check engine NISSAN PULSAR 1987 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 125 of 238

Clutch 125

(3) Remove the nuts retaining the outer cable

flange to the vehicle bulkhead.

(4) Working inside the ve hicle, disconnect the

inner cable from the top of the clutch pedal. (5) Pull the clutch cable through the bulkhead

into the engine compartment. (6) Release the clip retaining the centre of the

clutch cable and remove the cable from the vehicle. (7) Check the inner cable for fraying, wear and

damage. Check the outer cable for kinks, wear and

damage. If necessary, renew the cable assembly. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Lubricate the inner cable ends with lithium

base molybdenum disulphide grease prior to installa-

tion. (2) Tighten the nuts retaining the outer cable

flange to a torque of 11 Nm. (3) Check and if necessary , adjust the clutch

pedal height and free play as described under the

heading Clutch Adjustments.

6. CLUTCH ADJUSTMENTS

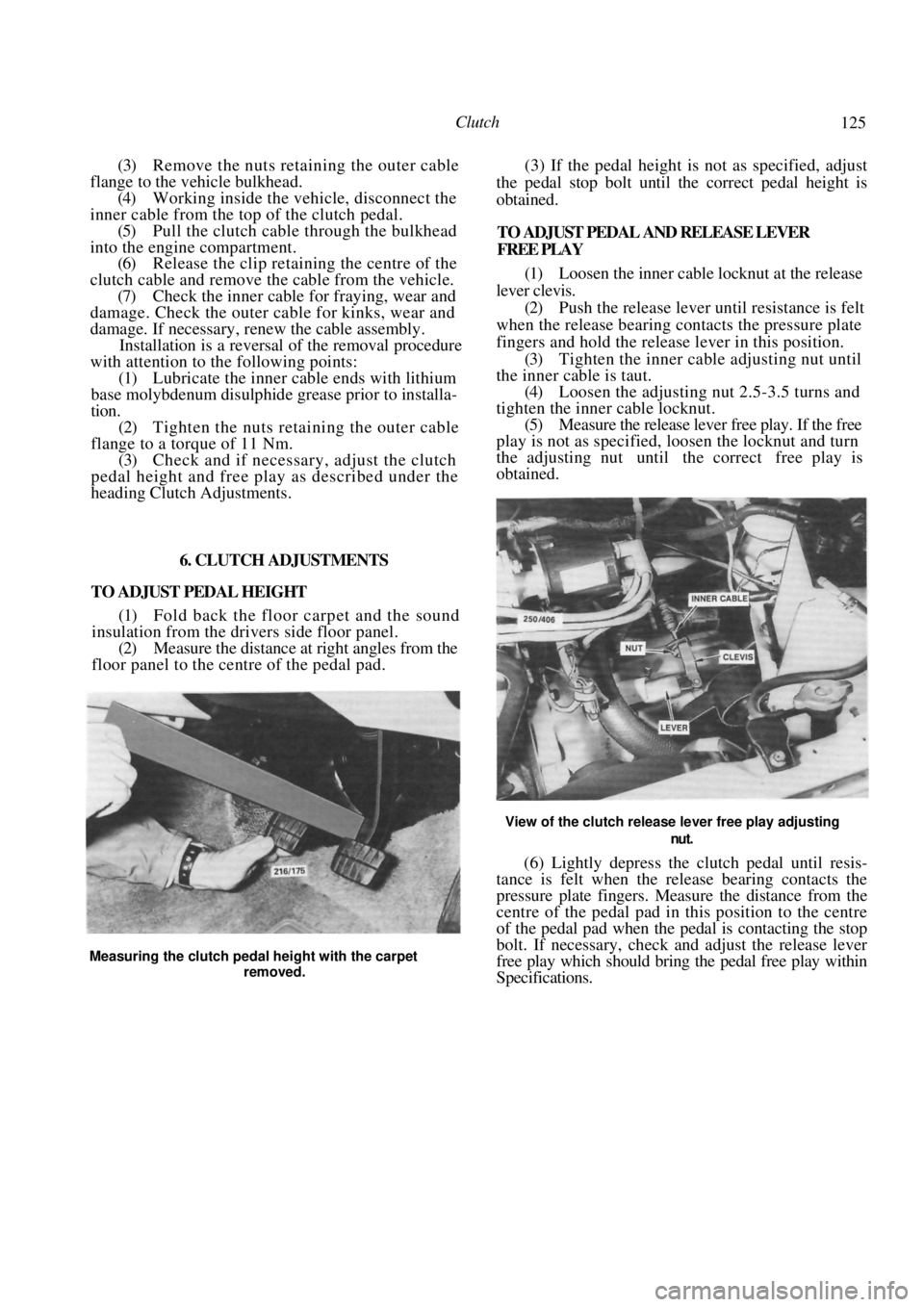

TO ADJUST PEDAL HEIGHT (1) Fold back the floor carpet and the sound

insulation from the drivers side floor panel.

(2) Measure the distance at right angles from the

floor panel to the centre of the pedal pad. (3) If the pedal height is not as specified, adjust

the pedal stop bolt until the correct pedal height is

obtained.

