radiator NISSAN PULSAR 1987 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 197 of 238

Electrical System 197

Switch on all lamps and allow them to

illuminate for approximately five minutes to reduce

the charge of the battery and to apply a load to the

circuit.

Start the engine and gradually increase the

speed to approximately 2 500 rpm. The reading on

the ammeter should be approximately 75% of the

rated output of the altern ator. See Specifications.

Switch off all the lamps and run the engine at

1 500-2 000 rpm until the indicated charge is below

10 amps. The voltmeter should now read in excess of

13.6 volts.

NOTE: Should the alternator fail to reach

the specific output, the unit will have to be

removed and overhauled or a replacement

unit installed.

Should the voltage reading be above or

below Specifications, the regulator will have

to be renewed.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

On 1.8 liter engines, remove the bolt secur-

ing the air cleaner intake duct and remove the air

cleaner intake duct. Drain the radiator by releasing the radiator

drain plug, located at the bottom of the radiator and

allow the coolant level to fall below the thermostat

housing level. NOTE: Refer to the Cooling and Heating

Systems section when refilling the radiator

coolant to its correct l

evel, failure to do so

could result in severe damage to engine

components.

Remove the retaining bolts securing the

thermostat housing, disconnect the hose from the

radiator and remove the thermostat housing and

radiator hose from the vehicle. Using a socket and extension bar, remove the

bolt securing the alternator to the drive belt tensioning

bar located under the alternator. On vehicles not equipped with air condition-

ing, remove the front splash guard from under the

front of the vehicle and remove the bolt securing the

alternator to the drive belt tensioning bar. Loosen the upper mounting bolts, slacken

the alternator drive belt and remove it from the

alternator pulley.

While supporting the alternator, remove the

upper mounting bolts and remove the alternator from

the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

Do not over tension the drive belt. Refer

to

the Engine Tune-up section for the correct belt

adjusting procedure. Ensure that the wiring and connectors are

securely located on the alternator.

