warning NISSAN PRIMERA 1999 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1999, Model line: PRIMERA, Model: NISSAN PRIMERA 1999Pages: 2267, PDF Size: 35.74 MB

Page 7 of 2267

Precautions for Supplemental Restraint System

(SRS) ªAIR BAGº and ªSEAT BELT

PRE-TENSIONERº

NCAT0002The Supplemental Restraint System ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº, used along with a seat

belt, help to reduce the risk or severity of injury to the driver and front passenger in a frontal collision. The

Supplemental Restraint System consists of air bag modules (located in the center of the steering wheel and

on the instrument panel on the passenger side), seat belt pre-tensioners, a diagnosis sensor unit, warning

lamp, wiring harness and spiral cable.

In addition to the supplemental air bag modules for a frontal collision, the supplemental side air bag used along

with the seat belt helps to reduce the risk or severity of injury to the driver and front passenger in a side col-

lision. The supplemental side air bag consists of air bag modules (located in the outer side of front seats),

satellite sensor, diagnosis sensor unit (one of components of supplemental air bags for a frontal collision),

wiring harness, warning lamp (one of components of supplemental air bags for a frontal collision). Information

necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized NISSAN dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT PRE-TENSIONERº connector) can be

identified with yellow harness connector (and with yellow harness protector or yellow insulation

tape before the harness connectors).

Precautions for On Board Diagnostic (OBD)

System of CVT and Engine

NCAT0198The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

IBe sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

IBe sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

IBe sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MI to light up due to a short circuit.

IBe sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to a malfunction of the EGR system or fuel injection system, etc.

IBe sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

PrecautionsNCAT0003IBefore connecting or disconnecting the TCM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if

ignition switch is turned off.

SEF289H

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

AT-5

Page 14 of 2267

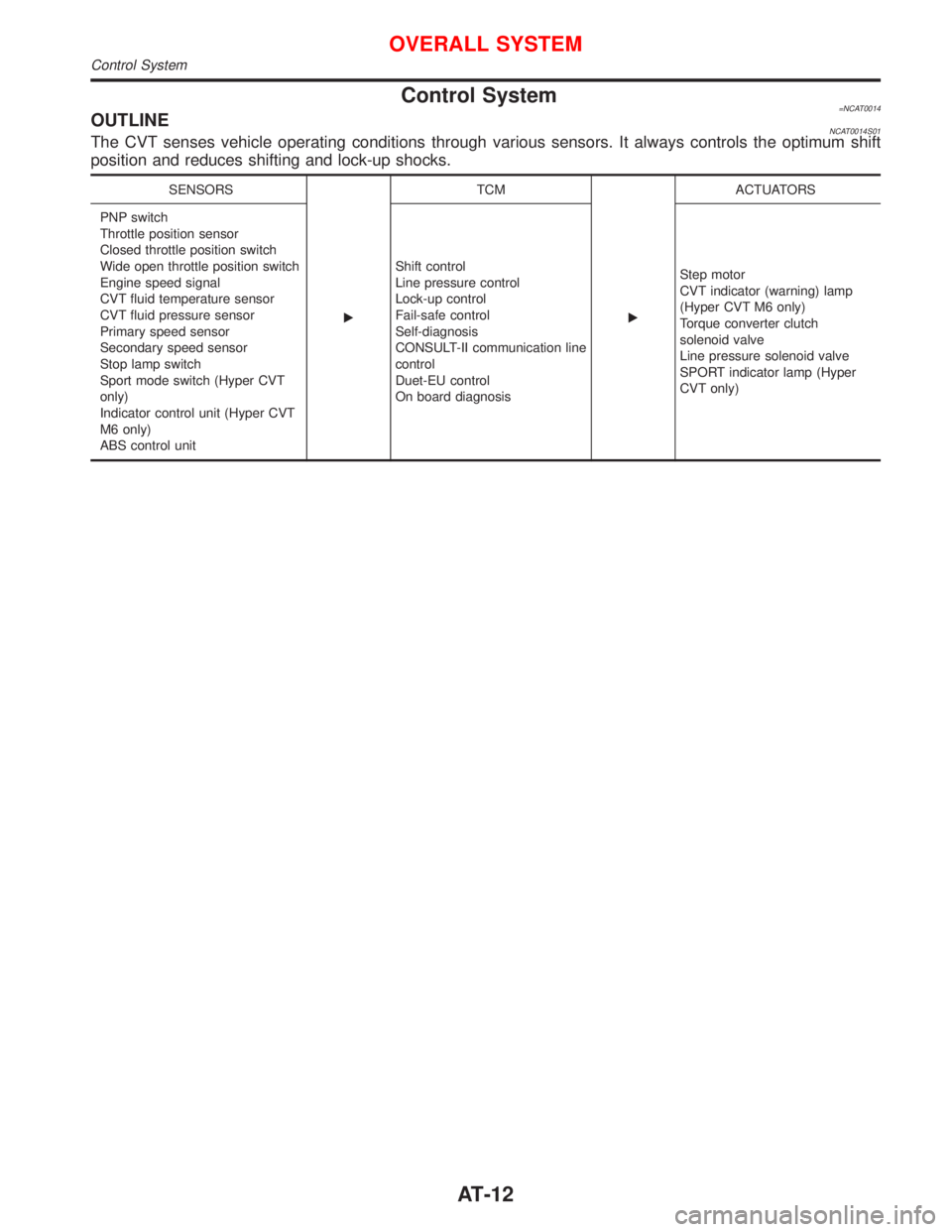

Control System=NCAT0014OUTLINENCAT0014S01The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

SENSORS

ETCM

EACTUATORS

PNP switch

Throttle position sensor

Closed throttle position switch

Wide open throttle position switch

Engine speed signal

CVT fluid temperature sensor

CVT fluid pressure sensor

Primary speed sensor

Secondary speed sensor

Stop lamp switch

Sport mode switch (Hyper CVT

only)