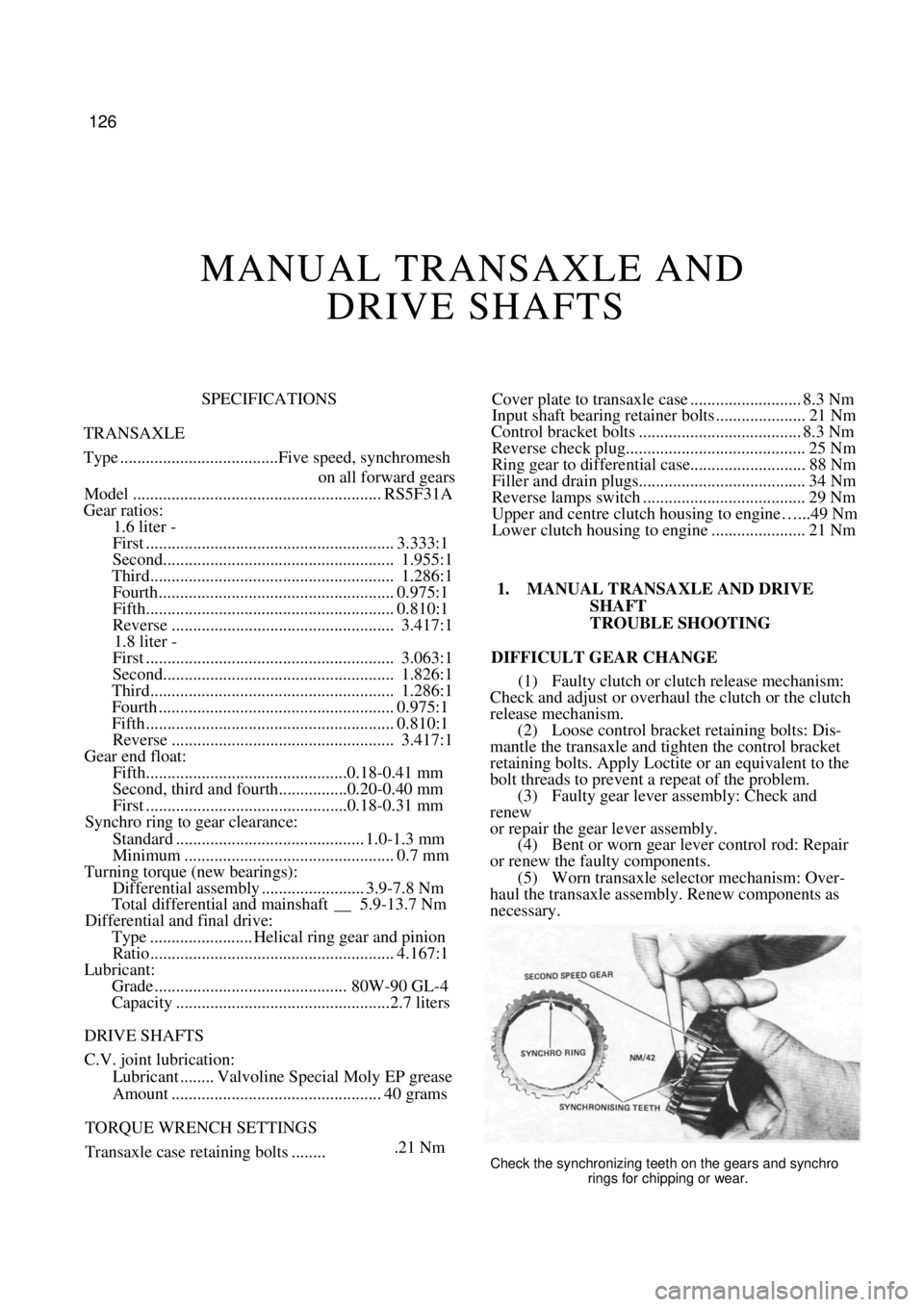

TO ADJUST PEDAL AND RELEASE LEVER

FREE PLAY

(1) Loosen the inner cable locknut at the release

lever clevis. (2) Push the release lever until resistance is felt

when the release bearing contacts the pressure plate

fingers and hold the release lever in this position.

(3) Tighten the inner cable adjusting nut until

the inner cable is taut.

(4) Loosen the adjusting nut 2.5-3.5 turns and

tighten the inner cable locknut. (5) Measure the release lever free play. If the free

play is not as specified, loosen the locknut and turn

the adjusting nut until the correct free play is

obtained.

View of the clutch release lever free play adjusting

nut.

(6) Lightly depress the clutch pedal until resis-

tance is felt when the release bearing contacts the

pressure plate fingers. Measure the distance from the

centre of the pedal pad in this position to the centre

of the pedal pad when the pedal is contacting the stop

bolt. If necessary, check and adjust the release lever

free play which should bring the pedal free play within

Specifications.

Measuring the clutch pedal height with the carpet

removed.

Page 126 of 238

126

MANUAL TRANSAXLE AND DRIVE SHAFTS

SPECIFICATIONS

TRANSAXLE

Type .....................................Five speed, synchromesh

on all forward gears

Model .......................................................... RS5F31A

Gear ratios: 1.6 liter -

First .......................................................... 3.333:1

Second...................................................... 1.955:1

Third......................................................... 1.286:1

Fourth....................................................... 0.975:1

Fifth.......................................................... 0.810:1

Reverse .................................................... 3.417:1

1.8 liter -

First .......................................................... 3.063:1

Second...................................................... 1.826:1

Third......................................................... 1.286:1

Fourth ....................................................... 0.975:1

Fifth.......................................................... 0.810:1

Reverse .................................................... 3.417:1

Gear end float:

Fifth...............................................0.18-0.41 mm

Second, third and fourth................0.20-0.40 mm

First ...............................................0.18-0.31 mm

Synchro ring to gear clearance:

Standard ............................................ 1.0-1.3 mm

Minimum ................................................. 0.7 mm

Turning torque (new bearings):

Differential assembly ........................ 3.9-7.8 Nm

Total differential and mainshaft __ 5.9-13.7 Nm

Differential and final drive:

Type ........................ Helical ring gear and pinion

Ratio......................................................... 4.167:1

Lubricant:

Grade ............................................. 80W-90 GL-4

Capacity ..................................................2.7 liters

DRIVE SHAFTS

C.V. joint lubrication:

Lubricant ........ Valvoline Special Moly EP grease

Amount ................................................. 40 grams

TORQUE WRENCH SETTINGS

Transaxle case retaining bolts ........

Cover plate to transaxle case .......................... 8.3 Nm

Input shaft bearing retainer bolts ..................... 21 Nm

Control bracket bolts ...................................... 8.3 Nm

Reverse check plug.......................................... 25 Nm

Ring gear to differential case........................... 88 Nm

Filler and drain plugs....................................... 34 Nm

Reverse lamps switch ...................................... 29 Nm

Upper and centre clutch housing to engine…...49 Nm

Lower clutch housing to engine ...................... 21 Nm

1. MANUAL TRANSAXLE AND DRIVE

SHAFT

TROUBLE SHOOTING

DIFFICULT GEAR CHANGE

(1) Faulty clutch or clutch release mechanism:

Check and adjust or overhaul the clutch or the clutch

release mechanism. (2) Loose control bracket retaining bolts: Dis-

mantle the transaxle and tighten the control bracket

retaining bolts. Apply Loctite or an equivalent to the

bolt threads to prevent a repeat of the problem.

(3) Faulty gear lever assembly: Check and

renew

or repair the gear lever assembly. (4) Bent or worn gear lever control rod: Repair

or renew the faulty components. (5) Worn transaxle selector mechanism: Over-

haul the transaxle assembly. Renew components as

necessary.

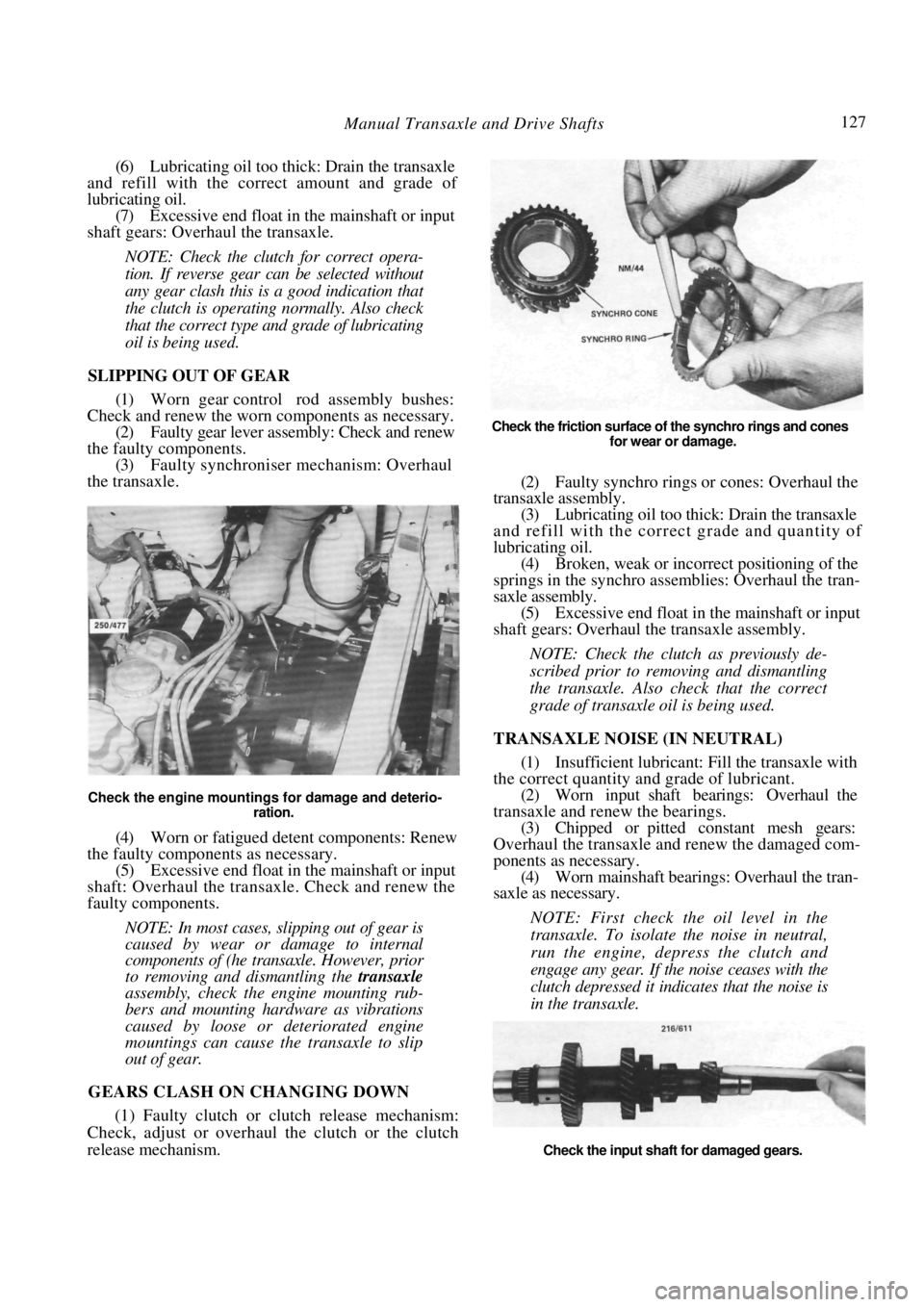

.21 NmCheck the synchronizing teeth on the gears and synchro

rings for chipping or wear.