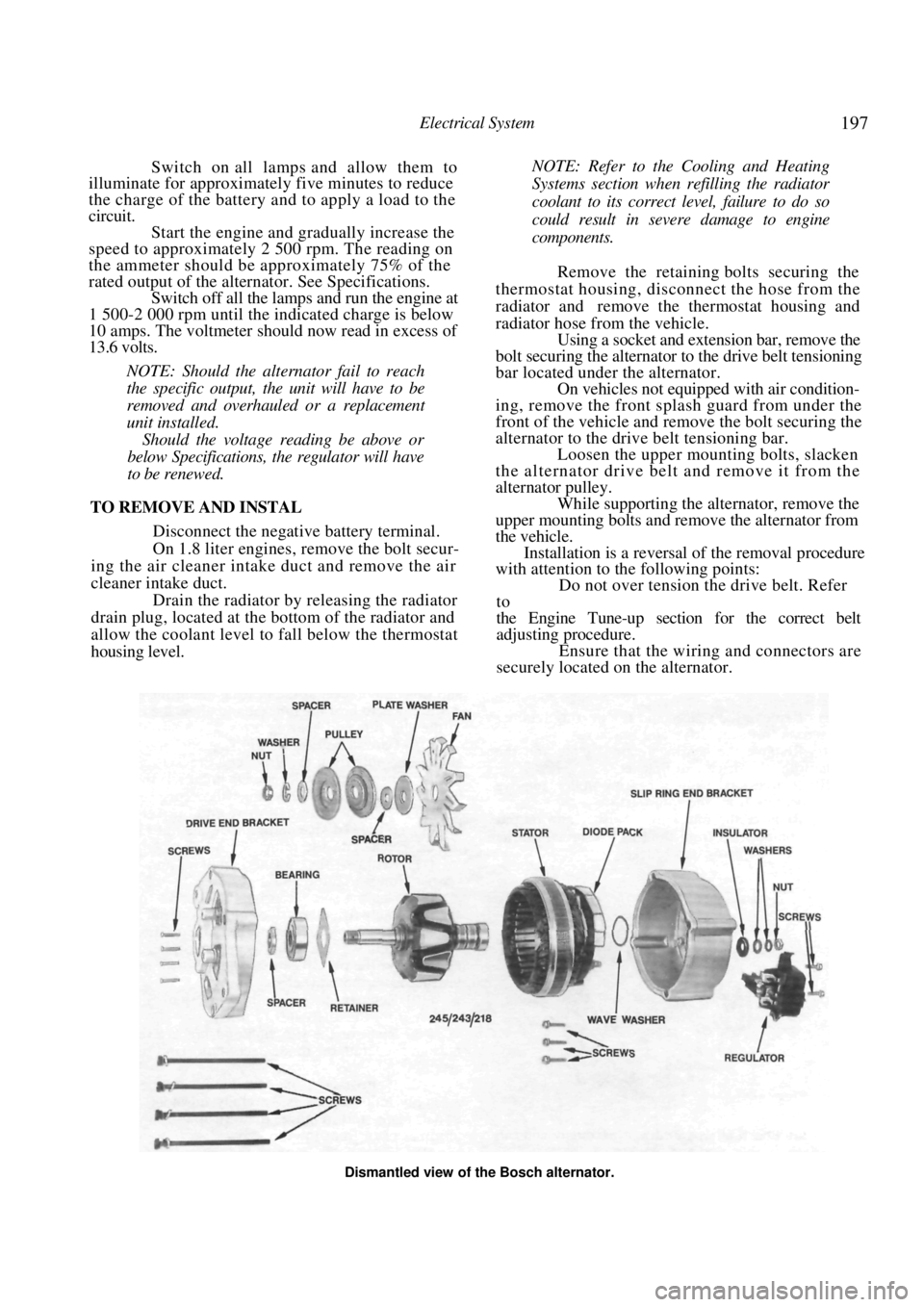

Dismantled view of the Bosch alternator.

Page 198 of 238

198 Electrical System

(3) Replenish the coolant in the radiator. Refer

to the Cooling and Heating Systems section for the

correct procedure.

TO DISMANTLE

Bosch Alternator

Remove the alternator from the vehicle as

previously described.

Scribe a mark across the drive end bracket,

stator and slip ring end bracket to facilitate correct

alignment during assembly. Remove the screws and washers securing the

regulator and brush holder assembly. Withdraw the

regulator and brush holder assembly from the alter-

nator. Remove the long screws securing the drive

end bracket to the slip ring end bracket and withdraw

the drive end bracket, rotor and pulley assembly.

NOTE: Ensure that the wave washer behind

the rotor shaft rear bearing in the slip ring

end bracket is not mislaid.

Holding the rotor in a soft jawed vice,

remove the split drive pulley retaining nut, washer

and spacer from the rotor shaft. Remove the split driv e pulley, spacer, plate

washer and fan from the rotor shaft. Using a suitable pres s and press plates,

support the drive end bracket with the pulley end of

the rotor shaft uppermost a nd carefully press the rotor

shaft from the spacer, bearing and the drive end

bracket.

Remove the spacer and the bearing retainer

plate screws from the drive end bracket. Remove the bearing retainer plate and the

bearing from the drive end bracket. If necessary, using a bearing puller, remove

the rear bearing from the rotor shaft. Remove the nut, spring washer and output

terminal components from the {B + ) terminal on the

outside of the slip ring end bracket.

