NISSAN PRIMERA 1999 Electronic Repair Manual

PRIMERA 1999

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57377/w960_57377-0.png

NISSAN PRIMERA 1999 Electronic Repair Manual

Trending: weight, trailer, oil capacity, driver seat adjustment, torque, fuses, radio

Page 2101 of 2267

8. Select correct snap ring of 5th synchronizer hub to minimize

clearance of groove in input shaft and install it.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Snap rings of 5th synchronizer:

Refer to SDS, MT-87.

Mainshaft and Gears

DISASSEMBLY

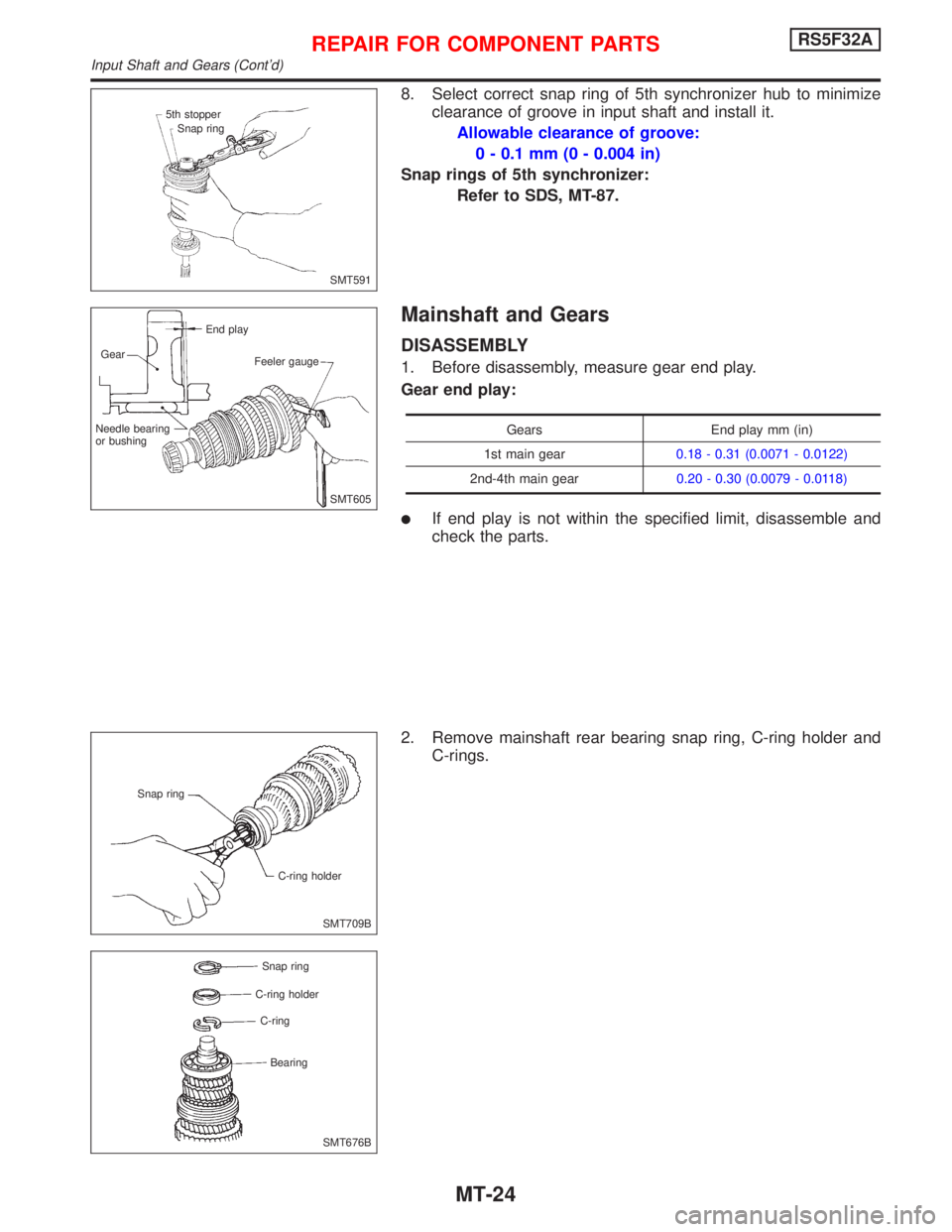

1. Before disassembly, measure gear end play.

Gear end play:

Gears End play mm (in)

1st main gear0.18 - 0.31 (0.0071 - 0.0122)

2nd-4th main gear0.20 - 0.30 (0.0079 - 0.0118)

lIf end play is not within the specified limit, disassemble and

check the parts.

2. Remove mainshaft rear bearing snap ring, C-ring holder and

C-rings.

SMT591 5th stopper

Snap ring

SMT605 End play

Gear

Feeler gauge

Needle bearing

or bushing

SMT709B Snap ring

C-ring holder

SMT676B Snap ring

C-ring holder

C-ring

Bearing

REPAIR FOR COMPONENT PARTSRS5F32A

Input Shaft and Gears (Cont'd)