Page 127 of 238

Manual Transaxle and Drive Shafts 127

(6) Lubricating oil too thick: Drain the transaxle

and refill with the corre ct amount and grade of

lubricating oil. (7) Excessive end float in the mainshaft or input

shaft gears: Overhaul the transaxle.

NOTE: Check the clutch for correct opera-

tion. If reverse gear can be selected without

any gear clash this is a good indication that

the clutch is operating normally. Also check

that the correct type and grade of lubricating

oil is being used.

SLIPPING OUT OF GEAR

(1) Worn gear control rod assembly bushes:

Check and renew the worn components as necessary. (2) Faulty gear lever assembly: Check and renew

the faulty components. (3) Faulty synchroniser mechanism: Overhaul

the transaxle.

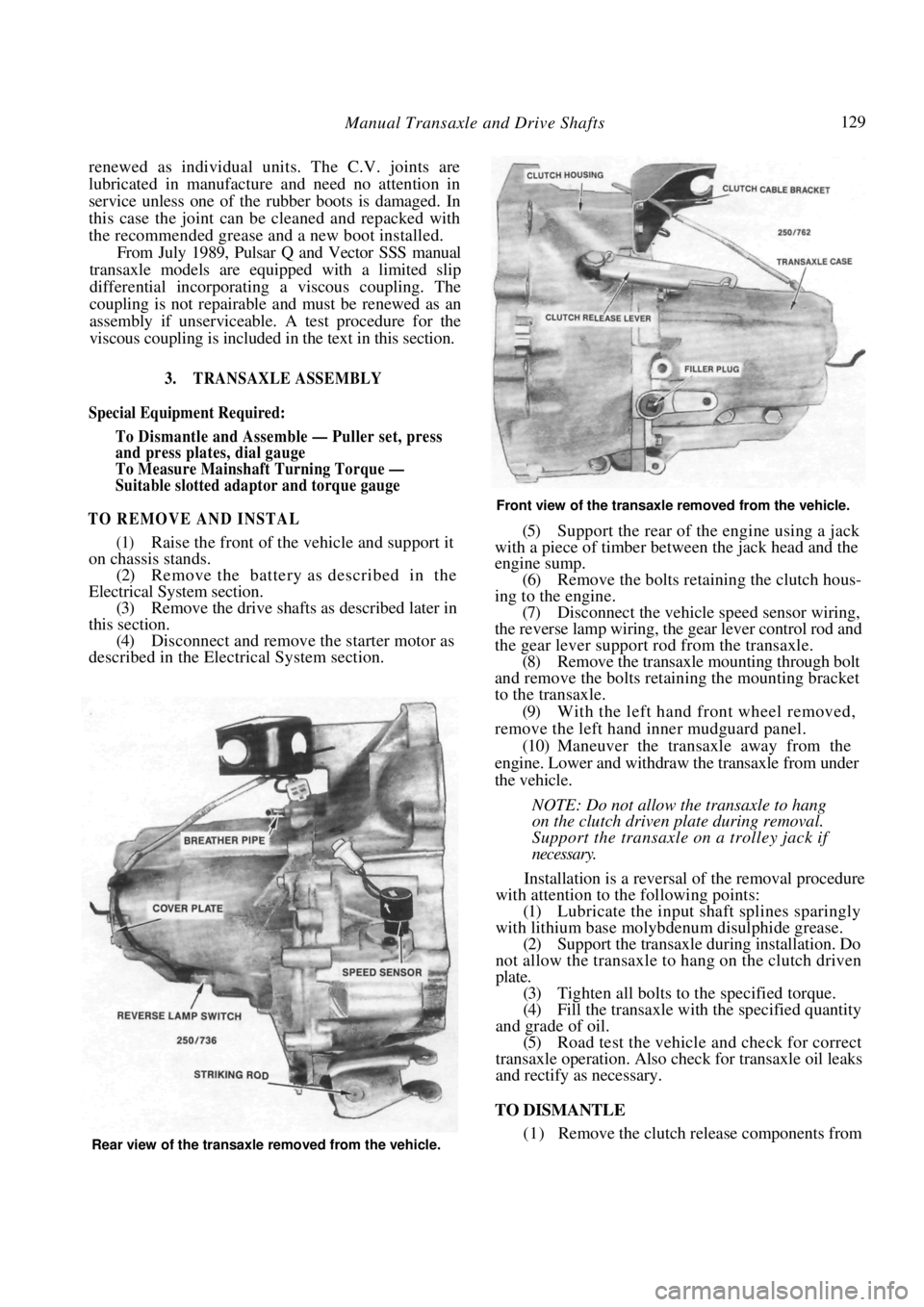

Check the engine mountings for damage and deterio-

ration.

(4) Worn or fatigued detent components: Renew

the faulty components as necessary.

(5) Excessive end float in the mainshaft or input

shaft: Overhaul the transaxle. Check and renew the

faulty components.

NOTE: In most cases, slipping out of gear is

caused by wear or damage to internal

components of (he tran saxle. However, prior

to removing and dismantling the transaxle

assembly, check the engine mounting rub-

bers and mounting hardware as vibrations

caused by loose or deteriorated engine

mountings can cause the transaxle to slip

out of gear.

GEARS CLASH ON CHANGING DOWN

(1) Faulty clutch or clutch release mechanism:

Check, adjust or overhaul the clutch or the clutch

release mechanism.

Check the friction surface of the synchro rings and cones

for wear or damage.

(2) Faulty synchro rings or cones: Overhaul the

transaxle assembly.

(3) Lubricating oil too thick: Drain the transaxle

and refill with the correct grade and quantity of

lubricating oil. (4) Broken, weak or incorrect positioning of the

springs in the synchro asse mblies: Overhaul the tran-

saxle assembly.

(5) Excessive end float in the mainshaft or input

shaft gears: Overhaul the transaxle assembly.

NOTE: Check the clutch as previously de-

scribed prior to removing and dismantling

the transaxle. Also check that the correct

grade of transaxle oil is being used.

TRANSAXLE NOISE (IN NEUTRAL)

(1) Insufficient lubricant: Fill the transaxle with

the correct quantity and grade of lubricant. (2) Worn input shaft bearings: Overhaul the

transaxle and renew the bearings. (3) Chipped or pitted constant mesh gears:

Overhaul the transaxle and renew the damaged com-

ponents as necessary. (4) Worn mainshaft bearings: Overhaul the tran-

saxle as necessary.

NOTE: First check the oil level in the

transaxle. To isolate the noise in neutral,

run the engine, depress the clutch and

engage any gear. If the noise ceases with the

clutch depressed it indicates that the noise is

in the transaxle.

Check the input shaft for damaged gears.

Page 129 of 238

Manual Transaxle and Drive Shafts 129

renewed as individual units. The C.V. joints are

lubricated in manufacture and need no attention in

service unless one of the r ubber boots is damaged. In

this case the joint can be cl eaned and repacked with

the recommended grease and a new boot installed.

From July 1989, Pulsar Q and Vector SSS manual

transaxle models are equipped with a limited slip

differential incorporating a viscous coupling. The

coupling is not repairable and must be renewed as an

assembly if unserviceable. A test procedure for the

viscous coupling is included in the text in this section.