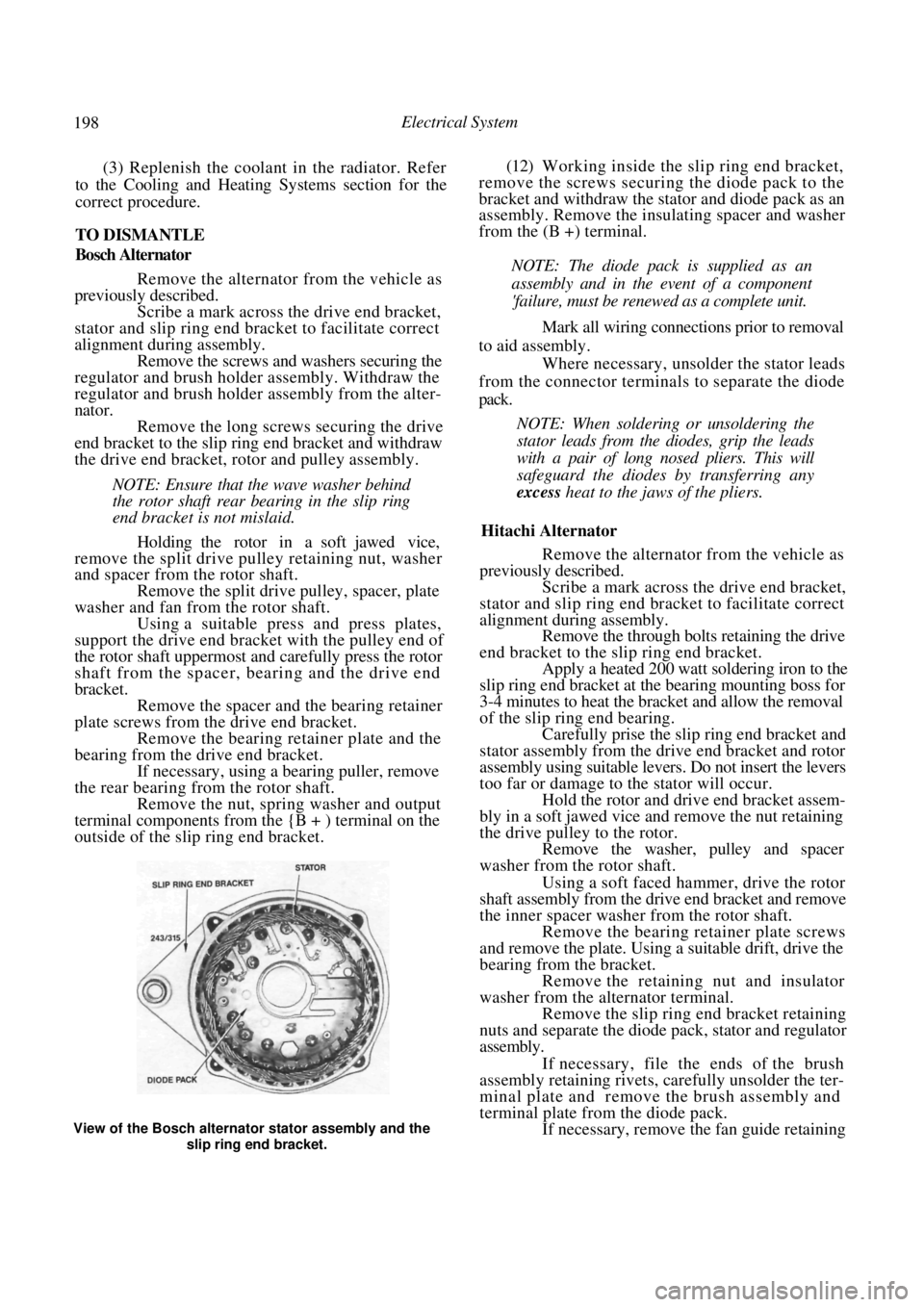

(12) Working inside the slip ring end bracket,

remove the screws securing the diode pack to the

bracket and withdraw the stator and diode pack as an

assembly. Remove the insulating spacer and washer

from the (B +) terminal.

NOTE: The diode pack is supplied as an

assembly and in the event of a component

'failure, must be renewed as a complete unit.

