clock NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 156 of 2267

lIt is not necessary to remove connecting bolt except for

disassembly or replacement of caliper assembly. In this

case, suspend cylinder body with wire so as not to

stretch brake hose.

lBurnish the brake contact surfaces after refinishing or

replacing rotors, after replacing pads, or if a soft pedal

occurs at very low mileage.

Refer to ªBrake Burnishing Procedureº, ªCHECK AND

ADJUSTMENTº, BR-7.

1. Remove master cylinder reservoir cap.

2. Remove brake cable mounting bolt and lock spring.

3. Release parking brake control lever, then disconnect cable

from the caliper.

4. Remove upper pin bolt.

5. Open cylinder body downward. Then remove pads inner and

outer shims.

Standard pad thickness:

9.3 mm (0.366 in)

Pad wear limit:

2.0 mm (0.079 in)

6. When installing new pads, push piston into cylinder body by

gently turning piston clockwise, as shown.

Carefully monitor brake fluid level because brake fluid

will return to reservoir when pushing back piston.

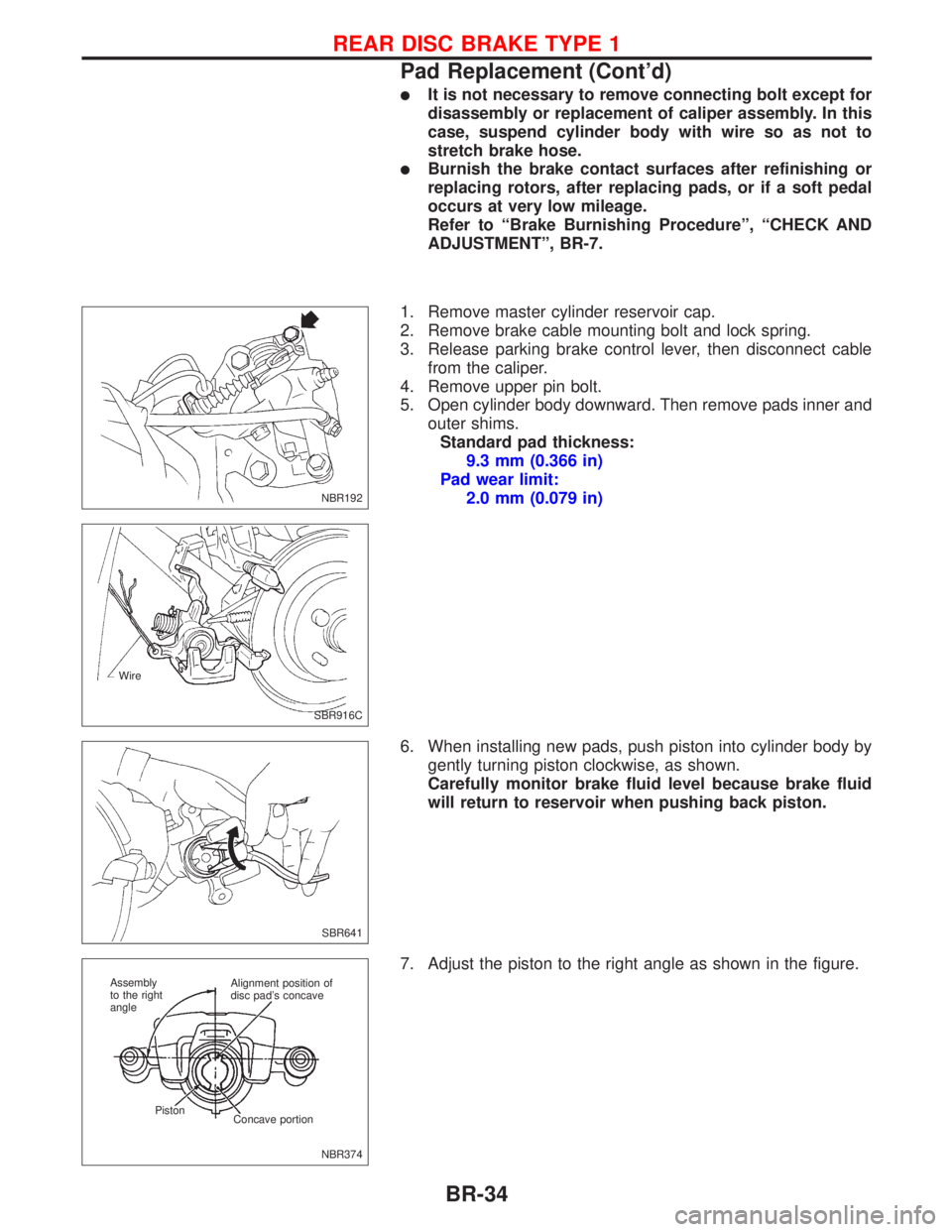

7. Adjust the piston to the right angle as shown in the figure.

NBR192

SBR916C Wire

SBR641

NBR374 Alignment position of

disc pad's concave

Concave portion Piston Assembly

to the right

angle

REAR DISC BRAKE TYPE 1

Pad Replacement (Cont'd)

