ECU NISSAN PULSAR 1987 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 139 of 238

Manual Transaxle and Drive Shafts 139

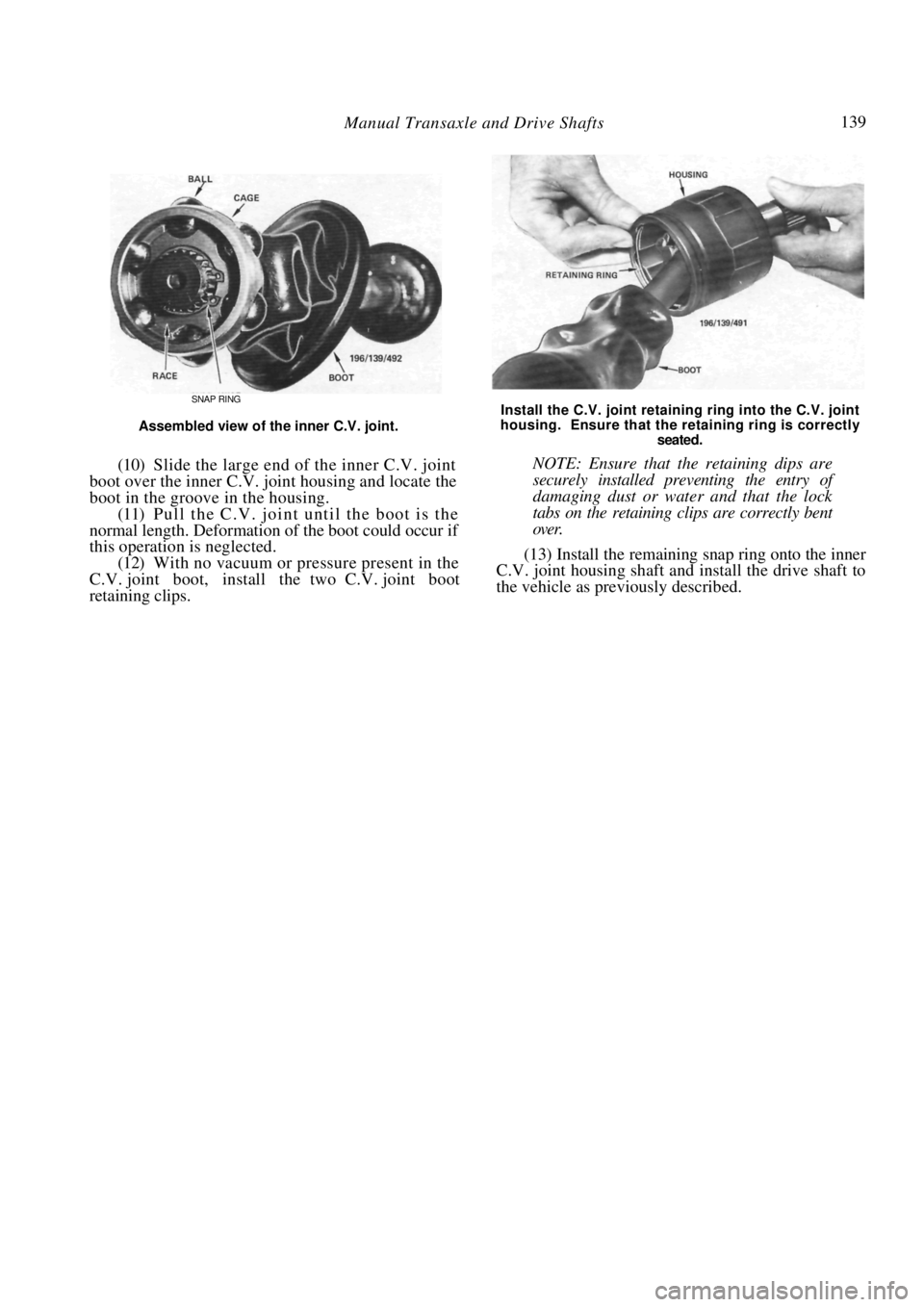

SNAP RING

Assembled view of the inner C.V. joint.

(10) Slide the large end of the inner C.V. joint

boot over the inner C.V. joint housing and locate the

boot in the groove in the housing.

(11) Pull the C.V. joint until the boot is the

normal length. Deformation of the boot could occur if

this operation is neglected. (12) With no vacuum or pressure present in the

C.V. joint boot, install the two C.V. joint boot

retaining clips.