Mark all wiring connections prior to removal

to aid assembly. Where necessary, unsolder the stator leads

from the connector terminals to separate the diode

pack.

NOTE: When soldering or unsoldering the

stator leads from the diodes, grip the leads

with a pair of long nosed pliers. This will

safeguard the diodes by transferring any

excess heat to the jaws of the pliers.

Hitachi Alternator

Remove the alternator from the vehicle as

previously described.

Scribe a mark across the drive end bracket,

stator and slip ring end bracket to facilitate correct

alignment during assembly. Remove the through bolts retaining the drive

end bracket to the slip ring end bracket. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the removal

of the slip ring end bearing. Carefully prise the slip ring end bracket and

stator assembly from the drive end bracket and rotor

assembly using suitable levers. Do not insert the levers

too far or damage to the stator will occur.

Hold the rotor and driv e end bracket assem-

bly in a soft jawed vice and remove the nut retaining

the drive pulley to the rotor. Remove the washer, pulley and spacer

washer from the rotor shaft.

Using a soft faced hammer, drive the rotor

shaft assembly from the drive end bracket and remove

the inner spacer washer from the rotor shaft.

Remove the bearing retainer plate screws

and remove the plate. Using a suitable drift, drive the

bearing from the bracket. Remove the retaining nut and insulator

washer from the alternator terminal. Remove the slip ring end bracket retaining

nuts and separate the diode pack, stator and regulator

assembly.

If necessary, file the ends of the brush

assembly retaining rivets, caref ully unsolder the ter-

minal plate and remove the brush assembly and

terminal plate from the diode pack. If necessary, remove the fan guide retaining

View of the Bosch alternator stator assembly and the

slip ring end bracket.

Page 210 of 238

210 Electrical System

Using the radio/cassette removal tools during removal of the unit.

Construct the special tools as illustrated,

insert both tools into the release holes on the radio/

cassette and carefully withdraw the radio/cassette

from the mounting bracket.

Disconnect the wiring harness terminal plug

and remove the radio/cassette.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the special tools from the radio/

cassette, connect the wiring harness terminal and push

the radio/cassette into the mounting bracket. Install the release hole covers on each side

of

the radio/cassette.

