fuse NISSAN PULSAR 1987 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 115 of 238

Fuel and Engine Management 115

Erase the fault codes and retest for fault codes as

follows:

(2) Start and run the engine until normal oper-

ating temperature is attained. (3) Drive the vehicle at a speed of at least 80

km/h and, with the throttle closed, allow the vehicle to

decelerate until the engine speed is below 1 500 rpm.

NOTE: After rectifying any fault it will be

necessary to retest for fault codes. To test for

Code 24 the vehicle must be driven as

previously described.

(4) Switch the engine Off and connect a jumper

lead between terminals A and B on the diagnostic link

connector. Switch the ignition On and note the fault

codes. If code 24 is displayed proceed as follows. (5) Check the operation of the speedometer and

the instrument cluster warning lamps. If the speed-

ometer only is not functioning, proceed to operation

(13).

If the speedometer and the instrument cluster

warning lamps are not functioning, a fault in the

instrument cluster wiring harness is indicated. Refer

the fault to an auto electrical workshop or a Nissan

dealer.

If the speedometer is functioning, proceed as

follows:

(6) Raise the front of the vehicle and support it

on chassis stands. (7) Place the transaxle in Neutral and switch the

ignition On. (8) With the aid of assistants, slowly spin the

front wheels by hand while backprobing the control

unit wiring connector terminal A10 with a digital

voltmeter to earth. The voltage should alternate from under 1 volt to

over 10 volts.

If the voltmeter readi ng is not as specified,

proceed to operation (9).

If the voltmeter reading is as specified, the vehicle

speed sensor is operating satisfactorily, indicating an

intermittent fault was the cause of the fault code.

Proceed as follows:

(a) Check for faulty wiri ng connections. Check

that all wiring connectors are clean and secure. (b) Check that all earth c onnections are secure.

(9) Remove the instrument cluster as described

in the Electrical System section. (10) With the ignition switched On, backprobe

the control unit wiring connector terminal A10 with a

voltmeter to earth. The voltage should be over 10

volts. If the voltage is less than specified, check the

wiring harness for shorts to earth between the black

and yellow wire terminal on the instrument cluster

wiring connector and the control unit connector

terminal A10. Repair or renew the wiring harness as

necessary. If no fault can be found, renew the control

unit.

(11) With the ignition switched On, backprobe

the black and yellow wire terminal on the instrument

cluster wiring connector with a voltmeter to earth.

The voltage should be over 10 volts.

If the voltage is less than specified, locate the open

circuit between the instrument cluster black and

yellow wire terminal and the control unit wiring

connector terminal A10. Repair or renew the wiring

harness as necessary.

(12) With a test lamp connected to 12 volts,

backprobe the black wire terminals on the instrument

cluster wiring connectors. The test lamp should light.

If the test lamp does not light locate the open

circuit between the black wire terminals and earth.

Repair or renew the wiring harness as necessary.

If the test lamp does light, renew the signal

divider circuit board which is located in the instru-

ment cluster.

(13) With the ignition switched On and the

engine not running, disconnect the vehicle speed

sensor wiring connector from the harness connector.

(14) With a test lamp connected to earth, probe

the yellow wire terminal on the harness wiring con-

nector. The test lamp should light. If the test lamp does not light, locate the open

circuit between the yellow wi re terminal and the Fuel

Pump fuse. Repair or renew the wiring harness as

necessary.

(15) With a test lamp connected to 12 volts,

probe the black wire terminal on the harness wiring

connector. The test lamp should light.

If the test lamp does not light, locate the open

circuit between the black wire terminal and earth.

Repair or renew the wiring harness as necessary.

(16) Using a voltmeter measure the voltage at the

red wire terminal on the harness wiring connector.

If the voltage is 5-9 volts proceed to operation

(19).

If the voltage is over 9 vol ts proceed to operation

(18).

Installed view of the vehicle speed sensor.

Page 192 of 238

192 Electrical System

transaxle models, check for a faulty or incorrectly

adjusted neutral safety switch.

1. Discharged battery: Check for a fault or short

circuit in the system. 2. Battery fully charged but will not crank

engine. Check for a locked drive and ring gear,

internal starter faul t or seized engine.

3. Fusible link blown: Check and repair the

cause and renew as necessary.

NOTE: Rotate the engine by hand to ensure

that the starter drive is not locked with the

flywheel ring gear and t hat the engine is not

seized. Ensure that the ignition key is

turned off before rotating the engine.

3. LIGHTING SYSTEM TROUBLE SHOOTING

LAMP OR LAMPS FAIL TO LIGHT

1. Faulty bulb(s): Check and renew the faulty

bulb(s). 2. Open circuit in the wiring or connections:

Check the lamp circuits and rectify as necessary.

1. Faulty lamp switch: Check and if necessary

renew the lamp switch. 2. Faulty fuse or fuse connection: Repair the

fuse connection or renew the fuse. 3. Lamp relay faulty: Check and renew as

necessary.

NOTE: Switch on the lamps concerned and

using a test lamp, check that the lamp

circuits are operating. This is best done by

starting at the lamp wiring connector or

bulb holder and work ing back to the power

source.

LAMP OR LAMPS INCORRECTLY

ILLUMINATED

1. Lamp or lamps incorrectly earthed: Check

the lamp earth for loosene ss or clean the contact,

either at the lamp body or wire.

2. Incorrect bulbs installe d: Check the bulb

wattage and voltage and renew with the correct type if

necessary. 3. Dirty or damaged lamp reflector: Clean or

renew the lamp reflector. 4. Faulty bulb: Check with a known serviceable

bulb and renew if necessary. 5. Dirty lamp lens: Clean or renew the lamp

lens. 6. High resistance or faulty connections be-

tween the alternator and battery: Check the circuit

and rectify th e condition.

7. Poor earth connection between the battery

and the engine or alternat or: Check the battery earth

lead and the strap between the engine and the body. 8. Voltage regulator faulty: Check and renew

the voltage regulator.

NOTE: The most common cause for this

condition is dirty t erminals on the earth

leads. Check all earth leads at their earthing

points.

4. TURN SIGNAL LAMP TROUBLE SHOOTING

TURN SIGNAL LAMP DOES NOT LIGHT AND

NO AUDIBLE NOISE FROM FLASHER UNIT

(1) Fuse blown: Rectify the fault and renew the

fuse.

(2) The Flasher unit is faulty: Renew the unit

(3) Turn signal switch faulty: Renew the switch

(4) Fault in the wiring circuit: Check and repair

the fault.

TURN SIGNAL WARNING LAMP DOES NOT

FLASH BUT AUDIBLE CLICKING FROM

FLASHER UNIT

(1) Warning lamp bulb blown: Check and renew

the bulb.

