battery NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 45 of 238

Engine 45

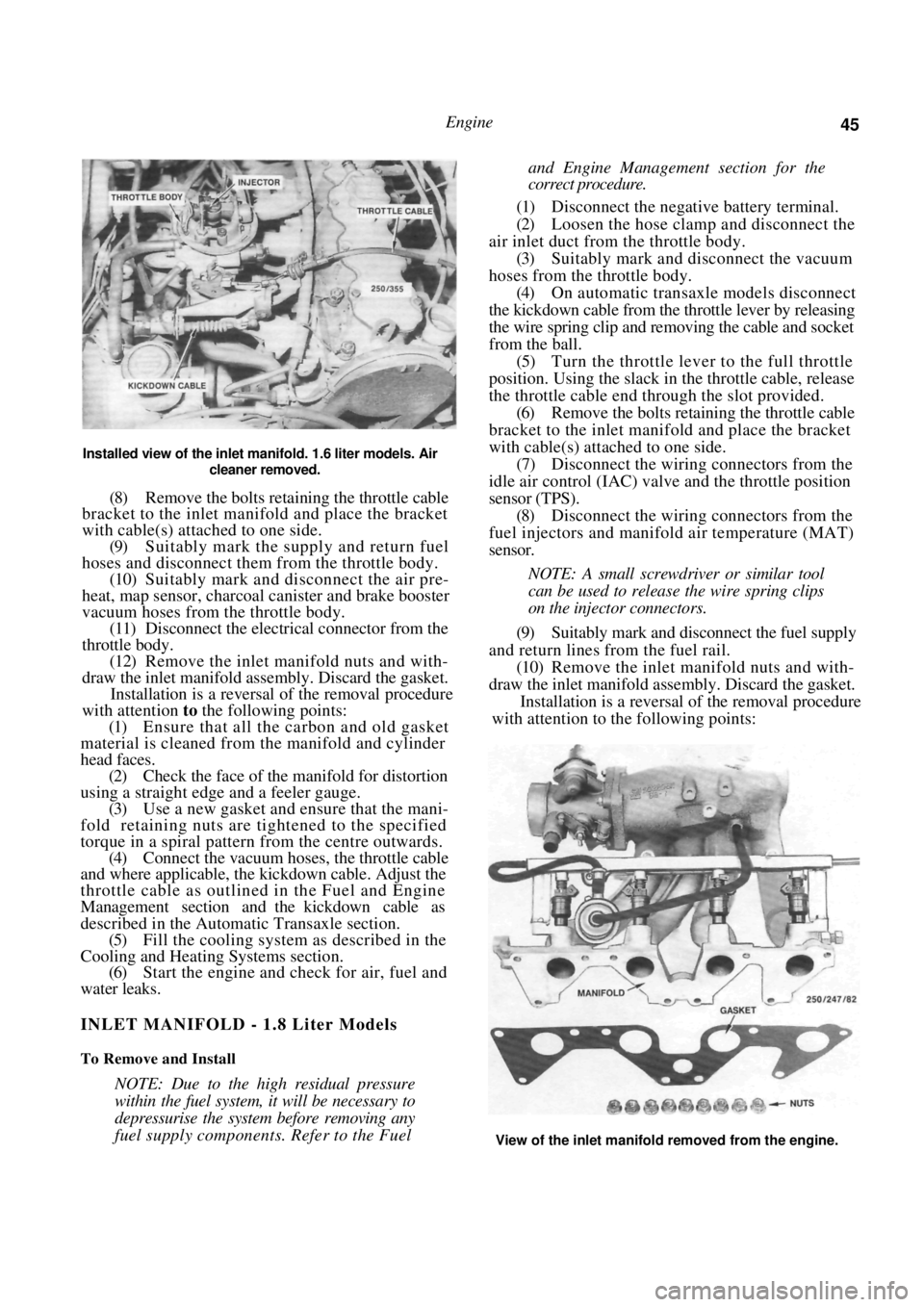

Installed view of the inlet manifold. 1.6 liter models. Air

cleaner removed.

(8) Remove the bolts retaining the throttle cable

bracket to the inlet manifold and place the bracket

with cable(s) attached to one side.

(9) Suitably mark the supply and return fuel

hoses and disconnect them from the throttle body.

(10) Suitably mark and disconnect the air pre-

heat, map sensor, charcoal canister and brake booster

vacuum hoses from the throttle body. (11) Disconnect the electrical connector from the

throttle body. (12) Remove the inlet manifold nuts and with-

draw the inlet manifold assembly. Discard the gasket. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all the carbon and old gasket

material is cleaned from the manifold and cylinder

head faces. (2) Check the face of the manifold for distortion

using a straight edge and a feeler gauge. (3) Use a new gasket and ensure that the mani-

fold retaining nuts are tightened to the specified

torque in a spiral pattern from the centre outwards. (4) Connect the vacuum hoses, the throttle cable

and where applicable, the kickdown cable. Adjust the

throttle cable as outlined in the Fuel and Engine

Management section and the kickdown cable as

described in the Automatic Transaxle section. (5) Fill the cooling system as described in the

Cooling and Heating Systems section. (6) Start the engine and check for air, fuel and

water leaks.

INLET MANIFOLD - 1.8 Liter Models

To Remove and Install

NOTE: Due to the high residual pressure

within the fuel system, it will be necessary to

depressurise the system before removing any

fuel supply components. Refer to the Fuel

and Engine Management section for the

correct procedure.

(1) Disconnect the negative battery terminal.

(2) Loosen the hose clamp and disconnect the

air inlet duct from the throttle body. (3) Suitably mark and disconnect the vacuum

hoses from the throttle body. (4) On automatic transaxle models disconnect

the kickdown cable from the throttle lever by releasing

the wire spring clip and re moving the cable and socket

from the ball. (5) Turn the throttle lever to the full throttle

position. Using the slack in the throttle cable, release

the throttle cable end thr ough the slot provided.

(6) Remove the bolts retaining the throttle cable

bracket to the inlet manifold and place the bracket

with cable(s) attached to one side. (7) Disconnect the wiring connectors from the

idle air control (IAC) valve and the throttle position

sensor (TPS).

(8) Disconnect the wiring connectors from the

fuel injectors and manifold air temperature (MAT)

sensor.

NOTE: A small screwdriver or similar tool

can be used to release the wire spring clips

on the injector connectors.

(9) Suitably mark and disconnect the fuel supply

and return lines from the fuel rail. (10) Remove the inlet manifold nuts and with-

draw the inlet manifold assembly. Discard the gasket. Installation is a reversal of the removal procedure

with attention to the following points:

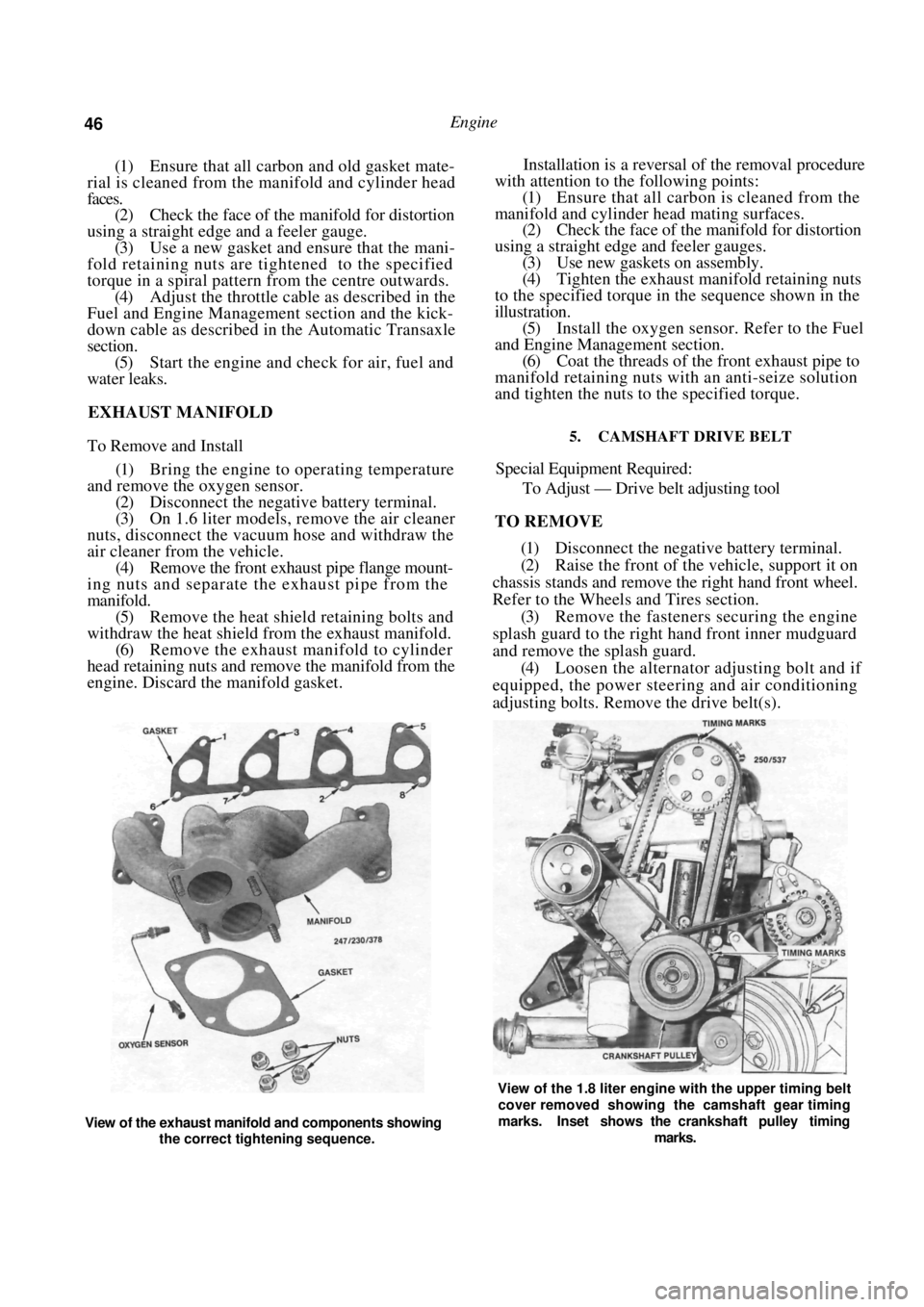

View of the inlet manifold removed from the engine.

Page 46 of 238

46 Engine

(1) Ensure that all carbon and old gasket mate-

rial is cleaned from the manifold and cylinder head

faces. (2) Check the face of the manifold for distortion

using a straight edge and a feeler gauge. (3) Use a new gasket and ensure that the mani-

fold retaining nuts are tightened to the specified

torque in a spiral pattern from the centre outwards. (4) Adjust the throttle cabl e as described in the

Fuel and Engine Management section and the kick-

down cable as described in the Automatic Transaxle

section.

(5) Start the engine and check for air, fuel and

water leaks.

EXHAUST MANIFOLD

To Remove and Install

(1) Bring the engine to operating temperature

and remove the oxygen sensor.

(2) Disconnect the negative battery terminal.

(3) On 1.6 liter models, remove the air cleaner

nuts, disconnect the vacuum hose and withdraw the

air cleaner from the vehicle. (4) Remove the front exhaust pipe flange mount-

ing nuts and separate the exhaust pipe from the

manifold. (5) Remove the heat shield retaining bolts and

withdraw the heat shield from the exhaust manifold. (6) Remove the exhaust manifold to cylinder

head retaining nuts and remove the manifold from the

engine. Discard the manifold gasket. Installation is a reversal of the removal procedure

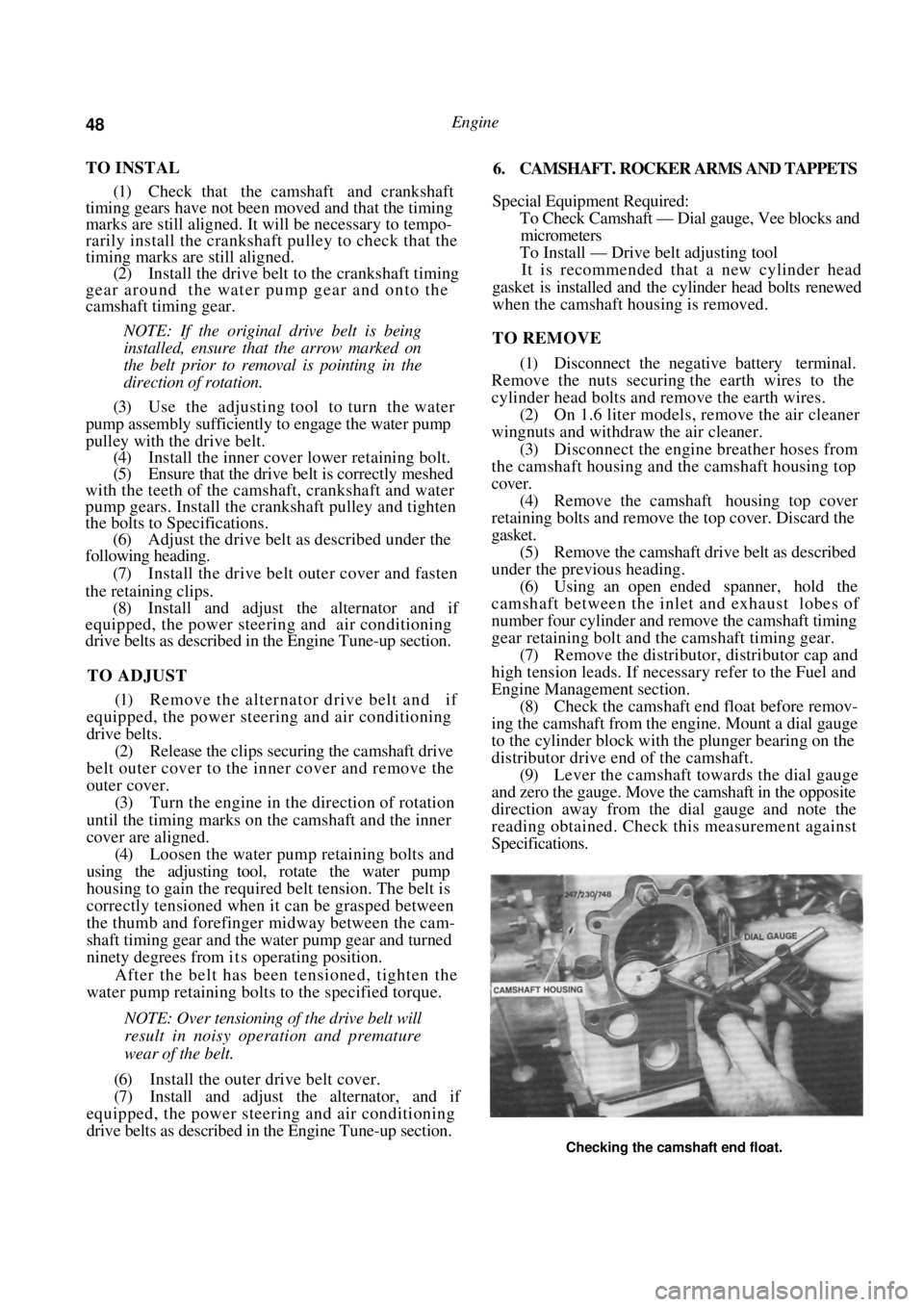

with attention to the following points:

(1) Ensure that all carbon is cleaned from the

manifold and cylinder head mating surfaces. (2) Check the face of the manifold for distortion

using a straight edge and feeler gauges. (3) Use new gaskets on assembly.

(4) Tighten the exhaust manifold retaining nuts

to the specified torque in the sequence shown in the

illustration. (5) Install the oxygen sensor. Refer to the Fuel

and Engine Management section. (6) Coat the threads of the front exhaust pipe to

manifold retaining nuts with an anti-seize solution

and tighten the nuts to the specified torque.

5. CAMSHAFT DRIVE BELT

Special Equipment Required:

To Adjust — Drive belt adjusting tool

TO REMOVE

(1) Disconnect the negative battery terminal.

