sensor NISSAN PRIMERA 1999 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 86 of 2267

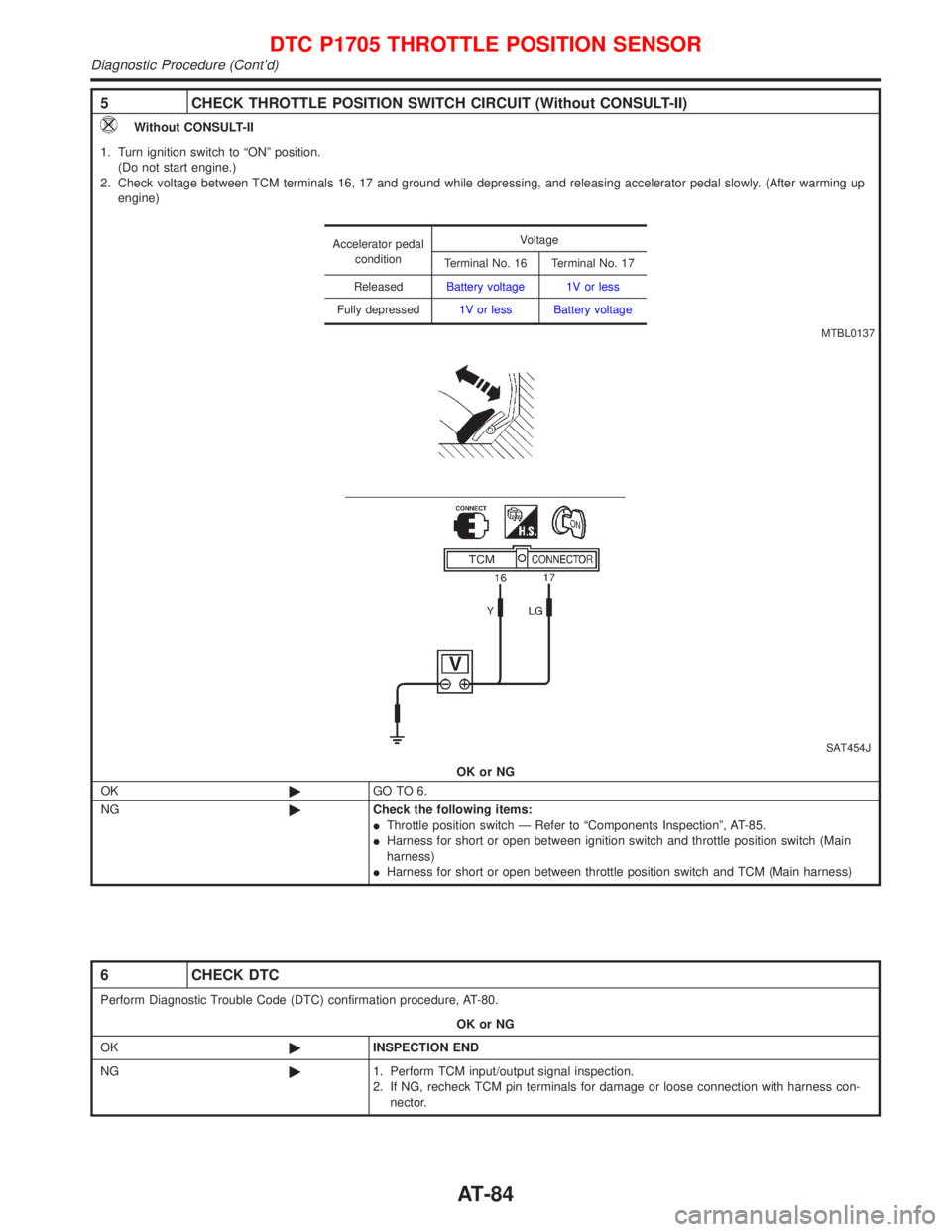

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly. (After warming up

engine)

SAT454J

OK or NG

OK©GO TO 6.

NG©Check the following items:

IThrottle position switch Ð Refer to ªComponents Inspectionº, AT-85.

IHarness for short or open between ignition switch and throttle position switch (Main

harness)

IHarness for short or open between throttle position switch and TCM (Main harness)

Accelerator pedal

conditionVoltage

Terminal No. 16 Terminal No. 17

ReleasedBattery voltage 1V or less

Fully depressed1V or less Battery voltage

MTBL0137

6 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-80.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P1705 THROTTLE POSITION SENSOR

Diagnostic Procedure (Cont'd)

