ECU NISSAN PULSAR 1987 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 56 of 238

56 Engine

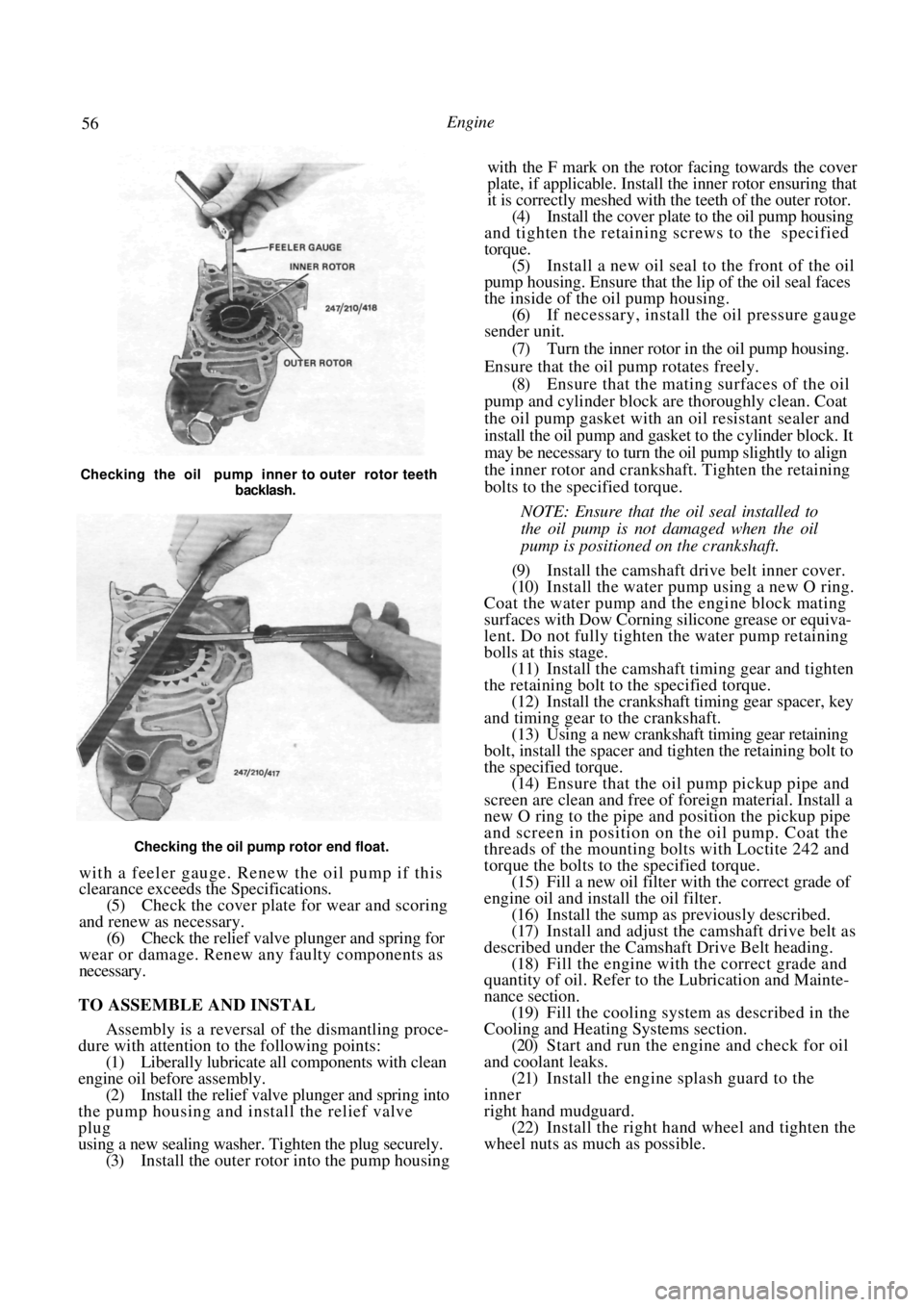

Checking the oil pump rotor end float.

with a feeler gauge. Renew the oil pump if this

clearance exceeds the Specifications.

(5) Check the cover plate for wear and scoring

and renew as necessary. (6) Check the relief valve plunger and spring for

wear or damage. Renew any faulty components as

necessary.

TO ASSEMBLE AND INSTAL

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Liberally lubricate all components with clean

engine oil before assembly. (2) Install the relief valve plunger and spring into

the pump housing and install the relief valve

plug

using a new sealing washer. Tighten the plug securely. (3) Install the outer rotor into the pump housing with the F mark on the rotor facing towards the cover

plate, if applicable. Install the inner rotor ensuring that

it is correctly meshed with the teeth of the outer rotor.

(4)

Install the cover plate to the oil pump housing

and tighten the retaining screws to the specified

torque. (5) Install a new oil seal to the front of the oil

pump housing. Ensure that the lip of the oil seal faces

the inside of the oil pump housing. (6) If necessary, install the oil pressure gauge

sender unit.

(7) Turn the inner rotor in the oil pump housing.

Ensure that the oil pump rotates freely. (8) Ensure that the mating surfaces of the oil

pump and cylinder block are thoroughly clean. Coat

the oil pump gasket with an oil resistant sealer and

install the oil pump and gasket to the cylinder block. It

may be necessary to turn the oil pump slightly to align

the inner rotor and crankshaft. Tighten the retaining

bolts to the specified torque.

NOTE: Ensure that the oil seal installed to

the oil pump is not damaged when the oil

pump is positioned on the crankshaft.

(9) Install the camshaft drive belt inner cover.

(10) Install the water pump using a new O ring.

Coat the water pump and the engine block mating

surfaces with Dow Corning silicone grease or equiva-

lent. Do not fully tighten the water pump retaining

bolls at this stage. (11) Install the camshaft timing gear and tighten

the retaining bolt to the specified torque.

