control NISSAN PRIMERA 1999 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 22 of 2267

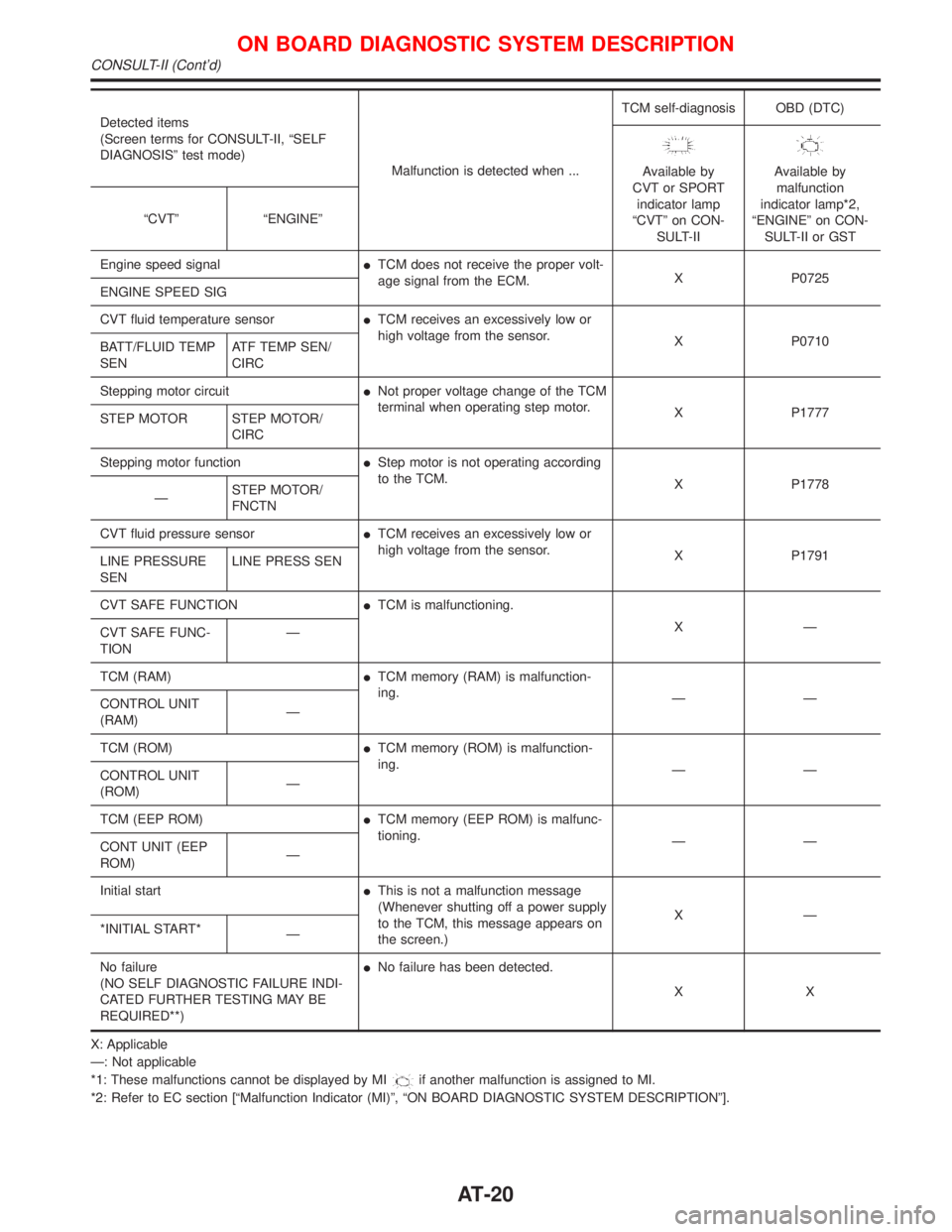

Detected items

(Screen terms for CONSULT-II, ªSELF

DIAGNOSISº test mode)

Malfunction is detected when ...TCM self-diagnosis OBD (DTC)

Available by

CVT or SPORT

indicator lamp

ªCVTº on CON-

SULT-IIAvailable by

malfunction

indicator lamp*2,

ªENGINEº on CON-

SULT-II or GST ªCVTº ªENGINEº

Engine speed signalITCM does not receive the proper volt-

age signal from the ECM.X P0725

ENGINE SPEED SIG

CVT fluid temperature sensorITCM receives an excessively low or

high voltage from the sensor.

X P0710

BATT/FLUID TEMP

SENATF TEMP SEN/

CIRC

Stepping motor circuitINot proper voltage change of the TCM

terminal when operating step motor.

X P1777

STEP MOTOR STEP MOTOR/

CIRC

Stepping motor functionIStep motor is not operating according

to the TCM.

X P1778

ÐSTEP MOTOR/

FNCTN

CVT fluid pressure sensorITCM receives an excessively low or

high voltage from the sensor.

X P1791

LINE PRESSURE

SENLINE PRESS SEN

CVT SAFE FUNCTIONITCM is malfunctioning.

XÐ

CVT SAFE FUNC-

TIONÐ

TCM (RAM)ITCM memory (RAM) is malfunction-

ing.

ÐÐ

CONTROL UNIT

(RAM)Ð

TCM (ROM)ITCM memory (ROM) is malfunction-

ing.

ÐÐ

CONTROL UNIT

(ROM)Ð

TCM (EEP ROM)ITCM memory (EEP ROM) is malfunc-

tioning.

ÐÐ

CONT UNIT (EEP

ROM)Ð

Initial startIThis is not a malfunction message

(Whenever shutting off a power supply

to the TCM, this message appears on

the screen.)XÐ

*INITIAL START*

Ð

No failure

(NO SELF DIAGNOSTIC FAILURE INDI-

CATED FURTHER TESTING MAY BE

REQUIRED**)INo failure has been detected.

XX

X: Applicable

Ð: Not applicable

*1: These malfunctions cannot be displayed by MI

if another malfunction is assigned to MI.

*2: Refer to EC section [ªMalfunction Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº].