AT-84

Page 87 of 2267

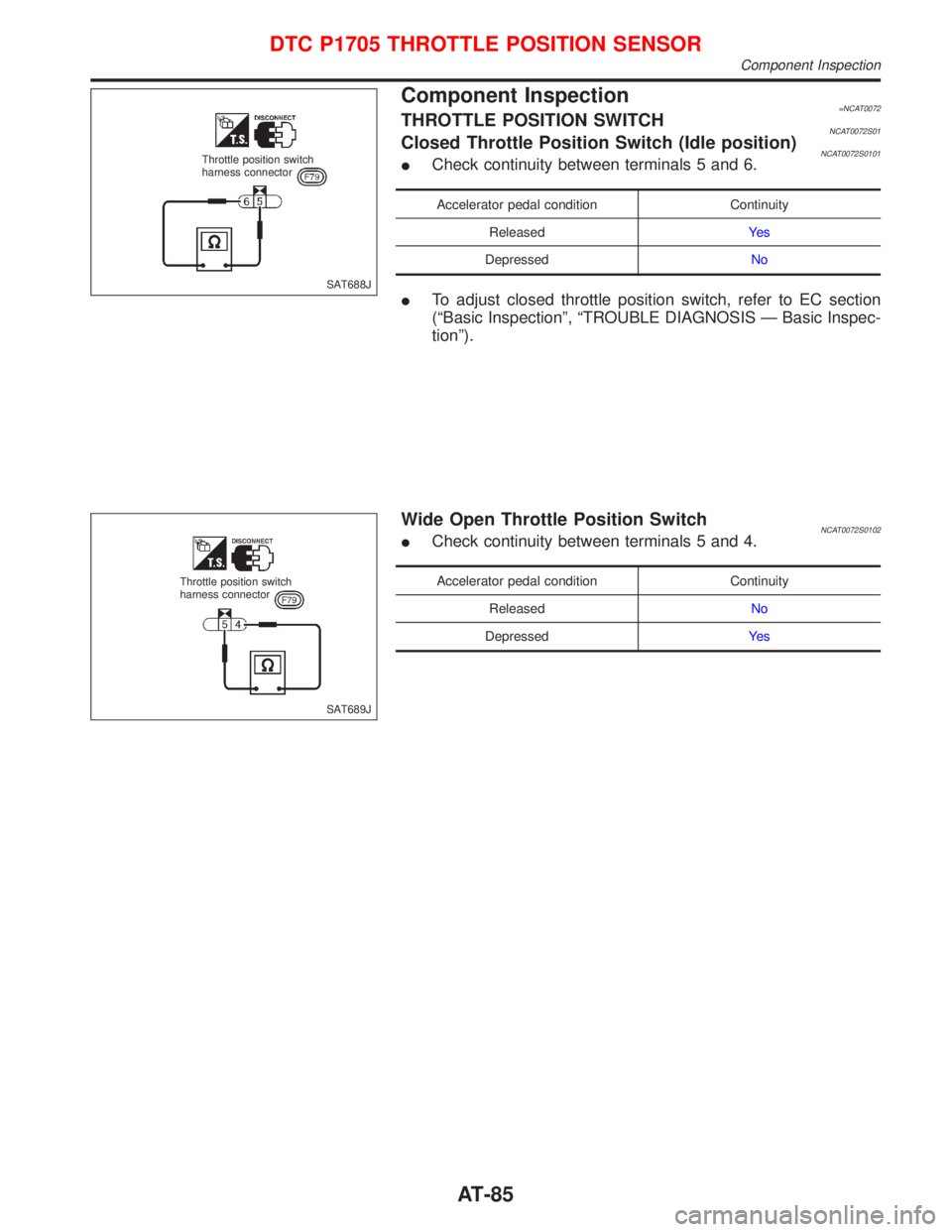

Component Inspection=NCAT0072THROTTLE POSITION SWITCHNCAT0072S01Closed Throttle Position Switch (Idle position)NCAT0072S0101ICheck continuity between terminals 5 and 6.

Accelerator pedal condition Continuity

ReleasedYe s

DepressedNo

ITo adjust closed throttle position switch, refer to EC section

(ªBasic Inspectionº, ªTROUBLE DIAGNOSIS Ð Basic Inspec-

tionº).

Wide Open Throttle Position SwitchNCAT0072S0102ICheck continuity between terminals 5 and 4.