(12) Install the crankshaft timing gear spacer, key

and timing gear to the crankshaft. (13) Using a new crankshaft timing gear retaining

bolt, install the spacer and tighten the retaining bolt to

the specified torque. (14) Ensure that the oil pump pickup pipe and

screen are clean and free of foreign material. Install a

new O ring to the pipe and position the pickup pipe

and screen in position on the oil pump. Coat the

threads of the mounting bolts with Loctite 242 and

torque the bolts to the specified torque. (15) Fill a new oil filter with the correct grade of

engine oil and install the oil filter. (16) Install the sump as previously described.

(17) Install and adjust the camshaft drive belt as

described under the Camshaft Drive Belt heading. (18) Fill the engine with the correct grade and

quantity of oil. Refer to the Lubrication and Mainte-

nance section.

(19) Fill the cooling system as described in the

Cooling and Heating Systems section. (20) Start and run the engine and check for oil

and coolant leaks. (21) Install the engine splash guard to the

inner

right hand mudguard. (22) Install the right hand wheel and tighten the

wheel nuts as much as possible.

Checking the oil pump inner to outer rotor teeth

backlash.

Page 57 of 238

Engine 57

(23) Lower the vehicle to the ground and securely

tighten the wheel nuts.

10. PISTONS, CONNECTING RODS AND

CYLINDER BORES

Special Equipment Required:

To Inspect — Micrometer, cylinder measuring

gauge

To Remove Ridge from Bores — Ridge removal tool

To Deglaze Cylinder Bores — Cylinder surfacing

hone

To Install — Piston ring compressor

TO REMOVE

(1) Remove the engine sump and oil pump

pickup pipe as previously described. (2) Remove the cylinder head as previously

described. (3) Mark the relationship of the pistons to their

respective cylinders and the bearing caps to their

respective connecting rods by letter stamps or centre

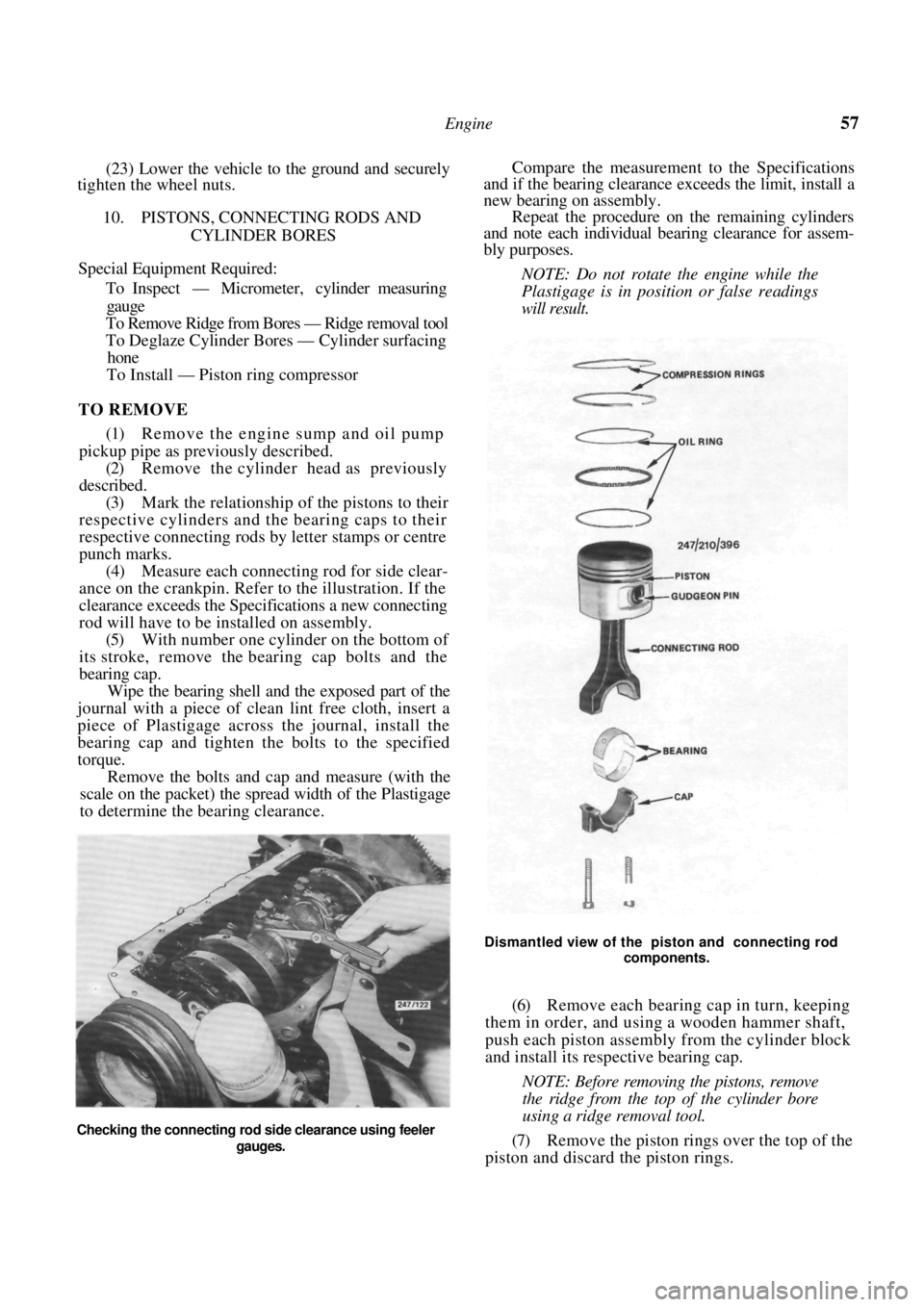

punch marks. (4) Measure each connecting rod for side clear-

ance on the crankpin. Refer to the illustration. If the

clearance exceeds the Speci fications a new connecting

rod will have to be installed on assembly. (5) With number one cylinder on the bottom of

its stroke, remove the bear ing cap bolts and the

bearing cap. Wipe the bearing shell and the exposed part of the

journal with a piece of clean lint free cloth, insert a

piece of Plastigage across the journal, install the

bearing cap and tighten the bolts to the specified

torque.

Remove the bolts and cap and measure (with the

scale on the packet) the spread width of the Plastigage

to determine the bearing clearance.

