sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 556 of 2267

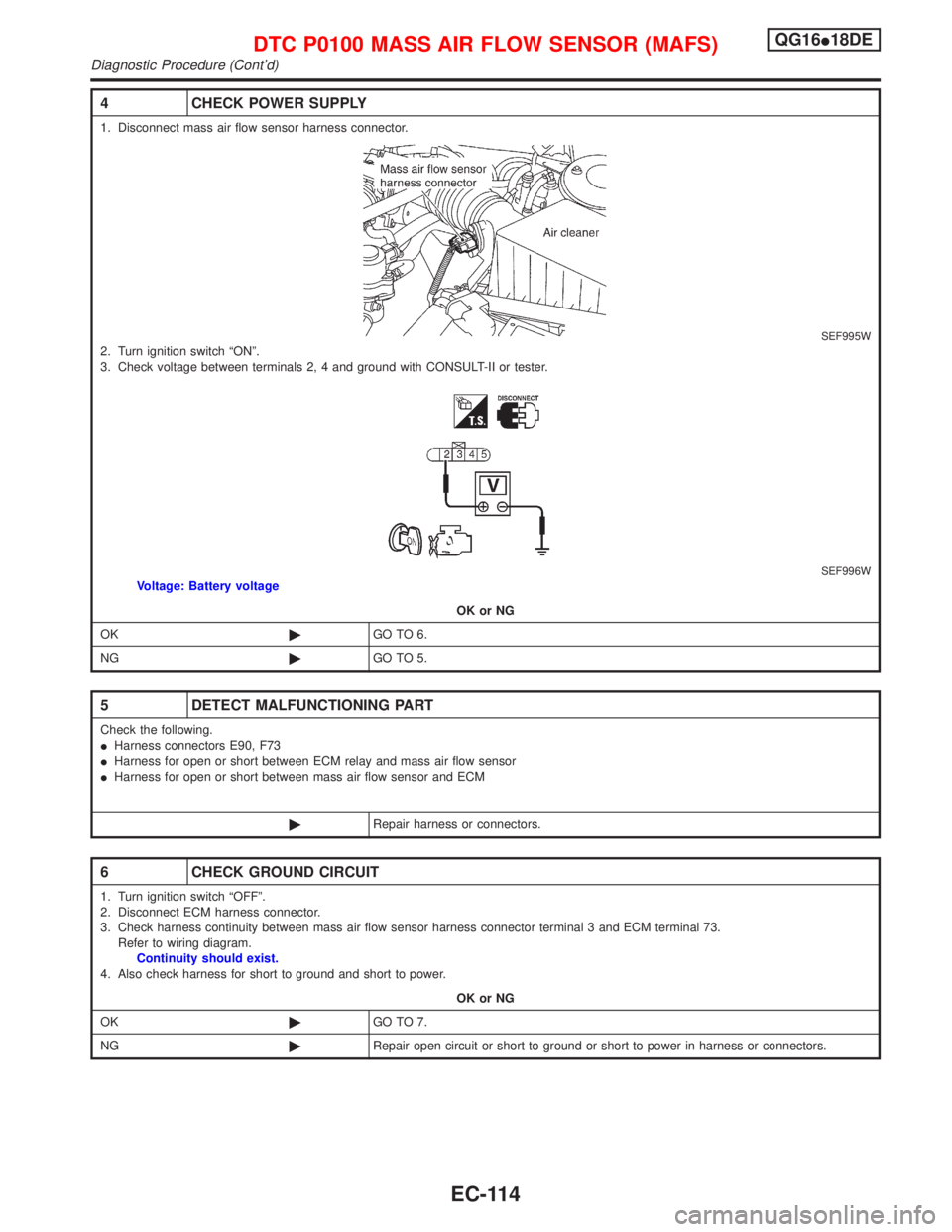

4 CHECK POWER SUPPLY

1. Disconnect mass air flow sensor harness connector.

SEF995W2. Turn ignition switch ªONº.

3. Check voltage between terminals 2, 4 and ground with CONSULT-II or tester.

SEF996WVoltage: Battery voltage

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E90, F73

IHarness for open or short between ECM relay and mass air flow sensor

IHarness for open or short between mass air flow sensor and ECM

©Repair harness or connectors.

6 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between mass air flow sensor harness connector terminal 3 and ECM terminal 73.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-114

Page 557 of 2267

7 CHECK INPUT SIGNAL CIRCUIT

1. Check harness continuity between mass air flow sensor harness connector terminal 5 and ECM terminal 61.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK MASS AIR FLOW SENSOR

Refer to ªComponent Inspectionº, EC-QG-115.

OK or NG

OK©GO TO 9.

