sensor NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 492 of 2267

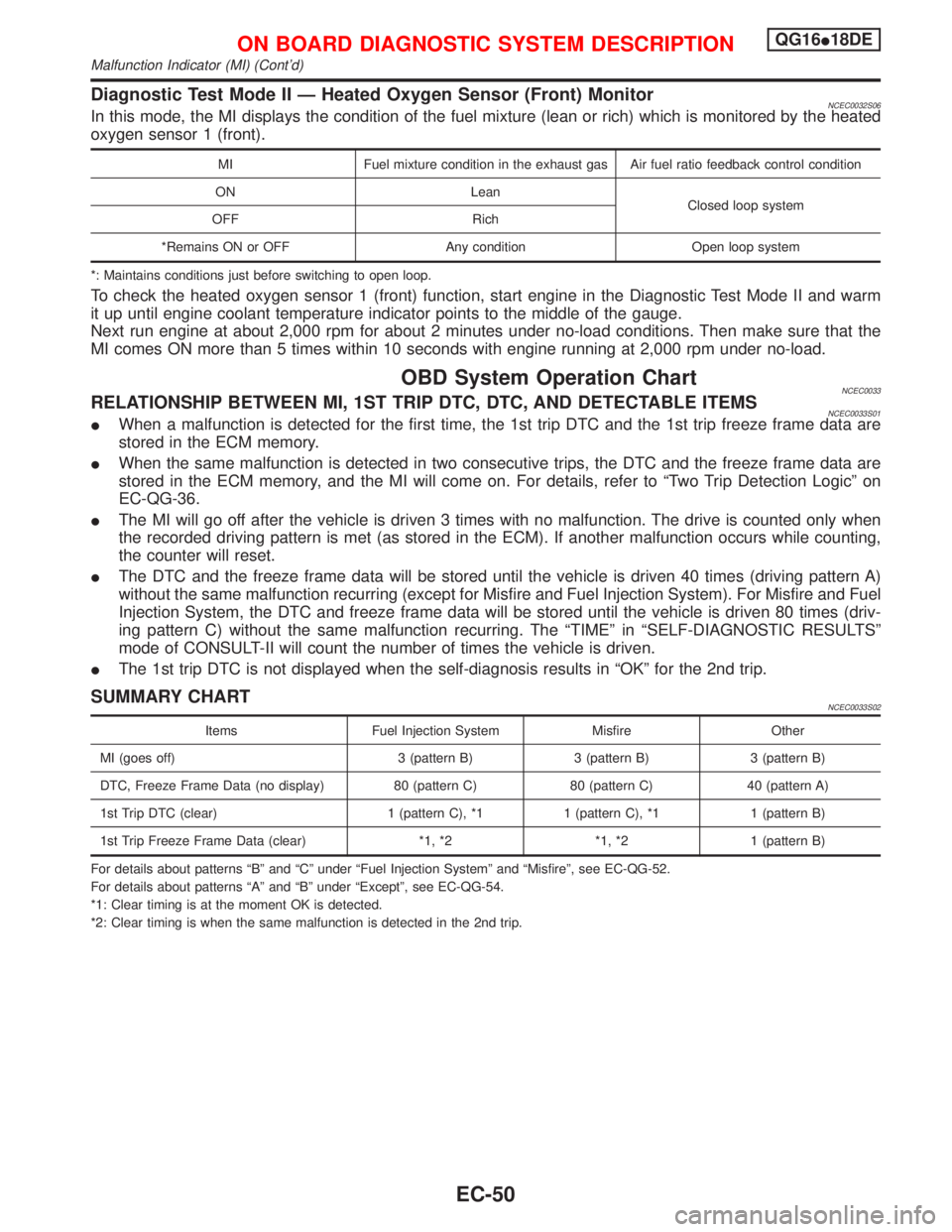

Diagnostic Test Mode II Ð Heated Oxygen Sensor (Front) MonitorNCEC0032S06In this mode, the MI displays the condition of the fuel mixture (lean or rich) which is monitored by the heated

oxygen sensor 1 (front).

MI Fuel mixture condition in the exhaust gas Air fuel ratio feedback control condition

ON Lean

Closed loop system

OFF Rich

*Remains ON or OFF Any condition Open loop system

*: Maintains conditions just before switching to open loop.

To check the heated oxygen sensor 1 (front) function, start engine in the Diagnostic Test Mode II and warm

it up until engine coolant temperature indicator points to the middle of the gauge.

Next run engine at about 2,000 rpm for about 2 minutes under no-load conditions. Then make sure that the

MI comes ON more than 5 times within 10 seconds with engine running at 2,000 rpm under no-load.

OBD System Operation ChartNCEC0033RELATIONSHIP BETWEEN MI, 1ST TRIP DTC, DTC, AND DETECTABLE ITEMSNCEC0033S01IWhen a malfunction is detected for the first time, the 1st trip DTC and the 1st trip freeze frame data are

stored in the ECM memory.

IWhen the same malfunction is detected in two consecutive trips, the DTC and the freeze frame data are

stored in the ECM memory, and the MI will come on. For details, refer to ªTwo Trip Detection Logicº on

EC-QG-36.

IThe MI will go off after the vehicle is driven 3 times with no malfunction. The drive is counted only when

the recorded driving pattern is met (as stored in the ECM). If another malfunction occurs while counting,

the counter will reset.

IThe DTC and the freeze frame data will be stored until the vehicle is driven 40 times (driving pattern A)

without the same malfunction recurring (except for Misfire and Fuel Injection System). For Misfire and Fuel

Injection System, the DTC and freeze frame data will be stored until the vehicle is driven 80 times (driv-

ing pattern C) without the same malfunction recurring. The ªTIMEº in ªSELF-DIAGNOSTIC RESULTSº

mode of CONSULT-II will count the number of times the vehicle is driven.