MT-24

Page 2102 of 2267

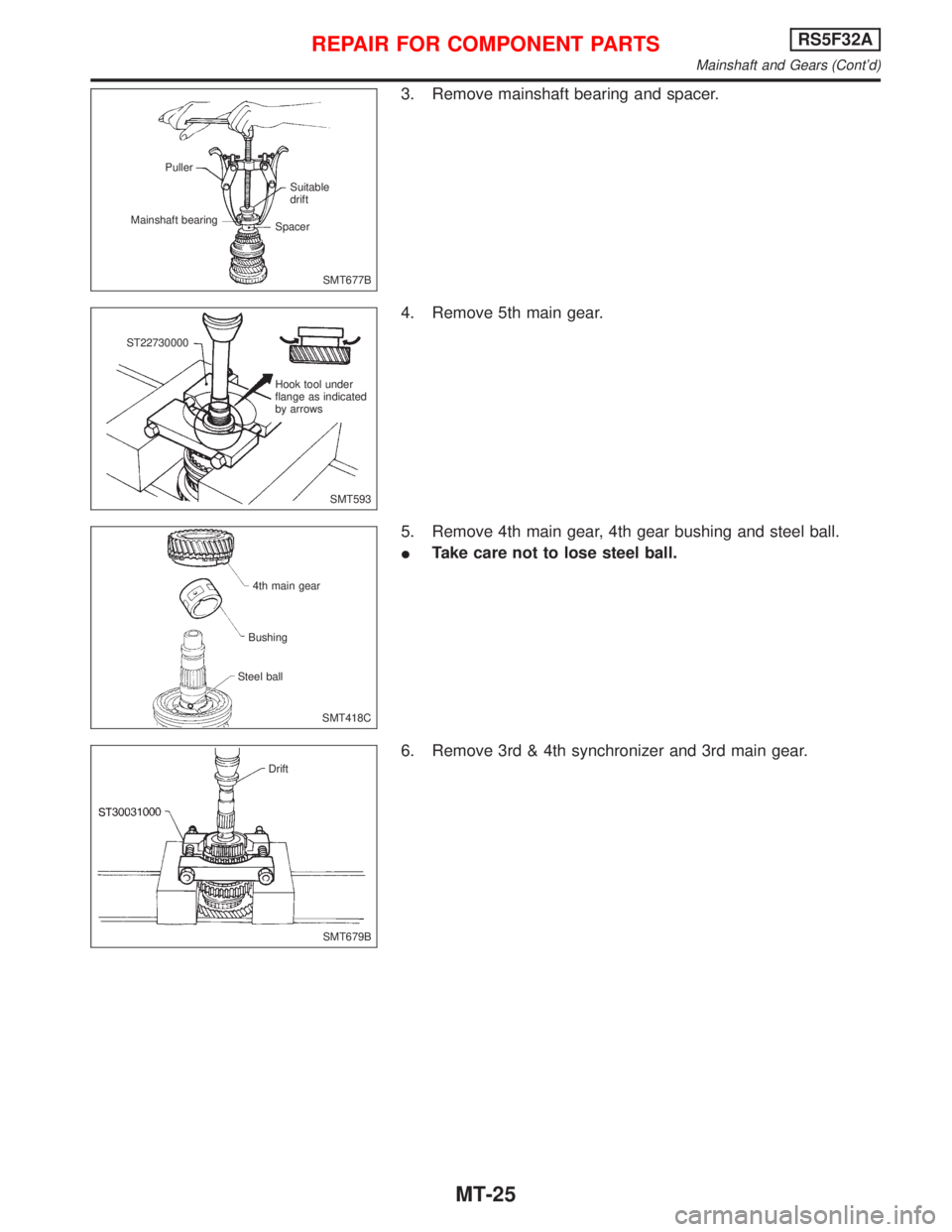

3. Remove mainshaft bearing and spacer.

4. Remove 5th main gear.

5. Remove 4th main gear, 4th gear bushing and steel ball.

ITake care not to lose steel ball.

6. Remove 3rd & 4th synchronizer and 3rd main gear.

SMT677B Puller

Mainshaft bearingSuitable

drift

Spacer

SMT593 ST22730000

Hook tool under

flange as indicated

by arrows

SMT418C 4th main gear

Bushing

Steel ball

SMT679B Drift

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-25

Page 2103 of 2267

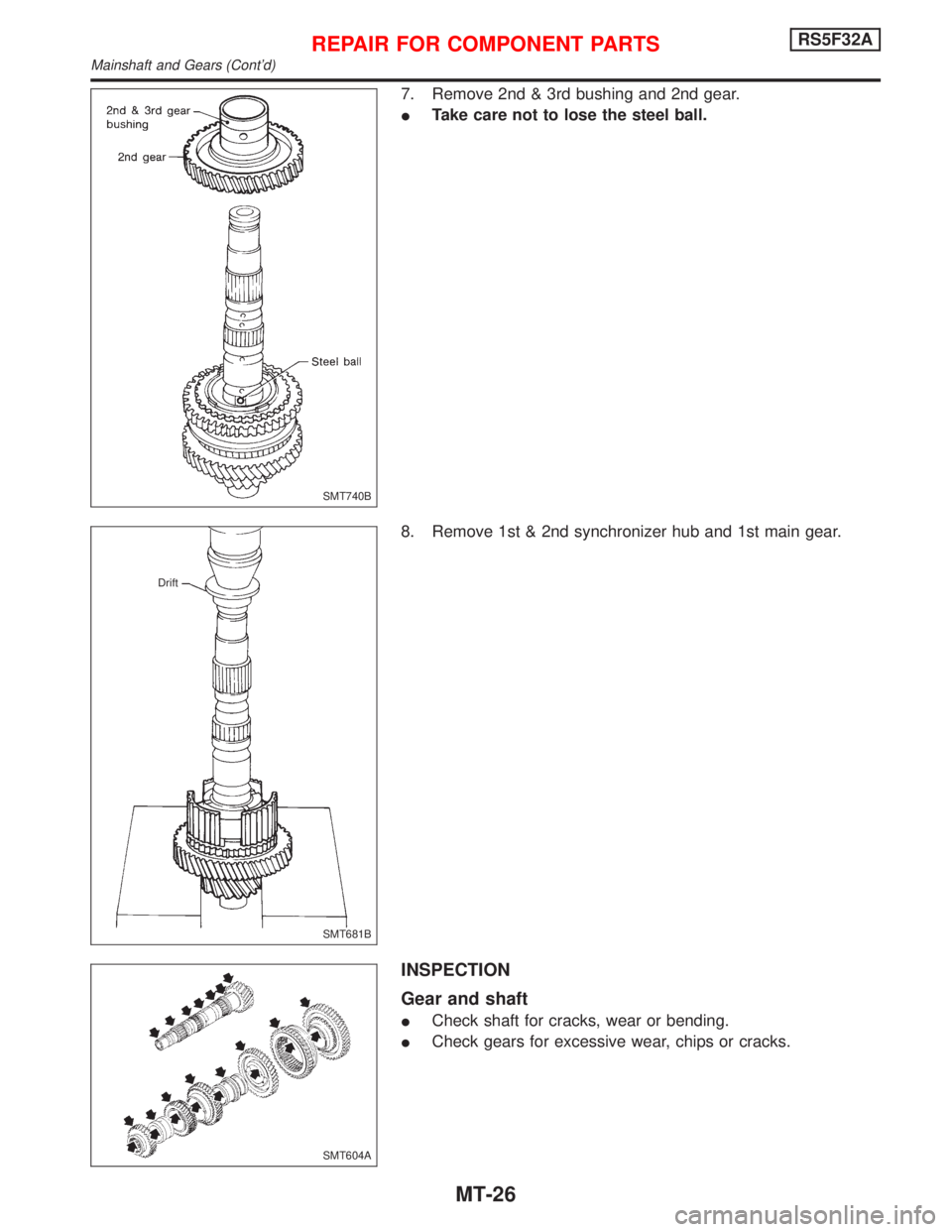

7. Remove 2nd & 3rd bushing and 2nd gear.

ITake care not to lose the steel ball.

