boot NISSAN PRIMERA 1999 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 2125 of 2267

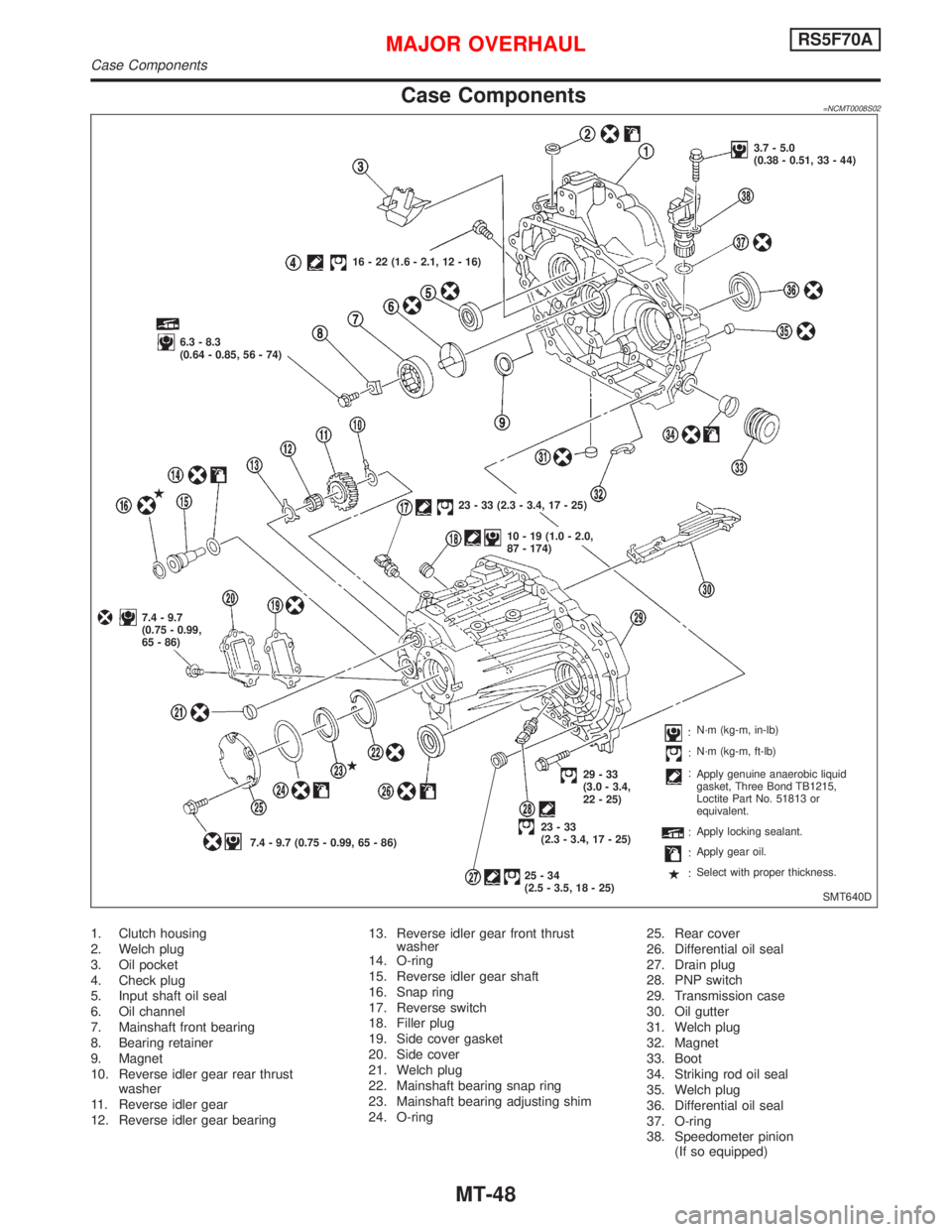

Case Components=NCMT0008S02

1. Clutch housing

2. Welch plug

3. Oil pocket

4. Check plug

5. Input shaft oil seal

6. Oil channel

7. Mainshaft front bearing

8. Bearing retainer

9. Magnet

10. Reverse idler gear rear thrust

washer

11. Reverse idler gear

12. Reverse idler gear bearing13. Reverse idler gear front thrust

washer

14. O-ring

15. Reverse idler gear shaft

16. Snap ring

17. Reverse switch

18. Filler plug

19. Side cover gasket

20. Side cover

21. Welch plug

22. Mainshaft bearing snap ring

23. Mainshaft bearing adjusting shim

24. O-ring25. Rear cover

26. Differential oil seal

27. Drain plug

28. PNP switch

29. Transmission case

30. Oil gutter

31. Welch plug

32. Magnet

33. Boot

34. Striking rod oil seal

35. Welch plug

36. Differential oil seal

37. O-ring

38. Speedometer pinion

(If so equipped)

SMT640D 16 - 22 (1.6 - 2.1, 12 - 16)

6.3 - 8.3

(0.64 - 0.85, 56 - 74)

