Control NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 1 of 2267

Edition:May 2001

GENERA LINFORMATIONGI

MAINTENANCEMA

ENGIN EMECHANICALEM

ENGIN ELUBRICATIO N&LC

ENGIN ECONTRO LSYSTEMQG16/18DE

ENGIN ECONTRO LSYSTEMSR20DE

ENGIN ECONTRO LSYSTEMCD20T

ACCELERATO RCONTROL,FE

CLUTCHCL

MANUA LTRANSAXLEMT

AUTOMATI CTRANSAXLEAT

FRON TAXL E& FRON TSUSPENSIONFA

REA RAXL E& REA RSUSPENSIONRA

BRAK ESYSTEMBR

STEERIN GSYSTEMST

RESTRAIN TSYSTEMRS

BOD Y& TRIMBT

HEATE R&AIR CONDITIONERHA

ELECTRICA LSYSTEMEL

ALPHABETICA LINDEXIDX

PRIMERA

NISSA NEUROP EN.V.

Page 3 of 2267

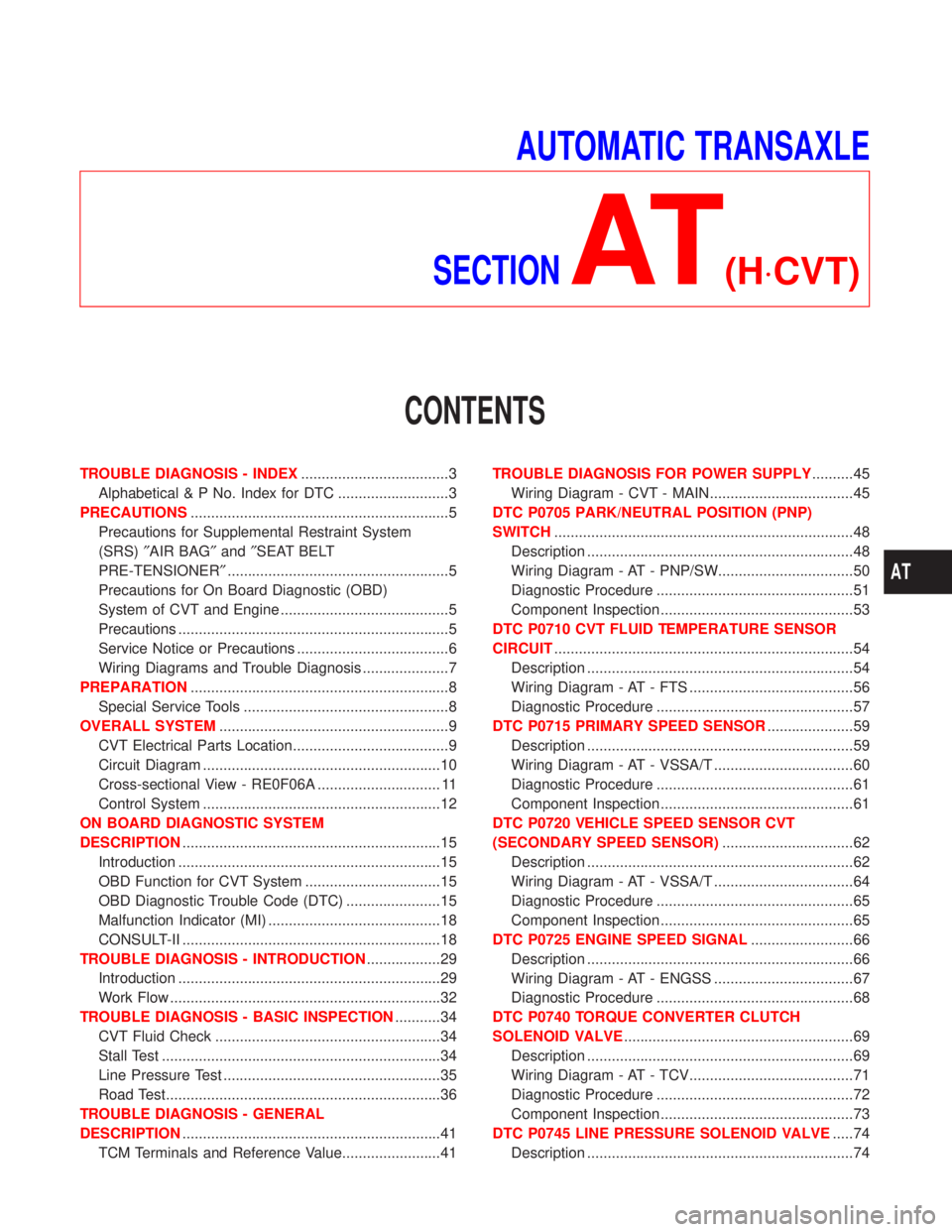

AUTOMATIC TRANSAXLE

SECTION

AT(H×CVT)

CONTENTS

TROUBLE DIAGNOSIS - INDEX....................................3

Alphabetical & P No. Index for DTC ...........................3

PRECAUTIONS...............................................................5

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²......................................................5

Precautions for On Board Diagnostic (OBD)

