sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 516 of 2267

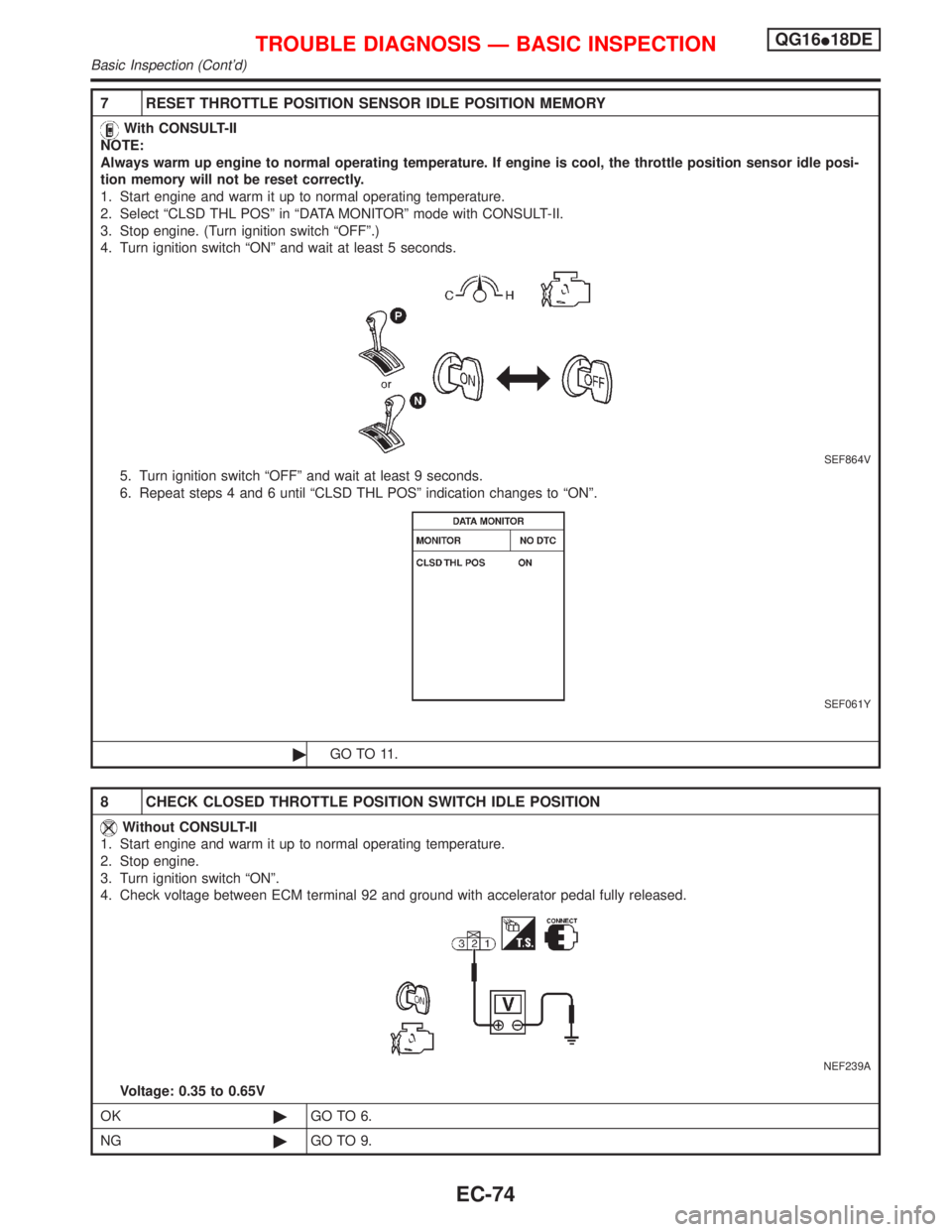

7 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Select ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

3. Stop engine. (Turn ignition switch ªOFFº.)

4. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

5. Turn ignition switch ªOFFº and wait at least 9 seconds.

6. Repeat steps 4 and 6 until ªCLSD THL POSº indication changes to ªONº.

SEF061Y

©GO TO 11.