Compare the measurement to the Specifications

and if the bearing clearance exceeds the limit, install a

new bearing on assembly.

Repeat the procedure on the remaining cylinders

and note each individual bearing clearance for assem-

bly purposes.

NOTE: Do not rotate the engine while the

Plastigage is in position or false readings

will result.

Dismantled view of the piston and connecting rod

components.

(6) Remove each bearing cap in turn, keeping

them in order, and using a wooden hammer shaft,

push each piston assembly from the cylinder block

and install its respective bearing cap.

NOTE: Before removing the pistons, remove

the ridge from the top of the cylinder bore

using a ridge removal tool.

(7) Remove the piston rings over the top of the

piston and discard the piston rings.

Checking the connecting rod side clearance using feeler

gauges.

Page 62 of 238

Engine

Main bearing cap removed showing the location of the rear seal and sealant grooves.

until the sealant appears at the inner, lower edge of the

bearing cap to cylinder block joint. Install the bearing

cap bolts and tighten to the specified torque.

(5) Tighten the remaining main bearing cap

bolts and the connecting rod cap bolts to their

respective tensions and rotate the crankshaft to check

for binding. (6) Install the crankshaft oil seal to the end of the

crankshaft after applying lithium grease to the lip of

the oil seal. Ensure that the l i p of the seal is facing

towards the engine.

(7) Install the remainder of the engine compo-

nents by referring to the relevant headings in this

section.

TO RENEW MAIN BEARINGS -

CRANKSHAFT INSTALLED

(1) Remove the automatic transaxle or manual

transaxle as described in the appropriate section.

(2) Remove the flywheel/drive plate as outlined

under the Flywheel/Drive Plate heading. (3) Remove the engine sump and oil pump

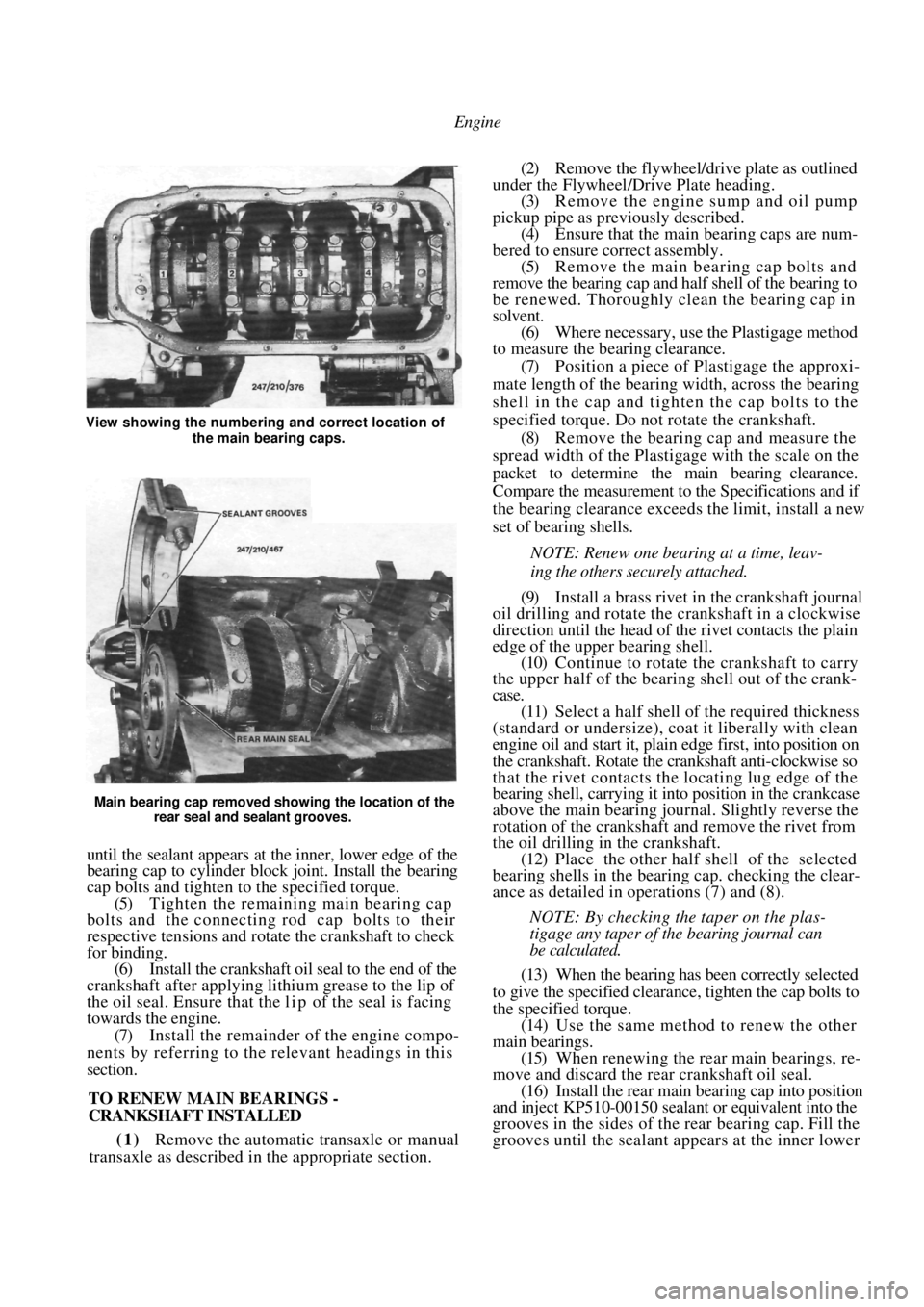

pickup pipe as previously described. (4) Ensure that the main bearing caps are num-

bered to ensure correct assembly. (5) Remove the main bearing cap bolts and

remove the bearing cap and half shell of the bearing to

be renewed. Thoroughly clean the bearing cap in

solvent. (6) Where necessary, use the Plastigage method

to measure the bearing clearance.

(7) Position a piece of Plastigage the approxi-

mate length of the bearing width, across the bearing

shell in the cap and tigh ten the cap bolts to the

specified torque. Do not rotate the crankshaft. (8) Remove the bearing cap and measure the

spread width of the Plastigage with the scale on the

packet to determine the main bearing clearance.