15. LAMP UNITS

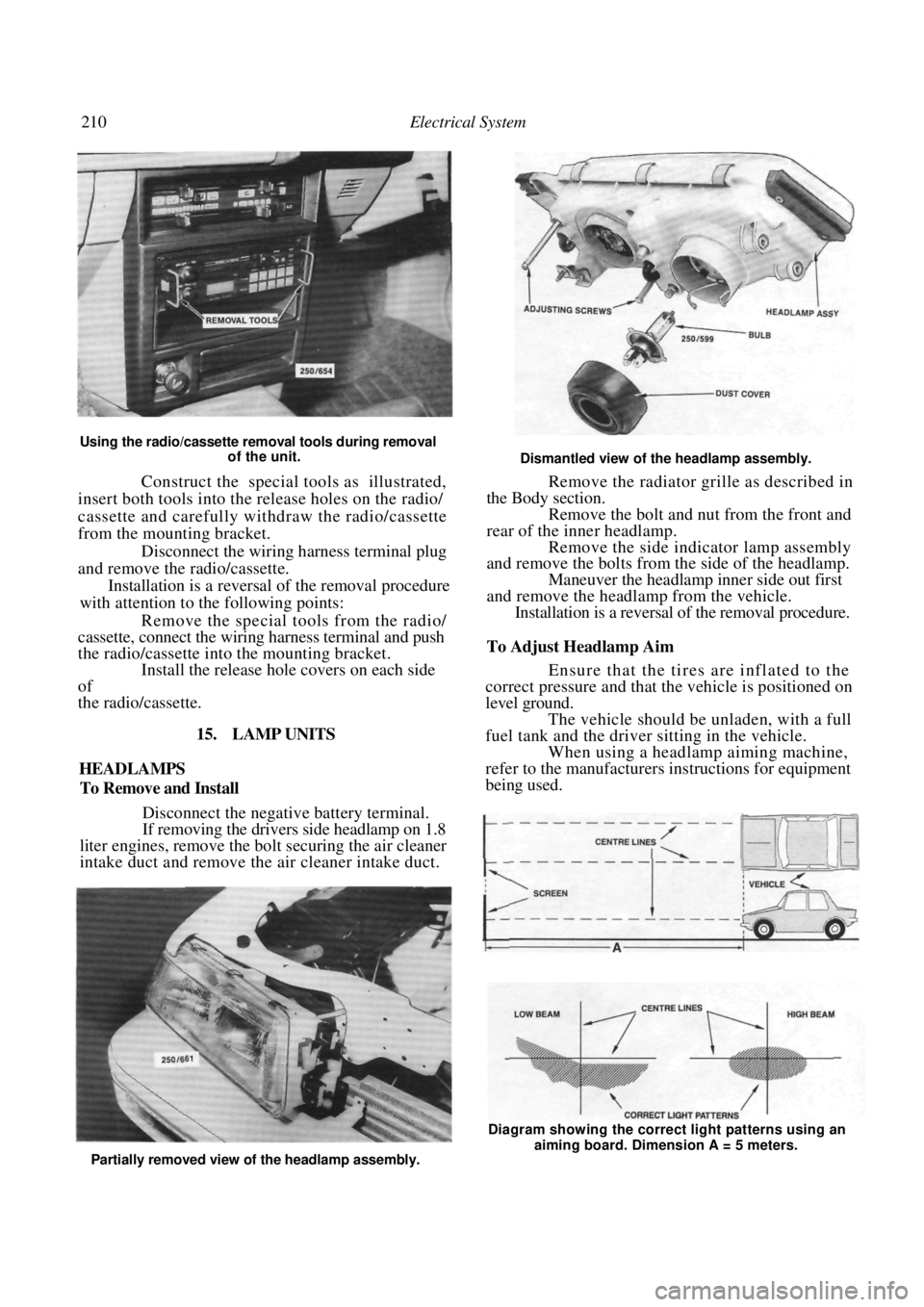

HEADLAMPS

To Remove and Install

Disconnect the negative battery terminal.

If removing the drivers side headlamp on 1.8

liter engines, remove the bo lt securing the air cleaner

intake duct and remove the air cleaner intake duct.

Dismantled view of the headlamp assembly.

Remove the radiator grille as described in

the Body section. Remove the bolt and nut from the front and

rear of the inner headlamp. Remove the side indicator lamp assembly

and remove the bolts from the side of the headlamp.

Maneuver the headlamp inner side out first

and remove the headlamp from the vehicle. Installation is a reversal of the removal procedure.

To Adjust Headlamp Aim

Ensure that the tires are inflated to the

correct pressure and that the vehicle is positioned on

level ground.

The vehicle should be unladen, with a full

fuel tank and the driver sitting in the vehicle. When using a headlamp aiming machine,

refer to the manufacturers instructions for equipment

being used.

Partially removed view of the headlamp assembly. Diagram showing the correct light patterns using an

aiming board. Dimension A = 5 meters.

