control NISSAN PRIMERA 1999 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 62 of 2267

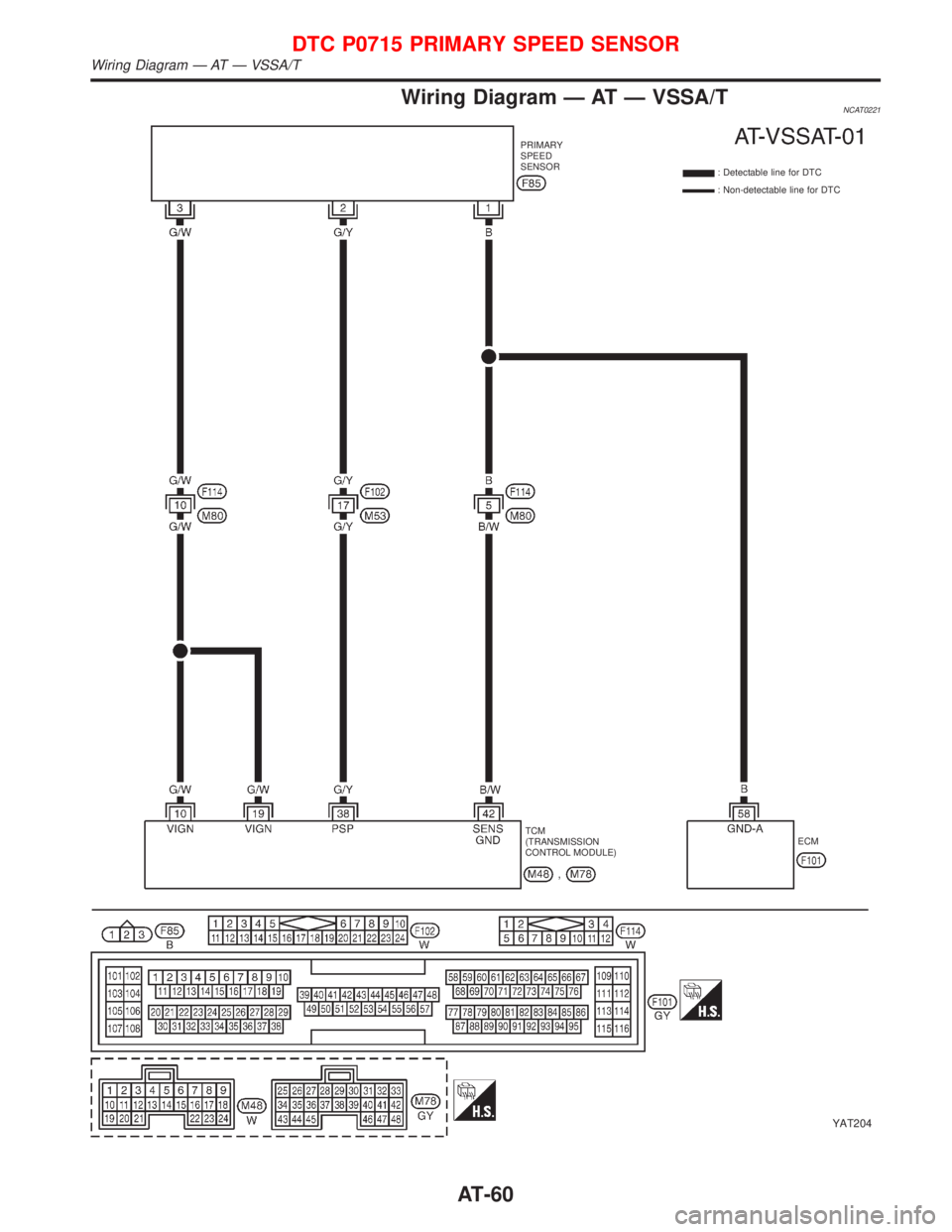

Wiring Diagram Ð AT Ð VSSA/TNCAT0221

YAT204

PRIMARY

SPEED

SENSOR

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL MODULE)ECM

DTC P0715 PRIMARY SPEED SENSOR

Wiring Diagram Ð AT Ð VSSA/T

AT-60

Page 66 of 2267

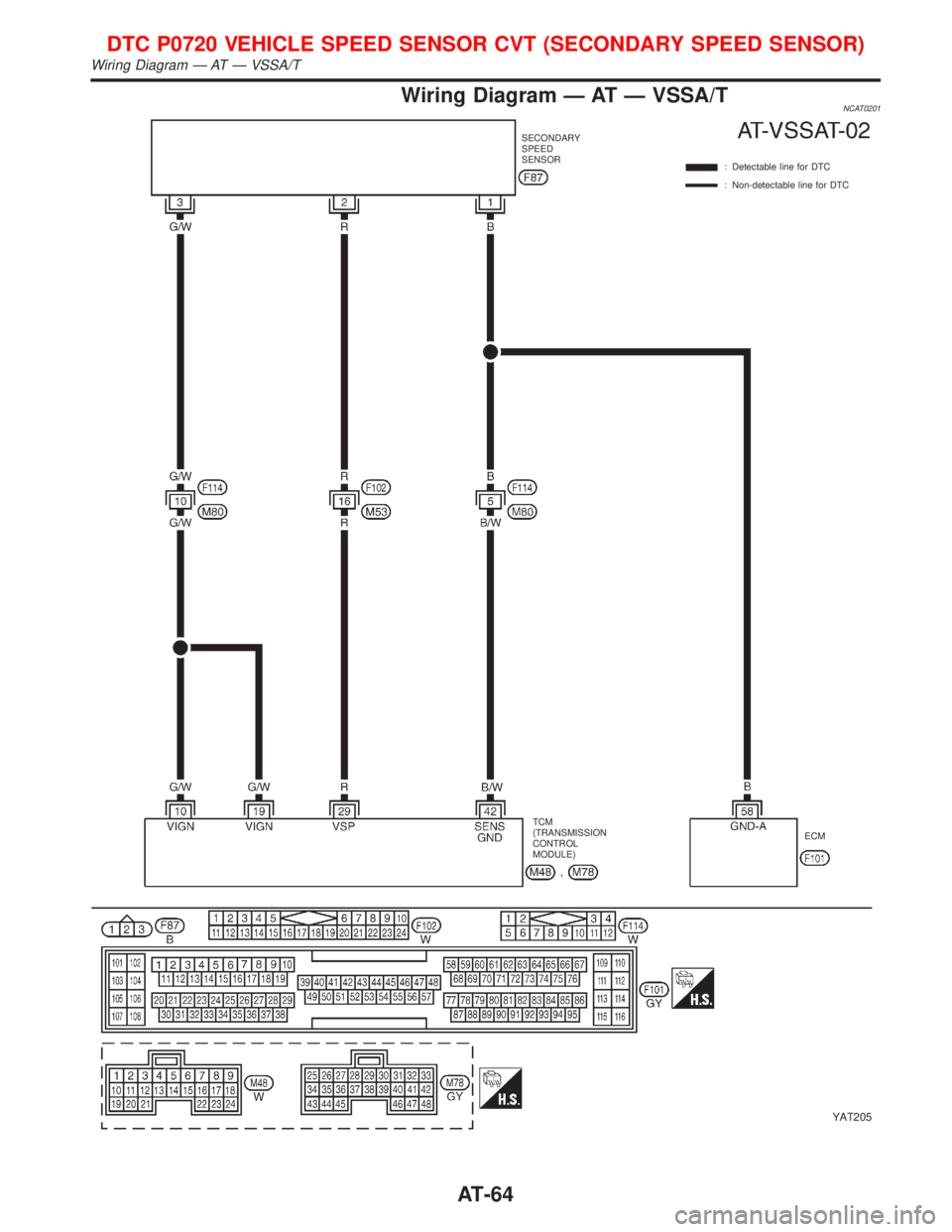

Wiring Diagram Ð AT Ð VSSA/TNCAT0201

YAT205

SECONDARY

SPEED

SENSOR

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL

MODULE)ECM

DTC P0720 VEHICLE SPEED SENSOR CVT (SECONDARY SPEED SENSOR)