IThe 1st trip DTC is not displayed when the self-diagnosis results in ªOKº for the 2nd trip.

SUMMARY CHARTNCEC0033S02

Items Fuel Injection System Misfire Other

MI (goes off) 3 (pattern B) 3 (pattern B) 3 (pattern B)

DTC, Freeze Frame Data (no display) 80 (pattern C) 80 (pattern C) 40 (pattern A)

1st Trip DTC (clear) 1 (pattern C), *1 1 (pattern C), *1 1 (pattern B)

1st Trip Freeze Frame Data (clear) *1, *2 *1, *2 1 (pattern B)

For details about patterns ªBº and ªCº under ªFuel Injection Systemº and ªMisfireº, see EC-QG-52.

For details about patterns ªAº and ªBº under ªExceptº, see EC-QG-54.

*1: Clear timing is at the moment OK is detected.

*2: Clear timing is when the same malfunction is detected in the 2nd trip.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

Malfunction Indicator (MI) (Cont'd)

EC-50

Page 498 of 2267

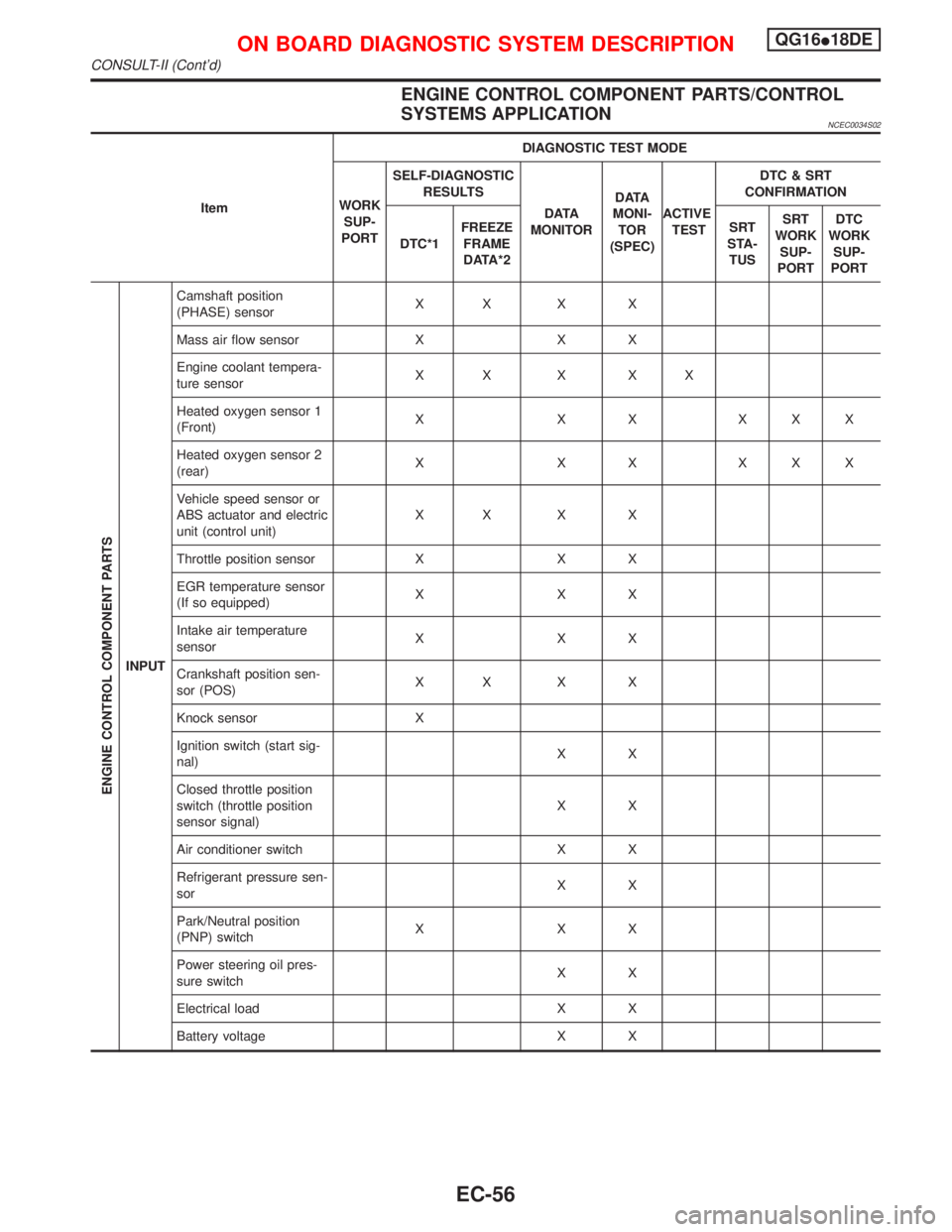

ENGINE CONTROL COMPONENT PARTS/CONTROL

SYSTEMS APPLICATION

NCEC0034S02

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

D ATA

MONITORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STA-

TUSSRT

WORK

SUP-

PORTDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

INPUTCamshaft position

(PHASE) sensorXX X X

Mass air flow sensor X X X

Engine coolant tempera-

ture sensorXX X XX

Heated oxygen sensor 1

(Front)X X X XXX

Heated oxygen sensor 2

(rear)X X X XXX

Vehicle speed sensor or

ABS actuator and electric

unit (control unit)XX X X

Throttle position sensor X X X

EGR temperature sensor

(If so equipped)XXX

Intake air temperature

sensorXXX

Crankshaft position sen-

sor (POS)XX X X

Knock sensor X

Ignition switch (start sig-

nal)XX

Closed throttle position

switch (throttle position

sensor signal)XX

Air conditioner switch X X

Refrigerant pressure sen-

sorXX

Park/Neutral position