Page 231 of 238

Body 231

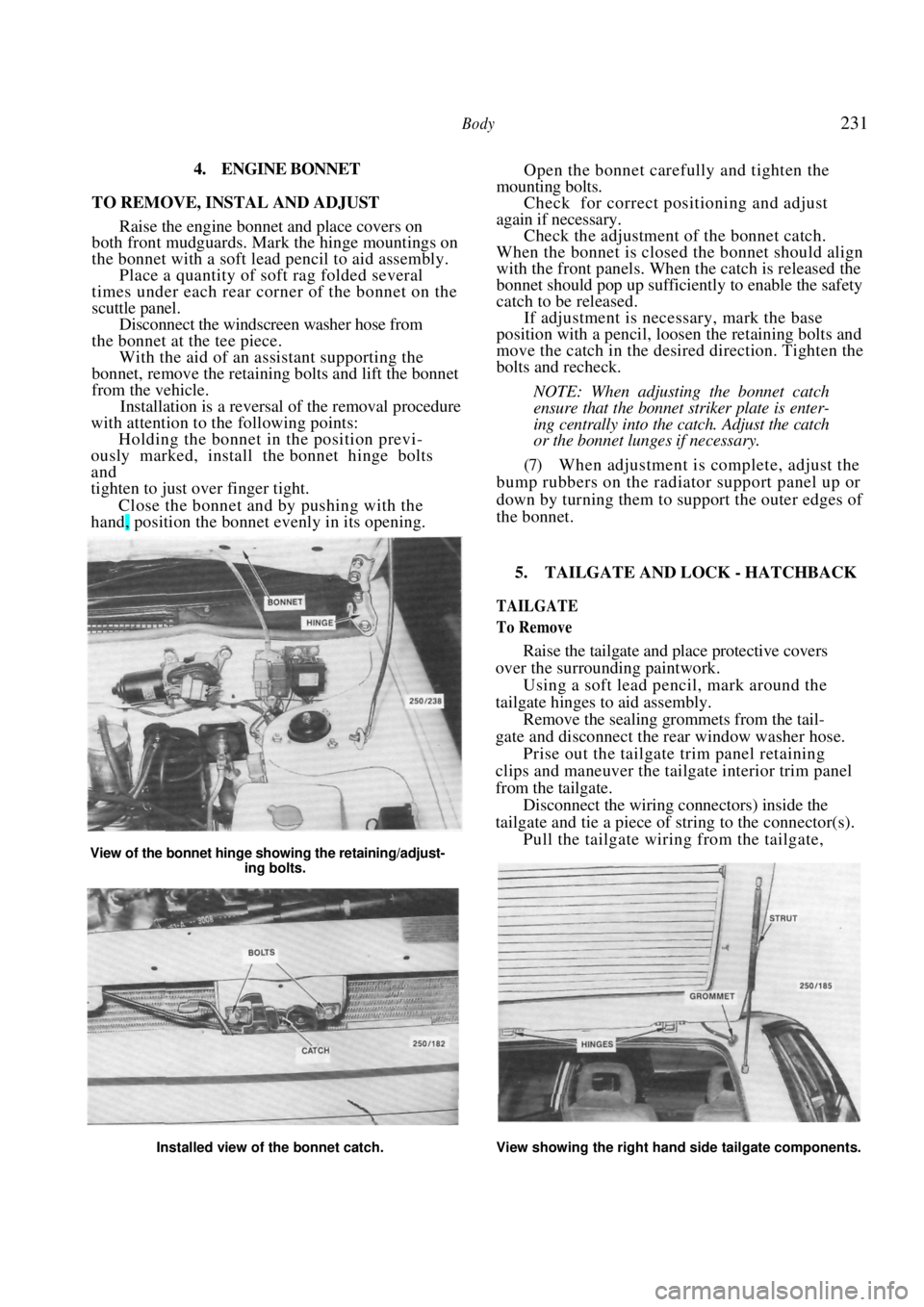

4. ENGINE BONNET

TO REMOVE, INSTAL AND ADJUST

Raise the engine bonnet and place covers on

both front mudguards. Mark the hinge mountings on

the bonnet with a soft lead pencil to aid assembly.

Place a quantity of soft rag folded several

times under each rear corner of the bonnet on the

scuttle panel. Disconnect the windscreen washer hose from

the bonnet at the tee piece. With the aid of an assistant supporting the

bonnet, remove the retaining bolts and lift the bonnet

from the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

Holding the bonnet in the position previ-

ously marked, install the bonnet hinge bolts

and

tighten to just over finger tight.