System of CVT and Engine .........................................5

Precautions ..................................................................5

Service Notice or Precautions .....................................6

Wiring Diagrams and Trouble Diagnosis .....................7

PREPARATION...............................................................8

Special Service Tools ..................................................8

OVERALL SYSTEM........................................................9

CVT Electrical Parts Location......................................9

Circuit Diagram ..........................................................10

Cross-sectional View - RE0F06A .............................. 11

Control System ..........................................................12

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................15

Introduction ................................................................15

OBD Function for CVT System .................................15

OBD Diagnostic Trouble Code (DTC) .......................15

Malfunction Indicator (MI) ..........................................18

CONSULT-II ...............................................................18

TROUBLE DIAGNOSIS - INTRODUCTION..................29

Introduction ................................................................29

Work Flow ..................................................................32

TROUBLE DIAGNOSIS - BASIC INSPECTION...........34

CVT Fluid Check .......................................................34

Stall Test ....................................................................34

Line Pressure Test .....................................................35

Road Test...................................................................36

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................41

TCM Terminals and Reference Value........................41TROUBLE DIAGNOSIS FOR POWER SUPPLY..........45

Wiring Diagram - CVT - MAIN...................................45

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH.........................................................................48

Description .................................................................48

Wiring Diagram - AT - PNP/SW.................................50

Diagnostic Procedure ................................................51

Component Inspection ...............................................53

DTC P0710 CVT FLUID TEMPERATURE SENSOR

CIRCUIT.........................................................................54

Description .................................................................54

Wiring Diagram - AT - FTS ........................................56

Diagnostic Procedure ................................................57

DTC P0715 PRIMARY SPEED SENSOR.....................59

Description .................................................................59

Wiring Diagram - AT - VSSA/T ..................................60

Diagnostic Procedure ................................................61

Component Inspection ...............................................61

DTC P0720 VEHICLE SPEED SENSOR CVT

(SECONDARY SPEED SENSOR)................................62

Description .................................................................62

Wiring Diagram - AT - VSSA/T ..................................64

Diagnostic Procedure ................................................65

Component Inspection ...............................................65

DTC P0725 ENGINE SPEED SIGNAL.........................66

Description .................................................................66

Wiring Diagram - AT - ENGSS ..................................67

Diagnostic Procedure ................................................68

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE........................................................69