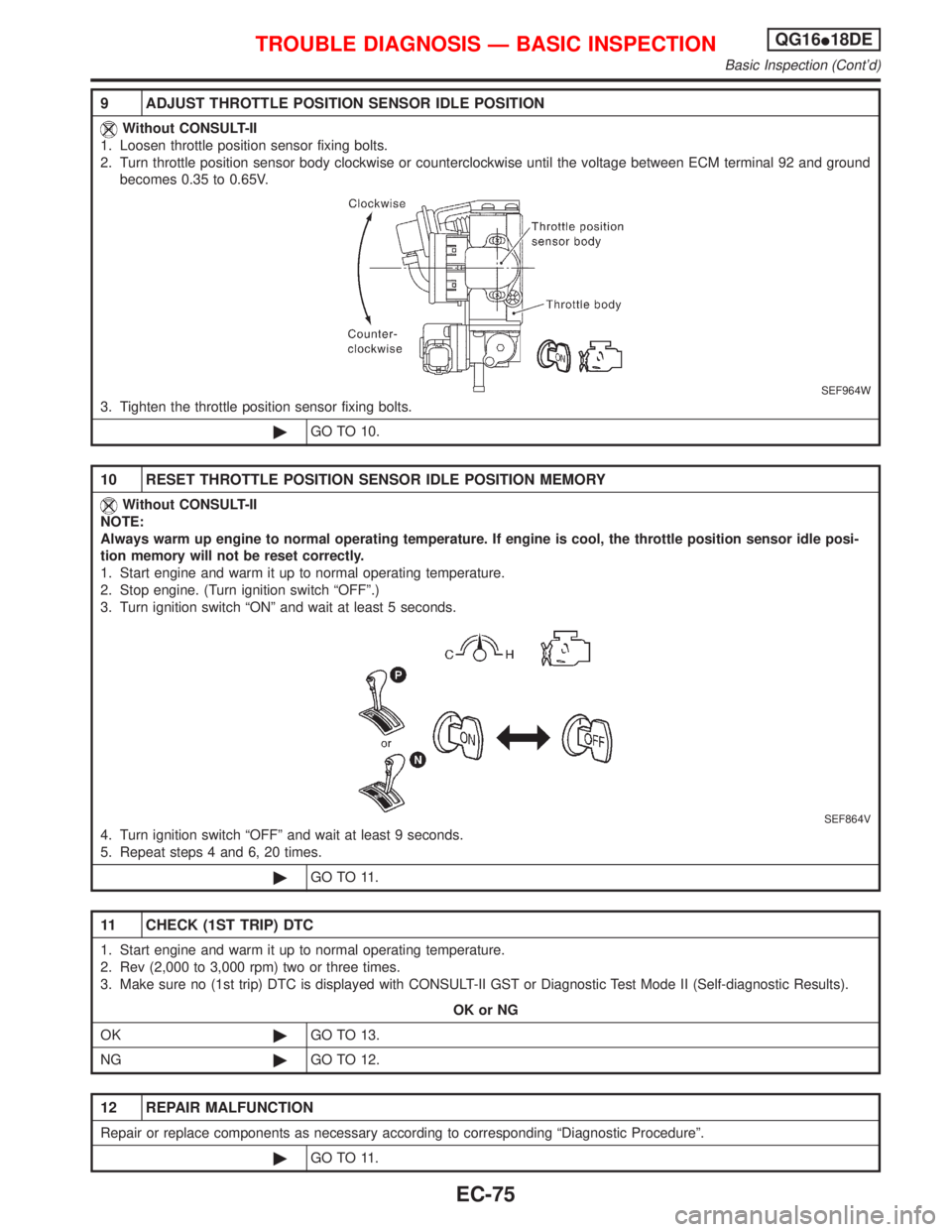

8 CHECK CLOSED THROTTLE POSITION SWITCH IDLE POSITION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Check voltage between ECM terminal 92 and ground with accelerator pedal fully released.

NEF239A

Voltage: 0.35 to 0.65V

OK©GO TO 6.

NG©GO TO 9.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG16I18DE

Basic Inspection (Cont'd)

EC-74

Page 517 of 2267

9 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until the voltage between ECM terminal 92 and ground

becomes 0.35 to 0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 10.

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Stop engine. (Turn ignition switch ªOFFº.)

3. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

4. Turn ignition switch ªOFFº and wait at least 9 seconds.

5. Repeat steps 4 and 6, 20 times.

©GO TO 11.

11 CHECK (1ST TRIP) DTC

1. Start engine and warm it up to normal operating temperature.

2. Rev (2,000 to 3,000 rpm) two or three times.

3. Make sure no (1st trip) DTC is displayed with CONSULT-II GST or Diagnostic Test Mode II (Self-diagnostic Results).

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 REPAIR MALFUNCTION

Repair or replace components as necessary according to corresponding ªDiagnostic Procedureº.

©GO TO 11.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG16I18DE

Basic Inspection (Cont'd)

EC-75

Page 522 of 2267

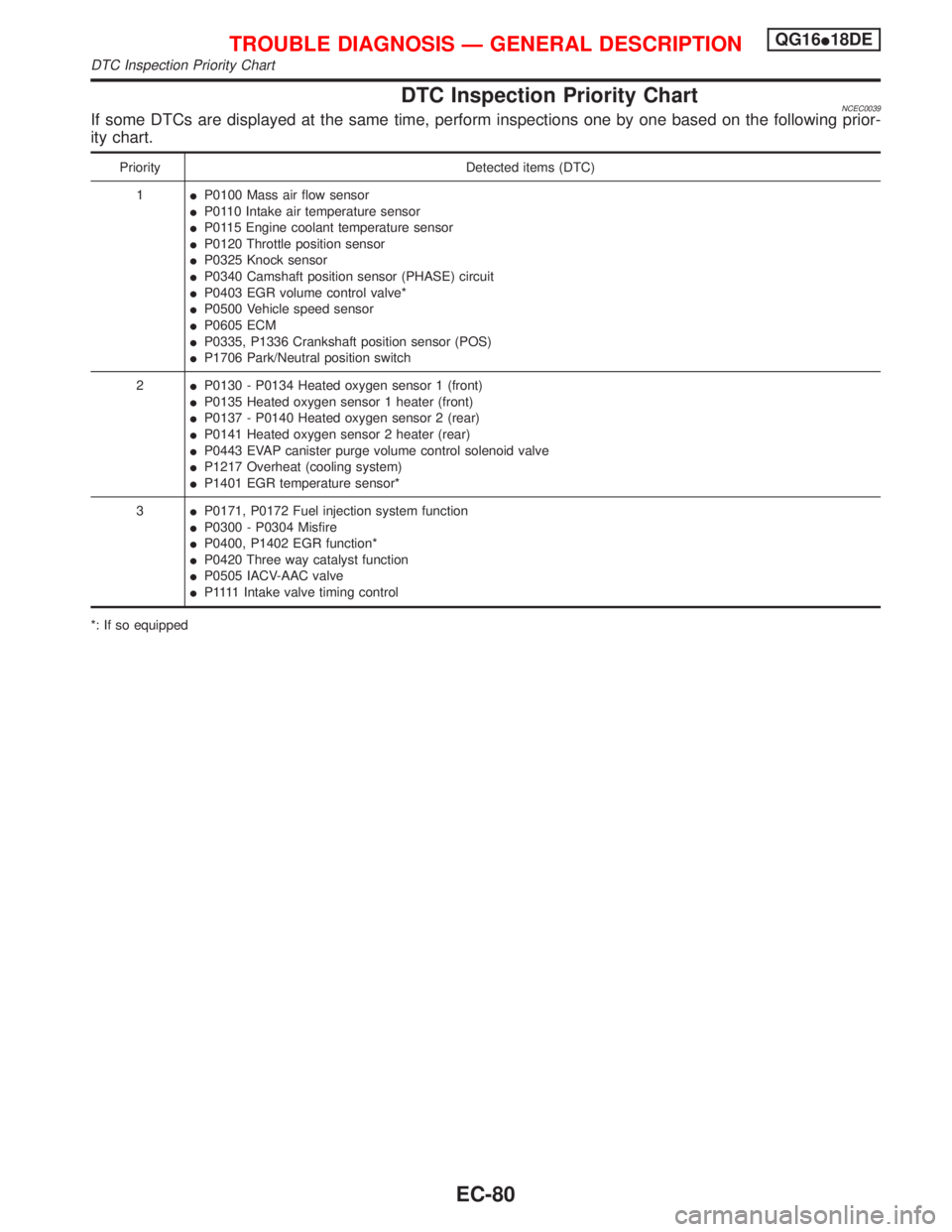

DTC Inspection Priority ChartNCEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0325 Knock sensor

