sensor NISSAN PRIMERA 1999 Electronic Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 124 of 2267

Inspection................................................................. 36

Assembly ................................................................. 37

Installation ................................................................ 39

REAR DISC BRAKE TYPE 2...................................... 40

Component .............................................................. 40

Pad Replacement .................................................... 40

Removal ................................................................... 42

Disassembly............................................................. 42

Inspection................................................................. 42

Installation ................................................................ 43

REAR DRUM BRAKE................................................. 44

Components............................................................. 44

Removal ................................................................... 44

Inspection - Wheel Cylinder .................................... 45

Wheel Cylinder Overhaul......................................... 46

Inspection - Drum .................................................... 46

Inspection - Lining ................................................... 46

Installation ................................................................ 46

PARKING BRAKE CONTROL.................................... 48

Removal and Installation ......................................... 48

Inspection................................................................. 49

Adjustment ............................................................... 49

ANTI-LOCK BRAKE SYSTEM.................................... 50

Purpose.................................................................... 50

Operation ................................................................. 50

ABS Hydraulic Circuit .............................................. 50

System Components ............................................... 51

System Description .................................................. 51

Removal and Installation ......................................... 53

TROUBLE DIAGNOSES............................................. 57

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ................................................ 57

Preliminary Check.................................................... 59

Component Parts and Harness Connector

Location ................................................................... 60

Circuit Diagram for Quick Pinpoint Check............... 61Wiring Diagram - ABS - ........................................... 62

Self-diagnosis (Only models with data link

connector terminal No. 8) ........................................ 67

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 69

CONSULT-II ............................................................. 69

CONSULT-II Inspection Procedure.......................... 70

Ground Circuit Check .............................................. 75

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 76

Malfunction Code/Symptom Chart........................... 76

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC

ITEMS........................................................................... 77

Diagnostic Procedure 1 (Wheel sensor or rotor) .... 77

Diagnostic Procedure 2 (ABS actuator solenoid

valve and solenoid valve relay) ............................... 79

Diagnostic Procedure 3 (Motor Relay or motor) ..... 81

Diagnostic Procedure 4 (Low voltage) .................... 83

Diagnostic Procedure 5 (Control unit) ..................... 84

TROUBLE DIAGNOSES FOR SYMPTOMS............... 85

Diagnostic Procedure 6 (ABS works frequently) ..... 85

Diagnostic Procedure 7 (Unexpected pedal

action) ...................................................................... 86

Diagnostic Procedure 8 (Long stopping distance) .. 86

Diagnostic Procedure 9 (ABS does not work.) ....... 87

Diagnostic Procedure 10 (Pedal vibration and

noise) ....................................................................... 87

Diagnostic Procedure 11 (ABS Warning lamp

does not come on when ignition switch is turned

ON) .......................................................................... 88

Diagnostic Procedure 12 (Warning lamp stays on

when ignition switch is turned ON).......................... 90

SERVICE DATA AND SPECIFICATIONS (SDS)........ 91

General Specifications ............................................. 91

Inspection and Adjustment ...................................... 92

When you read wiring diagrams:

lRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

lSee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

lSee EL section for NATS information and wiring diagram.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENTº.

BR-2

Page 125 of 2267

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL P11 is as follows (The

composition varies according to the destination and optional equipment.):

lFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

front seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

lFor a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a

frontal collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Brake System

lRecommended fluid is brake fluid ªDOT 4º.

lNever reuse drained brake fluid.

lBe careful not to splash brake fluid on painted areas.

lTo clean or wash all parts of master cylinder, disc brake

caliper and wheel cylinder, use clean brake fluid.

lNever use mineral oils such as gasoline or kerosene.

They will ruin rubber parts of the hydraulic system.

lUse flare nut wrench when removing and installing brake

tube.

lAlways torque brake lines when installing.

lBurnish the brake contact surfaces after refinishing or

replacing rotors, after replacing pads, or if a soft pedal

occurs at very low mileage.

Refer to ªBrake Burnishing Procedureº, ªCheck and

Adjustmentº, BR-7.

WARNING:

lClean brake pads with a waste cloth, then wipe with a

dust collector.

