sensor NISSAN PRIMERA 1999 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 195 of 2267

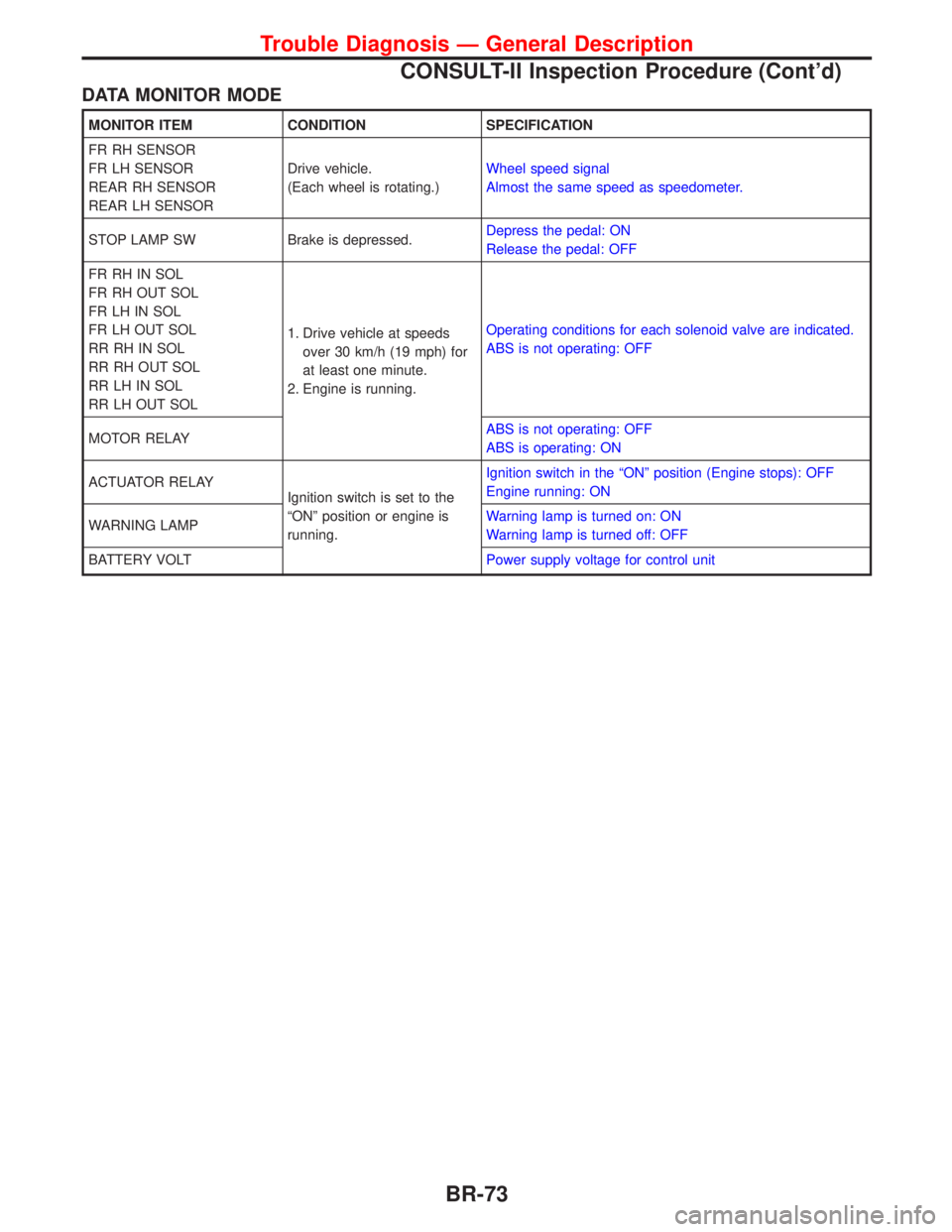

DATA MONITOR MODE

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

REAR RH SENSOR

REAR LH SENSORDrive vehicle.

(Each wheel is rotating.)Wheel speed signal

Almost the same speed as speedometer.

STOP LAMP SW Brake is depressed.Depress the pedal: ON

Release the pedal: OFF

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOL1. Drive vehicle at speeds

over 30 km/h (19 mph) for

at least one minute.

2. Engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY

Ignition switch is set to the

ªONº position or engine is

running.Ignition switch in the ªONº position (Engine stops): OFF

Engine running: ON

WARNING LAMPWarning lamp is turned on: ON

Warning lamp is turned off: OFF

BATTERY VOLTPower supply voltage for control unit

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-73

Page 198 of 2267

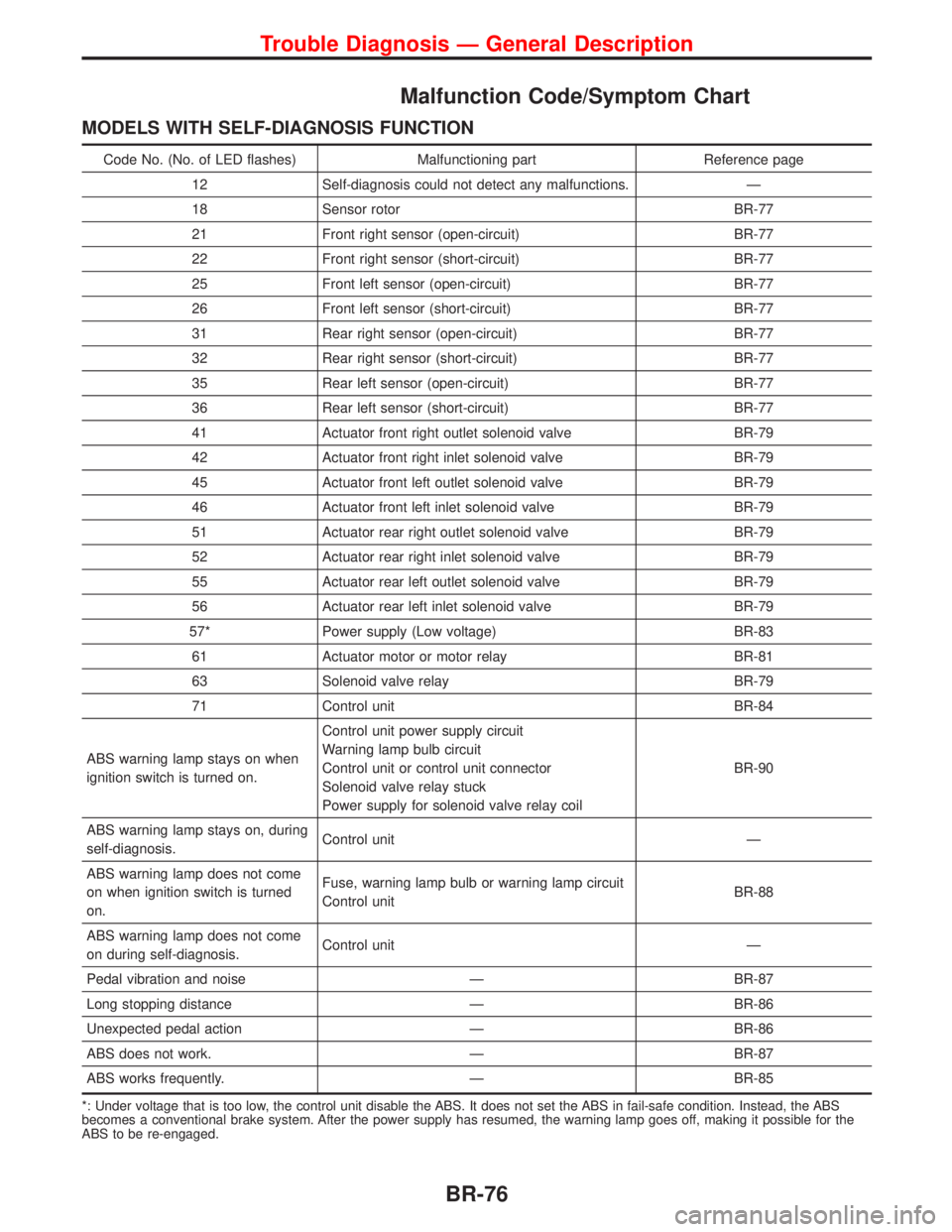

Malfunction Code/Symptom Chart

MODELS WITH SELF-DIAGNOSIS FUNCTION

Code No. (No. of LED flashes) Malfunctioning part Reference page

12 Self-diagnosis could not detect any malfunctions. Ð

18 Sensor rotor BR-77

21 Front right sensor (open-circuit) BR-77

22 Front right sensor (short-circuit) BR-77

25 Front left sensor (open-circuit) BR-77

26 Front left sensor (short-circuit) BR-77

31 Rear right sensor (open-circuit) BR-77

32 Rear right sensor (short-circuit) BR-77

35 Rear left sensor (open-circuit) BR-77

36 Rear left sensor (short-circuit) BR-77

41 Actuator front right outlet solenoid valve BR-79

42 Actuator front right inlet solenoid valve BR-79

45 Actuator front left outlet solenoid valve BR-79

46 Actuator front left inlet solenoid valve BR-79

51 Actuator rear right outlet solenoid valve BR-79

52 Actuator rear right inlet solenoid valve BR-79

55 Actuator rear left outlet solenoid valve BR-79

56 Actuator rear left inlet solenoid valve BR-79

57* Power supply (Low voltage) BR-83

61 Actuator motor or motor relay BR-81

63 Solenoid valve relay BR-79

71 Control unit BR-84

ABS warning lamp stays on when

ignition switch is turned on.Control unit power supply circuit

Warning lamp bulb circuit

Control unit or control unit connector

Solenoid valve relay stuck

Power supply for solenoid valve relay coilBR-90

ABS warning lamp stays on, during

self-diagnosis.Control unit Ð

ABS warning lamp does not come

on when ignition switch is turned

on.Fuse, warning lamp bulb or warning lamp circuit

Control unitBR-88

ABS warning lamp does not come

on during self-diagnosis.Control unit Ð

Pedal vibration and noise Ð BR-87

Long stopping distance Ð BR-86

Unexpected pedal action Ð BR-86

ABS does not work. Ð BR-87

ABS works frequently. Ð BR-85

*: Under voltage that is too low, the control unit disable the ABS. It does not set the ABS in fail-safe condition. Instead, the ABS

becomes a conventional brake system. After the power supply has resumed, the warning lamp goes off, making it possible for the

ABS to be re-engaged.