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

AT-20

Page 24 of 2267

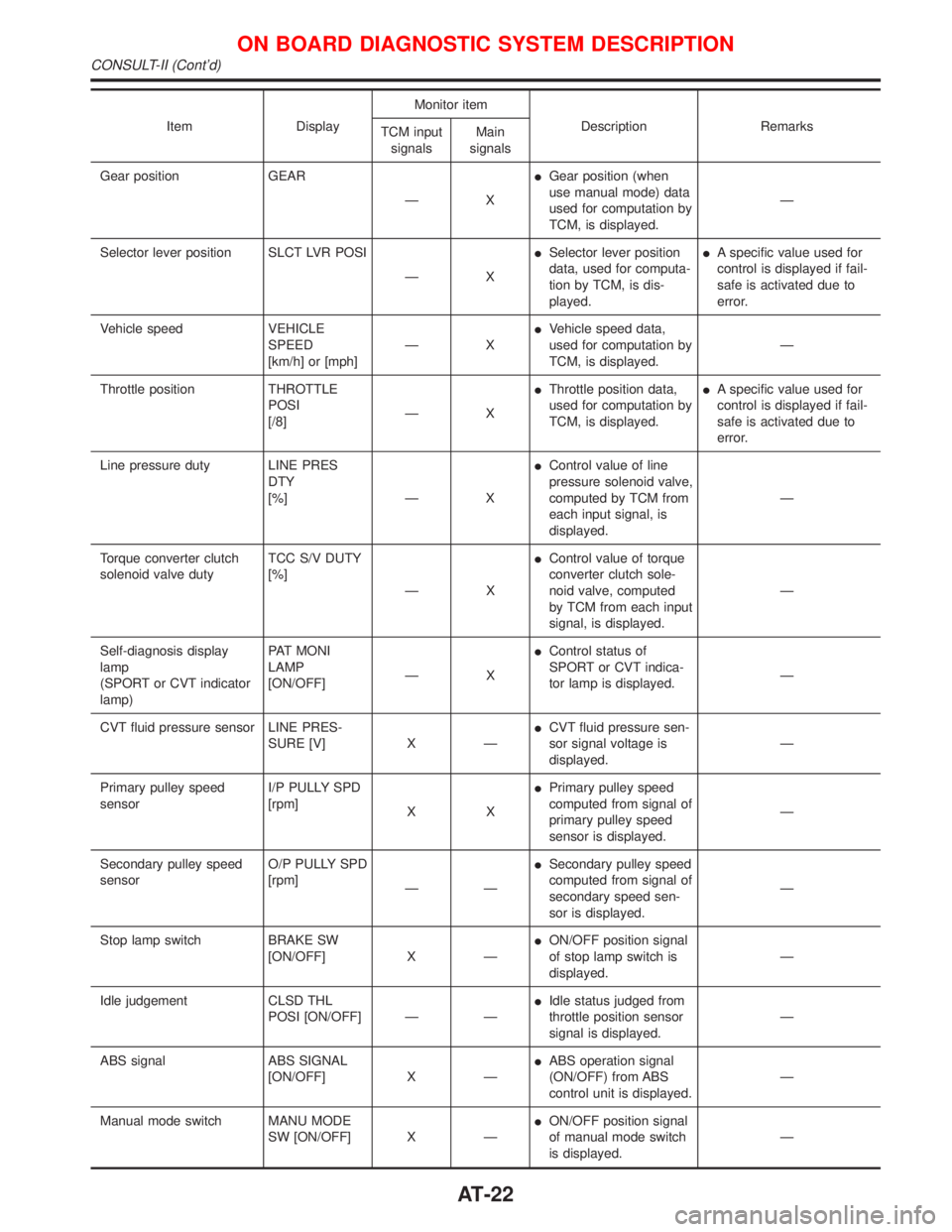

Item DisplayMonitor item

Description Remarks

TCM input

signalsMain

signals

Gear position GEAR

ÐXIGear position (when

use manual mode) data

used for computation by

TCM, is displayed.Ð

Selector lever position SLCT LVR POSI

ÐXISelector lever position

data, used for computa-

tion by TCM, is dis-

played.IA specific value used for

control is displayed if fail-

safe is activated due to

error.

Vehicle speed VEHICLE

SPEED

[km/h] or [mph]ÐXIVehicle speed data,

used for computation by

TCM, is displayed.Ð

Throttle position THROTTLE

POSI

[/8]ÐXIThrottle position data,

used for computation by

TCM, is displayed.IA specific value used for

control is displayed if fail-

safe is activated due to

error.

Line pressure duty LINE PRES

DTY

[%] Ð XIControl value of line

pressure solenoid valve,

computed by TCM from

each input signal, is

displayed.Ð

Torque converter clutch

solenoid valve dutyTCC S/V DUTY

[%]

ÐXIControl value of torque

converter clutch sole-

noid valve, computed

by TCM from each input

signal, is displayed.Ð

Self-diagnosis display

lamp

(SPORT or CVT indicator

lamp)PAT MONI

LAMP

[ON/OFF]ÐXIControl status of

SPORT or CVT indica-

tor lamp is displayed.Ð

CVT fluid pressure sensor LINE PRES-

SURE [V] X ÐICVT fluid pressure sen-

sor signal voltage is

displayed.Ð

Primary pulley speed

sensorI/P PULLY SPD

[rpm]

XXIPrimary pulley speed

computed from signal of

primary pulley speed

sensor is displayed.Ð

Secondary pulley speed

sensorO/P PULLY SPD

[rpm]

ÐÐISecondary pulley speed

computed from signal of

secondary speed sen-

sor is displayed.Ð

Stop lamp switch BRAKE SW

[ON/OFF] X ÐION/OFF position signal

of stop lamp switch is

displayed.Ð

Idle judgement CLSD THL

POSI [ON/OFF] Ð ÐIIdle status judged from

throttle position sensor

signal is displayed.Ð

ABS signal ABS SIGNAL

[ON/OFF] X ÐIABS operation signal

(ON/OFF) from ABS

control unit is displayed.Ð

Manual mode switch MANU MODE

SW [ON/OFF] X ÐION/OFF position signal

of manual mode switch

is displayed.Ð

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

AT-22

Page 25 of 2267

![NISSAN PRIMERA 1999 Electronic User Guide Item DisplayMonitor item

Description Remarks

TCM input

signalsMain

signals

Non-manual mode switch NON M MODE

SW [ON/OFF] X ÐION/OFF position signal

of non-manual mode

switch is displayed.Ð

Up switch NISSAN PRIMERA 1999 Electronic User Guide Item DisplayMonitor item

Description Remarks

TCM input

signalsMain

signals

Non-manual mode switch NON M MODE

SW [ON/OFF] X ÐION/OFF position signal

of non-manual mode

switch is displayed.Ð

Up switch](/img/5/57377/w960_57377-24.png)