Wiring Diagram Ð AT Ð VSSA/T

AT-64

Page 69 of 2267

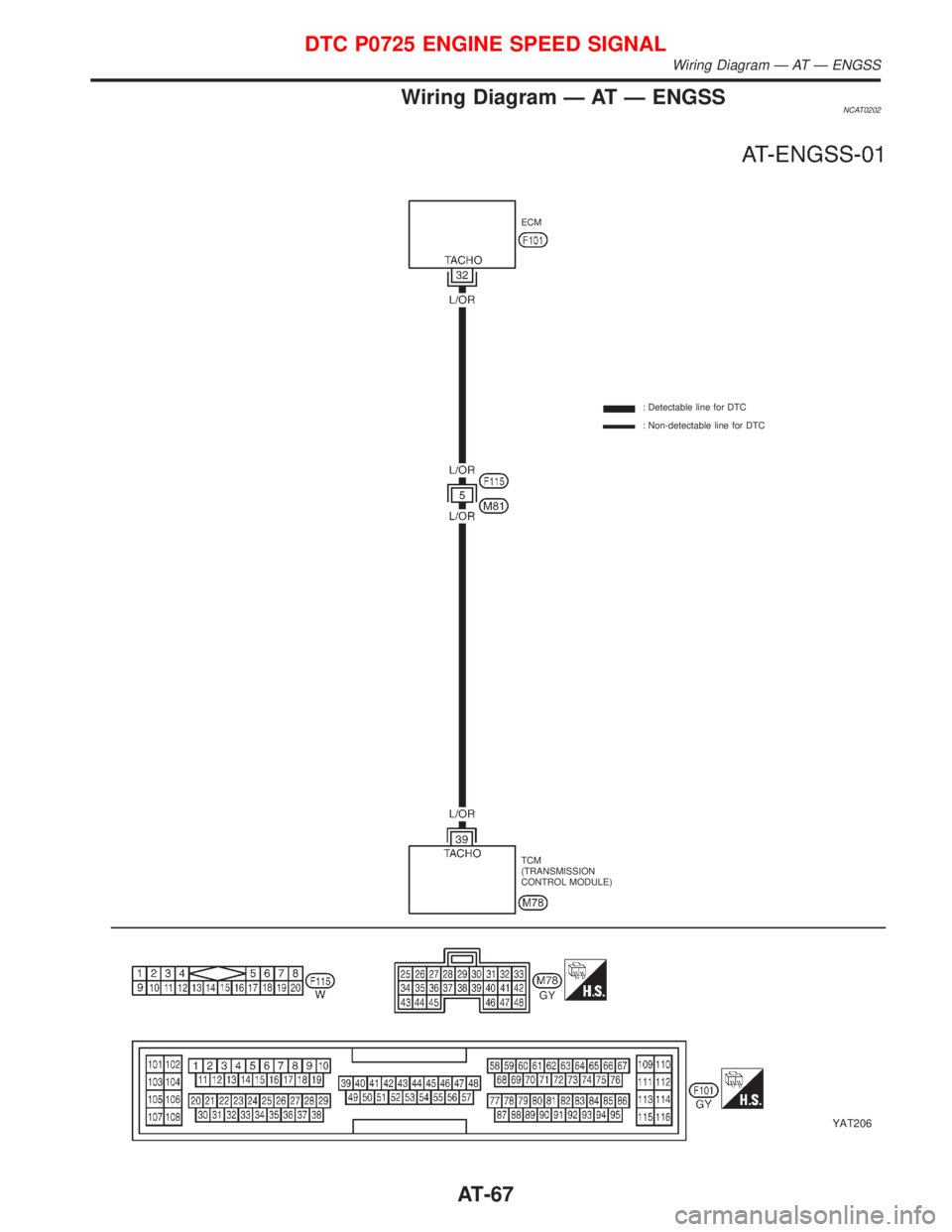

Wiring Diagram Ð AT Ð ENGSSNCAT0202

YAT206

ECM

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL MODULE)

DTC P0725 ENGINE SPEED SIGNAL

Wiring Diagram Ð AT Ð ENGSS

AT-67

Page 70 of 2267

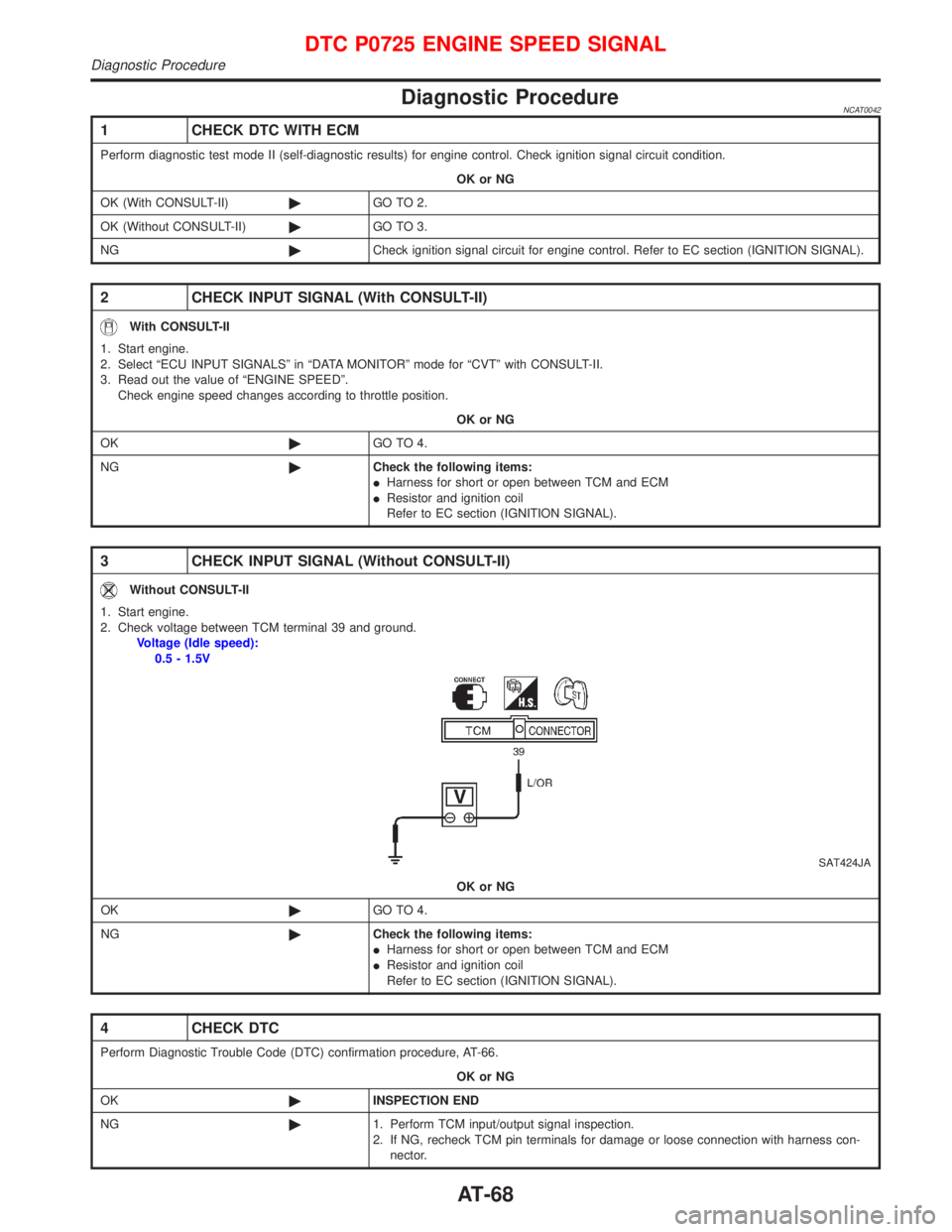

Diagnostic ProcedureNCAT0042

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control. Check ignition signal circuit condition.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Check ignition signal circuit for engine control. Refer to EC section (IGNITION SIGNAL).

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes according to throttle position.

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM and ECM

IResistor and ignition coil

Refer to EC section (IGNITION SIGNAL).

3 CHECK INPUT SIGNAL (Without CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 39 and ground.

Voltage (Idle speed):

0.5 - 1.5V

SAT424JA

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM and ECM

IResistor and ignition coil

Refer to EC section (IGNITION SIGNAL).