Accelerator pedal condition Continuity

ReleasedNo

DepressedYe s

SAT688J Throttle position switch

harness connector

SAT689J Throttle position switch

harness connector

DTC P1705 THROTTLE POSITION SENSOR

Component Inspection

AT-85

Page 92 of 2267

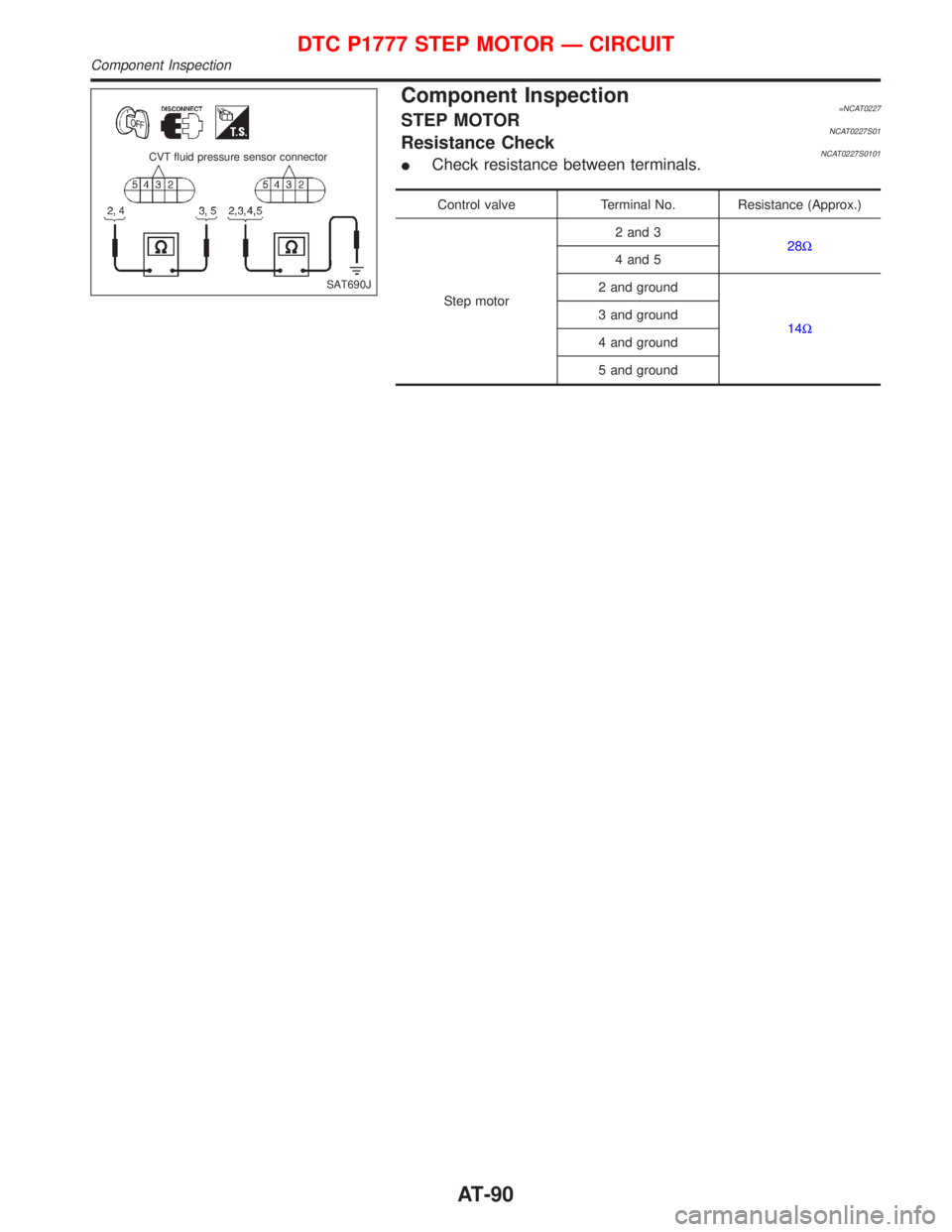

Component Inspection=NCAT0227STEP MOTORNCAT0227S01Resistance CheckNCAT0227S0101ICheck resistance between terminals.

Control valve Terminal No. Resistance (Approx.)

Step motor2 and 3

28W

4 and 5

2 and ground

14W 3 and ground

4 and ground

5 and ground

SAT690J CVT fluid pressure sensor connector

DTC P1777 STEP MOTOR Ð CIRCUIT

Component Inspection

AT-90

Page 96 of 2267

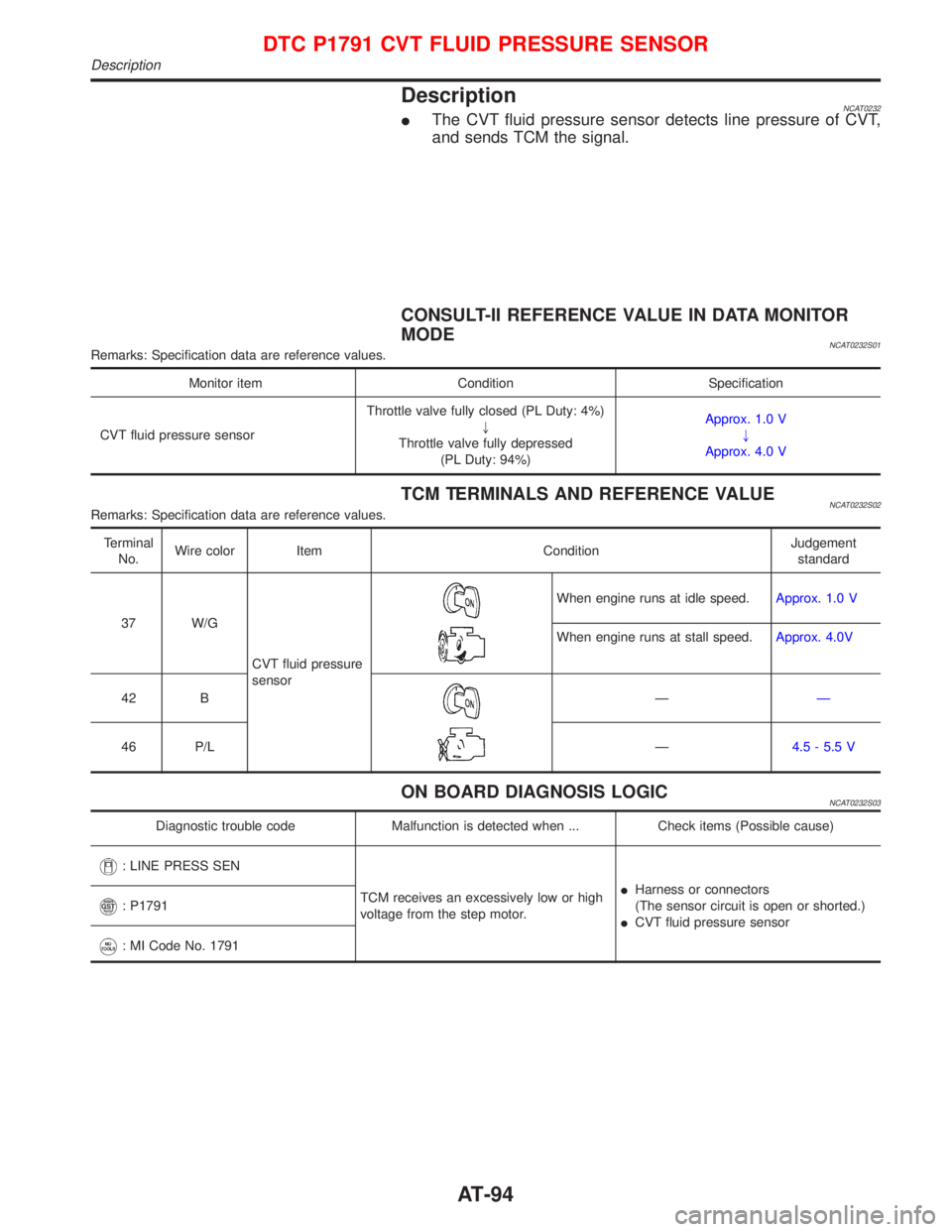

DescriptionNCAT0232IThe CVT fluid pressure sensor detects line pressure of CVT,

and sends TCM the signal.

CONSULT-II REFERENCE VALUE IN DATA MONITOR

MODE

NCAT0232S01Remarks: Specification data are reference values.