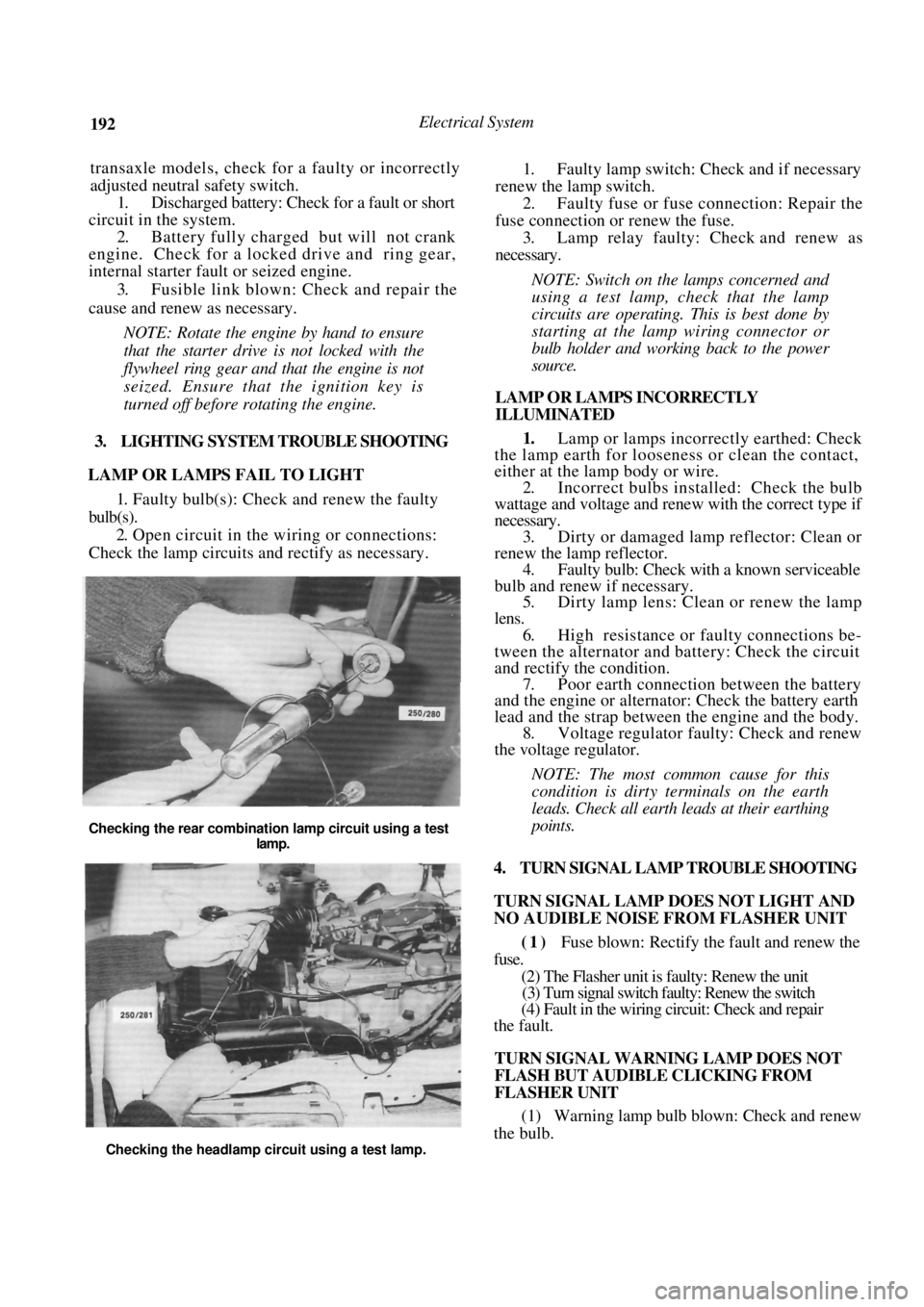

Checking the rear combination lamp circuit using a test

lamp.

Checking the headlamp circuit using a test lamp.

Page 193 of 238

Electrical System 193

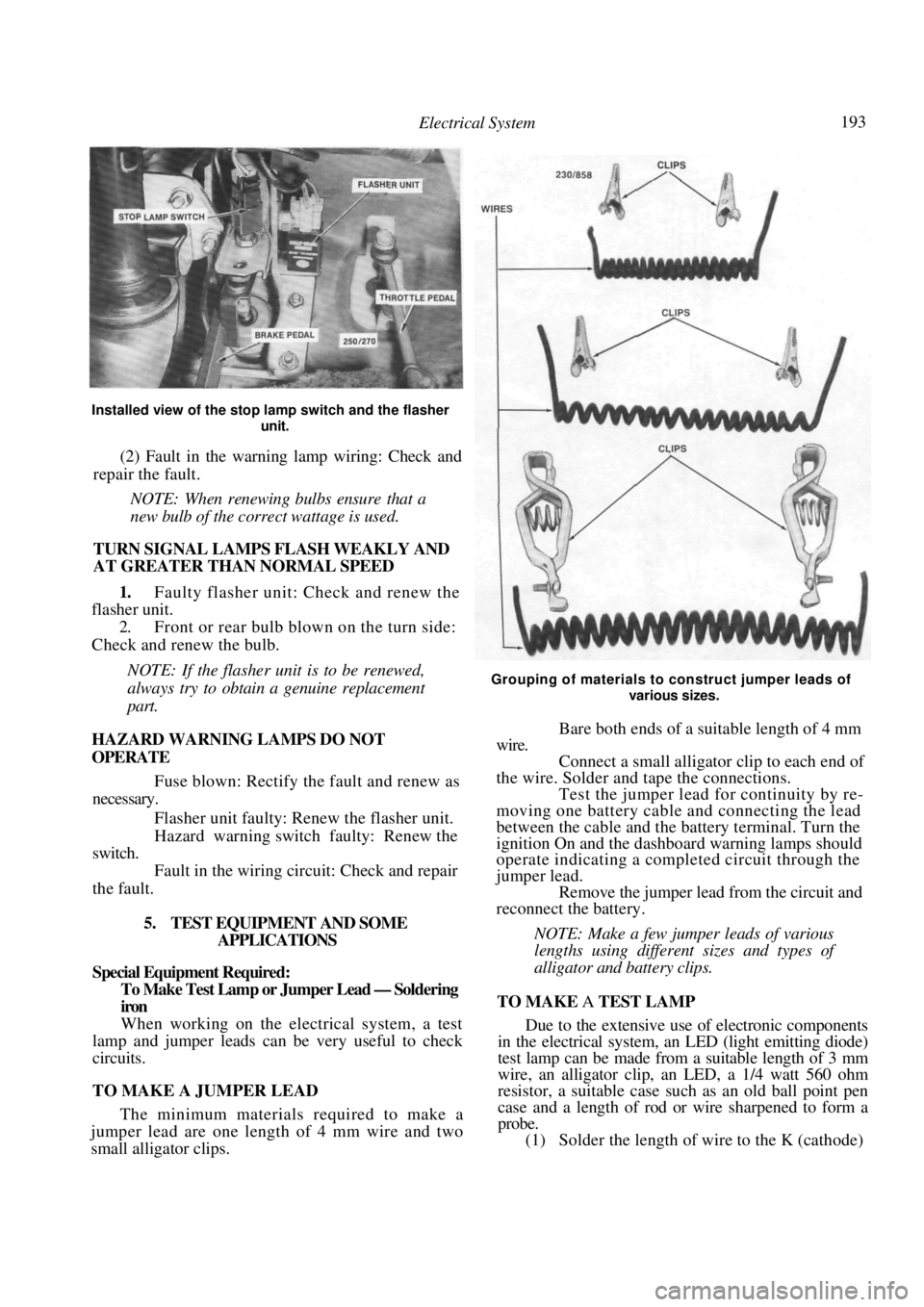

Installed view of the stop lamp switch and the flasher

unit.