(2) Raise the front of the vehicle, support it on

chassis stands and remove the right hand front wheel.

Refer to the Wheels and Tires section. (3) Remove the fasteners securing the engine

splash guard to the right hand front inner mudguard

and remove the splash guard. (4) Loosen the alternator adjusting bolt and if

equipped, the power steering and air conditioning

adjusting bolts. Remove the drive belt(s).

View of the exhaust manifold and components showing

the correct tightening sequence.

View of the 1.8 liter engine with the upper timing belt

cover removed showing the camshaft gear timing

marks. Inset shows the crankshaft pulley timing

marks.

Page 48 of 238

48 Engine

TO INSTAL

(1) Check that the camshaft and crankshaft

timing gears have not been moved and that the timing

marks are still aligned. It will be necessary to tempo-

rarily install the crankshaft pulley to check that the

timing marks are still aligned. (2) Install the drive belt to the crankshaft timing

gear around the water pump gear and onto the

camshaft timing gear.

NOTE: If the original drive belt is being

installed, ensure that the arrow marked on

the belt prior to removal is pointing in the

direction of rotation.

(3) Use the adjusting tool to turn the water

pump assembly sufficiently to engage the water pump

pulley with the drive belt. (4) Install the inner cover lower retaining bolt.

(5) Ensure that the drive be lt is correctly meshed

with the teeth of the camshaft, crankshaft and water

pump gears. Install the crankshaft pulley and tighten

the bolts to Specifications. (6) Adjust the drive belt as described under the

following heading.

(7) Install the drive belt outer cover and fasten

the retaining clips. (8) Install and adjust the alternator and if

equipped, the power steeri ng and air conditioning

drive belts as desc ribed in the Engine Tune-up section.

TO ADJUST

(1) Remove the alternator drive belt and if

equipped, the power steering and air conditioning

drive belts. (2) Release the clips securing the camshaft drive

belt outer cover to the inner cover and remove the

outer cover. (3) Turn the engine in the direction of rotation

until the timing marks on the camshaft and the inner

cover are aligned. (4) Loosen the water pump retaining bolts and

using the adjusting tool, rotate the water pump

housing to gain the required belt tension. The belt is

correctly tensioned when it can be grasped between

the thumb and forefinger midway between the cam-

shaft timing gear and the water pump gear and turned

ninety degrees from i t s operating position.

After the belt has been tensioned, tighten the

water pump retaining bolts to the specified torque.

NOTE: Over tensioning of the drive belt will

result in noisy operation and premature

wear of the belt.

(6) Install the outer drive belt cover.

(7) Install and adjust the alternator, and if

equipped, the power steering and air conditioning

drive belts as desc ribed in the Engine Tune-up section. 6. CAMSHAFT. ROCKER ARMS AND TAPPETS

Special Equipment Required:

To Check Camshaft — Dial gauge, Vee blocks and

micrometers

To Install — Drive belt adjusting tool

It is recommended that a new cylinder head

gasket is installed and the cylinder head bolts renewed

when the camshaft housing is removed.

TO REMOVE

(1) Disconnect the negative battery terminal.

Remove the nuts securing the earth wires to the

cylinder head bolts and remove the earth wires.

(2) On 1.6 liter models, remove the air cleaner

wingnuts and withdraw the air cleaner.

(3) Disconnect the engine breather hoses from

the camshaft housing and the camshaft housing top

cover. (4) Remove the camshaft housing top cover

retaining bolts and remove the top cover. Discard the

gasket.

(5) Remove the camshaft dr ive belt as described

under the previous heading. (6) Using an open ended spanner, hold the

camshaft between the inle t and exhaust lobes of

number four cylinder and remove the camshaft timing

gear retaining bolt and the camshaft timing gear.

(7) Remove the distributor, distributor cap and

high tension leads. If necessary refer to the Fuel and

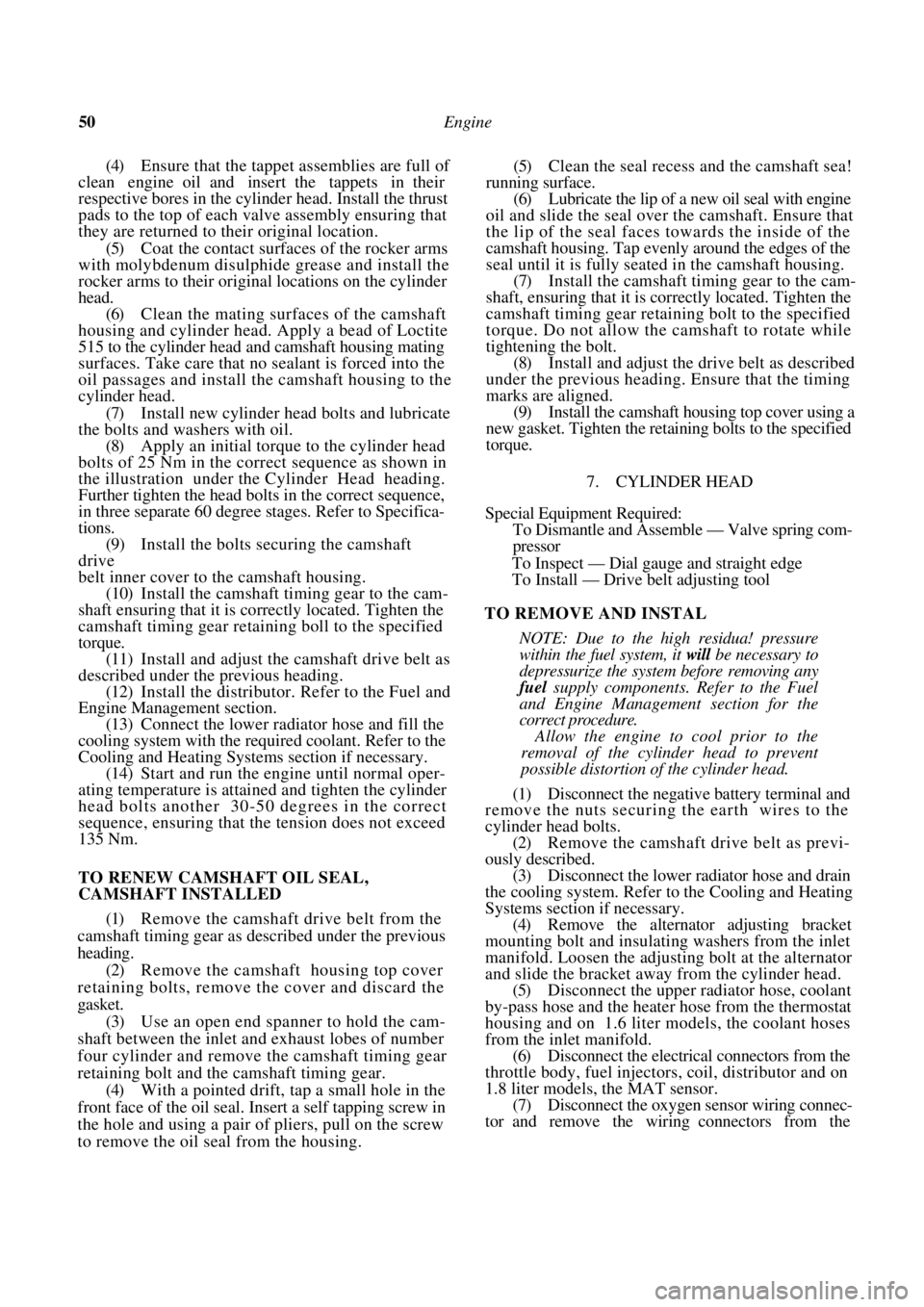

Engine Management section. (8) Check the camshaft end float before remov-

ing the camshaft from the engine. Mount a dial gauge

to the cylinder block with the plunger bearing on the

distributor drive end of the camshaft. (9) Lever the camshaft towards the dial gauge

and zero the gauge. Move the camshaft in the opposite

direction away from the dial gauge and note the

reading obtained. Check this measurement against

Specifications.

Checking the camshaft end float.

Page 50 of 238

50 Engine

(4) Ensure that the tappet assemblies are full of

clean engine oil and insert the tappets in their

respective bores in the cylinde r head. Install the thrust

pads to the top of each valve assembly ensuring that

they are returned to their original location.