Monitor item Condition Specification

CVT fluid pressure sensorThrottle valve fully closed (PL Duty: 4%)

"

Throttle valve fully depressed

(PL Duty: 94%)Approx. 1.0 V

"

Approx. 4.0 V

TCM TERMINALS AND REFERENCE VALUENCAT0232S02Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement

standard

37 W/G

CVT fluid pressure

sensor

When engine runs at idle speed.Approx. 1.0 V

When engine runs at stall speed.Approx. 4.0V

42 B

ÐÐ

46 P/LÐ4.5 - 5.5 V

ON BOARD DIAGNOSIS LOGICNCAT0232S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: LINE PRESS SEN

TCM receives an excessively low or high

voltage from the step motor.IHarness or connectors

(The sensor circuit is open or shorted.)

ICVT fluid pressure sensor

: P1791

: MI Code No. 1791

DTC P1791 CVT FLUID PRESSURE SENSOR

Description

AT-94

Page 97 of 2267

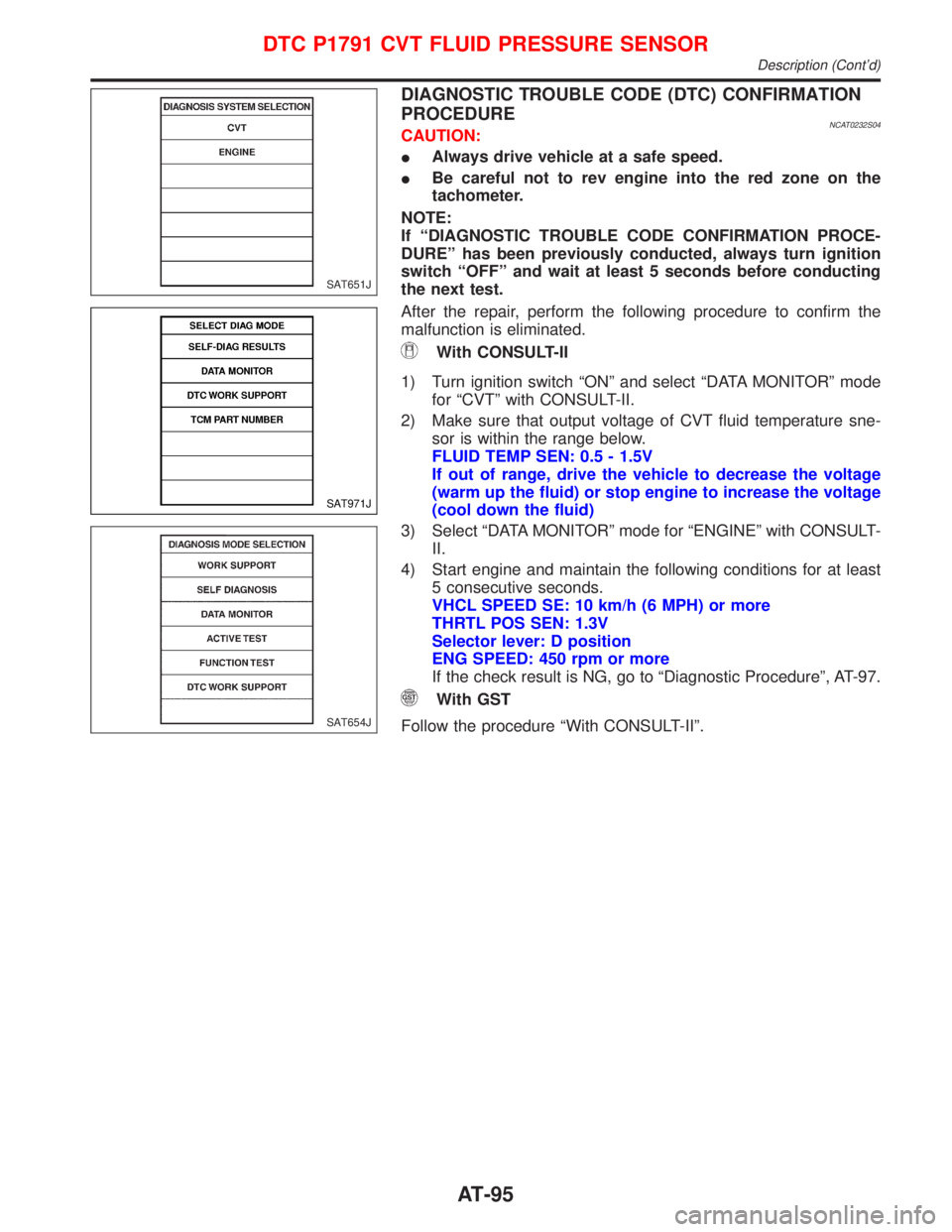

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NCAT0232S04CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªCVTº with CONSULT-II.

2) Make sure that output voltage of CVT fluid temperature sne-

sor is within the range below.

FLUID TEMP SEN: 0.5 - 1.5V

If out of range, drive the vehicle to decrease the voltage

(warm up the fluid) or stop engine to increase the voltage

(cool down the fluid)

3) Select ªDATA MONITORº mode for ªENGINEº with CONSULT-

II.

4) Start engine and maintain the following conditions for at least

5 consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: 1.3V

Selector lever: D position

ENG SPEED: 450 rpm or more

If the check result is NG, go to ªDiagnostic Procedureº, AT-97.

With GST

Follow the procedure ªWith CONSULT-IIº.