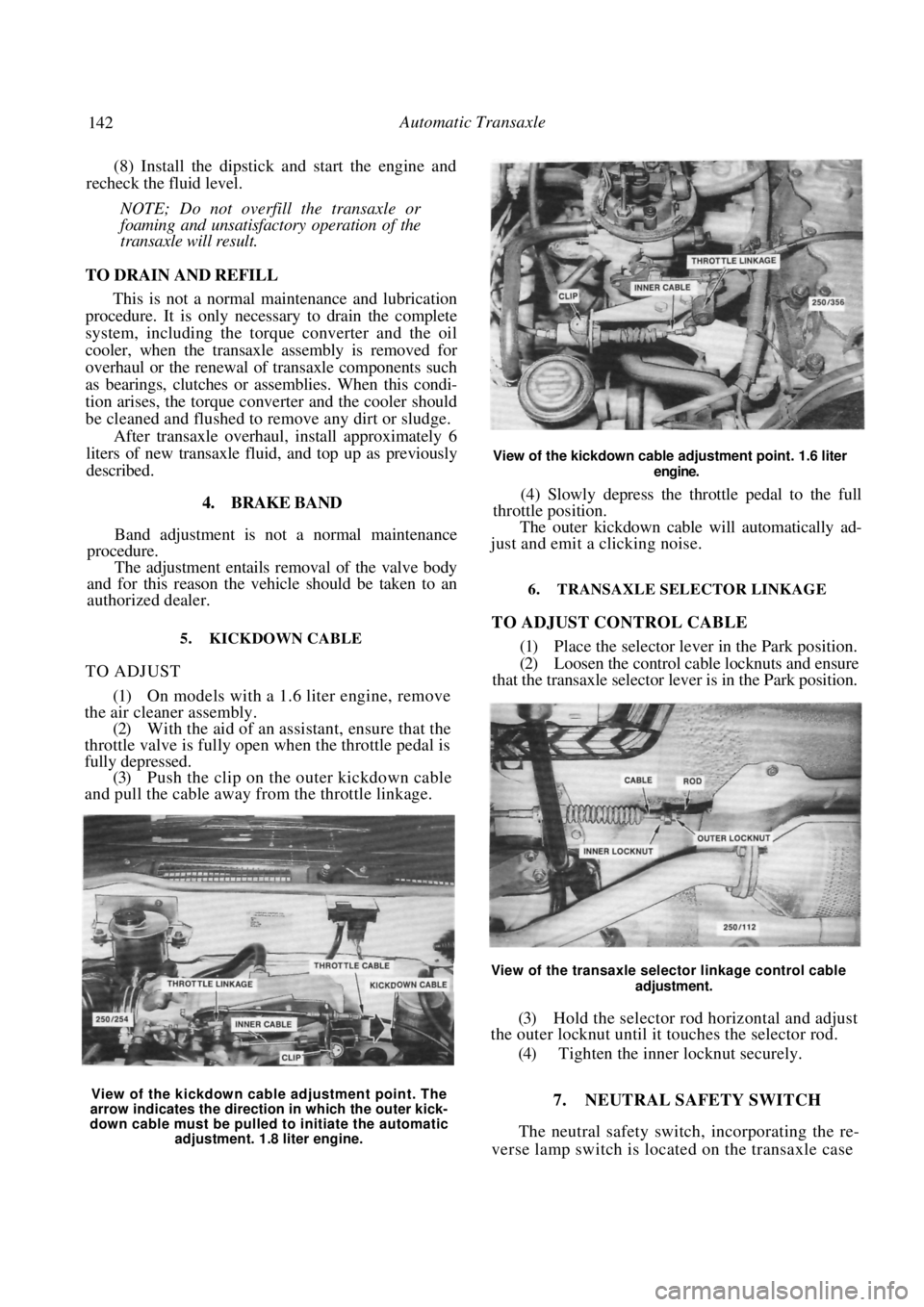

Install the C.V. joint retain ing ring into the C.V. joint

housing. Ensure that the retaining ring is correctly

seated.

NOTE: Ensure that the retaining dips are

securely installed preven ting the entry of

damaging dust or water and that the lock

tabs on the retaining clips are correctly bent

over.

(13) Install the remaining snap ring onto the inner

C.V. joint housing shaft and install the drive shaft to

the vehicle as previously described.

Page 142 of 238

142 Automatic Transaxle

(8) Install the dipstick and start the engine and

recheck the fluid level.

NOTE; Do not overfill the transaxle or

foaming and unsatisfactory operation of the

transaxle will result.

TO DRAIN AND REFILL

This is not a normal maintenance and lubrication

procedure. It is only necessary to drain the complete

system, including the torq ue converter and the oil

cooler, when the transaxle assembly is removed for

overhaul or the renewal of transaxle components such

as bearings, clutches or as semblies. When this condi-

tion arises, the torque converter and the cooler should

be cleaned and flushed to remove any dirt or sludge.

After transaxle overhaul, install approximately 6

liters of new transaxle fluid, and top up as previously

described.

4. BRAKE BAND

Band adjustment is not a normal maintenance

procedure.

The adjustment entails removal of the valve body

and for this reason the vehicle should be taken to an

authorized dealer.

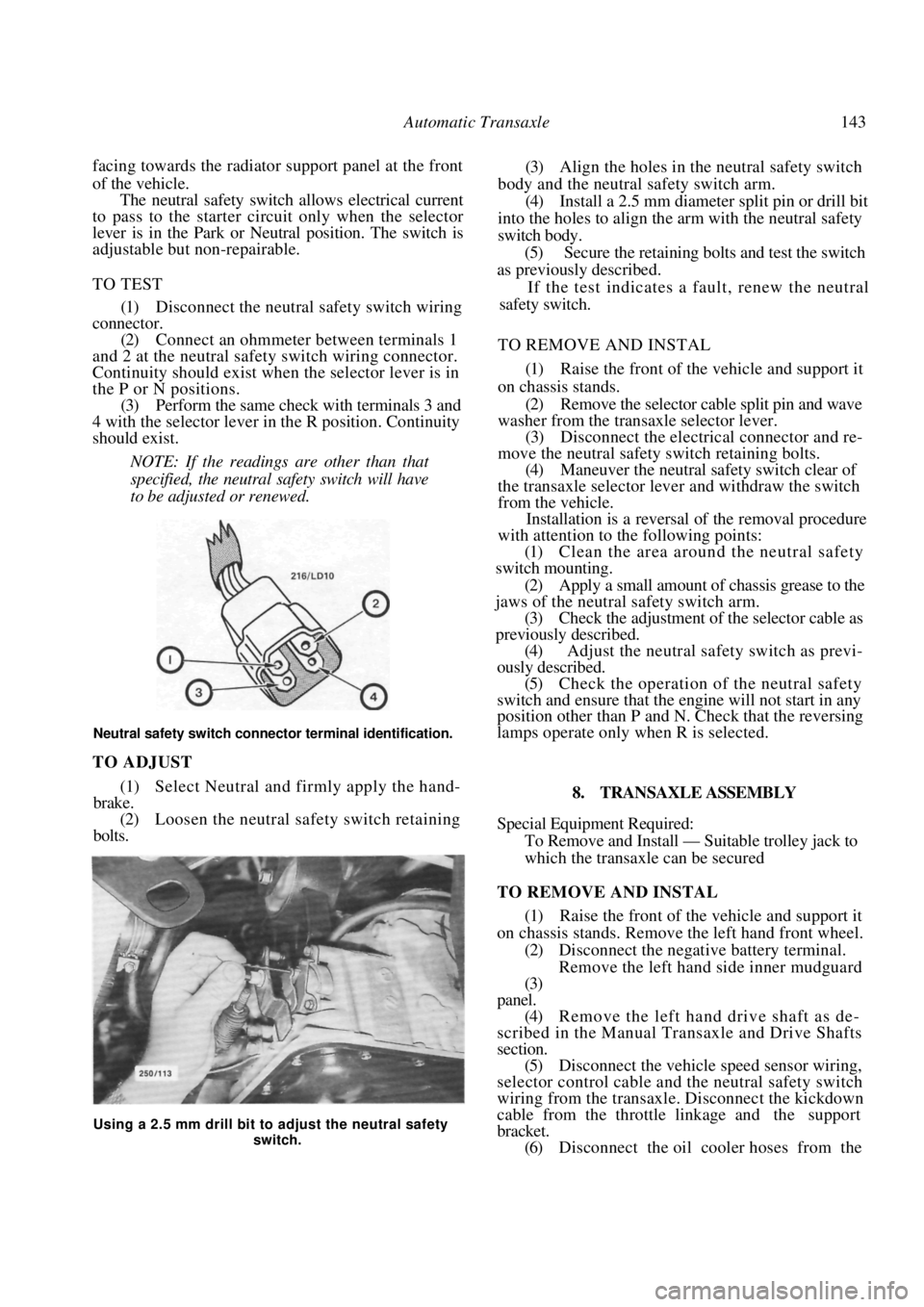

5. KICKDOWN CABLE

TO ADJUST

(1) On models with a 1.6 liter engine, remove

the air cleaner assembly. (2) With the aid of an assistant, ensure that the

throttle valve is fully open when the throttle pedal is

fully depressed. (3) Push the clip on the outer kickdown cable

and pull the cable away from the throttle linkage.

View of the kickdown cable adjustment point. 1.6 liter

engine.

(4) Slowly depress the throttle pedal to the full

throttle position.