8. Remove 1st & 2nd synchronizer hub and 1st main gear.

INSPECTION

Gear and shaft

ICheck shaft for cracks, wear or bending.

ICheck gears for excessive wear, chips or cracks.

SMT740B

SMT681B Drift

SMT604A

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-26

Page 2104 of 2267

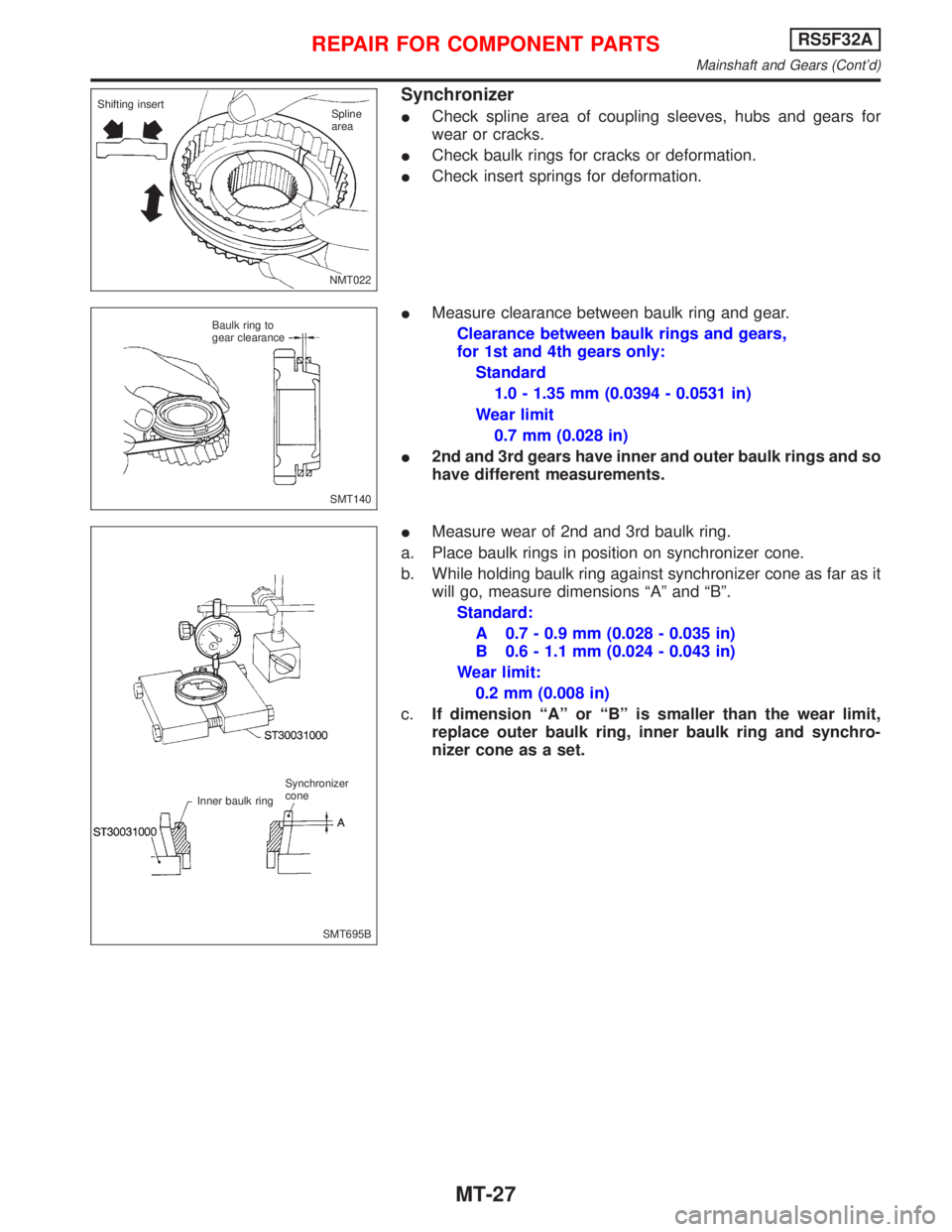

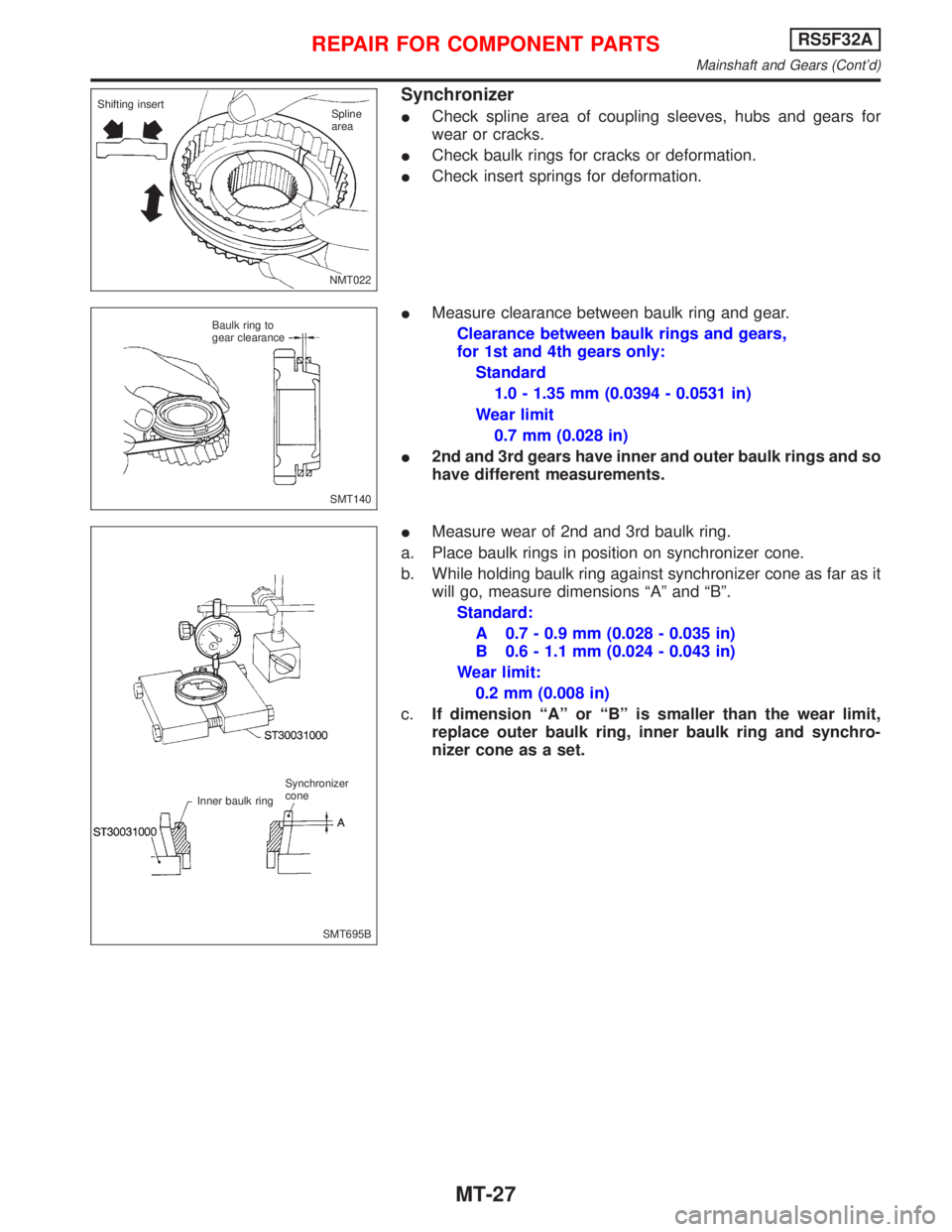

Synchronizer

ICheck spline area of coupling sleeves, hubs and gears for

wear or cracks.

ICheck baulk rings for cracks or deformation.

ICheck insert springs for deformation.

IMeasure clearance between baulk ring and gear.

Clearance between baulk rings and gears,

for 1st and 4th gears only:

Standard

1.0 - 1.35 mm (0.0394 - 0.0531 in)

Wear limit

0.7 mm (0.028 in)

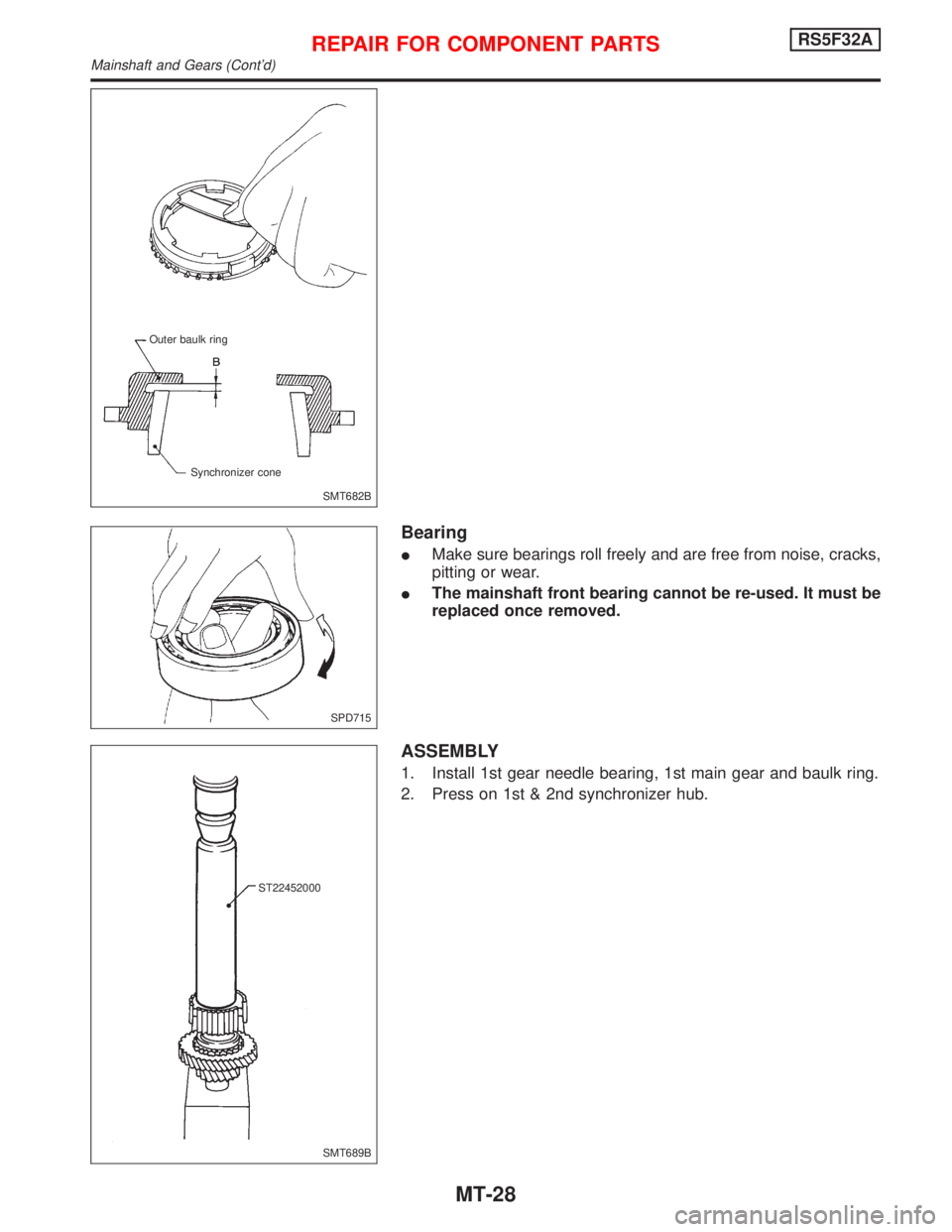

I2nd and 3rd gears have inner and outer baulk rings and so

have different measurements.

IMeasure wear of 2nd and 3rd baulk ring.

a. Place baulk rings in position on synchronizer cone.

b. While holding baulk ring against synchronizer cone as far as it

will go, measure dimensions ªAº and ªBº.

Standard:

A 0.7 - 0.9 mm (0.028 - 0.035 in)

B 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit:

0.2 mm (0.008 in)

c.If dimension ªAº or ªBº is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchro-

nizer cone as a set.