Compare the measurement to the Specifications and if

the bearing clearance exceeds the limit, install a new

set of bearing shells.

NOTE: Renew one bearing at a time, leav-

ing the others securely attached.

(9) Install a brass rivet in the crankshaft journal

oil drilling and rotate the crankshaft in a clockwise

direction until the head of the rivet contacts the plain

edge of the upper bearing shell. (10) Continue to rotate the crankshaft to carry

the upper half of the bearing shell out of the crank-

case.

(11) Select a half shell of the required thickness

(standard or undersize), coat it liberally with clean

engine oil and start it, plai n edge first, into position on

the crankshaft. Rotate the crankshaft anti-clockwise so

that the rivet contacts the locating lug edge of the

bearing shell, carrying it into position in the crankcase

above the main bearing journal. Slightly reverse the

rotation of the crankshaft and remove the rivet from

the oil drilling in the crankshaft. (12) Place the other half shell of the selected

bearing shells in the bear ing cap. checking the clear-

ance as detailed in operations (7) and (8).

NOTE: By checking the taper on the plas-

tigage any taper of the bearing journal can

be calculated.

(13) When the bearing has been correctly selected

to give the specified clearance, tighten the cap bolts to

the specified torque. (14) Use the same method to renew the other

main bearings. (15) When renewing the rear main bearings, re-

move and discard the rear crankshaft oil seal. (16) Install the rear main bearing cap into position

and inject KP510-00150 sealant or equivalent into the

grooves in the sides of the rear bearing cap. Fill the

grooves until the sealant a ppears at the inner lower

View showing the numbering and correct location of

the main bearing caps.

Page 64 of 238

64 Engine

automatic transaxle models the complete drive plate

must be renewed.

(3) Inspect the drive plate bolt holes for elonga-

tion which is caused by loose retaining bolts.

(4) Inspect the drive plate for cracks.

(5) Repair or renew the flywheel if necessary.

TO INSTAL

Installation is a reversal of the removal procedure

with attention to the following points:

(1) The flywheel and drive plate retaining bolts

are special micro-encapsulated fasteners.

Install new micro-encapsulated bolts of the

correct

strength classification on assembly.

(2) Thoroughly clean the crankshaft threads with

a thread tap. Clean the threads with solvent and dry

before installing the flywh eel or drive plate retaining

bolts.

(3) Tighten the flywheel or drive plate retaining

bolts to the specified torque and on manual transaxle

models, align the clutch plate as described in the

Clutch section.

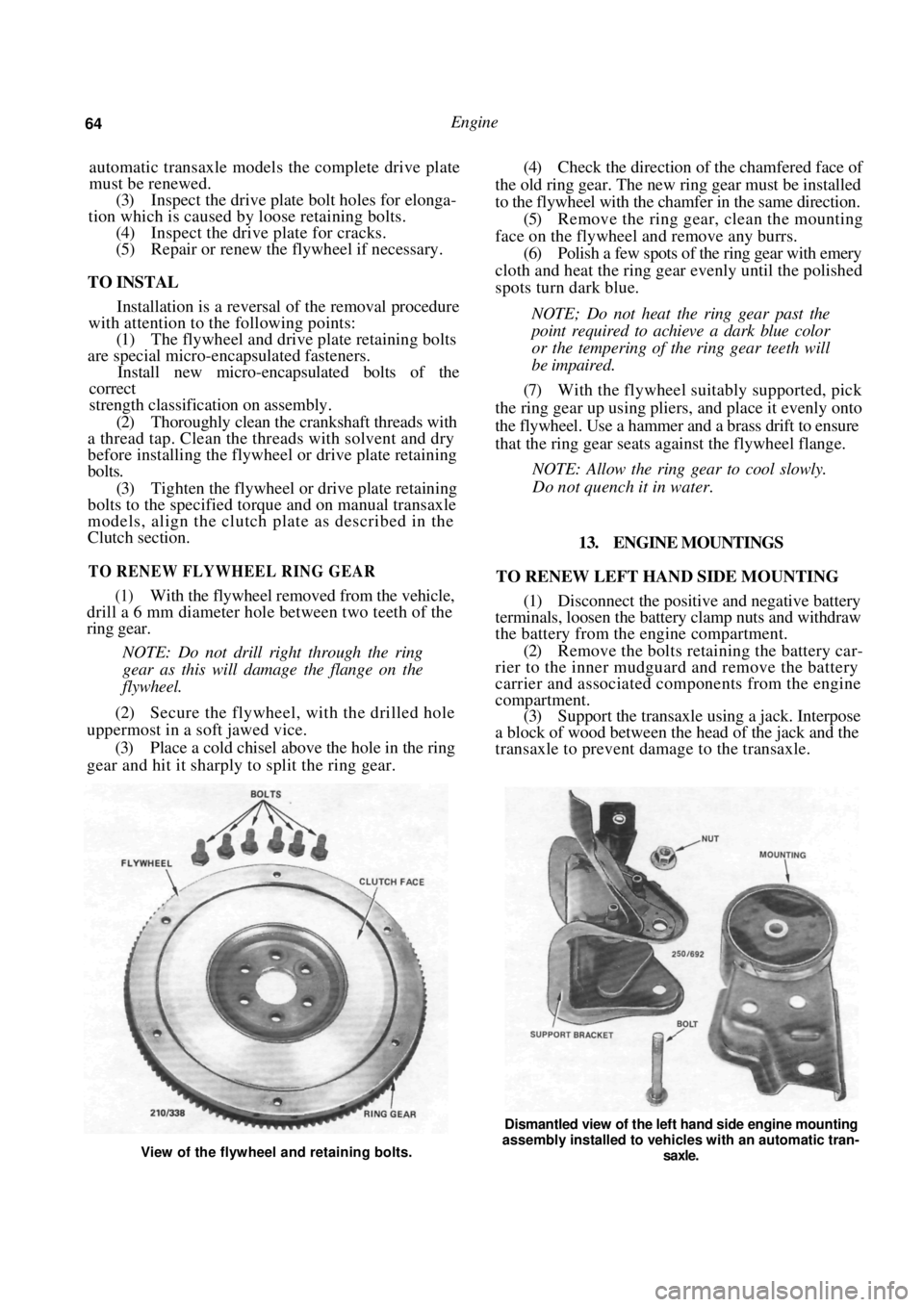

TO RENEW FLYWHEEL RING GEAR

(1) With the flywheel removed from the vehicle,

drill a 6 mm diameter hole between two teeth of the

ring gear.