IP0340 Camshaft position sensor (PHASE) circuit

IP0403 EGR volume control valve*

IP0500 Vehicle speed sensor

IP0605 ECM

IP0335, P1336 Crankshaft position sensor (POS)

IP1706 Park/Neutral position switch

2IP0130 - P0134 Heated oxygen sensor 1 (front)

IP0135 Heated oxygen sensor 1 heater (front)

IP0137 - P0140 Heated oxygen sensor 2 (rear)

IP0141 Heated oxygen sensor 2 heater (rear)

IP0443 EVAP canister purge volume control solenoid valve

IP1217 Overheat (cooling system)

IP1401 EGR temperature sensor*

3IP0171, P0172 Fuel injection system function

IP0300 - P0304 Misfire

IP0400, P1402 EGR function*

IP0420 Three way catalyst function

IP0505 IACV-AAC valve

IP 1111Intake valve timing control

*: If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

DTC Inspection Priority Chart

EC-80

Page 523 of 2267

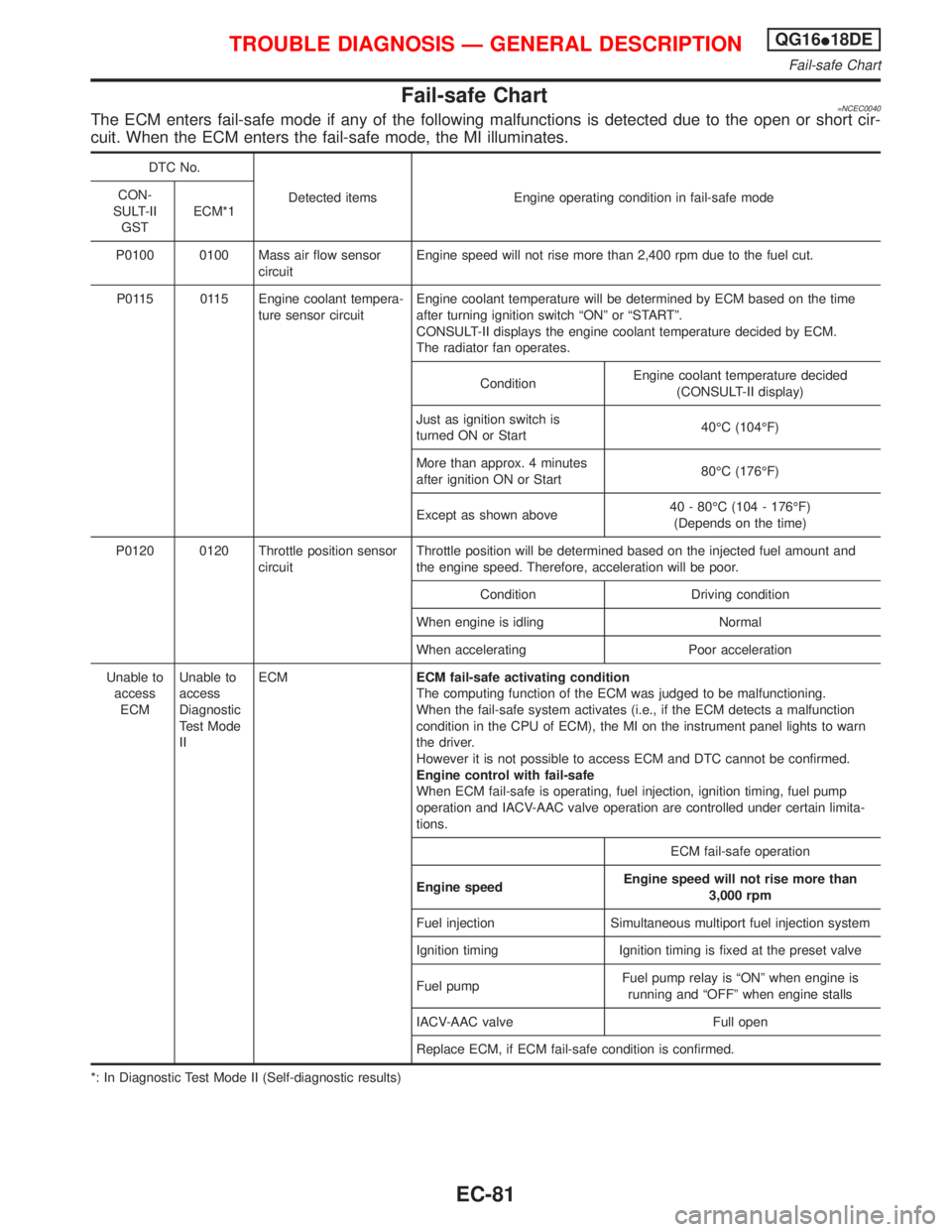

Fail-safe Chart=NCEC0040The ECM enters fail-safe mode if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MI illuminates.

DTC No.

Detected items Engine operating condition in fail-safe mode CON-

SULT-II

GSTECM*1

P0100 0100 Mass air flow sensor

circuitEngine speed will not rise more than 2,400 rpm due to the fuel cut.

P0115 0115 Engine coolant tempera-

ture sensor circuitEngine coolant temperature will be determined by ECM based on the time

after turning ignition switch ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

The radiator fan operates.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is

turned ON or Start40ÉC (104ÉF)

More than approx. 4 minutes

after ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0120 0120 Throttle position sensor

circuitThrottle position will be determined based on the injected fuel amount and

the engine speed. Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

Unable to

access

ECMUnable to

access

Diagnostic

Test Mode

IIECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction

condition in the CPU of ECM), the MI on the instrument panel lights to warn

the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump

operation and IACV-AAC valve operation are controlled under certain limita-

tions.