(2) Fault in the warning lamp wiring: Check and

repair the fault.

NOTE: When renewing bulbs ensure that a

new bulb of the correct wattage is used.

TURN SIGNAL LAMPS FLASH WEAKLY AND

AT GREATER THAN NORMAL SPEED

1. Faulty flasher unit: Check and renew the

flasher unit.

2. Front or rear bulb blown on the turn side:

Check and renew the bulb.

NOTE: If the flasher unit is to be renewed,

always try to obtain a genuine replacement

part.

HAZARD WARNING LAMPS DO NOT

OPERATE

Fuse blown: Rectify the fault and renew as

necessary.

Flasher unit faulty: Re new the flasher unit.

Hazard warning switch faulty: Renew the

switch.

Fault in the wiring circuit: Check and repair

the fault.

5. TEST EQUIPMENT AND SOME APPLICATIONS

Special Equipment Required:

To Make Test Lamp or Jumper Lead — Soldering

iron

When working on the electrical system, a test

lamp and jumper leads can be very useful to check

circuits.

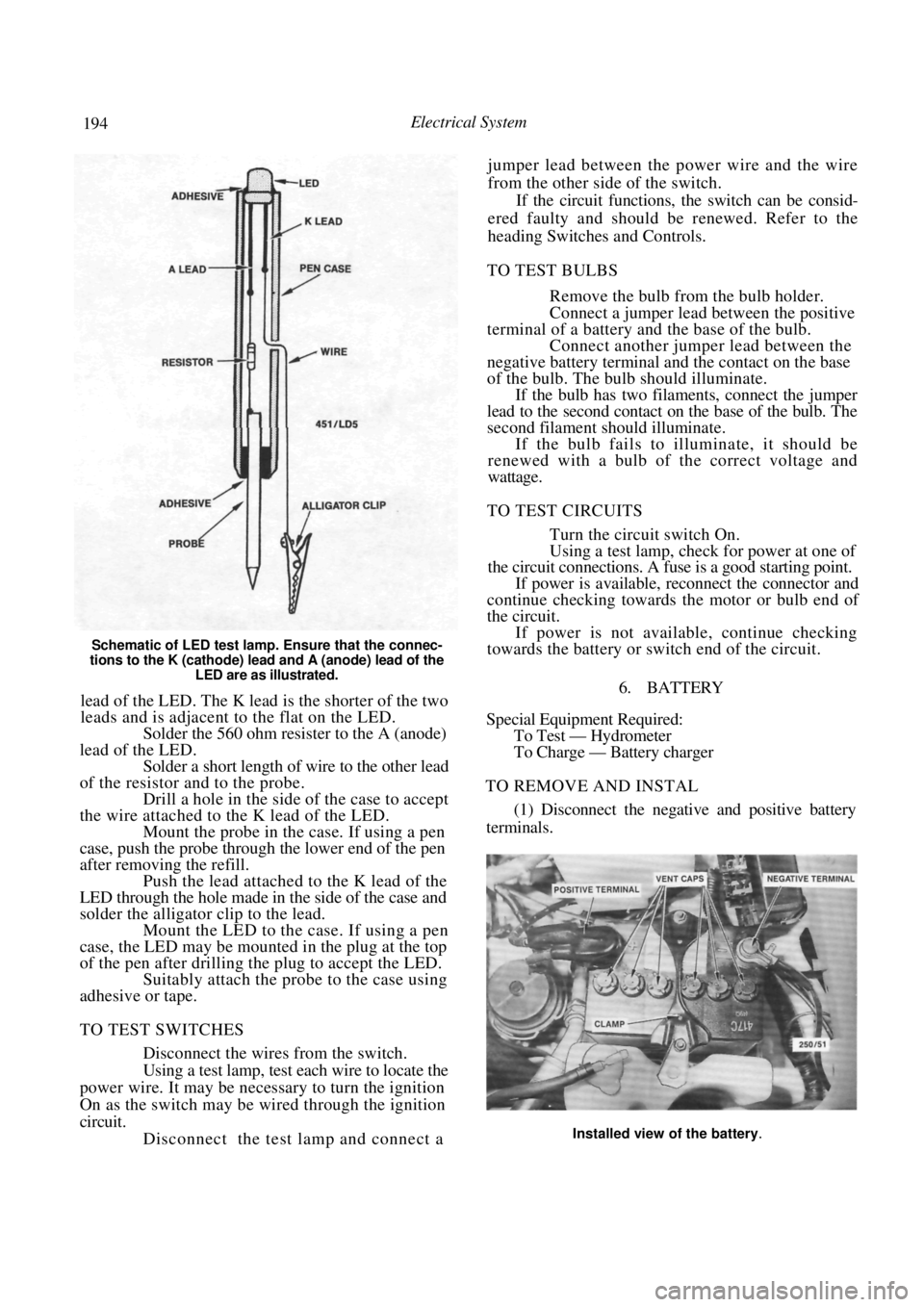

TO MAKE A JUMPER LEAD

The minimum materials required to make a

jumper lead are one length of 4 mm wire and two

small alligator clips.

Grouping of materials to construct jumper leads of

various sizes.

Bare both ends of a suitable length of 4 mm

wire. Connect a small alligato r clip to each end of

the wire. Solder and tape the connections. Test the jumper lead for continuity by re-

moving one battery cable and connecting the lead

between the cable and the battery terminal. Turn the

ignition On and the dashboard warning lamps should

operate indicating a completed circuit through the

jumper lead. Remove the jumper lead from the circuit and

reconnect the battery.

NOTE: Make a few jumper leads of various

lengths using different sizes and types of

alligator and battery clips.

TO MAKE A TEST LAMP

Due to the extensive use of electronic components

in the electrical system, an LED (light emitting diode)

test lamp can be made from a suitable length of 3 mm

wire, an alligator clip, an LED, a 1/4 watt 560 ohm

resistor, a suitable case such as an old ball point pen

case and a length of rod or wire sharpened to form a

probe.

(1) Solder the length of wire to the K (cathode)

Page 194 of 238

194 Electrical System

Schematic of LED test lamp. Ensure that the connec-

tions to the K (cathode) lead and A (anode) lead of the LED are as illustrated.

lead of the LED. The K lead is the shorter of the two

leads and is adjacent to the flat on the LED.

