width NISSAN PRIMERA 1999 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1734 of 2267

CRANKSHAFT

Unit: mm (in)

Main journal dia. ªDmº

Grade No. 0 54.974 - 54.980 (2.1643 - 2.1646)

Grade No. 1 54.968 - 54.974 (2.1641 - 2.1643)

Grade No. 2 54.962 - 54.968 (2.1639 - 2.1641)

Grade No. 3 54.956 - 54.962 (2.1636 - 2.1639)

Pin journal dia. ªDpº

Grade No. 0 47.968 - 47.974 (1.8885 - 1.8887)

Grade No. 1 47.962 - 47.968 (1.8883 - 1.8885)

Grade No. 2 47.956 - 47.962 (1.8880 - 1.8883)

Center distance ªrº 42.96 - 43.04 (1.6913 - 1.6945)

Out-of-round (X þ Y)

StandardPin journal: Less than 0.0025 (0.0001)

Main journal: Less than 0.005 (0.0002)

Taper (A þ B)

StandardPin journal: Less than 0.0025 (0.0001)

Main journal: Less than 0.005 (0.0002)

Runout [TIR]

Standard Less than 0.025 (0.0010)

Limit Less than 0.05 (0.0020)

Free end play

Standard 0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.0118)

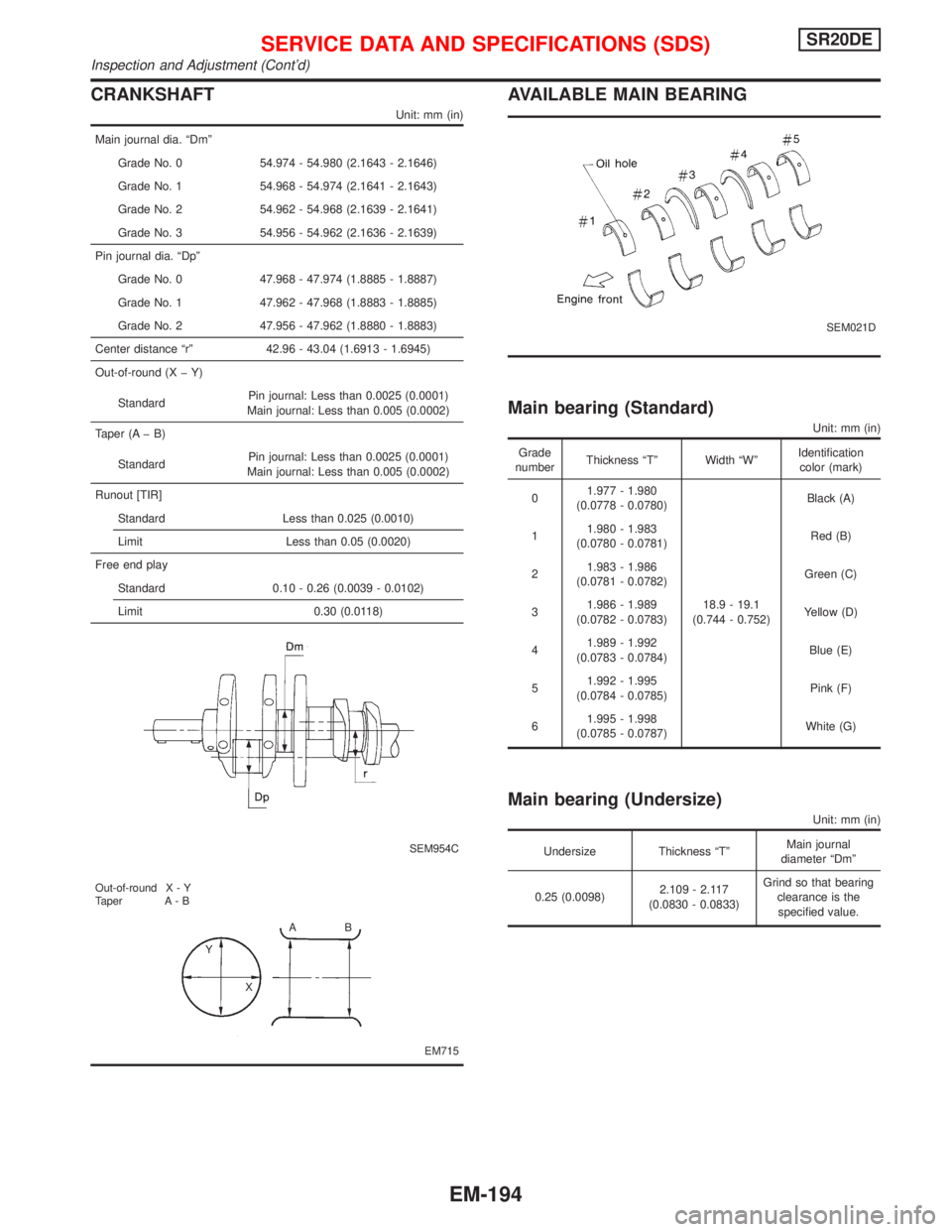

SEM954C

EM715 Out-of-round X - Y

Taper A - B

AB

Y

X

AVAILABLE MAIN BEARING

SEM021D

Main bearing (Standard)

Unit: mm (in)

Grade

numberThickness ªTº Width ªWºIdentification

color (mark)

01.977 - 1.980

(0.0778 - 0.0780)

18.9 - 19.1

(0.744 - 0.752)Black (A)

11.980 - 1.983

(0.0780 - 0.0781)Red (B)

21.983 - 1.986

(0.0781 - 0.0782)Green (C)

31.986 - 1.989

(0.0782 - 0.0783)Yellow (D)

41.989 - 1.992

(0.0783 - 0.0784)Blue (E)

51.992 - 1.995

(0.0784 - 0.0785)Pink (F)

61.995 - 1.998

(0.0785 - 0.0787)White (G)

Main bearing (Undersize)

Unit: mm (in)

Undersize Thickness ªTºMain journal

diameter ªDmº

0.25 (0.0098)2.109 - 2.117

(0.0830 - 0.0833)Grind so that bearing

clearance is the

specified value.