NOTE: Do not drill right through the ring

gear as this will damage the flange on the

flywheel.

(2) Secure the flywheel, with the drilled hole

uppermost in a soft jawed vice.

(3) Place a cold chisel above the hole in the ring

gear and hit it sharply to split the ring gear.

(4) Check the direction of the chamfered face of

the old ring gear. The new ring gear must be installed

to the flywheel with the chamfer in the same direction. (5) Remove the ring gear, clean the mounting

face on the flywheel and remove any burrs. (6) Polish a few spots of the ring gear with emery

cloth and heat the ring gear evenly until the polished

spots turn dark blue.

NOTE; Do not heat the ring gear past the

point required to achieve a dark blue color

or the tempering of the ring gear teeth will

be impaired.

(7) With the flywheel suitably supported, pick

the ring gear up using plie rs, and place it evenly onto

the flywheel. Use a hammer and a brass drift to ensure

that the ring gear seats ag ainst the flywheel flange.

NOTE: Allow the ring gear to cool slowly.

Do not quench it in water.

13. ENGINE MOUNTINGS

TO RENEW LEFT HAND SIDE MOUNTING

(1) Disconnect the positive and negative battery

terminals, loosen the battery clamp nuts and withdraw

the battery from the engine compartment.

(2) Remove the bolts retaining the battery car-

rier to the inner mudguard and remove the battery

carrier and associ ated components from the engine

compartment. (3) Support the transaxle using a jack. Interpose

a block of wood between the head of the jack and the

transaxle to prevent damage to the transaxle.

View of the flywheel and retaining bolts.

Dismantled view of the left hand side engine mounting

assembly installed to vehicles with an automatic tran-

saxle.

Page 65 of 238

Engine 65

(4) Hold the nut and remove the mounting

through bolt. (5) Remove the bolts retaining the mounting to

the transaxle and maneuver the mounting from the

engine compartment. (6) If necessary remove the bolts retaining the

support bracket to the inner mudguard and withdraw

the support bracket. Installation is a reversal of the removal procedure

ensuring that the weight of the engine is bearing on

the engine mounting before tightening the through

bolt securely.

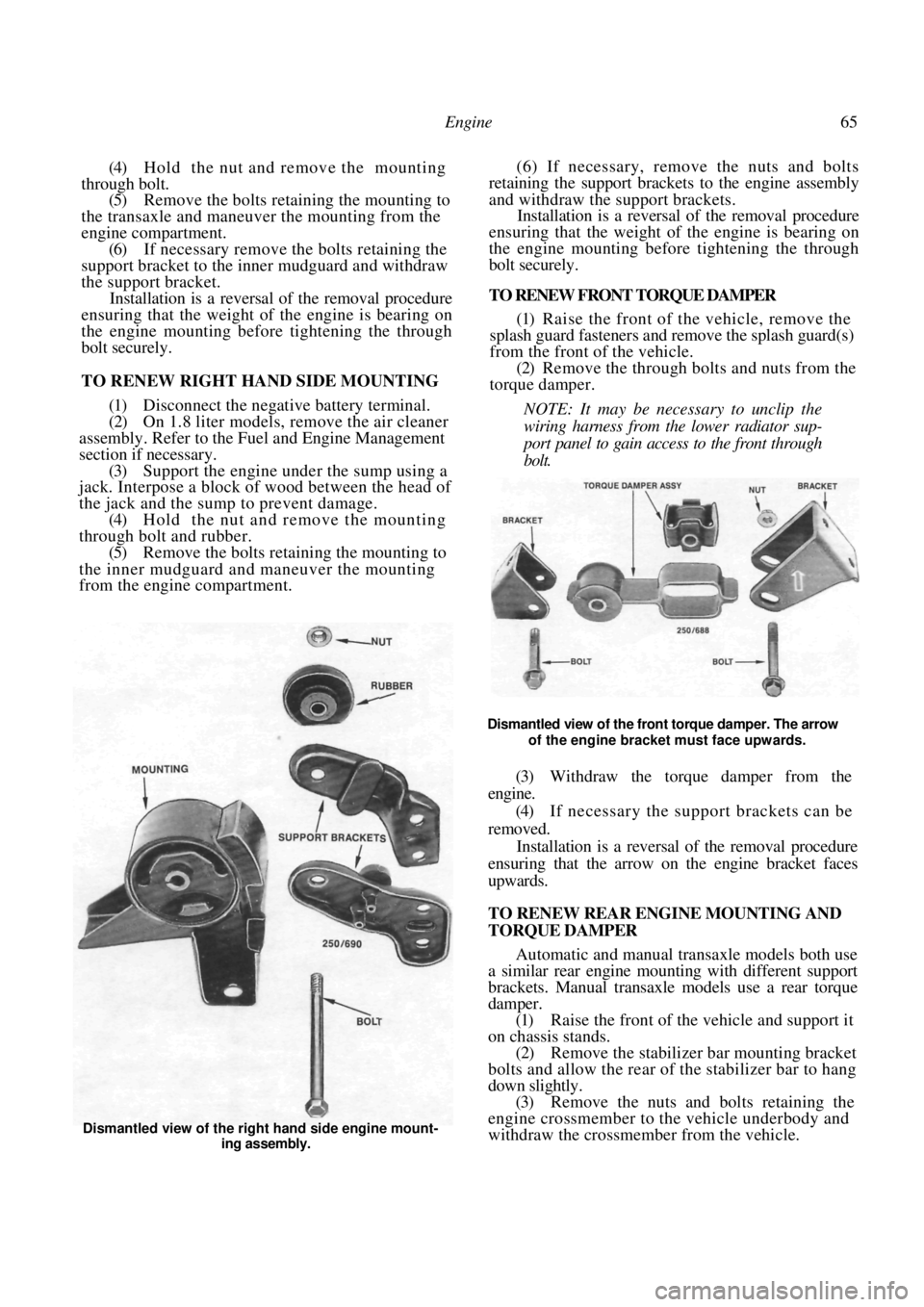

TO RENEW RIGHT HAND SIDE MOUNTING

(1) Disconnect the negative battery terminal.