BR-34

Page 157 of 2267

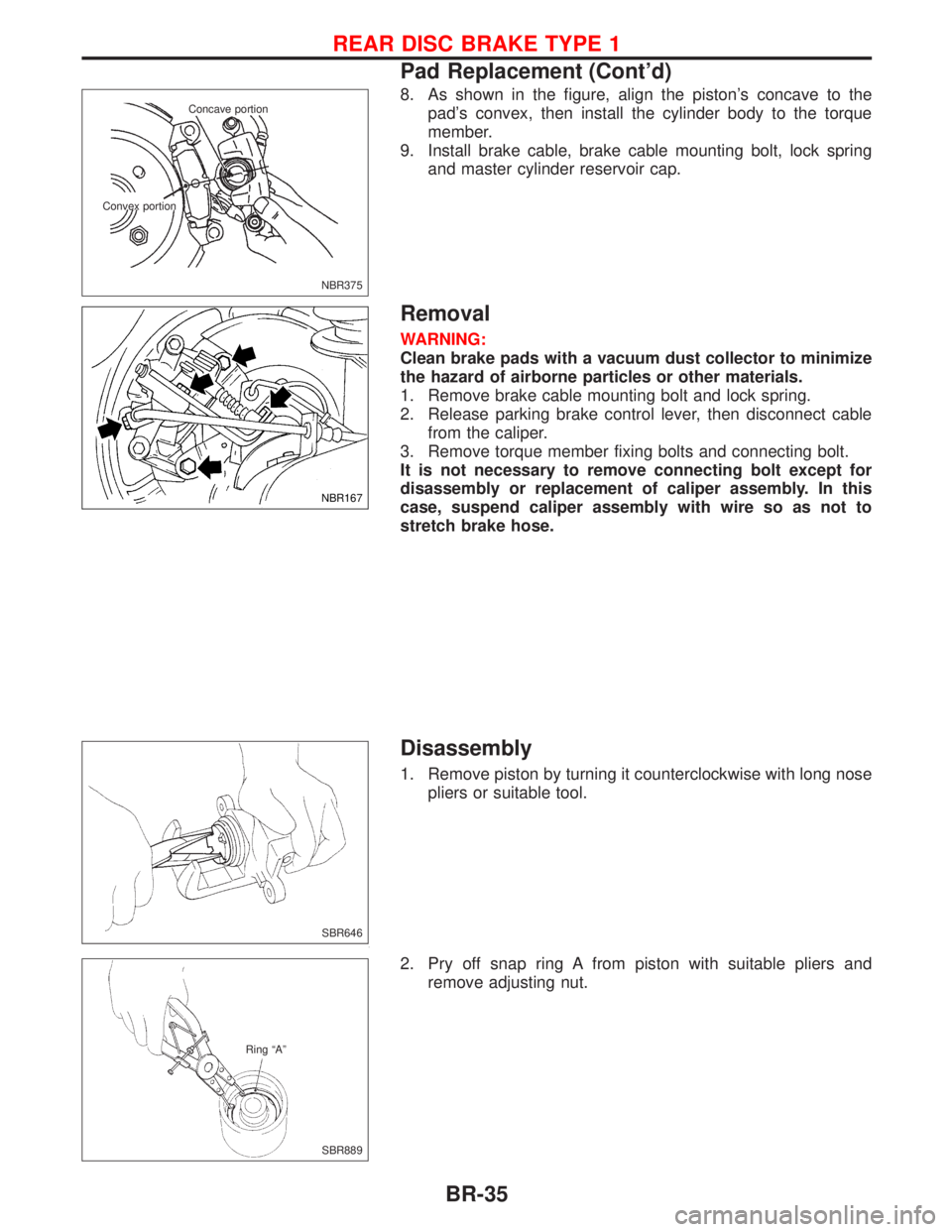

8. As shown in the figure, align the piston's concave to the

pad's convex, then install the cylinder body to the torque

member.

9. Install brake cable, brake cable mounting bolt, lock spring

and master cylinder reservoir cap.

Removal

WARNING:

Clean brake pads with a vacuum dust collector to minimize

the hazard of airborne particles or other materials.

1. Remove brake cable mounting bolt and lock spring.

2. Release parking brake control lever, then disconnect cable

from the caliper.

3. Remove torque member fixing bolts and connecting bolt.

It is not necessary to remove connecting bolt except for

disassembly or replacement of caliper assembly. In this

case, suspend caliper assembly with wire so as not to

stretch brake hose.

Disassembly

1. Remove piston by turning it counterclockwise with long nose

pliers or suitable tool.

2. Pry off snap ring A from piston with suitable pliers and

remove adjusting nut.

NBR375 Concave portion

Convex portion

NBR167

SBR646

SBR889 Ring ªAº

REAR DISC BRAKE TYPE 1

Pad Replacement (Cont'd)

BR-35

Page 161 of 2267

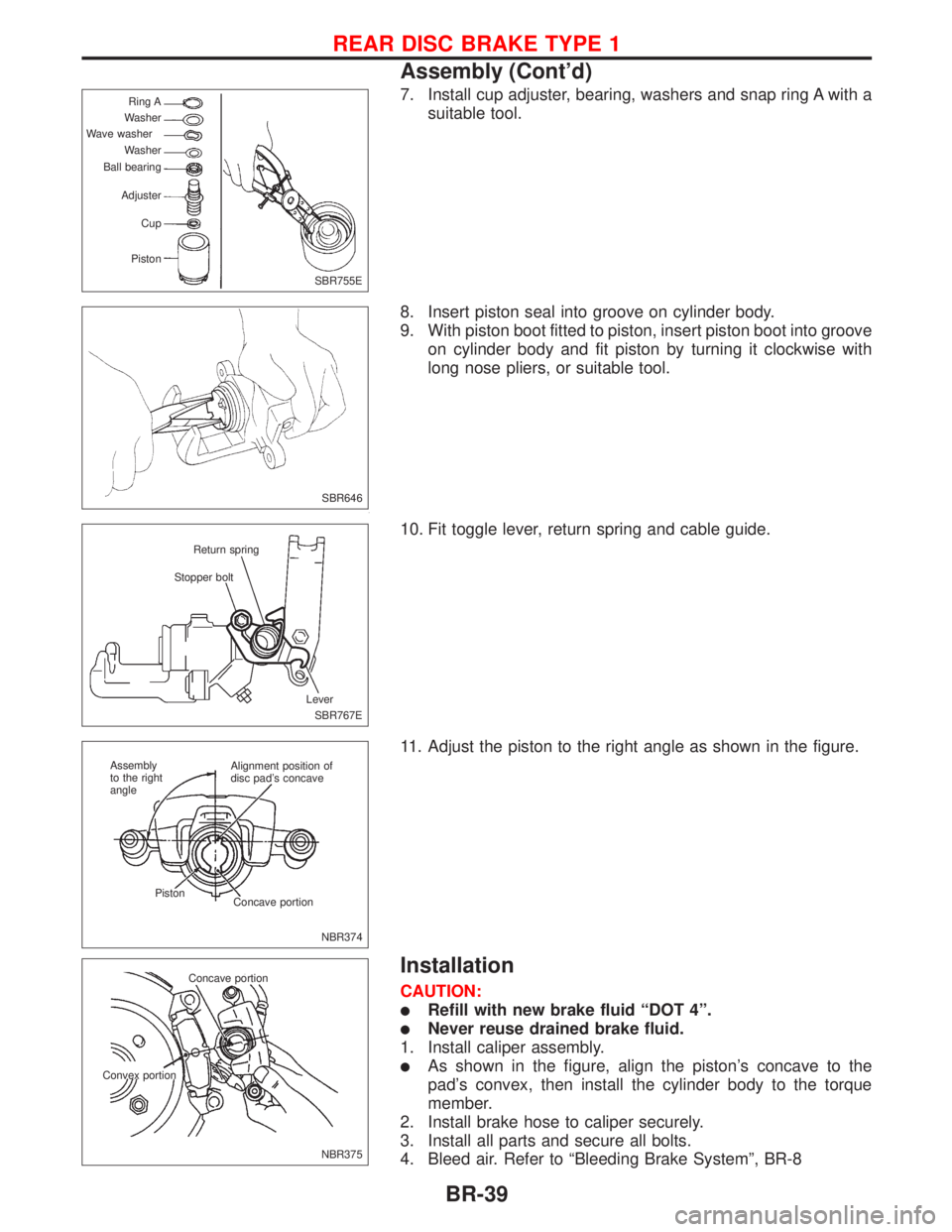

7. Install cup adjuster, bearing, washers and snap ring A with a

suitable tool.