(5) Coat the contact surfaces of the rocker arms

with molybdenum disulphide grease and install the

rocker arms to their origin al locations on the cylinder

head. (6) Clean the mating surfaces of the camshaft

housing and cylinder head. Apply a bead of Loctite

515 to the cylinder head and camshaft housing mating

surfaces. Take care that no sea lant is forced into the

oil passages and install the camshaft housing to the

cylinder head.

(7) Install new cylinder head bolts and lubricate

the bolts and washers with oil.

(8) Apply an initial torque to the cylinder head

bolts of 25 Nm in the corr ect sequence as shown in

the illustration under the Cylinder Head heading.

Further tighten the head bolts in the correct sequence,

in three separate 60 degree stages. Refer to Specifica-

tions. (9) Install the bolts securing the camshaft

drive

belt inner cover to the camshaft housing. (10) Install the camshaft timing gear to the cam-

shaft ensuring that it is correctly located. Tighten the

camshaft timing gear retain ing boll to the specified

torque. (11) Install and adjust the camshaft drive belt as

described under the previous heading. (12) Install the distributor. Refer to the Fuel and

Engine Management section.

(13) Connect the lower radiat or hose and fill the

cooling system with the required coolant. Refer to the

Cooling and Heating Systems section if necessary. (14) Start and run the engine until normal oper-

ating temperature is attained and tighten the cylinder

head bolts another 30-50 degrees in the correct

sequence, ensuring that the tension does not exceed

135 Nm.

TO RENEW CAMSHAFT OIL SEAL,

CAMSHAFT INSTALLED

(1) Remove the camshaft drive belt from the

camshaft timing gear as described under the previous

heading.

(2) Remove the camshaft housing top cover

retaining bolts, remove the cover and discard the

gasket.

(3) Use an open end spanner to hold the cam-

shaft between the inlet and exhaust lobes of number

four cylinder and remove the camshaft timing gear

retaining bolt and the camshaft timing gear. (4) With a pointed drift, tap a small hole in the

front face of the oil seal. Insert a self tapping screw in

the hole and using a pair of pliers, pull on the screw

to remove the oil seal from the housing.

(5) Clean the seal recess and the camshaft sea!

running surface. (6) Lubricate the lip of a new oil seal with engine

oil and slide the seal over the camshaft. Ensure that

the lip of the seal faces to wards the inside of the

camshaft housing. Tap evenly around the edges of the

seal until it is fully seated in the camshaft housing.

(7) Install the camshaft timing gear to the cam-

shaft, ensuring that it is co rrectly located. Tighten the

camshaft timing gear retain ing bolt to the specified

torque. Do not allow the camshaft to rotate while

tightening the bolt. (8) Install and adjust the drive belt as described

under the previous heading. Ensure that the timing

marks are aligned. (9) Install the camshaft hou sing top cover using a

new gasket. Tighten the retaining bolts to the specified

torque.

7. CYLINDER HEAD

Special Equipment Required:

To Dismantle and Assemble — Valve spring com-

pressor

To Inspect — Dial gauge and straight edge

To Install — Drive belt adjusting tool

TO REMOVE AND INSTAL

NOTE: Due to the high residua! pressure

within the fuel system, it will be necessary to

depressurize the system before removing any

fuel supply components. Refer to the Fuel

and Engine Management section for the

correct procedure.

Allow the engine to cool prior to the

removal of the cylinder head to prevent

possible distortion of the cylinder head.

(1) Disconnect the negative battery terminal and

remove the nuts securing the earth wires to the

cylinder head bolts.

(2) Remove the camshaft drive belt as previ-

ously described.

(3) Disconnect the lower radiator hose and drain

the cooling system. Refer to the Cooling and Heating

Systems section if necessary. (4) Remove the alternator adjusting bracket

mounting bolt and insulating washers from the inlet

manifold. Loosen the adjusting bolt at the alternator

and slide the bracket away from the cylinder head. (5) Disconnect the upper radiator hose, coolant

by-pass hose and the heater hose from the thermostat

housing and on 1.6 liter m odels, the coolant hoses

from the inlet manifold. (6) Disconnect the electrica l connectors from the

throttle body, fuel injectors, coil, distributor and on

1.8 liter models, the MAT sensor. (7) Disconnect the oxygen sensor wiring connec-

tor and remove the wiring connectors from the

Page 54 of 238

54 Engine

in the valve stem groove before releasing the spring

compressor. A sharp tap to the top of the valve stem

with a soft faced hammer will ensure that the collets

are correctly seated.

(7) Install the inlet and exhaust manifolds using

new gaskets and tighten the mounting nuts to the

specified torque as previously described. (8) Install a new sealing ring to the

thermostat

housing, install the housing to the cylinder head and

tighten the mounting bolts to the specified torque.

(9) Ensure that the lappet assemblies are filled

with clean engine oil and install the tappets in

their

respective bores in the cylinder head. (10) Install the thrust pads to the top of each

valve

assembly, ensuring that they are returned to their

original locations. (11) Coat the contact surfaces of the rocker arms

with molybdenum disulphide grease and install the

rocker arms to their origin al locations on the cylinder

head. (12) Install the cylinder head to the engine as

previously described.

8. ENGINE SUMP AND OIL PUMP PICKUP . PIPE

TO REMOVE

(1) Disconnect the negative battery terminal.

(2) Raise the front of the vehicle and support it

on chassis stands. Refer to the Wheels and Tires

section for the correct procedure.

(3) Remove the sump plug and drain the engine

oil into a container. Install and tighten the plug

after the oil has been drained.

(4)

Remove the engine pipe as described at the

end of this section.

(5) Remove the nuts and bolts retaining the

engine crossmember to the vehicle underbody and

withdraw the crossmember from the vehicle. On

automatic transaxle models, it will be necessary to

release the selector cable from the crossmember

bracket.

(6) Remove the sump retaining bolts and wash-

ers and if necessary firmly bump the sump with the

palm of the hand and remove it from the engine. (7) Remove the bolts retaining the oil pump

pickup pipe to the oil pump and disconnect the

pickup pipe from the support bracket. Remove the

pickup pipe and discard the O ring seal. (8) Remove the scraper and gasket from the

engine. (9) Clean the gasket material from the sump,

engine block and the scraper.

NOTE: If the scraper assembly is damaged

it should be renewed.

TO INSTAL

(1) Wash the inside of the sump to remove

carbon and sludge deposits. Check for any metal

deposits which may indicate an imminent component

failure. (2) Inspect the sump for dents and cracks.

Ensure that the gasket sea ling face is not distorted or

damaged. (3) Clean the pickup pipe screen with solvent

and a brush. (4) Using a new O ring seal, install the pickup

pipe. Coat the pipe retain ing bolts with Loctite 242

and tighten to the specified torque. (5) Apply a bead of KP510-00150 sealer or

equivalent to the oil pump to cylinder block mating

joint area. (6) Ensure that the sump gasket is correctly

located on the scraper and install the sump to

the

engine. Apply Loctite 242 to the threads of the sump

bolts and tighten the bolts to the specified torque.

(7) Install the front exhaust pipe using a

new

gasket and coat the threads of the flange nuts with an

anti-seize compound before tightening the nuts to the

specified torque. (8) Install the engine crossmember and

tighten

the nuts and bolts securely. If applicable, connect the

automatic transaxle selector cable to the crossmember

bracket. (9) Ensure that the sump drain plug is secure

and lower the vehicle to the ground. (10) Fill the engine with the specified amount and

grade of engine oil. Refer to the Lubrication and

Maintenance section if necessary. (11) Start and run the engine and check for oil

leaks.

View of the sump, oil pump pickup, gasket and scraper

removed from the engine.