SAT651J

SAT971J

SAT654J

DTC P1791 CVT FLUID PRESSURE SENSOR

Description (Cont'd)

AT-95

Page 98 of 2267

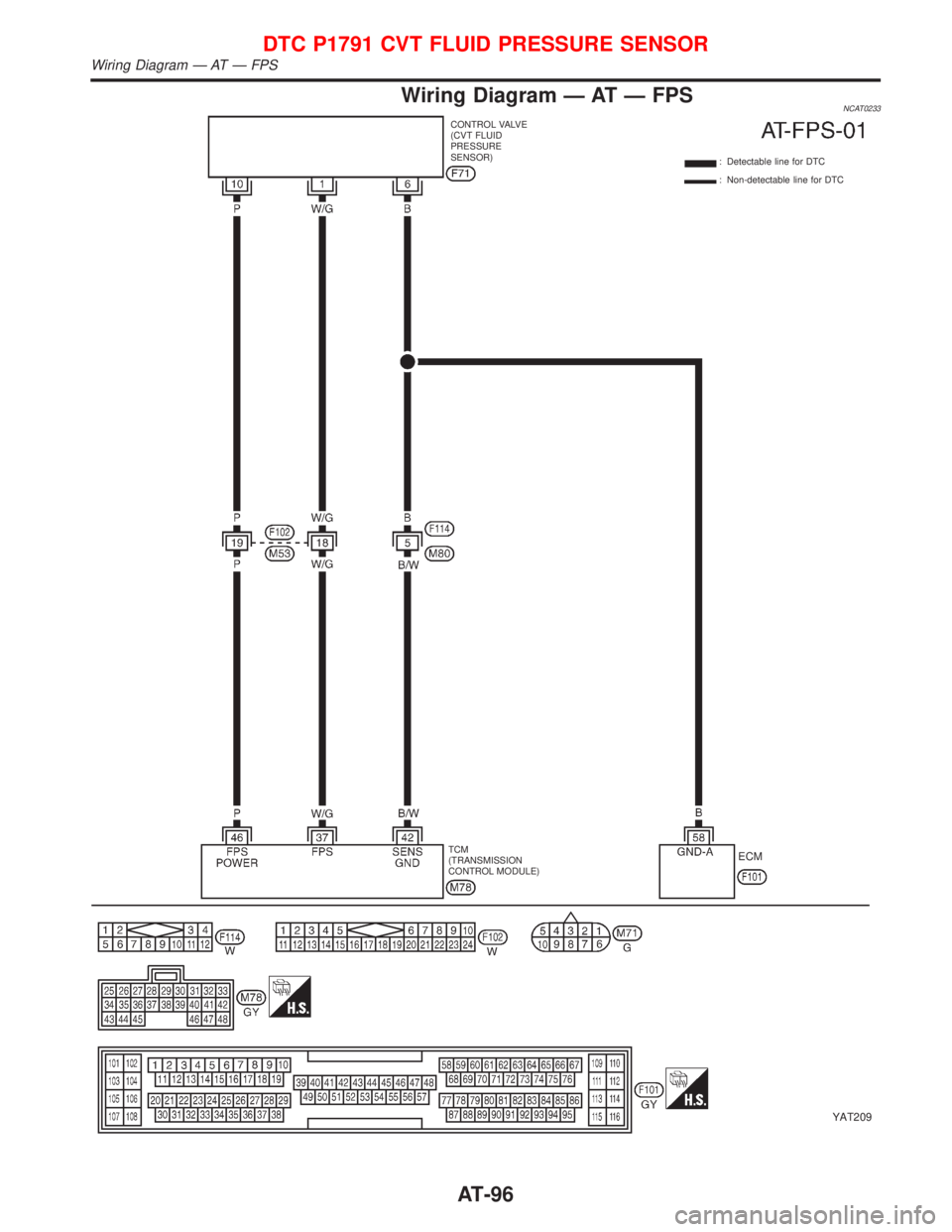

Wiring Diagram Ð AT Ð FPSNCAT0233

YAT209

TCM

(TRANSMISSION

CONTROL MODULE): Detectable line for DTC

: Non-detectable line for DTC CONTROL VALVE

(CVT FLUID

PRESSURE

SENSOR)ECM

DTC P1791 CVT FLUID PRESSURE SENSOR

Wiring Diagram Ð AT Ð FPS

AT-96

Page 99 of 2267

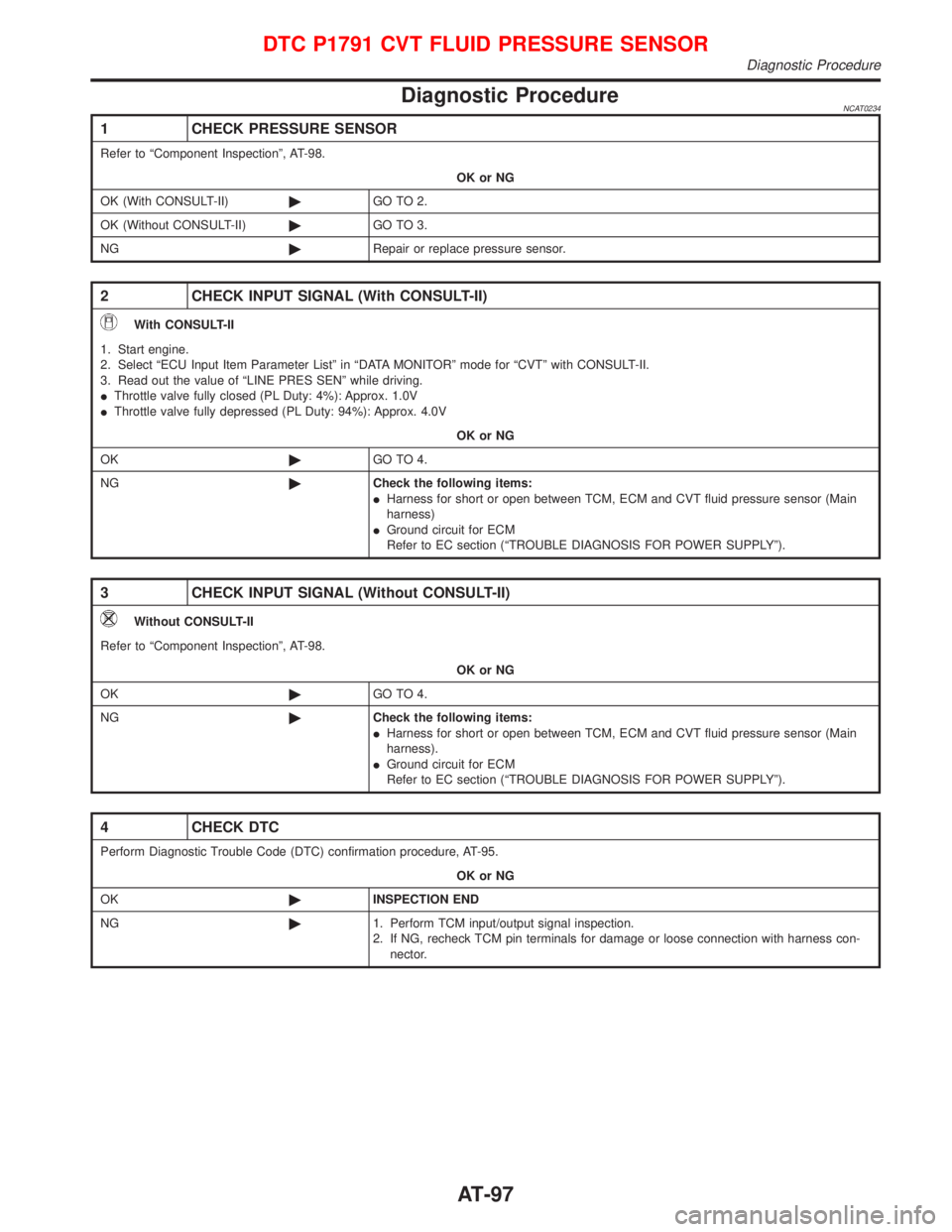

Diagnostic ProcedureNCAT0234

1 CHECK PRESSURE SENSOR

Refer to ªComponent Inspectionº, AT-98.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-II)©GO TO 3.

NG©Repair or replace pressure sensor.

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU Input Item Parameter Listº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

3. Read out the value of ªLINE PRES SENº while driving.

IThrottle valve fully closed (PL Duty: 4%): Approx. 1.0V