(2) On 1.8 liter models, remove the air cleaner

assembly. Refer to the Fuel and Engine Management

section if necessary. (3) Support the engine under the sump using a

jack. Interpose a block of wood between the head of

the jack and the sump to prevent damage.

(4) Hold the nut and remove the mounting

through bolt and rubber. (5) Remove the bolts retain ing the mounting to

the inner mudguard and maneuver the mounting

from the engine compartment. (6) If necessary, remove the nuts and bolts

retaining the support brackets to the engine assembly

and withdraw the support brackets.

Installation is a reversal of the removal procedure

ensuring that the weight of the engine is bearing on

the engine mounting before tightening the through

bolt securely.

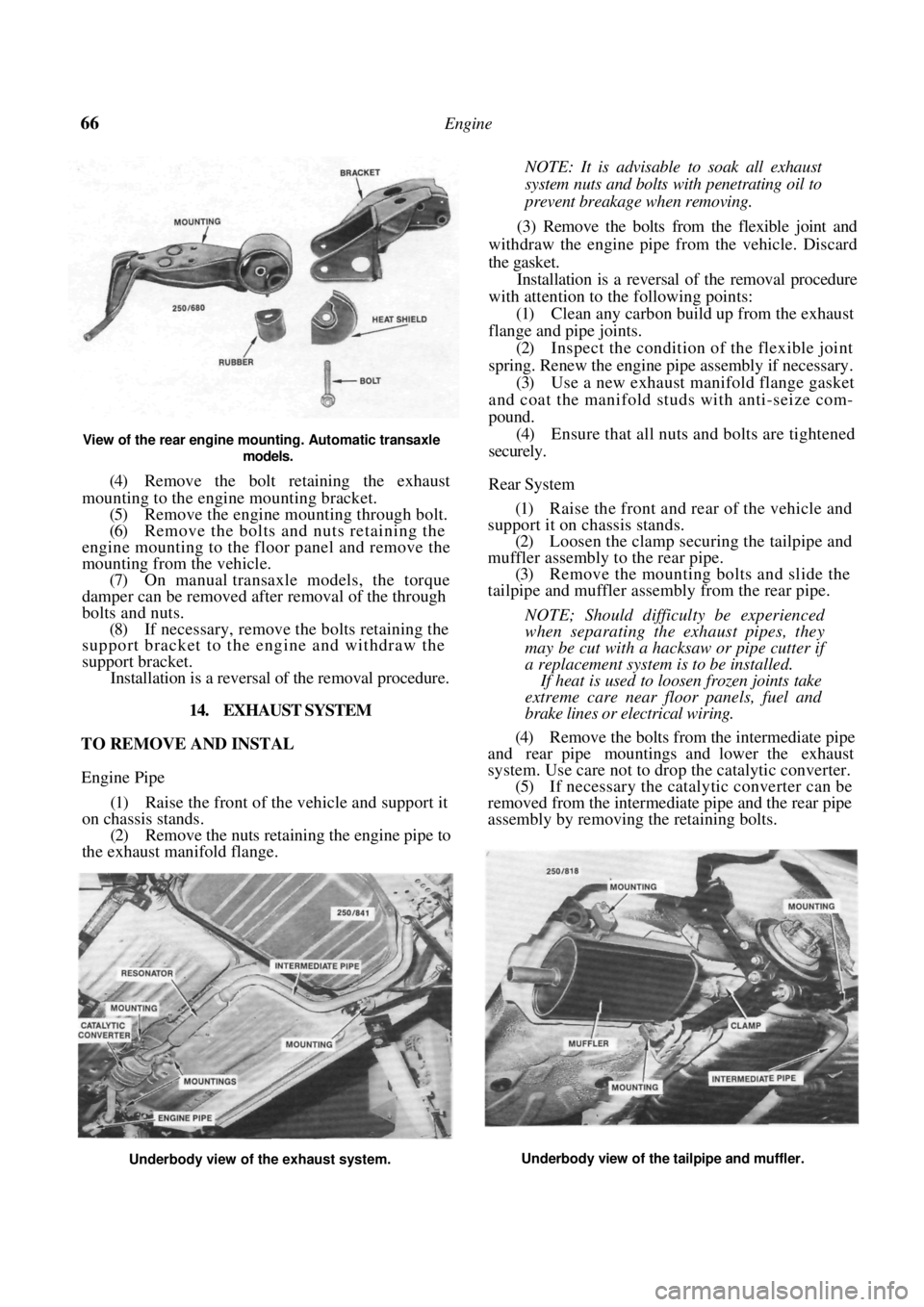

TO RENEW FRONT TORQUE DAMPER

(1) Raise the front of the vehicle, remove the

splash guard fasteners and remove the splash guard(s)

from the front of the vehicle.

(2) Remove the through bolts and nuts from the

torque damper.

NOTE: It may be necessary to unclip the

wiring harness from the lower radiator sup-

port panel to gain access to the front through

bolt.

Dismantled view of the front torque damper. The arrow of the engine bracket must face upwards.

(3) Withdraw the torque damper from the

engine.

(4) If necessary the support brackets can be

removed. Installation is a reversal of the removal procedure

ensuring that the arrow on the engine bracket faces

upwards.

TO RENEW REAR ENGINE MOUNTING AND

TORQUE DAMPER

Automatic and manual transaxle models both use

a similar rear engine moun ting with different support

brackets. Manual transaxle models use a rear torque

damper.

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the stabilizer bar mounting bracket

bolts and allow the rear of the stabilizer bar to hang

down slightly. (3) Remove the nuts and bolts retaining the

engine crossmember to the vehicle underbody and

withdraw the crossmember from the vehicle.