8. Insert piston seal into groove on cylinder body.

9. With piston boot fitted to piston, insert piston boot into groove

on cylinder body and fit piston by turning it clockwise with

long nose pliers, or suitable tool.

10. Fit toggle lever, return spring and cable guide.

11. Adjust the piston to the right angle as shown in the figure.

Installation

CAUTION:

lRefill with new brake fluid ªDOT 4º.

lNever reuse drained brake fluid.

1. Install caliper assembly.

lAs shown in the figure, align the piston's concave to the

pad's convex, then install the cylinder body to the torque

member.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to ªBleeding Brake Systemº, BR-8

SBR755E Ring A

Washer

Wave washer

Washer

Ball bearing

Adjuster

Cup

Piston

SBR646

SBR767E Stopper boltReturn spring

Lever

NBR374 Alignment position of

disc pad's concave

Concave portion Piston Assembly

to the right

angle

NBR375 Concave portion

Convex portion

REAR DISC BRAKE TYPE 1

Assembly (Cont'd)

BR-39

Page 163 of 2267

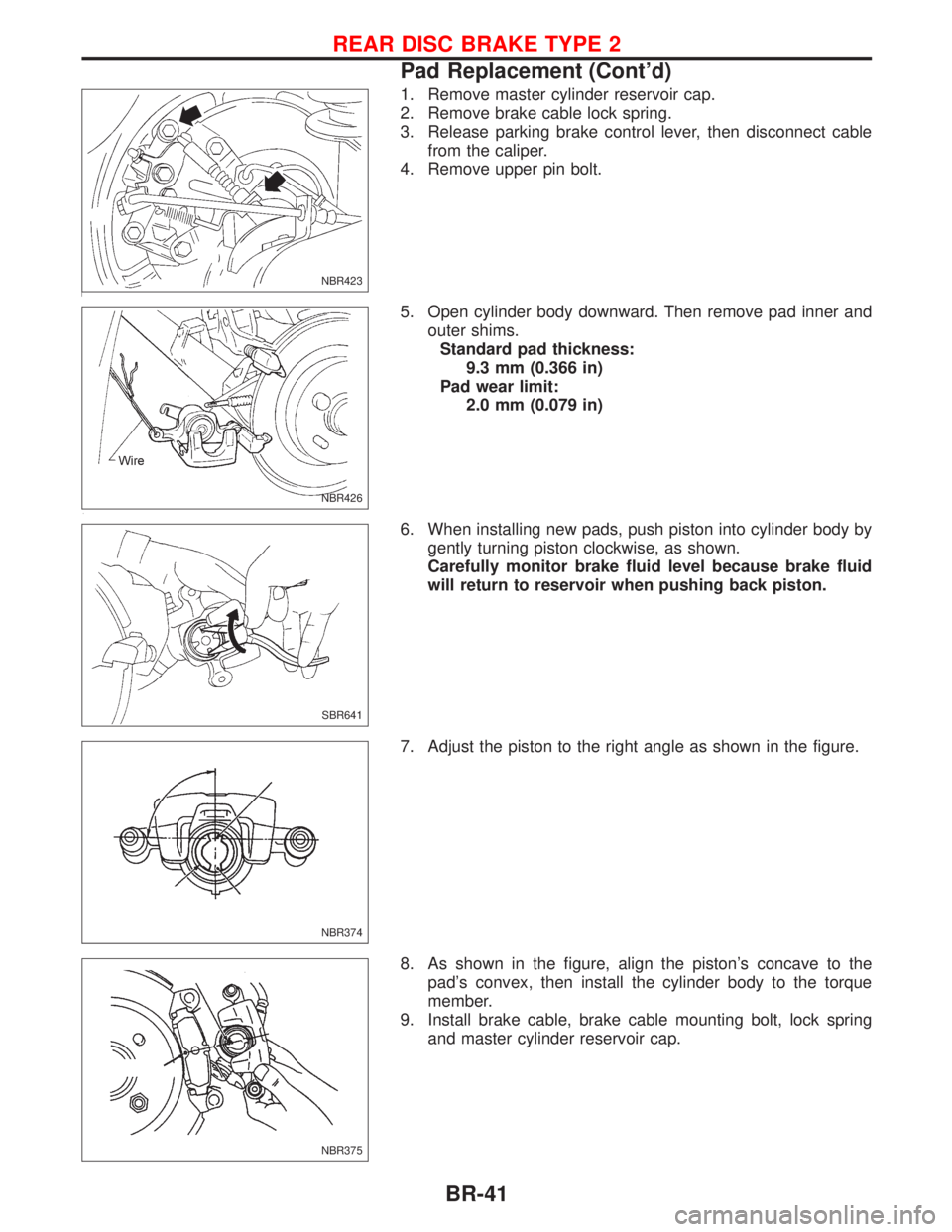

1. Remove master cylinder reservoir cap.

2. Remove brake cable lock spring.

3. Release parking brake control lever, then disconnect cable

from the caliper.

4. Remove upper pin bolt.

5. Open cylinder body downward. Then remove pad inner and

outer shims.

Standard pad thickness:

9.3 mm (0.366 in)

Pad wear limit:

2.0 mm (0.079 in)

6. When installing new pads, push piston into cylinder body by

gently turning piston clockwise, as shown.

Carefully monitor brake fluid level because brake fluid

will return to reservoir when pushing back piston.

7. Adjust the piston to the right angle as shown in the figure.

8. As shown in the figure, align the piston's concave to the

pad's convex, then install the cylinder body to the torque

member.

9. Install brake cable, brake cable mounting bolt, lock spring

and master cylinder reservoir cap.