ECM fail-safe operation

Engine speedEngine speed will not rise more than

3,000 rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is

running and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

*: In Diagnostic Test Mode II (Self-diagnostic results)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Fail-safe Chart

EC-81

Page 525 of 2267

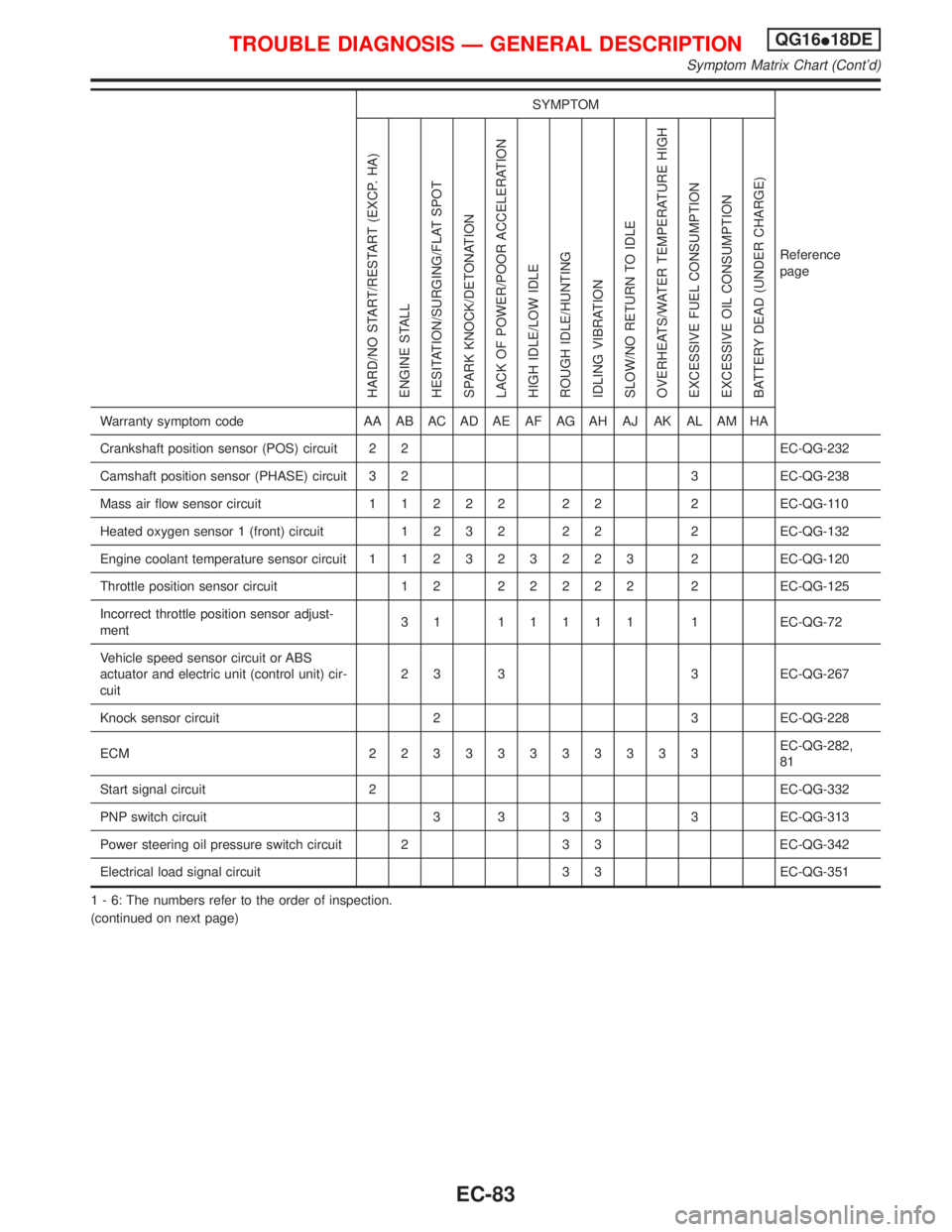

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Crankshaft position sensor (POS) circuit 2 2 EC-QG-232

Camshaft position sensor (PHASE) circuit 3 2 3 EC-QG-238

Mass air flow sensor circuit11222 22 2EC-QG-110

Heated oxygen sensor 1 (front) circuit1232 22 2EC-QG-132

Engine coolant temperature sensor circuit112323223 2EC-QG-120

Throttle position sensor circuit 1 222222 2EC-QG-125

Incorrect throttle position sensor adjust-

ment31 11111 1EC-QG-72

Vehicle speed sensor circuit or ABS

actuator and electric unit (control unit) cir-

cuit2 3 3 3 EC-QG-267

Knock sensor circuit 2 3 EC-QG-228

ECM 22333333333EC-QG-282,

81

Start signal circuit 2 EC-QG-332

PNP switch circuit 3 3 3 3 3 EC-QG-313

Power steering oil pressure switch circuit 2 3 3 EC-QG-342

Electrical load signal circuit 3 3 EC-QG-351

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Symptom Matrix Chart (Cont'd)