IThrottle valve fully depressed (PL Duty: 94%): Approx. 4.0V

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM, ECM and CVT fluid pressure sensor (Main

harness)

IGround circuit for ECM

Refer to EC section (ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº).

3 CHECK INPUT SIGNAL (Without CONSULT-II)

Without CONSULT-II

Refer to ªComponent Inspectionº, AT-98.

OK or NG

OK©GO TO 4.

NG©Check the following items:

IHarness for short or open between TCM, ECM and CVT fluid pressure sensor (Main

harness).

IGround circuit for ECM

Refer to EC section (ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº).

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-95.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC P1791 CVT FLUID PRESSURE SENSOR

Diagnostic Procedure

AT-97

Page 100 of 2267

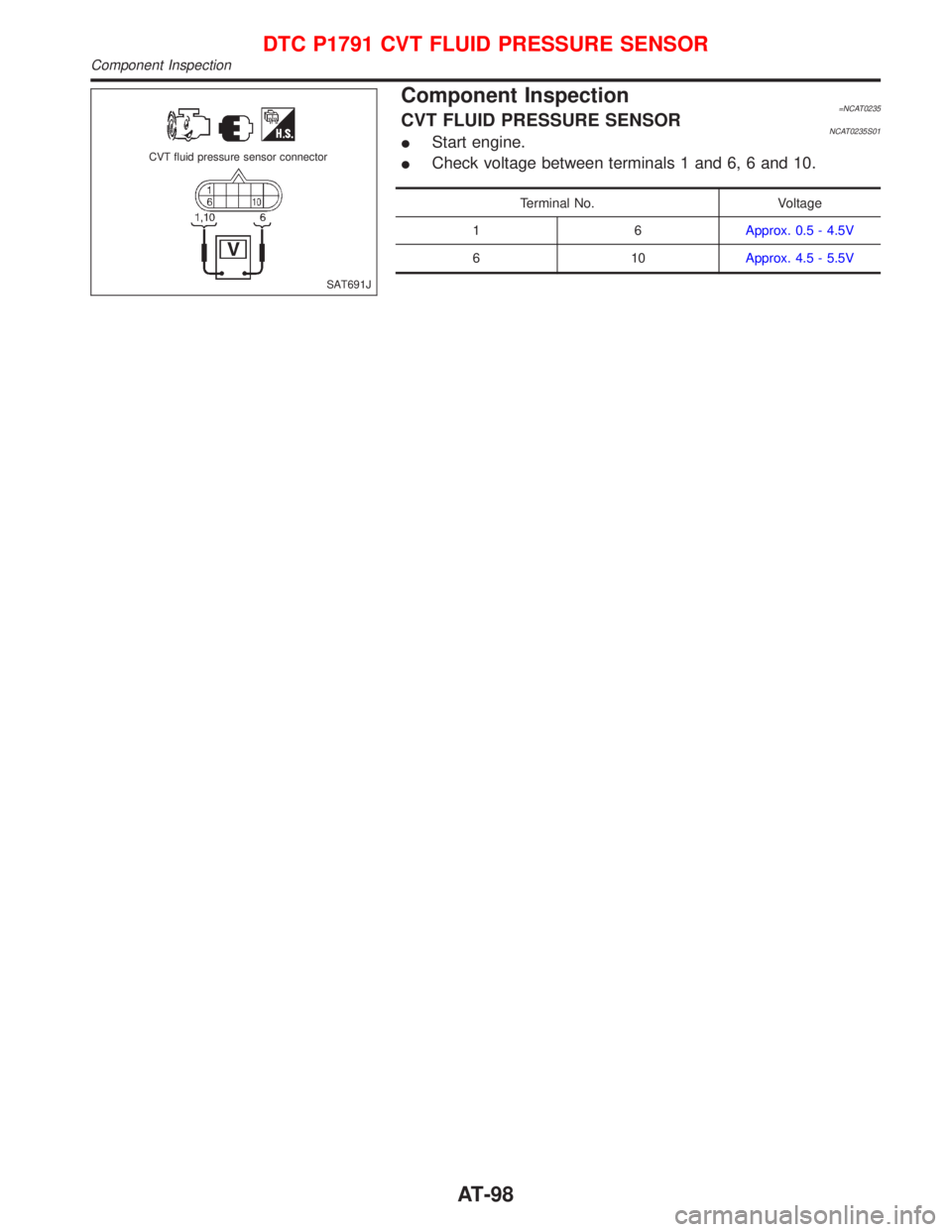

Component Inspection=NCAT0235CVT FLUID PRESSURE SENSORNCAT0235S01IStart engine.