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-66.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P0725 ENGINE SPEED SIGNAL

Diagnostic Procedure

AT-68

Page 71 of 2267

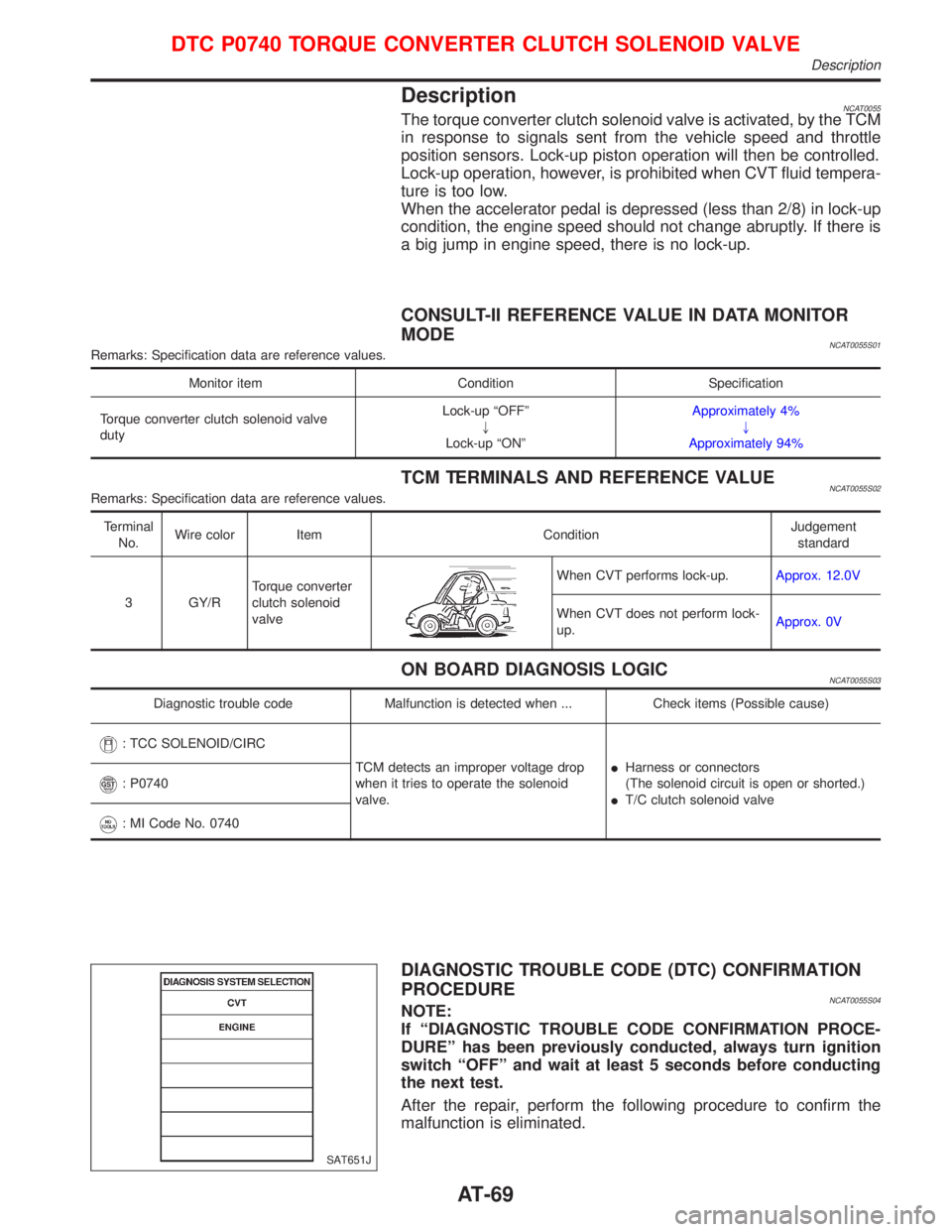

DescriptionNCAT0055The torque converter clutch solenoid valve is activated, by the TCM

in response to signals sent from the vehicle speed and throttle

position sensors. Lock-up piston operation will then be controlled.

Lock-up operation, however, is prohibited when CVT fluid tempera-

ture is too low.

When the accelerator pedal is depressed (less than 2/8) in lock-up

condition, the engine speed should not change abruptly. If there is

a big jump in engine speed, there is no lock-up.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0055S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Torque converter clutch solenoid valve

dutyLock-up ªOFFº

"

Lock-up ªONºApproximately 4%

"

Approximately 94%

TCM TERMINALS AND REFERENCE VALUENCAT0055S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

3 GY/RTorque converter

clutch solenoid

valve

When CVT performs lock-up.Approx. 12.0V

When CVT does not perform lock-

up.Approx. 0V

ON BOARD DIAGNOSIS LOGICNCAT0055S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TCC SOLENOID/CIRC

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.IHarness or connectors

(The solenoid circuit is open or shorted.)