SBR686C Commercial service tool

PRECAUTIONS

BR-3

Page 173 of 2267

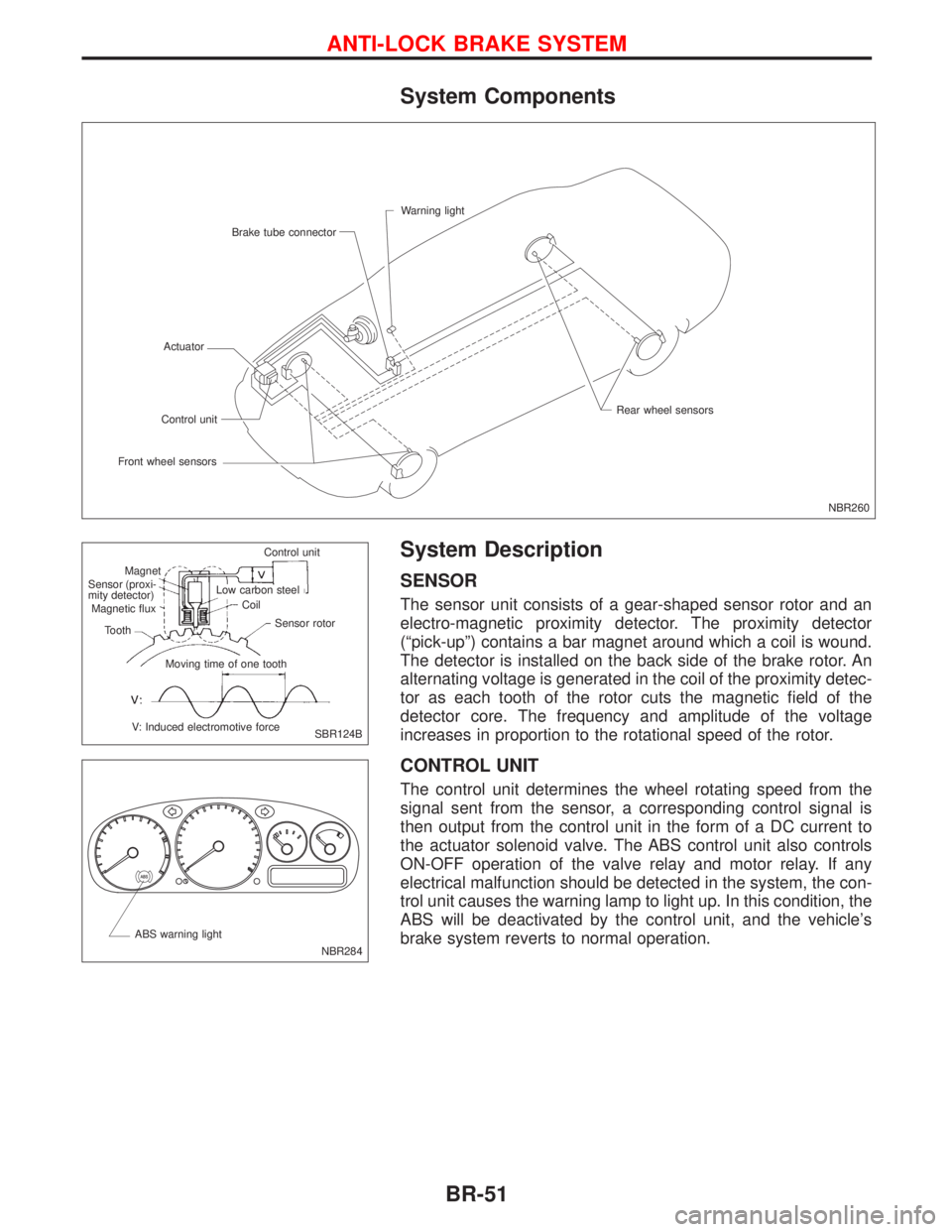

System Components

System Description

SENSOR

The sensor unit consists of a gear-shaped sensor rotor and an

electro-magnetic proximity detector. The proximity detector

(ªpick-upº) contains a bar magnet around which a coil is wound.

The detector is installed on the back side of the brake rotor. An

alternating voltage is generated in the coil of the proximity detec-

tor as each tooth of the rotor cuts the magnetic field of the

detector core. The frequency and amplitude of the voltage

increases in proportion to the rotational speed of the rotor.

CONTROL UNIT

The control unit determines the wheel rotating speed from the

signal sent from the sensor, a corresponding control signal is

then output from the control unit in the form of a DC current to

the actuator solenoid valve. The ABS control unit also controls

ON-OFF operation of the valve relay and motor relay. If any

electrical malfunction should be detected in the system, the con-

trol unit causes the warning lamp to light up. In this condition, the

ABS will be deactivated by the control unit, and the vehicle's

brake system reverts to normal operation.

NBR260 Warning light

Brake tube connector

Actuator

Front wheel sensorsControl unitRear wheel sensors

SBR124B Control unit

Magnet

.Sensor (proxi-

mity detector)

Magnetic flux

Tooth

V: Induced electromotive forceMoving time of one toothSensor rotor Coil Low carbon steel