Item DisplayMonitor item

Description Remarks

TCM input

signalsMain

signals

Non-manual mode switch NON M MODE

SW [ON/OFF] X ÐION/OFF position signal

of non-manual mode

switch is displayed.Ð

Up switch UP SW

[ON/OFF] X ÐION/OFF position signal

of up switch is dis-

played.Ð

Down switch DOWN SW

[ON/OFF] X ÐION/OFF position signal

of down switch is dis-

played.Ð

Step motor coil A S/M COIL [A]

[ON/OFF]

ÐÐIControl valve of step

motor coil A, computed

by TCM from each input

signal is displayed.Ð

Step motor coil B S/M COIL [B]

[ON/OFF]

ÐÐIControl valve of step

motor coil B, computed

by TCM from each input

signal is displayed.Ð

Step motor coil C S/M COIL [C]

[ON/OFF]

ÐÐIControl valve of step

motor coil C, computed

by TCM from each input

signal is displayed.Ð

Step motor coil D S/M COIL [D]

[ON/OFF]

ÐÐIControl valve of step

motor coil D, computed

by TCM from each input

signal is displayed.Ð

CVT ratio CVT RATIO [Ð]

ÐXIReal CVT ratio operated

TCM is displayed.Ð

Step PLY CONT

STEP [step]ÐXIStep motor position is

displayed.Ð

Line pressure LINE PRES-

SURE [MPa]

ÐXIReal line pressure cal-

culated from line pres-

sure sensor voltage

with TCM is displayed.Ð

Pulley rpm×in 2 T RPM [rpm]

ÐÐITarget primary pulley

speed operated with

TCM is displayed.Ð

CVT ratio 2 T RATIO [Ð]

ÐÐITarget changing the

speed ratio operated

with TCM is displayed.Ð

Step 2 T STEP [step]

ÐÐITarget step motor posi-

tion operated with TCM

is displayed.Ð

X: Applicable

Ð: Not applicable

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

AT-23

Page 27 of 2267

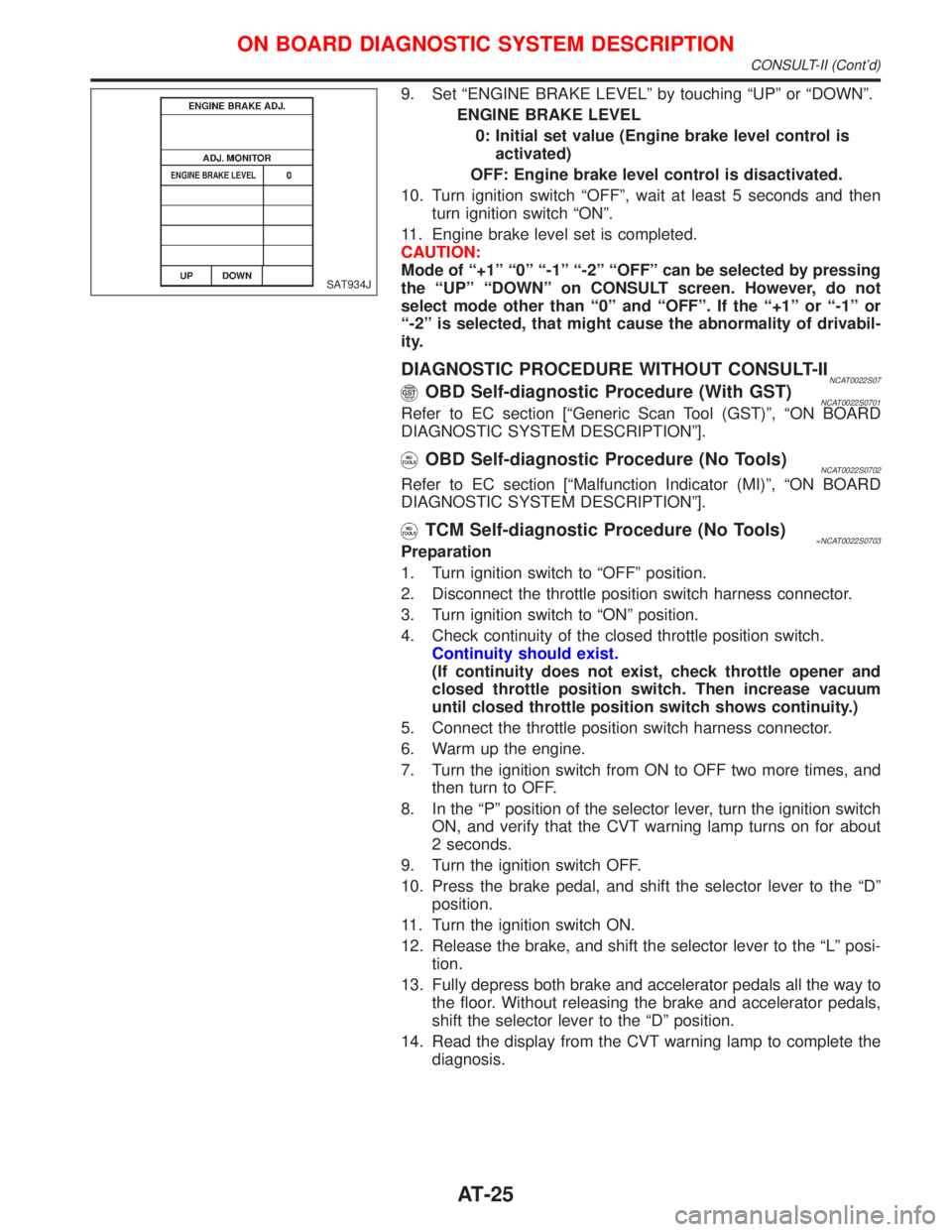

9. Set ªENGINE BRAKE LEVELº by touching ªUPº or ªDOWNº.

ENGINE BRAKE LEVEL

0: Initial set value (Engine brake level control is

activated)

OFF: Engine brake level control is disactivated.

10. Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ignition switch ªONº.

11. Engine brake level set is completed.

CAUTION:

Mode of ª+1º ª0º ª-1º ª-2º ªOFFº can be selected by pressing

the ªUPº ªDOWNº on CONSULT screen. However, do not

select mode other than ª0º and ªOFFº. If the ª+1º or ª-1º or

ª-2º is selected, that might cause the abnormality of drivabil-

ity.

DIAGNOSTIC PROCEDURE WITHOUT CONSULT-IINCAT0022S07OBD Self-diagnostic Procedure (With GST)NCAT0022S0701Refer to EC section [ªGeneric Scan Tool (GST)º, ªON BOARD

DIAGNOSTIC SYSTEM DESCRIPTIONº].

OBD Self-diagnostic Procedure (No Tools)NCAT0022S0702

Refer to EC section [ªMalfunction Indicator (MI)º, ªON BOARD

DIAGNOSTIC SYSTEM DESCRIPTIONº].

TCM Self-diagnostic Procedure (No Tools)=NCAT0022S0703Preparation

1. Turn ignition switch to ªOFFº position.

2. Disconnect the throttle position switch harness connector.

3. Turn ignition switch to ªONº position.

4. Check continuity of the closed throttle position switch.

Continuity should exist.

(If continuity does not exist, check throttle opener and

closed throttle position switch. Then increase vacuum

until closed throttle position switch shows continuity.)

5. Connect the throttle position switch harness connector.

6. Warm up the engine.

7. Turn the ignition switch from ON to OFF two more times, and

then turn to OFF.

8. In the ªPº position of the selector lever, turn the ignition switch

ON, and verify that the CVT warning lamp turns on for about

2 seconds.

9. Turn the ignition switch OFF.

10. Press the brake pedal, and shift the selector lever to the ªDº

position.

11. Turn the ignition switch ON.

12. Release the brake, and shift the selector lever to the ªLº posi-

tion.

13. Fully depress both brake and accelerator pedals all the way to

the floor. Without releasing the brake and accelerator pedals,

shift the selector lever to the ªDº position.

14. Read the display from the CVT warning lamp to complete the

diagnosis.

SAT934J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

AT-25

Page 31 of 2267

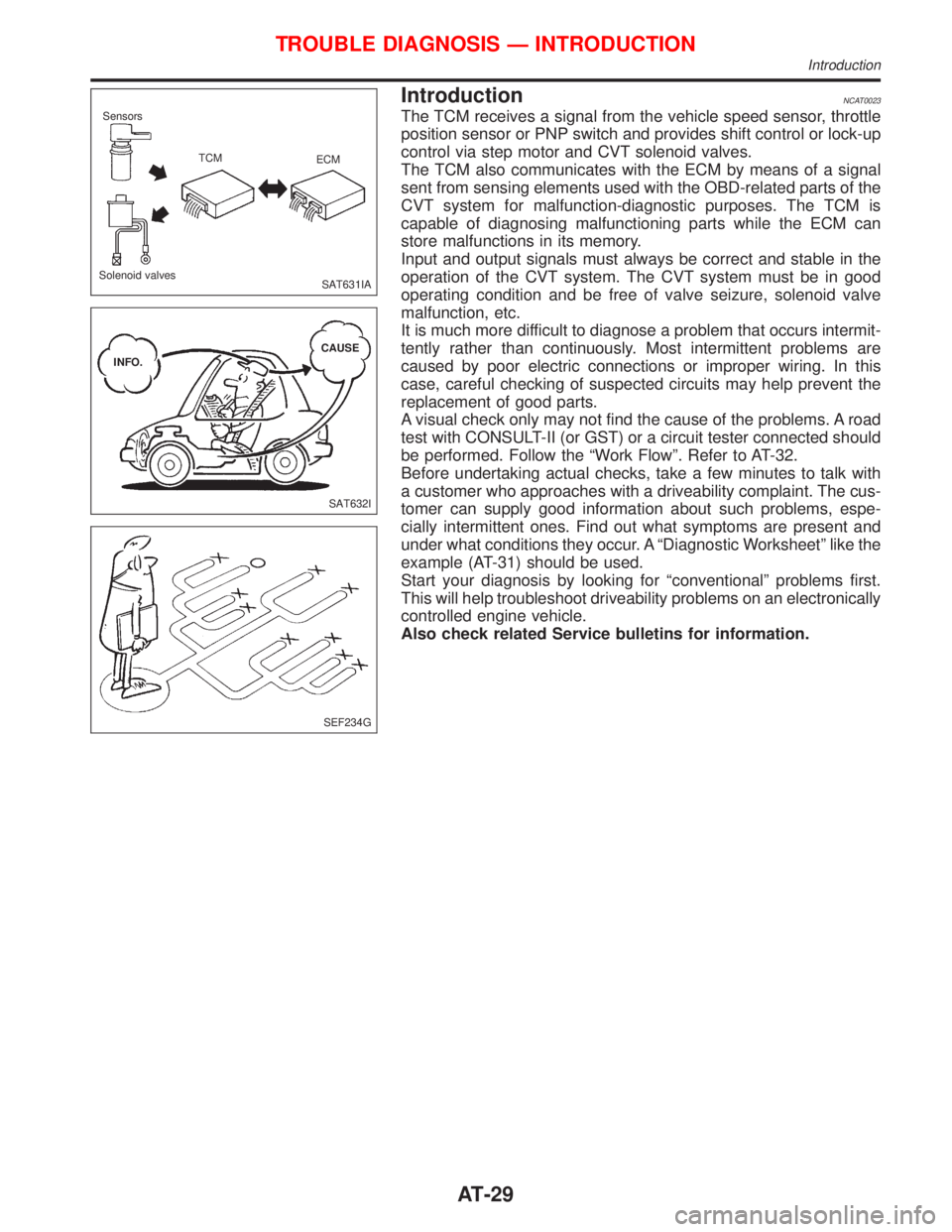

IntroductionNCAT0023

The TCM receives a signal from the vehicle speed sensor, throttle

position sensor or PNP switch and provides shift control or lock-up

control via step motor and CVT solenoid valves.