Indicator control unit (Hyper CVT

M6 only)

ABS control unitShift control

Line pressure control

Lock-up control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

control

Duet-EU control

On board diagnosisStep motor

CVT indicator (warning) lamp

(Hyper CVT M6 only)

Torque converter clutch

solenoid valve

Line pressure solenoid valve

SPORT indicator lamp (Hyper

CVT only)

OVERALL SYSTEM

Control System

AT-12

Page 15 of 2267

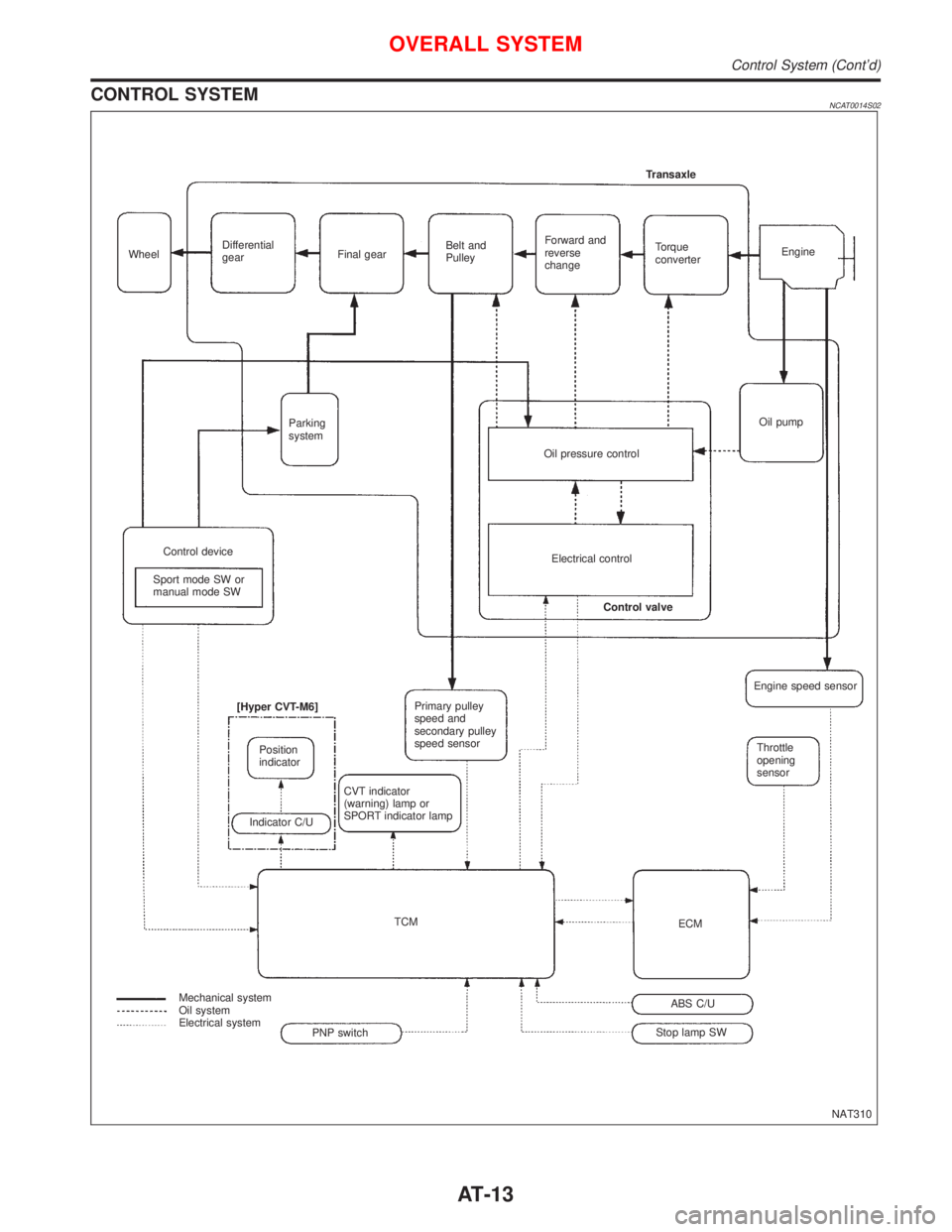

CONTROL SYSTEMNCAT0014S02

NAT310 WheelDifferential

gearFinal gearBelt and

PulleyForward and

reverse

changeTorque

converterEngine Transaxle

Oil pump

Oil pressure control Parking

system

Control device

Sport mode SW or

manual mode SWElectrical control

Control valve

Primary pulley

speed and

secondary pulley

speed sensor

CVT indicator

(warning) lamp or

SPORT indicator lamp [Hyper CVT-M6]

Position

indicator

Indicator C/U

TCM

Mechanical system

Oil system

Electrical system

Stop lamp SWABS C/UECMThrottle

opening

sensor Engine speed sensor

PNP switch

OVERALL SYSTEM

Control System (Cont'd)