IT/C clutch solenoid valve

: P0740

: MI Code No. 0740

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0055S04NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

SAT651J

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Description

AT-69

Page 73 of 2267

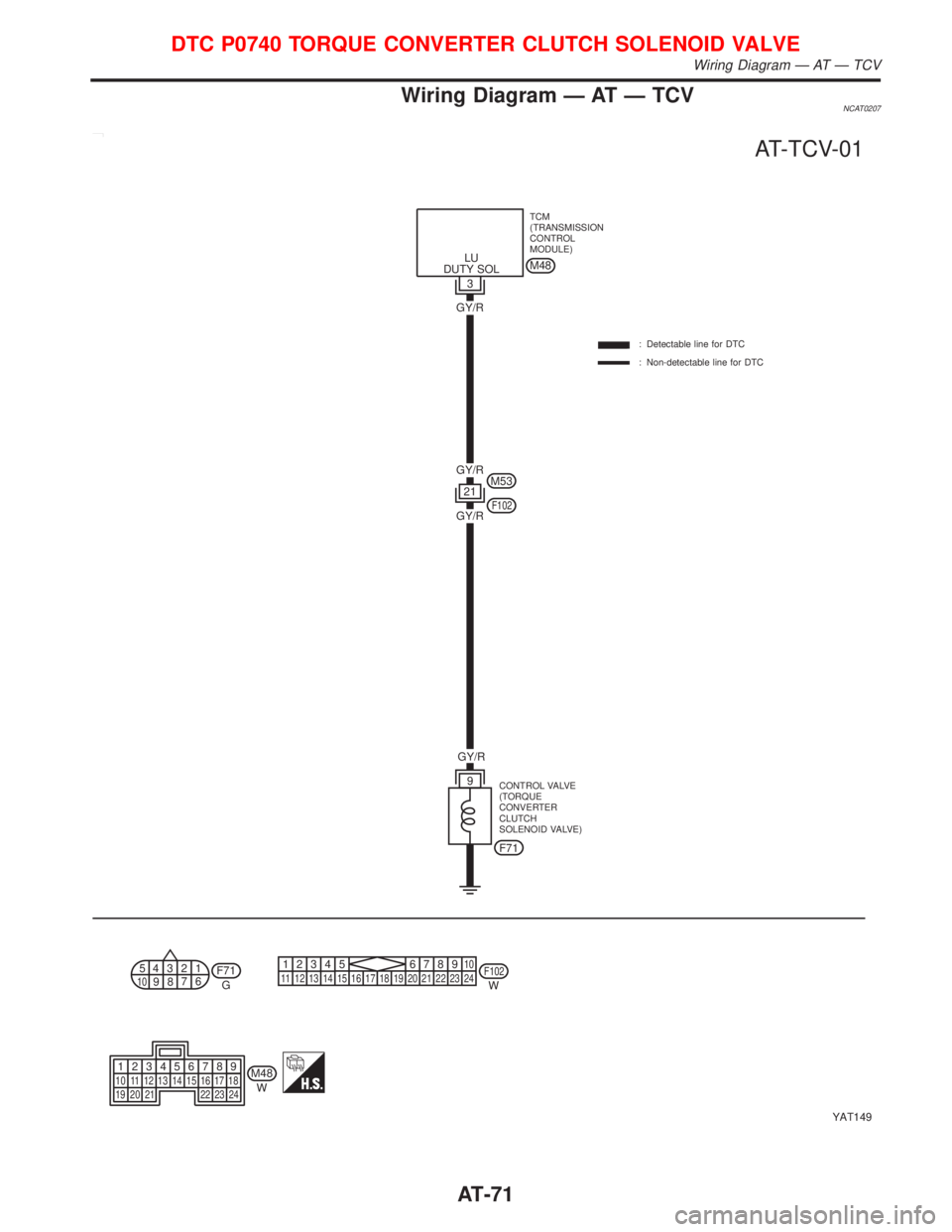

Wiring Diagram Ð AT Ð TCVNCAT0207

M48

GY/R GY/RF102

GY/R

M48

F71

AT-TCV-01

M53

5

15 16 17 1918620414313212721822923W 3

21LU

DUTY SOL

9

11110

24

W

3 2 1 45678

910 11 12 13 14 15 16 17 18

19 20 21 22 23 24

F71 GY/R

F10254

96 2

7 3

81

G10

YAT149

TCM

(TRANSMISSION

CONTROL

MODULE)

: Detectable line for DTC

: Non-detectable line for DTC

CONTROL VALVE

(TORQUE

CONVERTER

CLUTCH

SOLENOID VALVE)