NG©Replace mass air flow sensor.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

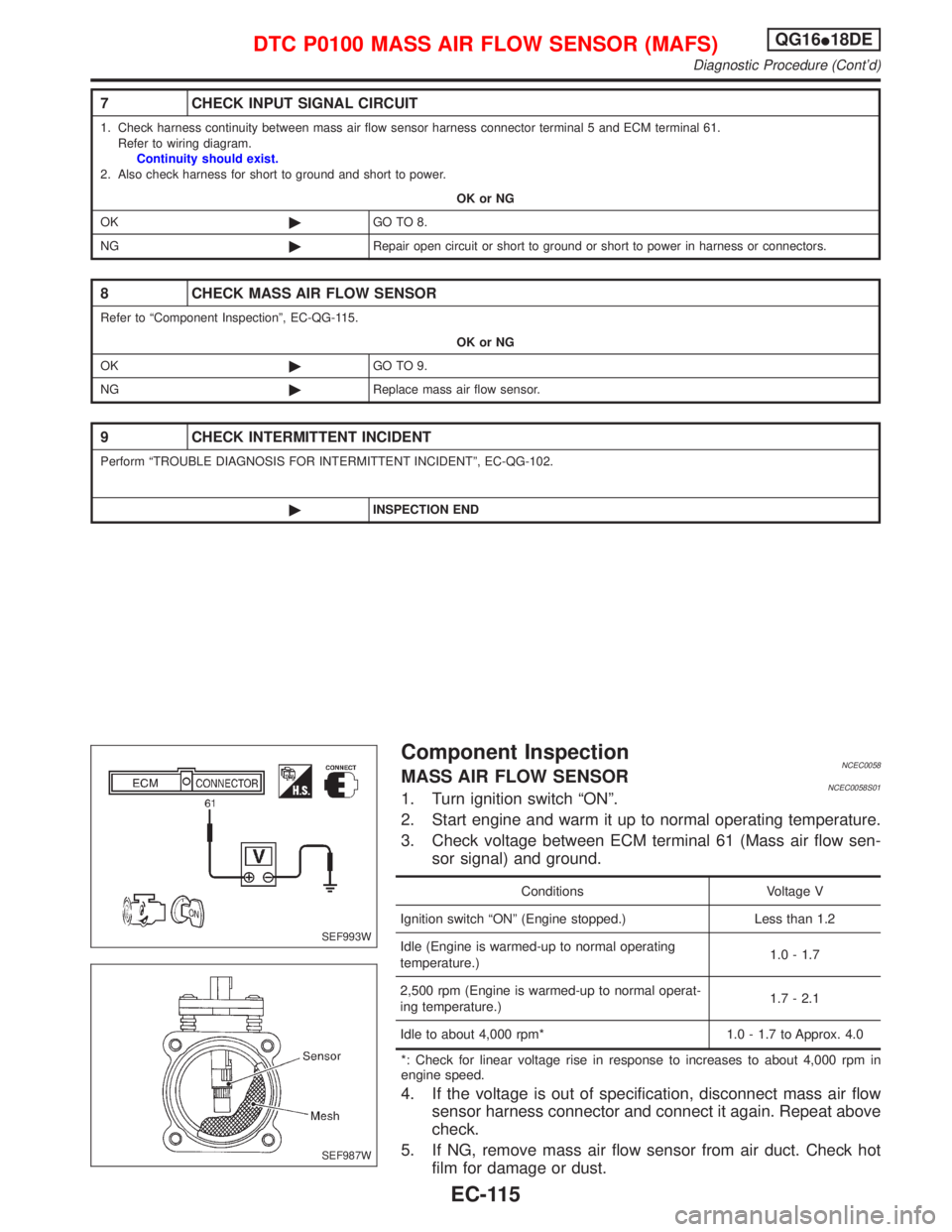

Component InspectionNCEC0058MASS AIR FLOW SENSORNCEC0058S011. Turn ignition switch ªONº.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 61 (Mass air flow sen-

sor signal) and ground.

Conditions Voltage V

Ignition switch ªONº (Engine stopped.) Less than 1.2

Idle (Engine is warmed-up to normal operating

temperature.)1.0 - 1.7

2,500 rpm (Engine is warmed-up to normal operat-

ing temperature.)1.7 - 2.1

Idle to about 4,000 rpm* 1.0 - 1.7 to Approx. 4.0

*: Check for linear voltage rise in response to increases to about 4,000 rpm in

engine speed.

4. If the voltage is out of specification, disconnect mass air flow

sensor harness connector and connect it again. Repeat above

check.

5. If NG, remove mass air flow sensor from air duct. Check hot

film for damage or dust.

SEF993W

SEF987W

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG16I18DE

Diagnostic Procedure (Cont'd)