AT-13

Page 16 of 2267

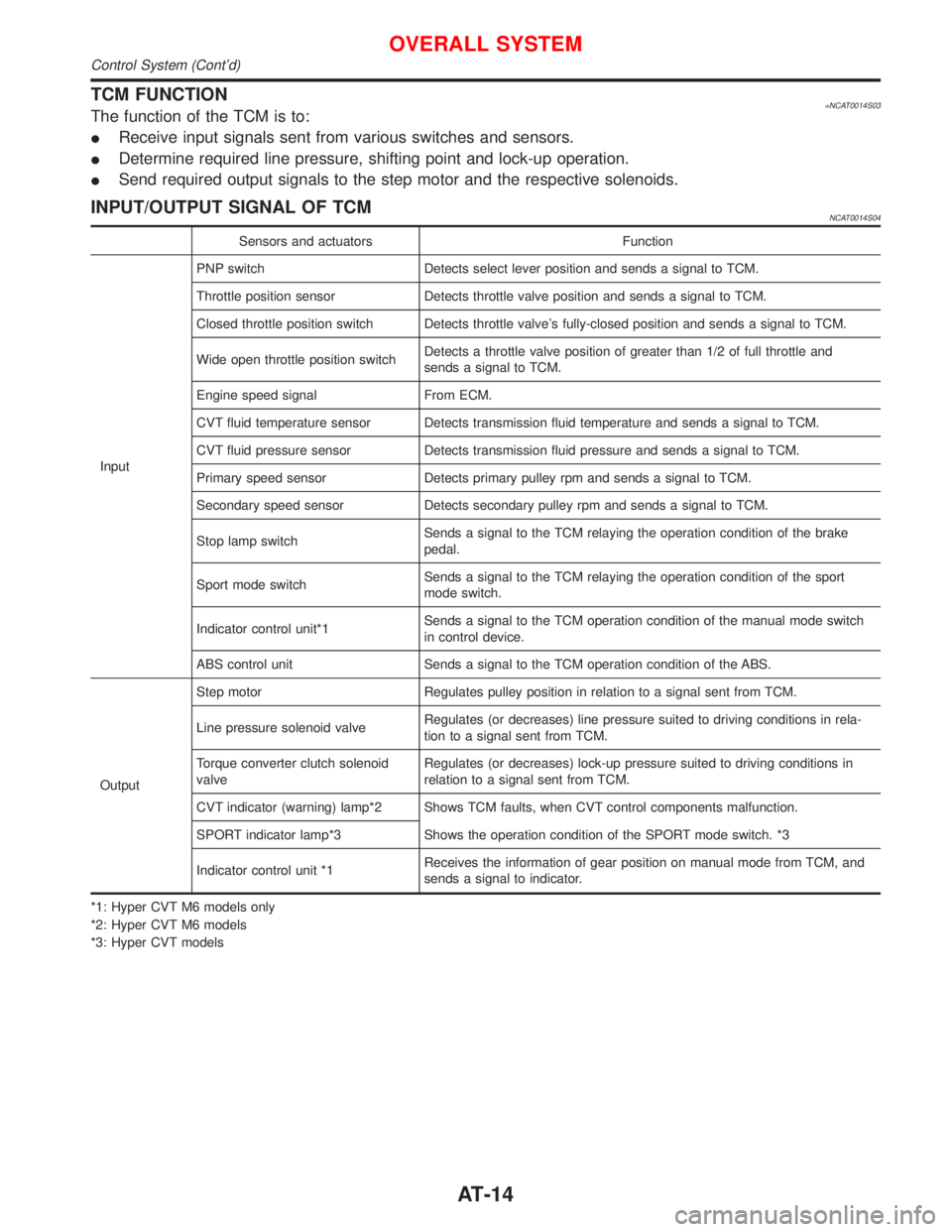

TCM FUNCTION=NCAT0014S03The function of the TCM is to:

IReceive input signals sent from various switches and sensors.

IDetermine required line pressure, shifting point and lock-up operation.

ISend required output signals to the step motor and the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCMNCAT0014S04

Sensors and actuators Function

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor Detects throttle valve position and sends a signal to TCM.

Closed throttle position switch Detects throttle valve's fully-closed position and sends a signal to TCM.

Wide open throttle position switchDetects a throttle valve position of greater than 1/2 of full throttle and

sends a signal to TCM.

Engine speed signal From ECM.

CVT fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

CVT fluid pressure sensor Detects transmission fluid pressure and sends a signal to TCM.

Primary speed sensor Detects primary pulley rpm and sends a signal to TCM.

Secondary speed sensor Detects secondary pulley rpm and sends a signal to TCM.

Stop lamp switchSends a signal to the TCM relaying the operation condition of the brake

pedal.

Sport mode switchSends a signal to the TCM relaying the operation condition of the sport

mode switch.

Indicator control unit*1Sends a signal to the TCM operation condition of the manual mode switch

in control device.

ABS control unit Sends a signal to the TCM operation condition of the ABS.

OutputStep motor Regulates pulley position in relation to a signal sent from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in

relation to a signal sent from TCM.

CVT indicator (warning) lamp*2 Shows TCM faults, when CVT control components malfunction.

SPORT indicator lamp*3 Shows the operation condition of the SPORT mode switch. *3

Indicator control unit *1Receives the information of gear position on manual mode from TCM, and

sends a signal to indicator.

*1: Hyper CVT M6 models only

*2: Hyper CVT M6 models

*3: Hyper CVT models

OVERALL SYSTEM

Control System (Cont'd)

AT-14

Page 17 of 2267

IntroductionNCAT0017The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD) performed by the TCM in combination with

the ECM. The malfunction is indicated by the MI (malfunction indicator) and is stored as a DTC in the ECM

memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the CVT indicator (warning) lamp or SPORT indi-

cator lamp. The malfunction is stored in the TCM memory. The detected items are overlapped with OBD self-

diagnostic items. For detail, refer to AT-26.

OBD Function for CVT SystemNCAT0018The ECM provides emission-related on board diagnostic (OBD) functions for the CVT system. One function

is to receive a signal from the TCM used with OBD-related parts of the CVT system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MI (malfunction indicator) on the instrument panel. Sensors, switches and

solenoid valves are used as sensing elements.

The MI automatically illuminates in Two Trip Detection Logic when a malfunction is sensed in relation to CVT

system parts.

OBD Diagnostic Trouble Code (DTC)NCAT0020HOW TO READ DTC AND 1ST TRIP DTCNCAT0020S01DTC and 1st trip DTC can be read by the following methods.