NMT022 Shifting insert

Spline

area

SMT140 Baulk ring to

gear clearance

SMT695B Synchronizer

cone

Inner baulk ring

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-27

Page 2105 of 2267

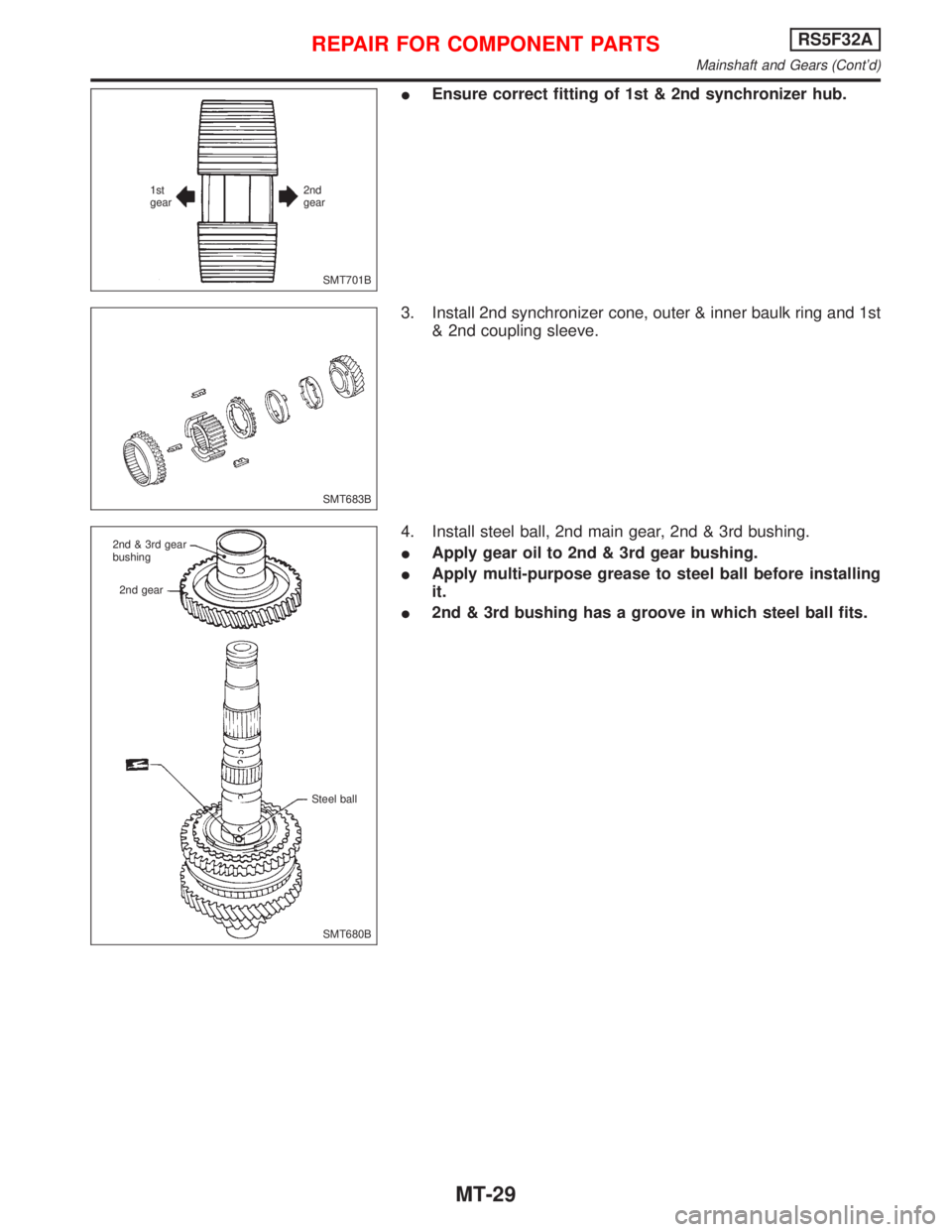

Bearing

IMake sure bearings roll freely and are free from noise, cracks,

pitting or wear.

IThe mainshaft front bearing cannot be re-used. It must be

replaced once removed.

ASSEMBLY

1. Install 1st gear needle bearing, 1st main gear and baulk ring.

2. Press on 1st & 2nd synchronizer hub.

SMT682B Outer baulk ring

Synchronizer cone

SPD715

SMT689B ST22452000

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-28

Page 2106 of 2267

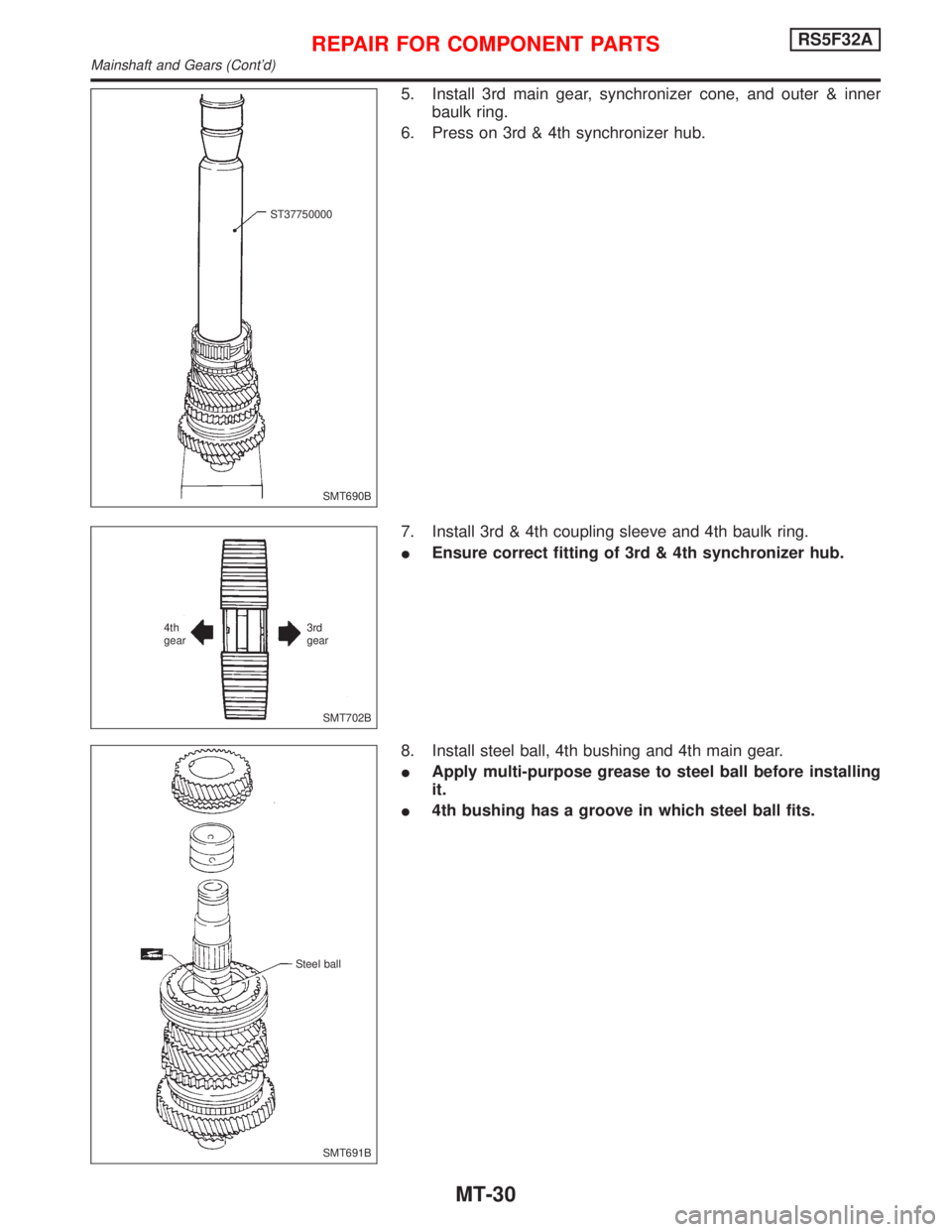

IEnsure correct fitting of 1st & 2nd synchronizer hub.