Page 55 of 238

Engine 55

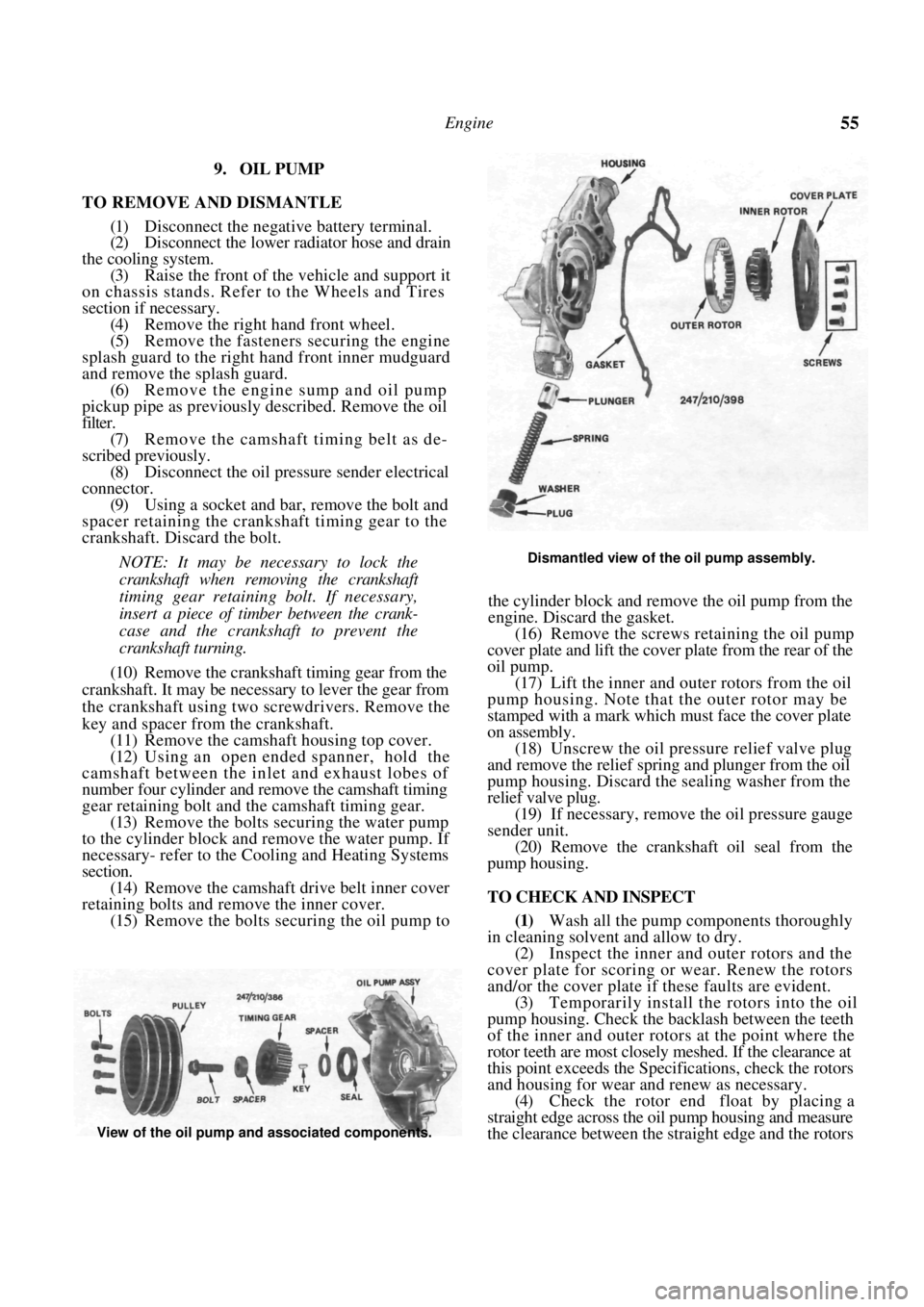

9. OIL PUMP

TO REMOVE AND DISMANTLE

(1) Disconnect the negative battery terminal.

(2) Disconnect the lower radiator hose and drain

the cooling system. (3) Raise the front of the vehicle and support it

on chassis stands. Refer to the Wheels and Tires

section if necessary. (4) Remove the right hand front wheel.

(5) Remove the fasteners securing the engine

splash guard to the right hand front inner mudguard

and remove the splash guard. (6) Remove the engine sump and oil pump

pickup pipe as previously described. Remove the oil

filter.

(7) Remove the camshaft timing belt as de-

scribed previously. (8) Disconnect the oil pressure sender electrical

connector. (9) Using a socket and bar, remove the bolt and

spacer retaining the crankshaft timing gear to the

crankshaft. Discard the bolt.

NOTE: It may be necessary to lock the

crankshaft when removing the crankshaft

timing gear retaining bolt. If necessary,

insert a piece of timber between the crank-

case and the crankshaft to prevent the

crankshaft turning.

(10) Remove the crankshaft timing gear from the

crankshaft. It may be necessary to lever the gear from

the crankshaft using two screwdrivers. Remove the

key and spacer from the crankshaft. (11) Remove the camshaft housing top cover.

(12) Using an open ended spanner, hold the

camshaft between the inlet and exhaust lobes of

number four cylinder and remove the camshaft timing

gear retaining bolt and the camshaft timing gear.

(13) Remove the bolts securing the water pump

to the cylinder block and remove the water pump. If

necessary- refer to the Cooling and Heating Systems

section. (14) Remove the camshaft drive belt inner cover

retaining bolts and remove the inner cover. (15) Remove the bolts securing the oil pump to

Dismantled view of the oil pump assembly.

the cylinder block and remove the oil pump from the

engine. Discard the gasket.

(16) Remove the screws retaining the oil pump

cover plate and lift the cover plate from the rear of the

oil pump. (17) Lift the inner and outer rotors from the oil

pump housing. Note that the outer rotor may be

stamped with a mark which must face the cover plate

on assembly. (18) Unscrew the oil pressure relief valve plug

and remove the relief spring and plunger from the oil

pump housing. Discard the sealing washer from the

relief valve plug. (19) If necessary, remove the oil pressure gauge

sender unit.

(20) Remove the crankshaft oil seal from the

pump housing.

TO CHECK AND INSPECT

(1) Wash all the pump components thoroughly

in cleaning solvent and allow to dry.

(2) Inspect the inner and outer rotors and the

cover plate for scoring or wear. Renew the rotors

and/or the cover plate if these faults are evident. (3) Temporarily install the rotors into the oil

pump housing. Check the b acklash between the teeth

of the inner and outer rotors at the point where the

rotor teeth are most closely meshed. If the clearance at

this point exceeds the Specif ications, check the rotors

and housing for wear and renew as necessary. (4) Check the rotor end float by placing a

straight edge across the oil pump housing and measure

the clearance between the straight edge and the rotors

View of the oil pump and associated components.

Page 64 of 238

64 Engine

automatic transaxle models the complete drive plate

must be renewed.

(3) Inspect the drive plate bolt holes for elonga-

tion which is caused by loose retaining bolts.

(4) Inspect the drive plate for cracks.

(5) Repair or renew the flywheel if necessary.

TO INSTAL

Installation is a reversal of the removal procedure

with attention to the following points:

(1) The flywheel and drive plate retaining bolts

are special micro-encapsulated fasteners.

Install new micro-encapsulated bolts of the

correct

strength classification on assembly.

(2) Thoroughly clean the crankshaft threads with

a thread tap. Clean the threads with solvent and dry

before installing the flywh eel or drive plate retaining

bolts.

(3) Tighten the flywheel or drive plate retaining

bolts to the specified torque and on manual transaxle

models, align the clutch plate as described in the

Clutch section.