EC-115

Page 558 of 2267

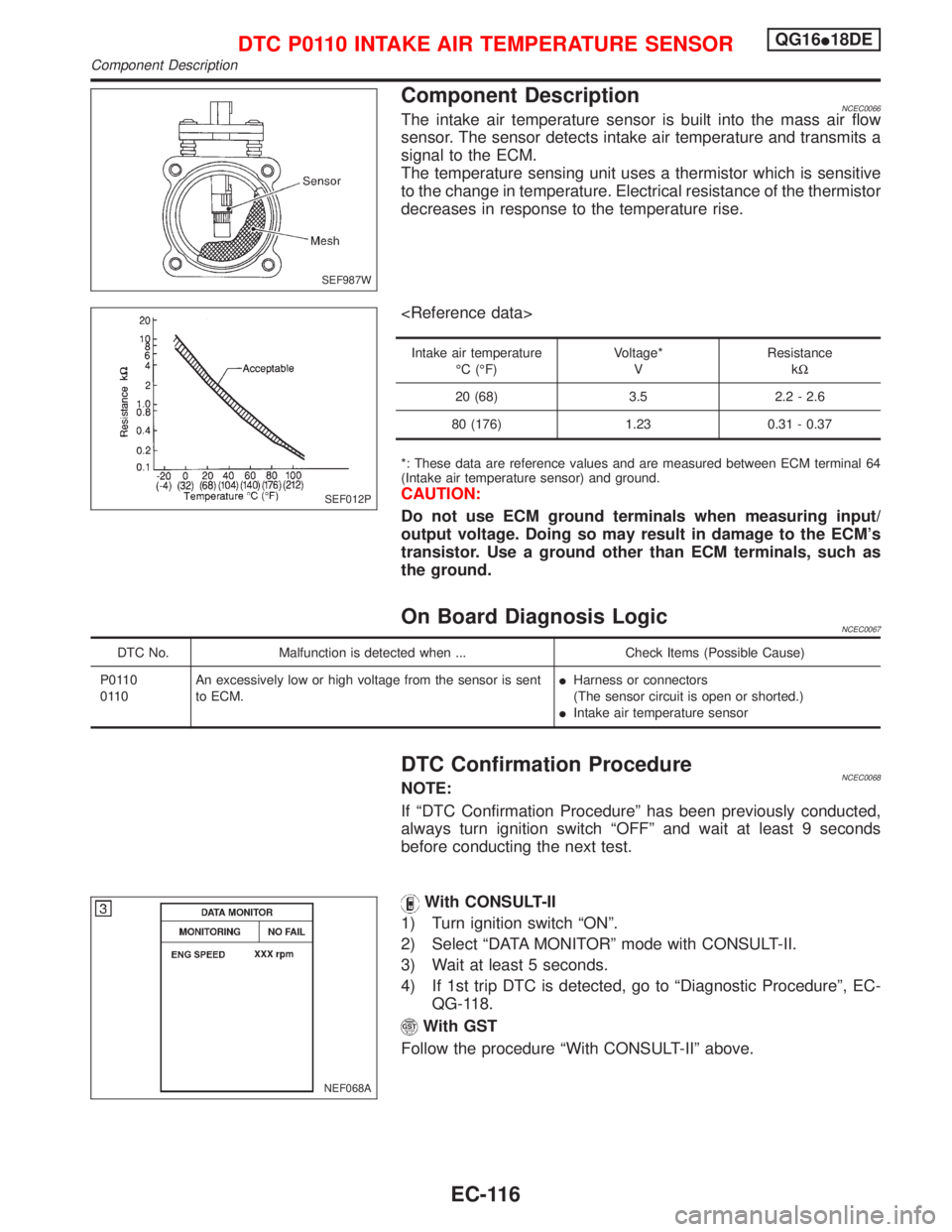

Component DescriptionNCEC0066The intake air temperature sensor is built into the mass air flow

sensor. The sensor detects intake air temperature and transmits a

signal to the ECM.

The temperature sensing unit uses a thermistor which is sensitive

to the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

Intake air temperature

ÉC (ÉF)Voltage*

VResistance

kW

20 (68) 3.5 2.2 - 2.6

80 (176) 1.23 0.31 - 0.37

*: These data are reference values and are measured between ECM terminal 64

(Intake air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNCEC0067

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0110

0110An excessively low or high voltage from the sensor is sent

to ECM.IHarness or connectors

(The sensor circuit is open or shorted.)

IIntake air temperature sensor

DTC Confirmation ProcedureNCEC0068NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-118.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF987W