7.4 - 9.7

(0.75 - 0.99,

65 - 86)

7.4 - 9.7 (0.75 - 0.99, 65 - 86)23 - 33 (2.3 - 3.4, 17 - 25)

10 - 19 (1.0 - 2.0,

87 - 174)3.7 - 5.0

(0.38 - 0.51, 33 - 44)

29-33

(3.0 - 3.4,

22 - 25)

23-33

(2.3 - 3.4, 17 - 25)

25-34

(2.5 - 3.5, 18 - 25)N´m (kg-m, in-lb)

N´m (kg-m, ft-lb)

Apply genuine anaerobic liquid

gasket, Three Bond TB1215,

Loctite Part No. 51813 or

equivalent.

Apply locking sealant.

Apply gear oil.

Select with proper thickness.

MAJOR OVERHAULRS5F70A

Case Components

MT-48

Page 2127 of 2267

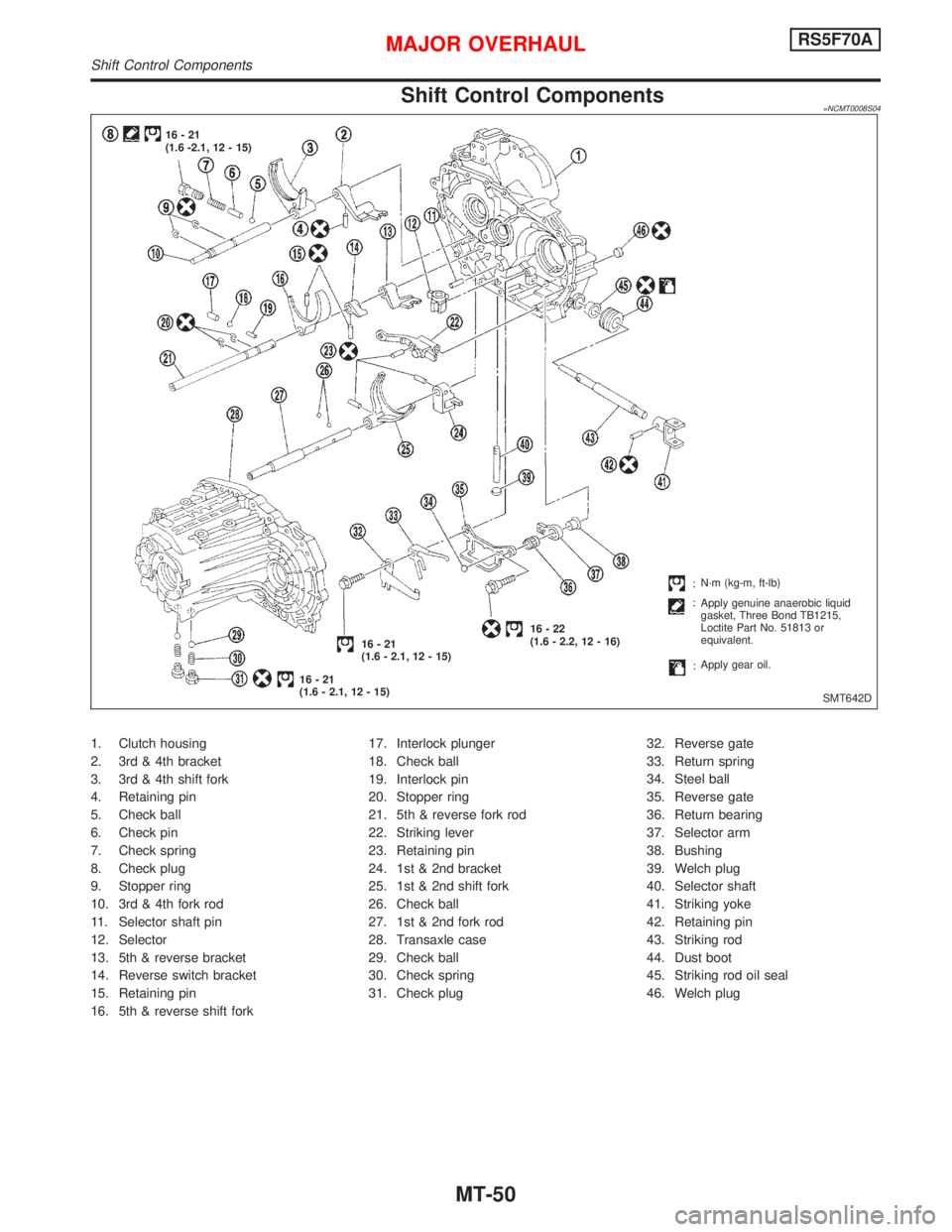

Shift Control Components=NCMT0008S04

1. Clutch housing

2. 3rd & 4th bracket

3. 3rd & 4th shift fork

4. Retaining pin

5. Check ball

6. Check pin

7. Check spring

8. Check plug

9. Stopper ring

10. 3rd & 4th fork rod

11. Selector shaft pin

12. Selector

13. 5th & reverse bracket

14. Reverse switch bracket

15. Retaining pin

16. 5th & reverse shift fork17. Interlock plunger

18. Check ball

19. Interlock pin