Solder the 560 ohm resister to the A (anode)

lead of the LED. Solder a short length of wire to the other lead

of the resistor and to the probe. Drill a hole in the side of the case to accept

the wire attached to the K lead of the LED. Mount the probe in the case. If using a pen

case, push the probe through the lower end of the pen

after removing the refill. Push the lead attached to the K lead of the

LED through the hole made in the side of the case and

solder the alligator clip to the lead.

Mount the LED to the case. If using a pen

case, the LED may be mounted in the plug at the top

of the pen after drilling the plug to accept the LED. Suitably attach the probe to the case using

adhesive or tape.

TO TEST SWITCHES

Disconnect the wires from the switch.

Using a test lamp, test each wire to locate the

power wire. It may be nec essary to turn the ignition

On as the switch may be wired through the ignition

circuit. Disconnect the test lamp and connect a jumper lead between the power wire and the wire

from the other side of the switch.

If the circuit functions, the switch can be consid-

ered faulty and should be renewed. Refer to the

heading Switches and Controls.

TO TEST BULBS

Remove the bulb from the bulb holder.

Connect a jumper lead between the positive

terminal of a battery a nd the base of the bulb.

Connect another jumper lead between the

negative battery terminal and the contact on the base

of the bulb. The bulb should illuminate. If the bulb has two filaments, connect the jumper

lead to the second contact on the base of the bulb. The

second filament should illuminate.

If the bulb fails to illuminate, it should be

renewed with a bulb of the correct voltage and

wattage.

TO TEST CIRCUITS

Turn the circuit switch On.

Using a test lamp, check for power at one of

the circuit connections. A fuse is a good starting point.

If power is available, reconnect the connector and

continue checking towards the motor or bulb end of

the circuit.

If power is not available, continue checking

towards the battery or switch end of the circuit.

6. BATTERY

Special Equipment Required: To Test — Hydrometer

To Charge — Battery charger

TO REMOVE AND INSTAL

(1) Disconnect the negative and positive battery

terminals.

Installed view of the battery.

Page 207 of 238

Electrical System 207

Disconnect the wiring connectors from the

rear of the combination switch.

Loosen the clamping screw located at the left

hand side of the combination switch. Push, turn and slide the combination switch

from the steering column. Installation is a reversal of the removal procedure.

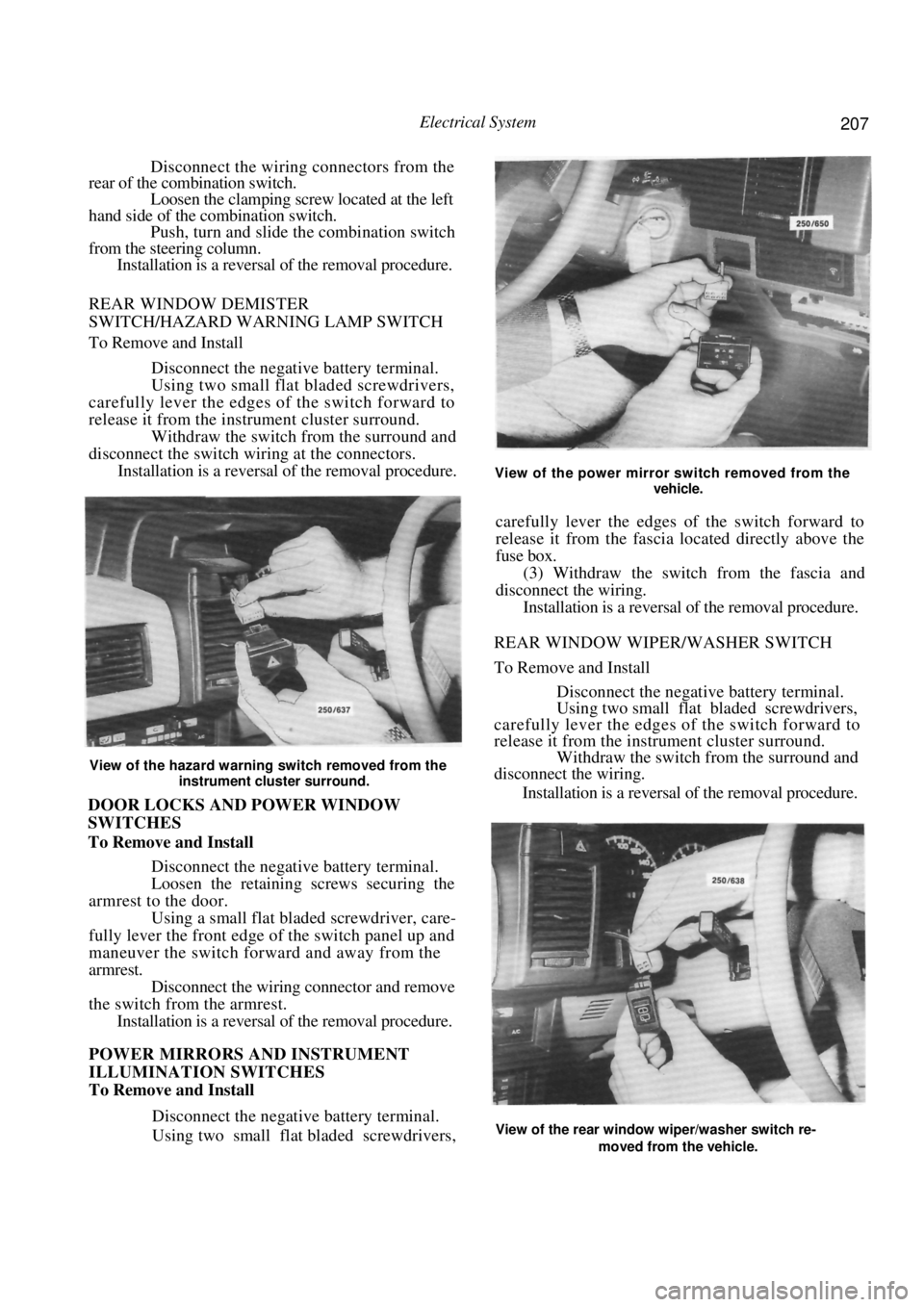

REAR WINDOW DEMISTER

SWITCH/HAZARD WARNING LAMP SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround.

Withdraw the switch from the surround and

disconnect the switch wiri ng at the connectors.

Installation is a reversal of the removal procedure.

View of the hazard warning switch removed from the

instrument cluster surround.

DOOR LOCKS AND POWER WINDOW

SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Loosen the retaining screws securing the

armrest to the door. Using a small flat bladed screwdriver, care-

fully lever the front edge of the switch panel up and

maneuver the switch forward and away from the

armrest. Disconnect the wiring connector and remove

the switch from the armrest. Installation is a reversal of the removal procedure.