1.(

No Tools)The number of blinks of the malfunction indicator in the Diagnostic Test Mode II (Self-Di-

agnostic Results) Examples: 0705, 0710, 0715, 0720, etc. For details, refer to EC section [ªMalfunction

Indicator (MI)º, ªON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONº].

These DTCs are controlled by NISSAN.

2.(

with CONSULT-II orGST)CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0710,

P0720, P0725, etc.

These DTCs are prescribed by ISO15031-6.

(CONSULT-II also displays the malfunctioning component or system.)

I1st trip DTC No. is the same as DTC No.

IOutput of the diagnostic trouble code indicates that the indicated circuit has a malfunction.

However, in case of the Mode II and GST they do not indicate whether the malfunction is still

occurring or occurred in the past and returned to normal.

CONSULT-II can identify them as shown below. Therefore, using CONSULT-II (if available) is rec-

ommended.

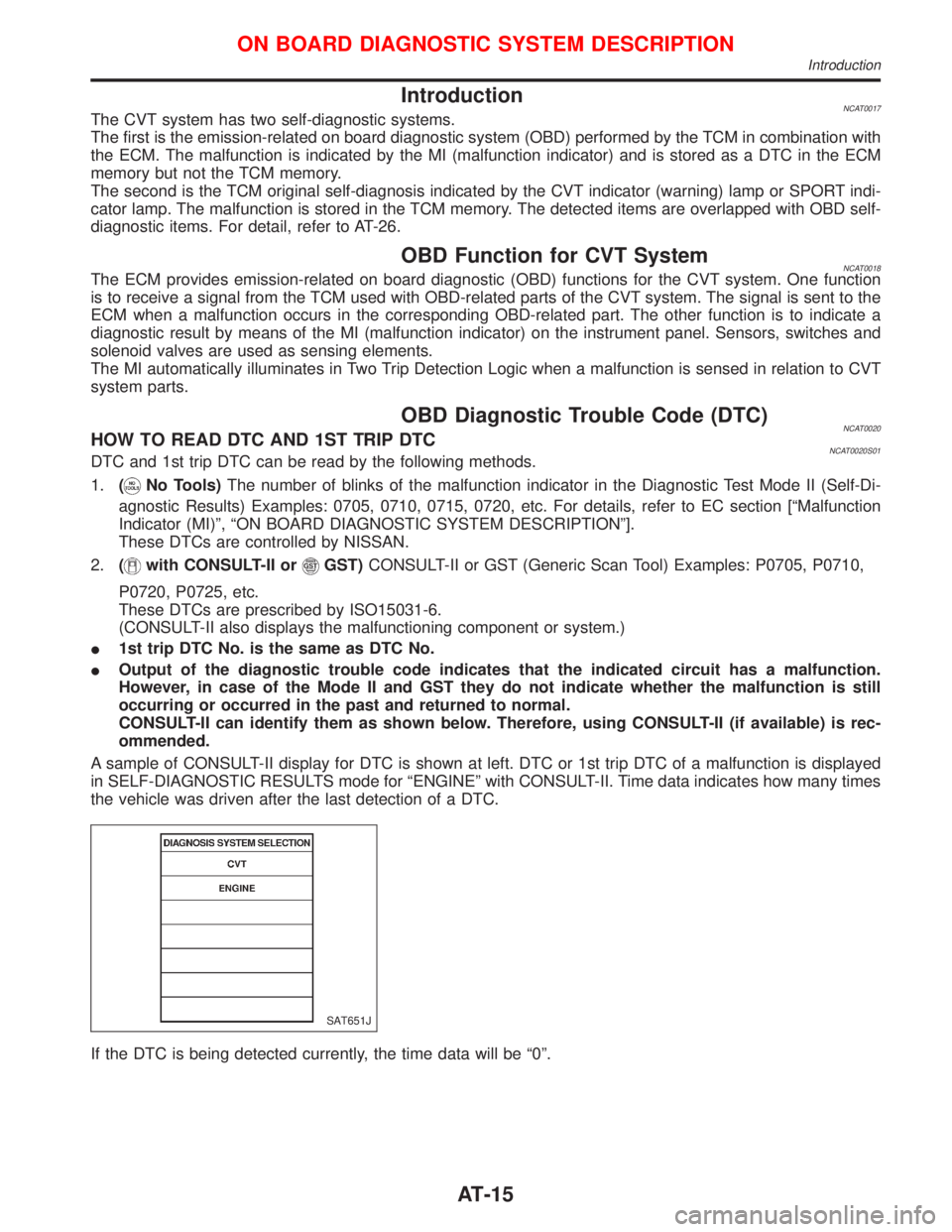

A sample of CONSULT-II display for DTC is shown at left. DTC or 1st trip DTC of a malfunction is displayed

in SELF-DIAGNOSTIC RESULTS mode for ªENGINEº with CONSULT-II. Time data indicates how many times

the vehicle was driven after the last detection of a DTC.

If the DTC is being detected currently, the time data will be ª0º.

SAT651J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Introduction

AT-15

Page 20 of 2267

HOW TO ERASE DTC (WITH GST)NCAT0020S041. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Perform ªOBD SELF-DIAGNOSTIC PROCEDURE (No Tools)º. Refer to AT-25. (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Select Mode 4 with Generic Scan Tool (GST). For details, refer to EC section ªGeneric Scan Tool (GST)º.

HOW TO ERASE DTC (NO TOOLS)NCAT0020S051. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Perform ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º. Refer to AT-25. (The engine warm-up step

can be skipped when performing the diagnosis only to erase the DTC.)

3. Change the diagnostic test mode from Mode II to Mode I by turning the mode selector on the ECM.

Refer to EC section ªHOW TO SWITCH DIAGNOSTIC TEST MODESº.