NBR284 ABS warning light

ANTI-LOCK BRAKE SYSTEM

BR-51

Page 175 of 2267

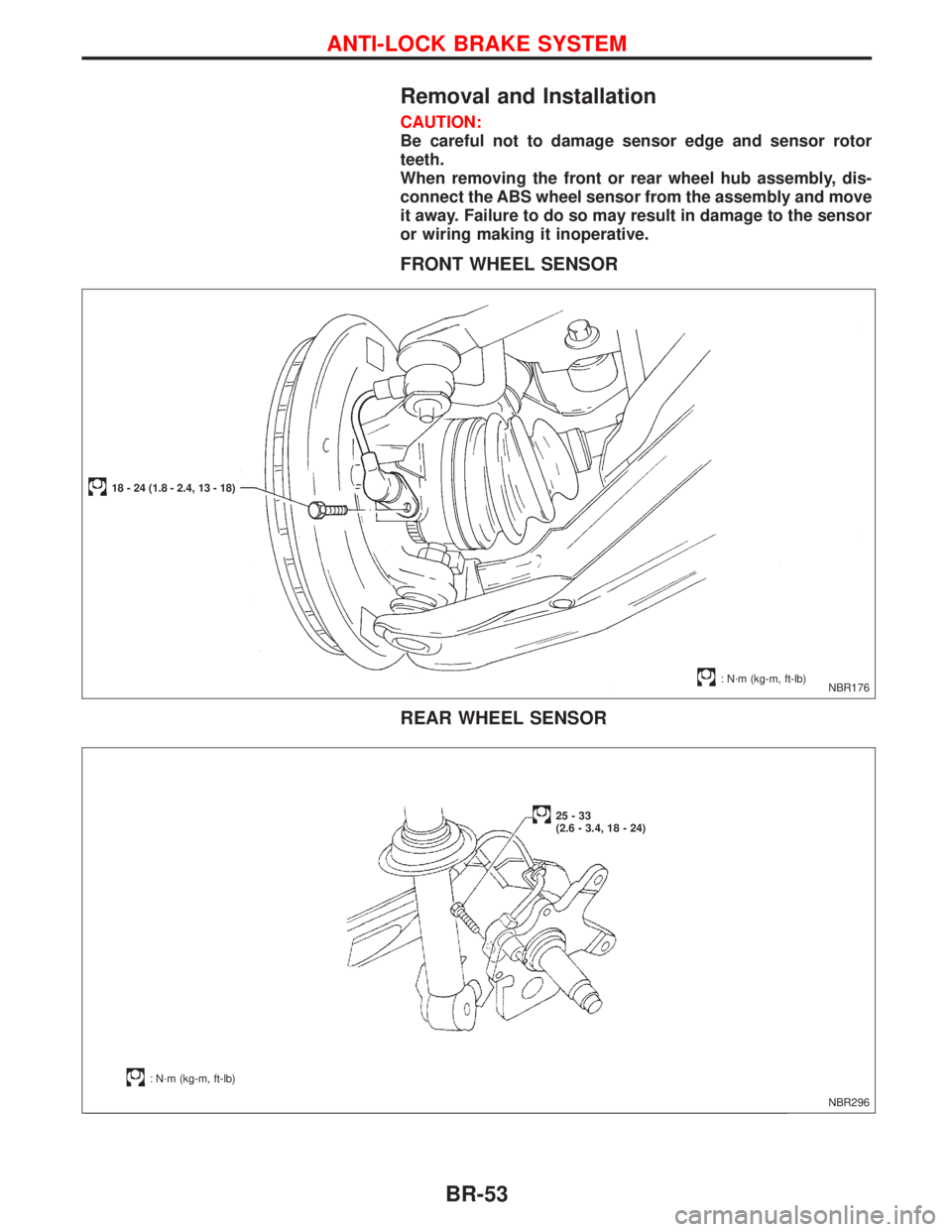

Removal and Installation

CAUTION:

Be careful not to damage sensor edge and sensor rotor

teeth.

When removing the front or rear wheel hub assembly, dis-

connect the ABS wheel sensor from the assembly and move

it away. Failure to do so may result in damage to the sensor

or wiring making it inoperative.

FRONT WHEEL SENSOR

REAR WHEEL SENSOR

NBR176

18 - 24 (1.8 - 2.4, 13 - 18)

: N´m (kg-m, ft-lb)

NBR296

: N´m (kg-m, ft-lb)

25-33

(2.6 - 3.4, 18 - 24)