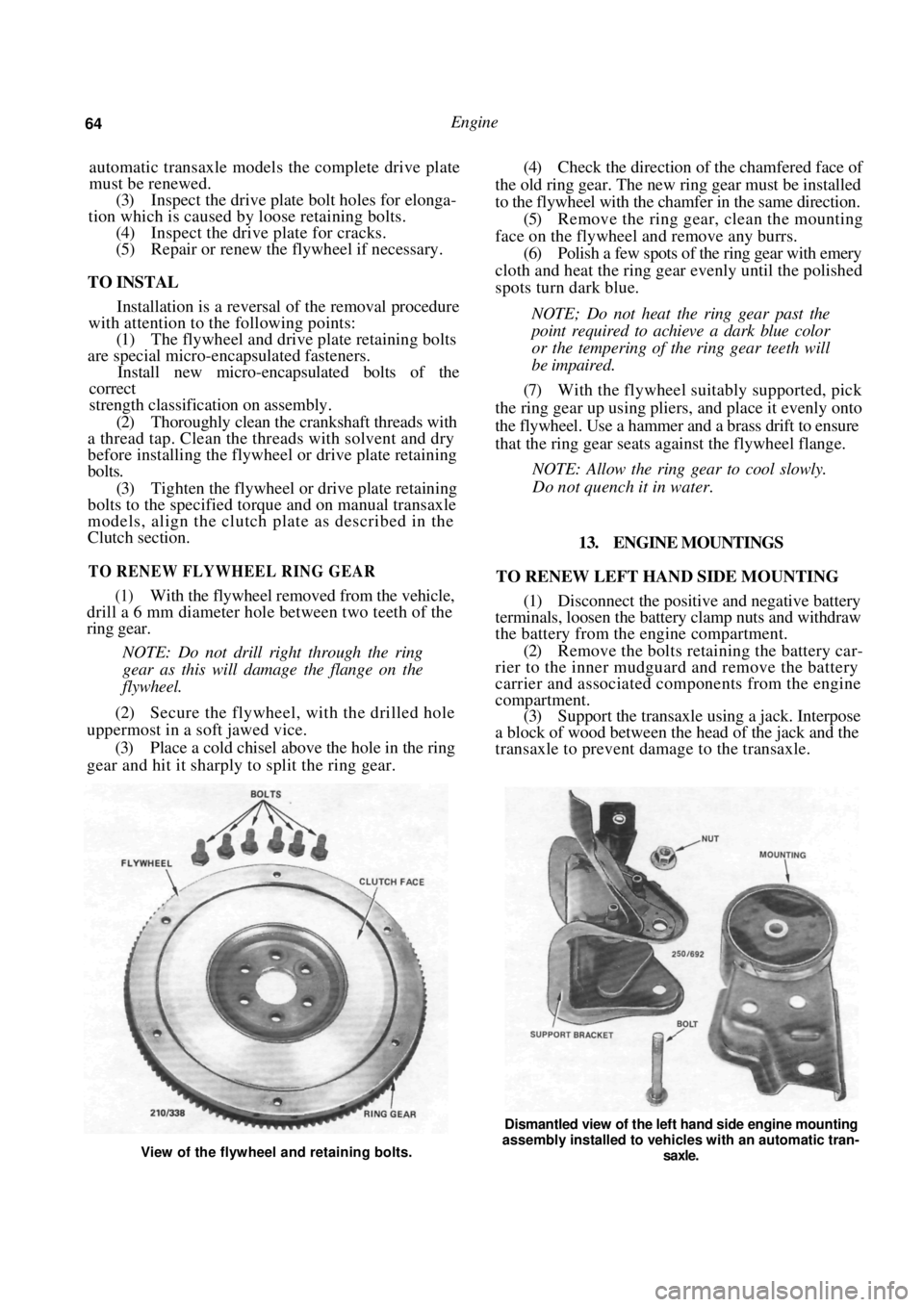

TO RENEW FLYWHEEL RING GEAR

(1) With the flywheel removed from the vehicle,

drill a 6 mm diameter hole between two teeth of the

ring gear.

NOTE: Do not drill right through the ring

gear as this will damage the flange on the

flywheel.

(2) Secure the flywheel, with the drilled hole

uppermost in a soft jawed vice.

(3) Place a cold chisel above the hole in the ring

gear and hit it sharply to split the ring gear.

(4) Check the direction of the chamfered face of

the old ring gear. The new ring gear must be installed

to the flywheel with the chamfer in the same direction. (5) Remove the ring gear, clean the mounting

face on the flywheel and remove any burrs. (6) Polish a few spots of the ring gear with emery

cloth and heat the ring gear evenly until the polished

spots turn dark blue.

NOTE; Do not heat the ring gear past the

point required to achieve a dark blue color

or the tempering of the ring gear teeth will

be impaired.

(7) With the flywheel suitably supported, pick

the ring gear up using plie rs, and place it evenly onto

the flywheel. Use a hammer and a brass drift to ensure

that the ring gear seats ag ainst the flywheel flange.

NOTE: Allow the ring gear to cool slowly.

Do not quench it in water.

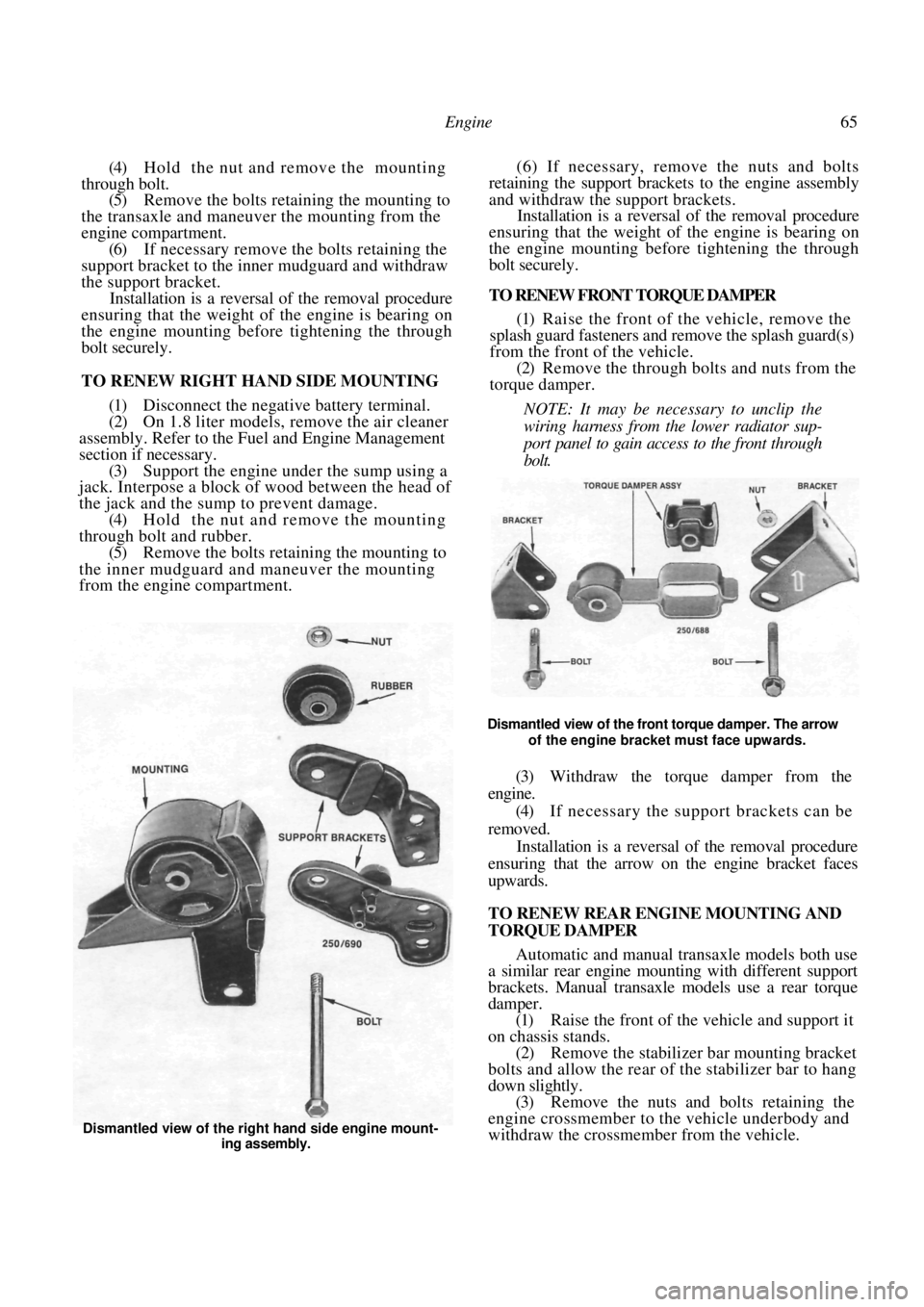

13. ENGINE MOUNTINGS

TO RENEW LEFT HAND SIDE MOUNTING

(1) Disconnect the positive and negative battery

terminals, loosen the battery clamp nuts and withdraw

the battery from the engine compartment.