The TCM also communicates with the ECM by means of a signal

sent from sensing elements used with the OBD-related parts of the

CVT system for malfunction-diagnostic purposes. The TCM is

capable of diagnosing malfunctioning parts while the ECM can

store malfunctions in its memory.

Input and output signals must always be correct and stable in the

operation of the CVT system. The CVT system must be in good

operating condition and be free of valve seizure, solenoid valve

malfunction, etc.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº. Refer to AT-32.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example (AT-31) should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

Also check related Service bulletins for information.

SAT631IA Sensors

TCM

ECM

Solenoid valves

SAT632I INFO.CAUSE

SEF234G

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction

AT-29

Page 44 of 2267

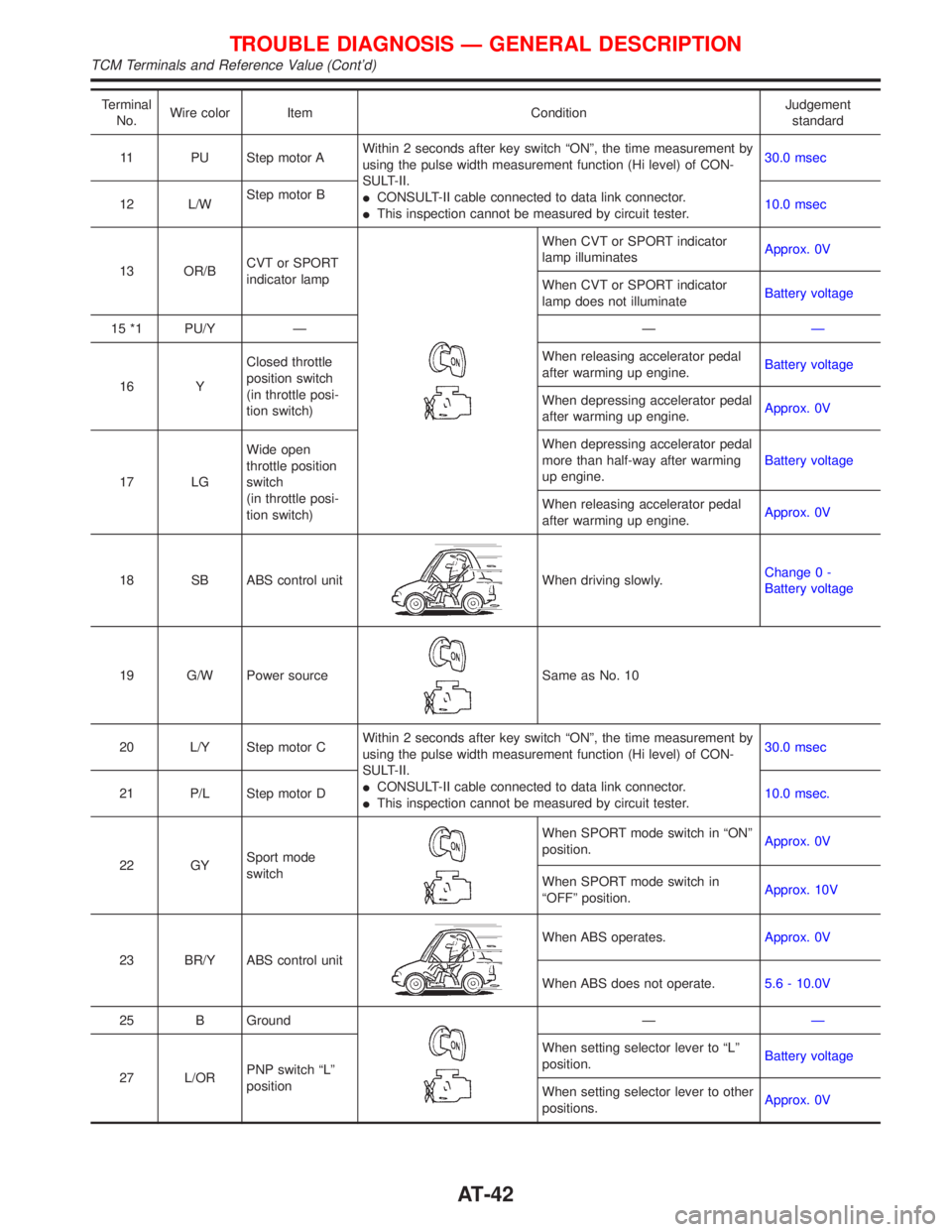

Terminal

No.Wire color Item ConditionJudgement

standard

11 PU Step motor AWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.30.0 msec

12 L/WStep motor B

10.0 msec

13 OR/BCVT or SPORT

indicator lamp

When CVT or SPORT indicator

lamp illuminatesApprox. 0V

When CVT or SPORT indicator

lamp does not illuminateBattery voltage

15 *1 PU/Y Ð ÐÐ

16 YClosed throttle

position switch

(in throttle posi-

tion switch)When releasing accelerator pedal

after warming up engine.Battery voltage

When depressing accelerator pedal

after warming up engine.Approx. 0V

17 LGWide open

throttle position

switch

(in throttle posi-

tion switch)When depressing accelerator pedal

more than half-way after warming

up engine.Battery voltage

When releasing accelerator pedal

after warming up engine.Approx. 0V

18 SB ABS control unit

When driving slowly.Change 0 -

Battery voltage

19 G/W Power source

Same as No. 10

20 L/Y Step motor CWithin 2 seconds after key switch ªONº, the time measurement by

using the pulse width measurement function (Hi level) of CON-

SULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.30.0 msec

21 P/L Step motor D10.0 msec.

22 GYSport mode

switch

When SPORT mode switch in ªONº

position.Approx. 0V

When SPORT mode switch in

ªOFFº position.Approx. 10V

23 BR/Y ABS control unit

When ABS operates.Approx. 0V

When ABS does not operate.5.6 - 10.0V

25 B Ground

ÐÐ

27 L/ORPNP switch ªLº

positionWhen setting selector lever to ªLº

position.Battery voltage

When setting selector lever to other

positions.Approx. 0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

TCM Terminals and Reference Value (Cont'd)