SEF012P

NEF068A

DTC P0110 INTAKE AIR TEMPERATURE SENSORQG16I18DE

Component Description

EC-116

Page 559 of 2267

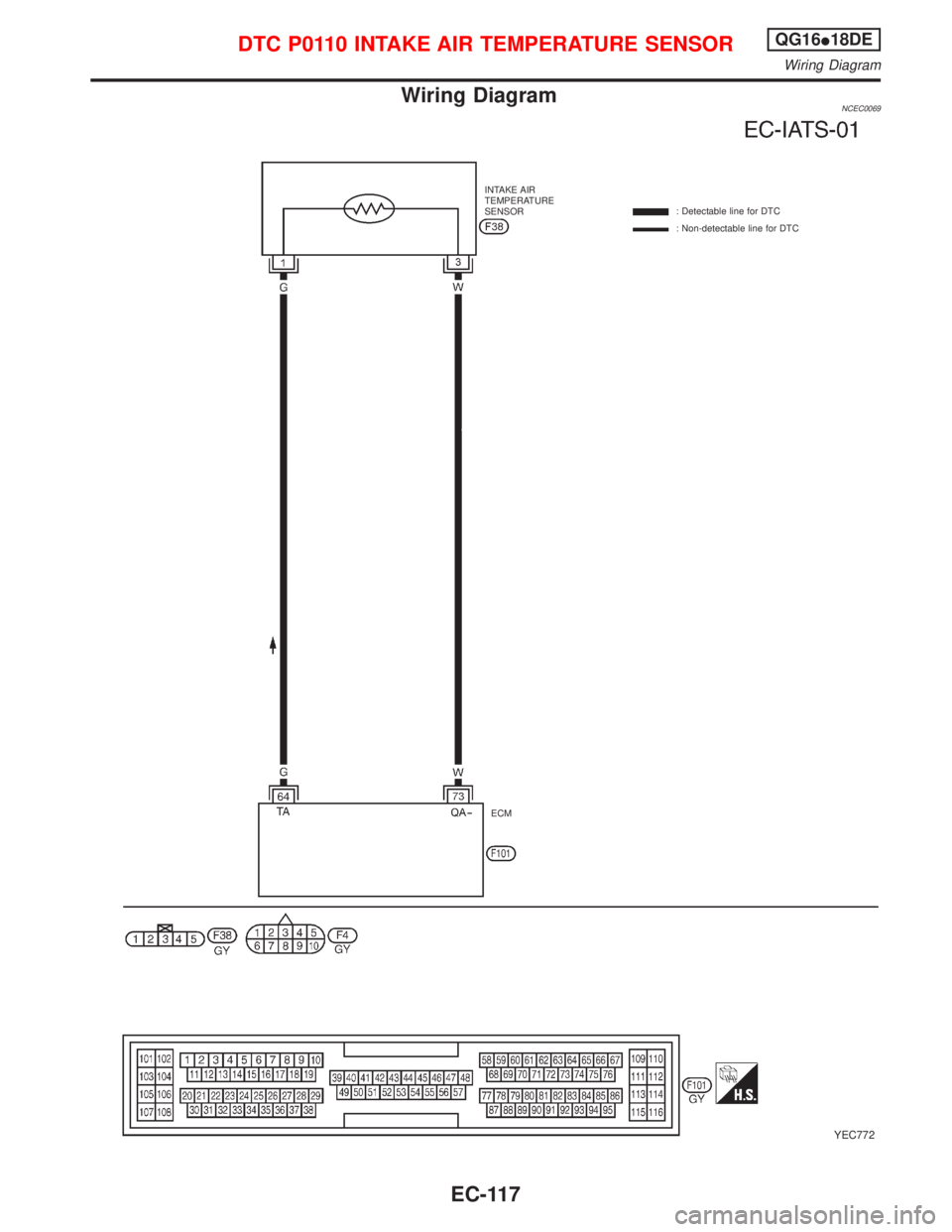

Wiring DiagramNCEC0069

YEC772

INTAKE AIR

TEMPERATURE

SENSOR: Detectable line for DTC

: Non-detectable line for DTC

ECM

DTC P0110 INTAKE AIR TEMPERATURE SENSORQG16I18DE

Wiring Diagram

EC-117

Page 560 of 2267

Diagnostic Procedure

1 CHECK POWER SUPPLY

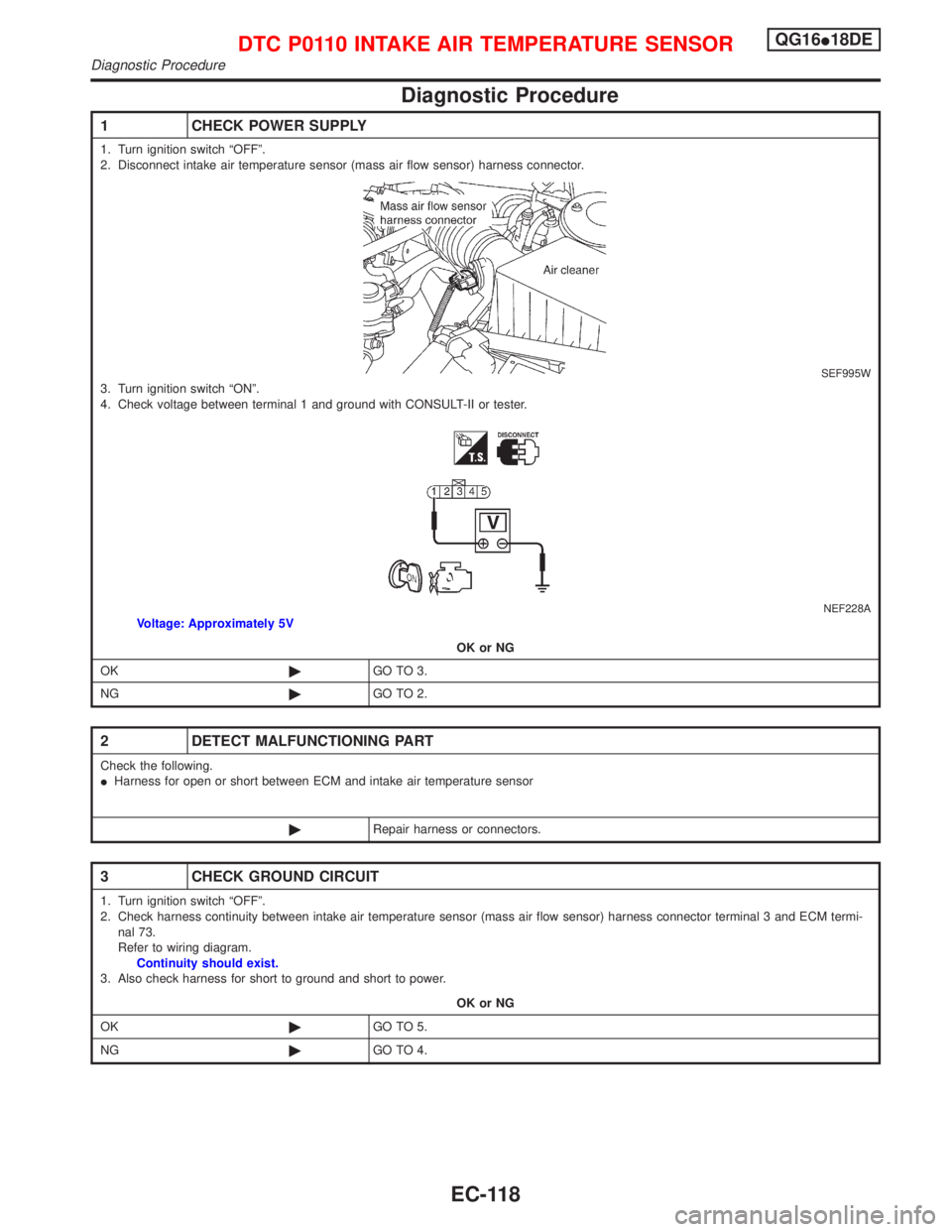

1. Turn ignition switch ªOFFº.

2. Disconnect intake air temperature sensor (mass air flow sensor) harness connector.

SEF995W3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

NEF228AVoltage: Approximately 5V

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and intake air temperature sensor

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between intake air temperature sensor (mass air flow sensor) harness connector terminal 3 and ECM termi-

nal 73.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

DTC P0110 INTAKE AIR TEMPERATURE SENSORQG16I18DE

Diagnostic Procedure

EC-118

Page 561 of 2267

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and intake air temperature sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTAKE AIR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-QG-119.

OK or NG

OK©GO TO 6.

NG©Replace intake air temperature sensor.

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-QG-102.