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Wiring Diagram Ð AT Ð TCV

AT-71

Page 78 of 2267

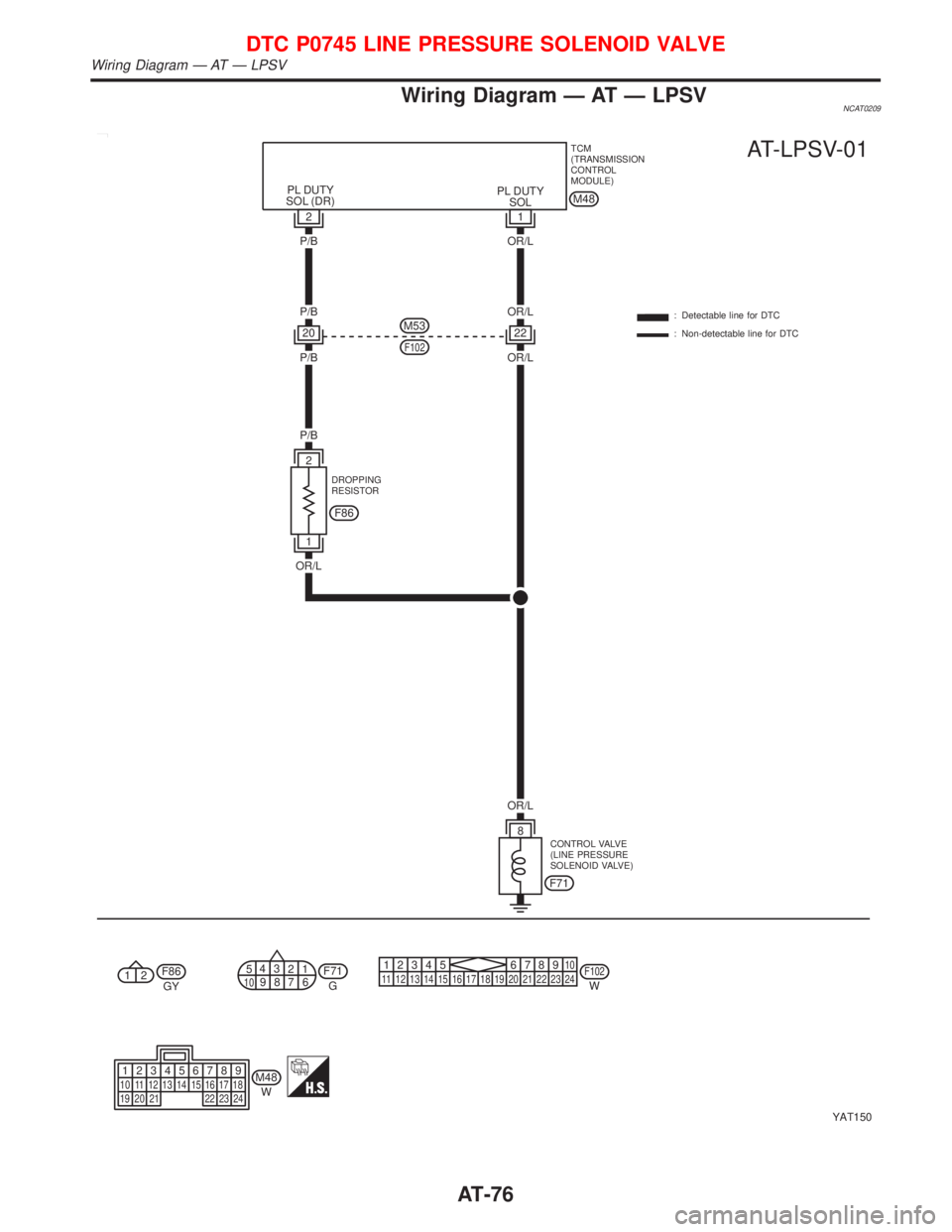

Wiring Diagram Ð AT Ð LPSVNCAT0209

OR/L P/B

OR/L P/B

OR/L P/B

P/B

OR/L22 20M53

M48

OR/L

M48

F86F102F71

AT-LPSV-01

515 16 17 1918620414313212721822923W 1 PL DUTY

SOL

8 2

2

1F86

11110

24

PL DUTY

SOL (DR)

W

3 2 1 45678

910 11 12 13 14 15 16 17 18

19 20 21 22 23 24

F71

F102

2 1

GY54

96 2

7 3

81

G10

YAT150

TCM

(TRANSMISSION

CONTROL

MODULE)

: Detectable line for DTC

: Non-detectable line for DTC

DROPPING

RESISTOR

CONTROL VALVE

(LINE PRESSURE

SOLENOID VALVE)