ANTI-LOCK BRAKE SYSTEM

BR-53

Page 176 of 2267

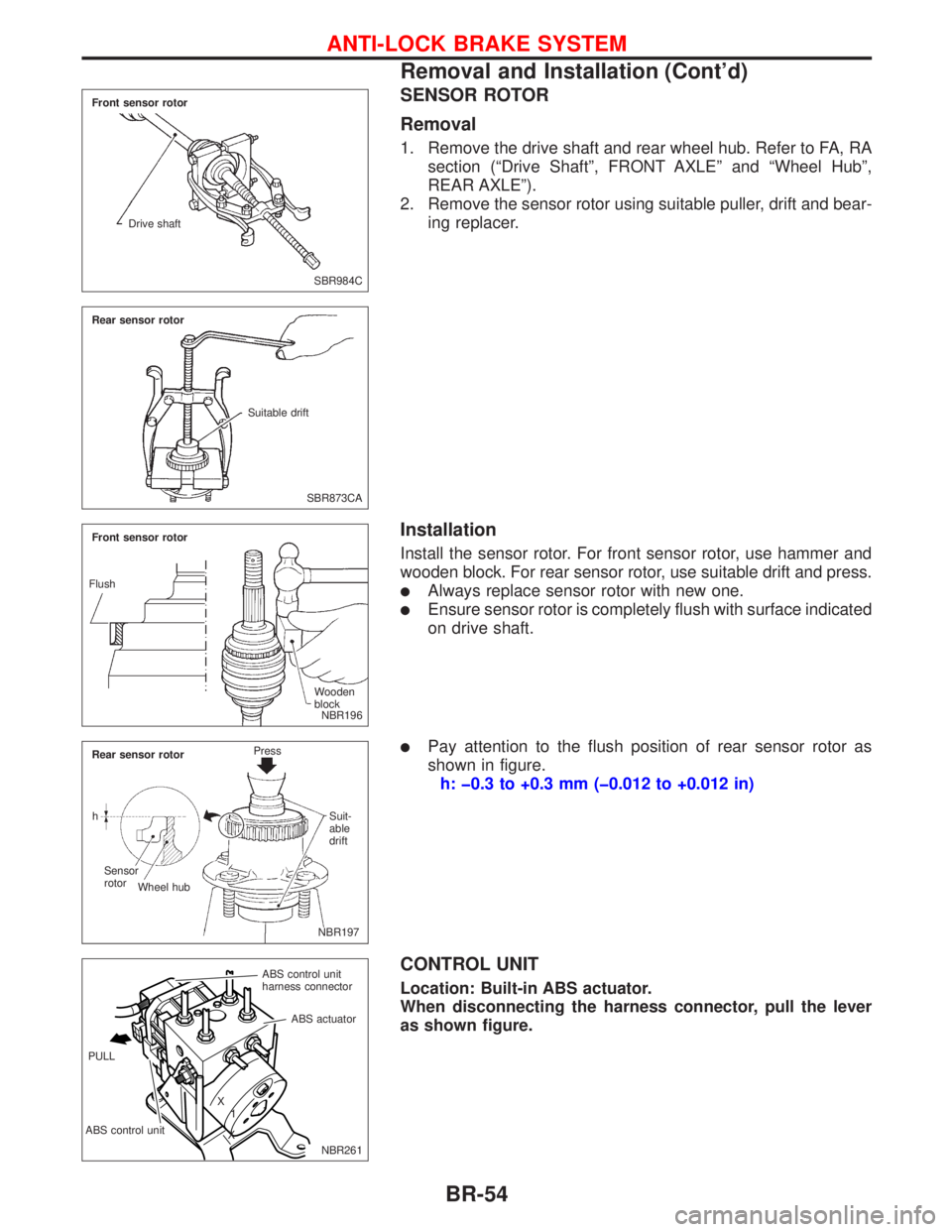

SENSOR ROTOR

Removal

1. Remove the drive shaft and rear wheel hub. Refer to FA, RA

section (ªDrive Shaftº, FRONT AXLEº and ªWheel Hubº,

REAR AXLEº).

2. Remove the sensor rotor using suitable puller, drift and bear-

ing replacer.

Installation

Install the sensor rotor. For front sensor rotor, use hammer and

wooden block. For rear sensor rotor, use suitable drift and press.

lAlways replace sensor rotor with new one.

lEnsure sensor rotor is completely flush with surface indicated

on drive shaft.

lPay attention to the flush position of rear sensor rotor as

shown in figure.

h: þ0.3 to +0.3 mm (þ0.012 to +0.012 in)

CONTROL UNIT

Location: Built-in ABS actuator.

When disconnecting the harness connector, pull the lever

as shown figure.

SBR984C Front sensor rotor

Drive shaft

SBR873CA Rear sensor rotor

Suitable drift

NBR196 Front sensor rotor

Wooden

block Flush

.NBR197 Rear sensor rotorPress

Suit-

able

drift

Sensor

rotor

Wheel hub h

NBR261 ABS control unit

harness connector

ABS control unitABS actuator

X

1

X PULL

ANTI-LOCK BRAKE SYSTEM

Removal and Installation (Cont'd)