Close the bonnet and by pushing with the

hand, position the bonnet evenly in its opening.

Open the bonnet carefully and tighten the

mounting bolts. Check for correct positioning and adjust

again if necessary. Check the adjustment of the bonnet catch.

When the bonnet is closed the bonnet should align

with the front panels. When the catch is released the

bonnet should pop up sufficiently to enable the safety

catch to be released. If adjustment is necessary, mark the base

position with a pencil, loosen the retaining bolts and

move the catch in the desired direction. Tighten the

bolts and recheck.

NOTE: When adjusting the bonnet catch

ensure that the bonnet striker plate is enter-

ing centrally into the catch. Adjust the catch

or the bonnet lunges if necessary.

(7) When adjustment is complete, adjust the

bump rubbers on the radiator support panel up or

down by turning them to support the outer edges of

the bonnet.

View of the bonnet hinge showing the retaining/adjust-

ing bolts.

5. TAILGATE AND LOCK - HATCHBACK

TAILGATE

To Remove

Raise the tailgate and place protective covers

over the surrounding paintwork.

Using a soft lead pencil, mark around the

tailgate hinges to aid assembly. Remove the sealing grommets from the tail-

gate and disconnect the rear window washer hose. Prise out the tailgate trim panel retaining

clips and maneuver the tailgate interior trim panel

from the tailgate.

Disconnect the wiring connectors) inside the

tailgate and tie a piece of st ring to the connector(s).

Pull the tailgate wiring from the tailgate,

Installed view of the bonnet catch. View showing the right hand side tailgate components.

Page 234 of 238

234 Body

LOCK ASSEMBLY

To Remove and Install

( 1 ) Remove the retaining bolts and withdraw the

lock assembly from the luggage compartment lid.

Installation is a reversal of the removal procedure

ensuring that the actuating arm on the lock is under

the lock cylinder pivot.

LOCK CYLINDER

Installed view of the lock and lock cylinder.

LOCK CYLINDER

To Remove and Install

Remove the bolt retaining the lock cylinder

pivot to the luggage compartment lid inner panel. Using a suitable screwdriver, remove the

lock cylinder retaining clip from under the lock. Withdraw the lock cylinder and pivot from

the vehicle. Installation is a reversal of the removal procedure.

(2) When the clips have been released, pull the

grille forward and remove it from the vehicle ensuring

that care is taken not to damage the grille.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the grille retaining clips from the

radiator support panel and install them to the

grille.

Renew any damaged clips. Install the grille to the vehicle being careful to

align the grille clips before pushing the grille inwards.

Post July 1989 Pulsar Models

Fabricate a tool to engage the radiator grille

clips from the inside; an old spanner of suitable

dimensions can be ground down if necessary.

Using the above tool, turn the lower radiator

clips slightly to allow removal of the grille.

7. RADIATOR GRILLE

TO REMOVE AND INSTAL

Astra Models and Pre July 1989 Pulsar Models

(1) Using a flat bladed screwdriver, turn the

grille clips slightly to allow removal of the grille.