SERVICE DATA AND SPECIFICATIONS (SDS)SR20DE

Inspection and Adjustment (Cont'd)

EM-194

Page 1735 of 2267

AVAILABLE CONNECTING ROD BEARING

Connecting rod bearing

Standard size

Unit: mm (in)

Grade

numberThickness ªTº Width ªWºIdentification

color (mark)

01.500 - 1.503

(0.0591 - 0.0592)

16.9 - 17.1

(0.665 - 0.673)Black or Yellow

11.503 - 1.506

(0.0592 - 0.0593)Brown or Red

21.506 - 1.509

(0.0593 - 0.0594)Green or Blue

Undersize

Unit: mm (in)

Undersize Thickness ªTºCrank pin journal

diameter ªDpº

0.08 (0.0031)1.541 - 1.549

(0.0607 - 0.0610)

Grind so that bearing

clearance is the

specified value. 0.12 (0.0047)1.561 - 1.569

(0.0615 - 0.0618)

0.25 (0.0098)1.626 - 1.634

(0.0640 - 0.0643)

Bearing clearance

Unit: mm (in)

Main bearing clearance

Standard 0.004 - 0.022 (0.0002 - 0.0009)

Limit 0.05 (0.0020)

Connecting rod bearing clearance

Standard 0.020 - 0.045 (0.0008 - 0.0018)

Limit 0.065 (0.00256)

MISCELLANEOUS COMPONENTS

Unit: mm (in)

Camshaft sprocket runout limit [TIR] 0.25 (0.0098)

Flywheel runout limit [TIR] 0.15 (0.0059)

Drive plate runout limit [TIR] 0.2 (0.008)

SERVICE DATA AND SPECIFICATIONS (SDS)SR20DE

Inspection and Adjustment (Cont'd)

EM-195

Page 1740 of 2267

Piston pin

Unit: mm (in)

Piston pin outer diameter27.994 - 28.000

(1.1021 - 1.1024)

Interference fit of piston pin to

pistonþ0.004 to 0 (þ0.0002 to 0)

Piston pin to connecting rod

clearance0.025 - 0.044

(0.0010 - 0.0017)

CONNECTING ROD

Unit: mm (in)

Bend [per 100 mm (3.94 in)]

Standard Less than 0.025 (0.0010)

Torsion

Standard Less than 0.025 (0.0010)

Piston pin bore dia.28.025 - 28.038

(1.1033 - 1.1039)

Big end play

Limit 0.3 (0.012)