The outer kickdown cable will automatically ad-

just and emit a clicking noise.

6. TRANSAXLE SELECTOR LINKAGE

TO ADJUST CONTROL CABLE

(1) Place the selector lever in the Park position.

(2) Loosen the control cable locknuts and ensure

that the transaxle selector lever is in the Park position.

View of the transaxle selector linkage control cable

adjustment.

(3) Hold the selector rod horizontal and adjust

the outer locknut until it touches the selector rod.

(4) Tighten the inner locknut securely.

7. NEUTRAL SAFETY SWITCH

The neutral safety switch, incorporating the re-

verse lamp switch is located on the transaxle case

View of the kickdown cable adjustment point. The

arrow indicates the direction in which the outer kick-

down cable must be pulled to initiate the automatic adjustment. 1.8 liter engine.

Page 143 of 238

Automatic Transaxle 143

facing towards the radiator support panel at the front

of the vehicle.

The neutral safety switch allows electrical current

to pass to the starter circ uit only when the selector

lever is in the Park or Neutral position. The switch is

adjustable but non-repairable.

TO TEST

(1) Disconnect the neutral safety switch wiring

connector.

(2) Connect an ohmmeter between terminals 1

and 2 at the neutral safety switch wiring connector.

Continuity should exist when the selector lever is in

the P or N positions. (3) Perform the same check with terminals 3 and

4 with the selector lever in the R position. Continuity

should exist.

NOTE: If the readings are other than that

specified, the neutral safety switch will have

to be adjusted or renewed.

Neutral safety switch connector terminal identification.

TO ADJUST

(1) Select Neutral and firmly apply the hand-

brake. (2) Loosen the neutral safety switch retaining

bolts.

(3) Align the holes in the neutral safety switch

body and the neutral safety switch arm. (4) Install a 2.5 mm diameter split pin or drill bit

into the holes to align the arm with the neutral safety

switch body. (5) Secure the retaining bolts and test the switch

as previously described.

If the test indicates a fault, renew the neutral

safety switch.

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the selector cable split pin and wave

washer from the transaxle selector lever.

(3) Disconnect the electric al connector and re-

move the neutral safety switch retaining bolts. (4) Maneuver the neutral safety switch clear of

the transaxle selector lever and withdraw the switch

from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Clean the area around the neutral safety

switch mounting.

(2) Apply a small amount of chassis grease to the

jaws of the neutral safety switch arm. (3) Check the adjustment of the selector cable as

previously described. (4) Adjust the neutral safety switch as previ-

ously described.

(5) Check the operation of the neutral safety

switch and ensure that the engine will not start in any

position other than P and N. Check that the reversing

lamps operate only when R is selected.

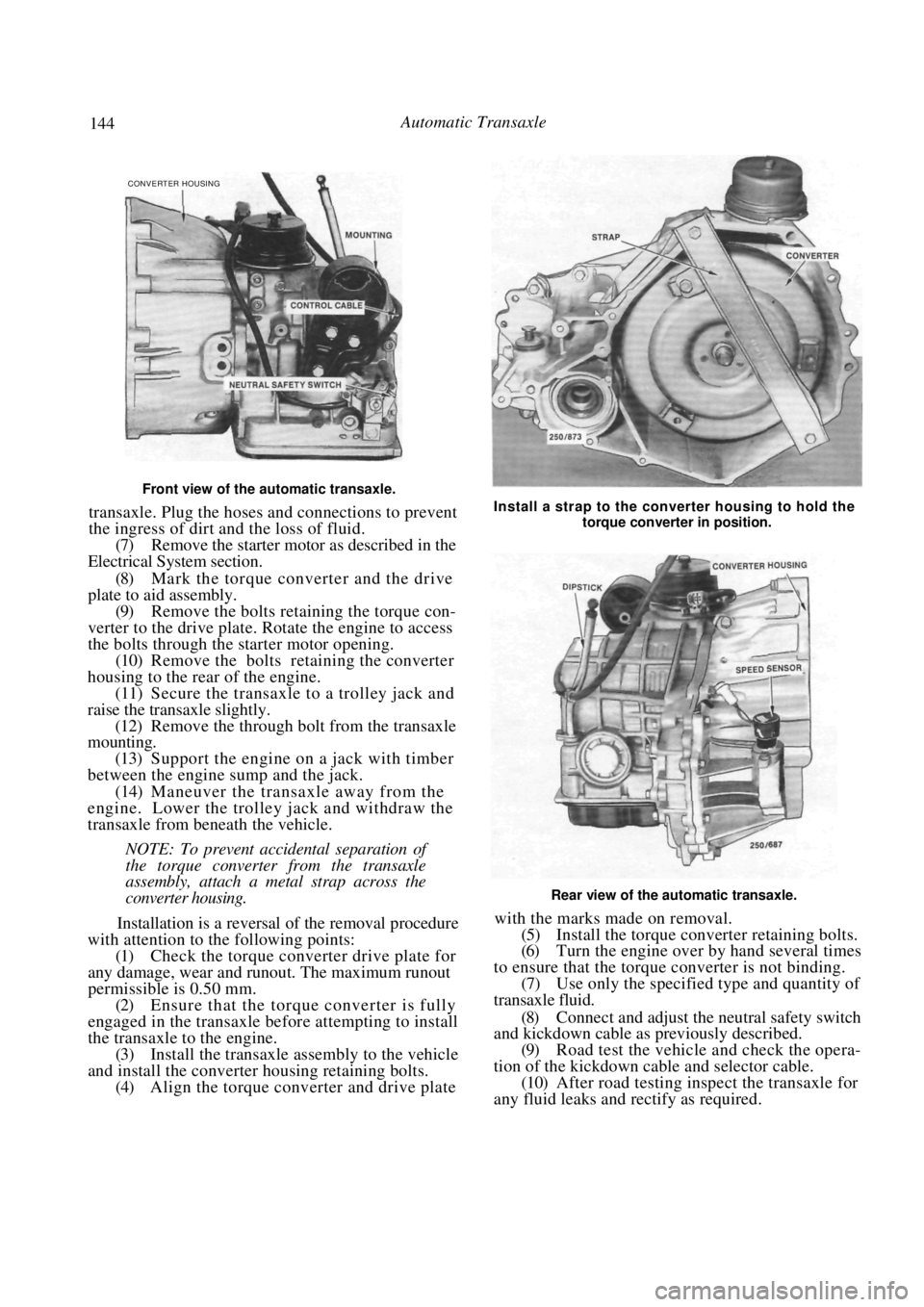

8. TRANSAXLE ASSEMBLY

Special Equipment Required:

To Remove and Install — Suitable trolley jack to

which the transaxle can be secured

TO REMOVE AND INSTAL

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the left hand front wheel.

(2) Disconnect the negative battery terminal. Remove the left hand side inner mudguard

(3)

panel.