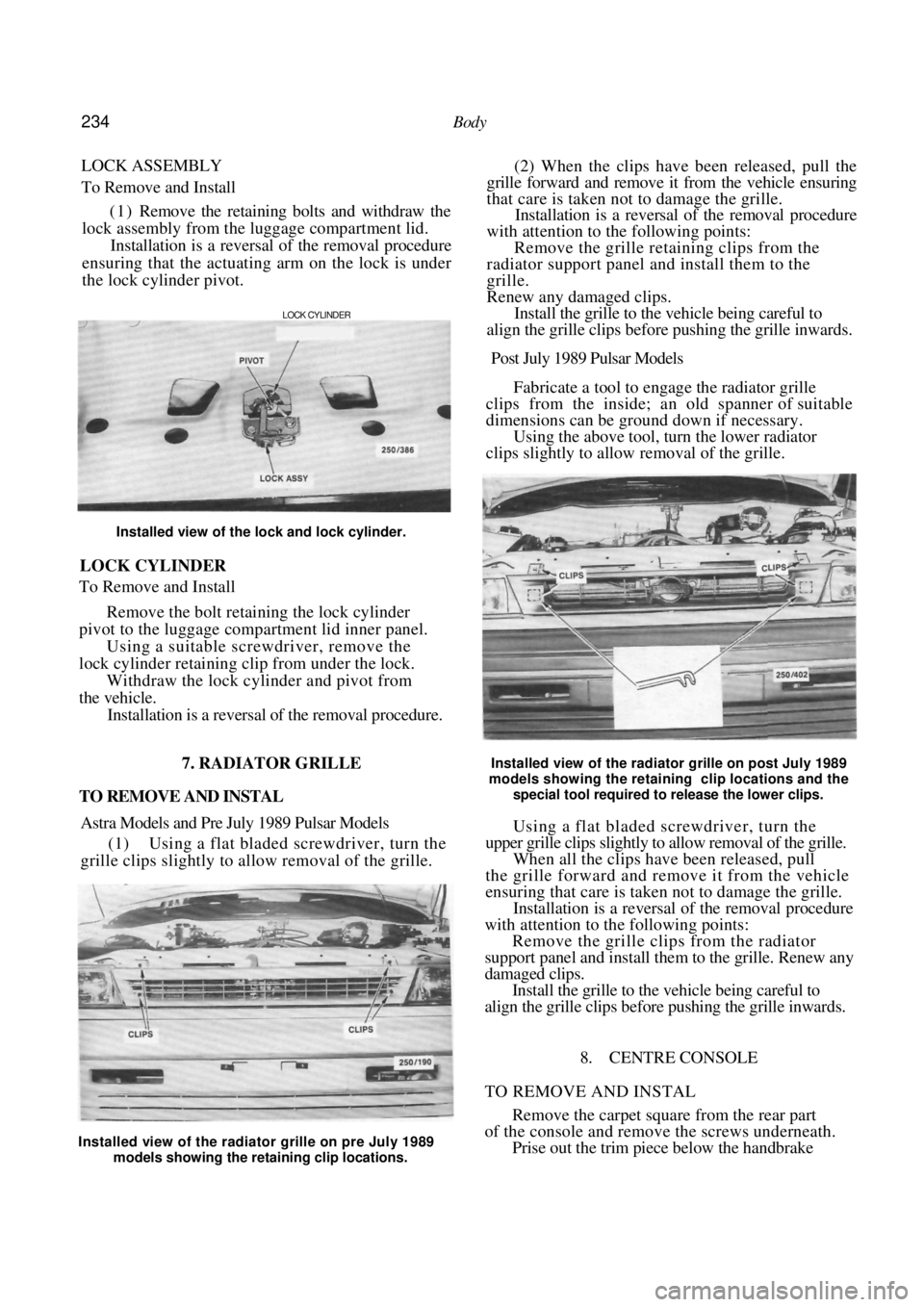

Installed view of the radiator grille on pre July 1989

models showing the retaining clip locations. Installed view of the radiator grille on post July 1989

models showing the retaining clip locations and the

special tool required to release the lower clips.

Using a flat bladed screwdriver, turn the

upper grille clips slightly to allow removal of the grille. When all the clips have been released, pull

the grille forward and remove it from the vehicle

ensuring that care is taken not to damage the grille.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the grille clips from the radiator

support panel and install them to the grille. Renew any

damaged clips.

Install the grille to the vehicle being careful to

align the grille clips before pushing the grille inwards.

8. CENTRE CONSOLE

TO REMOVE AND INSTAL

Remove the carpet square from the rear part

of the console and remove the screws underneath. Prise out the trim piece below the handbrake