CRANKSHAFT

Unit: mm (in)

Main journal dia.Grade No. 0

52.967 - 52.975

(2.0853 - 2.0856)

Grade No. 1

52.959 - 52.967

(2.0850 - 2.0853)

Grade No. 2

52.951 - 52.959

(2.0847 - 2.0850)

Pin journal dia.Grade No. 0

49.968 - 49.974

(1.9672 - 1.9675)

Grade No. 1

49.961 - 49.968

(1.9670 - 1.9672)

Grade No. 2

49.954 - 49.961

(1.9667 - 1.9670)

Out-of-round (X þ Y) and

taper (A þ B)

Standard Less than 0.005 (0.0002)

Runout

Standard Less than 0.05 (0.0020)

Free end play

Standard 0.05 - 0.18 (0.0020 - 0.0071)

Limit 0.3 (0.012)

AVAILABLE MAIN BEARINGS

No. 1, No. 2, No. 4 and No. 5 main bearings

Grade number Thickness ªTº mm (in) Width ªWº mm (in) Identification color

0 1.816 - 1.820 (0.0715 - 0.0717) Yellow

1 1.820 - 1.824 (0.0717 - 0.0718) Green

2 1.824 - 1.828 (0.0718 - 0.0720)20.0 (0.787)

17.8 (0.701)*Brown

3 1.828 - 1.832 (0.0720 - 0.0721) Black

4 1.832 - 1.836 (0.0721 - 0.0723) Blue

*: Contacting width

No. 3 main bearings

Grade number Thickness ªTº mm (in) Width ªWº mm (in) Identification color

0 1.816 - 1.820 (0.0715 - 0.0717) Yellow

1 1.820 - 1.824 (0.0717 - 0.0718) Green

2 1.824 - 1.828 (0.0718 - 0.0720)27.95 (1.1004)

21.35 (0.8405)*Brown

3 1.828 - 1.832 (0.0720 - 0.0721) Black

4 1.832 - 1.836 (0.0721 - 0.0723) Blue

*: Contacting width

SERVICE DATA AND SPECIFICATIONS (SDS)CD20T

Inspection and Adjustment (Cont'd)

EM-200

Page 1840 of 2267

Dimensions

Unit: mm (in)

H/B & Sedan Wagon

Overall length 4522 (178.03) 4566 (179.76)

Overall width 1715 (67.52) *1 1715 (67.52) *1

Overall height 1410 (55.51) *2 1410 (55.51) *2

Front tread 1470 (57.87) 1470 (57.87)

Rear tread 1450 (57.09) 1450 (57.09)

Wheelbase 2600 (102.36) 2600 (102.36)

*1: Without mirrors.

*2: Without roof mounted antenna.

Wheels and Tires

Road

wheelSteel 15 x 6J

ÐÐÐ

Offset

mm (in)45 (1.77)

Aluminum

Ð15x6J 15x6J 16x7J

Offset

mm (in)45 (1.77) 45 (1.77) 45 (1.77)

Tire

sizeConven-

tional185/65HR15 195/60VR15 195/60R15 205/50R16

SpareConven-

tionalConven-

tionalConven-

tional185/65

HR15

IDENTIFICATION INFORMATION

GI-45

Page 1975 of 2267

Wide open & closed throttle position

switch.............................EC-QG-125, EC-SR-137

Width (Dimensions) .........................................GI-45

WINDOW - Wiring diagram ..........................EL-240

Windshield.......................................................BT-53

WIP/R - Wiring diagram ................................EL-195Wiper and washer .........................................EL-188