EC-83

Page 526 of 2267

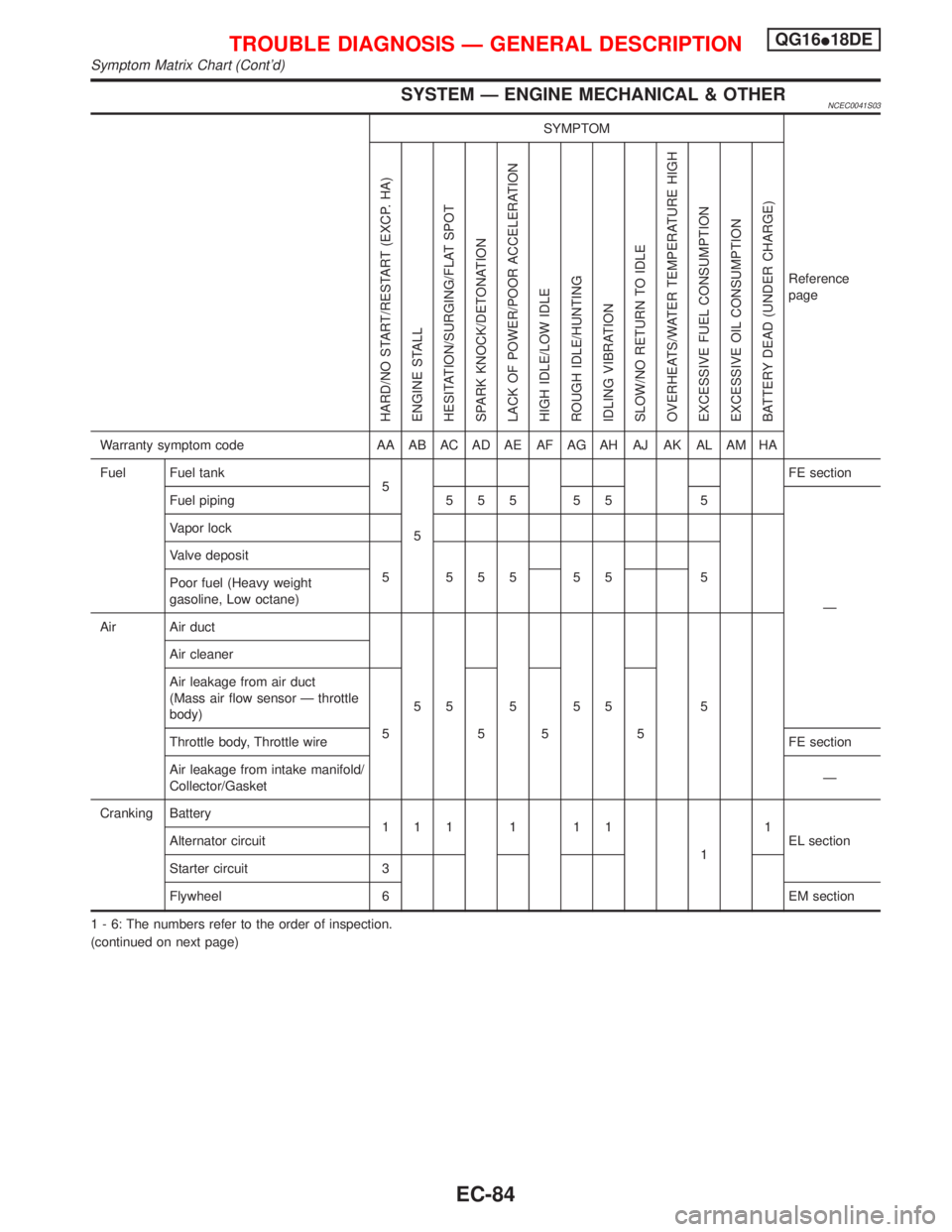

SYSTEM Ð ENGINE MECHANICAL & OTHERNCEC0041S03

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank

5

5FE section

Fuel piping 5 5 5 5 5 5

Ð Vapor lock

Valve deposit

5 555 55 5

Poor fuel (Heavy weight

gasoline, Low octane)

Air Air duct

55555 5 Air cleaner

Air leakage from air duct

(Mass air flow sensor Ð throttle

body)

5555

Throttle body, Throttle wireFE section

Air leakage from intake manifold/

Collector/GasketÐ

Cranking Battery

111111

11

EL section Alternator circuit

Starter circuit 3

Flywheel 6 EM section

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Symptom Matrix Chart (Cont'd)