(4) Remove the left hand drive shaft as de-

scribed in the Manual Tran saxle and Drive Shafts

section. (5) Disconnect the vehicle speed sensor wiring,

selector control cable and the neutral safety switch

wiring from the transaxle. Disconnect the kickdown

cable from the throttle linkage and the support

bracket. (6) Disconnect the oil cooler hoses from the

Using a 2.5 mm drill bit to adjust the neutral safety

switch.

Page 144 of 238

144 Automatic Transaxle

Front view of the automatic transaxle.

transaxle. Plug the hoses and connections to prevent

the ingress of dirt and the loss of fluid.

(7) Remove the starter motor as described in the

Electrical System section.

(8) Mark the torque converter and the drive

plate to aid assembly.

(9) Remove the bolts retaining the torque con-

verter to the drive plate. Rotate the engine to access

the bolts through the starter motor opening. (10) Remove the bolts retaining the converter

housing to the rear of the engine. (11) Secure the transaxle to a trolley jack and

raise the transaxle slightly. (12) Remove the through bolt from the transaxle

mounting.

(13) Support the engine on a jack with timber

between the engine sump and the jack. (14) Maneuver the transaxle away from the

engine. Lower the trolley jack and withdraw the

transaxle from beneath the vehicle.

NOTE: To prevent accidental separation of

the torque converter from the transaxle

assembly, attach a metal strap across the

converter housing.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Check the torque converter drive plate for

any damage, wear and runout. The maximum runout

permissible is 0.50 mm.

(2) Ensure that the torque converter is fully

engaged in the transaxle be fore attempting to install

the transaxle to the engine. (3) Install the transaxle assembly to the vehicle

and install the converter housing retaining bolts. (4) Align the torque converter and drive plate

Install a strap to the converter housing to hold the

torque converter in position.

Rear view of the automatic transaxle.

with the marks made on removal.

(5) Install the torque converter retaining bolts.

(6) Turn the engine over by hand several times

to ensure that the torque converter is not binding. (7) Use only the specified type and quantity of

transaxle fluid.

(8) Connect and adjust the neutral safety switch

and kickdown cable as previously described.

(9) Road test the vehicle and check the opera-

tion of the kickdown cable and selector cable. (10) After road testing inspect the transaxle for

any fluid leaks and rectify as required.

CONVERTER HOUSING

Page 146 of 238

146 Steering — Part 1

STEERING PULLS TO ONE SIDE

(1) Uneven tire wear or pressures: Check the

condition of the tires and inflate to the recommended

pressures.

(2) Incorrect front wheel alignment: Check and

align the front end.

(3) Dragging brakes: Check each wheel for drag-

ging brakes. Overhaul the brakes as necessary. (4) Damaged suspension or crossmember: In-

spect and renew the damaged components. (5) Faulty power steering gear assembly: Re-

move the power steering gear for overhaul.

FRONT WHEEL WOBBLE OR SHIMMY

(1) Uneven tire wear or incorrect tire pressures;

Check the condition of the tires and inflate to the

recommended pressures. (2) Tire or wheel imbalance: Check and balance

as necessary (3) Worn or badly adjusted hub bearings: Check

the condition and adjust the front hub bearings.

(4) Faulty or worn suspension, units: Check and

overhaul or renew as a pair.

NOTE: Check the steering linkage as previ-

ously described. Raise the front of the vehi-

cle and check the adjustment of the hub

bearings by moving the road wheel in and

out at the top and bottom. No movement in

the bearings should be felt. Check the sus-

pension units as outlined in the Front Sus-

pension section.

STEERING ERRATIC OR WANDERING

(1) Incorrect or uneven wheel alignment setting:

Check and adjust th e steering geometry.

(2) Smooth front tires: Check and renew the

tires as necessary.

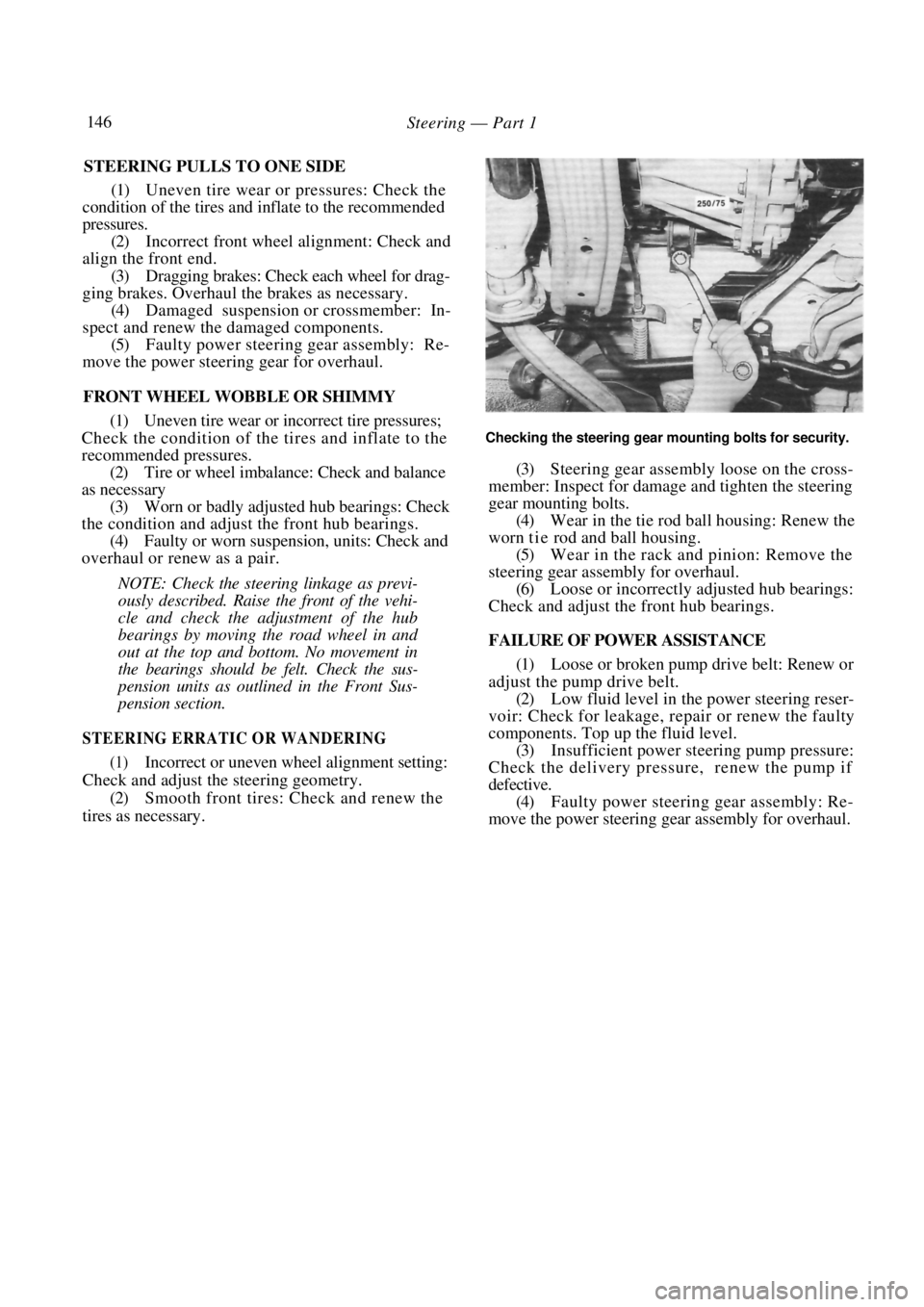

Checking the steering gear mounting bolts for security.