ICheck voltage between terminals 1 and 6, 6 and 10.

Terminal No. Voltage

16Approx. 0.5 - 4.5V

610Approx. 4.5 - 5.5V

SAT691J CVT fluid pressure sensor connector

DTC P1791 CVT FLUID PRESSURE SENSOR

Component Inspection

AT-98

Page 118 of 2267

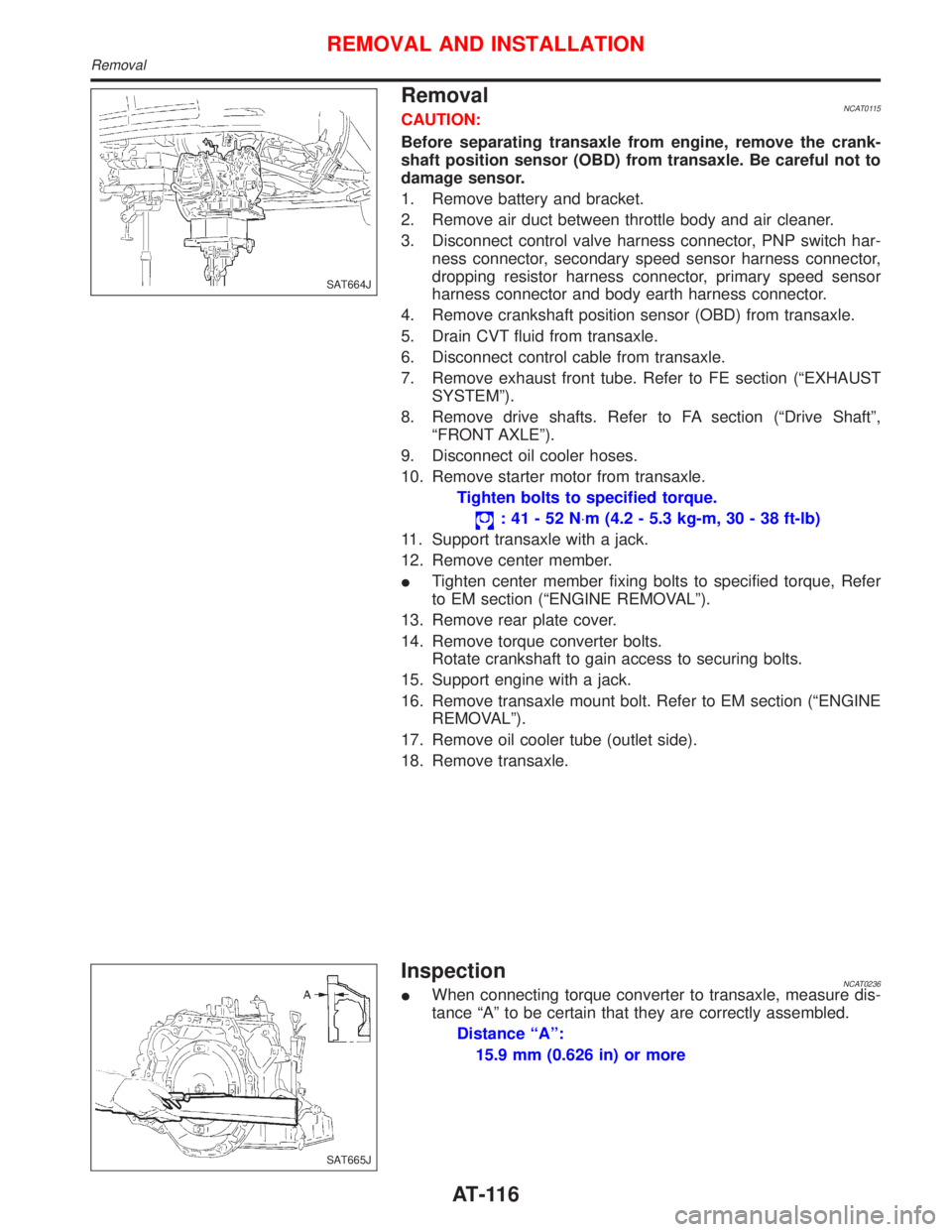

RemovalNCAT0115CAUTION:

Before separating transaxle from engine, remove the crank-

shaft position sensor (OBD) from transaxle. Be careful not to

damage sensor.

1. Remove battery and bracket.

2. Remove air duct between throttle body and air cleaner.

3. Disconnect control valve harness connector, PNP switch har-

ness connector, secondary speed sensor harness connector,

dropping resistor harness connector, primary speed sensor

harness connector and body earth harness connector.

4. Remove crankshaft position sensor (OBD) from transaxle.

5. Drain CVT fluid from transaxle.

6. Disconnect control cable from transaxle.

7. Remove exhaust front tube. Refer to FE section (ªEXHAUST

SYSTEMº).

8. Remove drive shafts. Refer to FA section (ªDrive Shaftº,

ªFRONT AXLEº).

9. Disconnect oil cooler hoses.

10. Remove starter motor from transaxle.

Tighten bolts to specified torque.

:41-52N×m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

11. Support transaxle with a jack.

12. Remove center member.

ITighten center member fixing bolts to specified torque, Refer

to EM section (ªENGINE REMOVALº).

13. Remove rear plate cover.

14. Remove torque converter bolts.

Rotate crankshaft to gain access to securing bolts.