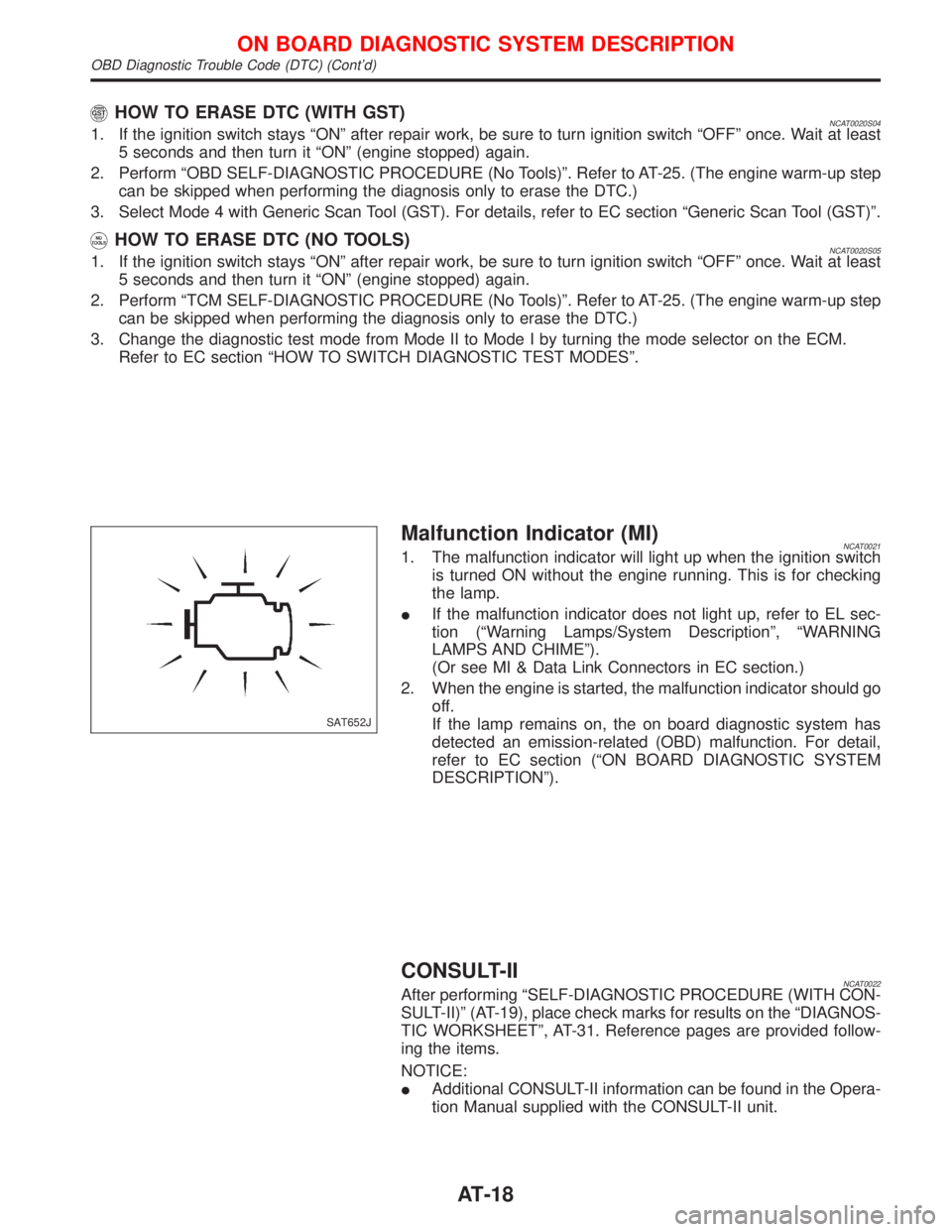

Malfunction Indicator (MI)NCAT00211. The malfunction indicator will light up when the ignition switch

is turned ON without the engine running. This is for checking

the lamp.

IIf the malfunction indicator does not light up, refer to EL sec-

tion (ªWarning Lamps/System Descriptionº, ªWARNING

LAMPS AND CHIMEº).

(Or see MI & Data Link Connectors in EC section.)

2. When the engine is started, the malfunction indicator should go

off.

If the lamp remains on, the on board diagnostic system has

detected an emission-related (OBD) malfunction. For detail,

refer to EC section (ªON BOARD DIAGNOSTIC SYSTEM

DESCRIPTIONº).

CONSULT-IINCAT0022After performing ªSELF-DIAGNOSTIC PROCEDURE (WITH CON-

SULT-II)º (AT-19), place check marks for results on the ªDIAGNOS-

TIC WORKSHEETº, AT-31. Reference pages are provided follow-

ing the items.

NOTICE:

IAdditional CONSULT-II information can be found in the Opera-

tion Manual supplied with the CONSULT-II unit.

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

OBD Diagnostic Trouble Code (DTC) (Cont'd)