(3) Steering gear assembly loose on the cross-

member: Inspect for damage and tighten the steering

gear mounting bolts.

(4) Wear in the tie rod ball housing: Renew the

worn t i e rod and ball housing. (5) Wear in the rack and pinion: Remove the

steering gear assembly for overhaul. (6) Loose or incorrectly adjusted hub bearings:

Check and adjust the front hub bearings.

FAILURE OF POWER ASSISTANCE

(1) Loose or broken pump drive belt: Renew or

adjust the pump drive belt.

(2) Low fluid level in the power steering reser-

voir: Check for leakage, repair or renew the faulty

components. Top up the fluid level. (3) Insufficient power steering pump pressure:

Check the delivery pressure, renew the pump if

defective. (4) Faulty power steering gear assembly: Re-

move the power steering gear assembly for overhaul.

Page 148 of 238

148 Steering — Part 2

3. STEERING COLUMN

Special Equipment Required:

To Remove Steering Wheel — Steering wheel

puller

TO REMOVE AND INSTAL

(1) Disconnect the negative battery terminal.

(2) Working in the engine compartment, mark

the relationship between the steering shaft universal

coupling joint and the steering gear pinion shaft. (3) Remove the pinch bolts from the universal

joint. (4) Working inside the vehi cle, remove the steer-

ing wheel as previously described. (5) Remove the steering column shroud screws,

unclip the lower and upper covers and remove them

from the steering column. (6) Disconnect all the steering column wiring

connectors. (7) Remove the lower trim from underneath the

steering column.

(8) Fold back the insulator and remove the nuts

from the steering colu mn floor bracket.

(9) Remove the nuts from the lower steering

column bracket. (10) Remove the bolts from the tilt bracket

assembly. (11) Maneuver the steering column from the

vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

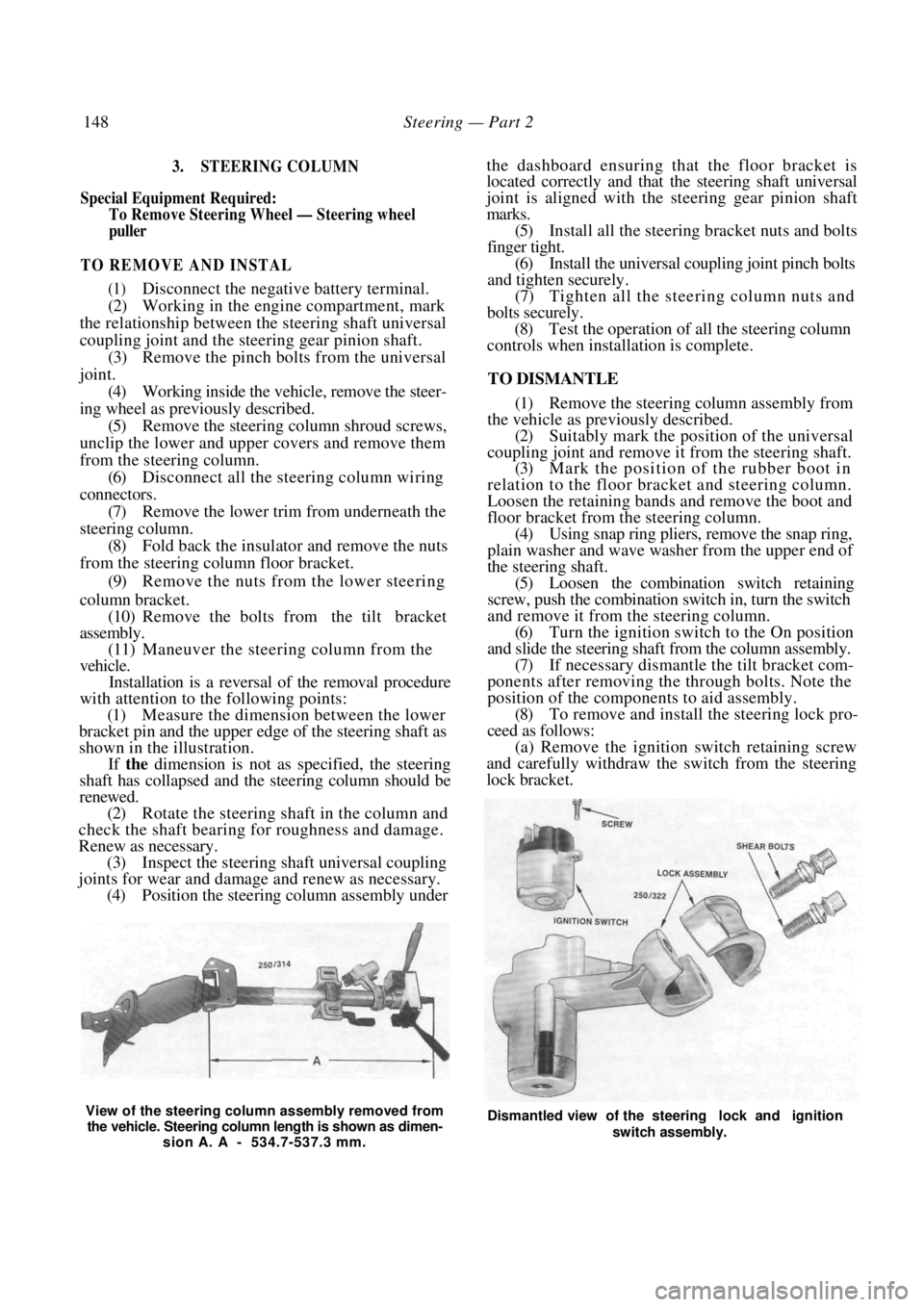

(1) Measure the dimension between the lower

bracket pin and the upper edge of the steering shaft as

shown in the illustration.

If the dimension is not as specified, the steering

shaft has collapsed and the steering column should be

renewed.

(2) Rotate the steering shaft in the column and

check the shaft bearing for roughness and damage.

Renew as necessary. (3) Inspect the steering shaft universal coupling

joints for wear and damage and renew as necessary. (4) Position the steering column assembly under

the dashboard ensuring that the floor bracket is

located correctly and that the steering shaft universal

joint is aligned with the steering gear pinion shaft

marks.

(5) Install all the steering bracket nuts and bolts

finger tight. (6) Install the universal coupling joint pinch bolts

and tighten securely.

(7) Tighten all the stee ring column nuts and

bolts securely. (8) Test the operation of all the steering column

controls when installation is complete.