DTC P0745 LINE PRESSURE SOLENOID VALVE

Wiring Diagram Ð AT Ð LPSV

AT-76

Page 84 of 2267

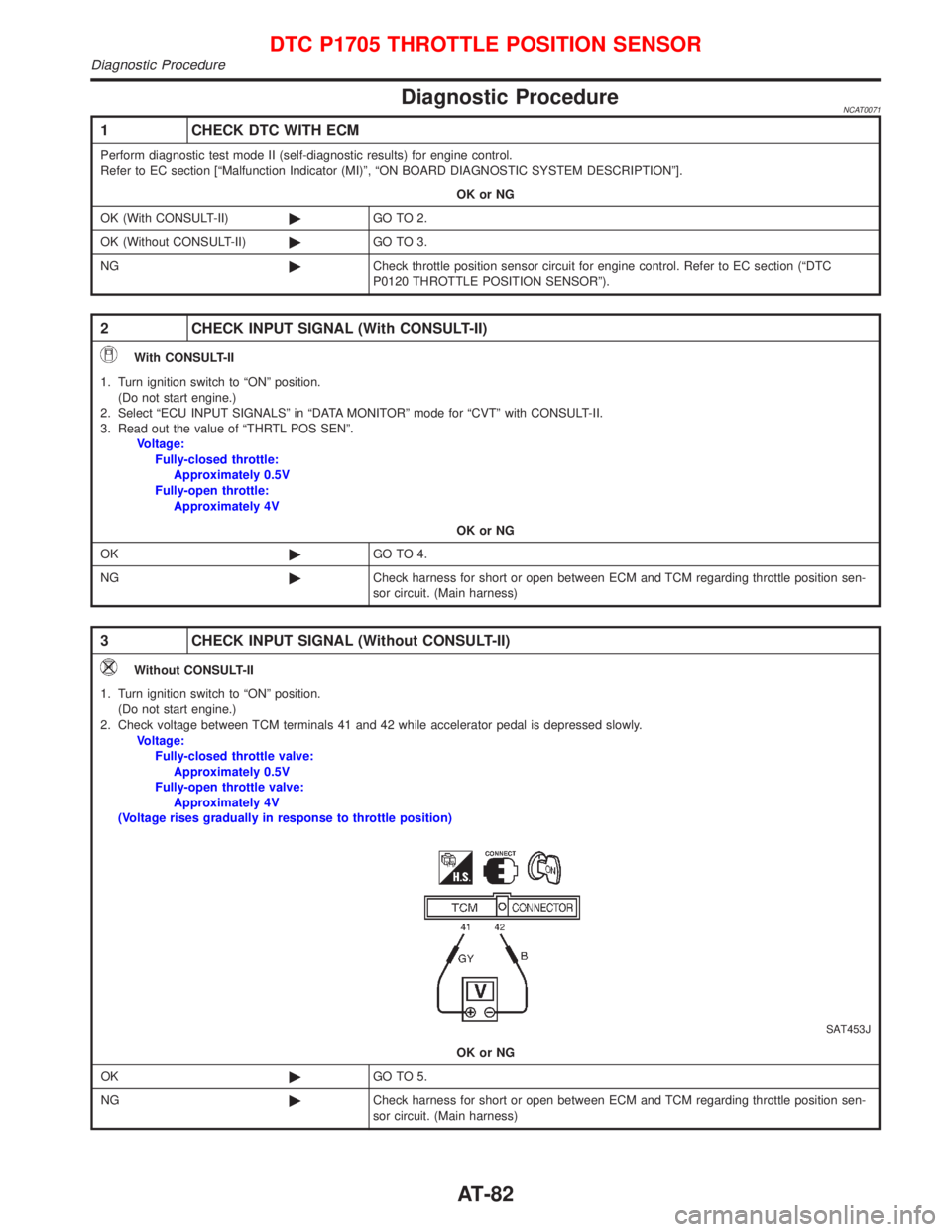

Diagnostic ProcedureNCAT0071

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control.

Refer to EC section [ªMalfunction Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº].

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Check throttle position sensor circuit for engine control. Refer to EC section (ªDTC

P0120 THROTTLE POSITION SENSORº).

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªTHRTL POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

OK or NG

OK©GO TO 4.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

3 CHECK INPUT SIGNAL (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 41 and 42 while accelerator pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in response to throttle position)

SAT453J

OK or NG

OK©GO TO 5.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

DTC P1705 THROTTLE POSITION SENSOR

Diagnostic Procedure

AT-82

Page 88 of 2267

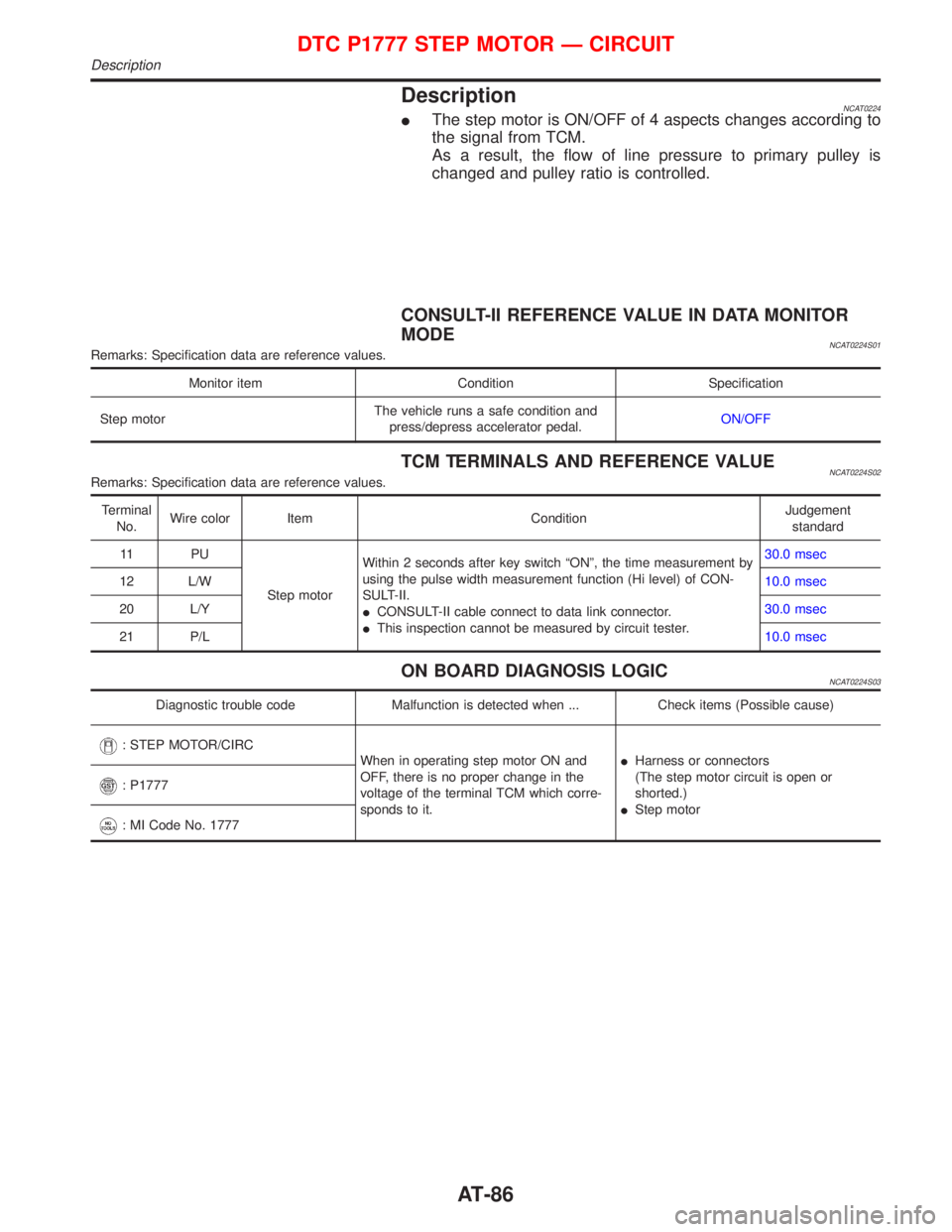

DescriptionNCAT0224IThe step motor is ON/OFF of 4 aspects changes according to

the signal from TCM.