BR-54

Page 179 of 2267

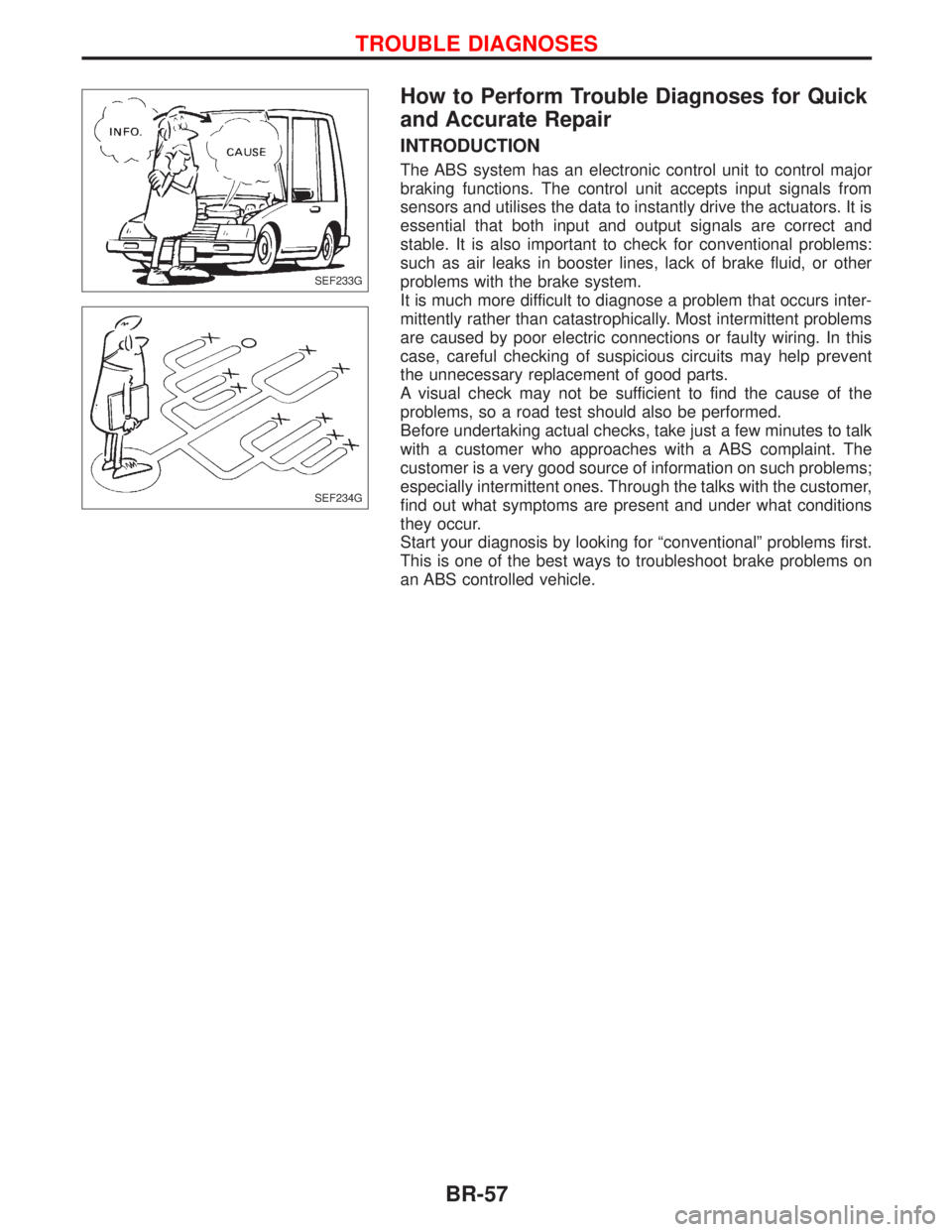

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

INTRODUCTION

The ABS system has an electronic control unit to control major

braking functions. The control unit accepts input signals from

sensors and utilises the data to instantly drive the actuators. It is

essential that both input and output signals are correct and

stable. It is also important to check for conventional problems:

such as air leaks in booster lines, lack of brake fluid, or other

problems with the brake system.

It is much more difficult to diagnose a problem that occurs inter-

mittently rather than catastrophically. Most intermittent problems

are caused by poor electric connections or faulty wiring. In this

case, careful checking of suspicious circuits may help prevent

the unnecessary replacement of good parts.

A visual check may not be sufficient to find the cause of the

problems, so a road test should also be performed.

Before undertaking actual checks, take just a few minutes to talk

with a customer who approaches with a ABS complaint. The

customer is a very good source of information on such problems;

especially intermittent ones. Through the talks with the customer,

find out what symptoms are present and under what conditions

they occur.

Start your diagnosis by looking for ªconventionalº problems first.

This is one of the best ways to troubleshoot brake problems on

an ABS controlled vehicle.