TO DISMANTLE

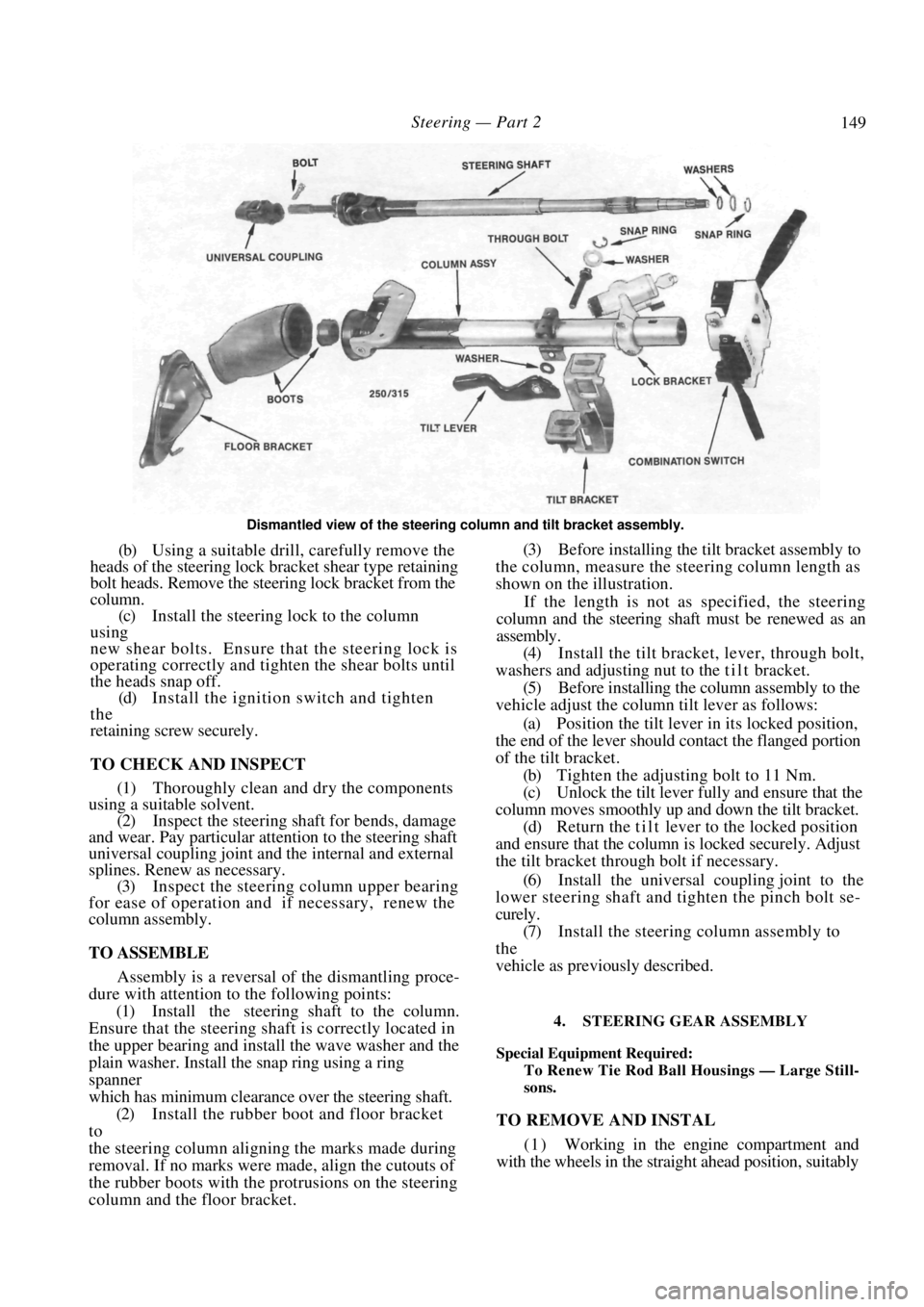

(1) Remove the steering column assembly from

the vehicle as previously described. (2) Suitably mark the position of the universal

coupling joint and remove it from the steering shaft. (3) Mark the position of the rubber boot in

relation to the floor bracket and steering column.

Loosen the retaining bands and remove the boot and

floor bracket from th e steering column.

(4) Using snap ring pliers, remove the snap ring,

plain washer and wave washer from the upper end of

the steering shaft. (5) Loosen the combination switch retaining

screw, push the combination switch in, turn the switch

and remove it from the steering column. (6) Turn the ignition switch to the On position

and slide the steering shaft from the column assembly. (7) If necessary dismantle the tilt bracket com-

ponents after removing the through bolts. Note the

position of the components to aid assembly. (8) To remove and install the steering lock pro-

ceed as follows: (a) Remove the ignition switch retaining screw

and carefully withdraw the switch from the steering

lock bracket.

View of the steering column assembly removed from

the vehicle. Steering column length is shown as dimen- sion A. A - 534.7-537.3 mm. Dismantled view of the steering lock and ignition

switch assembly.

Page 149 of 238

Steering — Part 2 149

Dismantled view of the steering column and tilt bracket assembly.

(b) Using a suitable drill, carefully remove the

heads of the steering lock br acket shear type retaining

bolt heads. Remove the steering lock bracket from the

column.

(c) Install the steering lock to the column

using

new shear bolts. Ensure that the steering lock is

operating correctly and tigh ten the shear bolts until

the heads snap off.

(d) Install the ignition switch and tighten

the

retaining screw securely.

TO CHECK AND INSPECT

(1) Thoroughly clean and dry the components

using a suitable solvent.

(2) Inspect the steering shaft for bends, damage

and wear. Pay particular attention to the steering shaft

universal coupling joint and the internal and external

splines. Renew as necessary. (3) Inspect the steering column upper bearing

for ease of operation and if necessary, renew the

column assembly.

TO ASSEMBLE

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Install the steering shaft to the column.

Ensure that the steering shaft is correctly located in

the upper bearing and insta ll the wave washer and the

plain washer. Install the snap ring using a ring

spanner

which has minimum clearan ce over the steering shaft.

(2) Install the rubber boot and floor bracket

to

the steering column aligning the marks made during

removal. If no marks were made, align the cutouts of

the rubber boots with the protrusions on the steering

column and the floor bracket. (3) Before installing the tilt bracket assembly to

the column, measure the steering column length as

shown on the illustration.

If the length is not as specified, the steering

column and the steering shaft must be renewed as an

assembly.

(4) Install the tilt bracket, lever, through bolt,

washers and adjusting nu t to the t i l t bracket.

(5) Before installing the column assembly to the

vehicle adjust the column tilt lever as follows:

(a) Position the tilt lever in its locked position,

the end of the lever should contact the flanged portion

of the tilt bracket.

(b) Tighten the adjusting bolt to 11 Nm.

(c) Unlock the tilt lever fully and ensure that the

column moves smoothly up and down the tilt bracket. (d) Return the tilt lever to the locked position

and ensure that the column is locked securely. Adjust

the tilt bracket thro ugh bolt if necessary.