Description .................................................................69

Wiring Diagram - AT - TCV........................................71

Diagnostic Procedure ................................................72

Component Inspection ...............................................73

DTC P0745 LINE PRESSURE SOLENOID VALVE.....74

Description .................................................................74

AT

Page 4 of 2267

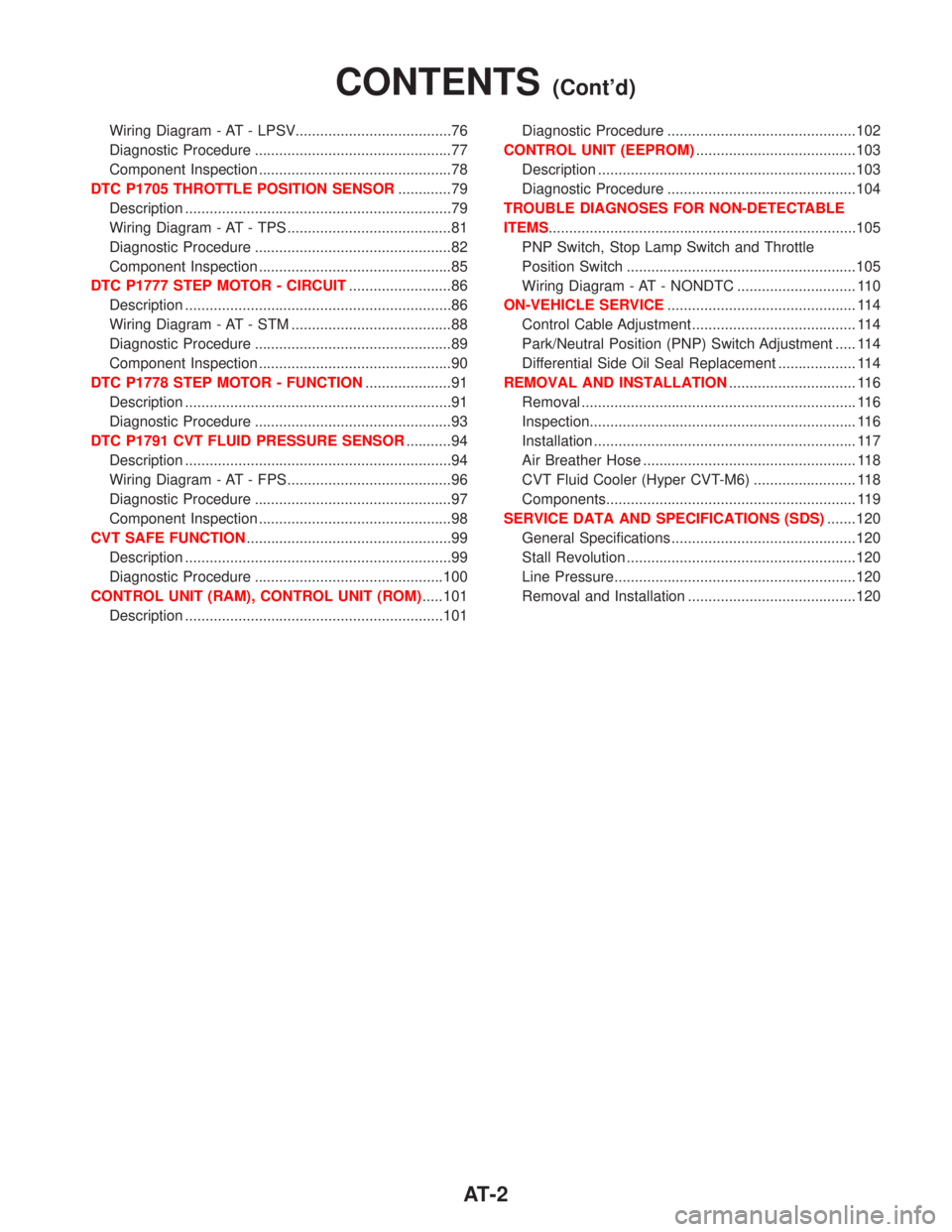

Wiring Diagram - AT - LPSV......................................76

Diagnostic Procedure ................................................77

Component Inspection ...............................................78

DTC P1705 THROTTLE POSITION SENSOR.............79

Description .................................................................79

Wiring Diagram - AT - TPS ........................................81

Diagnostic Procedure ................................................82

Component Inspection ...............................................85

DTC P1777 STEP MOTOR - CIRCUIT.........................86

Description .................................................................86

Wiring Diagram - AT - STM .......................................88

Diagnostic Procedure ................................................89

Component Inspection ...............................................90

DTC P1778 STEP MOTOR - FUNCTION.....................91

Description .................................................................91

Diagnostic Procedure ................................................93

DTC P1791 CVT FLUID PRESSURE SENSOR...........94

Description .................................................................94

Wiring Diagram - AT - FPS ........................................96

Diagnostic Procedure ................................................97

Component Inspection ...............................................98

CVT SAFE FUNCTION..................................................99

Description .................................................................99

Diagnostic Procedure ..............................................100

CONTROL UNIT (RAM), CONTROL UNIT (ROM).....101

Description ...............................................................101Diagnostic Procedure ..............................................102

CONTROL UNIT (EEPROM).......................................103

Description ...............................................................103

Diagnostic Procedure ..............................................104

TROUBLE DIAGNOSES FOR NON-DETECTABLE

ITEMS...........................................................................105

PNP Switch, Stop Lamp Switch and Throttle

Position Switch ........................................................105

Wiring Diagram - AT - NONDTC ............................. 110

ON-VEHICLE SERVICE.............................................. 114

Control Cable Adjustment ........................................ 114

Park/Neutral Position (PNP) Switch Adjustment ..... 114

Differential Side Oil Seal Replacement ................... 114

REMOVAL AND INSTALLATION............................... 116

Removal ................................................................... 116

Inspection................................................................. 116

Installation ................................................................ 117

Air Breather Hose .................................................... 118

CVT Fluid Cooler (Hyper CVT-M6) ......................... 118

Components............................................................. 119

SERVICE DATA AND SPECIFICATIONS (SDS).......120

General Specifications .............................................120

Stall Revolution ........................................................120

Line Pressure...........................................................120

Removal and Installation .........................................120

CONTENTS(Cont'd)