AT-18

Page 27 of 2267

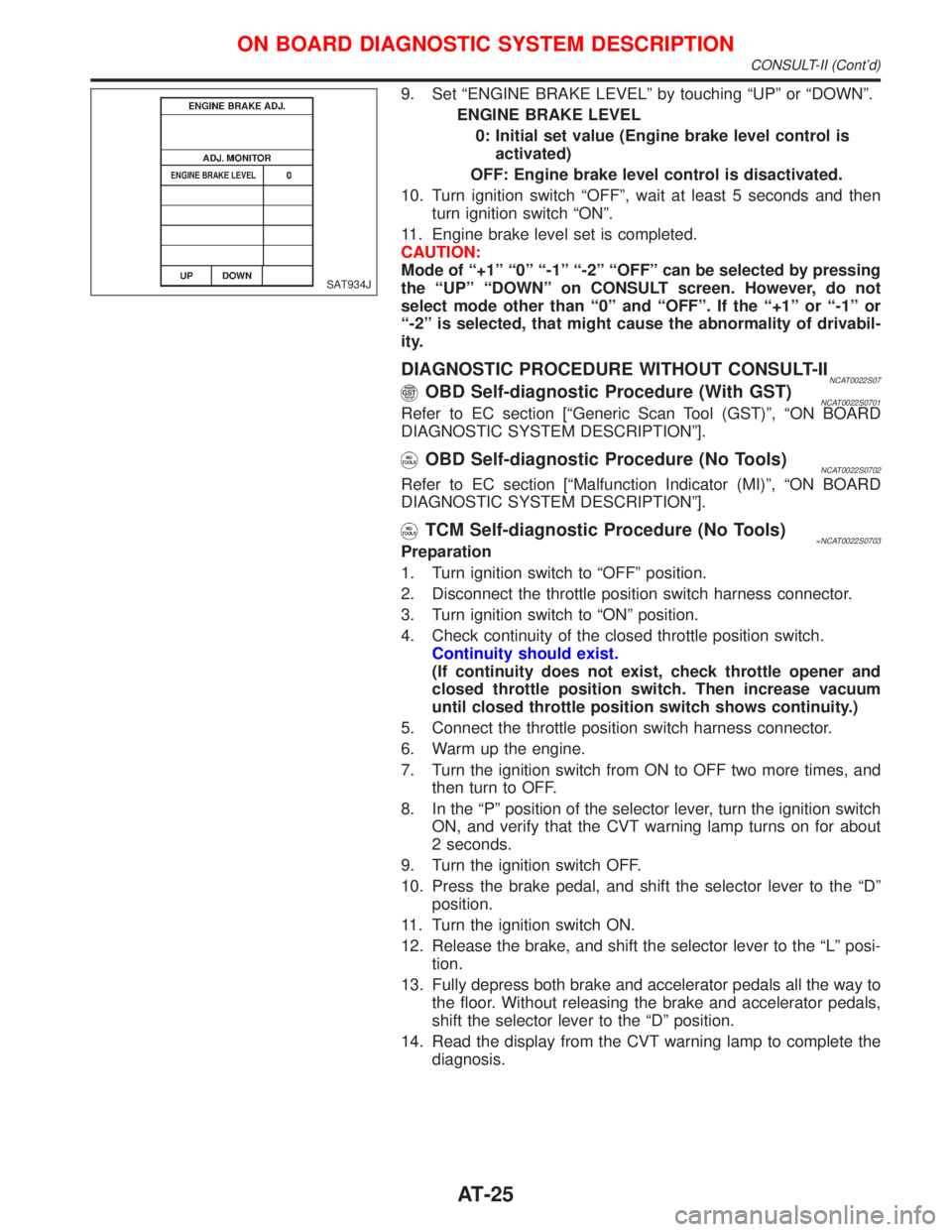

9. Set ªENGINE BRAKE LEVELº by touching ªUPº or ªDOWNº.

ENGINE BRAKE LEVEL

0: Initial set value (Engine brake level control is

activated)

OFF: Engine brake level control is disactivated.

10. Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ignition switch ªONº.

11. Engine brake level set is completed.

CAUTION:

Mode of ª+1º ª0º ª-1º ª-2º ªOFFº can be selected by pressing

the ªUPº ªDOWNº on CONSULT screen. However, do not

select mode other than ª0º and ªOFFº. If the ª+1º or ª-1º or

ª-2º is selected, that might cause the abnormality of drivabil-

ity.

DIAGNOSTIC PROCEDURE WITHOUT CONSULT-IINCAT0022S07OBD Self-diagnostic Procedure (With GST)NCAT0022S0701Refer to EC section [ªGeneric Scan Tool (GST)º, ªON BOARD

DIAGNOSTIC SYSTEM DESCRIPTIONº].

OBD Self-diagnostic Procedure (No Tools)NCAT0022S0702

Refer to EC section [ªMalfunction Indicator (MI)º, ªON BOARD

DIAGNOSTIC SYSTEM DESCRIPTIONº].

TCM Self-diagnostic Procedure (No Tools)=NCAT0022S0703Preparation

1. Turn ignition switch to ªOFFº position.

2. Disconnect the throttle position switch harness connector.

3. Turn ignition switch to ªONº position.

4. Check continuity of the closed throttle position switch.

Continuity should exist.

(If continuity does not exist, check throttle opener and

closed throttle position switch. Then increase vacuum

until closed throttle position switch shows continuity.)

5. Connect the throttle position switch harness connector.

6. Warm up the engine.

7. Turn the ignition switch from ON to OFF two more times, and

then turn to OFF.

8. In the ªPº position of the selector lever, turn the ignition switch

ON, and verify that the CVT warning lamp turns on for about

2 seconds.

9. Turn the ignition switch OFF.

10. Press the brake pedal, and shift the selector lever to the ªDº

position.

11. Turn the ignition switch ON.

12. Release the brake, and shift the selector lever to the ªLº posi-

tion.

13. Fully depress both brake and accelerator pedals all the way to

the floor. Without releasing the brake and accelerator pedals,

shift the selector lever to the ªDº position.

14. Read the display from the CVT warning lamp to complete the

diagnosis.