AT-42

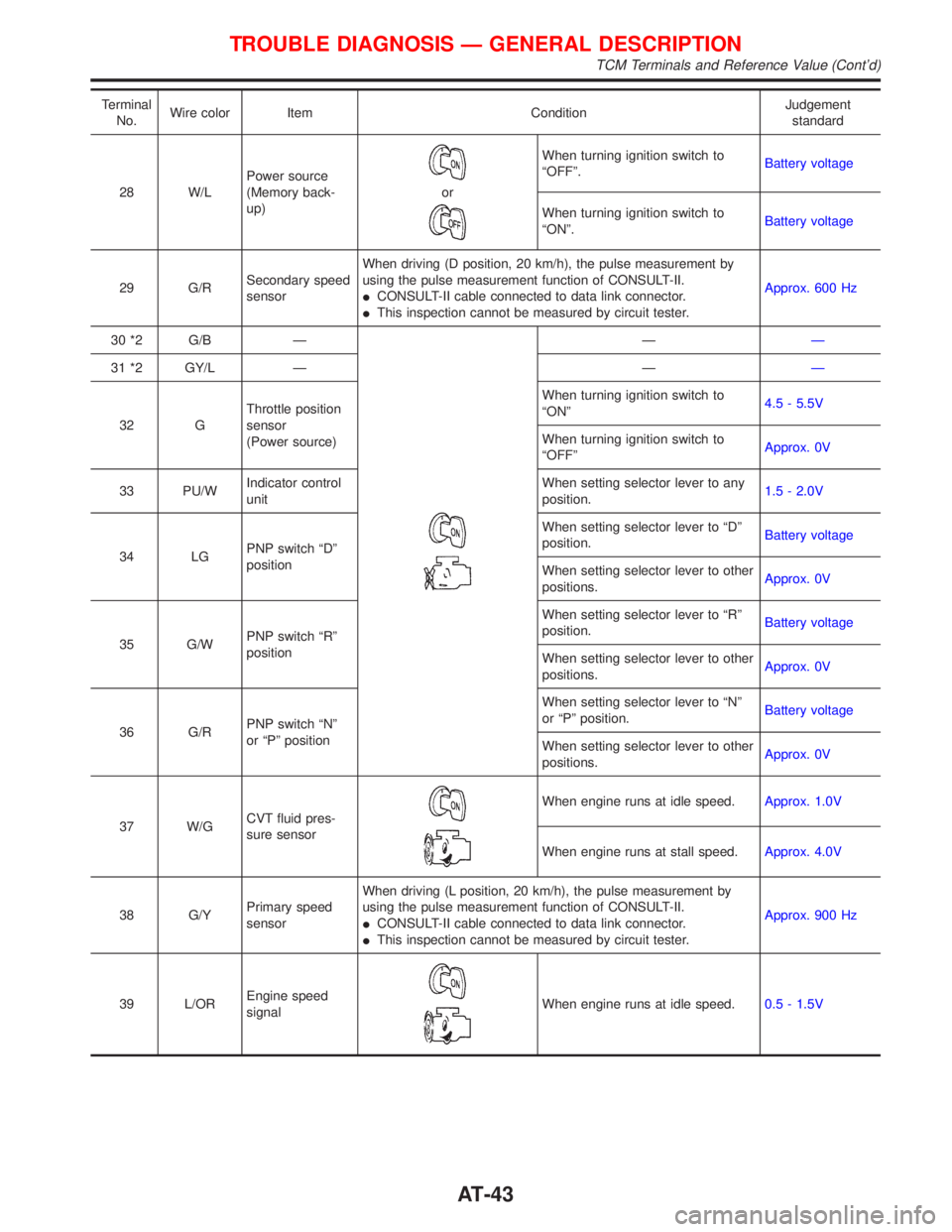

Page 45 of 2267

Terminal

No.Wire color Item ConditionJudgement

standard

28 W/LPower source

(Memory back-

up)

or

When turning ignition switch to

ªOFFº.Battery voltage

When turning ignition switch to

ªONº.Battery voltage

29 G/RSecondary speed

sensorWhen driving (D position, 20 km/h), the pulse measurement by

using the pulse measurement function of CONSULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.Approx. 600 Hz

30 *2 G/B Ð

ÐÐ

31 *2 GY/L Ð ÐÐ

32 GThrottle position

sensor

(Power source)When turning ignition switch to

ªONº4.5 - 5.5V

When turning ignition switch to

ªOFFºApprox. 0V

33 PU/WIndicator control

unitWhen setting selector lever to any

position.1.5 - 2.0V

34 LGPNP switch ªDº

positionWhen setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.Approx. 0V

35 G/WPNP switch ªRº

positionWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.Approx. 0V

36 G/RPNP switch ªNº

or ªPº positionWhen setting selector lever to ªNº

or ªPº position.Battery voltage

When setting selector lever to other

positions.Approx. 0V

37 W/GCVT fluid pres-

sure sensor

When engine runs at idle speed.Approx. 1.0V

When engine runs at stall speed.Approx. 4.0V

38 G/YPrimary speed

sensorWhen driving (L position, 20 km/h), the pulse measurement by

using the pulse measurement function of CONSULT-II.

ICONSULT-II cable connected to data link connector.

IThis inspection cannot be measured by circuit tester.Approx. 900 Hz

39 L/OREngine speed

signal

When engine runs at idle speed.0.5 - 1.5V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

TCM Terminals and Reference Value (Cont'd)