(PNP) switchXXX

Power steering oil pres-

sure switchXX

Electrical load X X

Battery voltage X X

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-56

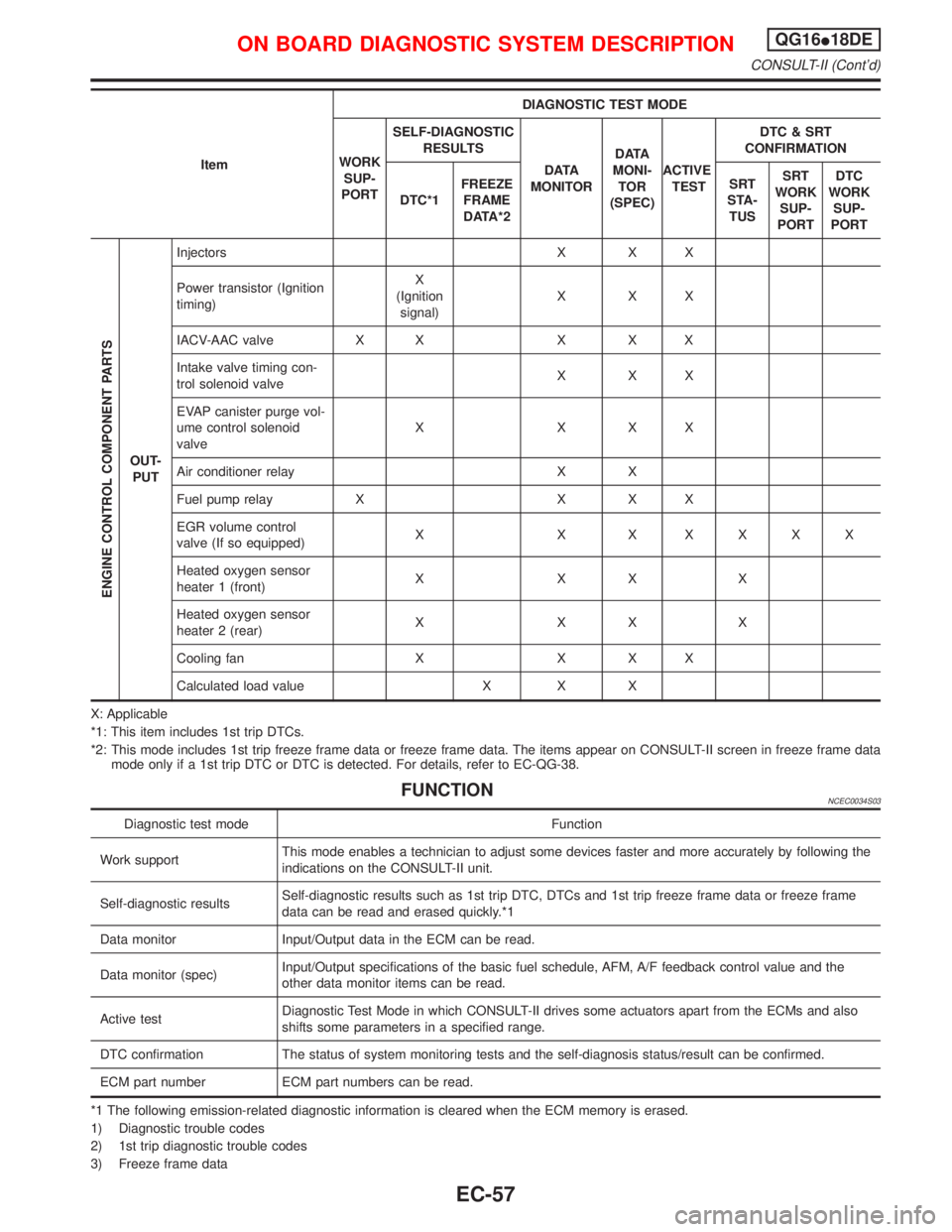

Page 499 of 2267

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

D ATA

MONITORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STA-

TUSSRT

WORK

SUP-

PORTDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

OUT-

PUTInjectors X X X

Power transistor (Ignition

timing)X

(Ignition

signal)XXX

IACV-AAC valve X X X X X

Intake valve timing con-

trol solenoid valveXXX

EVAP canister purge vol-

ume control solenoid

valveXXXX

Air conditioner relay X X

Fuel pump relay X X X X

EGR volume control

valve (If so equipped)X X X XXXX

Heated oxygen sensor

heater 1 (front)XXXX

Heated oxygen sensor

heater 2 (rear)XXXX

Cooling fan X X X X

Calculated load value X X X

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-II screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to EC-QG-38.

FUNCTIONNCEC0034S03

Diagnostic test mode Function

Work supportThis mode enables a technician to adjust some devices faster and more accurately by following the

indications on the CONSULT-II unit.

Self-diagnostic resultsSelf-diagnostic results such as 1st trip DTC, DTCs and 1st trip freeze frame data or freeze frame

data can be read and erased quickly.*1

Data monitor Input/Output data in the ECM can be read.

Data monitor (spec)Input/Output specifications of the basic fuel schedule, AFM, A/F feedback control value and the

other data monitor items can be read.

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from the ECMs and also

shifts some parameters in a specified range.

DTC confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECM part number ECM part numbers can be read.