3. Install 2nd synchronizer cone, outer & inner baulk ring and 1st

& 2nd coupling sleeve.

4. Install steel ball, 2nd main gear, 2nd & 3rd bushing.

IApply gear oil to 2nd & 3rd gear bushing.

IApply multi-purpose grease to steel ball before installing

it.

I2nd & 3rd bushing has a groove in which steel ball fits.

SMT701B 2nd

gear 1st

gear

SMT683B

SMT680B 2nd & 3rd gear

bushing

2nd gear

Steel ball

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-29

Page 2107 of 2267

5. Install 3rd main gear, synchronizer cone, and outer & inner

baulk ring.

6. Press on 3rd & 4th synchronizer hub.

7. Install 3rd & 4th coupling sleeve and 4th baulk ring.

IEnsure correct fitting of 3rd & 4th synchronizer hub.

8. Install steel ball, 4th bushing and 4th main gear.

IApply multi-purpose grease to steel ball before installing

it.

I4th bushing has a groove in which steel ball fits.

SMT690B ST37750000

SMT702B 3rd

gear 4th

gear

SMT691B Steel ball

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-30

Page 2108 of 2267

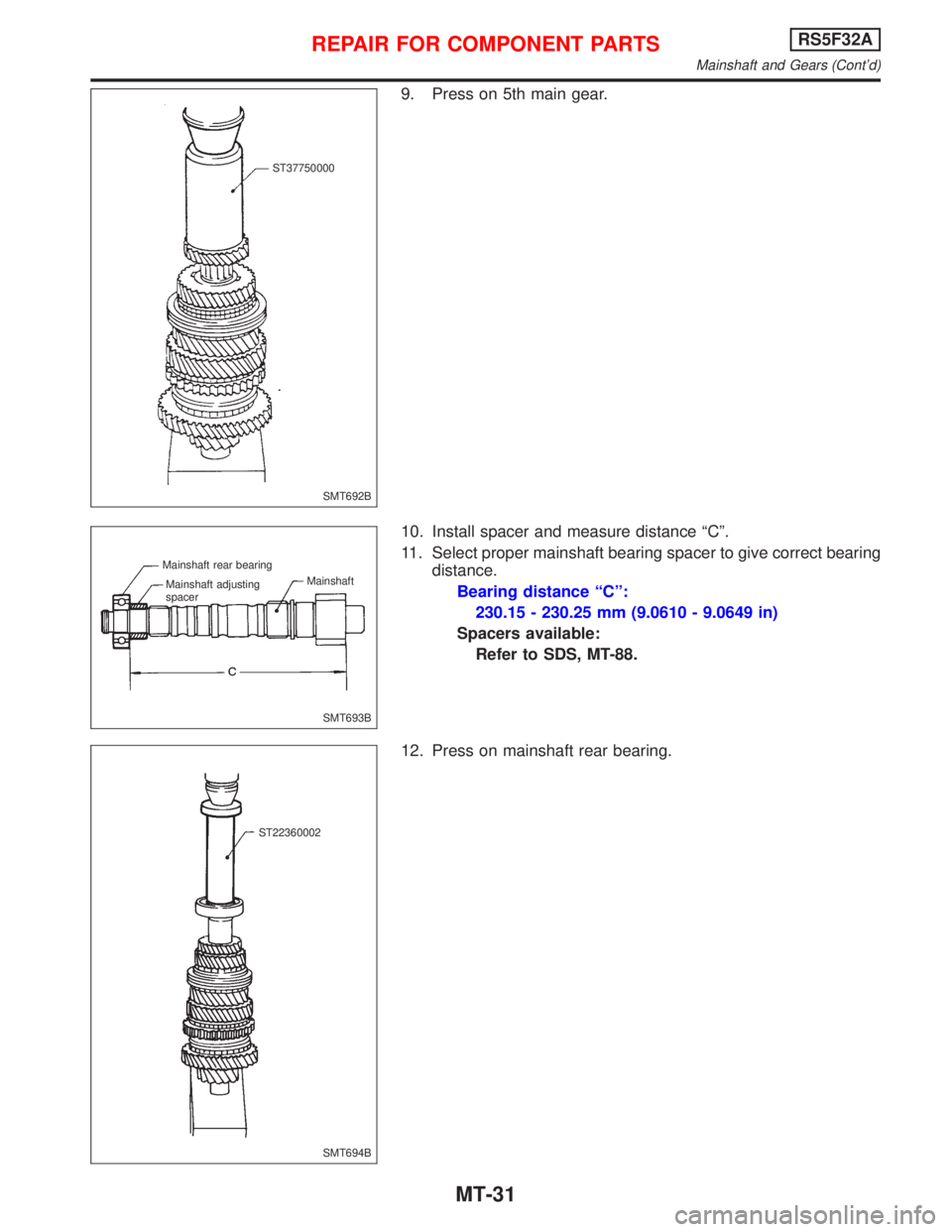

9. Press on 5th main gear.

10. Install spacer and measure distance ªCº.

11. Select proper mainshaft bearing spacer to give correct bearing

distance.

Bearing distance ªCº:

230.15 - 230.25 mm (9.0610 - 9.0649 in)

Spacers available:

Refer to SDS, MT-88.