As a result, the flow of line pressure to primary pulley is

changed and pulley ratio is controlled.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0224S01Remarks: Specification data are reference values.

Monitor item Condition Specification

Step motorThe vehicle runs a safe condition and

press/depress accelerator pedal.ON/OFF

TCM TERMINALS AND REFERENCE VALUENCAT0224S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

11 P U

Step motorWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

ICONSULT-II cable connect to data link connector.

IThis inspection cannot be measured by circuit tester.30.0 msec

12 L/W10.0 msec

20 L/Y30.0 msec

21 P/L10.0 msec

ON BOARD DIAGNOSIS LOGICNCAT0224S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: STEP MOTOR/CIRC

When in operating step motor ON and

OFF, there is no proper change in the

voltage of the terminal TCM which corre-

sponds to it.IHarness or connectors

(The step motor circuit is open or

shorted.)

IStep motor

: P1777

: MI Code No. 1777

DTC P1777 STEP MOTOR Ð CIRCUIT

Description

AT-86

Page 90 of 2267

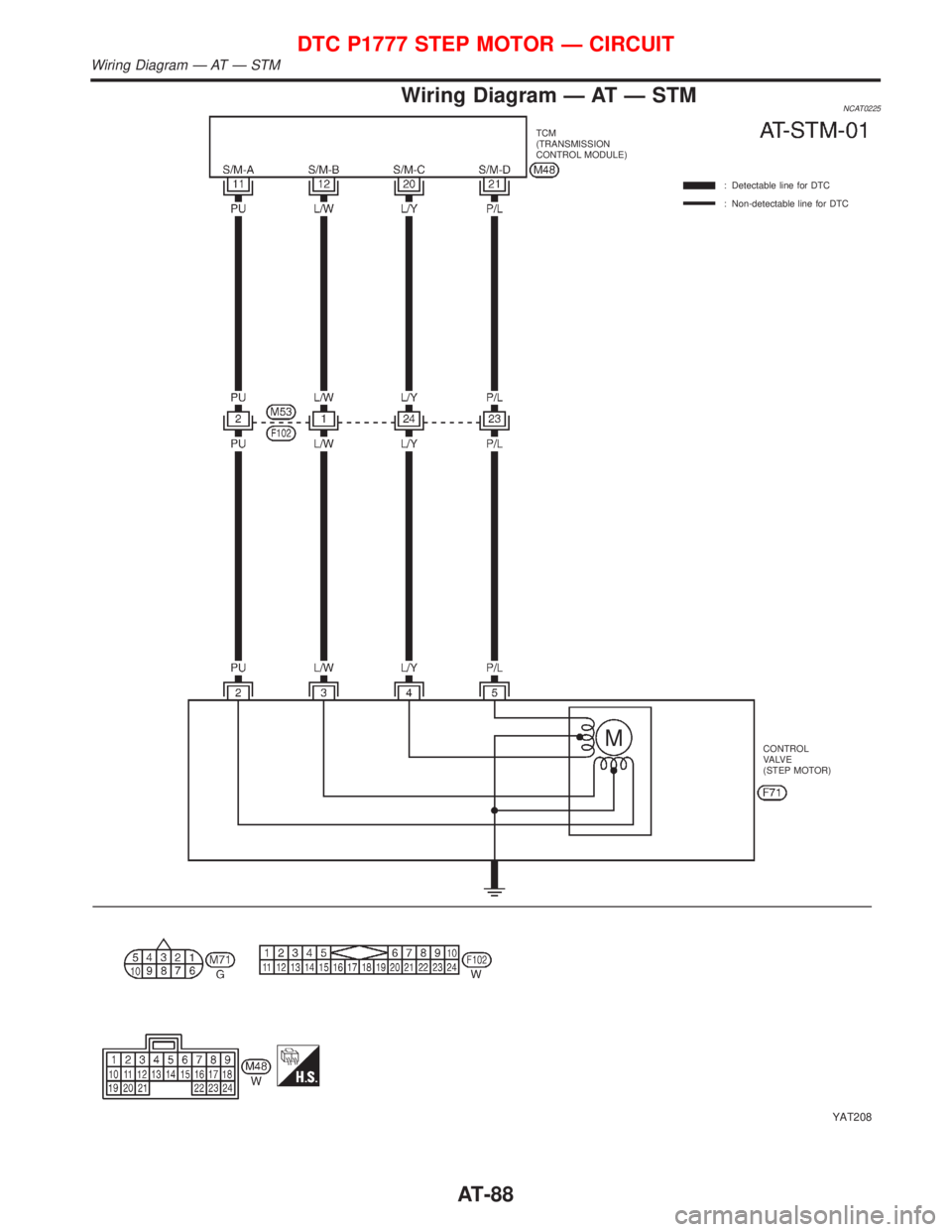

Wiring Diagram Ð AT Ð STMNCAT0225

YAT208

TCM

(TRANSMISSION

CONTROL MODULE)

: Detectable line for DTC

: Non-detectable line for DTC

CONTROL

VA LV E

(STEP MOTOR)

DTC P1777 STEP MOTOR Ð CIRCUIT

Wiring Diagram Ð AT Ð STM

AT-88