(6) Install the universal coupling joint to the

lower steering shaft and tighten the pinch bolt se-

curely.

(7) Install the steering column assembly to

the

vehicle as previously described.

4. STEERING GEAR ASSEMBLY

Special Equipment Required:

To Renew Tie Rod Ball Housings — Large Still-

sons.

TO REMOVE AND INSTAL

( 1 ) Working in the engine compartment and

with the wheels in the straight ahead position, suitably

Page 150 of 238

150 Steering — Part 2

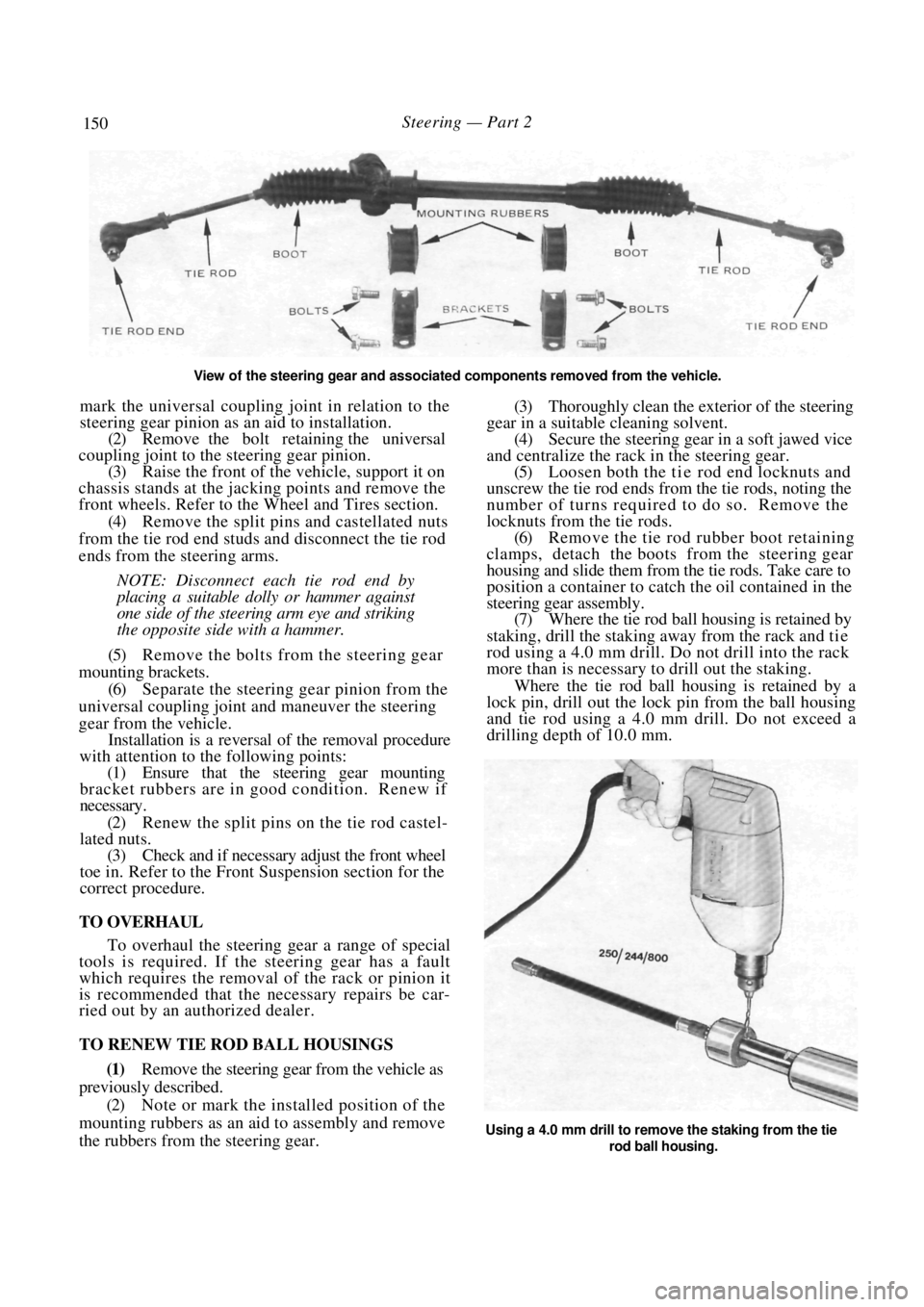

View of the steering gear and associated components removed from the vehicle.

mark the universal coupling joint in relation to the

steering gear pinion as an aid to installation.

(2) Remove the bolt retaining the universal

coupling joint to the steering gear pinion. (3) Raise the front of the vehicle, support it on

chassis stands at the jack ing points and remove the

front wheels. Refer to the Wheel and Tires section.

(4) Remove the split pins and castellated nuts

from the tie rod end studs and disconnect the tie rod

ends from the steering arms.

NOTE: Disconnect each tie rod end by

placing a suitable dolly or hammer against

one side of the steer ing arm eye and striking

the opposite side with a hammer.

(5) Remove the bolts from the steering gear

mounting brackets. (6) Separate the steering gear pinion from the

universal coupling joint and maneuver the steering

gear from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Ensure that the steering gear mounting

bracket rubbers are in good condition. Renew if

necessary.

(2) Renew the split pins on the tie rod castel-

lated nuts.

(3) Check and if necessary adjust the front wheel

toe in. Refer to the Front Suspension section for the

correct procedure.

TO OVERHAUL

To overhaul the steering gear a range of special

tools is required. If the steering gear has a fault

which requires the removal of the rack or pinion it

is recommended that the necessary repairs be car-

ried out by an authorized dealer.

TO RENEW TIE ROD BALL HOUSINGS

(1) Remove the steering gear from the vehicle as

previously described.

(2) Note or mark the installed position of the

mounting rubbers as an aid to assembly and remove

the rubbers from the steering gear.

(3) Thoroughly clean the exterior of the steering

gear in a suitable cleaning solvent.

(4) Secure the steering gear in a soft jawed vice

and centralize the rack in the steering gear. (5) Loosen both the ti e rod end locknuts and

unscrew the tie rod ends from the tie rods, noting the

number of turns required to do so. Remove the

locknuts from the tie rods. (6) Remove the tie rod rubber boot retaining

clamps, detach the boot s from the steering gear

housing and slide them from the tie rods. Take care to

position a container to catch the oil contained in the

steering gear assembly. (7) Where the tie rod ball housing is retained by

staking, drill the staking away from the rack and t i e

rod using a 4.0 mm drill. Do not drill into the rack

more than is necessary to drill out the staking.

Where the tie rod ball housing is retained by a

lock pin, drill out the lock pin from the ball housing

and tie rod using a 4.0 mm drill. Do not exceed a

drilling depth of 10.0 mm.

Using a 4.0 mm drill to remove the staking from the tie

rod ball housing.