AT-43

Page 47 of 2267

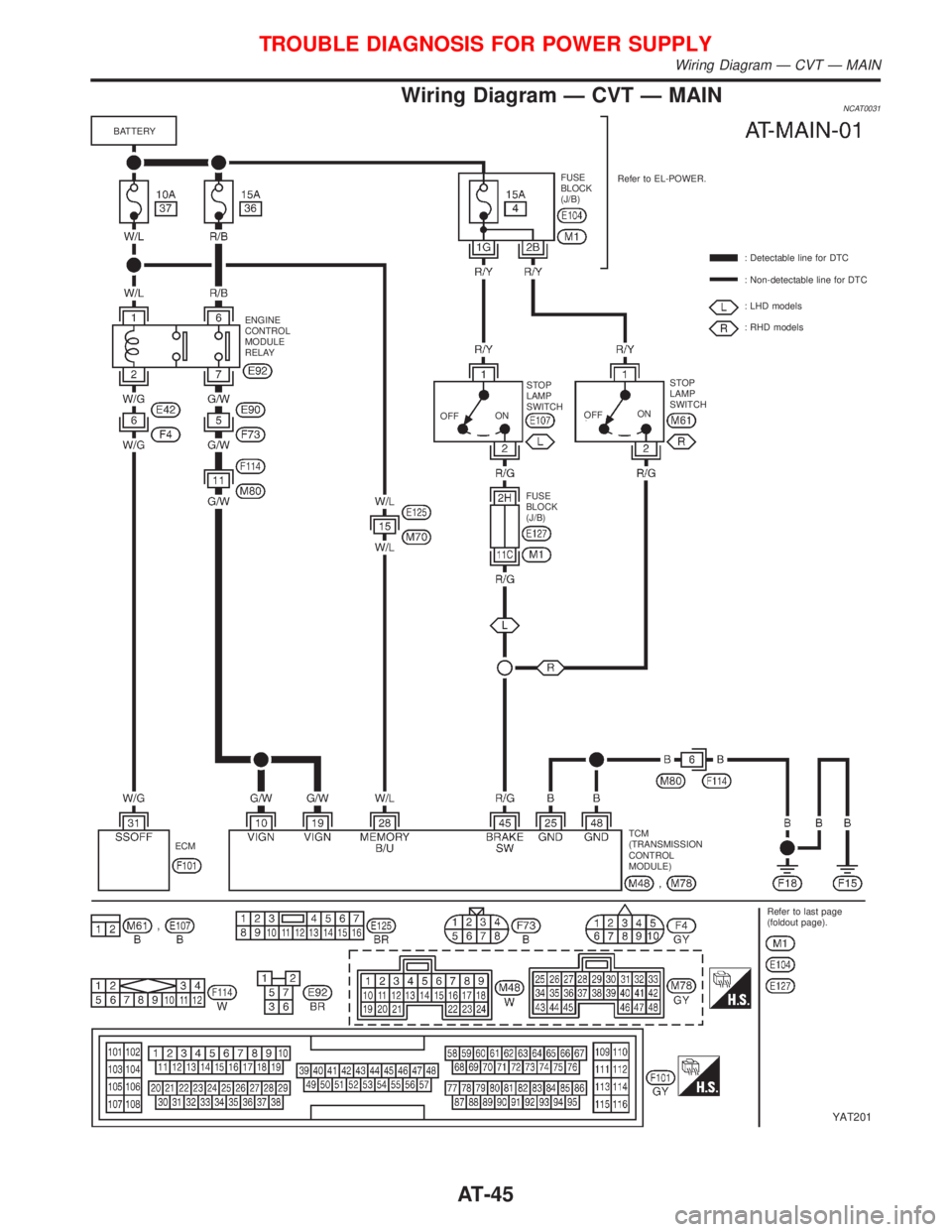

Wiring Diagram Ð CVT Ð MAINNCAT0031

YAT201

BATTERY

ENGINE

CONTROL

MODULE

RELAY

OFFONSTOP

LAMP

SWITCH

FUSE

BLOCK

(J/B)OFFONSTOP

LAMP

SWITCH: Detectable line for DTC

: Non-detectable line for DTC

: LHD models

: RHD models Refer to EL-POWER. FUSE

BLOCK

(J/B)

TCM

(TRANSMISSION

CONTROL

MODULE)