SEF233G

SEF234G

TROUBLE DIAGNOSES

BR-57

Page 182 of 2267

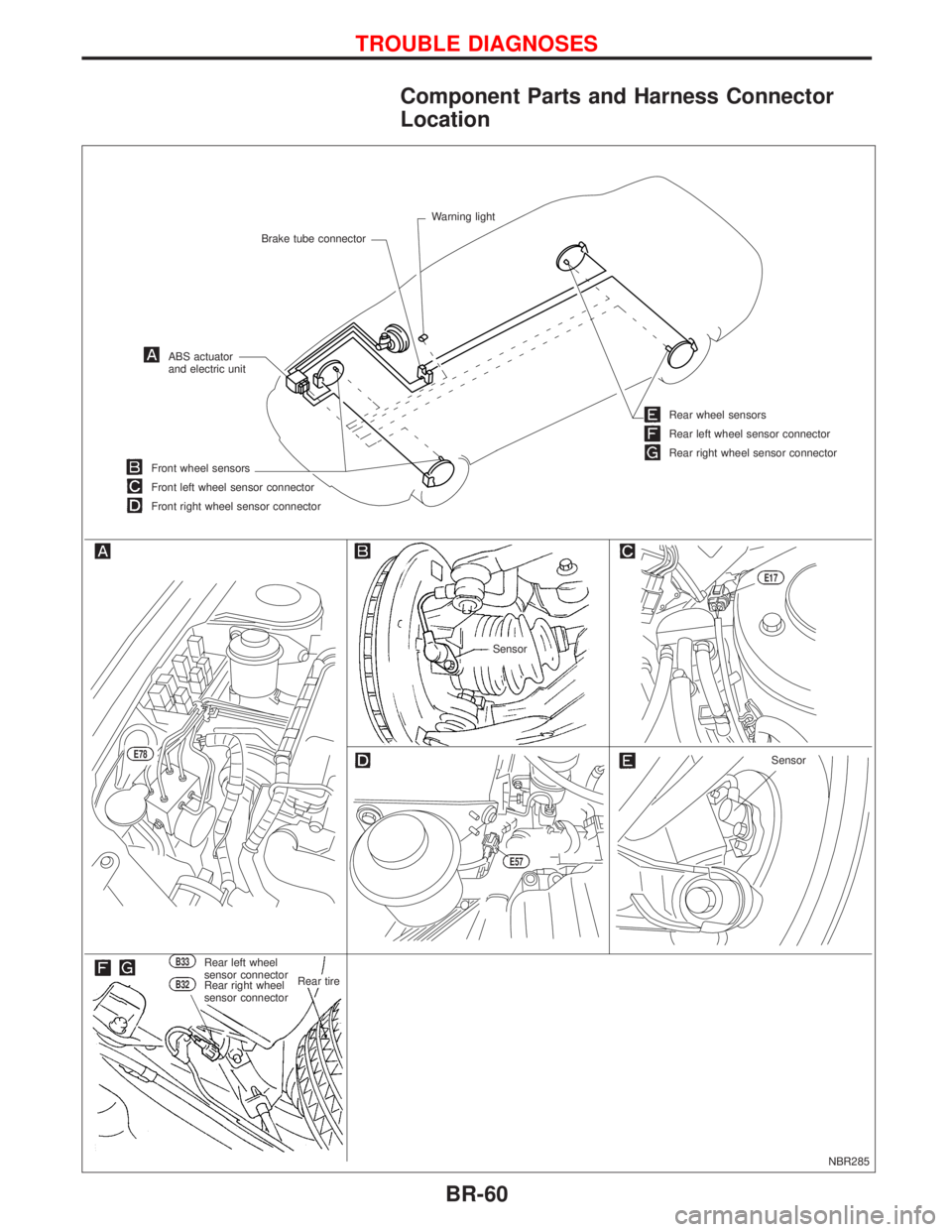

Component Parts and Harness Connector

Location

NBR285

Brake tube connectorWarning light

ABS actuator

and electric unit

Front wheel sensors

Front left wheel sensor connector

Front right wheel sensor connector

Sensor

E17

Rear wheel sensors

Rear left wheel sensor connector

Rear right wheel sensor connector

B33Rear left wheel

sensor connector

B32Rear right wheel

sensor connector.Rear tire

.E78

E57

Sensor

TROUBLE DIAGNOSES

BR-60

Page 190 of 2267

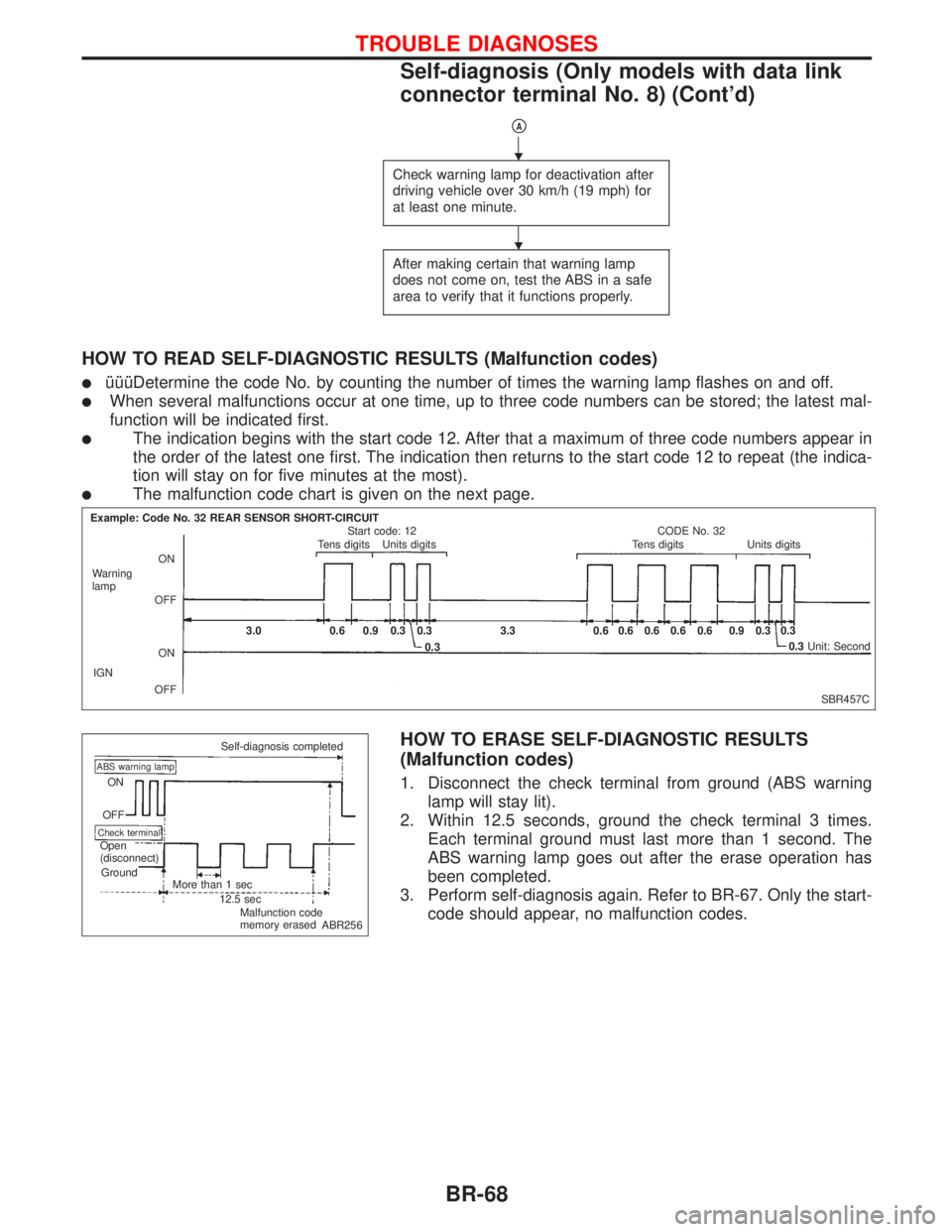

pA

Check warning lamp for deactivation after

driving vehicle over 30 km/h (19 mph) for

at least one minute.

After making certain that warning lamp

does not come on, test the ABS in a safe

area to verify that it functions properly.