NBR423

NBR426

SBR641

NBR374

NBR375

REAR DISC BRAKE TYPE 2

Pad Replacement (Cont'd)

BR-41

Page 332 of 2267

pA

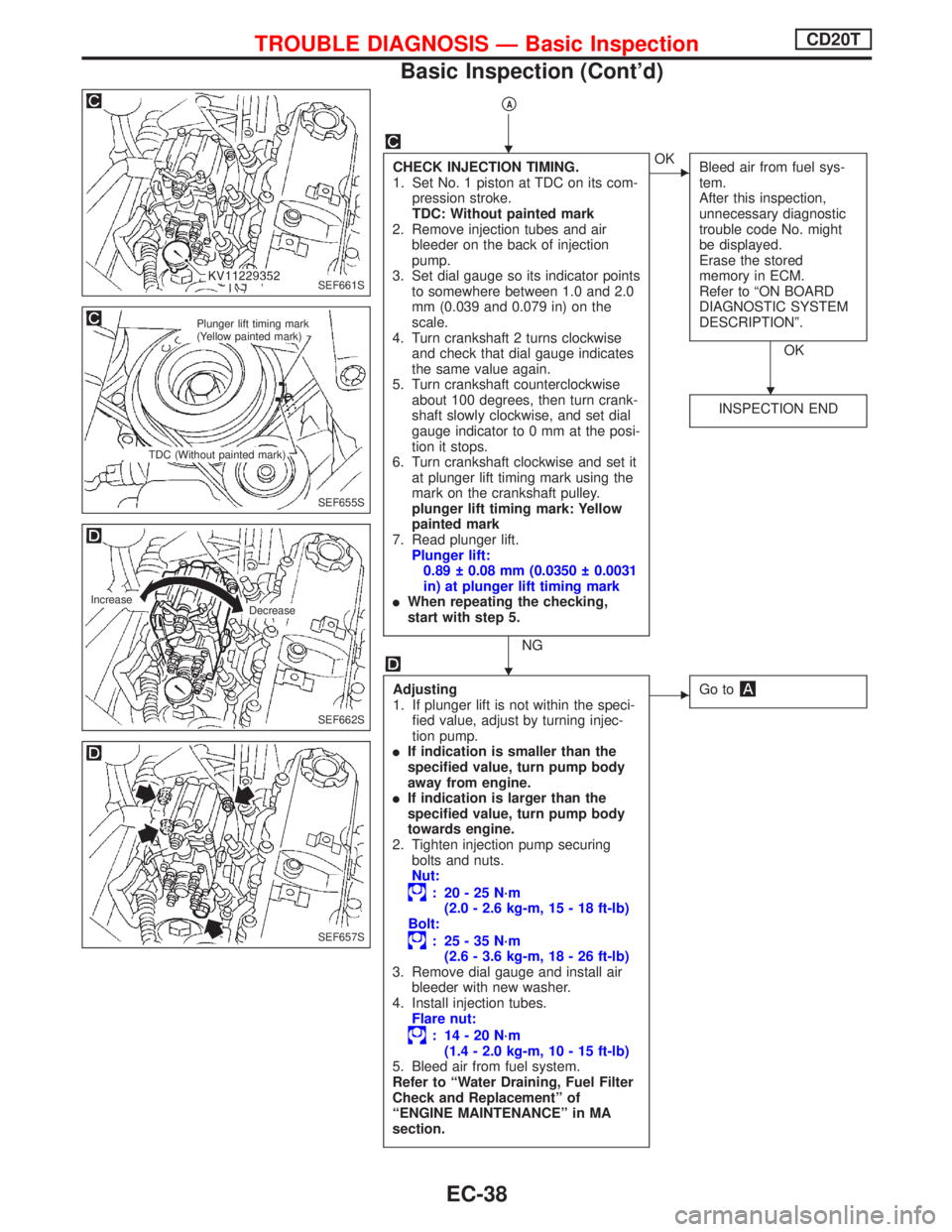

CHECK INJECTION TIMING.

1. Set No. 1 piston at TDC on its com-

pression stroke.

TDC: Without painted mark

2. Remove injection tubes and air

bleeder on the back of injection

pump.

3. Set dial gauge so its indicator points

to somewhere between 1.0 and 2.0

mm (0.039 and 0.079 in) on the

scale.

4. Turn crankshaft 2 turns clockwise

and check that dial gauge indicates

the same value again.

5. Turn crankshaft counterclockwise

about 100 degrees, then turn crank-

shaft slowly clockwise, and set dial

gauge indicator to 0 mm at the posi-

tion it stops.

6. Turn crankshaft clockwise and set it

at plunger lift timing mark using the

mark on the crankshaft pulley.

plunger lift timing mark: Yellow

painted mark

7. Read plunger lift.

Plunger lift:

0.89 0.08 mm (0.0350 0.0031

in) at plunger lift timing mark

lWhen repeating the checking,

start with step 5.

NG

EOK

Bleed air from fuel sys-

tem.

After this inspection,

unnecessary diagnostic

trouble code No. might

be displayed.

Erase the stored

memory in ECM.

Refer to ªON BOARD

DIAGNOSTIC SYSTEM

DESCRIPTIONº.

OK

INSPECTION END

Adjusting

1. If plunger lift is not within the speci-

fied value, adjust by turning injec-

tion pump.

lIf indication is smaller than the

specified value, turn pump body

away from engine.

lIf indication is larger than the

specified value, turn pump body

towards engine.

2. Tighten injection pump securing

bolts and nuts.

Nut:

: 20-25N´m

(2.0 - 2.6 kg-m, 15 - 18 ft-lb)

Bolt:

: 25-35N´m

(2.6 - 3.6 kg-m, 18 - 26 ft-lb)

3. Remove dial gauge and install air

bleeder with new washer.

4. Install injection tubes.

Flare nut:

: 14-20N´m

(1.4 - 2.0 kg-m, 10 - 15 ft-lb)

5. Bleed air from fuel system.

Refer to ªWater Draining, Fuel Filter

Check and Replacementº of

ªENGINE MAINTENANCEº in MA

section.

EGo to

SEF661S

SEF655S

Plunger lift timing mark

(Yellow painted mark)

TDC (Without painted mark)

SEF662S

Increase

Decrease

SEF657S

H

H

H

TROUBLE DIAGNOSIS Ð Basic InspectionCD20T

Basic Inspection (Cont'd)