AT-2

Page 5 of 2267

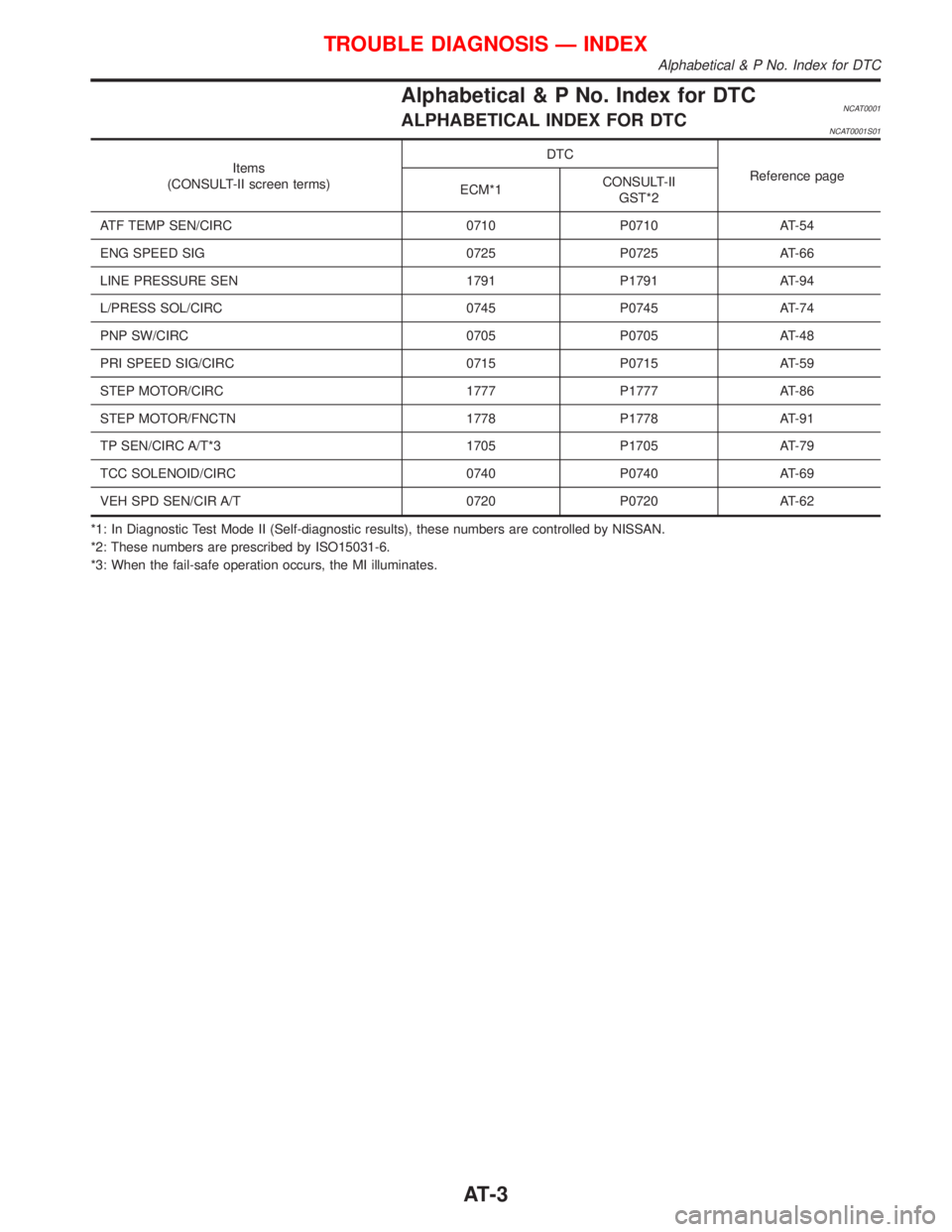

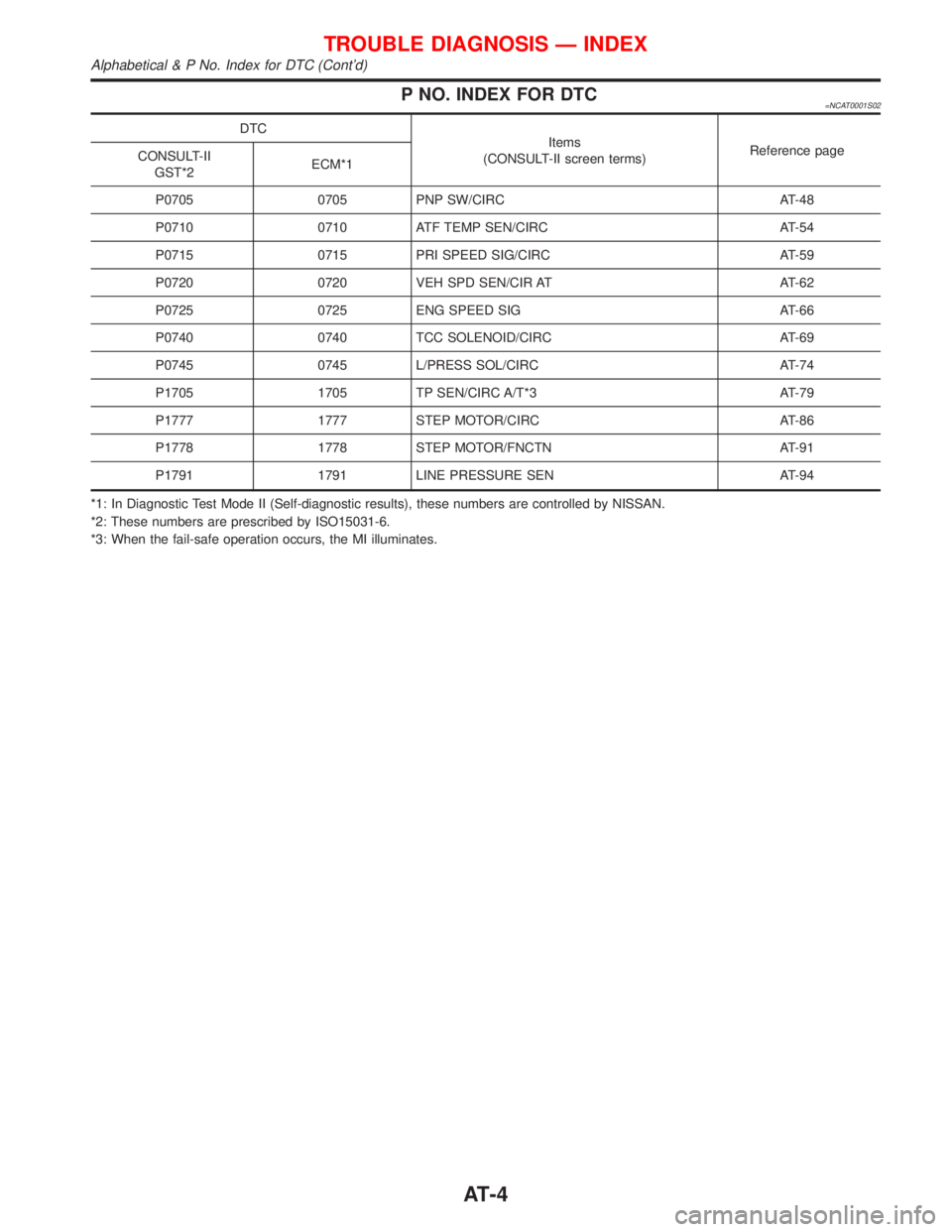

Alphabetical & P No. Index for DTCNCAT0001ALPHABETICAL INDEX FOR DTCNCAT0001S01

Items

(CONSULT-II screen terms)DTC

Reference page

ECM*1CONSULT-II

GST*2

ATF TEMP SEN/CIRC 0710 P0710 AT-54

ENG SPEED SIG 0725 P0725 AT-66

LINE PRESSURE SEN 1791 P1791 AT-94

L/PRESS SOL/CIRC 0745 P0745 AT-74

PNP SW/CIRC 0705 P0705 AT-48

PRI SPEED SIG/CIRC 0715 P0715 AT-59

STEP MOTOR/CIRC 1777 P1777 AT-86

STEP MOTOR/FNCTN 1778 P1778 AT-91

TP SEN/CIRC A/T*3 1705 P1705 AT-79

TCC SOLENOID/CIRC 0740 P0740 AT-69

VEH SPD SEN/CIR A/T 0720 P0720 AT-62

*1: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO15031-6.

