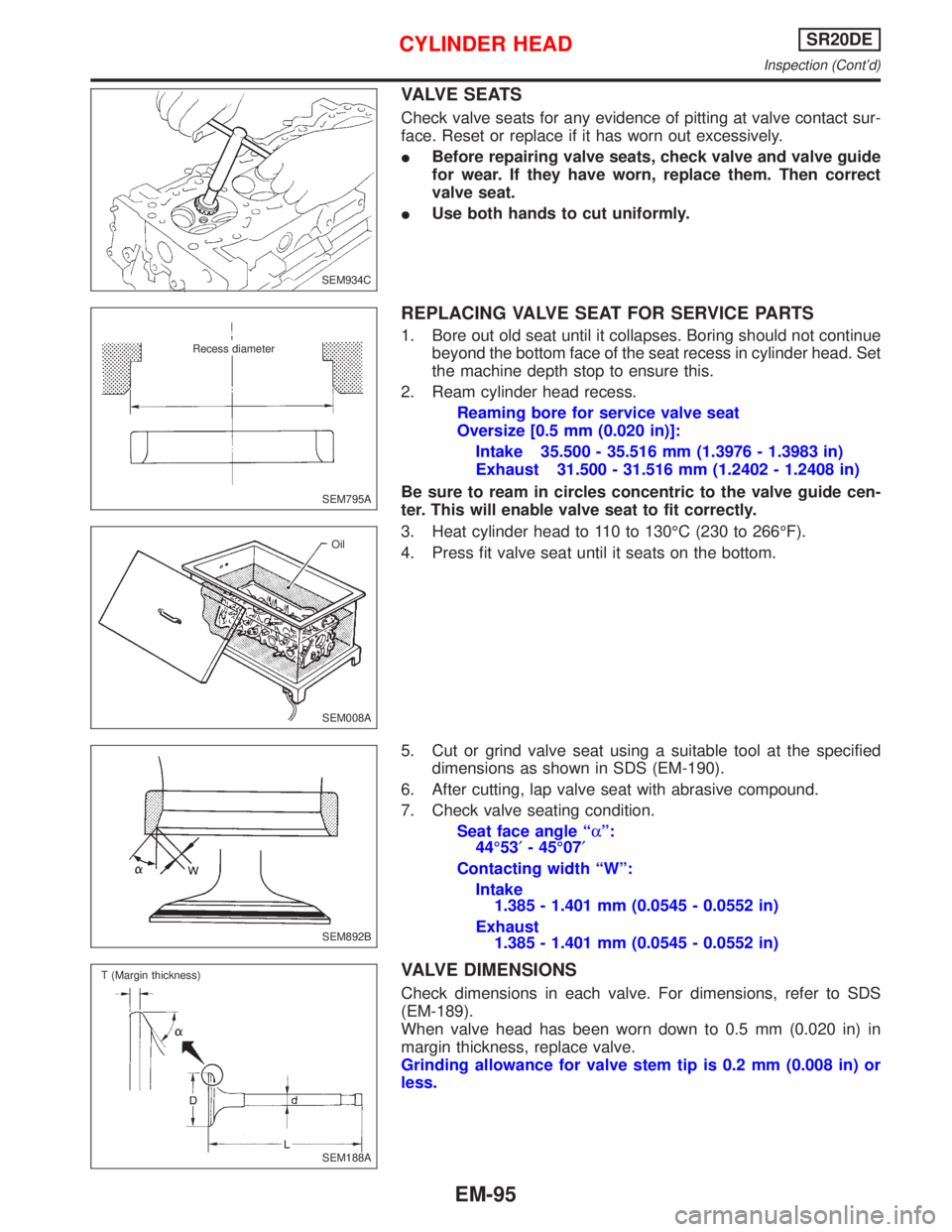

VALVE SEATS

Check valve seats for any evidence of pitting at valve contact sur-

face. Reset or replace if it has worn out excessively.

IBefore repairing valve seats, check valve and valve guide

for wear. If they have worn, replace them. Then correct

valve seat.