12. Press on mainshaft rear bearing.

SMT692B ST37750000

SMT693B Mainshaft rear bearing

Mainshaft

Mainshaft adjusting

spacer

SMT694B ST22360002

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-31

Page 2109 of 2267

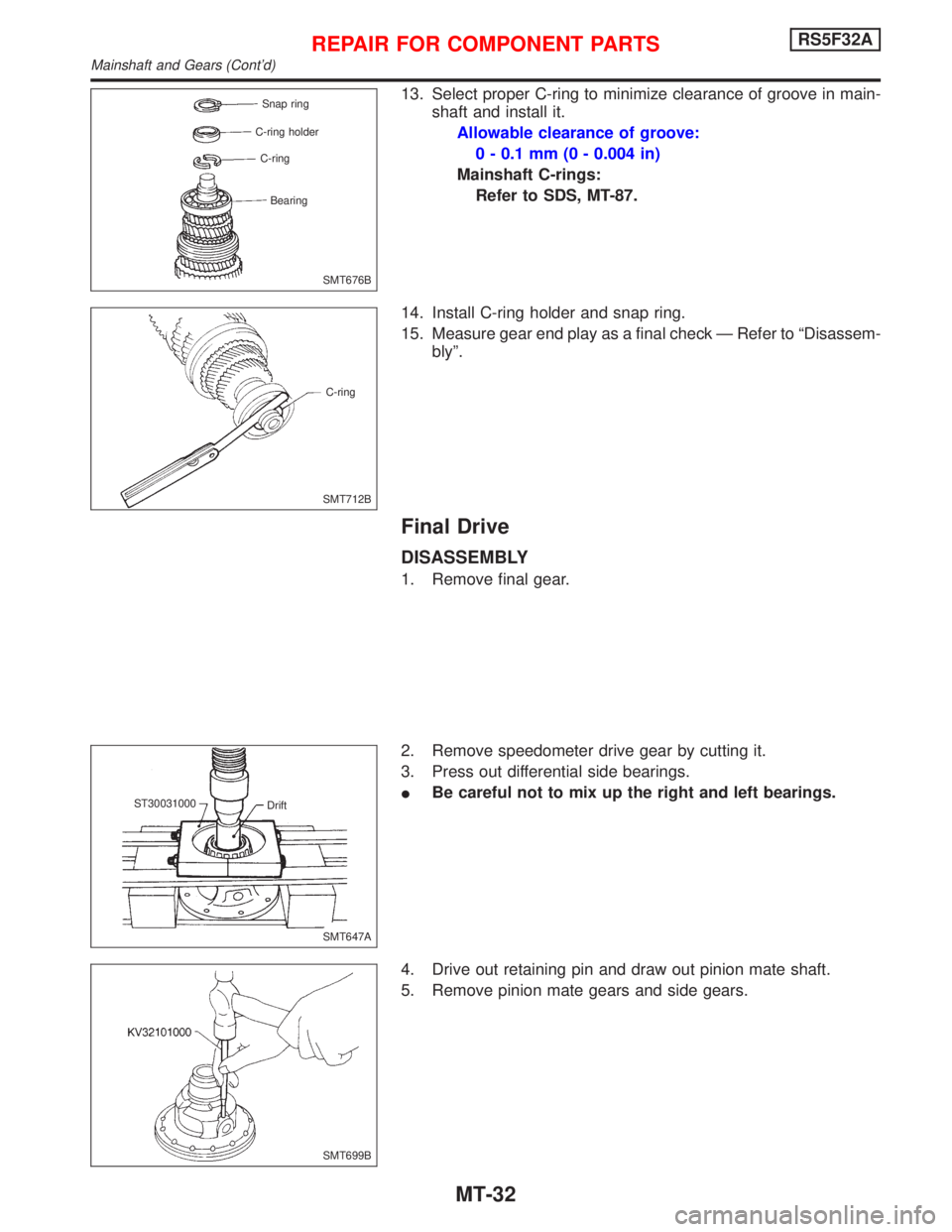

13. Select proper C-ring to minimize clearance of groove in main-

shaft and install it.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Mainshaft C-rings:

Refer to SDS, MT-87.

14. Install C-ring holder and snap ring.

15. Measure gear end play as a final check Ð Refer to ªDisassem-

blyº.