3. TRANSAXLE ASSEMBLY

Special Equipment Required:

To Dismantle and Assemble — Puller set, press

and press plates, dial gauge

To Measure Mainshaft Turning Torque —

Suitable slotted adaptor and torque gauge

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands.

(2) Remove the battery as described in the

Electrical System section. (3) Remove the drive shafts as described later in

this section. (4) Disconnect and remove the starter motor as

described in the Elect rical System section.

Front view of the transaxle removed from the vehicle.

(5) Support the rear of the engine using a jack

with a piece of timber between the jack head and the

engine sump.

(6) Remove the bolts retaining the clutch hous-

ing to the engine. (7) Disconnect the vehicle speed sensor wiring,

the reverse lamp wiring, the gear lever control rod and

the gear lever support rod from the transaxle. (8) Remove the transaxle mounting through bolt

and remove the bolts retaining the mounting bracket

to the transaxle.

(9) With the left hand front wheel removed,

remove the left hand inner mudguard panel. (10) Maneuver the transaxle away from the

engine. Lower and withdraw the transaxle from under

the vehicle.

NOTE: Do not allow the transaxle to hang

on the clutch driven plate during removal.

Support the transaxle on a trolley jack if

necessary.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Lubricate the input shaft splines sparingly

with lithium base molybdenum disulphide grease. (2) Support the transaxle during installation. Do

not allow the transaxle to hang on the clutch driven

plate. (3) Tighten all bolts to the specified torque.

(4) Fill the transaxle with the specified quantity

and grade of oil. (5) Road test the vehicle and check for correct

transaxle operation. Also ch eck for transaxle oil leaks

and rectify as necessary.

TO DISMANTLE

(1) Remove the clutch release components from Rear view of the transaxle removed from the vehicle.

Page 140 of 238

140

AUTOMATIC TRANSAXLE

SPECIFICATIONS

Make .............................................. JATCO RL3F01A

Type .....................3 speed and reverse epicyclic gear

train with lock up torque converter

Operation .................................... Automatic hydraulic

Lubricant:

Type....................................................... Dexron IT

Capacity................................................. 6.3 liters

TORQUE WRENCH SETTINGS

Drive plate to crankshaft bolls ........................60 Nm

Drive plate to torque converter bolts ..............49 Nm

Convener housing to engine ...........................22 Nm

Converter housing to transaxle ........................23 Nm

Transaxle sump to transaxle ............................. 7 Nm

Oil cooler pipe to transaxle .............................49 Nm

Selector shaft locknut .......................................42 Nm

Transaxle filter bolts.........................................12 Nm

1. AUTOMATIC TRANSAXLE TROUBLE SHOOTING

NO DRIVE IN D RANGE

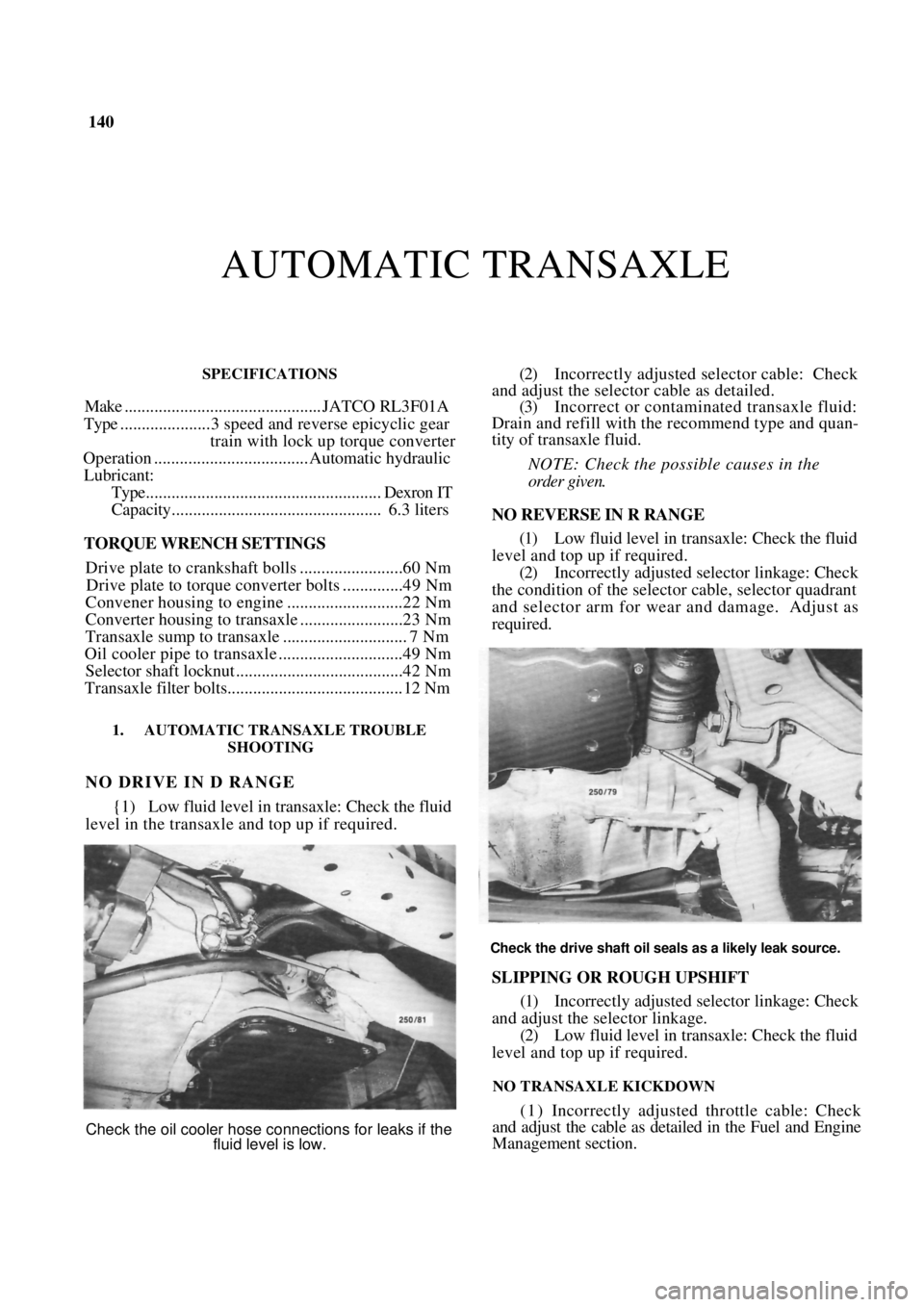

{1) Low fluid level in transaxle: Check the fluid

level in the transaxle and top up if required.

(2) Incorrectly adjusted selector cable: Check

and adjust the selector cable as detailed. (3) Incorrect or contaminated transaxle fluid:

Drain and refill with the recommend type and quan-

tity of transaxle fluid.

NOTE: Check the possible causes in the

order given.

NO REVERSE IN R RANGE

(1) Low fluid level in transaxle: Check the fluid

level and top up if required. (2) Incorrectly adjusted selector linkage: Check

the condition of the selector cable, selector quadrant

and selector arm for wear and damage. Adjust as

required.