IUse both hands to cut uniformly.

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses. Boring should not continue

beyond the bottom face of the seat recess in cylinder head. Set

the machine depth stop to ensure this.

2. Ream cylinder head recess.

Reaming bore for service valve seat

Oversize [0.5 mm (0.020 in)]:

Intake 35.500 - 35.516 mm (1.3976 - 1.3983 in)

Exhaust 31.500 - 31.516 mm (1.2402 - 1.2408 in)

Be sure to ream in circles concentric to the valve guide cen-

ter. This will enable valve seat to fit correctly.

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using a suitable tool at the specified

dimensions as shown in SDS (EM-190).

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ªaº:

44É53¢- 45É07¢

Contacting width ªWº:

Intake

1.385 - 1.401 mm (0.0545 - 0.0552 in)

Exhaust

1.385 - 1.401 mm (0.0545 - 0.0552 in)

VALVE DIMENSIONS

Check dimensions in each valve. For dimensions, refer to SDS

(EM-189).

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM934C

SEM795A

.Recess diameter

SEM008AOil

SEM892B

.SEM188A T (Margin thickness)

CYLINDER HEADSR20DE

Inspection (Cont'd)

EM-95

Page 1688 of 2267

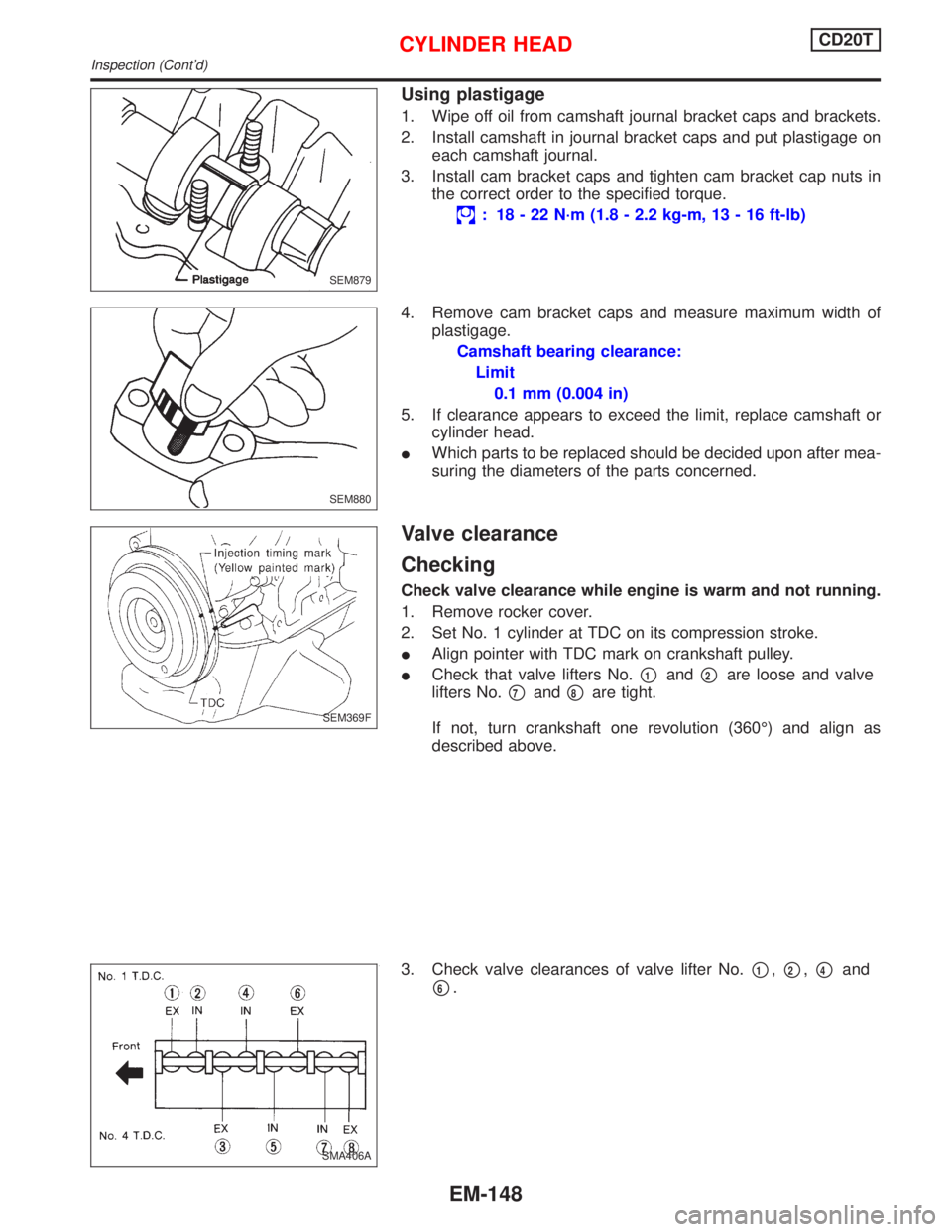

Using plastigage

1. Wipe off oil from camshaft journal bracket caps and brackets.

2. Install camshaft in journal bracket caps and put plastigage on

each camshaft journal.

3. Install cam bracket caps and tighten cam bracket cap nuts in

the correct order to the specified torque.

: 18 - 22 N´m (1.8 - 2.2 kg-m, 13 - 16 ft-lb)

4. Remove cam bracket caps and measure maximum width of

plastigage.

Camshaft bearing clearance:

Limit

0.1 mm (0.004 in)

5. If clearance appears to exceed the limit, replace camshaft or

cylinder head.

IWhich parts to be replaced should be decided upon after mea-

suring the diameters of the parts concerned.

Valve clearance

Checking

Check valve clearance while engine is warm and not running.

1. Remove rocker cover.

2. Set No. 1 cylinder at TDC on its compression stroke.

IAlign pointer with TDC mark on crankshaft pulley.

ICheck that valve lifters No.

p1andp2are loose and valve

lifters No.

p7andp8are tight.

If not, turn crankshaft one revolution (360É) and align as

described above.

3. Check valve clearances of valve lifter No.

p1,p2,p4and

p6.

SEM879

SEM880

SEM369F

SMA406A

CYLINDER HEADCD20T

Inspection (Cont'd)