Trouble Diagnosis Ð General Description

BR-76

Page 199 of 2267

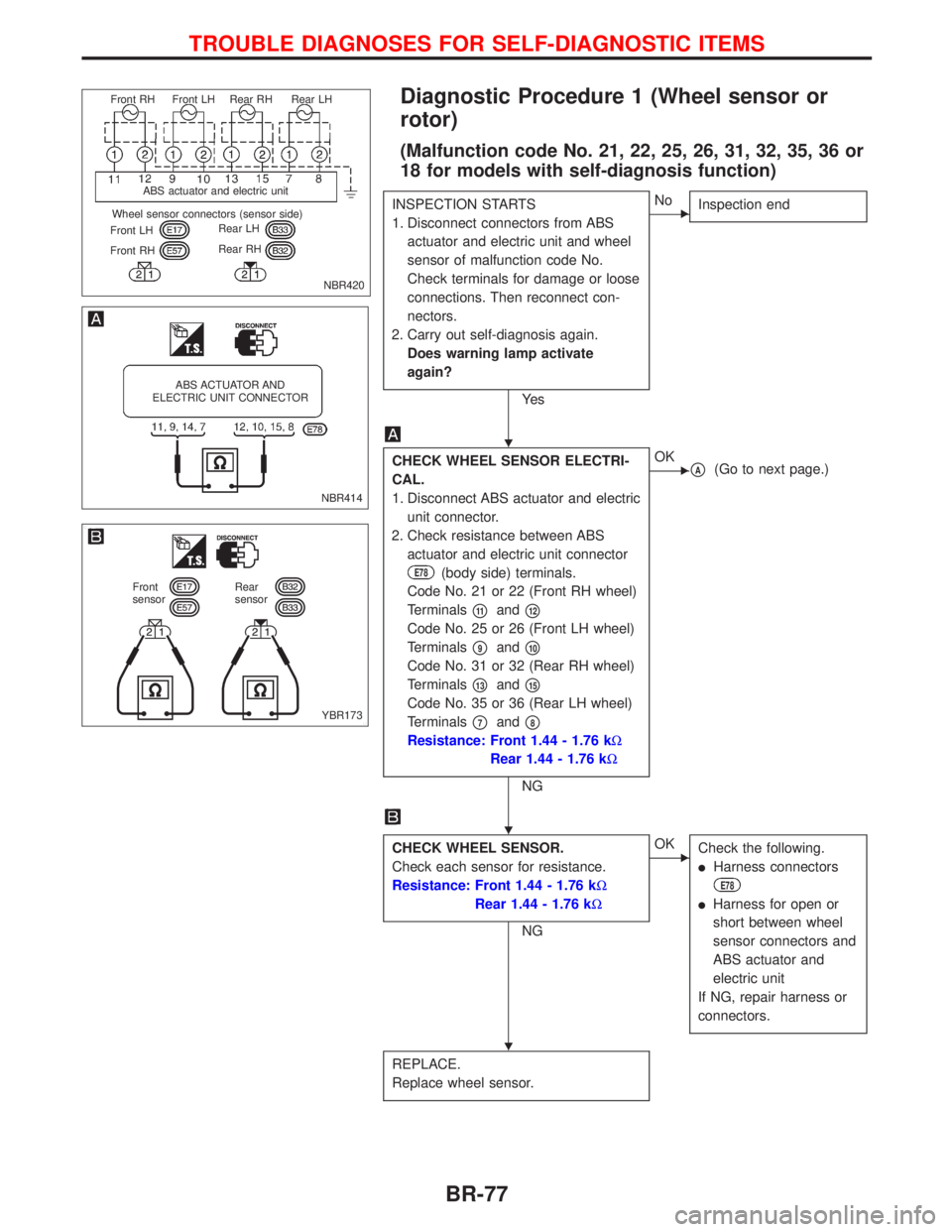

Diagnostic Procedure 1 (Wheel sensor or

rotor)

(Malfunction code No. 21, 22, 25, 26, 31, 32, 35, 36 or

18 for models with self-diagnosis function)

INSPECTION STARTS

1. Disconnect connectors from ABS

actuator and electric unit and wheel

sensor of malfunction code No.

Check terminals for damage or loose

connections. Then reconnect con-

nectors.

2. Carry out self-diagnosis again.

Does warning lamp activate

again?

Ye s

ENo

Inspection end

CHECK WHEEL SENSOR ELECTRI-

CAL.

1. Disconnect ABS actuator and electric

unit connector.

2. Check resistance between ABS

actuator and electric unit connector

E78(body side) terminals.

Code No. 21 or 22 (Front RH wheel)

Terminals

p11andp12

Code No. 25 or 26 (Front LH wheel)

Terminals

p9andp10

Code No. 31 or 32 (Rear RH wheel)

Terminals

p13andp15

Code No. 35 or 36 (Rear LH wheel)

Terminals

p7andp8

Resistance: Front 1.44 - 1.76 kW

Rear 1.44 - 1.76 kW

NG

EOKpA(Go to next page.)

CHECK WHEEL SENSOR.