20. Stopper ring

21. 5th & reverse fork rod

22. Striking lever

23. Retaining pin

24. 1st & 2nd bracket

25. 1st & 2nd shift fork

26. Check ball

27. 1st & 2nd fork rod

28. Transaxle case

29. Check ball

30. Check spring

31. Check plug32. Reverse gate

33. Return spring

34. Steel ball

35. Reverse gate

36. Return bearing

37. Selector arm

38. Bushing

39. Welch plug

40. Selector shaft

41. Striking yoke

42. Retaining pin

43. Striking rod

44. Dust boot

45. Striking rod oil seal

46. Welch plug

SMT642D 16-21

(1.6 -2.1, 12 - 15)

16-21

(1.6 - 2.1, 12 - 15)16-21

(1.6 - 2.1, 12 - 15)16-22

(1.6 - 2.2, 12 - 16)N´m (kg-m, ft-lb)

Apply genuine anaerobic liquid

gasket, Three Bond TB1215,

Loctite Part No. 51813 or

equivalent.

Apply gear oil.

MAJOR OVERHAULRS5F70A

Shift Control Components

MT-50

Page 2154 of 2267

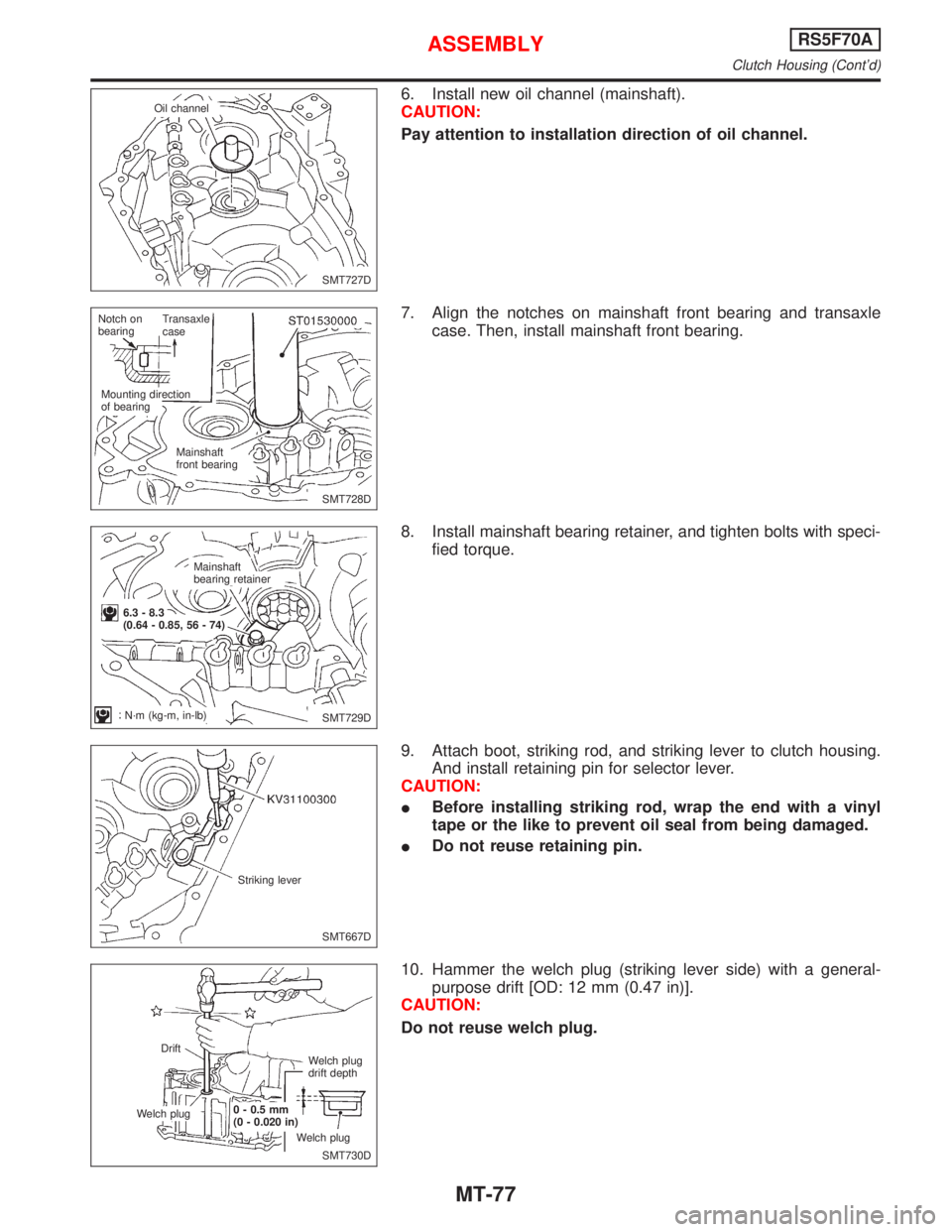

6. Install new oil channel (mainshaft).

CAUTION:

Pay attention to installation direction of oil channel.