Dismantled view of the right hand side engine mount-

ing assembly.

Page 66 of 238

66 Engine

View of the rear engine mounting. Automatic transaxle models.

(4) Remove the bolt retaining the exhaust

mounting to the engine mounting bracket. (5) Remove the engine mounting through bolt.

(6) Remove the bolts and nuts retaining the

engine mounting to the floor panel and remove the

mounting from the vehicle.

(7) On manual transaxle models, the torque

damper can be removed after removal of the through

bolts and nuts. (8) If necessary, remove the bolts retaining the

support bracket to the engine and withdraw the

support bracket.

Installation is a reversal of the removal procedure.

14. EXHAUST SYSTEM

TO REMOVE AND INSTAL

Engine Pipe

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the nuts retaining the engine pipe to

the exhaust manifold flange.

NOTE: It is advisable to soak all exhaust

system nuts and bolts wi th penetrating oil to

prevent breakage when removing.

(3) Remove the bolts from the flexible joint and

withdraw the engine pipe from the vehicle. Discard

the gasket.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Clean any carbon build up from the exhaust

flange and pipe joints. (2) Inspect the condition of the flexible joint

spring. Renew the engine pipe assembly if necessary. (3) Use a new exhaust manifold flange gasket

and coat the manifold studs with anti-seize com-

pound. (4) Ensure that all nuts and bolts are tightened

securely.

Rear System

(1) Raise the front and rear of the vehicle and

support it on chassis stands. (2) Loosen the clamp securing the tailpipe and

muffler assembly to the rear pipe. (3) Remove the mounting bolts and slide the

tailpipe and muffler assembly from the rear pipe.

NOTE; Should difficulty be experienced

when separating the exhaust pipes, they

may be cut with a hacksaw or pipe cutter if

a replacement system is to be installed.

If heat is used to loosen frozen joints take

extreme care near floor panels, fuel and

brake lines or electrical wiring.

(4) Remove the bolts from the intermediate pipe

and rear pipe mountings and lower the exhaust

system. Use care not to drop the catalytic converter.

(5) If necessary the cataly tic converter can be

removed from the intermediate pipe and the rear pipe

assembly by removing the retaining bolts.

Underbody view of the exhaust system. Underbody view of the tailpipe and muffler.

Page 71 of 238

Cooling and Heating Systems 71

TO DRAIN AND REFILL

(1) Place a drain tin under the radiator drain

plug.

(2) Switch the heater controls to the maximum

heat position. (3) Remove the radiator cap and open the

radiator drain plug.

(4) Disconnect the reserve tank hose from the

radiator filler neck. (5) Lower the end of the hose and drain the

coolant from the reserve tank. (6) After all the coolant has drained from the

cooling system, install the radiator drain plug

ensuring

that the plug seal is in good condition. (7) Disconnect the wire from the temperature

sender switch and remove the switch using a suitable

spanner.

(8) Using a clean container, mix Nissan long life

coolant with clean soft water to the proportions

stipulated on the coolant container.

(9) Slowly pour the premixed coolant into the

radiator until the radiator is full and all air has

escaped through the temperat ure sender switch hole.

Install the radiator cap. (10) Fill the coolant reserve tank to the Maxi-

mum mark.

(11) Start the engine and allow it to idle.

(12) When coolant starts to flow through the

temperature sender switch hole, install the temperature

sender switch and tighten securely. (13) Continue idling the engine until the cooling

fan is activated.

(14) Switch the engine off and allow it to cool.

(15) Refill the radiator using coolant and install

the radiator cap.

Dismantled view of the radiator and associated components. Automatic transaxle model with

air conditioning.

Page 75 of 238

Cooling and Heating Systems 75

(4) Remove the bolts retaining the fan shroud

assembly to the radiator and carefully move the

shroud assembly upwards and towards the engine to

release it from the lower mountings.

NOTE: On models with air conditioning, it

will be necessary to hold the air conditioning

compressor hoses toward s the engine to

allow clearance for removal of the shroud

assembly.

(5) If necessary, remove the fan from the fan

motor by removing the retaining bolts or on some

models the nut and washers.

(6) If necessary, remove the fan motor from the

shroud assembly by removing the retaining bolts or

nuts. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure all the fan motor and fan retaining

nuts and bolts are tightened securely. (2) Ensure that all the rubber mountings are in

good condition. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that all sealing surfaces are clean.

(2) Renew the O ring on installation.

(3) Tighten the thermostat cover retaining bolts

securely.

(4) Fill the cooling system as previously de-

scribed ensuring that the heater control lever is in the

maximum heat position. Check for coolant leaks.

TO CHECK

NOTE: A visual examination of the thermo-

stat will often determine its serviceability

and make further testing unnecessary. For

instance, a thermostat with its valve fully-

open when removed from a cold engine is

obviously faulty and should be renewed.

Remove the thermostat from the thermostat

6. THERMOSTAT

Special Equipment Required:

To Check — Thermometer

TO REMOVE AND INSTAL

(1) Drain the cooling system as previously de-

scribed under the Radiator heading.

(2) On 1.6 liter models, remove the air cleaner

assembly. Refer to the Fuel and Engine Management

section if necessary. (3) Disconnect the top radiator hose from the

thermostat cover.

(4) Remove the bolts retaining the thermostat

cover to the thermostat housing. (5) Remove the thermostat cover, thermostat

and O ring from the thermostat housing.

NOTE: The thermostat and cover are ser-

viced as a unit and cannot be renewed

separately.

View of the thermostat removed from the vehicle and dismantled for testing. Line drawing showing the correct method to test the

thermostat.

(4) Progressively heat the mixture noting the

temperature reading on the thermometer as the ther-

mostat valve commences to open and when it is fully

open.

See the Specifications for opening and fully open

temperatures.

A thermostat which is not opening or is not open

at the specified temperatures should be renewed.

Page 80 of 238

Cooling and Heating Systems

11. BLOWER FAN

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) Working below the glov e compartment, dis-

connect the wiring connector to the blower fan motor.