Check each sensor for resistance.

Resistance: Front 1.44 - 1.76 kW

Rear 1.44 - 1.76 kW

NG

EOK

Check the following.

lHarness connectors

E78

lHarness for open or

short between wheel

sensor connectors and

ABS actuator and

electric unit

If NG, repair harness or

connectors.

REPLACE.

Replace wheel sensor.

NBR420 Front RH Front LH Rear RH Rear LH

ABS actuator and electric unit

Wheel sensor connectors (sensor side)

Front LH

Front RHRear LH

Rear RH

NBR414

ABS ACTUATOR AND

ELECTRIC UNIT CONNECTOR

YBR173

Front

sensorRear

sensor

H

H

H

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

BR-77

Page 200 of 2267

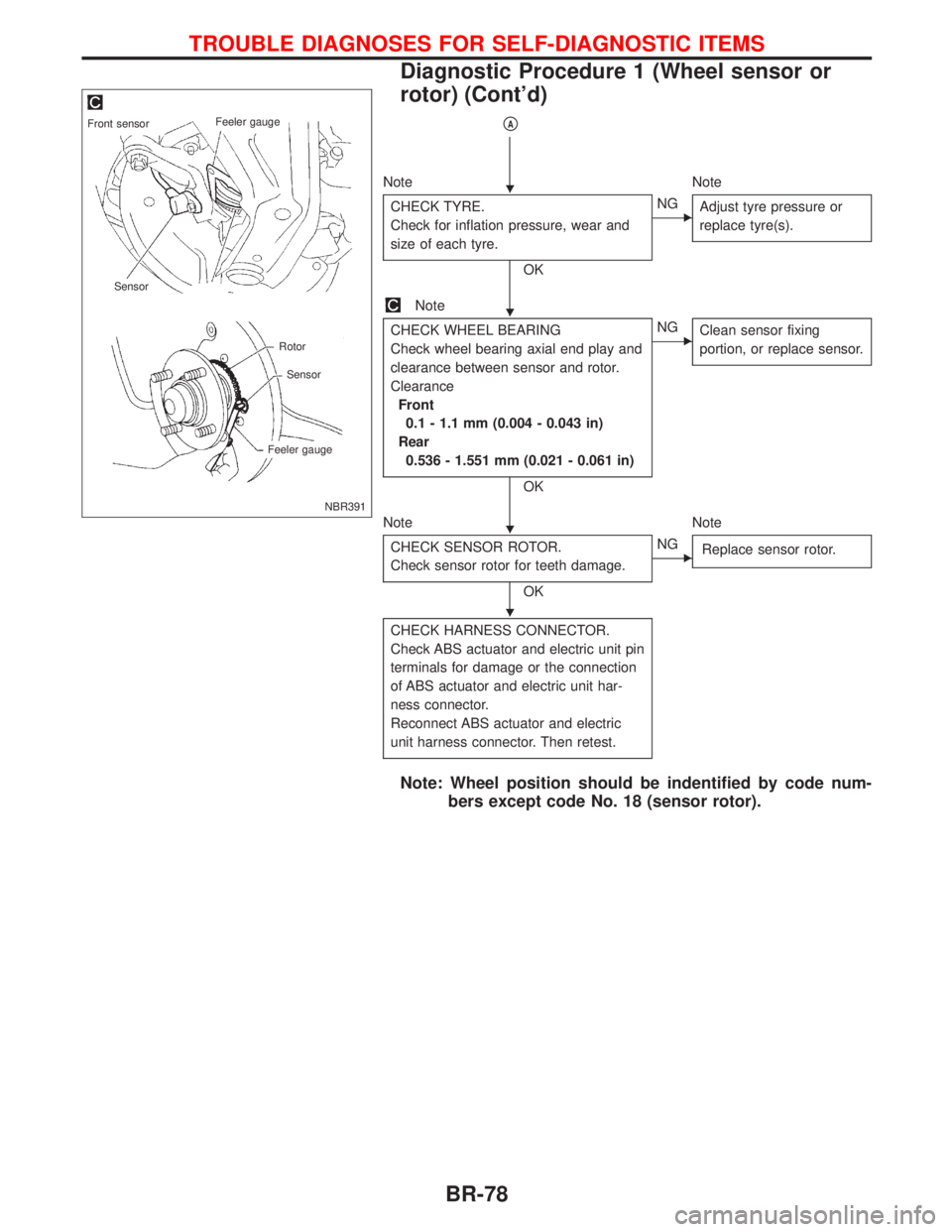

pA

Note Note

CHECK TYRE.

Check for inflation pressure, wear and

size of each tyre.

OK

ENG

Adjust tyre pressure or

replace tyre(s).

Note

CHECK WHEEL BEARING

Check wheel bearing axial end play and

clearance between sensor and rotor.

Clearance

Front

0.1 - 1.1 mm (0.004 - 0.043 in)

Rear

0.536 - 1.551 mm (0.021 - 0.061 in)

OK

ENG

Clean sensor fixing

portion, or replace sensor.

Note Note

CHECK SENSOR ROTOR.

Check sensor rotor for teeth damage.

OK

ENG

Replace sensor rotor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit pin

terminals for damage or the connection

of ABS actuator and electric unit har-

ness connector.