7. Align the notches on mainshaft front bearing and transaxle

case. Then, install mainshaft front bearing.

8. Install mainshaft bearing retainer, and tighten bolts with speci-

fied torque.

9. Attach boot, striking rod, and striking lever to clutch housing.

And install retaining pin for selector lever.

CAUTION:

IBefore installing striking rod, wrap the end with a vinyl

tape or the like to prevent oil seal from being damaged.

IDo not reuse retaining pin.

10. Hammer the welch plug (striking lever side) with a general-

purpose drift [OD: 12 mm (0.47 in)].

CAUTION:

Do not reuse welch plug.

SMT727D Oil channel

SMT728D Notch on

bearingTransaxle

case

Mounting direction

of bearing

Mainshaft

front bearing

SMT729D Mainshaft

bearing retainer

6.3 - 8.3

(0.64 - 0.85, 56 - 74)

N´m (kg-m, in-lb)

SMT667D Striking lever

SMT730D Drift

Welch plug0 - 0.5 mm

(0 - 0.020 in)

Welch plugWelch plug

drift depth

ASSEMBLYRS5F70A

Clutch Housing (Cont'd)

MT-77

Page 2249 of 2267

Checking and Adjusting Drive Belts

Refer to section MA for Drive Belt Inspection.

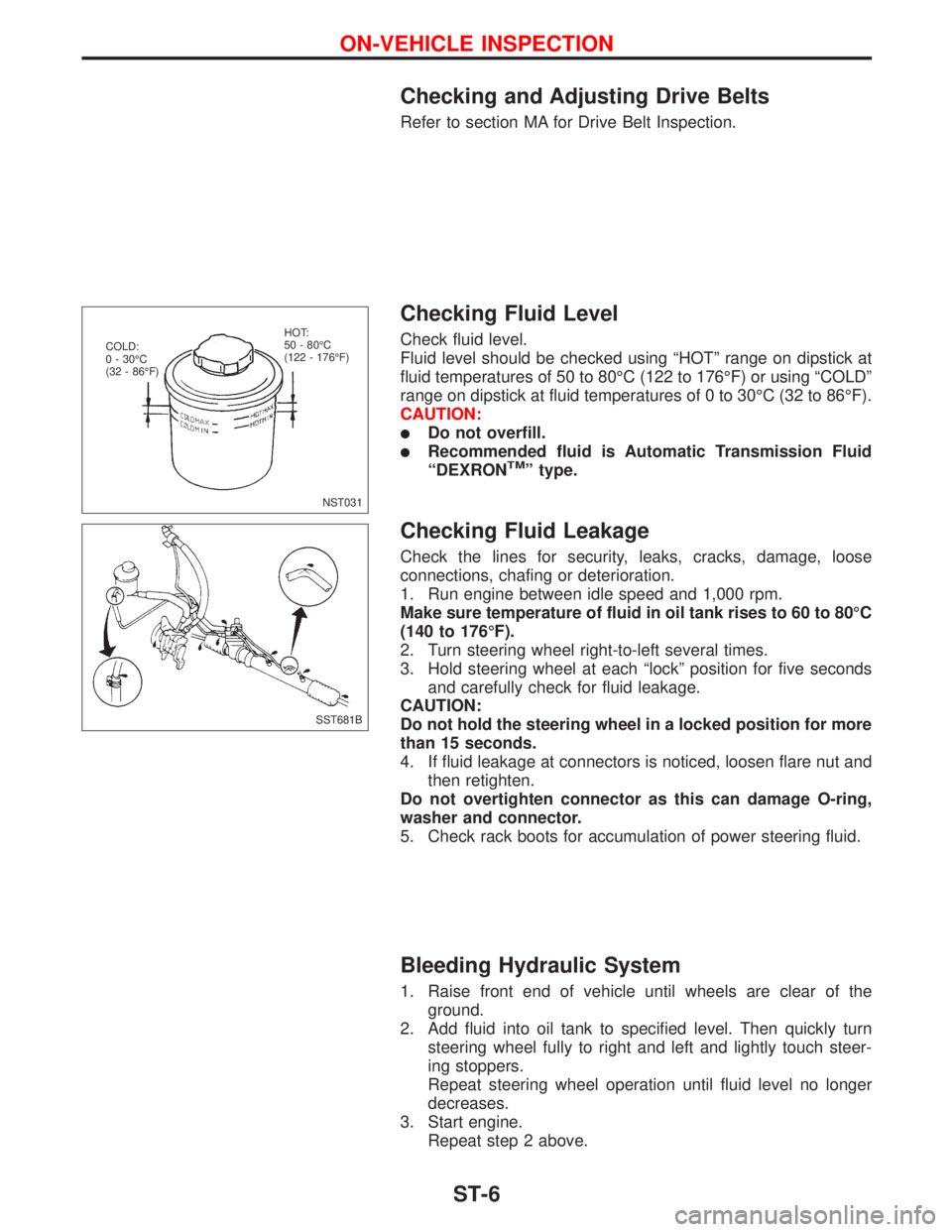

Checking Fluid Level

Check fluid level.