©INSPECTION END

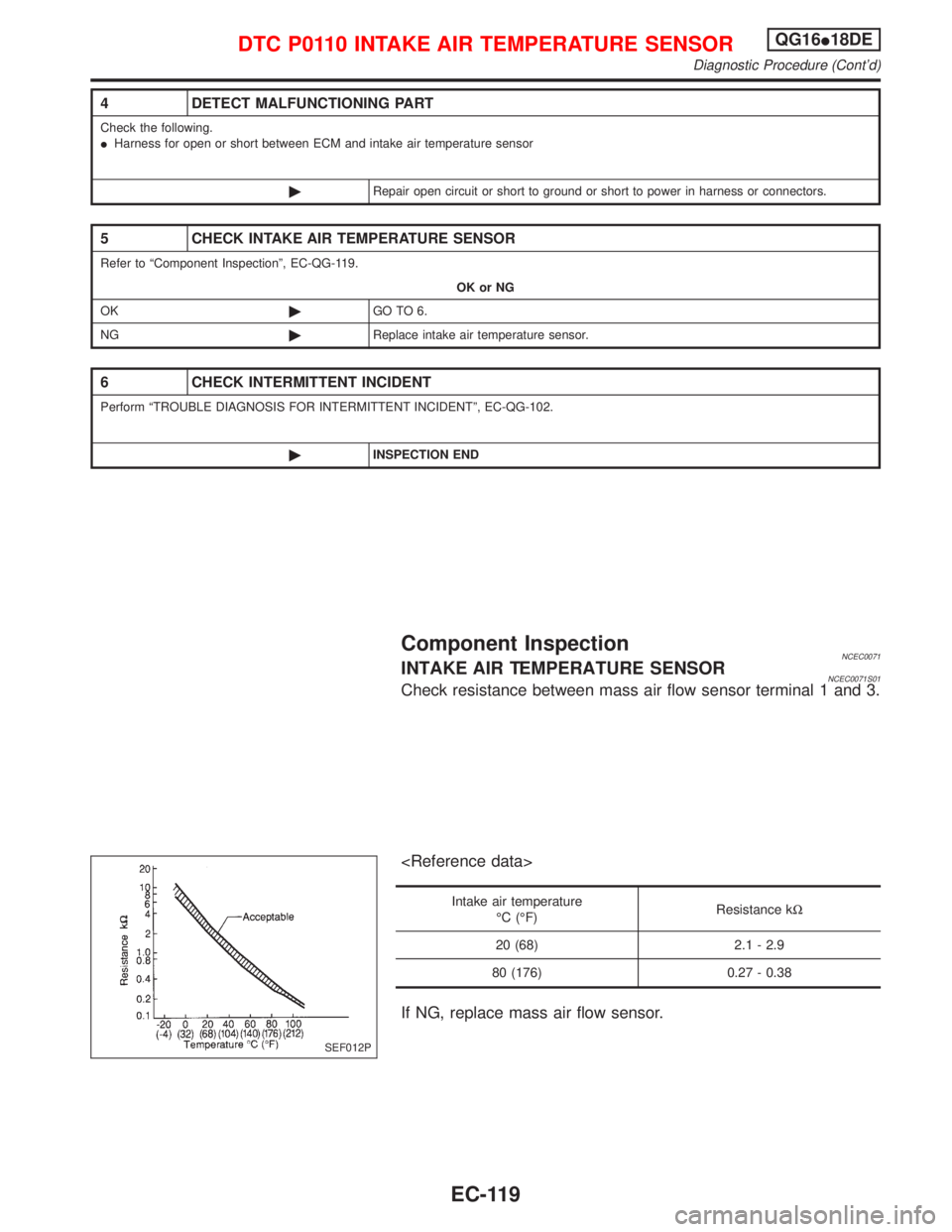

Component InspectionNCEC0071INTAKE AIR TEMPERATURE SENSORNCEC0071S01Check resistance between mass air flow sensor terminal 1 and 3.

Intake air temperature

ÉC (ÉF)Resistance kW

20 (68) 2.1 - 2.9

80 (176) 0.27 - 0.38

If NG, replace mass air flow sensor.

SEF012P

DTC P0110 INTAKE AIR TEMPERATURE SENSORQG16I18DE

Diagnostic Procedure (Cont'd)

EC-119

Page 562 of 2267

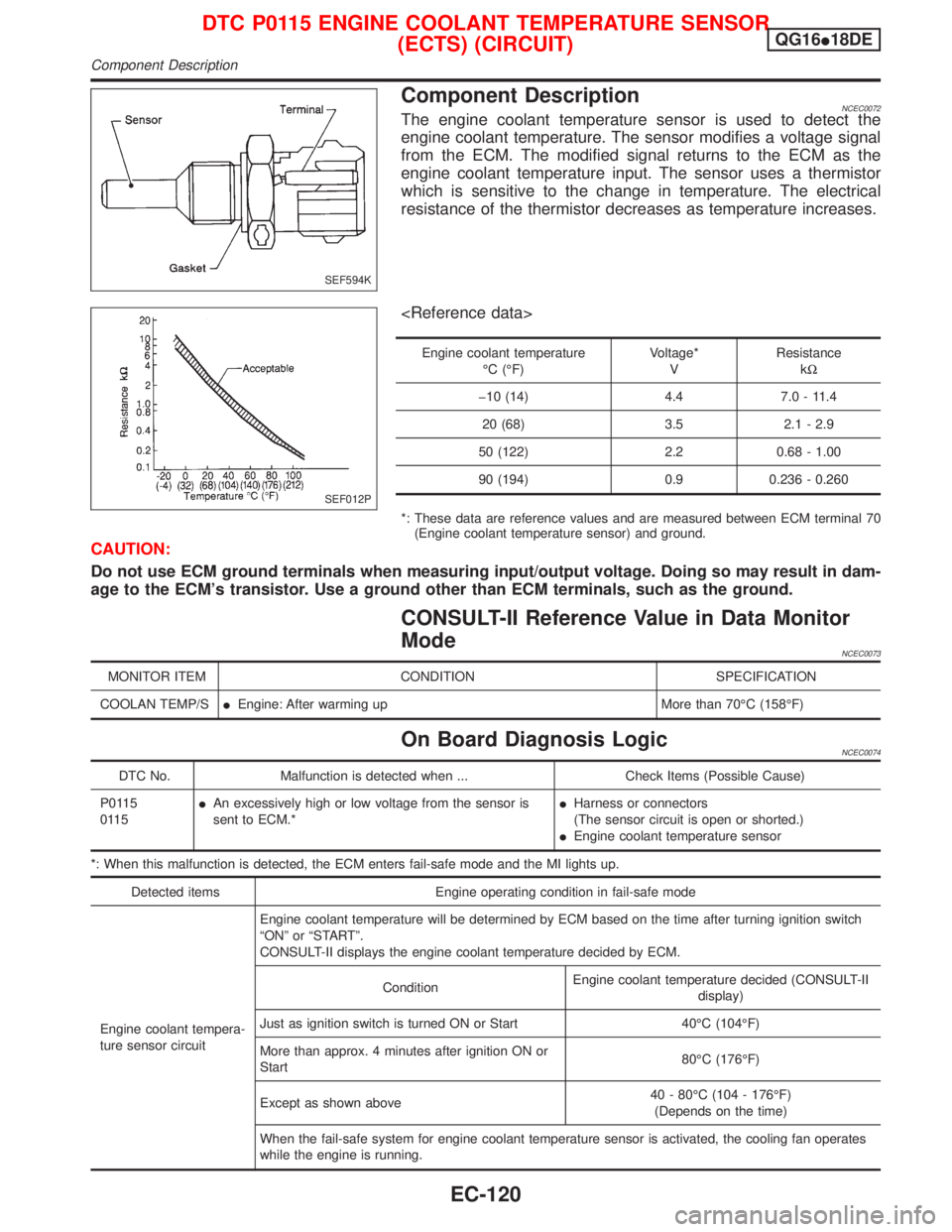

Component DescriptionNCEC0072The engine coolant temperature sensor is used to detect the

engine coolant temperature. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the

engine coolant temperature input. The sensor uses a thermistor

which is sensitive to the change in temperature. The electrical

resistance of the thermistor decreases as temperature increases.