*3: When the fail-safe operation occurs, the MI illuminates.

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC

AT-3

Page 6 of 2267

P NO. INDEX FOR DTC=NCAT0001S02

DTC

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1

P0705 0705 PNP SW/CIRC AT-48

P0710 0710 ATF TEMP SEN/CIRC AT-54

P0715 0715 PRI SPEED SIG/CIRC AT-59

P0720 0720 VEH SPD SEN/CIR AT AT-62

P0725 0725 ENG SPEED SIG AT-66

P0740 0740 TCC SOLENOID/CIRC AT-69

P0745 0745 L/PRESS SOL/CIRC AT-74

P1705 1705 TP SEN/CIRC A/T*3 AT-79

P1777 1777 STEP MOTOR/CIRC AT-86

P1778 1778 STEP MOTOR/FNCTN AT-91

P1791 1791 LINE PRESSURE SEN AT-94

*1: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO15031-6.

*3: When the fail-safe operation occurs, the MI illuminates.

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

AT-4

Page 11 of 2267

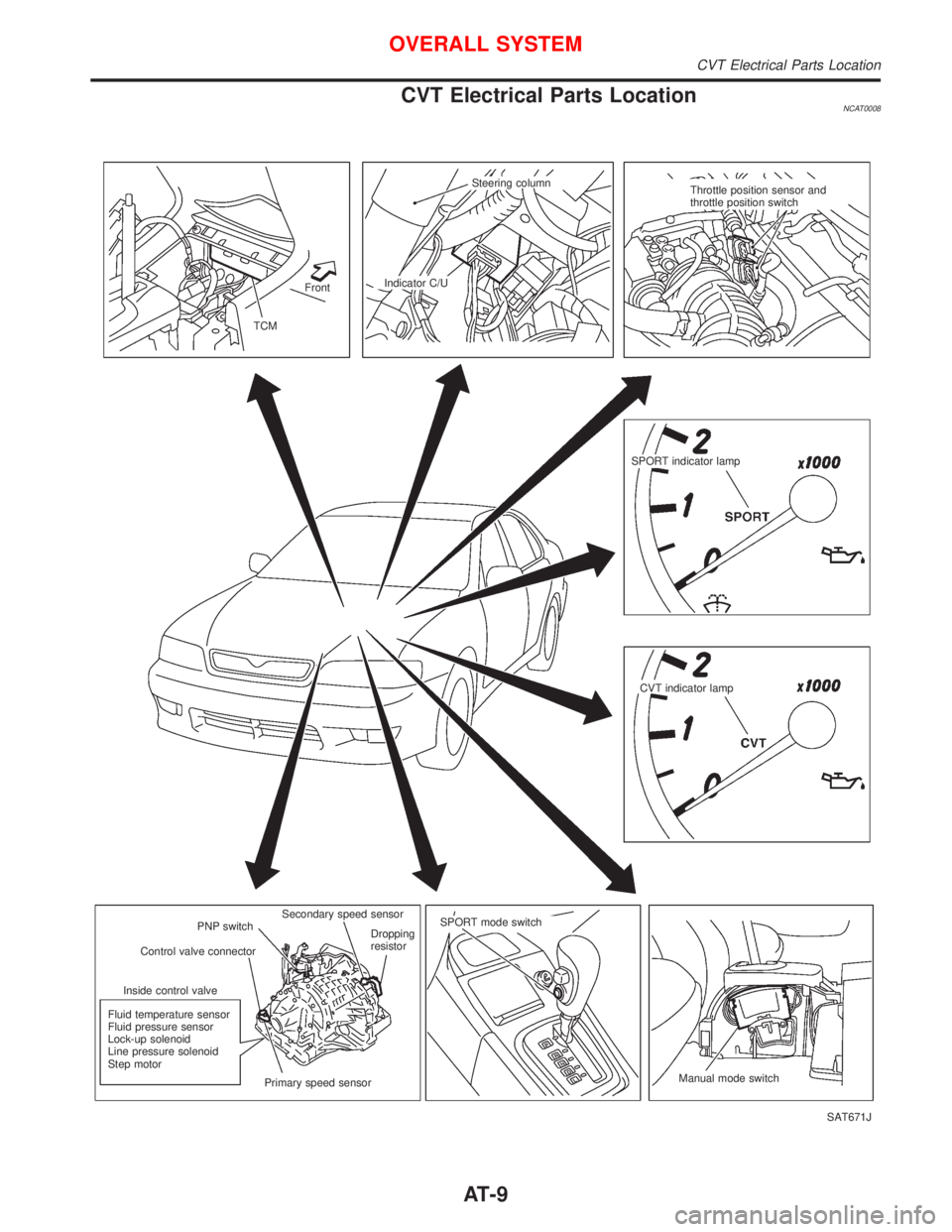

CVT Electrical Parts LocationNCAT0008

SAT671J Front

TCMIndicator C/USteering column

Throttle position sensor and

throttle position switch

SPORT indicator lamp

CVT indicator lamp

Manual mode switch SPORT mode switch

Dropping

resistor

Primary speed sensor Fluid temperature sensor

Fluid pressure sensor

Lock-up solenoid

Line pressure solenoid

Step motorInside control valveControl valve connectorPNP switchSecondary speed sensor