Fluid level should be checked using ªHOTº range on dipstick at

fluid temperatures of 50 to 80ÉC (122 to 176ÉF) or using ªCOLDº

range on dipstick at fluid temperatures of 0 to 30ÉC (32 to 86ÉF).

CAUTION:

lDo not overfill.

lRecommended fluid is Automatic Transmission Fluid

ªDEXRONTMº type.

Checking Fluid Leakage

Check the lines for security, leaks, cracks, damage, loose

connections, chafing or deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds

and carefully check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

4. If fluid leakage at connectors is noticed, loosen flare nut and

then retighten.

Do not overtighten connector as this can damage O-ring,

washer and connector.

5. Check rack boots for accumulation of power steering fluid.

Bleeding Hydraulic System

1. Raise front end of vehicle until wheels are clear of the

ground.

2. Add fluid into oil tank to specified level. Then quickly turn

steering wheel fully to right and left and lightly touch steer-

ing stoppers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2 above.

NST031 COLD:

0 - 30ÉC

(32 - 86ÉF)HOT:

50 - 80ÉC

(122 - 176ÉF)

SST681B

ON-VEHICLE INSPECTION

ST-6

Page 2254 of 2267

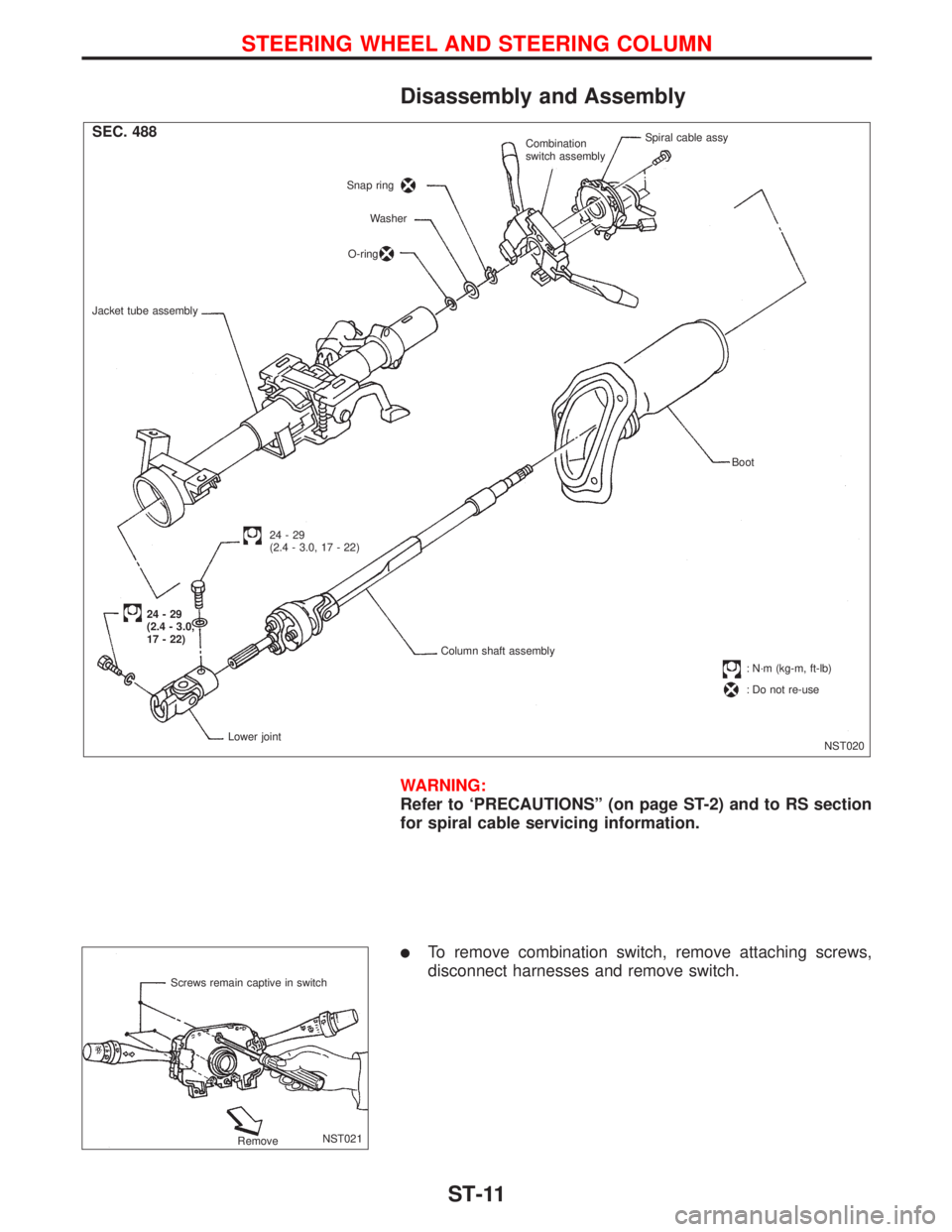

Disassembly and Assembly

WARNING:

Refer to `PRECAUTIONSº (on page ST-2) and to RS section

for spiral cable servicing information.

lTo remove combination switch, remove attaching screws,

disconnect harnesses and remove switch.