Reconnect ABS actuator and electric

unit harness connector. Then retest.

Note: Wheel position should be indentified by code num-

bers except code No. 18 (sensor rotor).

NBR391

Front sensorFeeler gauge

Sensor

Rotor

Sensor

Feeler gauge

H

H

H

H

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Procedure 1 (Wheel sensor or

rotor) (Cont'd)

BR-78

Page 207 of 2267

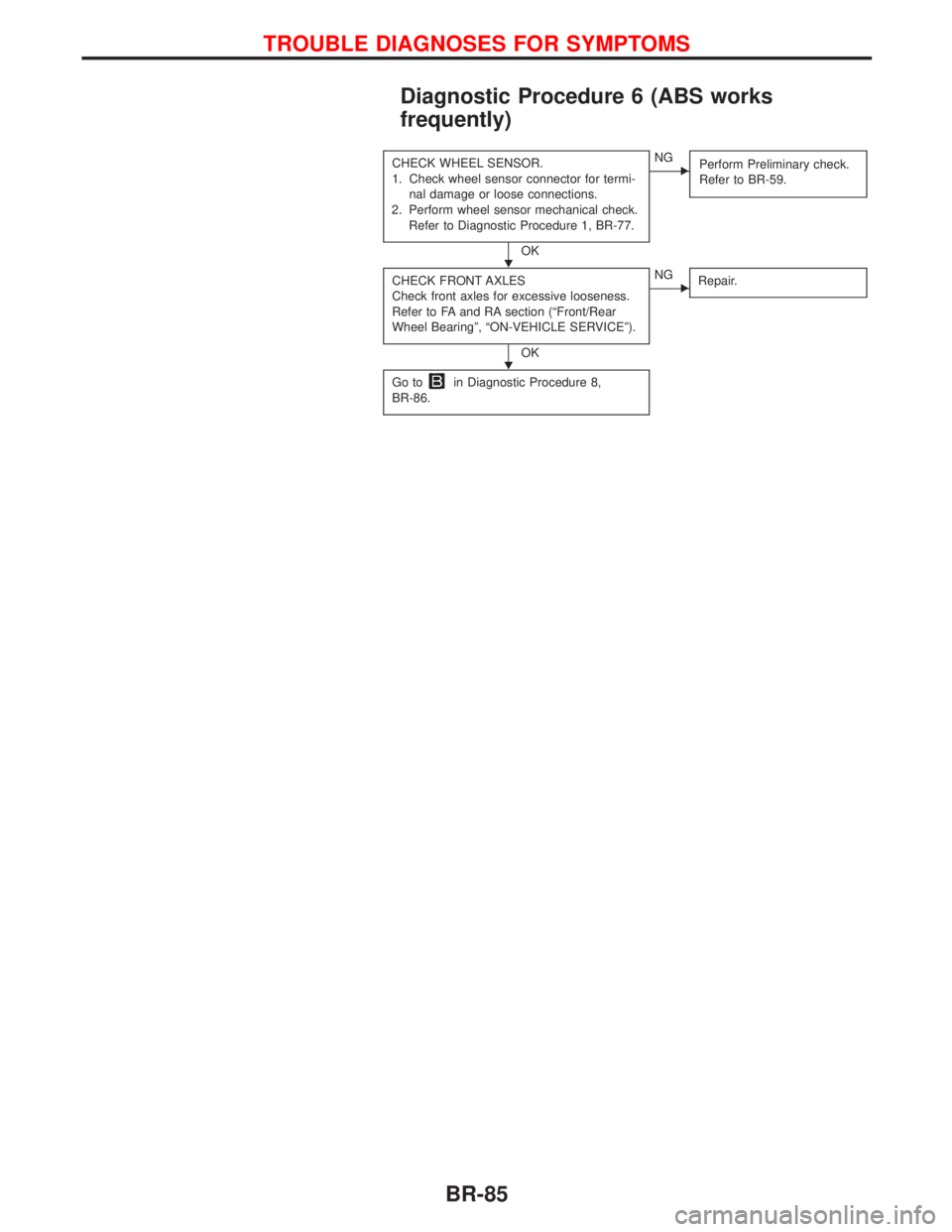

Diagnostic Procedure 6 (ABS works

frequently)

CHECK WHEEL SENSOR.

1. Check wheel sensor connector for termi-

nal damage or loose connections.

2. Perform wheel sensor mechanical check.

Refer to Diagnostic Procedure 1, BR-77.

OK

ENG

Perform Preliminary check.

Refer to BR-59.

CHECK FRONT AXLES

Check front axles for excessive looseness.

Refer to FA and RA section (ªFront/Rear

Wheel Bearingº, ªON-VEHICLE SERVICEº).

OK

ENG

Repair.

Go toin Diagnostic Procedure 8,

BR-86.