Page 151 of 238

Steering — Part 2 151

(8) Slide the rack out of the housing slightly so

that an adjustable spanner can be used to hold the

rack. (9) Using a Stillsons wrench, unscrew the ball

housings in turn using care not to allow the rack to

rotate. Keep all the tie rod parts in order. (10) Inspect the rack boots for cracks and deteri-

oration and renew as necessary. (11) Inspect the tie rod ends for wear and damage

and renew as necessary.

Dismantled view of the tie rod ball housing and the tie

rod end assemblies removed from the steering gear.

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

(1) Using large Stillsons and a large adjustable

spanner, install the tie rod and ball housing

assemblies

to the rack. Tighten the ball housings to the specified

torque.

NOTE: To avoid damage to the rack or

pinion the adjustable spanner must be

firmly tightened over the rack teeth and the

rack must not be allowed to rotate when

installing the ball housings.

(2) Measure a point 9 mm in from the rear face

of the ball housing of the rack and at 90 deg to the

rack teeth. Centre punch this point.

(3) At this point drill a 4 mm hole, 10 mm deep

through the rack and into the ball housing thread.

(4) Place a locking pin above the hole and drive

it into position.

(5) Lubricate the rack, rack teeth and t i e rod

boot groove with suitable EPL 1 grease. (6) Install the rack boots and secure with the

clamps. Renew the clamps if necessary. (7) Install the tie rod end locknuts and then the

tie rod ends, ensuring that they are screwed on the

same number of turns as was necessary to remove

them.

(8) Tighten the locknuts to the specified torque.

(9) Install the mounting rubbers and brackets

to

the steering gear as noted on removal. (10) Install the steering gear assembly to

the

vehicle as previously described. (11) Check and if necessary adjust the front wheel toe in as described in the Front Suspension section

under the appropriate heading.

TO RENEW TIE ROD END

(1)

Raise the front of the vehicle and support it

on chassis stands. (2) Remove the relevant front wheel.

(3) Loosen the tie rod end locknut and remove

the tie rod end castellated nut. Disconnect the tie rod

from the steering arm by plac ing a suitable dolly or

hammer against one side of the steering arm eye and

striking the opposite side with a hammer. (4) Unscrew the tie rod end from the tie rod,

noting the number of turns necessary to remove it.

(5) Screw the new tie rod end onto the t i e rod

the same number of turn s noted during removal.

(6) Connect the t i e rod to the steering arm and

install the castellated nut. Tighten the nut to the

specified torque and secure it with a new split pin.

(7) Install the front wheel and lower the vehicle

to the ground. (8) Check and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. Ensure that the rubber boots are not distorted

or twisted on the tie rod when the adjustment is

completed.

TO RENEW RUBBER BOOT

(1) Raise the front of the vehicle and support it

on chassis stands. (2) Remove the relevant t i e rod end as previ-

ously described. (3) Release the clamps securi ng the boot to the

tie rod and steering gear housing. (4) Unscrew and remove the locknut from the

tie rod. (5) Remove the rubber boot together with the

outer retaining clamp from the t i e rod. (6) Sparingly lubricate th e tie rod boot groove

with EPL 1 grease, install the new boot to the t i e

rod

and push it onto the steering gear rack housing. Install

and secure the inner and outer retaining clamps.

(7) Install the tie rod end locknut and screw

the

tie rod end onto the tie ro d the same number of turns

noted during removal. (8) Connect the tie rod to the steering arm and

install the castellated nut. Tighten the nut to the

specified torque and secure it with a new split pin. (9) Install the wheel and lower the vehicle to the

ground. (10) Check and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. Ensure that the rubber boots are not distorted

or twisted when the adjustment is completed.

Page 154 of 238

154 Steering —

(2) Remove the air inlet duct from the air

cleaner and throttle body. (3) Position a container or a piece of cloth

beneath the steering pump reservoir and disconnect

the fluid return and power steering pump supply hose

from the reservoir.

(4) Loosen the steering pump drive belt as

described in the Engi ne Tune-up section.

(5) Loosen the return hose clamp and the supply

union and disconnect the hoses from the power

steering pump. Plug the hoses to prevent the loss of

fluid.

(6) Loosen the retaining bolts and withdraw the

pump. (7) Thoroughly clean the exterior of the steering

pump and inspect it for cracks, damage and signs of

leakage.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pump and retaining bolts.

(2) Install the drive belt and adjust it as de-

scribed in the Engine Tune-up section. (3) Install the hoses to the power steering pump

and tighten securely. (4) Top up the pump reservoir and purge the

power steering system of air as previously described.

TO OVERHAUL

As specialist knowledge and equipment arc re-

quired to overhaul the power steering pump, it is

recommended that this operation be performed by an

authorized dealer or steering specialist.

6. POWER STEERING GEAR ASSEMBLY

Special Equipment Required:

To Renew Tie Rod Ball Housings — Large Still-

sons

TO REMOVE AND INSTAL

The procedures for removing and installing the

power steering gear are similar to those carried out in

the Manual Steering section under the Steering Gear

Assembly heading except fo r the following differences.

(1) Place a container under the pressure and

return pipes that are conn ected to the steering gear

valve housing. Remove the pipes and allow the fluid

to drain into the container. (2) Suitably seal the pipes and the steering gear

to prevent the entry of di rt whilst the pipes are

removed.

(3) Upon removal of the power steering gear,

thoroughly clean the steering gear except the tie rod

ends in a suitable solvent. Be careful not to allow the

solvent to enter the apertu res where the pressure and

return pipes were removed. (4) Check the pipes and co nnections for cracks,

damage or obstructions and renew as necessary.

Installed view of the power steering gear with the

engine removed.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Install the pressure and return pipes to the

steering gear valve housing and tighten securely. (2) Fill the power steering reservoir to the cor-

rect level and bleed the system as described previously

under the heading In Car Adjustments. Checks and

Minor Repairs. (3) Check all power steering pipe connections

for leaks and repair as necessary. (4) Check, and if necessary, adjust the front

wheel toe in as described in the Front Suspension

section. After adjustment ensure that the rubber boots

are not distorted or twisted and the rubber boot

clamps and clips are facing downward.

TO OVERHAUL

As specialist knowledge and equipment are re-

quired to overhaul the power steering gear, it is rec-

ommended that this opera tion be performed by an

authorized dealer or steering specialist.

TO RENEW TIE ROD BALL HOUSINGS

TRW Steering Gear

The renewal of the tie rod ball housings is the

same as for the manual steering gear. Refer to Part 2.

Manual Steering section.

PR24SA Steering Gear

(1) Remove the power steering gear assembly

from the vehicle as previously described.

(2) Carefully mount the power steering gear in a

vice equipped with soft jaws. Loosen the tie rod end

locknuts without disturbing the location of the tie rod

ends and unscrew the tie rod ends, taking note of the

number of turns required to remove them. Unscrew

and remove the locknuts from the tie rod. (3) Remove the clamps from the rubber boots

and remove the boots.