NST020 Boot Combination

switch assembly

24-29

(2.4 - 3.0,

17 - 22) Jacket tube assemblyWasherSpiral cable assy

: N´m (kg-m, ft-lb)

: Do not re-use

SEC. 488

O-ring

Snap ring

24-29

(2.4 - 3.0, 17 - 22)

Lower jointColumn shaft assembly

NST021 Screws remain captive in switch

Remove

STEERING WHEEL AND STEERING COLUMN

ST-11

Page 2260 of 2267

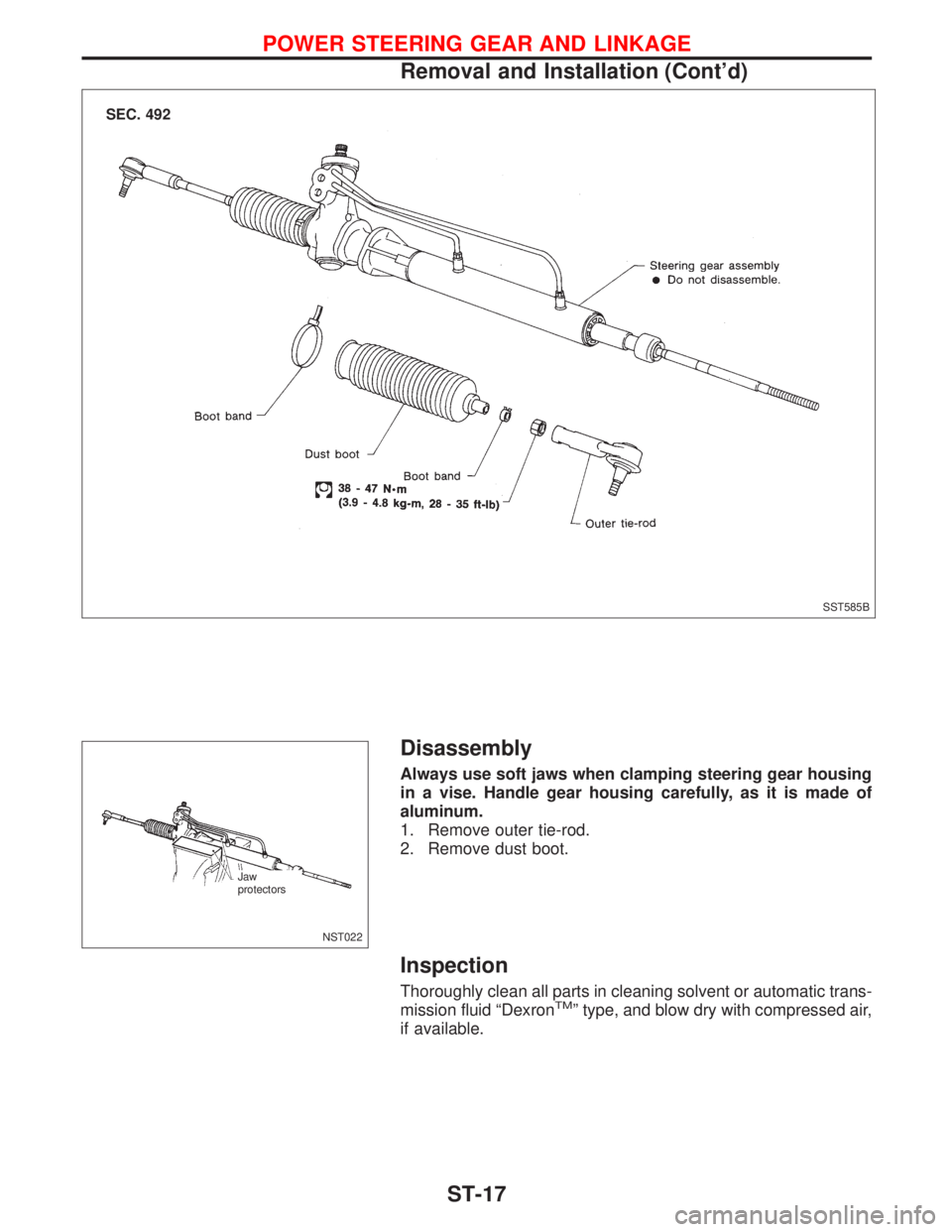

Disassembly

Always use soft jaws when clamping steering gear housing

in a vise. Handle gear housing carefully, as it is made of

aluminum.