HOW TO READ SELF-DIAGNOSTIC RESULTS (Malfunction codes)

lîîîDetermine the code No. by counting the number of times the warning lamp flashes on and off.

lWhen several malfunctions occur at one time, up to three code numbers can be stored; the latest mal-

function will be indicated first.

lThe indication begins with the start code 12. After that a maximum of three code numbers appear in

the order of the latest one first. The indication then returns to the start code 12 to repeat (the indica-

tion will stay on for five minutes at the most).

lThe malfunction code chart is given on the next page.

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

1. Disconnect the check terminal from ground (ABS warning

lamp will stay lit).

2. Within 12.5 seconds, ground the check terminal 3 times.

Each terminal ground must last more than 1 second. The

ABS warning lamp goes out after the erase operation has

been completed.

3. Perform self-diagnosis again. Refer to BR-67. Only the start-

code should appear, no malfunction codes.

SBR457C Example: Code No. 32 REAR SENSOR SHORT-CIRCUIT

Warning

lampON

OFF

ON

OFF IGNStart code: 12

Tens digits Units digits

Unit: Second CODE No. 32

Tens digits Units digits

3.0 0.6 0.9 0.3 0.3

0.33.3 0.6 0.6 0.6 0.6 0.6 0.9 0.3

0.3 0.3

ABR256 Self-diagnosis completed

ABS warning lamp

ON

OFF

Check terminalOpen

(disconnect)

Ground

More than 1 sec

12.5 sec

Malfunction code

memory erased

H

H

TROUBLE DIAGNOSES

Self-diagnosis (Only models with data link

connector terminal No. 8) (Cont'd)