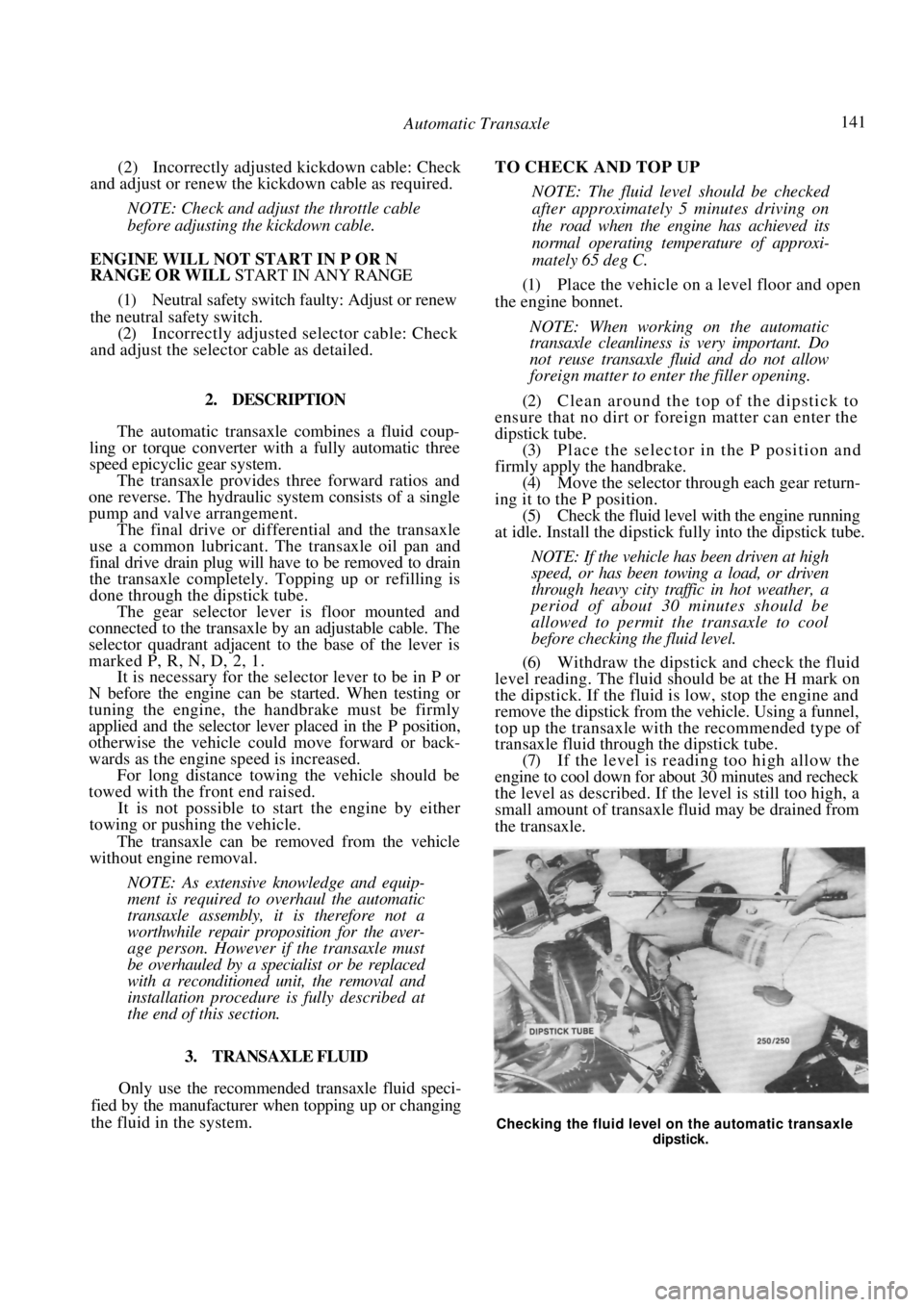

Check the drive shaft oil seals as a likely leak source.

SLIPPING OR ROUGH UPSHIFT

(1) Incorrectly adjusted selector linkage: Check

and adjust the selector linkage. (2) Low fluid level in transaxle: Check the fluid

level and top up if required.

NO TRANSAXLE KICKDOWN

(1) Incorrectly adjusted throttle cable: Check

and adjust the cable as detailed in the Fuel and Engine

Management section.

Check the oil cooler hose connections for leaks if the

fluid level is low.

Page 141 of 238

Automatic Transaxle 141

(2) Incorrectly adjusted kickdown cable: Check

and adjust or renew the kickdown cable as required.

NOTE: Check and adjust the throttle cable

before adjusting the kickdown cable.

ENGINE WILL NOT START IN P OR N

RANGE OR WILL START IN ANY RANGE

(1) Neutral safety switch faulty: Adjust or renew

the neutral safety switch. (2) Incorrectly adjusted selector cable: Check

and adjust the selector cable as detailed.

2. DESCRIPTION

The automatic transaxle combines a fluid coup-

ling or torque converter with a fully automatic three

speed epicyclic gear system.

The transaxle provides th ree forward ratios and

one reverse. The hydraulic system consists of a single

pump and valv e arrangement.

The final drive or differential and the transaxle

use a common lubricant. The transaxle oil pan and

final drive drain plug will have to be removed to drain

the transaxle completely. Topping up or refilling is

done through the dipstick tube.

The gear selector lever is floor mounted and

connected to the transaxle by an adjustable cable. The

selector quadrant adjacent to the base of the lever is

marked P, R, N, D, 2, 1.

It is necessary for the selector lever to be in P or

N before the engine can be started. When testing or

tuning the engine, the handbrake must be firmly

applied and the selector lever placed in the P position,

otherwise the vehicle could move forward or back-

wards as the engine speed is increased.

For long distance towing the vehicle should be

towed with the front end raised.

It is not possible to start the engine by either

towing or pushing the vehicle.

The transaxle can be removed from the vehicle

without engine removal.

NOTE: As extensive knowledge and equip-

ment is required to overhaul the automatic

transaxle assembly, it is therefore not a

worthwhile repair proposition for the aver-

age person. However if the transaxle must

be overhauled by a specialist or be replaced

with a reconditioned unit, the removal and

installation procedure is fully described at

the end of this section.

3. TRANSAXLE FLUID

Only use the recommended transaxle fluid speci-

fied by the manufacturer when topping up or changing

the fluid in the system.

TO CHECK AND TOP UP

NOTE: The fluid level should be checked

after approximately 5 minutes driving on

the road when the engine has achieved its

normal operating temperature of approxi-

mately 65 deg C.

(1) Place the vehicle on a level floor and open

the engine bonnet.

NOTE: When working on the automatic

transaxle cleanliness is very important. Do

not reuse transaxle fluid and do not allow

foreign matter to enter the filler opening.

(2) Clean around the top of the dipstick to

ensure that no dirt or foreign matter can enter the

dipstick tube.

(3) Place the selector in the P position and

firmly apply the handbrake. (4) Move the selector thro ugh each gear return-

ing it to the P position.

(5) Check the fluid level with the engine running

at idle. Install the dipstick fully into the dipstick tube.

NOTE: If the vehicle has been driven at high

speed, or has been towing a load, or driven

through heavy city traffic in hot weather, a

period of about 30 minutes should be

allowed to permit the transaxle to cool

before checking the fluid level.

(6) Withdraw the dipstick and check the fluid

level reading. The fluid should be at the H mark on

the dipstick. If the fluid is low, stop the engine and

remove the dipstick from the vehicle. Using a funnel,

top up the transaxle with the recommended type of

transaxle fluid through the dipstick tube. (7) If the level is reading too high allow the

engine to cool down for about 30 minutes and recheck

the level as described. If the level is still too high, a

small amount of transaxle fluid may be drained from

the transaxle.

Checking the fluid level on the automatic transaxle

dipstick.

Page 142 of 238

142 Automatic Transaxle

(8) Install the dipstick and start the engine and

recheck the fluid level.

NOTE; Do not overfill the transaxle or

foaming and unsatisfactory operation of the

transaxle will result.

TO DRAIN AND REFILL

This is not a normal maintenance and lubrication

procedure. It is only necessary to drain the complete

system, including the torq ue converter and the oil

cooler, when the transaxle assembly is removed for

overhaul or the renewal of transaxle components such

as bearings, clutches or as semblies. When this condi-

tion arises, the torque converter and the cooler should

be cleaned and flushed to remove any dirt or sludge.

After transaxle overhaul, install approximately 6

liters of new transaxle fluid, and top up as previously

described.

4. BRAKE BAND

Band adjustment is not a normal maintenance

procedure.

The adjustment entails removal of the valve body

and for this reason the vehicle should be taken to an

authorized dealer.