H

H

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-85

Page 208 of 2267

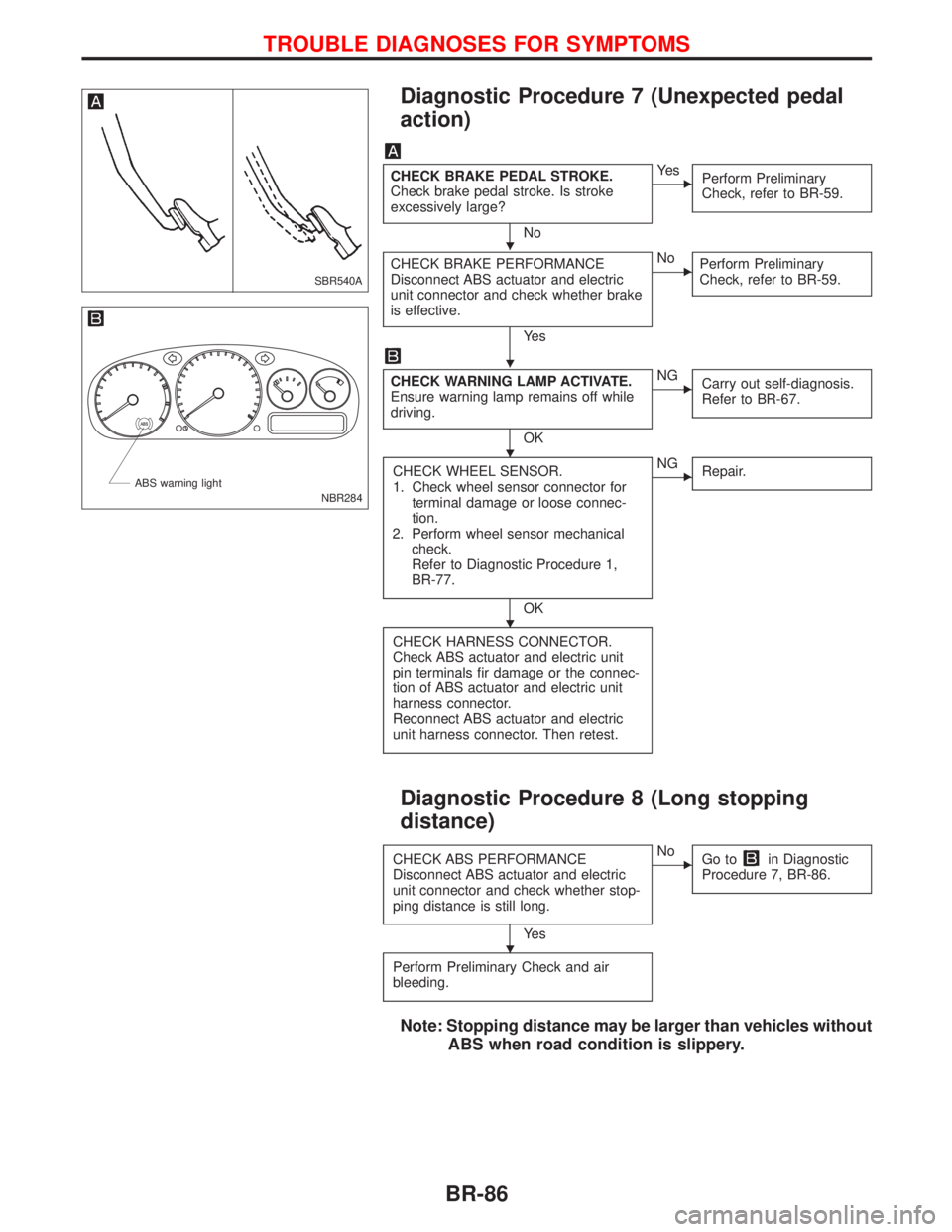

Diagnostic Procedure 7 (Unexpected pedal

action)

CHECK BRAKE PEDAL STROKE.

Check brake pedal stroke. Is stroke

excessively large?

No

EYe s

Perform Preliminary

Check, refer to BR-59.

CHECK BRAKE PERFORMANCE

Disconnect ABS actuator and electric

unit connector and check whether brake

is effective.

Ye s

ENo

Perform Preliminary

Check, refer to BR-59.

CHECK WARNING LAMP ACTIVATE.

Ensure warning lamp remains off while

driving.

OK

ENG

Carry out self-diagnosis.

Refer to BR-67.

CHECK WHEEL SENSOR.

1. Check wheel sensor connector for

terminal damage or loose connec-

tion.

2. Perform wheel sensor mechanical

check.

Refer to Diagnostic Procedure 1,

BR-77.

OK

ENG

Repair.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit

pin terminals fir damage or the connec-

tion of ABS actuator and electric unit

harness connector.

Reconnect ABS actuator and electric

unit harness connector. Then retest.

Diagnostic Procedure 8 (Long stopping

distance)

CHECK ABS PERFORMANCE

Disconnect ABS actuator and electric

unit connector and check whether stop-

ping distance is still long.

Ye s

ENo

Go toin Diagnostic

Procedure 7, BR-86.

Perform Preliminary Check and air

bleeding.

Note: Stopping distance may be larger than vehicles without

ABS when road condition is slippery.