1. Remove outer tie-rod.

2. Remove dust boot.

Inspection

Thoroughly clean all parts in cleaning solvent or automatic trans-

mission fluid ªDexronTMº type, and blow dry with compressed air,

if available.

SST585B

SEC. 492

NST022

.Jaw

protectors

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont'd)

ST-17

Page 2261 of 2267

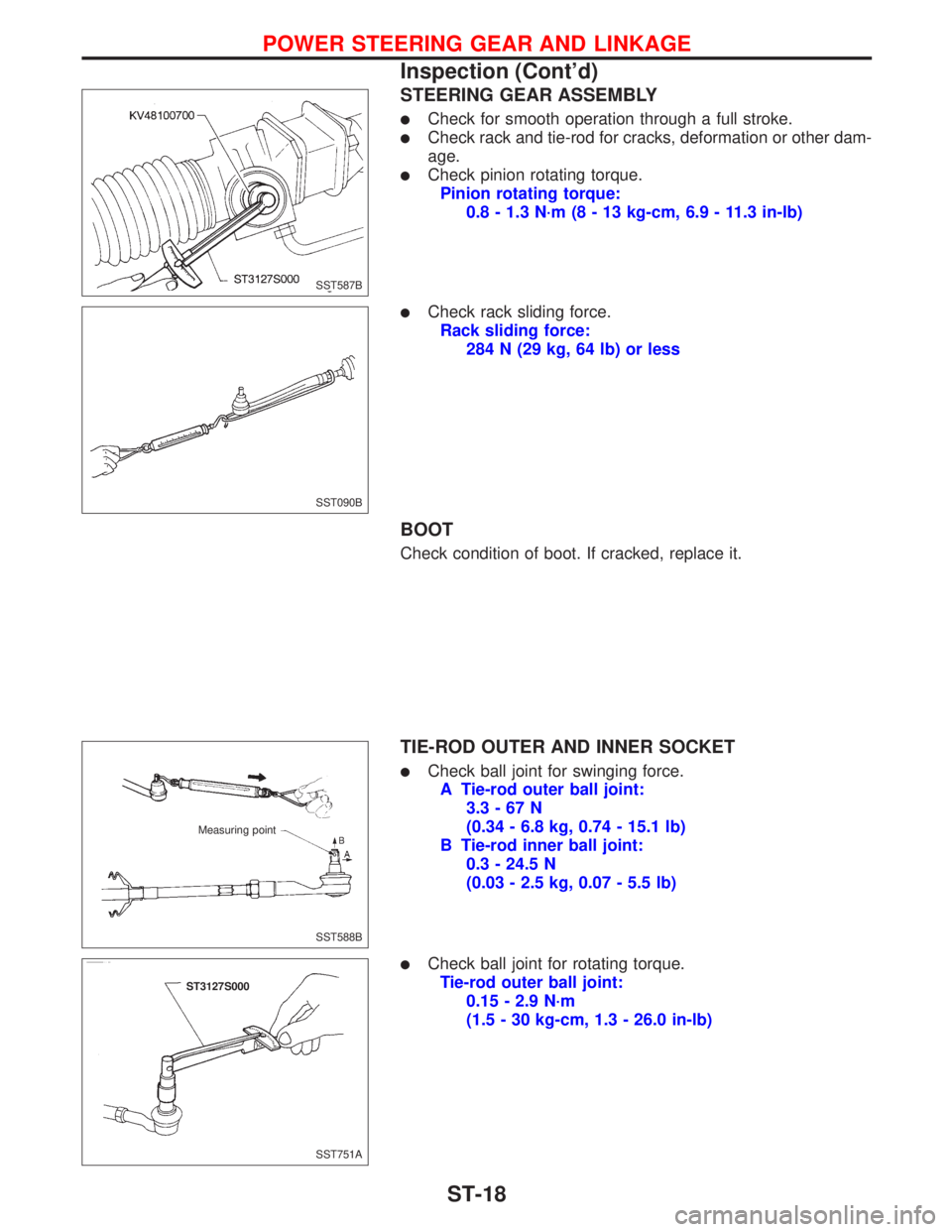

STEERING GEAR ASSEMBLY

lCheck for smooth operation through a full stroke.

lCheck rack and tie-rod for cracks, deformation or other dam-

age.

lCheck pinion rotating torque.

Pinion rotating torque:

0.8 - 1.3 N´m (8 - 13 kg-cm, 6.9 - 11.3 in-lb)

lCheck rack sliding force.

Rack sliding force:

284 N (29 kg, 64 lb) or less

BOOT

Check condition of boot. If cracked, replace it.

TIE-ROD OUTER AND INNER SOCKET

lCheck ball joint for swinging force.