OVERALL SYSTEM

CVT Electrical Parts Location

AT-9

Page 14 of 2267

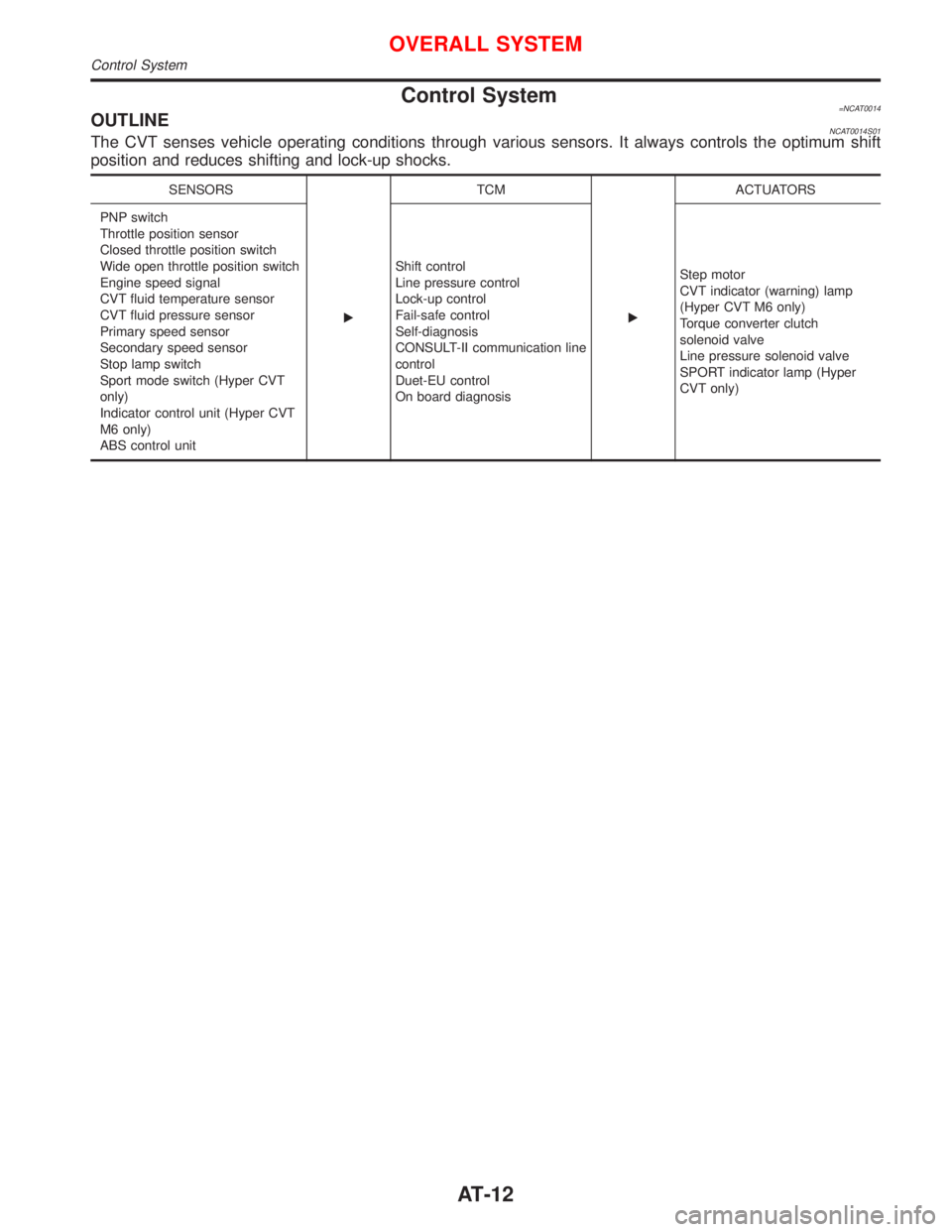

Control System=NCAT0014OUTLINENCAT0014S01The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

SENSORS

ETCM

EACTUATORS

PNP switch

Throttle position sensor

Closed throttle position switch

Wide open throttle position switch

Engine speed signal

CVT fluid temperature sensor

CVT fluid pressure sensor

Primary speed sensor

Secondary speed sensor

Stop lamp switch

Sport mode switch (Hyper CVT

only)

Indicator control unit (Hyper CVT

M6 only)

ABS control unitShift control

Line pressure control

Lock-up control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

control

Duet-EU control

On board diagnosisStep motor

CVT indicator (warning) lamp

(Hyper CVT M6 only)

Torque converter clutch

solenoid valve

Line pressure solenoid valve

SPORT indicator lamp (Hyper

CVT only)