*1 The following emission-related diagnostic information is cleared when the ECM memory is erased.

1) Diagnostic trouble codes

2) 1st trip diagnostic trouble codes

3) Freeze frame data

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-57

Page 500 of 2267

4) 1st trip freeze frame data

5) System readiness test (SRT) codes

6) Test values

7) Distance traveled while MI is activated.

8) Others

WORK SUPPORT MODENCEC0034S04

WORK ITEM CONDITION USAGE

FUEL PRESSURE RELEASEIFUEL PUMP WILL STOP BY TOUCHING ªSTARTº

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.When releasing fuel pressure

from fuel line

TARGET IDLE RPM ADJ*IIDLE CONDITION When setting target idle speed

TARGET IGNITION TIMING ADJ*IIDLE CONDITION When adjusting target ignition tim-

ing

After adjustment, confirm target

ignition timing with a timing light.

*: This function is not necessary in the usual service procedure.

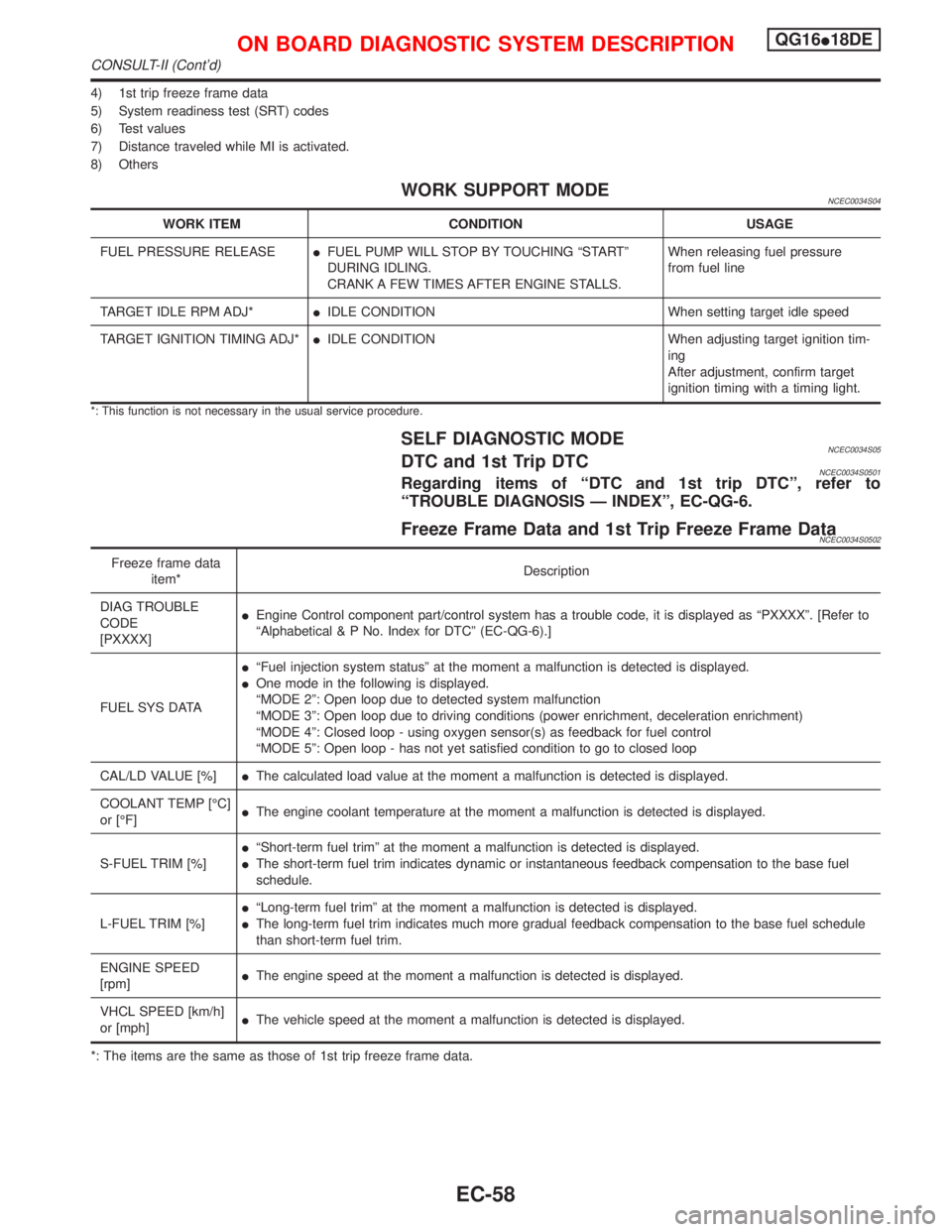

SELF DIAGNOSTIC MODENCEC0034S05DTC and 1st Trip DTCNCEC0034S0501Regarding items of ªDTC and 1st trip DTCº, refer to

ªTROUBLE DIAGNOSIS Ð INDEXº, EC-QG-6.

Freeze Frame Data and 1st Trip Freeze Frame DataNCEC0034S0502

Freeze frame data

item*Description

DIAG TROUBLE

CODE

[PXXXX]IEngine Control component part/control system has a trouble code, it is displayed as ªPXXXXº. [Refer to

ªAlphabetical & P No. Index for DTCº (EC-QG-6).]

FUEL SYS DATAIªFuel injection system statusº at the moment a malfunction is detected is displayed.

IOne mode in the following is displayed.

ªMODE 2º: Open loop due to detected system malfunction

ªMODE 3º: Open loop due to driving conditions (power enrichment, deceleration enrichment)

ªMODE 4º: Closed loop - using oxygen sensor(s) as feedback for fuel control

ªMODE 5º: Open loop - has not yet satisfied condition to go to closed loop

CAL/LD VALUE [%]IThe calculated load value at the moment a malfunction is detected is displayed.