POWER MIRRORS AND INSTRUMENT

ILLUMINATION SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

View of the power mirror switch removed from the

vehicle.

carefully lever the edges of the switch forward to

release it from the fascia lo cated directly above the

fuse box.

(3) Withdraw the switch from the fascia and

disconnect the wiring.

Installation is a reversal of the removal procedure.

REAR WINDOW WIPER/WASHER SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround. Withdraw the switch from the surround and

disconnect the wiring.

Installation is a reversal of the removal procedure.

View of the rear window wiper/washer switch re-

moved from the vehicle.

Page 215 of 238

Electrical System 215

Ensure that the wiper motor is in the Park

position before installing the wiper arm. If in doubt,

turn the wiper switch to the Off position and turn the

ignition switch to the On position until the wiper

motor stops.

Install the wiper arm to the pivot so that the

wiper blade is horizontal to the lower edge of the edge

of the rear window when in the Park position.

17. FUSES, FUSIBLE LINKS AND RELAYS

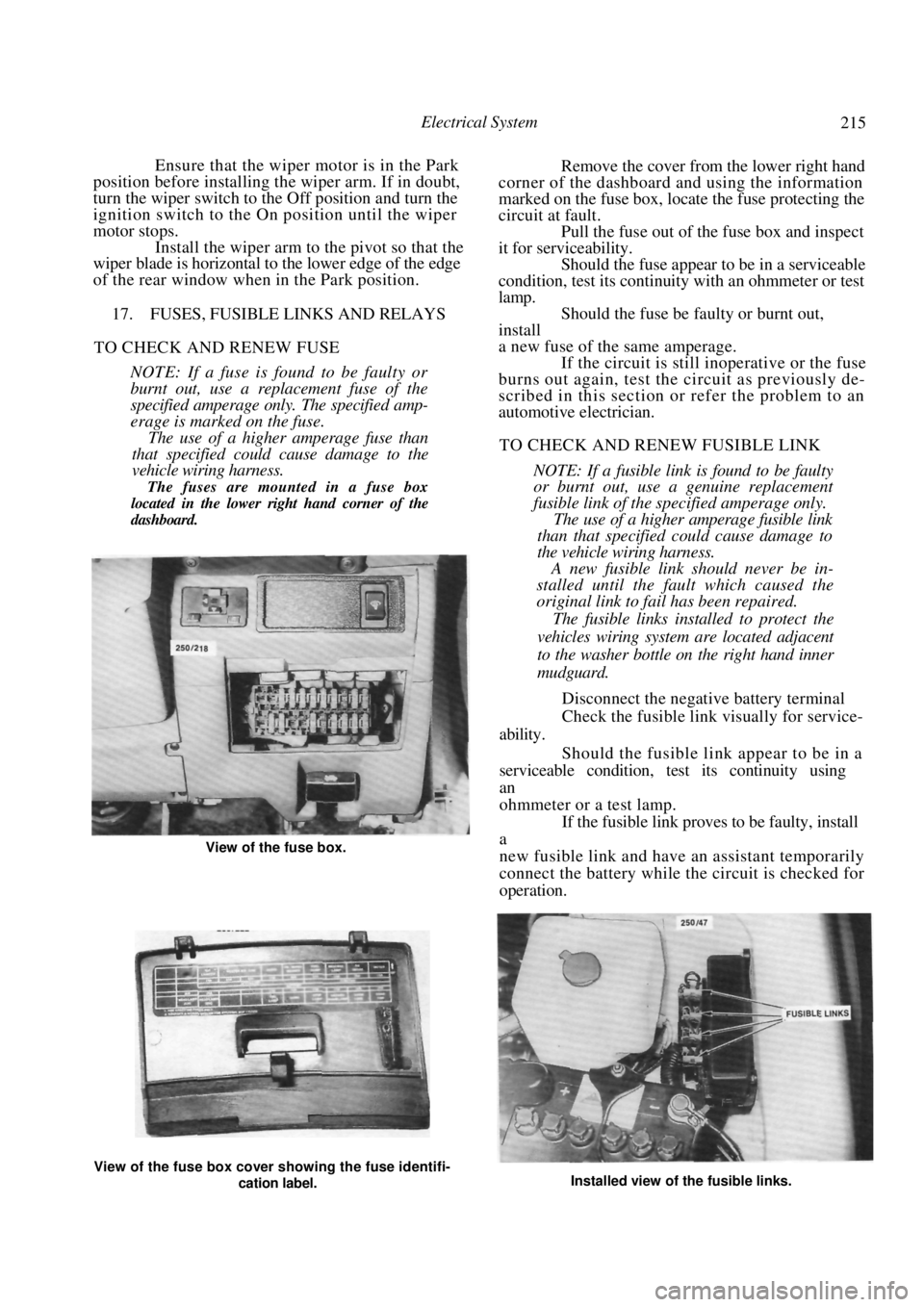

TO CHECK AND RENEW FUSE

NOTE: If a fuse is found to be faulty or

burnt out, use a replacement fuse of the

specified amperage only. The specified amp-

erage is marked on the fuse.

The use of a higher amperage fuse than

that specified could cause damage to the

vehicle wiring harness.

The fuses are mounted in a fuse box

located in the lower right hand corner of the

dashboard.

Remove the cover from the lower right hand

corner of the dashboard and using the information

marked on the fuse box, locate the fuse protecting the

circuit at fault. Pull the fuse out of the fuse box and inspect

it for serviceability.

Should the fuse appear to be in a serviceable

condition, test its continuity with an ohmmeter or test

lamp. Should the fuse be faulty or burnt out,

install

a new fuse of the same amperage. If the circuit is still inoperative or the fuse

burns out again, test the circuit as previously de-

scribed in this section or refer the problem to an

automotive electrician.