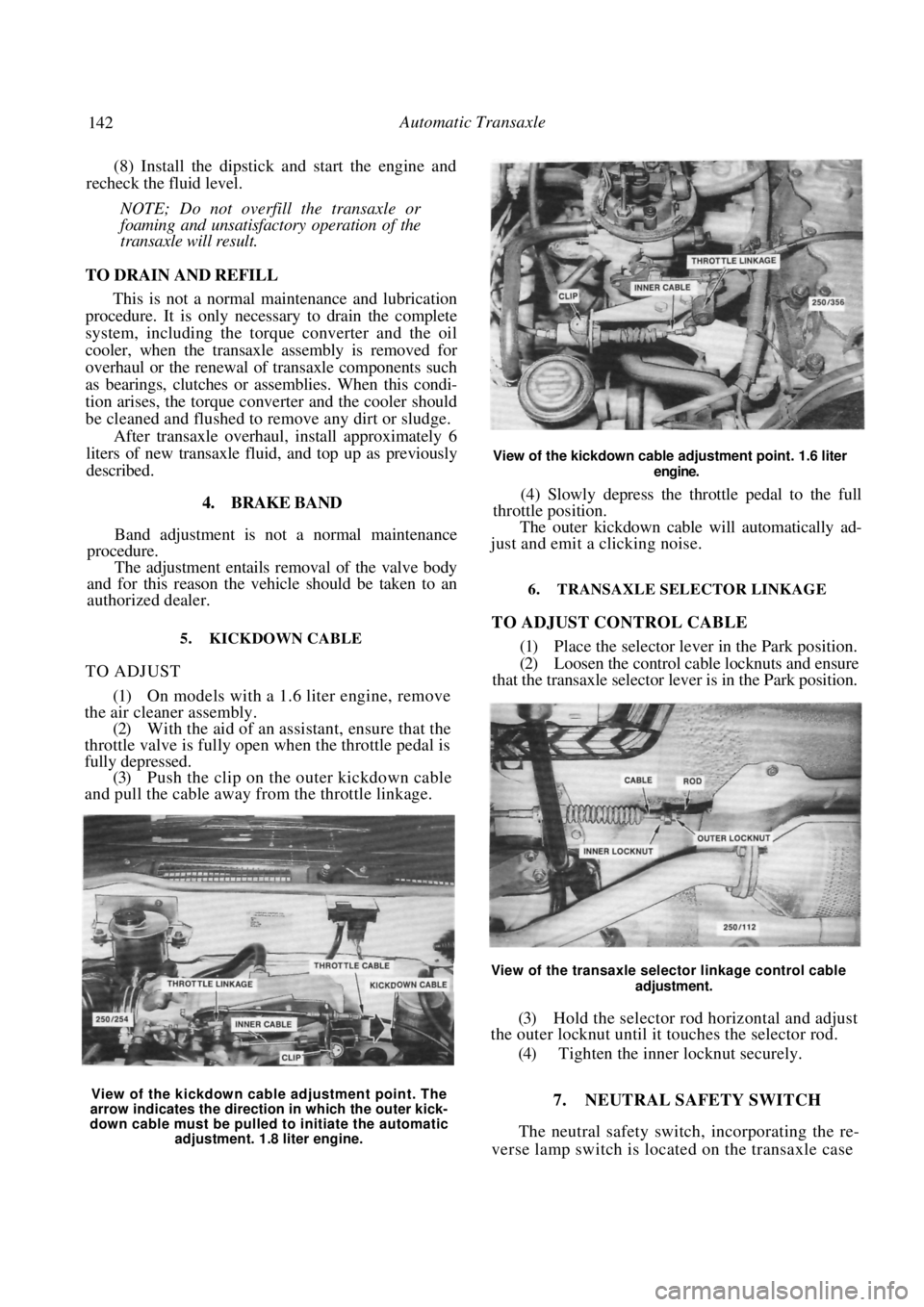

5. KICKDOWN CABLE

TO ADJUST

(1) On models with a 1.6 liter engine, remove

the air cleaner assembly. (2) With the aid of an assistant, ensure that the

throttle valve is fully open when the throttle pedal is

fully depressed. (3) Push the clip on the outer kickdown cable

and pull the cable away from the throttle linkage.

View of the kickdown cable adjustment point. 1.6 liter

engine.

(4) Slowly depress the throttle pedal to the full

throttle position.

The outer kickdown cable will automatically ad-

just and emit a clicking noise.

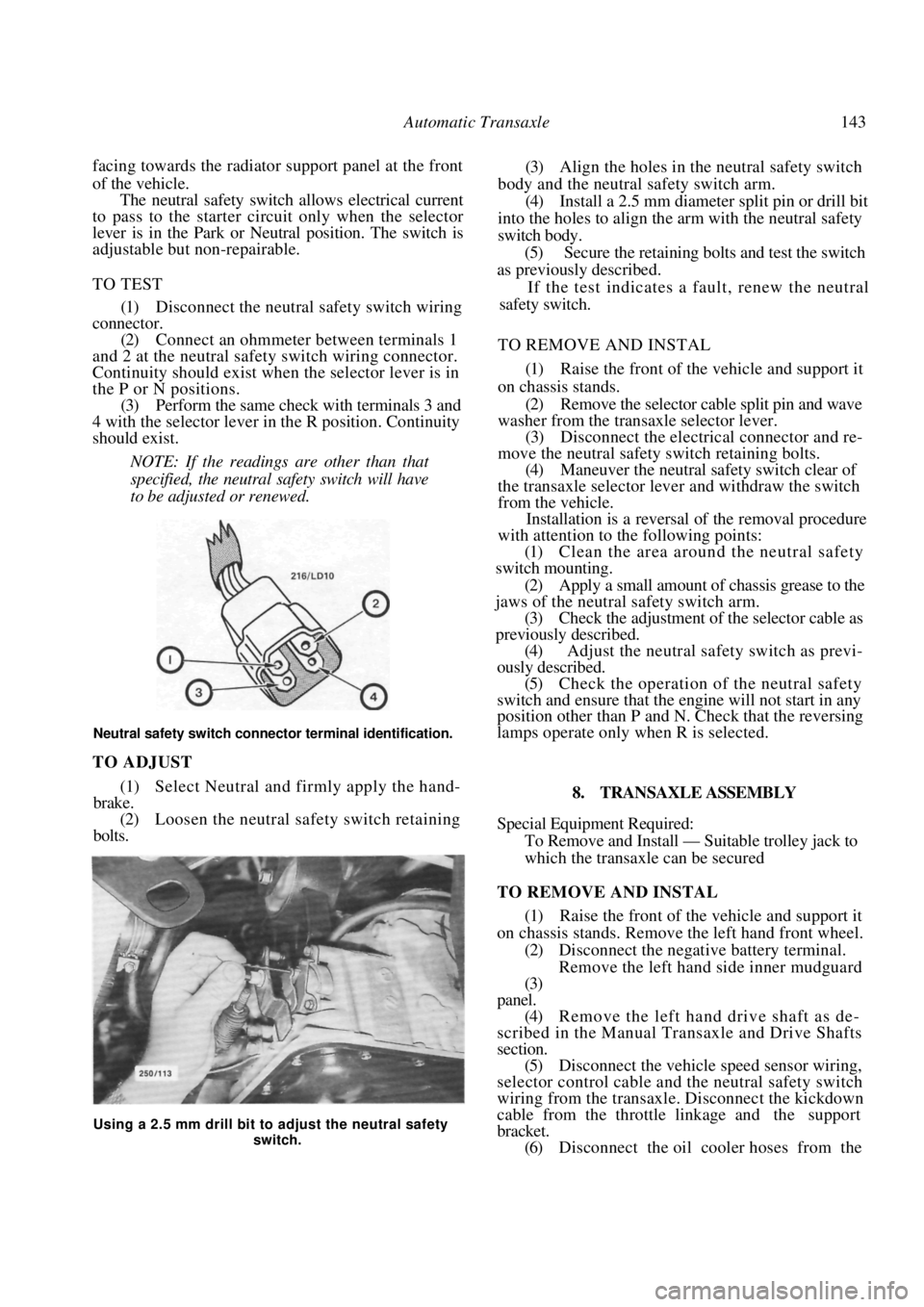

6. TRANSAXLE SELECTOR LINKAGE

TO ADJUST CONTROL CABLE

(1) Place the selector lever in the Park position.