(2) Remove the bolts retaining the battery car-

rier to the inner mudguard and remove the battery

carrier and associ ated components from the engine

compartment. (3) Support the transaxle using a jack. Interpose

a block of wood between the head of the jack and the

transaxle to prevent damage to the transaxle.

View of the flywheel and retaining bolts.

Dismantled view of the left hand side engine mounting

assembly installed to vehicles with an automatic tran-

saxle.

Page 65 of 238

Engine 65

(4) Hold the nut and remove the mounting

through bolt. (5) Remove the bolts retaining the mounting to

the transaxle and maneuver the mounting from the

engine compartment. (6) If necessary remove the bolts retaining the

support bracket to the inner mudguard and withdraw

the support bracket. Installation is a reversal of the removal procedure

ensuring that the weight of the engine is bearing on

the engine mounting before tightening the through

bolt securely.

TO RENEW RIGHT HAND SIDE MOUNTING

(1) Disconnect the negative battery terminal.

(2) On 1.8 liter models, remove the air cleaner

assembly. Refer to the Fuel and Engine Management

section if necessary. (3) Support the engine under the sump using a

jack. Interpose a block of wood between the head of

the jack and the sump to prevent damage.

(4) Hold the nut and remove the mounting

through bolt and rubber. (5) Remove the bolts retain ing the mounting to

the inner mudguard and maneuver the mounting

from the engine compartment. (6) If necessary, remove the nuts and bolts

retaining the support brackets to the engine assembly

and withdraw the support brackets.

Installation is a reversal of the removal procedure

ensuring that the weight of the engine is bearing on

the engine mounting before tightening the through

bolt securely.

TO RENEW FRONT TORQUE DAMPER

(1) Raise the front of the vehicle, remove the

splash guard fasteners and remove the splash guard(s)

from the front of the vehicle.

(2) Remove the through bolts and nuts from the

torque damper.

NOTE: It may be necessary to unclip the

wiring harness from the lower radiator sup-

port panel to gain access to the front through

bolt.

Dismantled view of the front torque damper. The arrow of the engine bracket must face upwards.

(3) Withdraw the torque damper from the

engine.

(4) If necessary the support brackets can be

removed. Installation is a reversal of the removal procedure

ensuring that the arrow on the engine bracket faces

upwards.

TO RENEW REAR ENGINE MOUNTING AND

TORQUE DAMPER

Automatic and manual transaxle models both use

a similar rear engine moun ting with different support

brackets. Manual transaxle models use a rear torque

damper.

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the stabilizer bar mounting bracket

bolts and allow the rear of the stabilizer bar to hang

down slightly. (3) Remove the nuts and bolts retaining the

engine crossmember to the vehicle underbody and

withdraw the crossmember from the vehicle.

Dismantled view of the right hand side engine mount-

ing assembly.

Page 70 of 238

70 Cooling and Heating Systems

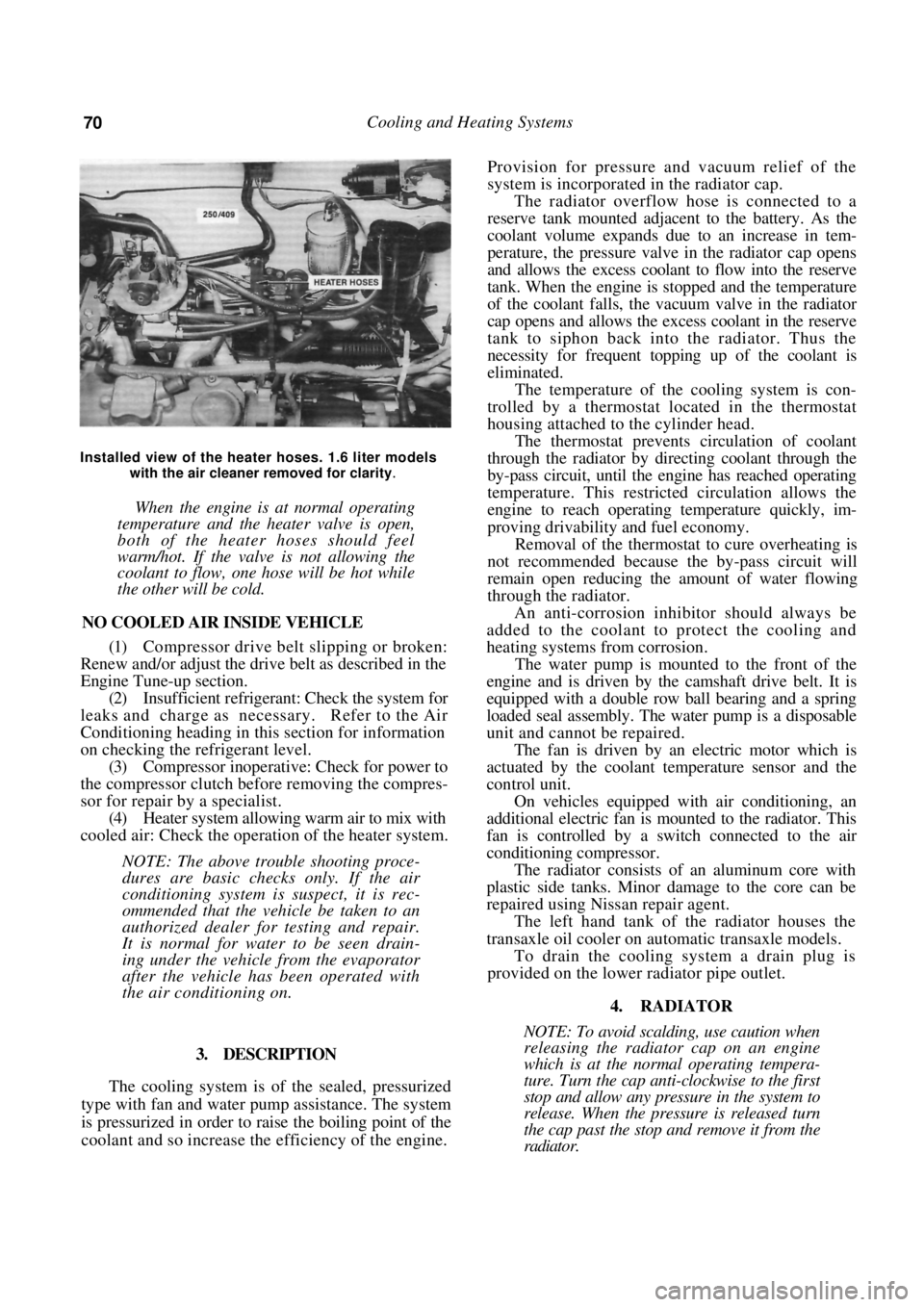

Installed view of the heater hoses. 1.6 liter models with the air cleaner removed for clarity

.

When the engine is at normal operating

temperature and the heater valve is open,

both of the heater hoses should feel

warm/hot. If the valve is not allowing the

coolant to flow, one hose will be hot while

the other will be cold.

NO COOLED AIR INSIDE VEHICLE

(1) Compressor drive belt slipping or broken:

Renew and/or adjust the drive belt as described in the

Engine Tune-up section.

(2) Insufficient refrigerant: Check the system for

leaks and charge as necessary. Refer to the Air

Conditioning heading in th is section for information

on checking the refrigerant level. (3) Compressor inoperative: Check for power to

the compressor clutch before removing the compres-

sor for repair by a specialist. (4) Heater system allowing warm air to mix with

cooled air: Check the operation of the heater system.

NOTE: The above trouble shooting proce-

dures are basic checks only. If the air

conditioning system is suspect, it is rec-

ommended that the vehicle be taken to an

authorized dealer for testing and repair.

It is normal for water to be seen drain-

ing under the vehicle from the evaporator

after the vehicle has been operated with

the air conditioning on.

3. DESCRIPTION

The cooling system is of the sealed, pressurized

type with fan and water pump assistance. The system

is pressurized in order to raise the boiling point of the

coolant and so increase the efficiency of the engine.