SBR540A

NBR284 ABS warning light

H

H

H

H

H

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-86

Page 209 of 2267

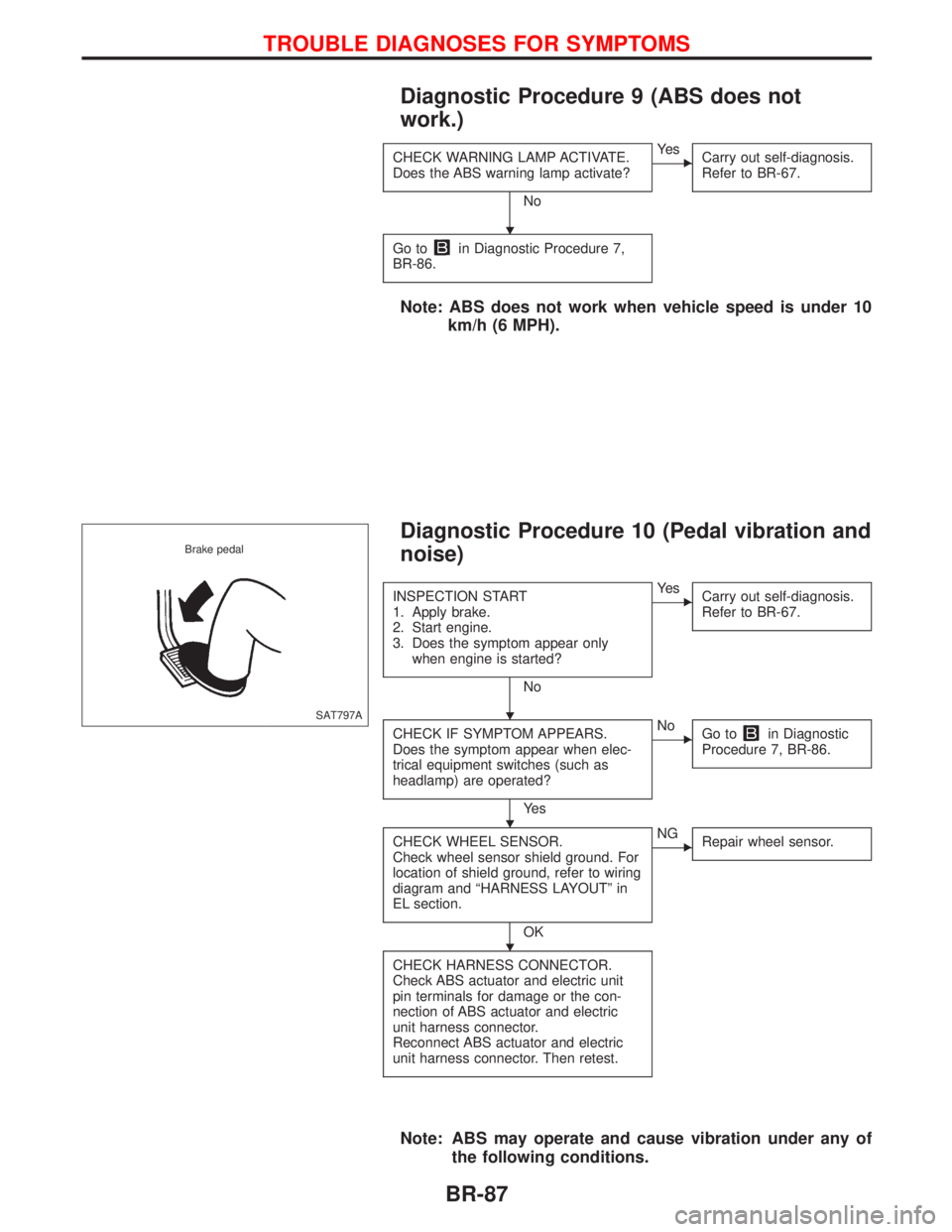

Diagnostic Procedure 9 (ABS does not

work.)

CHECK WARNING LAMP ACTIVATE.

Does the ABS warning lamp activate?

No

EYe s

Carry out self-diagnosis.

Refer to BR-67.

Go toin Diagnostic Procedure 7,

BR-86.

Note: ABS does not work when vehicle speed is under 10

km/h (6 MPH).

Diagnostic Procedure 10 (Pedal vibration and

noise)

INSPECTION START

1. Apply brake.

2. Start engine.

3. Does the symptom appear only

when engine is started?

No

EYe s

Carry out self-diagnosis.

Refer to BR-67.

CHECK IF SYMPTOM APPEARS.

Does the symptom appear when elec-

trical equipment switches (such as

headlamp) are operated?

Ye s

ENo

Go toin Diagnostic

Procedure 7, BR-86.

CHECK WHEEL SENSOR.

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ªHARNESS LAYOUTº in

EL section.

OK

ENG

Repair wheel sensor.

CHECK HARNESS CONNECTOR.

Check ABS actuator and electric unit

pin terminals for damage or the con-

nection of ABS actuator and electric

unit harness connector.

Reconnect ABS actuator and electric

unit harness connector. Then retest.

Note: ABS may operate and cause vibration under any of

the following conditions.

SAT797A Brake pedal

H

H

H

H

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-87

Page 216 of 2267

Service Notice

lWhen removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust

prevention measures.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System ªAir Bagº and ªSeat Belt Pre-tensionerº, used along with a seat belt,

helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable. Information necessary to service the system safely is included in the

RS sectionof the Service Manual.

If the vehicle is equipped with side air bag as the Supplemental Restraint System, the side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side

collision. The side air bag consists of air bag modules (located in the outer side of front seats), satellite

sensor, diagnosis sensor unit (which is one of components of air bags for a frontal collision), wiring harness,

warning lamp (which is one of components of air bags for a frontal collision).