BR-68

Page 191 of 2267

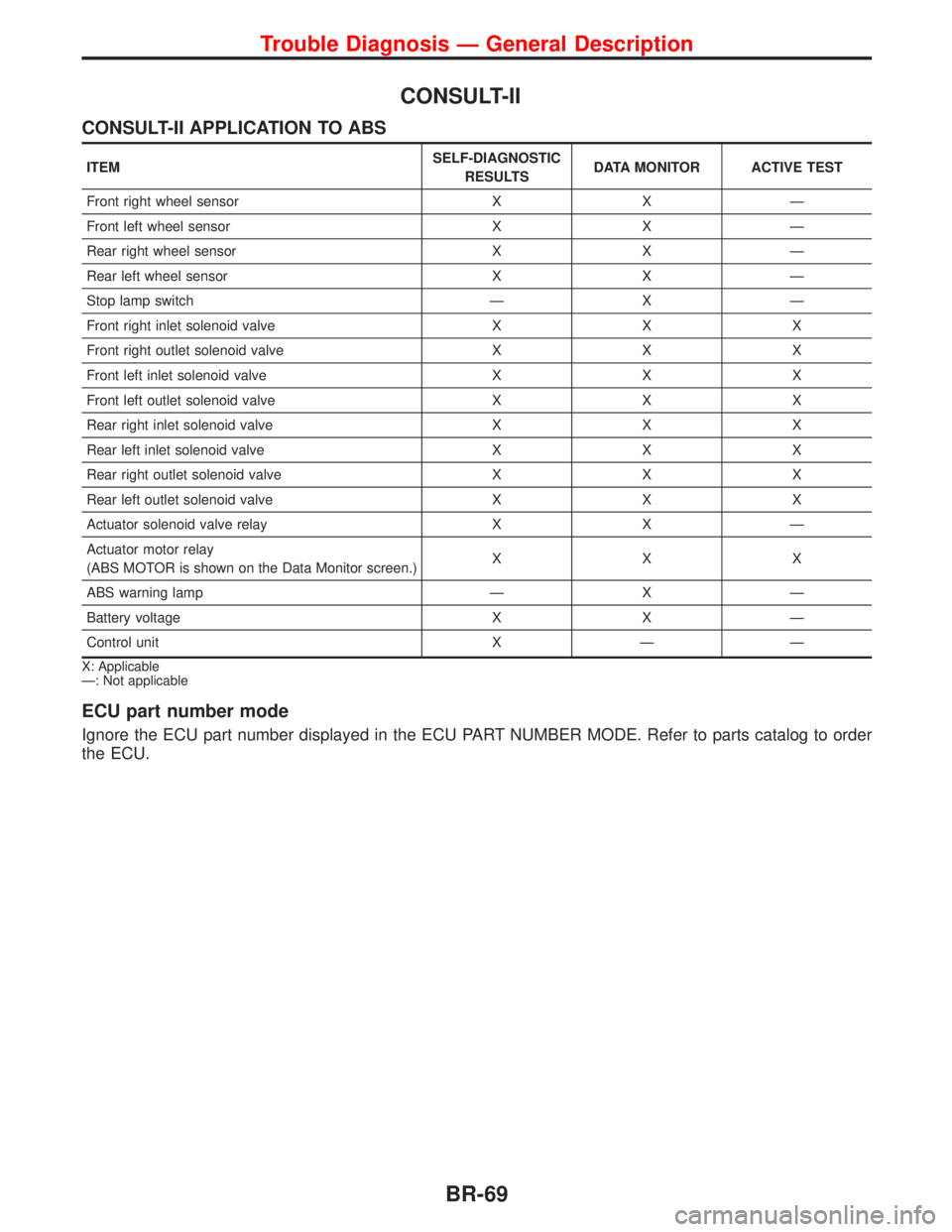

CONSULT-II

CONSULT-II APPLICATION TO ABS

ITEMSELF-DIAGNOSTIC

RESULTSDATA MONITOR ACTIVE TEST

Front right wheel sensor X X Ð

Front left wheel sensor X X Ð

Rear right wheel sensor X X Ð

Rear left wheel sensor X X Ð

Stop lamp switch Ð X Ð

Front right inlet solenoid valve X X X

Front right outlet solenoid valve X X X

Front left inlet solenoid valve X X X

Front left outlet solenoid valve X X X

Rear right inlet solenoid valve X X X

Rear left inlet solenoid valve X X X

Rear right outlet solenoid valve X X X

Rear left outlet solenoid valve X X X

Actuator solenoid valve relay X X Ð

Actuator motor relay

(ABS MOTOR is shown on the Data Monitor screen.)XXX

ABS warning lamp Ð X Ð

Battery voltage X X Ð

Control unit X Ð Ð

X: Applicable

Ð: Not applicable

ECU part number mode

Ignore the ECU part number displayed in the ECU PART NUMBER MODE. Refer to parts catalog to order

the ECU.

Trouble Diagnosis Ð General Description

BR-69

Page 193 of 2267

![NISSAN PRIMERA 1999 Electronic Workshop Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input volta NISSAN PRIMERA 1999 Electronic Workshop Manual SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input volta](/img/5/57377/w960_57377-192.png)

SELF-DIAGNOSTIC RESULTS MODE

Diagnostic item Diagnostic item is detected when...Diagnostic

procedure

FR RH SENSORH

[OPEN]

lCircuit for front right wheel sensor is open.

(An abnormally high input voltage is entered.)1

FR LH SENSORH

[OPEN]

lCircuit for front left wheel sensor is open.

(An abnormally high input voltage is entered.)1

RR RH SENSORH

[OPEN]

lCircuit for rear right sensor is open.

(An abnormally high input voltage is entered.)1

RR LH SENSORH

[OPEN]

lCircuit for rear left sensor is open.

(An abnormally high input voltage is entered.)1

FR RH SENSORH

[SHORT]

lCircuit for front right wheel sensor is shorted.

(An abnormally low input voltage is entered.)1

FR LH SENSORH

[SHORT]

lCircuit for front left wheel sensor is shorted.

(An abnormally low input voltage is entered.)1

RR RH SENSORH

[SHORT]

lCircuit for rear right sensor is shorted.

(An abnormally low input voltage is entered.)1

RR LH SENSOR

[SHORT]

lCircuit for rear left sensor is shorted.

(An abnormally low input voltage is entered.)1

ABS SENSORH

[ABNORMAL SIGNAL]

lTeeth damage on sensor rotor or improper installation of wheel sensor.

(Abnormal wheel sensor signal is entered.)1

FR RH IN ABS SOL

[OPEN]

lCircuit for front right inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR LH IN ABS SOL

[OPEN]

lCircuit for front left inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR RH IN ABS SOL

[OPEN]

lCircuit for rear right inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR LH IN ABS SOL

[OPEN]

lCircuit for rear left inlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR RH IN ABS SOL

[SHORT]

lCircuit for front right inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR LH IN ABS SOL

[SHORT]

lCircuit for front left inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR RH IN ABS SOL

[SHORT]

lCircuit for rear right inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR LH IN ABS SOL

[SHORT]

lCircuit for rear left inlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR RH OUT ABS SOL

[OPEN]

lCircuit for front right outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR LH OUT ABS SOL

[OPEN]

lCircuit for front left outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR RH OUT ABS SOL

[OPEN]

lCircuit for rear right outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

RR LH OUT ABS SOL

[OPEN]

lCircuit for rear left outlet solenoid valve is open.

(An abnormally low output voltage is entered.)2

FR RH OUT ABS SOL

[SHORT]

lCircuit for front right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

FR LH OUT ABS SOL

[SHORT]

lCircuit for front left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR RH OUT ABS SOL

[SHORT]

lCircuit for rear right outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

RR LH OUT ABS SOL

[SHORT]

lCircuit for rear left outlet solenoid valve is shorted.

(An abnormally high output voltage is entered.)2

ABS ACTUATOR RELAY

[ABNORMAL]

lActuator solenoid valve relay is ON, even control unit sends off signal.lActuator solenoid valve relay is OFF, even control unit sends on signal.2

ABS MOTOR RELAY

[ABNORMAL]

lCircuit for actuator motor is open or shorted.lActuator motor relay is stuck.lCircuit for actuator is open or shorted.3

BATTERY VOLT

[VB-LOW]

lPower source voltage supplied to ABS control unit is abnormally low. 4

CONTROL UNIT

lFunction of calculation in ABS control unit has failed. 5

H: If one or more wheels spin on a rough or slippery road for 40 seconds or more, the ABS warning lamp will illuminate. This does

not indicate a malfunction. Only in the case of the short-circuit after repair the ABS warning lamp also illuminates when the igni-

tion switch is turned ªONº. In this case, drive the vehicle at speeds greater than 30 km/h (19 MPH) for approximately 1 minute

as specified in ªSELF-DIAGNOSIS PROCEDUREº, BR-70. Check to ensure that the ABS warning lamp goes out while the

vehicle is being driven.

Trouble Diagnosis Ð General Description

CONSULT-II Inspection Procedure (Cont'd)

BR-71