COOLANT TEMP [ÉC]

or [ÉF]IThe engine coolant temperature at the moment a malfunction is detected is displayed.

S-FUEL TRIM [%]IªShort-term fuel trimº at the moment a malfunction is detected is displayed.

IThe short-term fuel trim indicates dynamic or instantaneous feedback compensation to the base fuel

schedule.

L-FUEL TRIM [%]IªLong-term fuel trimº at the moment a malfunction is detected is displayed.

IThe long-term fuel trim indicates much more gradual feedback compensation to the base fuel schedule

than short-term fuel trim.

ENGINE SPEED

[rpm]IThe engine speed at the moment a malfunction is detected is displayed.

VHCL SPEED [km/h]

or [mph]IThe vehicle speed at the moment a malfunction is detected is displayed.

*: The items are the same as those of 1st trip freeze frame data.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-58

Page 501 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual DATA MONITOR MODENCEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED

[rpm]qqIIndicates the engine speed computed from the

POS signal of the crankshaft position NISSAN PRIMERA 1999 Electronic Repair Manual DATA MONITOR MODENCEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED

[rpm]qqIIndicates the engine speed computed from the

POS signal of the crankshaft position](/img/5/57377/w960_57377-500.png)

DATA MONITOR MODENCEC0034S06

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

ENG SPEED

[rpm]qqIIndicates the engine speed computed from the

POS signal of the crankshaft position sensor.IAccuracy becomes poor if

engine speed drops below the

idle rpm.

IIf the signal is interrupted while

the engine is running, an abnor-

mal value may be indicated.

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sensor is

displayed.IWhen the engine is stopped, a

certain value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]qqIThe engine coolant temperature (determined by

the signal voltage of the engine coolant tem-

perature sensor) is displayed.IWhen the engine coolant tem-

perature sensor is open or

short-circuited, ECM enters fail-

safe mode. The engine coolant

temperature determined by the

ECM is displayed.

HO2S1 (B1) [V]qqIThe signal voltage of the heated oxygen sensor

1 (front) is displayed.

HO2S2 (B1) [V]qIThe signal voltage of the heated oxygen sensor

2 (rear) is displayed.

HO2S1 MNTR (B1)

[RICH/LEAN]qIDisplay of heated oxygen sensor 1 (front) signal

during air-fuel ratio feedback control:

RICH ... means the mixture became ªrichº, and

control is being affected toward a leaner mix-

ture.

LEAN ... means the mixture became ªleanº, and

control is being affected toward a rich mixture.IAfter turning ON the ignition

switch, ªRICHº is displayed until

air-fuel mixture ratio feedback

control begins.

IWhen the air-fuel ratio feedback

is clamped, the value just

before the clamping is dis-

played continuously.

HO2S2 MNTR (B1)

[RICH/LEAN]qIDisplay of heated oxygen sensor 2 (rear) signal:

RICH ... means the amount of oxygen after

three way catalyst is relatively small.

LEAN ... means the amount of oxygen after

three way catalyst is relatively large.IWhen the engine is stopped, a

certain value is indicated.

VHCL SPEED SE

[km/h] or [mph]qqIThe vehicle speed computed from the vehicle

speed sensor signal or ABS actuator and elec-

tric unit (control unit) signal is displayed.

BATTERY VOLT [V]qIThe power supply voltage of ECM is displayed.

THRTL POS SEN [V]qqIThe throttle position sensor signal voltage is dis-

played.

EGR TEMP SEN [V]

(If so equipped)qqIThe signal voltage of the EGR temperature sen-

sor is displayed.

INT/A TEMP SE

[ÉC] or [ÉF]qIThe intake air temperature determined by the

signal voltage of the intake air temperature sen-

sor is indicated.

START SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the starter

signal.IAfter starting the engine, [OFF]

is displayed regardless of the

starter signal.

CLSD THL POS

[ON/OFF]qqIIndicates idle position [ON/OFF] computed by

ECM according to the throttle position sensor

signal.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-59

Page 503 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

EGR VOL CON/V

[step]

(If so equipped)qIIndicates the EGR volume control valve com-

puted by the ECM according to the input sig-

na NISSAN PRIMERA 1999 Electronic Repair Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

EGR VOL CON/V

[step]

(If so equipped)qIIndicates the EGR volume control valve com-

puted by the ECM according to the input sig-

na](/img/5/57377/w960_57377-502.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

EGR VOL CON/V

[step]

(If so equipped)qIIndicates the EGR volume control valve com-

puted by the ECM according to the input sig-

nals.

IThe opening becomes larger as the value

increases.

HO2S1 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of heated oxygen

sensor 1 (front) heater determined by ECM

according to the input signals.

HO2S2 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of heated oxygen

sensor 2 (rear) heater determined by ECM

according to the input signals.

PURG VOL C/V [%]IIndicates the EVAP canister purge volume con-

trol solenoid valve computed by the ECM

according to the input signals.

IThe opening becomes larger as the value

increases.

CAL/LD VALUE [%]IªCalculated load valueº indicates the value of

the current air flow divided by peak air flow.

ABSOL TH.P/S [%]IªAbsolute throttle position sensorº indicates the

throttle opening computed by ECM according to

the signal voltage of the throttle position sensor.

MASS AIRFLOW

[gm/s]IIndicates the mass air flow computed by ECM

according to the signal voltage of the mass air

flow sensor.