Wiper, front....................................................EL-186

Wiper, rear ....................................................EL-193

Wiring diagrams ...............................................GI-11

ALPHABETICAL INDEX

IDX-8

Page 2151 of 2267

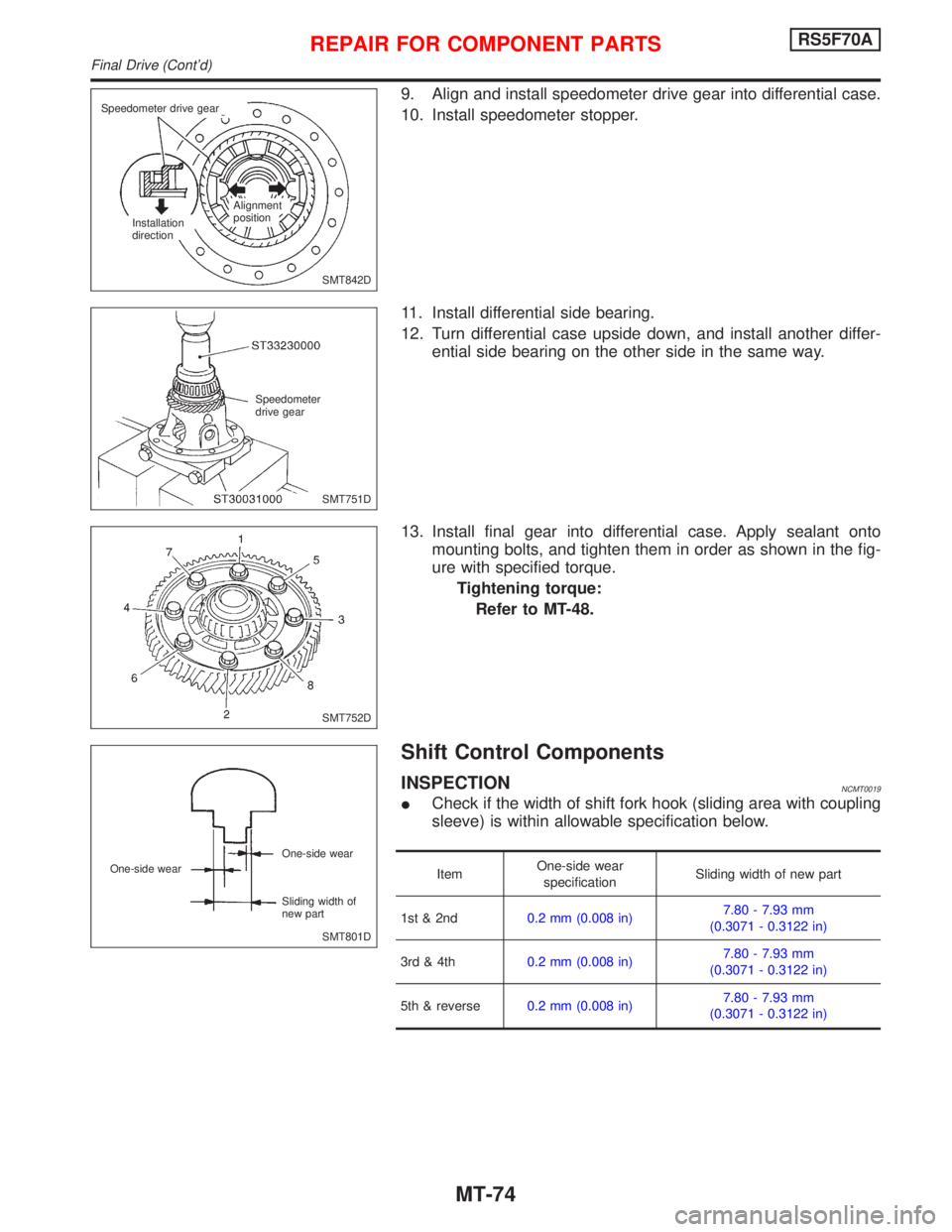

9. Align and install speedometer drive gear into differential case.

10. Install speedometer stopper.

11. Install differential side bearing.

12. Turn differential case upside down, and install another differ-

ential side bearing on the other side in the same way.

13. Install final gear into differential case. Apply sealant onto

mounting bolts, and tighten them in order as shown in the fig-

ure with specified torque.

Tightening torque:

Refer to MT-48.

Shift Control Components

INSPECTIONNCMT0019

ICheck if the width of shift fork hook (sliding area with coupling

sleeve) is within allowable specification below.

ItemOne-side wear

specificationSliding width of new part

1st & 2nd0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

3rd & 4th0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

5th & reverse0.2 mm (0.008 in)7.80 - 7.93 mm

(0.3071 - 0.3122 in)

SMT842D Speedometer drive gear

Installation

directionAlignment

position

SMT751D Speedometer

drive gear

SMT752D

SMT801D One-side wear

Sliding width of

new part One-side wear

REPAIR FOR COMPONENT PARTSRS5F70A

Final Drive (Cont'd)

MT-74