EM-148

Page 1730 of 2267

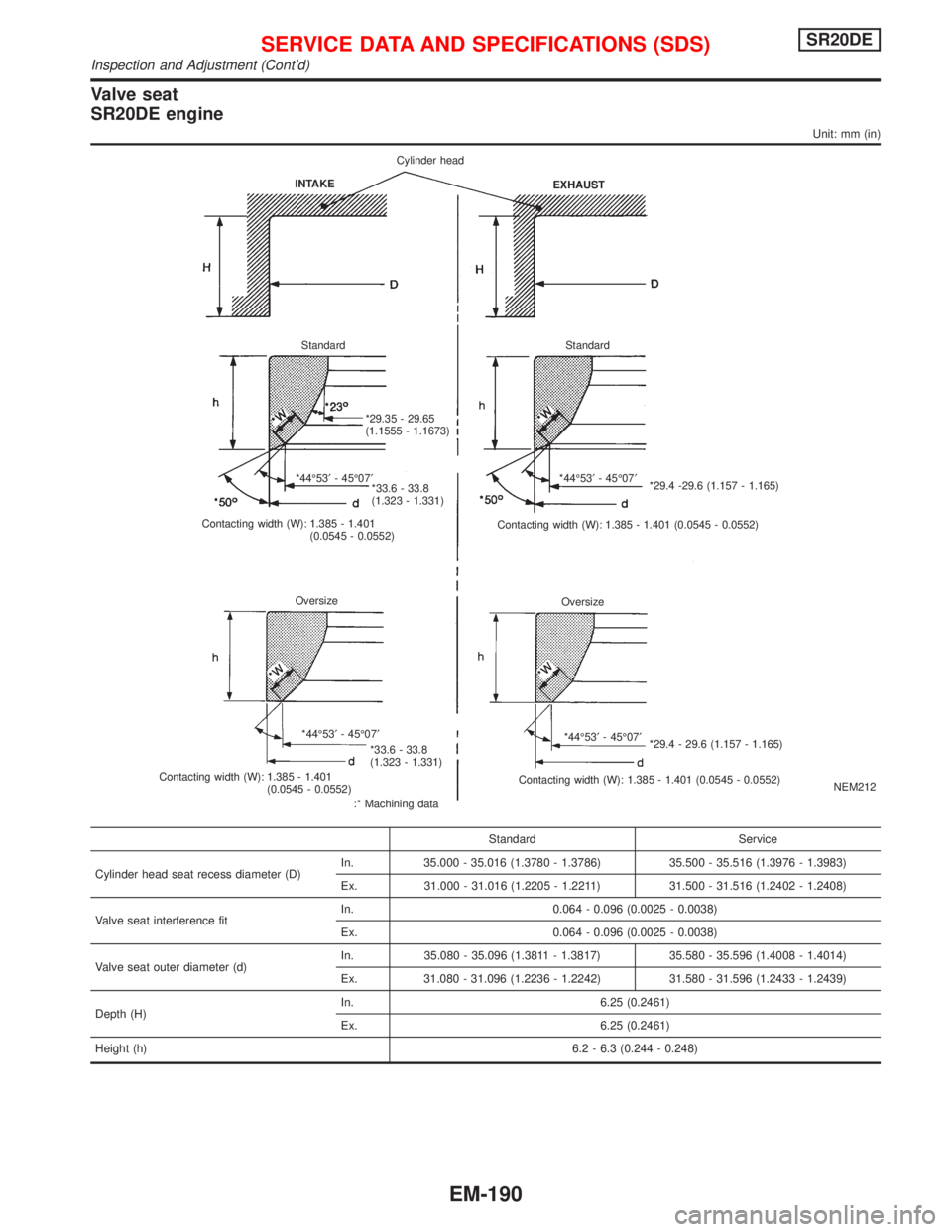

Valve seat

SR20DE engine

Unit: mm (in)

NEM212

Standard Service

Cylinder head seat recess diameter (D)In. 35.000 - 35.016 (1.3780 - 1.3786) 35.500 - 35.516 (1.3976 - 1.3983)

Ex. 31.000 - 31.016 (1.2205 - 1.2211) 31.500 - 31.516 (1.2402 - 1.2408)

Valve seat interference fitIn. 0.064 - 0.096 (0.0025 - 0.0038)

Ex. 0.064 - 0.096 (0.0025 - 0.0038)

Valve seat outer diameter (d)In. 35.080 - 35.096 (1.3811 - 1.3817) 35.580 - 35.596 (1.4008 - 1.4014)

Ex. 31.080 - 31.096 (1.2236 - 1.2242) 31.580 - 31.596 (1.2433 - 1.2439)

Depth (H)In. 6.25 (0.2461)

Ex. 6.25 (0.2461)

Height (h)6.2 - 6.3 (0.244 - 0.248)

INTAKECylinder head

EXHAUST

Standard Standard

*29.35 - 29.65

(1.1555 - 1.1673)

*44É53¢- 45É07¢

*33.6 - 33.8

(1.323 - 1.331)

Contacting width (W): 1.385 - 1.401

(0.0545 - 0.0552)*44É53¢- 45É07¢

*29.4 -29.6 (1.157 - 1.165)

Contacting width (W): 1.385 - 1.401 (0.0545 - 0.0552)

Oversize

Oversize

*44É53¢- 45É07¢

*33.6 - 33.8

(1.323 - 1.331)

Contacting width (W): 1.385 - 1.401

(0.0545 - 0.0552)

:* Machining data*44É53¢- 45É07¢

*29.4 - 29.6 (1.157 - 1.165)

Contacting width (W): 1.385 - 1.401 (0.0545 - 0.0552)

SERVICE DATA AND SPECIFICATIONS (SDS)SR20DE

Inspection and Adjustment (Cont'd)

EM-190