SAT934J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

AT-25

Page 32 of 2267

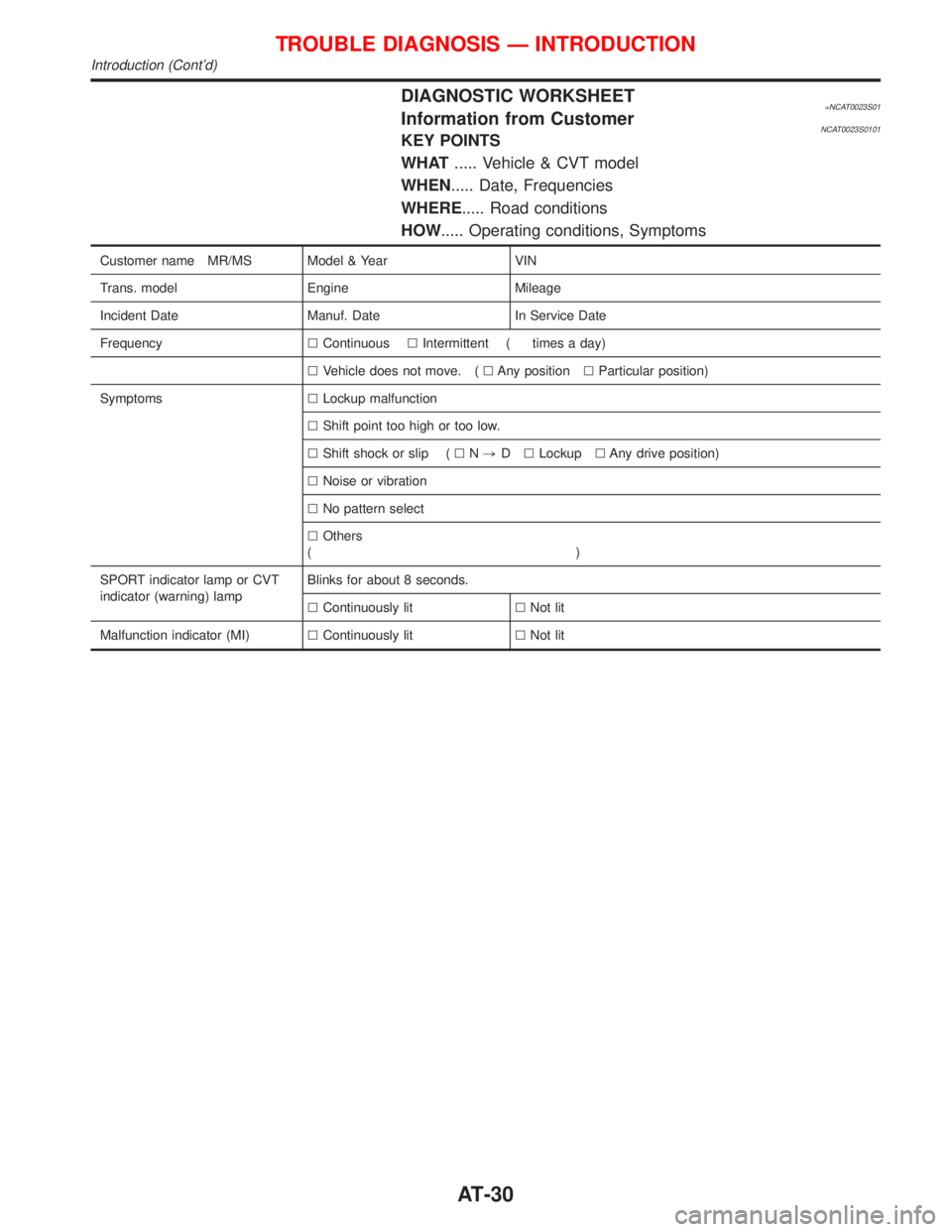

DIAGNOSTIC WORKSHEET=NCAT0023S01Information from CustomerNCAT0023S0101KEY POINTS

WHAT..... Vehicle & CVT model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. model Engine Mileage

Incident Date Manuf. Date In Service Date

FrequencylContinuouslIntermittent ( times a day)

lVehicle does not move. (lAny positionlParticular position)

SymptomslLockup malfunction

lShift point too high or too low.

lShift shock or slip (lN,DlLockuplAny drive position)

lNoise or vibration

lNo pattern select

lOthers

()

SPORT indicator lamp or CVT

indicator (warning) lampBlinks for about 8 seconds.

lContinuously litlNot lit

Malfunction indicator (MI)lContinuously litlNot lit

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction (Cont'd)