EC-38

Page 515 of 2267

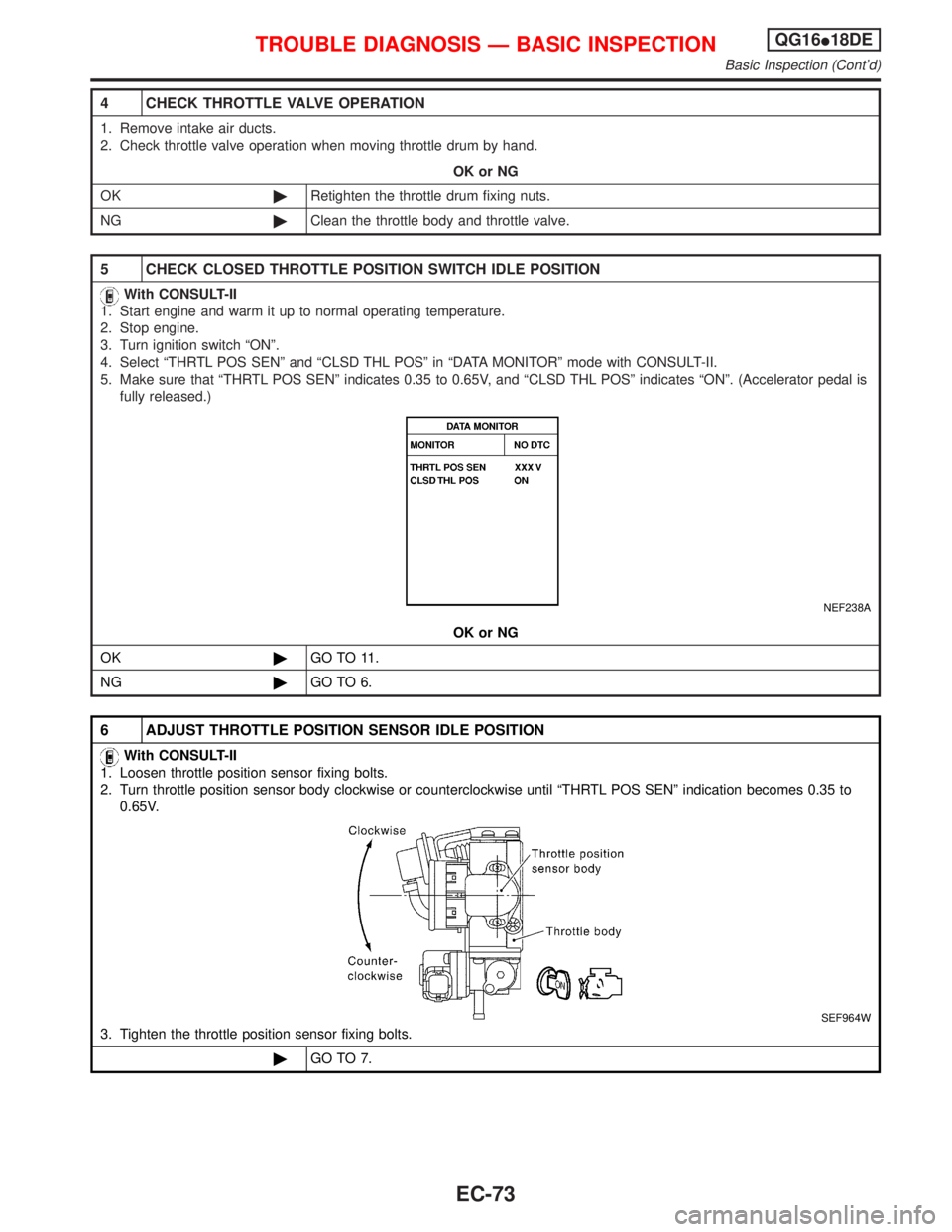

4 CHECK THROTTLE VALVE OPERATION

1. Remove intake air ducts.

2. Check throttle valve operation when moving throttle drum by hand.

OK or NG

OK©Retighten the throttle drum fixing nuts.

NG©Clean the throttle body and throttle valve.

5 CHECK CLOSED THROTTLE POSITION SWITCH IDLE POSITION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Select ªTHRTL POS SENº and ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

5. Make sure that ªTHRTL POS SENº indicates 0.35 to 0.65V, and ªCLSD THL POSº indicates ªONº. (Accelerator pedal is

fully released.)

NEF238A

OK or NG

OK©GO TO 11.

NG©GO TO 6.

6 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to

0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG16I18DE

Basic Inspection (Cont'd)