WARNING:

lTo avoid rendering the SRS inoperative (which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation) all maintenance must be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to do so

in this Service Manual. SRS wiring harnesses are covered with yellow insulation (either just

before the harness connectors or for the complete harness) for easy identification.

PRECAUTIONS

BT-2

Page 295 of 2267

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

CD20T

PRECAUTIONS AND PREPARATION.......................... 3

Special Service Tools ................................................ 3

Engine Fuel & Emission Control System .................. 5

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²............. 6

Precautions for On Board Diagnostic (OBD)

System of Engine ...................................................... 6

Precautions ................................................................ 7

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM......................................................................... 9

Engine Control Module Component Parts

Location ..................................................................... 9

Circuit Diagram ......................................................... 11

System Diagram ...................................................... 12

Vacuum Hose Drawing ............................................ 13

System Chart ........................................................... 14

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION............................................. 15

Glow Control System ............................................... 15

Fuel Injection System .............................................. 15

Fuel Injection Timing System .................................. 18

Air Conditioning Cut Control .................................... 20

Cooling Fan Control................................................. 20

CRANKCASE VENTILATION SYSTEM...................... 21

Description ............................................................... 21

Blow-by Control Valve ............................................. 21

Ventilation Hose ....................................................... 21

INJECTION NOZZLE................................................... 22

Removal and Installation ......................................... 22

Test and Adjustment ................................................ 22

ELECTRONIC FUEL INJECTION PUMP.................... 24

Removal ................................................................... 24

Installation ................................................................ 25Disassembly and Assembly ..................................... 26

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION............................................................. 27

CONSULT-II ............................................................. 27

TROUBLE DIAGNOSIS - INTRODUCTION................ 33

Introduction .............................................................. 33

Diagnostic Worksheet .............................................. 34

TROUBLE DIAGNOSIS - WORK FLOW.................... 35

Work Flow ................................................................ 35

Description for Work Flow ....................................... 36

TROUBLE DIAGNOSIS - BASIC INSPECTION......... 37

Basic Inspection....................................................... 37

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 39

Diagnostic Trouble Chart ......................................... 39

Symptom Matrix Chart ............................................. 47

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 50

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................ 51

ECM Terminals and Reference Value ..................... 52

TROUBLE DIAGNOSIS FOR POWER SUPPLY........ 59

Main Power Supply and Ground Circuit .................. 59

TROUBLE DIAGNOSIS 1............................................ 62

Mass Air Flow Sensor (MAFS) ................................ 62

TROUBLE DIAGNOSIS 2............................................ 66

Engine Coolant Temperature (ECT) Sensor ........... 66

TROUBLE DIAGNOSIS 3............................................ 70

Vehicle Speed Sensor (VSS) .................................. 70

TROUBLE DIAGNOSIS 4............................................ 74

Control Sleeve Position Sensor (CSPS) ................. 74

TROUBLE DIAGNOSIS 5............................................ 78

Electric Governor ..................................................... 78

TROUBLE DIAGNOSIS 6............................................ 82

EC

Page 296 of 2267

Injection Timing Control Valve ................................. 82

TROUBLE DIAGNOSIS 7............................................ 86

Engine Control Module (ECM) ................................ 86

TROUBLE DIAGNOSIS 8............................................ 87

Cooling Fan (Overheat) ........................................... 87

TROUBLE DIAGNOSIS 9............................................ 97

Needle Lift Sensor (NLS) ........................................ 97

TROUBLE DIAGNOSIS 10........................................ 100

Fuel Cut Solenoid Valve ........................................ 100

TROUBLE DIAGNOSIS 11........................................ 104

Fuel Temperature Sensor (FTS)............................ 104

TROUBLE DIAGNOSIS 12........................................ 108

Accelerator Position Sensor & Switch ................... 108

TROUBLE DIAGNOSIS 13......................................... 114

Crankshaft Position Sensor (TDC) ......................... 114

TROUBLE DIAGNOSES 14....................................... 118

Glow Control System .............................................. 118TROUBLE DIAGNOSES 15...................................... 126

Air Conditioner Cut Control ................................... 126

TROUBLE DIAGNOSES 16...................................... 129

EGRC-Solenoid Valve ........................................... 129

TROUBLE DIAGNOSES 17...................................... 136

Brake Switch .......................................................... 136

TROUBLE DIAGNOSES 18...................................... 140

ECM Relay............................................................. 140

TROUBLE DIAGNOSES 19...................................... 141

MI & Data Link Connectors ................................... 141

TROUBLE DIAGNOSES 20...................................... 145

Start Signal ............................................................ 145

SERVICE DATA AND SPECIFICATIONS (SDS)...... 147

General Specifications ........................................... 147

Injection Nozzle ..................................................... 147

Inspection and Adjustment .................................... 147

When you read wiring diagrams:

lRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

lSee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

lSee EL section for NATS information and wiring diagram.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW CHART

IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN

ELECTRICAL INCIDENTº.

For clarification of system component abbreviations and terminology read GI section

ªSAE J1930 TERMINOLOGY LISTº.

EC-2