EC-84

Page 528 of 2267

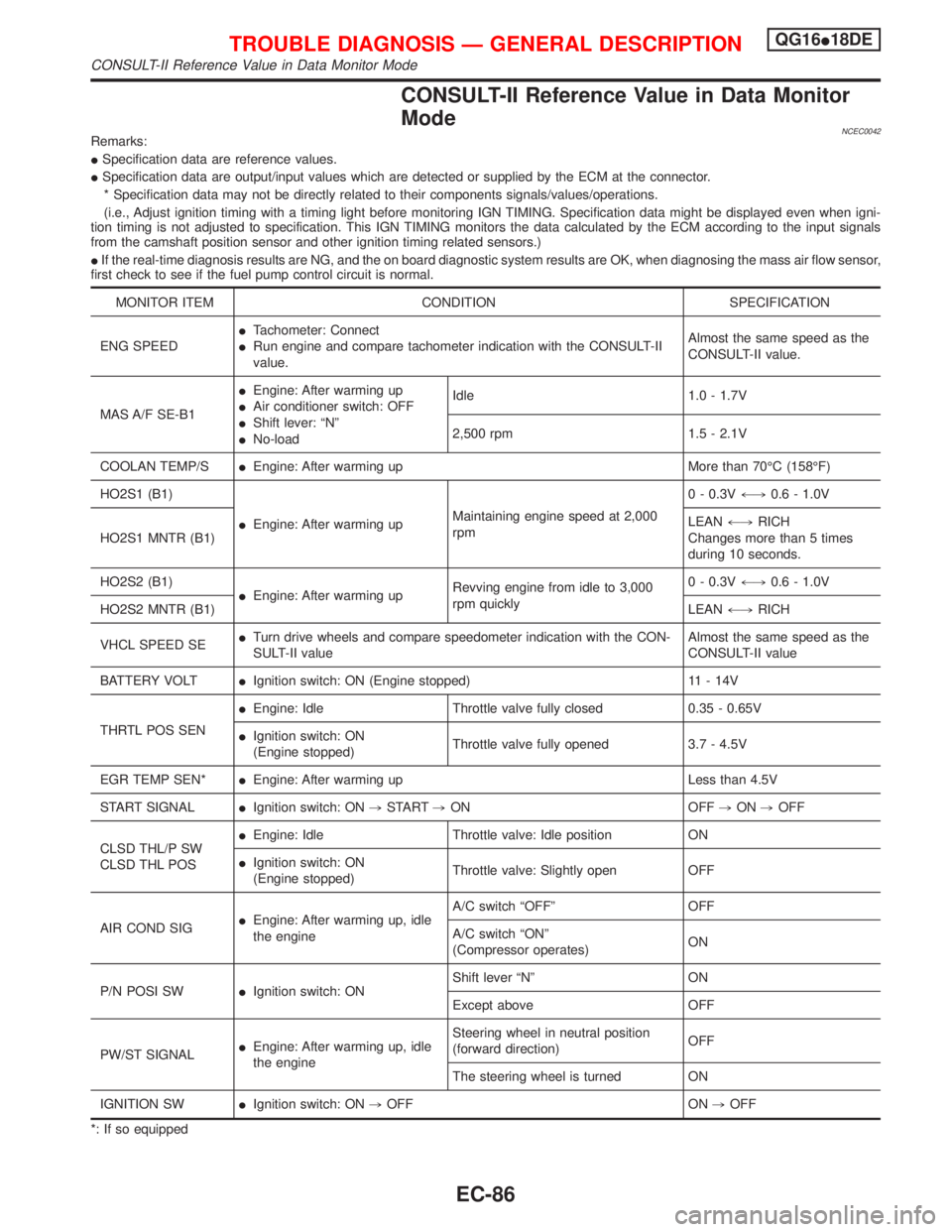

CONSULT-II Reference Value in Data Monitor

Mode

NCEC0042Remarks:

ISpecification data are reference values.

ISpecification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

(i.e., Adjust ignition timing with a timing light before monitoring IGN TIMING. Specification data might be displayed even when igni-

tion timing is not adjusted to specification. This IGN TIMING monitors the data calculated by the ECM according to the input signals

from the camshaft position sensor and other ignition timing related sensors.)

IIf the real-time diagnosis results are NG, and the on board diagnostic system results are OK, when diagnosing the mass air flow sensor,

first check to see if the fuel pump control circuit is normal.

MONITOR ITEM CONDITION SPECIFICATION

ENG SPEEDITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

MAS A/F SE-B1IEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle 1.0 - 1.7V

2,500 rpm 1.5 - 2.1V

COOLAN TEMP/SIEngine: After warming up More than 70ÉC (158ÉF)

HO2S1 (B1)

IEngine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V+,0.6 - 1.0V

HO2S1 MNTR (B1)LEAN+,RICH

Changes more than 5 times

during 10 seconds.

HO2S2 (B1)