(2) Loosen the control cable locknuts and ensure

that the transaxle selector lever is in the Park position.

View of the transaxle selector linkage control cable

adjustment.

(3) Hold the selector rod horizontal and adjust

the outer locknut until it touches the selector rod.

(4) Tighten the inner locknut securely.

7. NEUTRAL SAFETY SWITCH

The neutral safety switch, incorporating the re-

verse lamp switch is located on the transaxle case

View of the kickdown cable adjustment point. The

arrow indicates the direction in which the outer kick-

down cable must be pulled to initiate the automatic adjustment. 1.8 liter engine.

Page 143 of 238

Automatic Transaxle 143

facing towards the radiator support panel at the front

of the vehicle.

The neutral safety switch allows electrical current

to pass to the starter circ uit only when the selector

lever is in the Park or Neutral position. The switch is

adjustable but non-repairable.

TO TEST

(1) Disconnect the neutral safety switch wiring

connector.

(2) Connect an ohmmeter between terminals 1

and 2 at the neutral safety switch wiring connector.

Continuity should exist when the selector lever is in

the P or N positions. (3) Perform the same check with terminals 3 and

4 with the selector lever in the R position. Continuity

should exist.

NOTE: If the readings are other than that

specified, the neutral safety switch will have

to be adjusted or renewed.

Neutral safety switch connector terminal identification.

TO ADJUST

(1) Select Neutral and firmly apply the hand-

brake. (2) Loosen the neutral safety switch retaining

bolts.

(3) Align the holes in the neutral safety switch

body and the neutral safety switch arm. (4) Install a 2.5 mm diameter split pin or drill bit

into the holes to align the arm with the neutral safety

switch body. (5) Secure the retaining bolts and test the switch

as previously described.

If the test indicates a fault, renew the neutral

safety switch.

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the selector cable split pin and wave

washer from the transaxle selector lever.

(3) Disconnect the electric al connector and re-

move the neutral safety switch retaining bolts. (4) Maneuver the neutral safety switch clear of

the transaxle selector lever and withdraw the switch

from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Clean the area around the neutral safety

switch mounting.

(2) Apply a small amount of chassis grease to the

jaws of the neutral safety switch arm. (3) Check the adjustment of the selector cable as

previously described. (4) Adjust the neutral safety switch as previ-

ously described.

(5) Check the operation of the neutral safety

switch and ensure that the engine will not start in any

position other than P and N. Check that the reversing

lamps operate only when R is selected.

8. TRANSAXLE ASSEMBLY

Special Equipment Required:

To Remove and Install — Suitable trolley jack to

which the transaxle can be secured

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the left hand front wheel.

(2) Disconnect the negative battery terminal. Remove the left hand side inner mudguard

(3)

panel.

(4) Remove the left hand drive shaft as de-

scribed in the Manual Tran saxle and Drive Shafts

section. (5) Disconnect the vehicle speed sensor wiring,

selector control cable and the neutral safety switch

wiring from the transaxle. Disconnect the kickdown

cable from the throttle linkage and the support

bracket. (6) Disconnect the oil cooler hoses from the

Using a 2.5 mm drill bit to adjust the neutral safety

switch.

Page 144 of 238

144 Automatic Transaxle

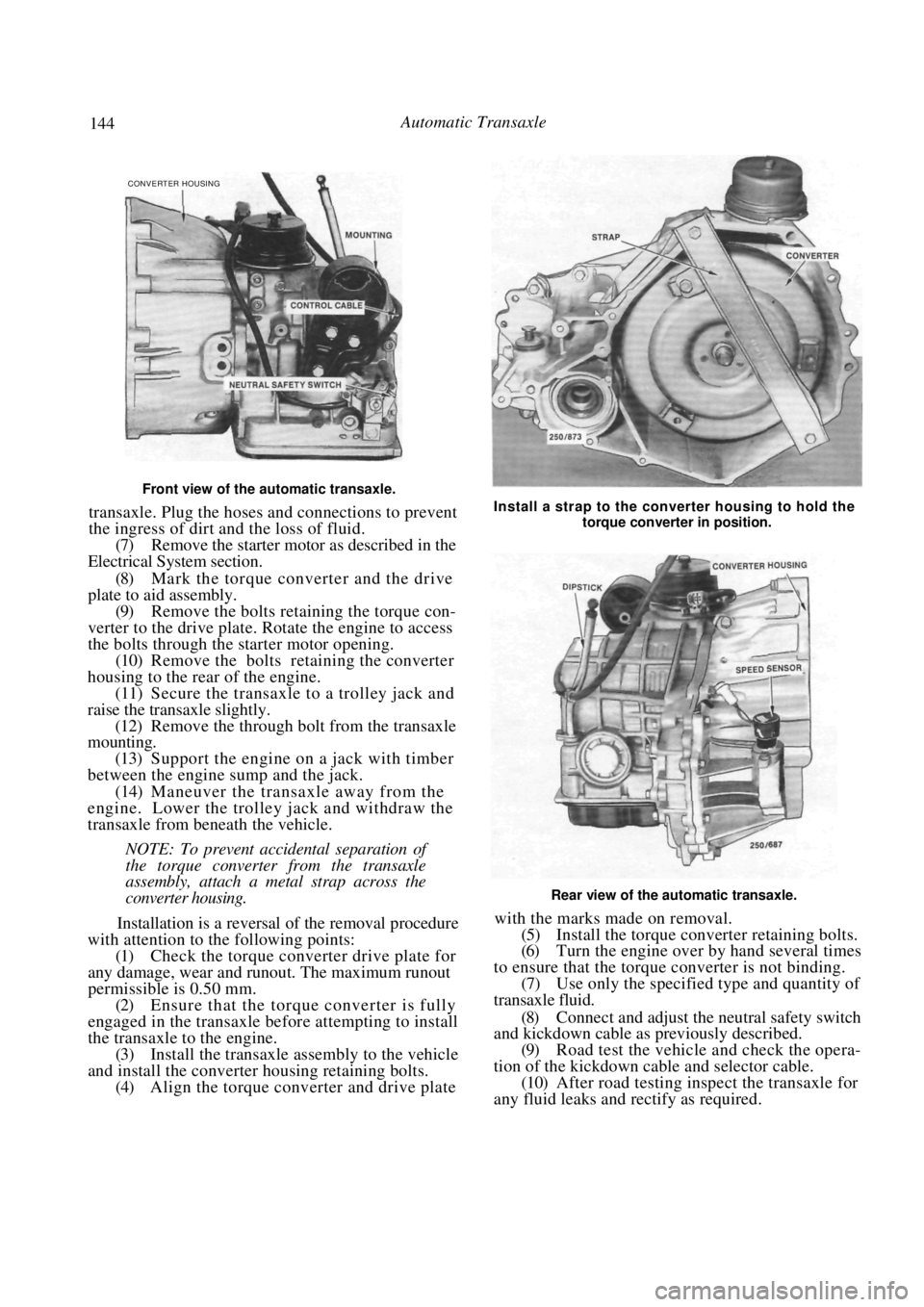

Front view of the automatic transaxle.

transaxle. Plug the hoses and connections to prevent

the ingress of dirt and the loss of fluid.

(7) Remove the starter motor as described in the

Electrical System section.

(8) Mark the torque converter and the drive

plate to aid assembly.

(9) Remove the bolts retaining the torque con-

verter to the drive plate. Rotate the engine to access

the bolts through the starter motor opening. (10) Remove the bolts retaining the converter

housing to the rear of the engine. (11) Secure the transaxle to a trolley jack and

raise the transaxle slightly. (12) Remove the through bolt from the transaxle

mounting.