TRVL AFTER MIL

[km] or [Mile]IDistance travelled while MI is activated

VOLTAGE [V]IVoltage measured by the voltage probe.

PULSE

[msec] or [Hz] or [%]IPulse width, frequency or duty cycle measured

by the pulse probe.IOnly ª#º is displayed if item is

unable to be measured.

IFigures with ª#ºs are temporary

ones. They are the same fig-

ures as an actual piece of data

which was just previously mea-

sured.

IDL A/V LEANIDisplay the condition of idle air volume learning

YET ... Idle air volume learning has not been

performed yet.

CMPLT ... Idle air volume learning has already

been performed successfully.

INCMP ... Idle air volume learning has not been

performed successfully.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-61

Page 504 of 2267

![NISSAN PRIMERA 1999 Electronic Repair Manual DATA MONITOR (SPEC) MODENLEC1365S07

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sen-

sor specification is displaye NISSAN PRIMERA 1999 Electronic Repair Manual DATA MONITOR (SPEC) MODENLEC1365S07

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sen-

sor specification is displaye](/img/5/57377/w960_57377-503.png)

DATA MONITOR (SPEC) MODENLEC1365S07

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sen-

sor specification is displayed.IWhen the engine is running, specifi-

cation range is indicated.

B/FUEL SCHDL

[msec]IªBase fuel scheduleº indicates the fuel injec-

tion pulse width programmed into ECM,

prior to any learned on board correction.IWhen the engine is running, specifi-

cation range is indicated.

A/F ALPHA-B1 [%]qIIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODENCEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor 1 (front)

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening steps using CONSULT-

II.Engine speed changes according

to the opening steps.IHarness and connector

IIACV-AAC valve

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature indication using CON-

SULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

IGNITION TIMINGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IªBase Idle Air Volume Initializingº

(Refer to EC-QG-33.)

ICamshaft position sensor

(PHASE)

ICrankshaft position sensor

(POS)

IEngine component parts and

installing conditions

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IAir conditioner switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

COOLING FANIIgnition switch: ON

ITurn the cooling fan ªONº and

ªOFFº using CONSULT-II.Cooling fan moves and stops.IHarness and connector

ICooling fan motor

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONQG16I18DE

CONSULT-II (Cont'd)

EC-62

Page 510 of 2267

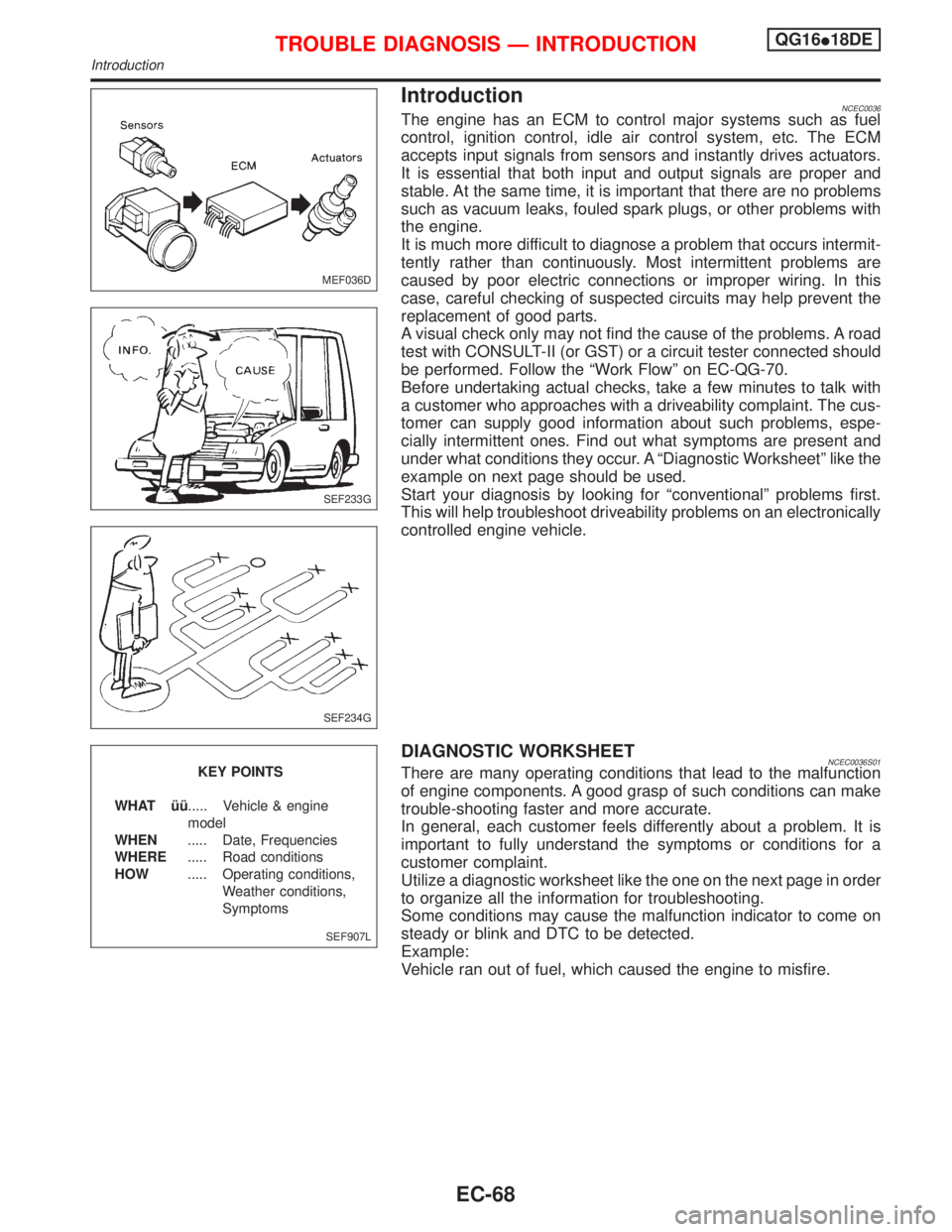

IntroductionNCEC0036The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-QG-70.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

DIAGNOSTIC WORKSHEETNCEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the malfunction indicator to come on

steady or blink and DTC to be detected.