IEngine: After warming upRevving engine from idle to 3,000

rpm quickly0 - 0.3V+,0.6 - 1.0V

HO2S2 MNTR (B1)LEAN+,RICH

VHCL SPEED SEITurn drive wheels and compare speedometer indication with the CON-

SULT-II valueAlmost the same speed as the

CONSULT-II value

BATTERY VOLTIIgnition switch: ON (Engine stopped) 11 - 14V

THRTL POS SENIEngine: Idle Throttle valve fully closed 0.35 - 0.65V

IIgnition switch: ON

(Engine stopped)Throttle valve fully opened 3.7 - 4.5V

EGR TEMP SEN*IEngine: After warming up Less than 4.5V

START SIGNALIIgnition switch: ON,START,ON OFF,ON,OFF

CLSD THL/P SW

CLSD THL POSIEngine: Idle Throttle valve: Idle position ON

IIgnition switch: ON

(Engine stopped)Throttle valve: Slightly open OFF

AIR COND SIGIEngine: After warming up, idle

the engineA/C switch ªOFFº OFF

A/C switch ªONº

(Compressor operates)ON

P/N POSI SWIIgnition switch: ONShift lever ªNº ON

Except above OFF

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is turned ON

IGNITION SWIIgnition switch: ON,OFF ON,OFF

*: If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

CONSULT-II Reference Value in Data Monitor Mode

EC-86

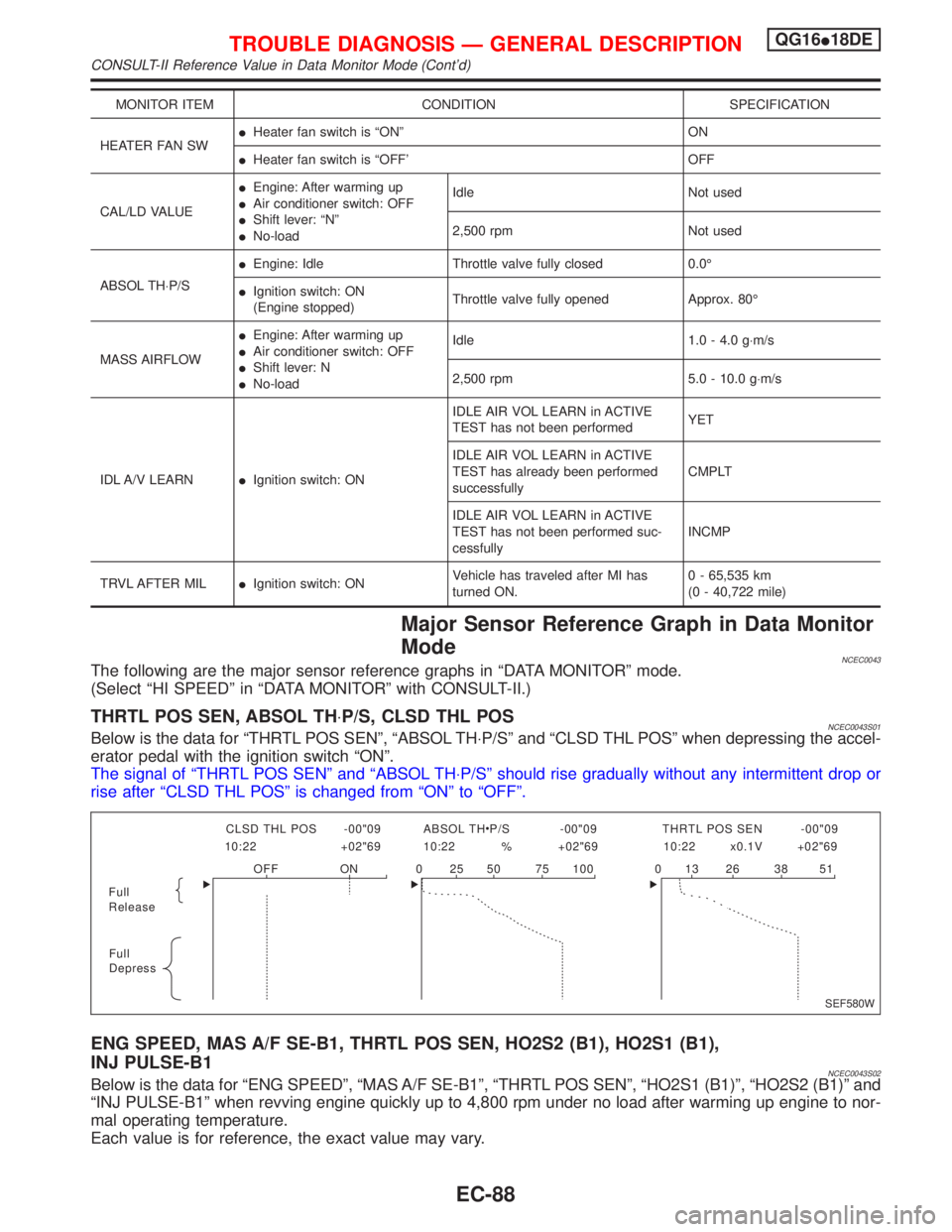

Page 530 of 2267

MONITOR ITEM CONDITION SPECIFICATION

HEATER FAN SWIHeater fan switch is ªONº ON

IHeater fan switch is ªOFF' OFF

CAL/LD VALUEIEngine: After warming up

IAir conditioner switch: OFF

IShift lever: ªNº

INo-loadIdle Not used

2,500 rpm Not used

ABSOL TH×P/SIEngine: Idle Throttle valve fully closed 0.0É

IIgnition switch: ON

(Engine stopped)Throttle valve fully opened Approx. 80É

MASS AIRFLOWIEngine: After warming up

IAir conditioner switch: OFF

IShift lever: N

INo-loadIdle 1.0 - 4.0 g×m/s

2,500 rpm 5.0 - 10.0 g×m/s

IDL A/V LEARNIIgnition switch: ONIDLE AIR VOL LEARN in ACTIVE

TEST has not been performedYET

IDLE AIR VOL LEARN in ACTIVE

TEST has already been performed

successfullyCMPLT

IDLE AIR VOL LEARN in ACTIVE

TEST has not been performed suc-

cessfullyINCMP

TRVL AFTER MILIIgnition switch: ONVehicle has traveled after MI has

turned ON.0 - 65,535 km

(0 - 40,722 mile)

Major Sensor Reference Graph in Data Monitor

Mode

NCEC0043The following are the major sensor reference graphs in ªDATA MONITORº mode.

(Select ªHI SPEEDº in ªDATA MONITORº with CONSULT-II.)

THRTL POS SEN, ABSOL TH×P/S, CLSD THL POSNCEC0043S01Below is the data for ªTHRTL POS SENº, ªABSOL TH×P/Sº and ªCLSD THL POSº when depressing the accel-

erator pedal with the ignition switch ªONº.

The signal of ªTHRTL POS SENº and ªABSOL TH×P/Sº should rise gradually without any intermittent drop or

rise after ªCLSD THL POSº is changed from ªONº to ªOFFº.