(13) Support the engine on a jack with timber

between the engine sump and the jack. (14) Maneuver the transaxle away from the

engine. Lower the trolley jack and withdraw the

transaxle from beneath the vehicle.

NOTE: To prevent accidental separation of

the torque converter from the transaxle

assembly, attach a metal strap across the

converter housing.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Check the torque converter drive plate for

any damage, wear and runout. The maximum runout

permissible is 0.50 mm.

(2) Ensure that the torque converter is fully

engaged in the transaxle be fore attempting to install

the transaxle to the engine. (3) Install the transaxle assembly to the vehicle

and install the converter housing retaining bolts. (4) Align the torque converter and drive plate

Install a strap to the converter housing to hold the

torque converter in position.

Rear view of the automatic transaxle.

with the marks made on removal.

(5) Install the torque converter retaining bolts.

(6) Turn the engine over by hand several times

to ensure that the torque converter is not binding. (7) Use only the specified type and quantity of

transaxle fluid.

(8) Connect and adjust the neutral safety switch

and kickdown cable as previously described.

(9) Road test the vehicle and check the opera-

tion of the kickdown cable and selector cable. (10) After road testing inspect the transaxle for

any fluid leaks and rectify as required.

CONVERTER HOUSING

Page 148 of 238

148 Steering — Part 2

3. STEERING COLUMN

Special Equipment Required:

To Remove Steering Wheel — Steering wheel

puller

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) Working in the engine compartment, mark

the relationship between the steering shaft universal

coupling joint and the steering gear pinion shaft. (3) Remove the pinch bolts from the universal

joint. (4) Working inside the vehi cle, remove the steer-

ing wheel as previously described. (5) Remove the steering column shroud screws,

unclip the lower and upper covers and remove them

from the steering column. (6) Disconnect all the steering column wiring

connectors. (7) Remove the lower trim from underneath the

steering column.

(8) Fold back the insulator and remove the nuts

from the steering colu mn floor bracket.

(9) Remove the nuts from the lower steering

column bracket. (10) Remove the bolts from the tilt bracket

assembly. (11) Maneuver the steering column from the

vehicle.

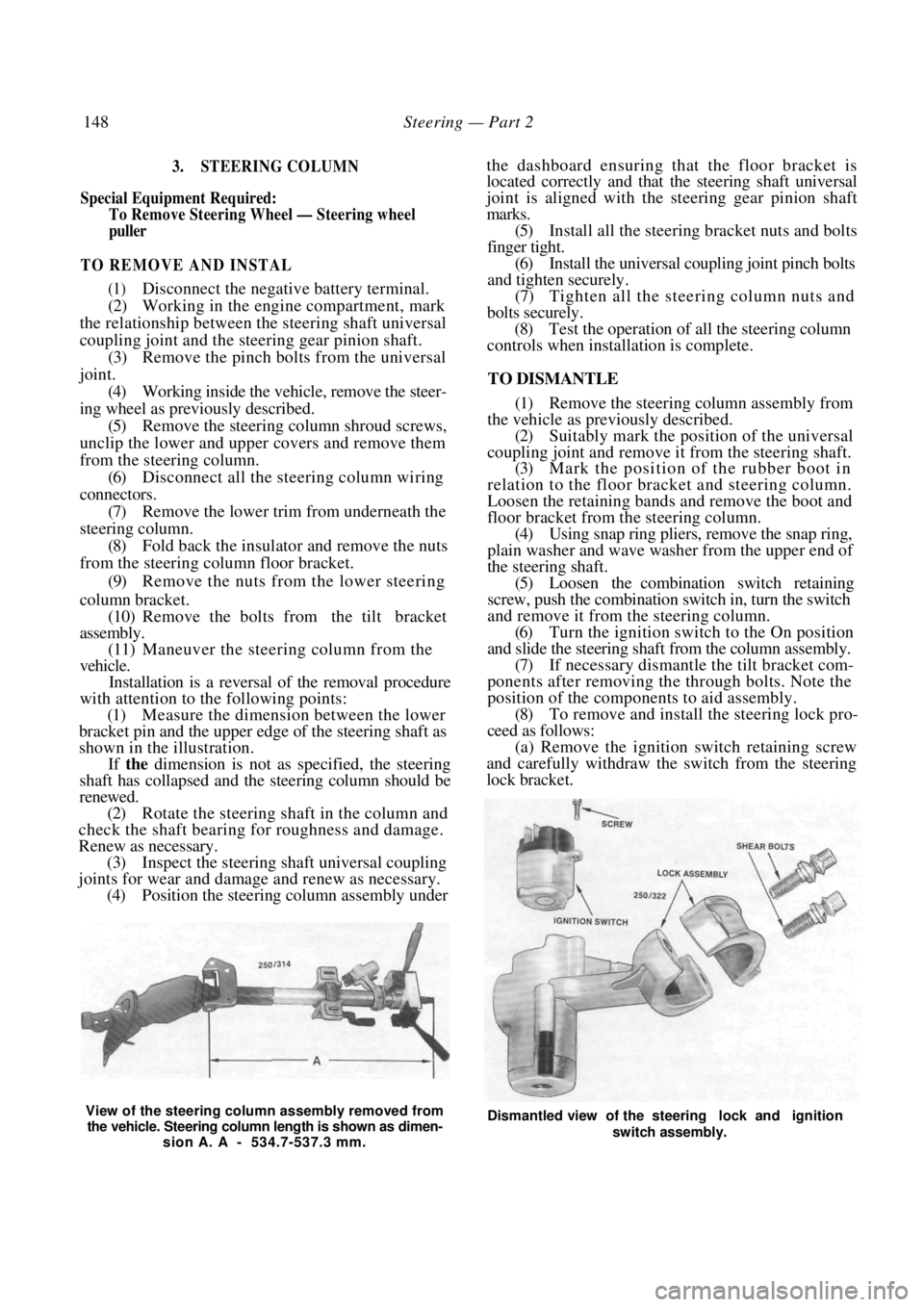

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Measure the dimension between the lower

bracket pin and the upper edge of the steering shaft as

shown in the illustration.

If the dimension is not as specified, the steering

shaft has collapsed and the steering column should be

renewed.

(2) Rotate the steering shaft in the column and

check the shaft bearing for roughness and damage.

Renew as necessary. (3) Inspect the steering shaft universal coupling

joints for wear and damage and renew as necessary. (4) Position the steering column assembly under

the dashboard ensuring that the floor bracket is

located correctly and that the steering shaft universal

joint is aligned with the steering gear pinion shaft

marks.

(5) Install all the steering bracket nuts and bolts

finger tight. (6) Install the universal coupling joint pinch bolts

and tighten securely.

(7) Tighten all the stee ring column nuts and

bolts securely. (8) Test the operation of all the steering column

controls when installation is complete.

TO DISMANTLE

(1) Remove the steering column assembly from

the vehicle as previously described. (2) Suitably mark the position of the universal

coupling joint and remove it from the steering shaft. (3) Mark the position of the rubber boot in

relation to the floor bracket and steering column.

Loosen the retaining bands and remove the boot and

floor bracket from th e steering column.

(4) Using snap ring pliers, remove the snap ring,

plain washer and wave washer from the upper end of

the steering shaft. (5) Loosen the combination switch retaining

screw, push the combination switch in, turn the switch

and remove it from the steering column. (6) Turn the ignition switch to the On position

and slide the steering shaft from the column assembly. (7) If necessary dismantle the tilt bracket com-

ponents after removing the through bolts. Note the

position of the components to aid assembly. (8) To remove and install the steering lock pro-

ceed as follows: (a) Remove the ignition switch retaining screw

and carefully withdraw the switch from the steering

lock bracket.

View of the steering column assembly removed from

the vehicle. Steering column length is shown as dimen- sion A. A - 534.7-537.3 mm. Dismantled view of the steering lock and ignition

switch assembly.