Final Drive

DISASSEMBLY

1. Remove final gear.

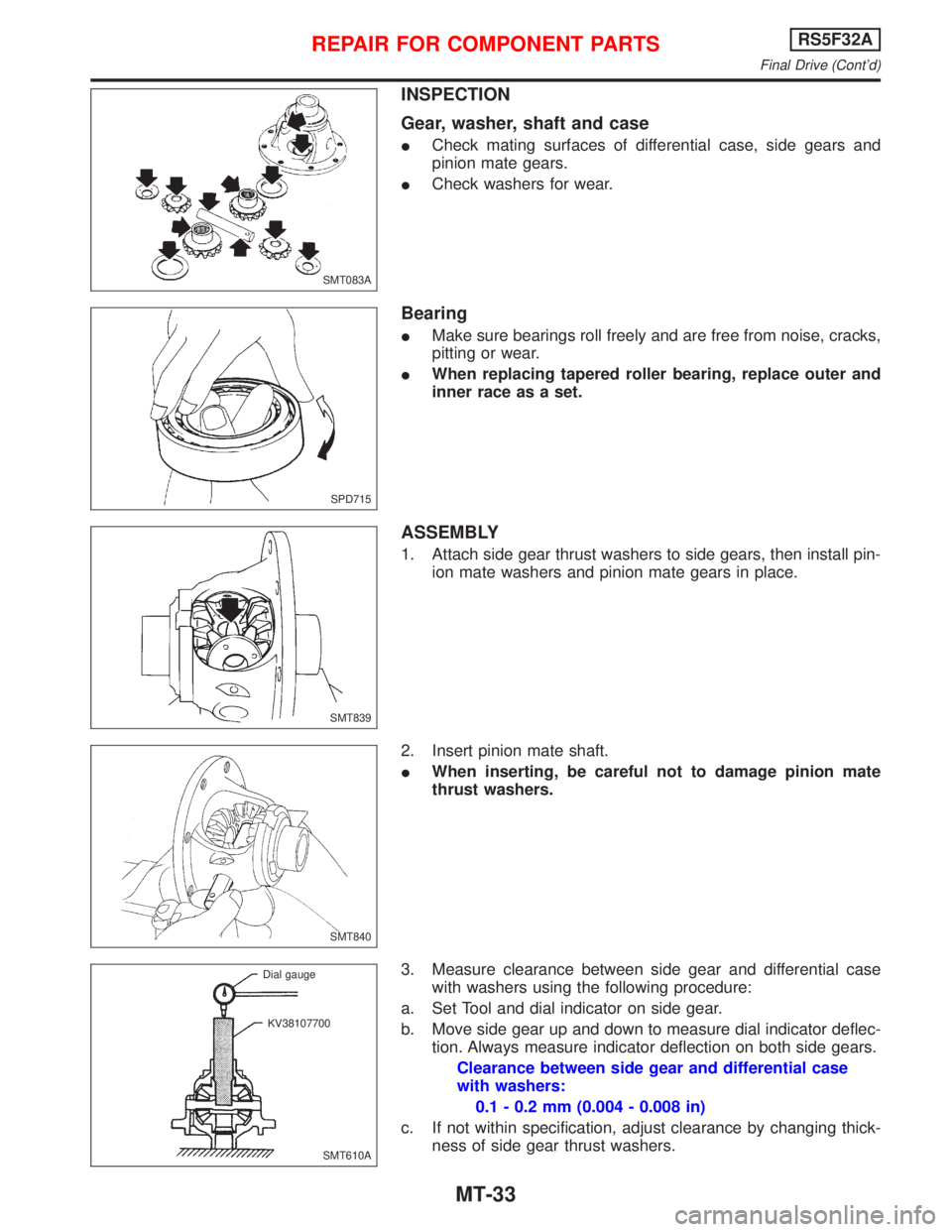

2. Remove speedometer drive gear by cutting it.

3. Press out differential side bearings.

IBe careful not to mix up the right and left bearings.

4. Drive out retaining pin and draw out pinion mate shaft.

5. Remove pinion mate gears and side gears.

SMT676B Snap ring

C-ring holder

C-ring

Bearing

SMT712BC-ring

SMT647A Drift ST30031000

SMT699B

REPAIR FOR COMPONENT PARTSRS5F32A

Mainshaft and Gears (Cont'd)

MT-32

Page 2110 of 2267

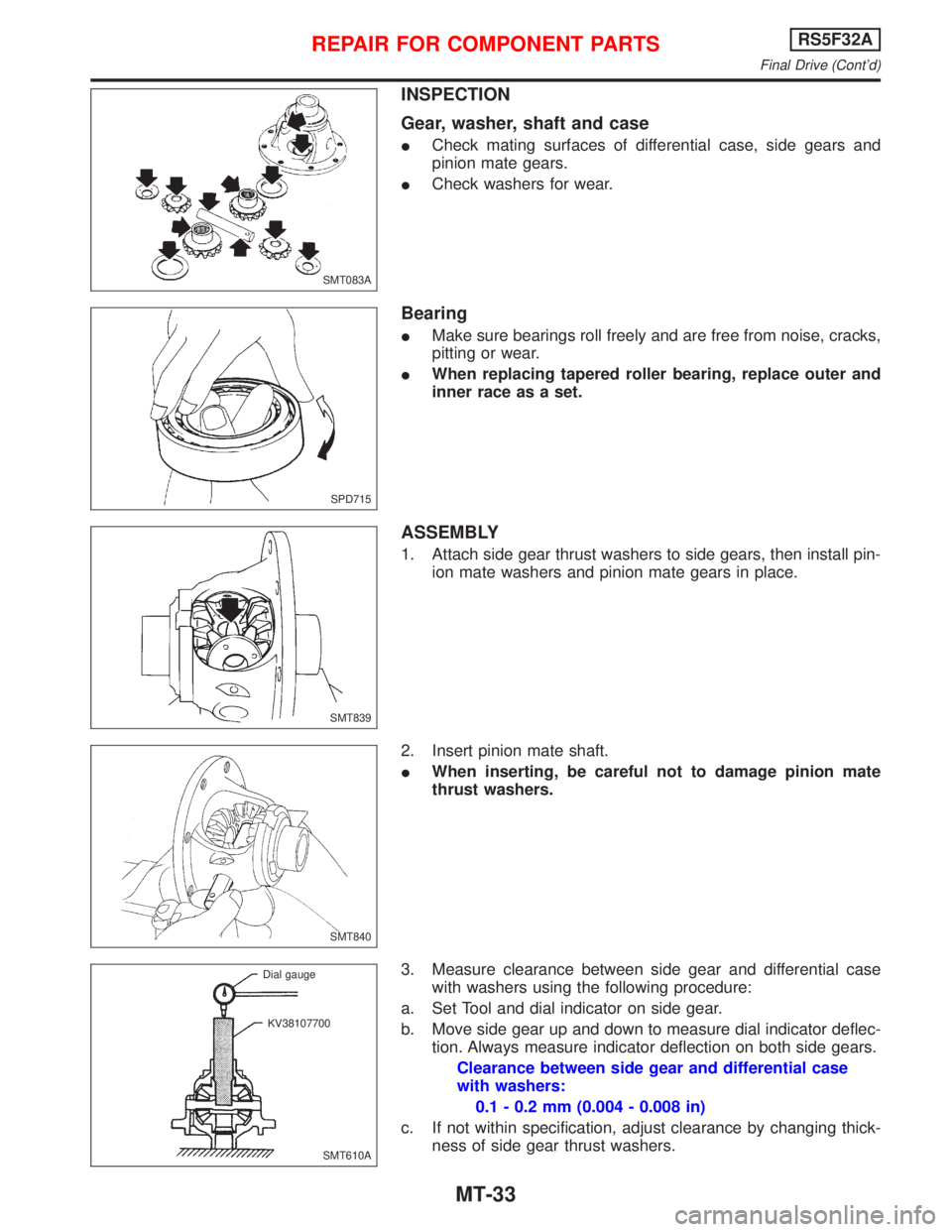

INSPECTION

Gear, washer, shaft and case

ICheck mating surfaces of differential case, side gears and

pinion mate gears.

ICheck washers for wear.

Bearing

IMake sure bearings roll freely and are free from noise, cracks,

pitting or wear.

IWhen replacing tapered roller bearing, replace outer and

inner race as a set.

ASSEMBLY

1. Attach side gear thrust washers to side gears, then install pin-

ion mate washers and pinion mate gears in place.

2. Insert pinion mate shaft.

IWhen inserting, be careful not to damage pinion mate

thrust washers.

3. Measure clearance between side gear and differential case

with washers using the following procedure:

a. Set Tool and dial indicator on side gear.

b. Move side gear up and down to measure dial indicator deflec-

tion. Always measure indicator deflection on both side gears.

Clearance between side gear and differential case

with washers:

0.1 - 0.2 mm (0.004 - 0.008 in)

c. If not within specification, adjust clearance by changing thick-

ness of side gear thrust washers.

SMT083A

SPD715

SMT839

SMT840

SMT610A Dial gauge

KV38107700

REPAIR FOR COMPONENT PARTSRS5F32A

Final Drive (Cont'd)

MT-33

Trending: fuse diagram, fuel, catalytic converter, fuel cap release, Oil engine, checking oil, audio