Provision for pressure a nd vacuum relief of the

system is incorporated in the radiator cap.

The radiator overflow hose is connected to a

reserve tank mounted adjacent to the battery. As the

coolant volume expands due to an increase in tem-

perature, the pressure valve in the radiator cap opens

and allows the excess coolant to flow into the reserve

tank. When the engine is stopped and the temperature

of the coolant falls, the vacuum valve in the radiator

cap opens and allows the excess coolant in the reserve

tank to siphon back into the radiator. Thus the

necessity for frequent topping up of the coolant is

eliminated.

The temperature of the cooling system is con-

trolled by a thermostat located in the thermostat

housing attached to the cylinder head.

The thermostat prevents circulation of coolant

through the radiator by directing coolant through the

by-pass circuit, until the engine has reached operating

temperature. This restricted circulation allows the

engine to reach operating temperature quickly, im-

proving drivability and fuel economy.

Removal of the thermostat to cure overheating is

not recommended because th e by-pass circuit will

remain open reducing the amount of water flowing

through the radiator.

An anti-corrosion inhibitor should always be

added to the coolant to protect the cooling and

heating systems from corrosion.

The water pump is mounted to the front of the

engine and is driven by the camshaft drive belt. It is

equipped with a double row ball bearing and a spring

loaded seal assembly. The water pump is a disposable

unit and cannot be repaired.

The fan is driven by an electric motor which is

actuated by the coolant temperature sensor and the

control unit.

On vehicles equipped with air conditioning, an

additional electric fan is m ounted to the radiator. This

fan is controlled by a sw itch connected to the air

conditioning compressor.

The radiator consists of an aluminum core with

plastic side tanks. Minor damage to the core can be

repaired using Nissan repair agent.

The left hand tank of the radiator houses the

transaxle oil cooler on automatic transaxle models.

To drain the cooling system a drain plug is

provided on the lower radiator pipe outlet.

4. RADIATOR

NOTE: To avoid scalding, use caution when

releasing the radiator cap on an engine

which is at the normal operating tempera-

ture. Turn the cap anti-clockwise to the first

stop and allow any pressure in the system to

release. When the pressure is released turn

the cap past the stop and remove it from the

radiator.

Page 73 of 238

Cooling and Heating Systems 73

(1) Renew all hoses that show signs of cracking

or perishing.

(2) Before finally tightening the hose clips, en-

sure that the hoses are push ed fully onto the radiator

and are not kinked. (3) On automatic transaxle models, ensure that

the oil cooler hoses are correctly installed to the

radiator and show no signs of leakage. Check and top

up the automatic transaxle fluid as necessary.

5. COOLING FAN

The radiator cooling fan is controlled by the

electronic control unit, and on vehicles with air

conditioning, the condenser fan relay. On vehicles

with air conditioning there are two cooling fans, one

is larger than the other. The large fan is for the

radiator and the smaller fan provides extra cooling

when the air conditioning is activated. Each fan is

controlled by a separate system.

TO TEST COOLING FAN AND SYSTEM

(1) With the cooling system cold and the air

conditioning, if applicable, switched off, switch the

ignition On and confirm that the cooling fan is

stationary.

NOTE: Leave the ignition On for all tests

unless otherwise stated.

(2) In the above test, if the cooling fan rotates,

proceed as follows:

(a) Disconnect the cooling fan relay from the

rear of the engine compartment relay box.

(b) If the fan stops, backprobe terminal C1 at

the electronic control unit using an LED test lamp

connected to the positive battery terminal. If no

circuit exists, renew the cooling fan relay.

View showing the location of the diagnostic link

connector. Passengers seat removed for clarity.

If a circuit exists, check the wiring harness

between the electronic control unit and the relay for

short circuits to earth and repair if necessary. If no

short circuit is present renew the electronic control

unit.

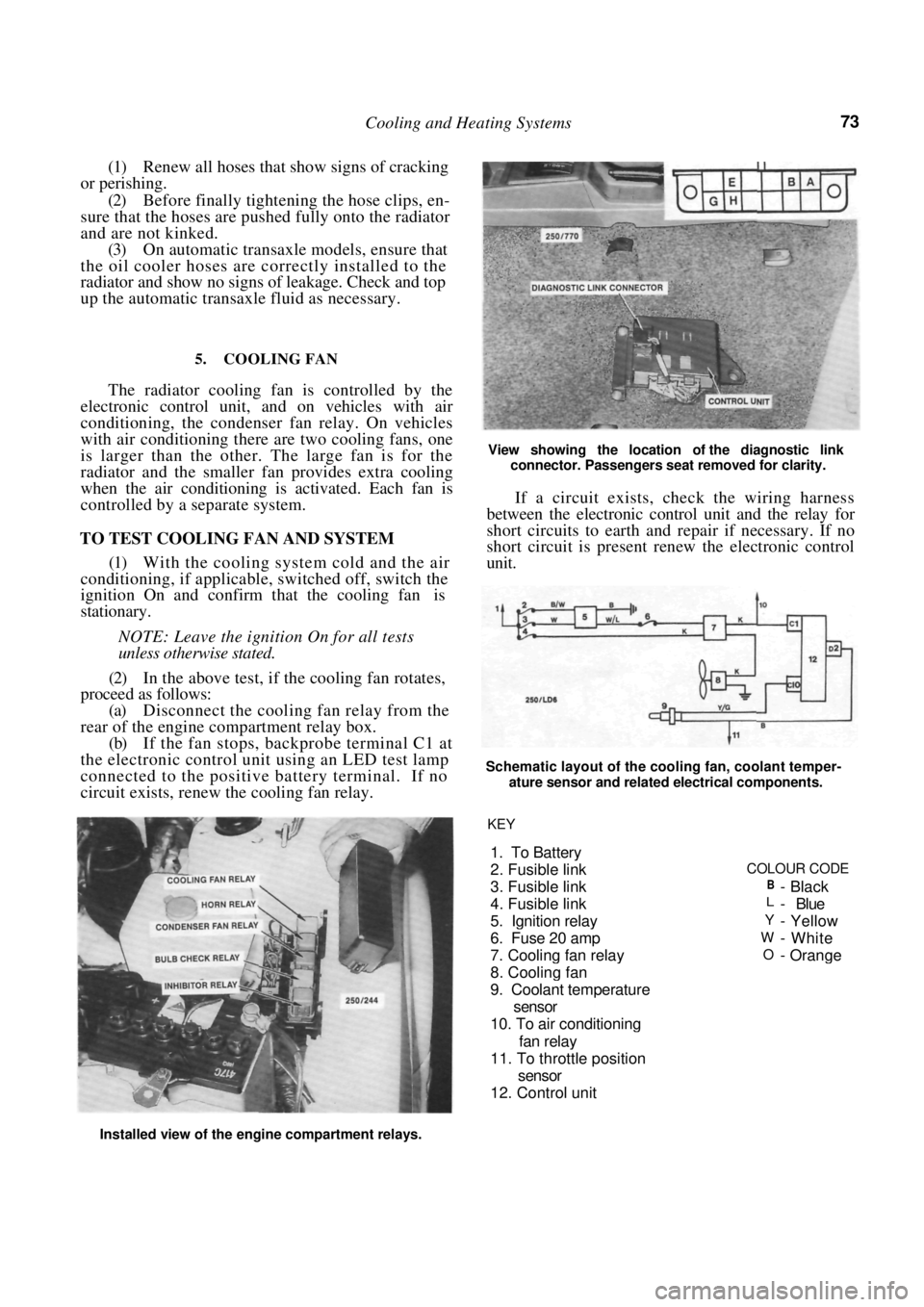

Schematic layout of the cooling fan, coolant temper-

ature sensor and related electrical components.

Installed view of the engine compartment relays. KEY

1. To Battery

2. Fusible link

COLOUR CODE

3. Fusible link

B-Black

4. Fusible linkL- Blue

5. I

gnition relayY- Yellow

6. Fuse 20 am

pW-White

7. Coolin

g fan relayO-Orange

8. Coolin

g fan

9. Coolant tem

perature

sensor

10. To air conditionin

g

fan rela

y

11. To throttle

position

sensor

12. Control unit