OVERALL SYSTEM

Control System

AT-12

Page 15 of 2267

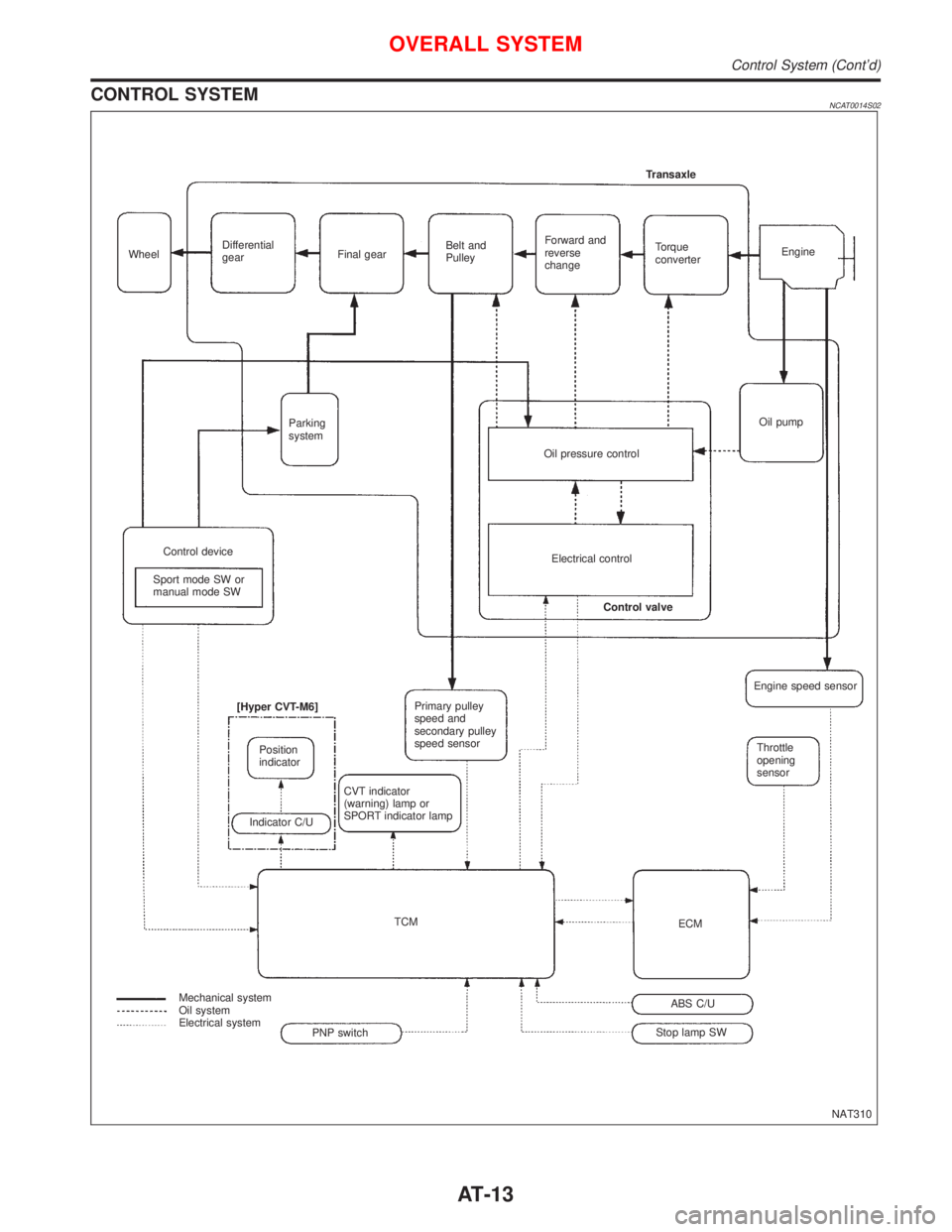

CONTROL SYSTEMNCAT0014S02

NAT310 WheelDifferential

gearFinal gearBelt and

PulleyForward and

reverse

changeTorque

converterEngine Transaxle

Oil pump

Oil pressure control Parking

system

Control device

Sport mode SW or

manual mode SWElectrical control

Control valve

Primary pulley

speed and

secondary pulley

speed sensor

CVT indicator

(warning) lamp or

SPORT indicator lamp [Hyper CVT-M6]

Position

indicator

Indicator C/U

TCM

Mechanical system

Oil system

Electrical system

Stop lamp SWABS C/UECMThrottle

opening

sensor Engine speed sensor

PNP switch

OVERALL SYSTEM

Control System (Cont'd)