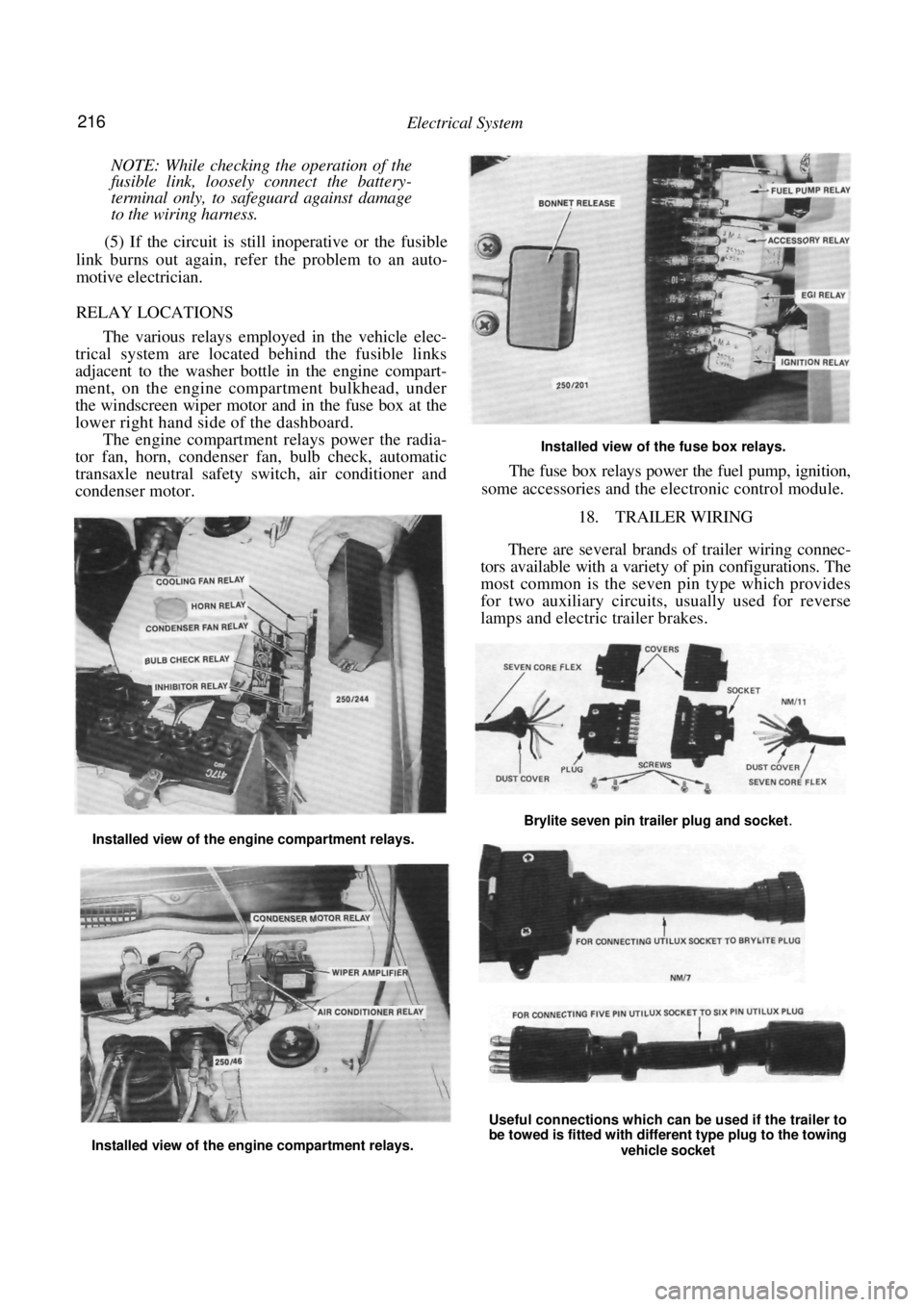

TO CHECK AND RENEW FUSIBLE LINK

NOTE: If a fusible link is found to be faulty

or burnt out, use a genuine replacement

fusible link of the specified amperage only.

The use of a higher amperage fusible link

than that specified could cause damage to

the vehicle wiring harness.

A new fusible link should never be in-

stalled until the fault which caused the

original link to fail has been repaired.

The fusible links installed to protect the

vehicles wiring system are located adjacent

to the washer bottle on the right hand inner

mudguard.

Disconnect the negative battery terminal

Check the fusible link visually for service-

ability.

Should the fusible link appear to be in a

serviceable condition, test its continuity using

an

ohmmeter or a test lamp. If the fusible link proves to be faulty, install

a

new fusible link and have an assistant temporarily

connect the battery while the circuit is checked for

operation.

View of the fuse box cover showing the fuse identifi-

cation label. Installed view of the fusible links.

View of the fuse box.

Page 216 of 238

216 Electrical System

NOTE: While checking the operation of the

fusible link, loosely connect the battery-

terminal only, to safeguard against damage

to the wiring harness.

(5) If the circuit is still inoperative or the fusible

link burns out again, refer the problem to an auto-

motive electrician.

RELAY LOCATIONS

The various relays employed in the vehicle elec-

trical system are located behind the fusible links

adjacent to the washer bottle in the engine compart-

ment, on the engine compartment bulkhead, under

the windscreen wiper motor and in the fuse box at the

lower right hand side of the dashboard.

The engine compartment relays power the radia-

tor fan, horn, condenser fan, bulb check, automatic

transaxle neutral safety switch, air conditioner and

condenser motor.

Installed view of the fuse box relays.

The fuse box relays power the fuel pump, ignition,

some accessories and the el ectronic control module.

18. TRAILER WIRING

There are several brands of trailer wiring connec-

tors available with a variet y of pin configurations. The

most common is the seven pin type which provides

for two auxiliary circuits, usually used for reverse

lamps and electric trailer brakes.

Installed view of the engine compartment relays.

Installed view of the engine compartment relays.

Useful connections which can be used if the trailer to

be towed is fitted with different type plug to the towing

vehicle socket

Brylite seven pin trailer plug and socket.