Refer to last page

(foldout page). ECM

TROUBLE DIAGNOSIS FOR POWER SUPPLY

Wiring Diagram Ð CVT Ð MAIN

AT-45

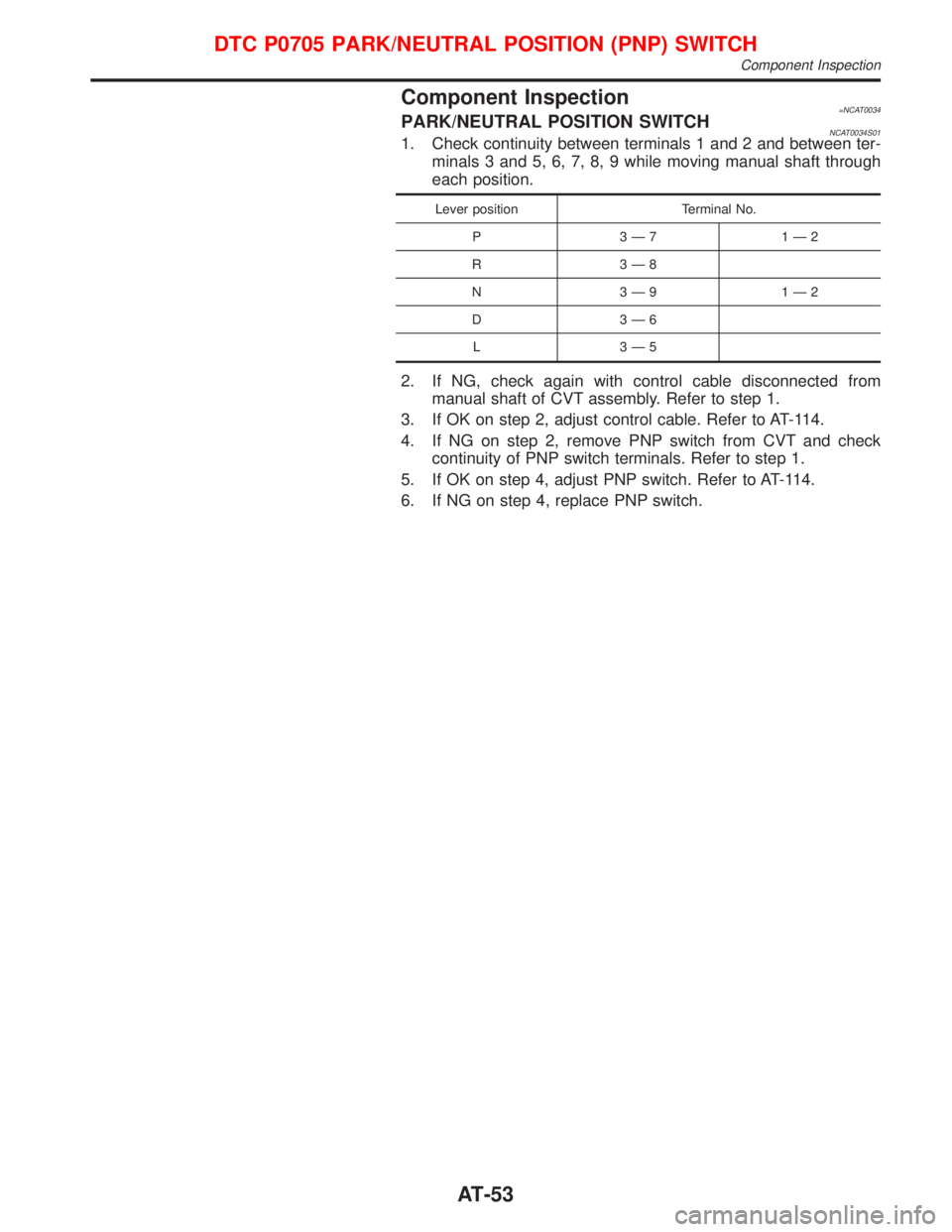

Page 55 of 2267

Component Inspection=NCAT0034PARK/NEUTRAL POSITION SWITCHNCAT0034S011. Check continuity between terminals 1 and 2 and between ter-

minals 3 and 5, 6, 7, 8, 9 while moving manual shaft through

each position.

Lever position Terminal No.

P 3Ð7 1Ð2

R 3Ð8

N 3Ð9 1Ð2

D 3Ð6

L 3Ð5

2. If NG, check again with control cable disconnected from

manual shaft of CVT assembly. Refer to step 1.

3. If OK on step 2, adjust control cable. Refer to AT-114.

4. If NG on step 2, remove PNP switch from CVT and check

continuity of PNP switch terminals. Refer to step 1.

5. If OK on step 4, adjust PNP switch. Refer to AT-114.

6. If NG on step 4, replace PNP switch.

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Component Inspection

AT-53

Page 58 of 2267

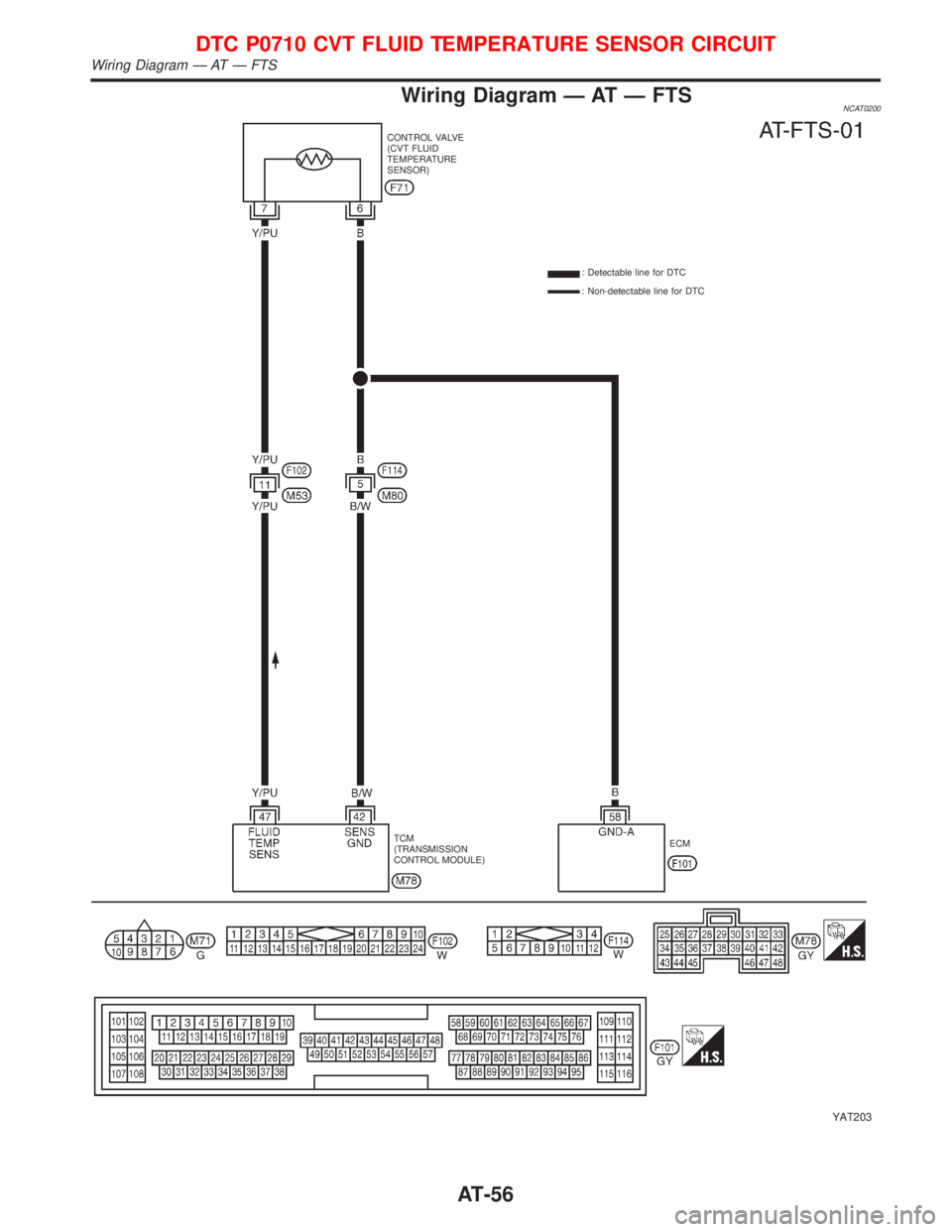

Wiring Diagram Ð AT Ð FTSNCAT0200

YAT203

CONTROL VALVE

(CVT FLUID

TEMPERATURE

SENSOR)

: Detectable line for DTC

: Non-detectable line for DTC

TCM

(TRANSMISSION

CONTROL MODULE)ECM

DTC P0710 CVT FLUID TEMPERATURE SENSOR CIRCUIT

Wiring Diagram Ð AT Ð FTS

AT-56