EC-73

Page 517 of 2267

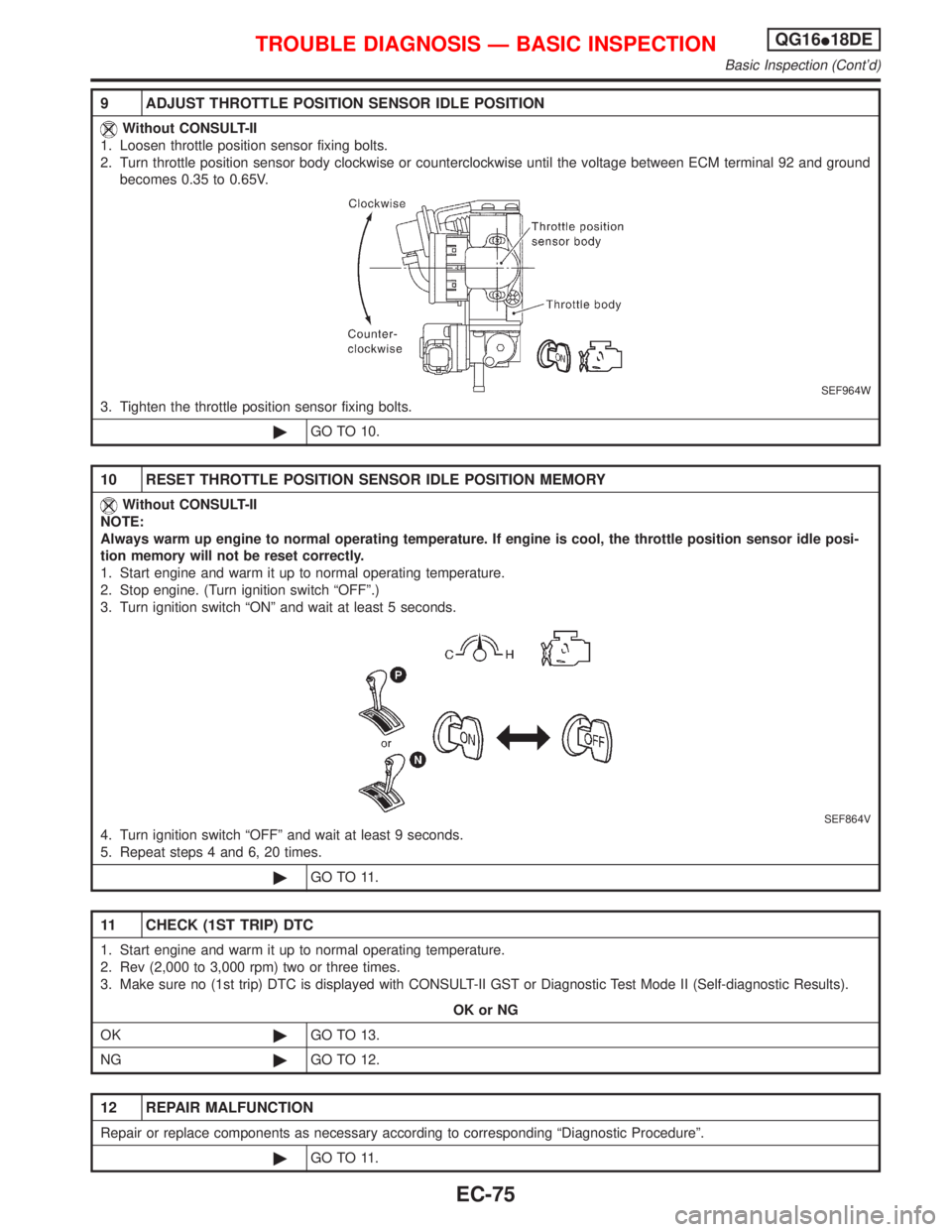

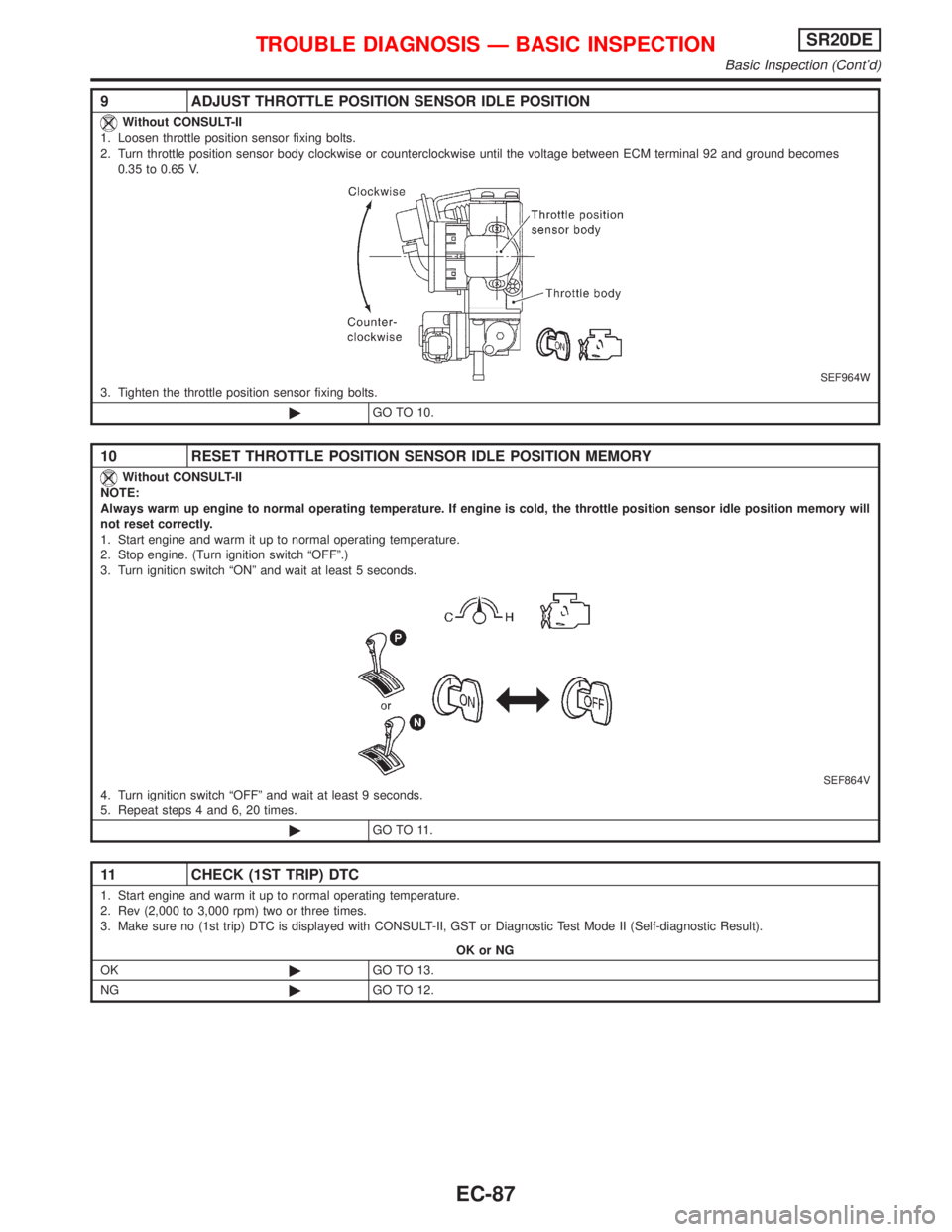

9 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until the voltage between ECM terminal 92 and ground

becomes 0.35 to 0.65V.

SEF964W

3. Tighten the throttle position sensor fixing bolts.

©GO TO 10.