(3) Remove the bolts retaining the blower fan

motor and carefully lower the motor while disconnect-

ing the drain hose.

Installation is a reversal of the removal procedure

with attention to the following points:

( t ) Tighten all bolts securely.

(2) Check that the blow er fan operates correctly.

Dismantled view of the blower fan and associated

components.

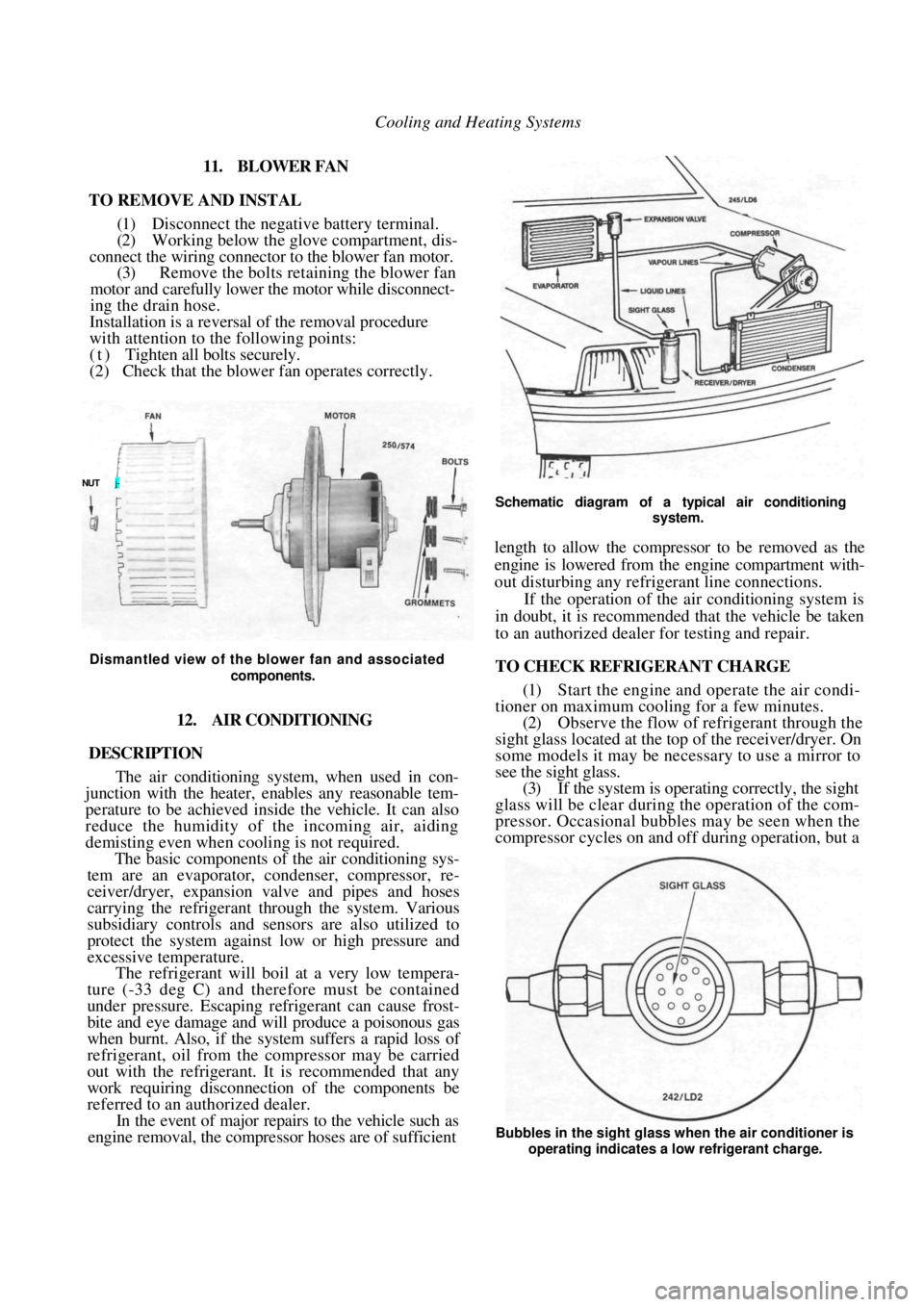

12. AIR CONDITIONING

DESCRIPTION

The air conditioning system, when used in con-

junction with the heater, enables any reasonable tem-

perature to be achieved inside the vehicle. It can also

reduce the humidity of the incoming air, aiding

demisting even when cooling is not required.

The basic components of the air conditioning sys-

tem are an evaporator, co ndenser, compressor, re-

ceiver/dryer, expansion valve and pipes and hoses

carrying the refrigerant through the system. Various

subsidiary controls and sensors are also utilized to

protect the system against low or high pressure and

excessive temperature.

The refrigerant will boil at a very low tempera-

ture (-33 deg C) and therefore must be contained

under pressure. Escaping refrigerant can cause frost-

bite and eye damage and will produce a poisonous gas

when burnt. Also, if the system suffers a rapid loss of

refrigerant, oil from the compressor may be carried

out with the refrigerant. It is recommended that any

work requiring disconnection of the components be

referred to an au thorized dealer.

In the event of major repair s to the vehicle such as

engine removal, the compress or hoses are of sufficient

Schematic diagram of a typical air conditioning

system.

length to allow the compressor to be removed as the

engine is lowered from the engine compartment with-

out disturbing any refrigerant line connections.

If the operation of the air conditioning system is

in doubt, it is recommended that the vehicle be taken

to an authorized dealer for testing and repair.

TO CHECK REFRIGERANT CHARGE

(1) Start the engine and operate the air condi-

tioner on maximum cooling for a few minutes.

(2) Observe the flow of refrigerant through the

sight glass located at the top of the receiver/dryer. On

some models it may be necessary to use a mirror to

see the sight glass. (3) If the system is operating correctly, the sight

glass will be clear during the operation of the com-

pressor. Occasional bubbles may be seen when the

compressor cycles on and off during operation, but a

NUT j-

Bubbles in the sight glass when the air conditioner is

operating indicates a low refrigerant charge.

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.