Example:

Vehicle ran out of fuel, which caused the engine to misfire.

MEF036D

SEF233G

SEF234G

SEF907L

KEY POINTS

WHAT îî..... Vehicle & engine

model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions,

Weather conditions,

Symptoms

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG16I18DE

Introduction

EC-68

Page 513 of 2267

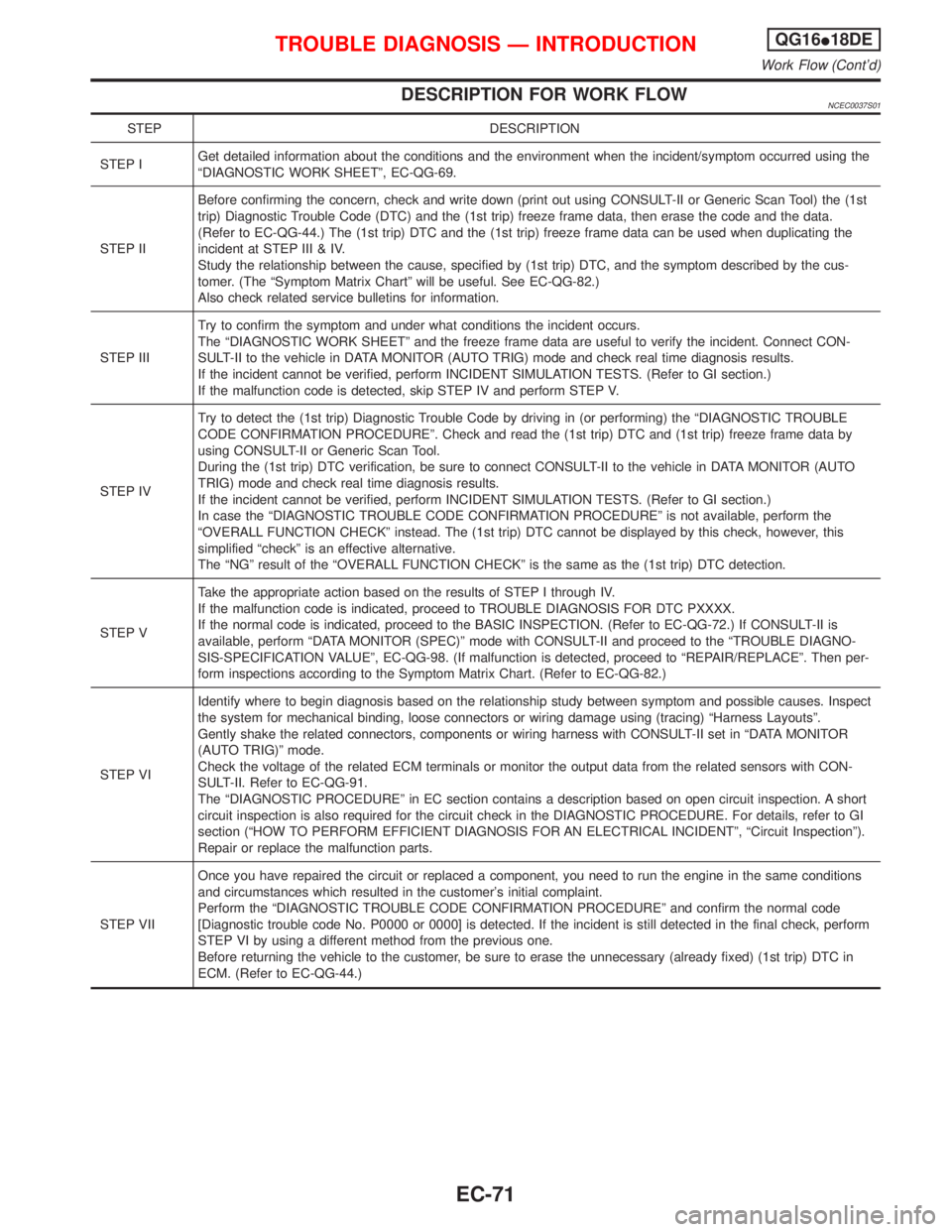

DESCRIPTION FOR WORK FLOWNCEC0037S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

ªDIAGNOSTIC WORK SHEETº, EC-QG-69.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or Generic Scan Tool) the (1st

trip) Diagnostic Trouble Code (DTC) and the (1st trip) freeze frame data, then erase the code and the data.

(Refer to EC-QG-44.) The (1st trip) DTC and the (1st trip) freeze frame data can be used when duplicating the

incident at STEP III & IV.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The ªSymptom Matrix Chartº will be useful. See EC-QG-82.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. (Refer to GI section.)

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) Diagnostic Trouble Code by driving in (or performing) the ªDIAGNOSTIC TROUBLE

CODE CONFIRMATION PROCEDUREº. Check and read the (1st trip) DTC and (1st trip) freeze frame data by

using CONSULT-II or Generic Scan Tool.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform INCIDENT SIMULATION TESTS. (Refer to GI section.)