A Tie-rod outer ball joint:

3.3-67N

(0.34 - 6.8 kg, 0.74 - 15.1 lb)

B Tie-rod inner ball joint:

0.3 - 24.5 N

(0.03 - 2.5 kg, 0.07 - 5.5 lb)

lCheck ball joint for rotating torque.

Tie-rod outer ball joint:

0.15 - 2.9 N´m

(1.5 - 30 kg-cm, 1.3 - 26.0 in-lb)

SST587B

SST090B

SST588B Measuring point

SST751A ST3127S000

POWER STEERING GEAR AND LINKAGE

Inspection (Cont'd)

ST-18

Page 2262 of 2267

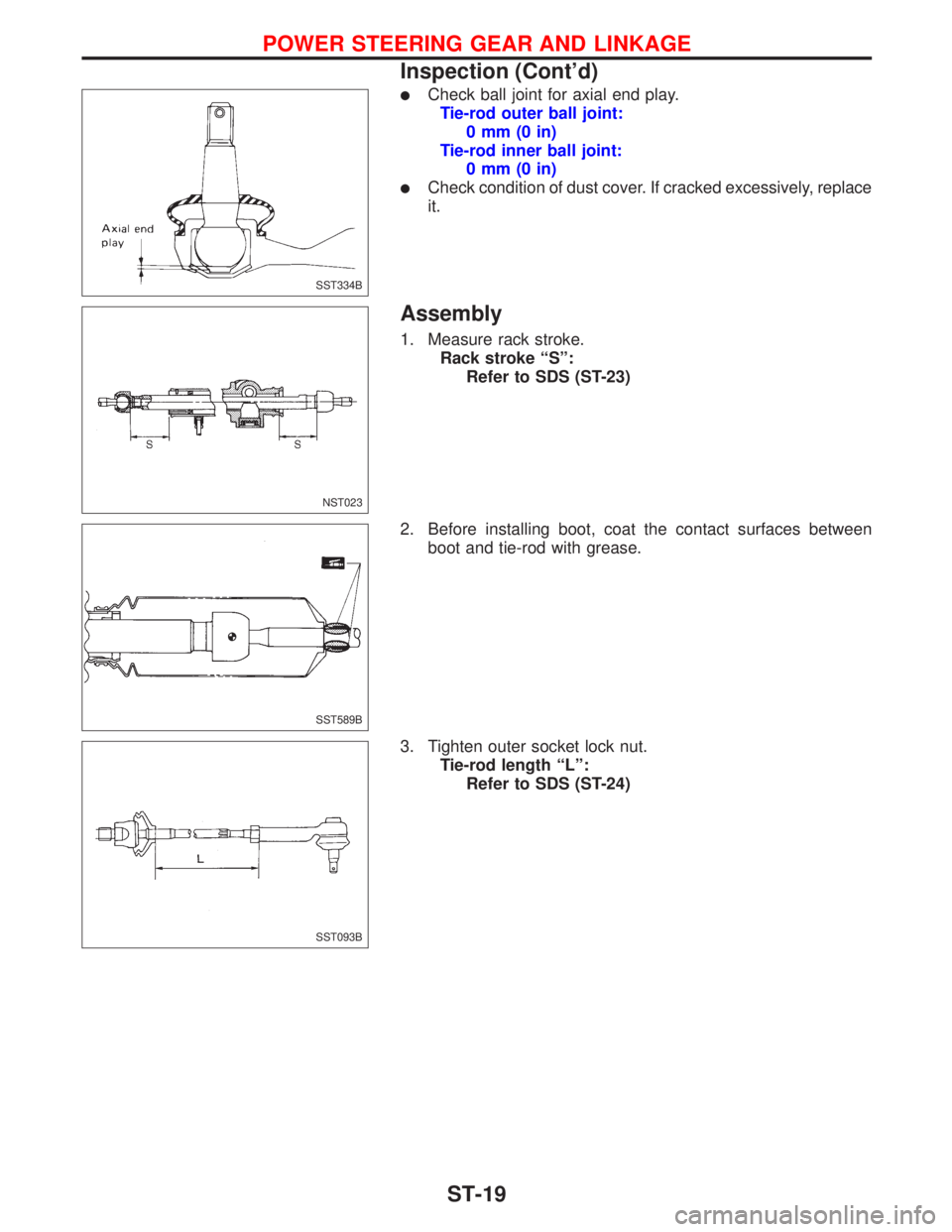

lCheck ball joint for axial end play.

Tie-rod outer ball joint:

0mm(0in)

Tie-rod inner ball joint:

0mm(0in)

lCheck condition of dust cover. If cracked excessively, replace

it.

Assembly

1. Measure rack stroke.

Rack stroke ªSº:

Refer to SDS (ST-23)

2. Before installing boot, coat the contact surfaces between

boot and tie-rod with grease.

3. Tighten outer socket lock nut.

Tie-rod length ªLº:

Refer to SDS (ST-24)

SST334B

NST023

SST589B

SST093B

POWER STEERING GEAR AND LINKAGE

Inspection (Cont'd)

ST-19