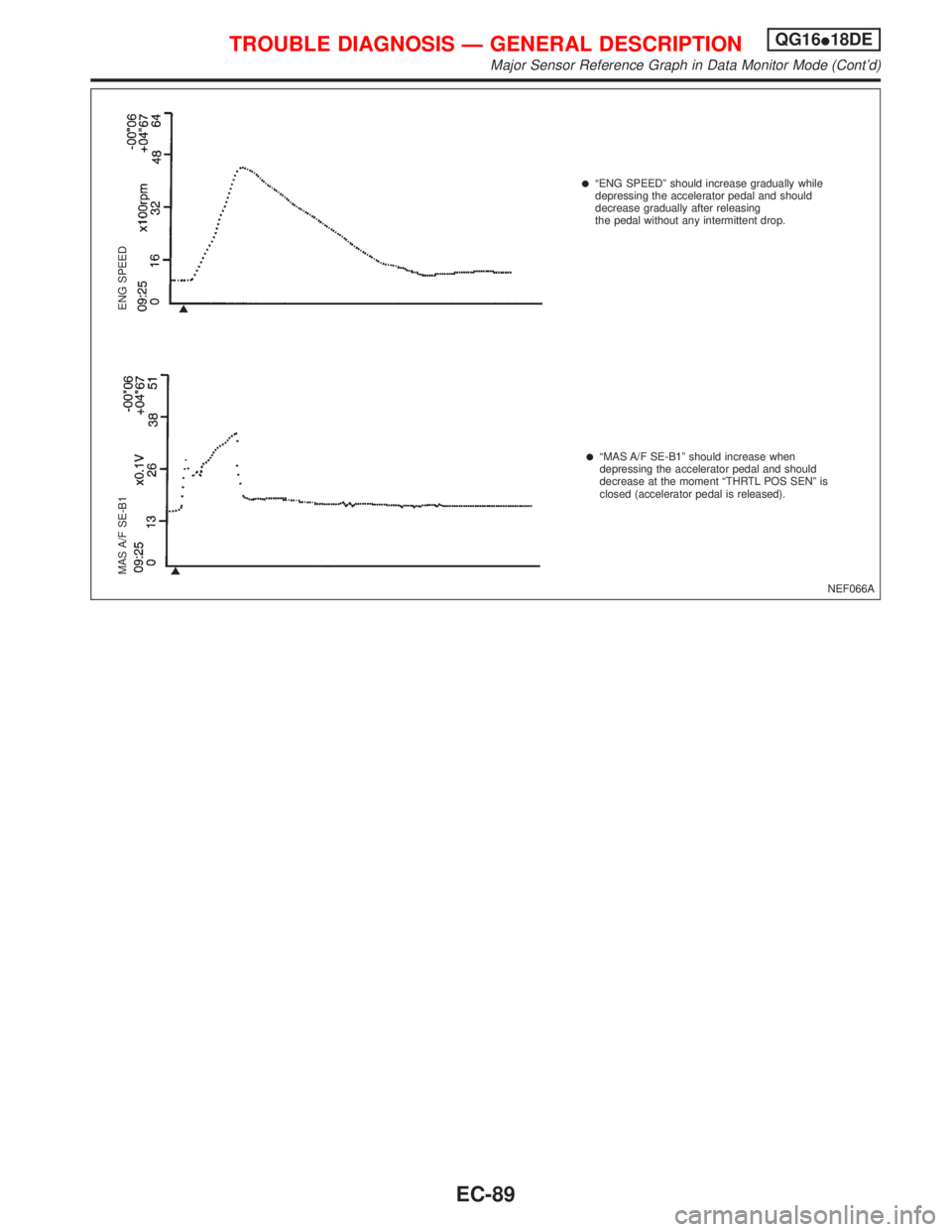

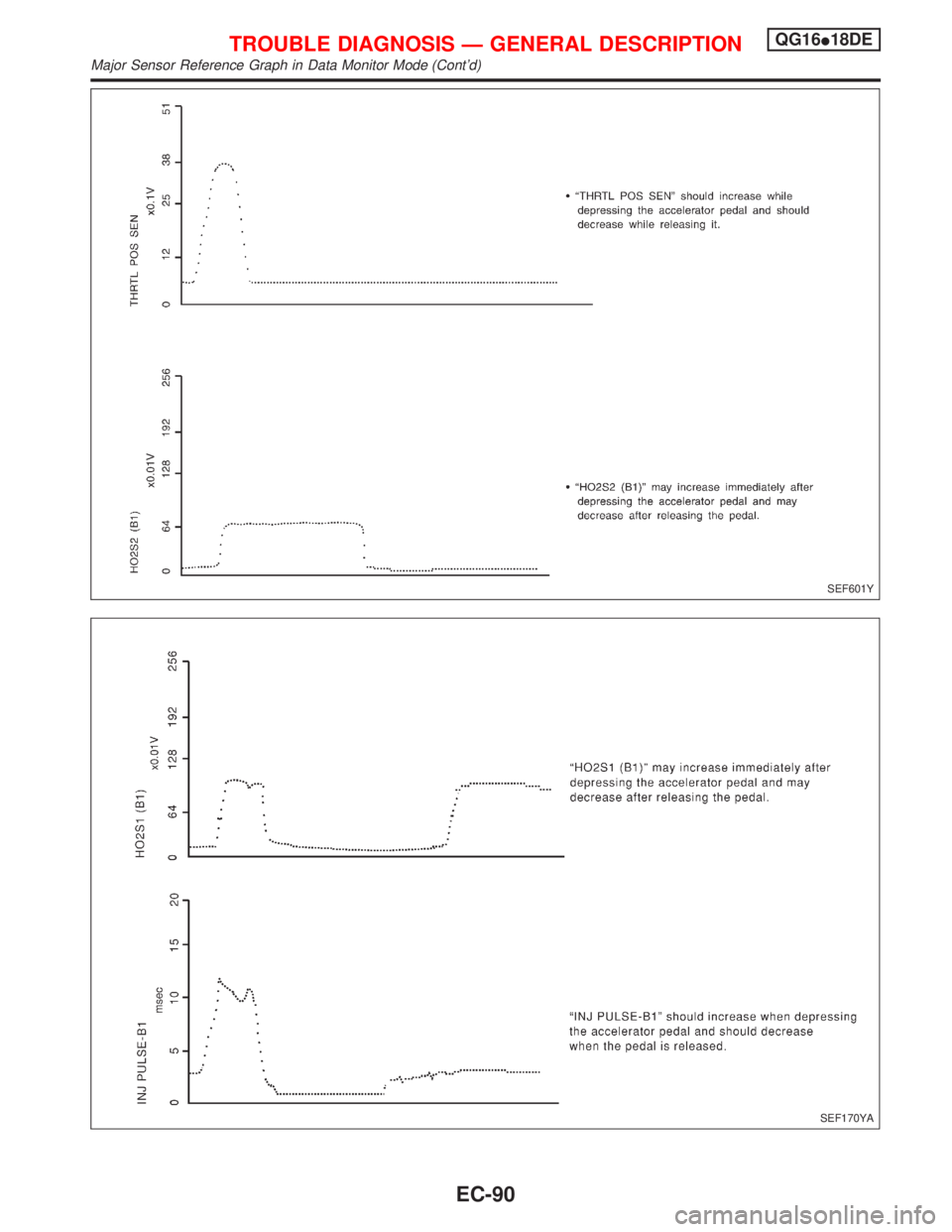

ENG SPEED, MAS A/F SE-B1, THRTL POS SEN, HO2S2 (B1), HO2S1 (B1),

INJ PULSE-B1

NCEC0043S02Below is the data for ªENG SPEEDº, ªMAS A/F SE-B1º, ªTHRTL POS SENº, ªHO2S1 (B1)º, ªHO2S2 (B1)º and

ªINJ PULSE-B1º when revving engine quickly up to 4,800 rpm under no load after warming up engine to nor-

mal operating temperature.

Each value is for reference, the exact value may vary.

Full

Release

Full

DepressCLSD THL POS -00"09 ABSOL TH P/S -00"09 THRTL POS SEN -00"09

10:22 +02"69 10:22 % +02"69 10:22 x0.1V +02"69

OFF ON 0 25 50 75 100 0 13 26 38 51

SEF580W

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

CONSULT-II Reference Value in Data Monitor Mode (Cont'd)

EC-88

Page 531 of 2267

NEF066A

lªENG SPEEDº should increase gradually while

depressing the accelerator pedal and should

decrease gradually after releasing

the pedal without any intermittent drop.

lªMAS A/F SE-B1º should increase when

depressing the accelerator pedal and should

decrease at the moment ªTHRTL POS SENº is

closed (accelerator pedal is released).

MAS A/F SE-B1 ENG SPEED

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Major Sensor Reference Graph in Data Monitor Mode (Cont'd)

EC-89

Page 532 of 2267

SEF601Y

SEF170YA

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG16I18DE

Major Sensor Reference Graph in Data Monitor Mode (Cont'd)

EC-90