AT-13

Page 16 of 2267

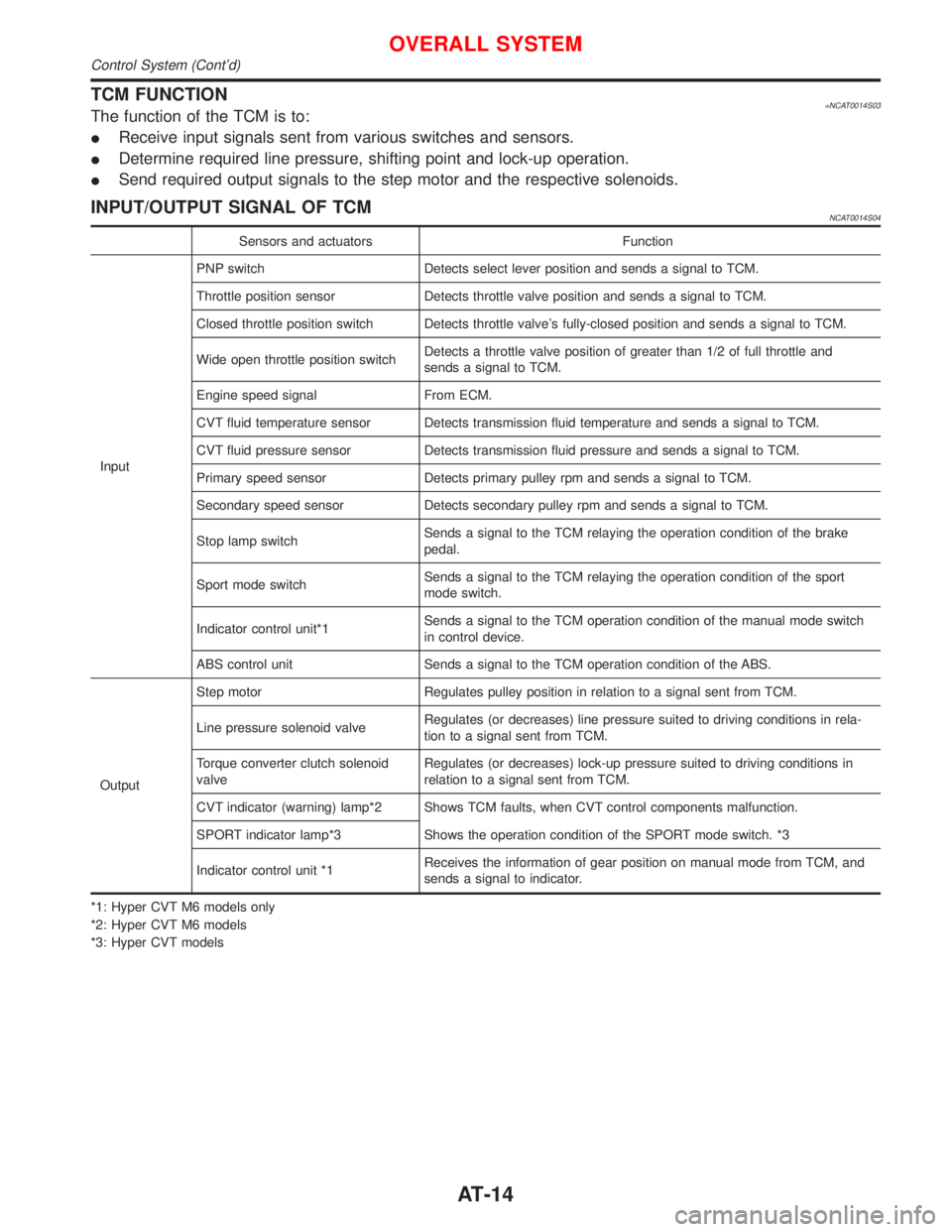

TCM FUNCTION=NCAT0014S03The function of the TCM is to:

IReceive input signals sent from various switches and sensors.

IDetermine required line pressure, shifting point and lock-up operation.

ISend required output signals to the step motor and the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCMNCAT0014S04

Sensors and actuators Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor Detects throttle valve position and sends a signal to TCM.

Closed throttle position switch Detects throttle valve's fully-closed position and sends a signal to TCM.

Wide open throttle position switchDetects a throttle valve position of greater than 1/2 of full throttle and

sends a signal to TCM.

Engine speed signal From ECM.

CVT fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

CVT fluid pressure sensor Detects transmission fluid pressure and sends a signal to TCM.

Primary speed sensor Detects primary pulley rpm and sends a signal to TCM.

Secondary speed sensor Detects secondary pulley rpm and sends a signal to TCM.

Stop lamp switchSends a signal to the TCM relaying the operation condition of the brake

pedal.

Sport mode switchSends a signal to the TCM relaying the operation condition of the sport

mode switch.

Indicator control unit*1Sends a signal to the TCM operation condition of the manual mode switch

in control device.

ABS control unit Sends a signal to the TCM operation condition of the ABS.

OutputStep motor Regulates pulley position in relation to a signal sent from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in

relation to a signal sent from TCM.

CVT indicator (warning) lamp*2 Shows TCM faults, when CVT control components malfunction.

SPORT indicator lamp*3 Shows the operation condition of the SPORT mode switch. *3

Indicator control unit *1Receives the information of gear position on manual mode from TCM, and

sends a signal to indicator.

*1: Hyper CVT M6 models only

*2: Hyper CVT M6 models

*3: Hyper CVT models

OVERALL SYSTEM

Control System (Cont'd)

AT-14

Page 17 of 2267

IntroductionNCAT0017The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MI (malfunction indicator) and is stored as a DTC in the ECM

memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the CVT indicator (warning) lamp or SPORT indi-

cator lamp. The malfunction is stored in the TCM memory. The detected items are overlapped with OBD self-

diagnostic items. For detail, refer to AT-26.

OBD Function for CVT SystemNCAT0018The ECM provides emission-related on board diagnostic (OBD) functions for the CVT system. One function

is to receive a signal from the TCM used with OBD-related parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MI (malfunction indicator) on the instrument panel. Sensors, switches and

solenoid valves are used as sensing elements.

The MI automatically illuminates in Two Trip Detection Logic when a malfunction is sensed in relation to CVT

system parts.

OBD Diagnostic Trouble Code (DTC)NCAT0020HOW TO READ DTC AND 1ST TRIP DTCNCAT0020S01DTC and 1st trip DTC can be read by the following methods.

1.(

No Tools)The number of blinks of the malfunction indicator in the Diagnostic Test Mode II (Self-Di-

agnostic Results) Examples: 0705, 0710, 0715, 0720, etc. For details, refer to EC section [ªMalfunction

Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº].

These DTCs are controlled by NISSAN.

2.(

with CONSULT-II orGST)CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0710,

P0720, P0725, etc.

These DTCs are prescribed by ISO15031-6.

(CONSULT-II also displays the malfunctioning component or system.)

I1st trip DTC No. is the same as DTC No.

IOutput of the diagnostic trouble code indicates that the indicated circuit has a malfunction.

However, in case of the Mode II and GST they do not indicate whether the malfunction is still

occurring or occurred in the past and returned to normal.

CONSULT-II can identify them as shown below. Therefore, using CONSULT-II (if available) is rec-

ommended.

A sample of CONSULT-II display for DTC is shown at left. DTC or 1st trip DTC of a malfunction is displayed

in SELF-DIAGNOSTIC RESULTS mode for ªENGINEº with CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be ª0º.

SAT651J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Introduction

AT-15