Engine coolant temperature

ÉC (ÉF)Voltage*

VResistance

kW

þ10 (14) 4.4 7.0 - 11.4

20 (68) 3.5 2.1 - 2.9

50 (122) 2.2 0.68 - 1.00

90 (194) 0.9 0.236 - 0.260

*: These data are reference values and are measured between ECM terminal 70

(Engine coolant temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0073

MONITOR ITEM CONDITION SPECIFICATION

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

On Board Diagnosis LogicNCEC0074

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0115

0115IAn excessively high or low voltage from the sensor is

sent to ECM.*IHarness or connectors

(The sensor circuit is open or shorted.)

IEngine coolant temperature sensor

*: When this malfunction is detected, the ECM enters fail-safe mode and the MI lights up.

Detected items Engine operating condition in fail-safe mode

Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch

ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided (CONSULT-II

display)

Just as ignition switch is turned ON or Start 40ÉC (104ÉF)

More than approx. 4 minutes after ignition ON or

Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates

while the engine is running.

SEF594K

SEF012P

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)QG16I18DE

Component Description

EC-120

Page 563 of 2267

DTC Confirmation ProcedureNCEC0075NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº, EC-

QG-123.

With GST

Follow the procedure ªWith CONSULT-IIº above.

NEF068A

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)QG16I18DE

DTC Confirmation Procedure

EC-121

Page 564 of 2267

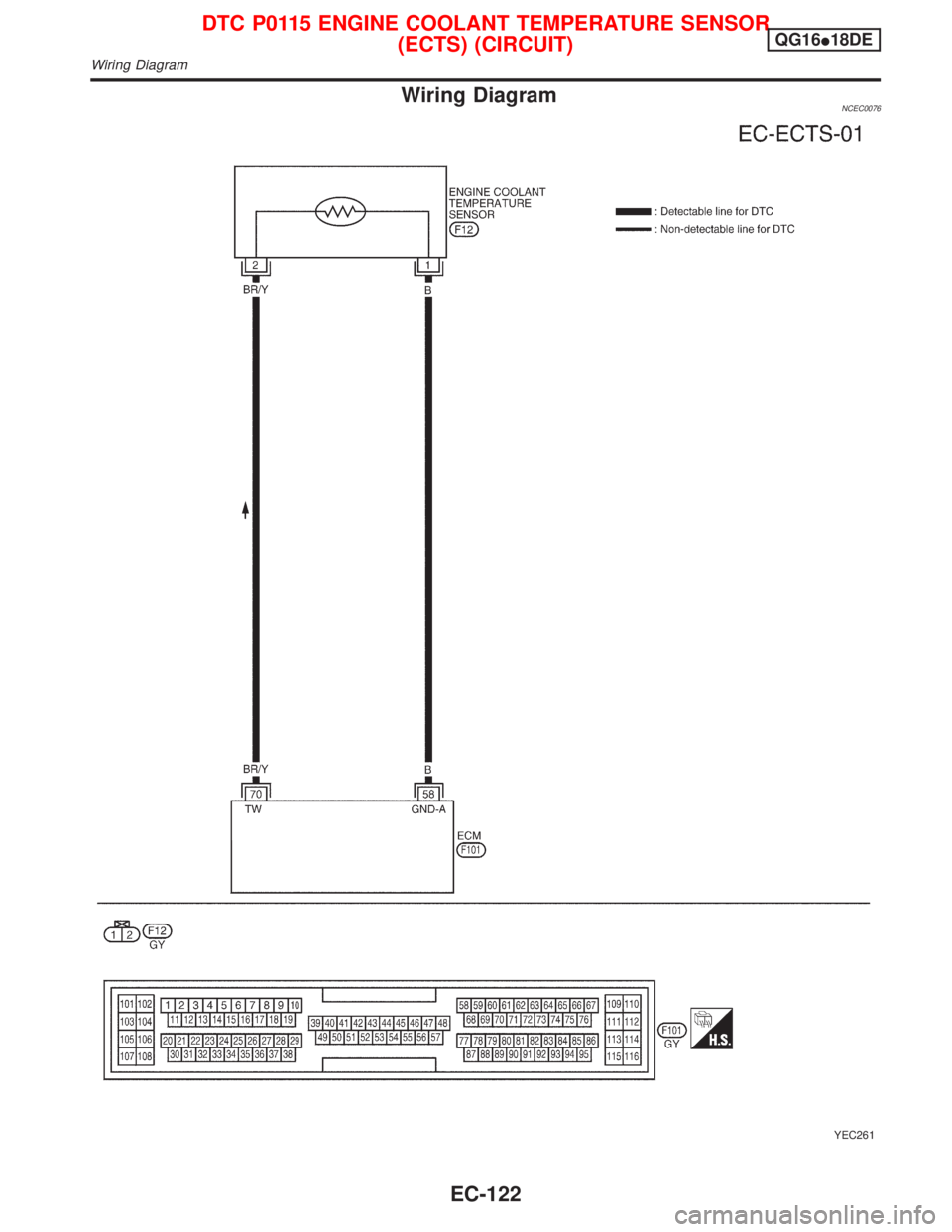

Wiring DiagramNCEC0076

YEC261

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)QG16I18DE

Wiring Diagram

EC-122

Page 565 of 2267

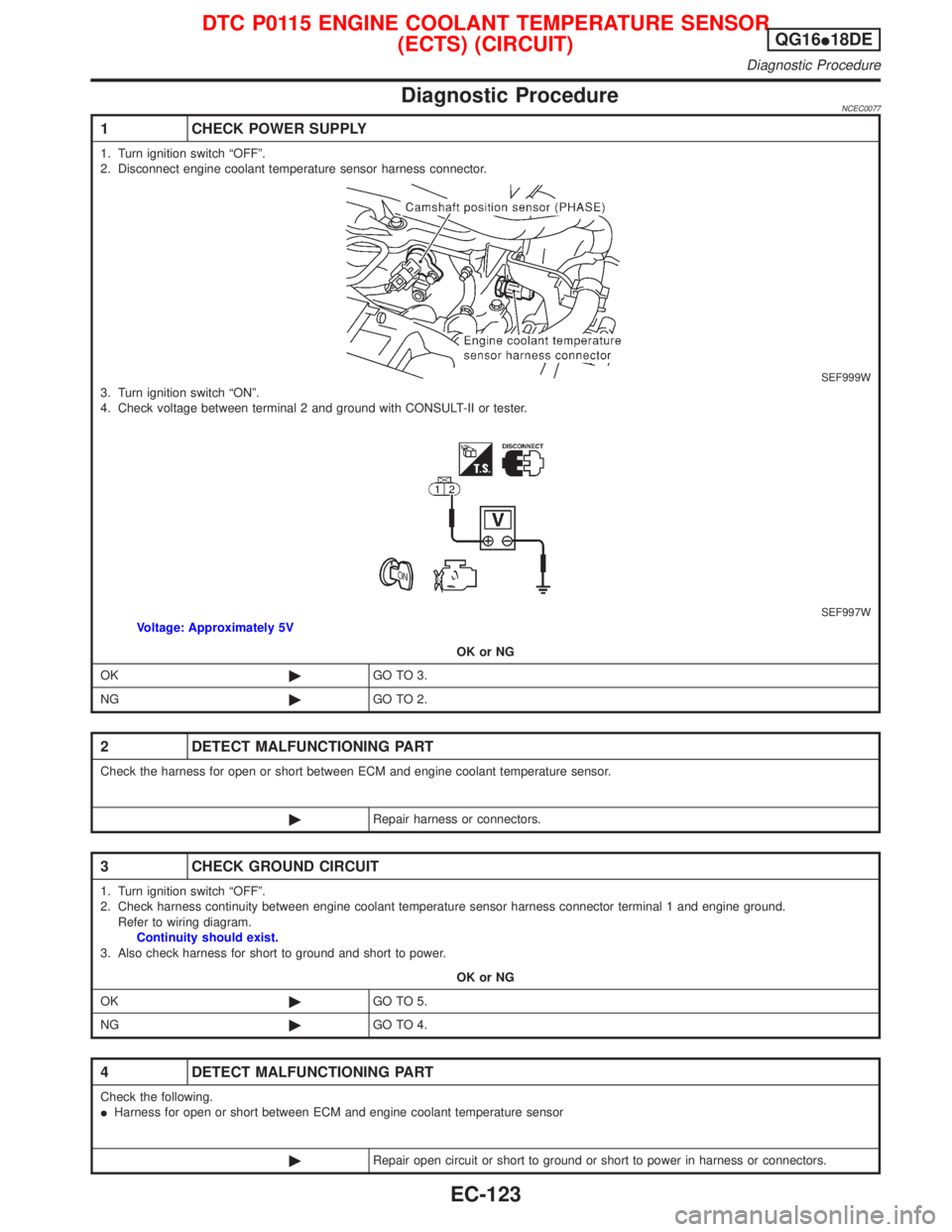

Diagnostic ProcedureNCEC0077

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect engine coolant temperature sensor harness connector.

SEF999W3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF997WVoltage: Approximately 5V

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and engine coolant temperature sensor.

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between engine coolant temperature sensor harness connector terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness for open or short between ECM and engine coolant temperature sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0115 ENGINE COOLANT TEMPERATURE SENSOR

(ECTS) (CIRCUIT)QG16I18DE

Diagnostic Procedure

EC-123