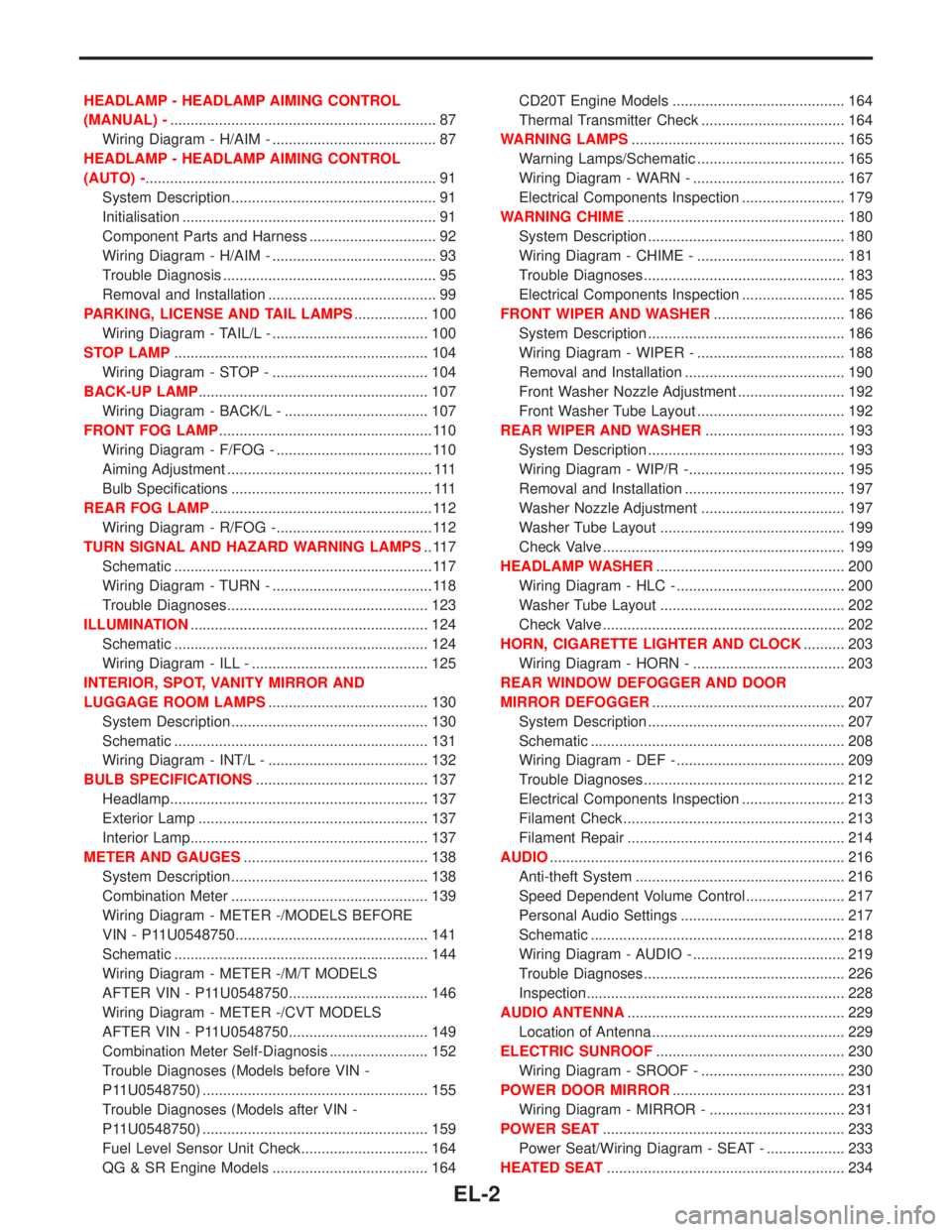

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cool, the throttle position sensor idle posi-

tion memory will not be reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Stop engine. (Turn ignition switch ªOFFº.)

3. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V

4. Turn ignition switch ªOFFº and wait at least 9 seconds.

5. Repeat steps 4 and 6, 20 times.

©GO TO 11.

11 CHECK (1ST TRIP) DTC

1. Start engine and warm it up to normal operating temperature.

2. Rev (2,000 to 3,000 rpm) two or three times.

3. Make sure no (1st trip) DTC is displayed with CONSULT-II GST or Diagnostic Test Mode II (Self-diagnostic Results).

OK or NG

OK©GO TO 13.

NG©GO TO 12.

12 REPAIR MALFUNCTION

Repair or replace components as necessary according to corresponding ªDiagnostic Procedureº.

©GO TO 11.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG16I18DE

Basic Inspection (Cont'd)

EC-75

Page 885 of 2267

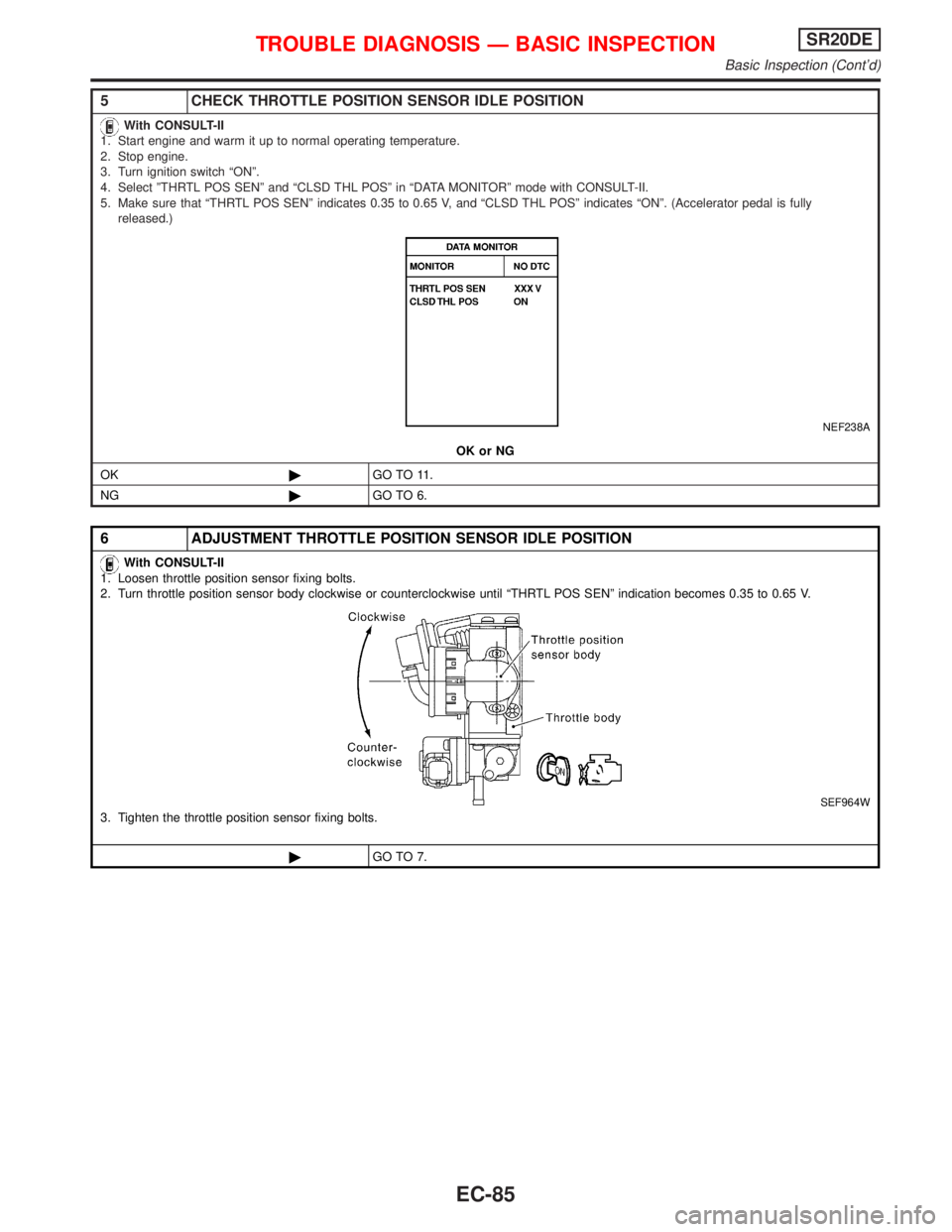

5 CHECK THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Turn ignition switch ªONº.

4. Select ºTHRTL POS SENº and ªCLSD THL POSº in ªDATA MONITORº mode with CONSULT-II.

5. Make sure that ªTHRTL POS SENº indicates 0.35 to 0.65 V, and ªCLSD THL POSº indicates ªONº. (Accelerator pedal is fully

released.)