Page 219 of 238

Electrical System 219

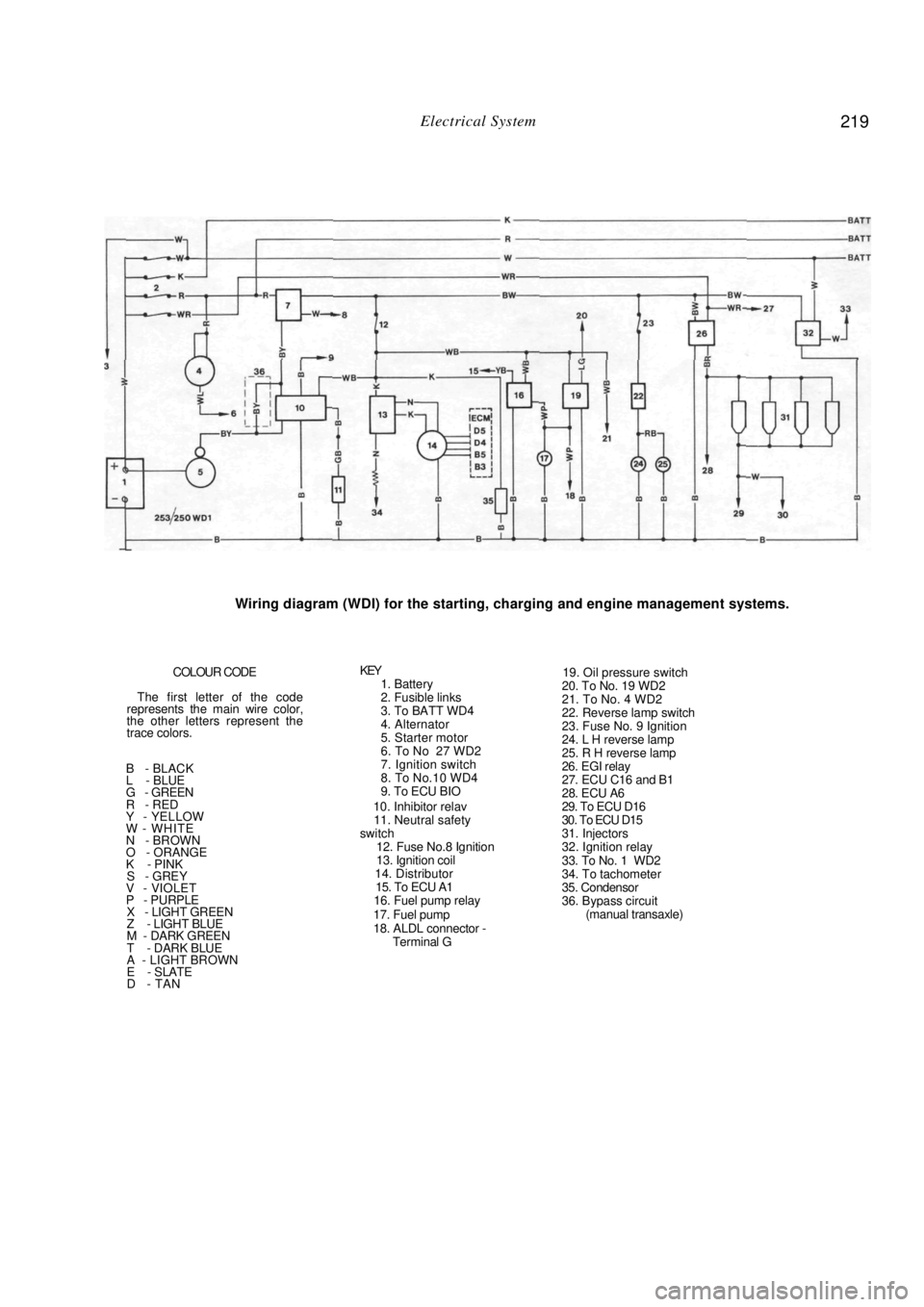

Wiring diagram (WDI) for the starting, charging and engine management systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W - WHITE

N - BROWN

O - ORANGE

K - PINK

S - GREY V - VIOLET

P - PURPLE X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN

KEY 1. Battery

2. Fusible links

3. To BATT WD4

4. Alternator

5. Starter motor

6. To No 27 WD2

7. Ignition switch

8. To No.10 WD4

9. To ECU BIO

10. Inhibitor relav

11. Neutral safety

switch

12. Fuse No.8 Ignition

13. Ignition coil

14. Distributor

15. To ECU A1

16. Fuel pump relay

17. Fuel pump

18. ALDL connector - Terminal G

19. Oil pressure switch

20. To No. 19 WD2

21. To No. 4 WD2

22. Reverse lamp switch

23. Fuse No. 9 Ignition

24. L H reverse lamp

25. R H reverse lamp

26. EGI relay

27. ECU C16 and B1

28. ECU A6

29. To ECU D16

30. To ECU D15

31. Injectors

32. Ignition relay

33. To No. 1 WD2

34. To tachometer

35. Condensor

36. Bypass circuit (manual transaxle)

Page 220 of 238

220 Electrical System

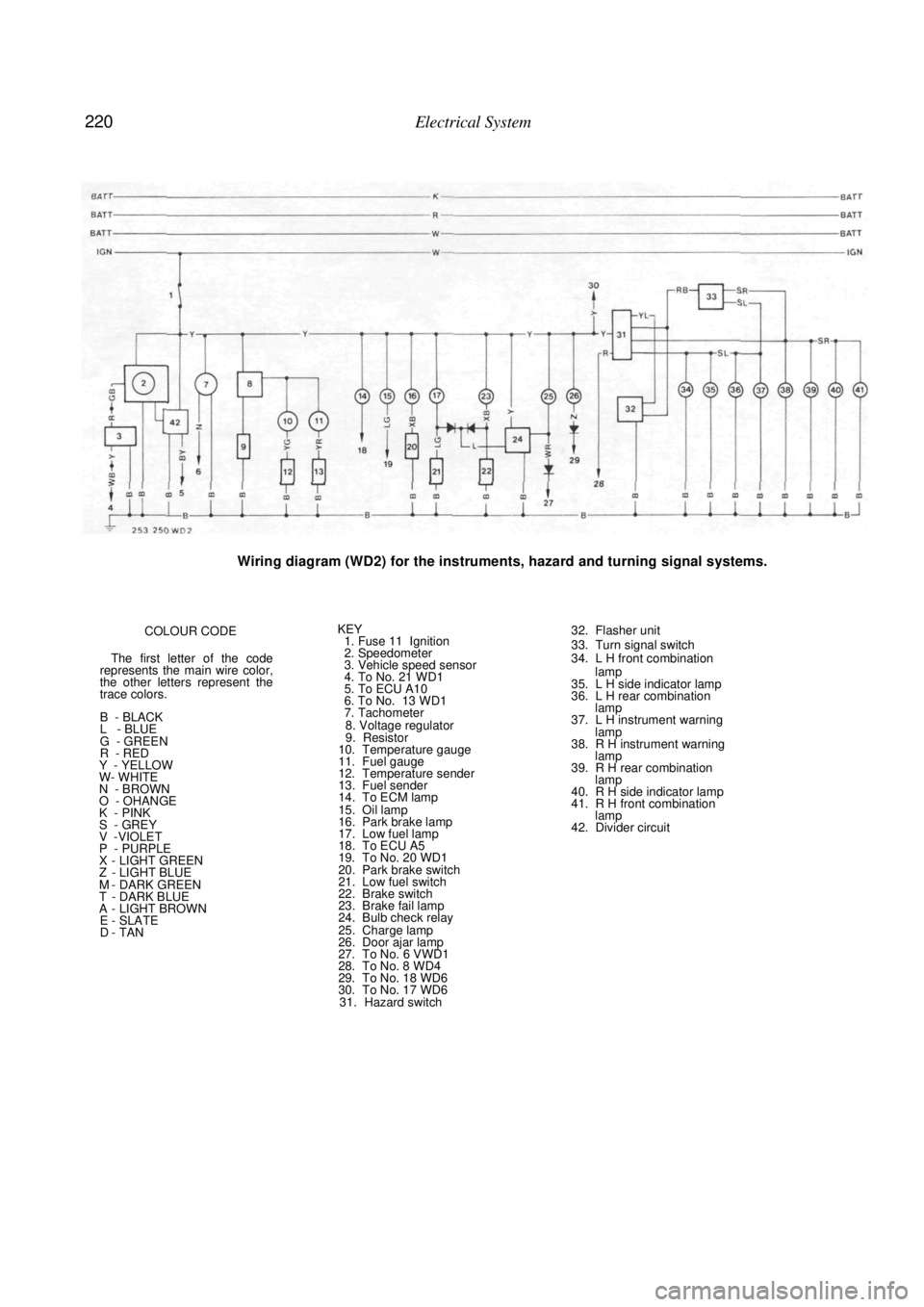

Wiring diagram (WD2) for the instruments, hazard and turning signal systems.

COLOUR CODE

The first letter of the code

represents the main wire color,

the other letters represent the

trace colors.