AT-30

Page 112 of 2267

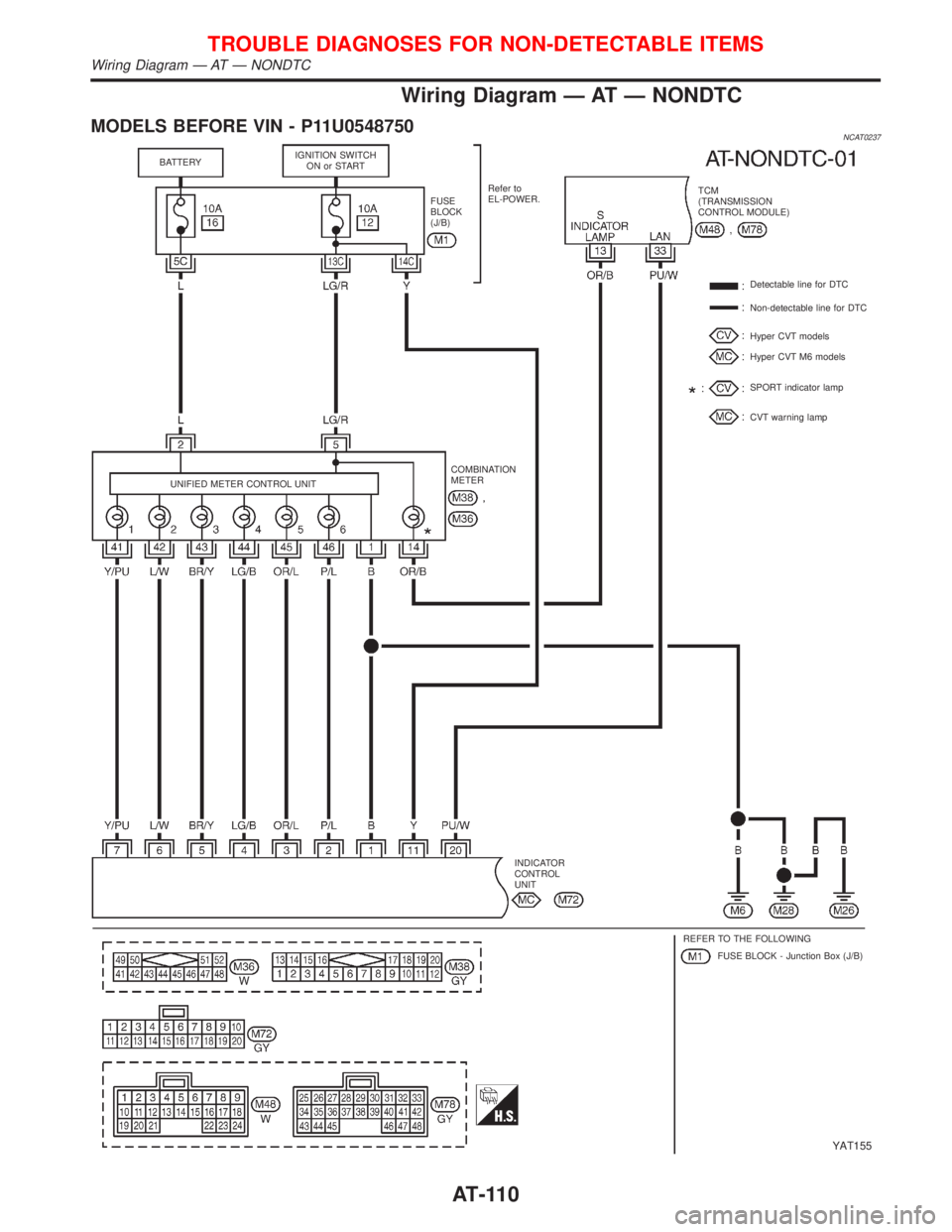

Wiring Diagram Ð AT Ð NONDTC

MODELS BEFORE VIN - P11U0548750NCAT0237

YAT155

BATTERYIGNITION SWITCH

ON or START

FUSE

BLOCK

(J/B)Refer to

EL-POWER.TCM

(TRANSMISSION

CONTROL MODULE)

Detectable line for DTC

Non-detectable line for DTC

Hyper CVT models

Hyper CVT M6 models

SPORT indicator lamp

CVT warning lamp

UNIFIED METER CONTROL UNITCOMBINATION

METER

INDICATOR

CONTROL

UNIT

REFER TO THE FOLLOWING

FUSE BLOCK - Junction Box (J/B)

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Wiring Diagram Ð AT Ð NONDTC

AT-110

Page 124 of 2267

Inspection................................................................. 36

Assembly ................................................................. 37

Installation ................................................................ 39

REAR DISC BRAKE TYPE 2...................................... 40

Component .............................................................. 40

Pad Replacement .................................................... 40

Removal ................................................................... 42

Disassembly............................................................. 42

Inspection................................................................. 42

Installation ................................................................ 43

REAR DRUM BRAKE................................................. 44

Components............................................................. 44

Removal ................................................................... 44

Inspection - Wheel Cylinder .................................... 45

Wheel Cylinder Overhaul......................................... 46

Inspection - Drum .................................................... 46

Inspection - Lining ................................................... 46

Installation ................................................................ 46

PARKING BRAKE CONTROL.................................... 48

Removal and Installation ......................................... 48

Inspection................................................................. 49

Adjustment ............................................................... 49

ANTI-LOCK BRAKE SYSTEM.................................... 50

Purpose.................................................................... 50

Operation ................................................................. 50

ABS Hydraulic Circuit .............................................. 50

System Components ............................................... 51

System Description .................................................. 51

Removal and Installation ......................................... 53

TROUBLE DIAGNOSES............................................. 57

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ................................................ 57

Preliminary Check.................................................... 59

Component Parts and Harness Connector

Location ................................................................... 60

Circuit Diagram for Quick Pinpoint Check............... 61Wiring Diagram - ABS - ........................................... 62

Self-diagnosis (Only models with data link

connector terminal No. 8) ........................................ 67

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 69

CONSULT-II ............................................................. 69

CONSULT-II Inspection Procedure.......................... 70

Ground Circuit Check .............................................. 75

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION............................................................. 76

Malfunction Code/Symptom Chart........................... 76

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC

ITEMS........................................................................... 77

Diagnostic Procedure 1 (Wheel sensor or rotor) .... 77

Diagnostic Procedure 2 (ABS actuator solenoid

valve and solenoid valve relay) ............................... 79

Diagnostic Procedure 3 (Motor Relay or motor) ..... 81

Diagnostic Procedure 4 (Low voltage) .................... 83

Diagnostic Procedure 5 (Control unit) ..................... 84

TROUBLE DIAGNOSES FOR SYMPTOMS............... 85

Diagnostic Procedure 6 (ABS works frequently) ..... 85

Diagnostic Procedure 7 (Unexpected pedal

action) ...................................................................... 86

Diagnostic Procedure 8 (Long stopping distance) .. 86

Diagnostic Procedure 9 (ABS does not work.) ....... 87

Diagnostic Procedure 10 (Pedal vibration and

noise) ....................................................................... 87

Diagnostic Procedure 11 (ABS Warning lamp

does not come on when ignition switch is turned

ON) .......................................................................... 88

Diagnostic Procedure 12 (Warning lamp stays on

when ignition switch is turned ON).......................... 90

SERVICE DATA AND SPECIFICATIONS (SDS)........ 91

General Specifications ............................................. 91

Inspection and Adjustment ...................................... 92

When you read wiring diagrams:

lRead GI section, ªHOW TO READ WIRING DIAGRAMSº.

lSee EL section, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

lSee EL section for NATS information and wiring diagram.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENTº.

BR-2