In case the ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCEDUREº is not available, perform the

ªOVERALL FUNCTION CHECKº instead. The (1st trip) DTC cannot be displayed by this check, however, this

simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOVERALL FUNCTION CHECKº is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-QG-72.) If CONSULT-II is

available, perform ªDATA MONITOR (SPEC)º mode with CONSULT-II and proceed to the ªTROUBLE DIAGNO-

SIS-SPECIFICATION VALUEº, EC-QG-98. (If malfunction is detected, proceed to ªREPAIR/REPLACEº. Then per-

form inspections according to the Symptom Matrix Chart. (Refer to EC-QG-82.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect

the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-QG-91.

The ªDIAGNOSTIC PROCEDUREº in EC section contains a description based on open circuit inspection. A short

circuit inspection is also required for the circuit check in the DIAGNOSTIC PROCEDURE. For details, refer to GI

section (ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº, ªCircuit Inspectionº).

Repair or replace the malfunction parts.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCEDUREº and confirm the normal code

[Diagnostic trouble code No. P0000 or 0000] is detected. If the incident is still detected in the final check, perform

STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM. (Refer to EC-QG-44.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG16I18DE

Work Flow (Cont'd)

EC-71

Page 515 of 2267

4 CHECK THROTTLE VALVE OPERATION

1. Remove intake air ducts.

2. Check throttle valve operation when moving throttle drum by hand.

OK or NG

OK©Retighten the throttle drum fixing nuts.

NG©Clean the throttle body and throttle valve.

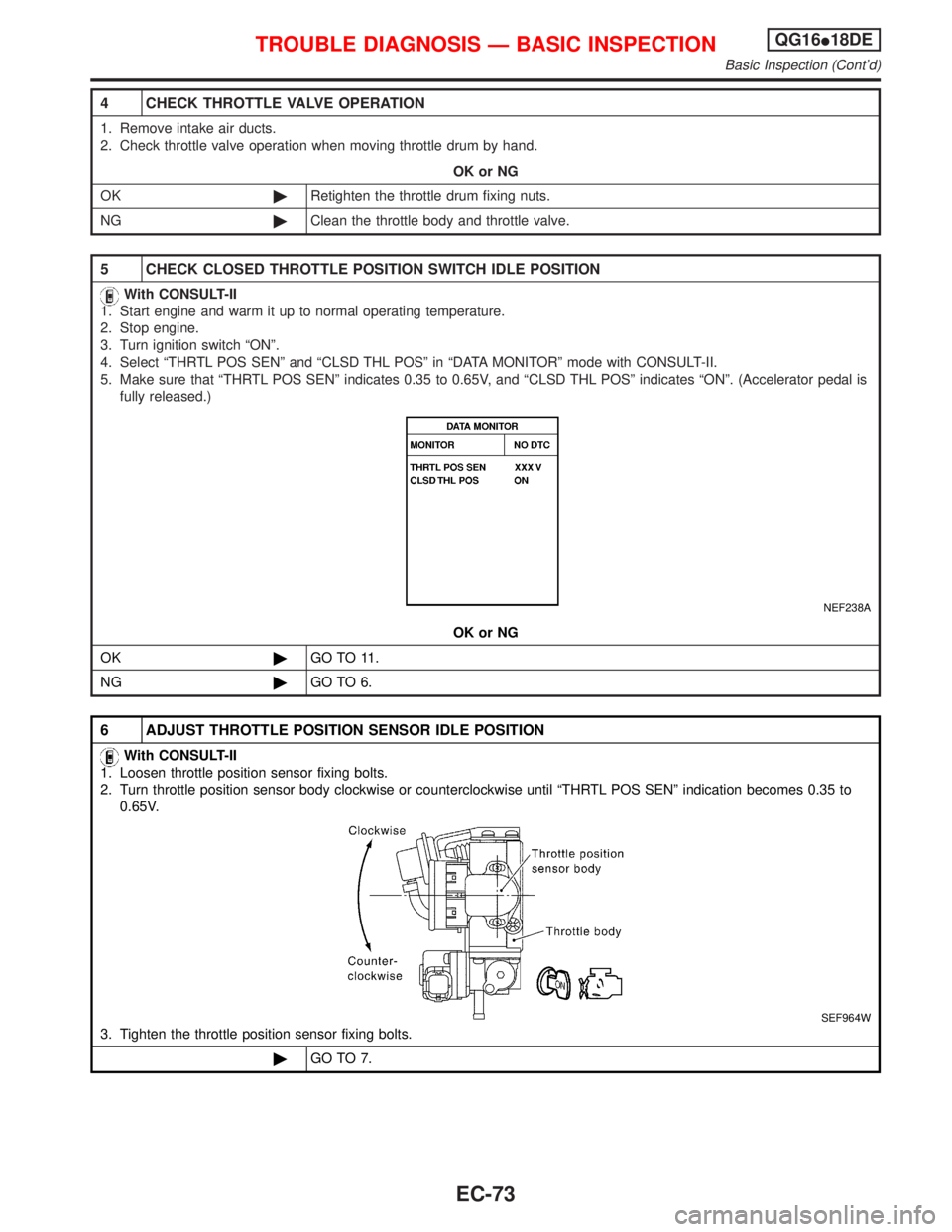

5 CHECK CLOSED THROTTLE POSITION SWITCH IDLE POSITION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Select ªTHRTL POS SENº and ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

5. Make sure that ªTHRTL POS SENº indicates 0.35 to 0.65V, and ªCLSD THL POSº indicates ªONº. (Accelerator pedal is

fully released.)

NEF238A

OK or NG

OK©GO TO 11.

NG©GO TO 6.

6 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to

0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG16I18DE

Basic Inspection (Cont'd)

EC-73