B - BLACK

L - BLUE

G - GREEN

R - RED

Y - YELLOW

W- WHITE

N - BROWN

O - OHANGE

K - PINK

S - GREY V -VIOLET

P - PURPLE X - LIGHT GREEN Z - LIGHT BLUE M - DARK GREEN T - DARK BLUE A - LIGHT BROWN E - SLATE D - TAN

KEY 1. Fuse 11 Ignition

2. Speedometer

3. Vehicle speed sensor

4. To No. 21 WD1

5. To ECU A10

6. To No. 13 WD1

7. Tachometer

8. Voltage regulator

9. Resistor

10. Temperature gauge

11. Fuel gauge

12. Temperature sender

13. Fuel sender

14. To ECM lamp

15. Oil lamp

16. Park brake lamp

17. Low fuel lamp

18. To ECU A5

19. To No. 20 WD1

20. Park brake switch

21. Low fuel switch

22. Brake switch

23. Brake fail lamp

24. Bulb check relay

25. Charge lamp

26. Door ajar lamp

27. To No. 6 VWD1

28. To No. 8 WD4

29. To No. 18 WD6

30. To No. 17 WD6 31. Hazard switch

32. Flasher unit

33. Turn signal switch

34. L H front combination

lamp

35. L H side indicator lamp

36. L H rear combination lamp

37. L H instrument warning

lamp

38. R H instrument warning lamp

39. R H rear combination lamp

40. R H side indicator lamp

41. R H front combination lamp

42. Divider circuit

Page 221 of 238

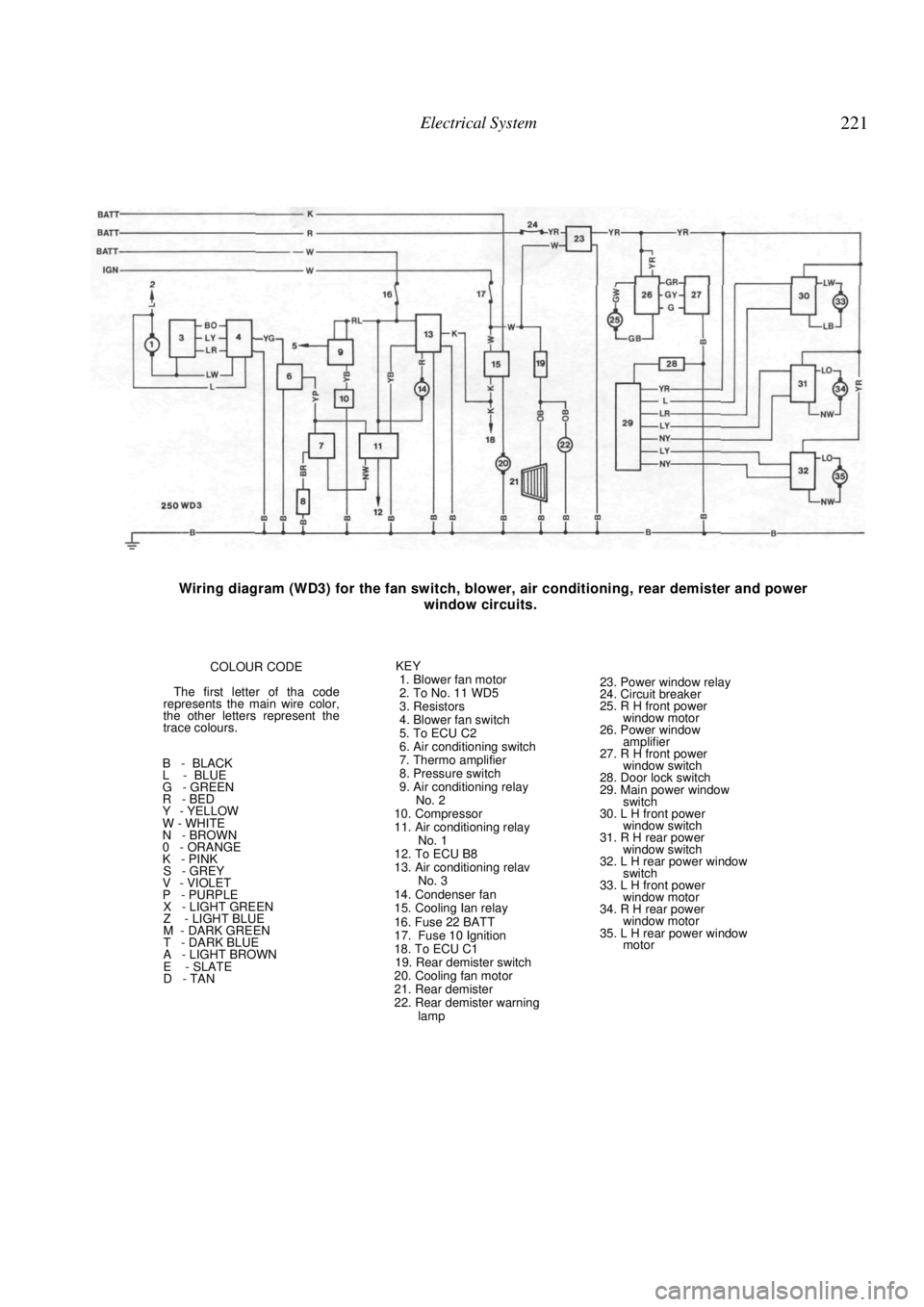

Electrical System 221

Wiring diagram (WD3) for the fan switch, blower, air conditioning, rear demister and power

window circuits.

COLOUR CODE

The first letter of tha code

represents the main wire color,

the other letters represent the

trace colours.

B - BLACK

L - BLUE

G - GREEN

R - BED

Y - YELLOW

W - WHITE

N - BROWN

0 - ORANGE

K - PINK

S - GREY

V - VIOLET

P - PURPLE

X - LIGHT GREEN

Z - LIGHT BLUE

M - DARK GREEN

T - DARK BLUE

A - LIGHT BROWN

E - SLATE

D - TAN KEY

1. Blower fan motor

2. To No. 11 WD5

3. Resistors

4. Blower fan switch

5. To ECU C2

6. Air conditioning switch

7. Thermo amplifier

8. Pressure switch

9. Air conditioning relay No. 2

10. Compressor

11. Air conditioning relay No. 1

12. To ECU B8

13. Air conditioning relav No. 3

14. Condenser fan

15. Cooling Ian relay

16. Fuse 22 BATT

17. Fuse 10 Ignition

18. To ECU C1

19. Rear demister switch

20. Cooling fan motor

21. Rear demister

22. Rear demister warning lamp

23. Power window relay

24. Circuit breaker

25. R H front power

window motor

26. Power window amplifier

27. R H front power window switch

28. Door lock switch

29. Main power window switch

30. L H front power

window switch

31. R H rear power window switch

32. L H rear power window switch

33. L H front power

window motor

34. R H rear power window motor

35. L H rear power window motor