NEF238A

OK or NG

OK©GO TO 11.

NG©GO TO 6.

6 ADJUSTMENT THROTTLE POSITION SENSOR IDLE POSITION

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until ªTHRTL POS SENº indication becomes 0.35 to 0.65 V.

SEF964W3. Tighten the throttle position sensor fixing bolts.

©GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-85

Page 887 of 2267

9 ADJUST THROTTLE POSITION SENSOR IDLE POSITION

Without CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Turn throttle position sensor body clockwise or counterclockwise until the voltage between ECM terminal 92 and ground becomes

0.35 to 0.65 V.

SEF964W3. Tighten the throttle position sensor fixing bolts.

©GO TO 10.

10 RESET THROTTLE POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

NOTE:

Always warm up engine to normal operating temperature. If engine is cold, the throttle position sensor idle position memory will

not reset correctly.

1. Start engine and warm it up to normal operating temperature.

2. Stop engine. (Turn ignition switch ªOFFº.)

3. Turn ignition switch ªONº and wait at least 5 seconds.

SEF864V4. Turn ignition switch ªOFFº and wait at least 9 seconds.

5. Repeat steps 4 and 6, 20 times.

©GO TO 11.

11 CHECK (1ST TRIP) DTC

1. Start engine and warm it up to normal operating temperature.

2. Rev (2,000 to 3,000 rpm) two or three times.

3. Make sure no (1st trip) DTC is displayed with CONSULT-II, GST or Diagnostic Test Mode II (Self-diagnostic Result).

OK or NG

OK©GO TO 13.

NG©GO TO 12.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONSR20DE

Basic Inspection (Cont'd)

EC-87

Page 1134 of 2267

HEADLAMP - HEADLAMP AIMING CONTROL

(MANUAL) -................................................................. 87

Wiring Diagram - H/AIM - ........................................ 87

HEADLAMP - HEADLAMP AIMING CONTROL

(AUTO) -....................................................................... 91

System Description .................................................. 91

Initialisation .............................................................. 91

Component Parts and Harness ............................... 92

Wiring Diagram - H/AIM - ........................................ 93

Trouble Diagnosis .................................................... 95

Removal and Installation ......................................... 99

PARKING, LICENSE AND TAIL LAMPS.................. 100

Wiring Diagram - TAIL/L - ...................................... 100

STOP LAMP.............................................................. 104

Wiring Diagram - STOP - ...................................... 104

BACK-UP LAMP........................................................ 107

Wiring Diagram - BACK/L - ................................... 107

FRONT FOG LAMP.................................................... 110

Wiring Diagram - F/FOG - ...................................... 110

Aiming Adjustment .................................................. 111

Bulb Specifications ................................................. 111

REAR FOG LAMP...................................................... 112

Wiring Diagram - R/FOG -...................................... 112

TURN SIGNAL AND HAZARD WARNING LAMPS.. 117

Schematic ............................................................... 117

Wiring Diagram - TURN - ....................................... 118

Trouble Diagnoses................................................. 123

ILLUMINATION.......................................................... 124

Schematic .............................................................. 124

Wiring Diagram - ILL - ........................................... 125

INTERIOR, SPOT, VANITY MIRROR AND

LUGGAGE ROOM LAMPS....................................... 130

System Description ................................................ 130

Schematic .............................................................. 131

Wiring Diagram - INT/L - ....................................... 132

BULB SPECIFICATIONS.......................................... 137

Headlamp............................................................... 137

Exterior Lamp ........................................................ 137

Interior Lamp.......................................................... 137

METER AND GAUGES............................................. 138

System Description ................................................ 138

Combination Meter ................................................ 139

Wiring Diagram - METER -/MODELS BEFORE

VIN - P11U0548750............................................... 141

Schematic .............................................................. 144

Wiring Diagram - METER -/M/T MODELS

AFTER VIN - P11U0548750.................................. 146

Wiring Diagram - METER -/CVT MODELS

AFTER VIN - P11U0548750.................................. 149

Combination Meter Self-Diagnosis ........................ 152

Trouble Diagnoses (Models before VIN -

P11U0548750) ....................................................... 155

Trouble Diagnoses (Models after VIN -

P11U0548750) ....................................................... 159

Fuel Level Sensor Unit Check............................... 164

QG & SR Engine Models ...................................... 164CD20T Engine Models .......................................... 164

Thermal Transmitter Check ................................... 164

WARNING LAMPS.................................................... 165

Warning Lamps/Schematic .................................... 165

Wiring Diagram - WARN - ..................................... 167

Electrical Components Inspection ......................... 179

WARNING CHIME..................................................... 180

System Description ................................................ 180

Wiring Diagram - CHIME - .................................... 181

Trouble Diagnoses................................................. 183

Electrical Components Inspection ......................... 185

FRONT WIPER AND WASHER................................ 186

System Description ................................................ 186

Wiring Diagram - WIPER - .................................... 188

Removal and Installation ....................................... 190

Front Washer Nozzle Adjustment .......................... 192

Front Washer Tube Layout .................................... 192

REAR WIPER AND WASHER.................................. 193

System Description ................................................ 193

Wiring Diagram - WIP/R -...................................... 195

Removal and Installation ....................................... 197

Washer Nozzle Adjustment ................................... 197

Washer Tube Layout ............................................. 199

Check Valve ........................................................... 199

HEADLAMP WASHER.............................................. 200

Wiring Diagram - HLC - ......................................... 200

Washer Tube Layout ............................................. 202

Check Valve ........................................................... 202

HORN, CIGARETTE LIGHTER AND CLOCK.......... 203

Wiring Diagram - HORN - ..................................... 203

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER............................................... 207

System Description ................................................ 207

Schematic .............................................................. 208

Wiring Diagram - DEF - ......................................... 209

Trouble Diagnoses................................................. 212

Electrical Components Inspection ......................... 213

Filament Check ...................................................... 213

Filament Repair ..................................................... 214

AUDIO........................................................................ 216

Anti-theft System ................................................... 216

Speed Dependent Volume Control ........................ 217

Personal Audio Settings ........................................ 217

Schematic .............................................................. 218

Wiring Diagram - AUDIO - ..................................... 219

Trouble Diagnoses................................................. 226

Inspection............................................................... 228

AUDIO ANTENNA..................................................... 229

Location of Antenna ............................................... 229

ELECTRIC SUNROOF.............................................. 230

Wiring Diagram - SROOF - ................................... 230

POWER DOOR MIRROR.......................................... 231

Wiring Diagram - MIRROR - ................................. 231

POWER SEAT........................................................... 233

Power Seat/Wiring Diagram - SEAT - ................... 233

HEATED SEAT.......................................................... 234

EL-2