15. Support engine with a jack.

16. Remove transaxle mount bolt. Refer to EM section (ªENGINE

REMOVALº).

17. Remove oil cooler tube (outlet side).

18. Remove transaxle.

InspectionNCAT0236IWhen connecting torque converter to transaxle, measure dis-

tance ªAº to be certain that they are correctly assembled.

Distance ªAº:

15.9 mm (0.626 in) or more

SAT664J

SAT665J

REMOVAL AND INSTALLATION

Removal

AT-116

Page 121 of 2267

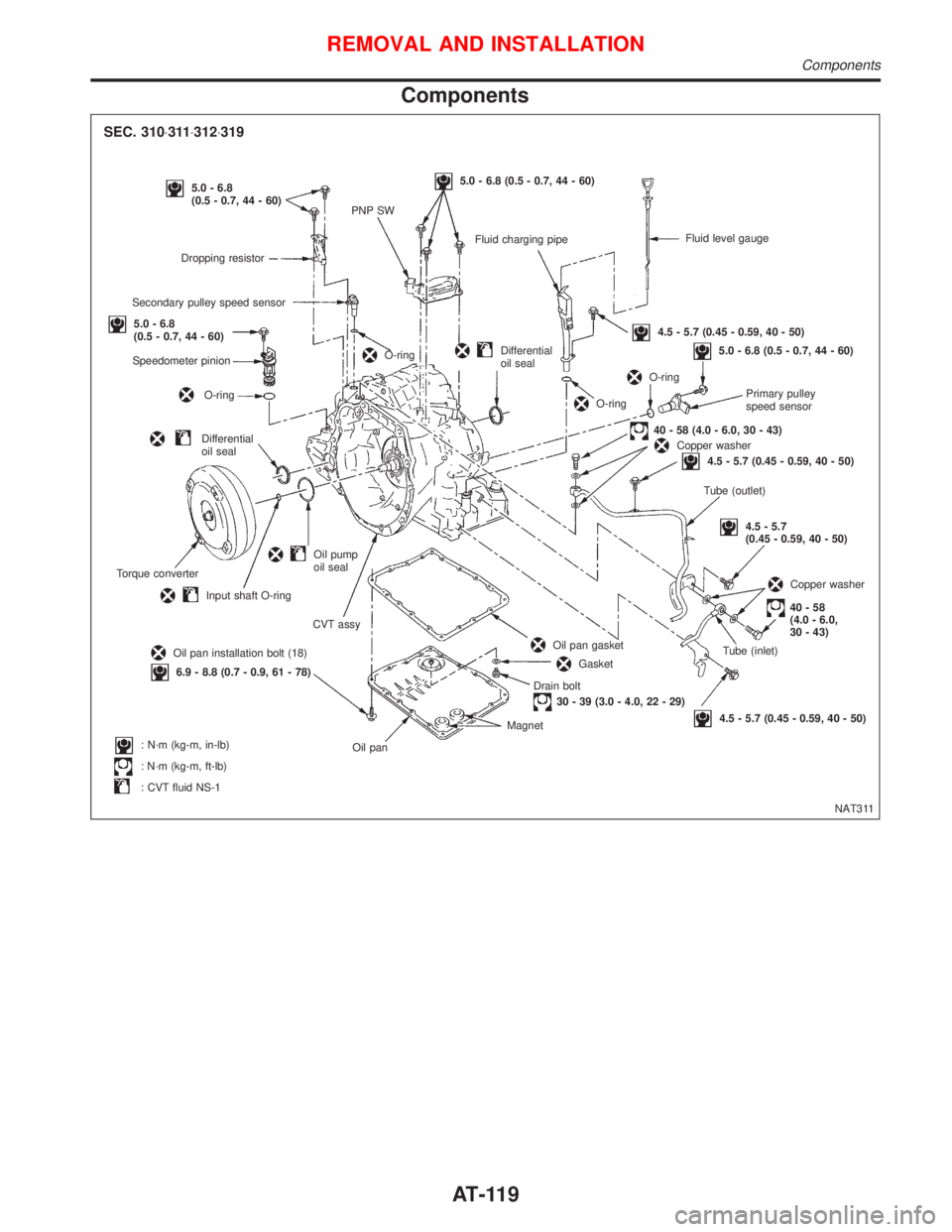

Components

NAT311 Fluid level gauge

Fluid charging pipe

5.0 - 6.8 (0.5 - 0.7, 44 - 60)

PNP SW5.0 - 6.8

(0.5 - 0.7, 44 - 60)

Dropping resistor

Secondary pulley speed sensor

5.0 - 6.8

(0.5 - 0.7, 44 - 60)

Speedometer pinion

O-ring

O-ringDifferential

oil seal

Torque converter

Input shaft O-ring

Oil pump

oil seal

CVT assy

Oil pan installation bolt (18)

6.9 - 8.8 (0.7 - 0.9, 61 - 78)

: N´m (kg-m, in-lb)

: N´m (kg-m, ft-lb)

: CVT fluid NS-1Oil panMagnetDrain bolt

30 - 39 (3.0 - 4.0, 22 - 29)

Gasket

Oil pan gasket

4.5 - 5.7 (0.45 - 0.59, 40 - 50)Tube (inlet)

40-58

(4.0 - 6.0,

30 - 43)

Copper washer

4.5 - 5.7

(0.45 - 0.59, 40 - 50) Tube (outlet)

4.5 - 5.7 (0.45 - 0.59, 40 - 50)Copper washer40 - 58 (4.0 - 6.0, 30 - 43)Primary pulley

speed sensor

5.0 - 6.8 (0.5 - 0.7, 44 - 60)

O-ring

O-ring

4.5 - 5.7 (0.45 - 0.59, 40 - 50)

Differential

oil seal

SEC. 310×311×312×319

REMOVAL AND INSTALLATION

Components

AT-119