wheel torque NISSAN PULSAR 1987 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 171 of 238

Rear Suspension 171

Installation is a reversal of the removal procedure

with attention to the following points:

(1) When installing the stabilizer bar to the

knuckle assembly bushes, ensu re that the thicker bush

is installed to the front of the knuckle assembly. Install

the rear bush, washers and nut but do not tighten at

this stage. (2) Install the stabil izer bar mounting

brackets,

ensuring that the end with the large bevel is facing the

front of the vehicle. Tighte n the retaining bolts to the

specified torque. (3) Using a new gasket, install the intermediate

exhaust pipe to the catalytic converter, ensuring that

the earth wire terminal is installed, and tighten the

bolts securely. Install the exhaust mounting

retaining

bolt. (4) Install the rear wheels and lower the

vehicle

to the ground. With the wei ght of the vehicle on the

road wheels, tighten the stabilizer bar retaining nuts to

the specified torque.

8. REAR WHEEL ALIGNMENT

Specialized equipment is required to measure the

rear wheel alignment. It is therefore recommended

that the vehicle be referred to a specialist suspension

workshop or an authorized dealer for measurement

and adjustment. The suspension components should

be inspected and renewed as necessary prior to having

the wheel alignment checked. If any suspension com-

ponents are renewed, the re ar wheel toe out may be

temporarily adjusted as described below.

TO INSPECT

Examine the tread of the tires. Excessive or

uneven wear will indicate misalignment or damaged

or worn components. Refer to the Tire Wear Trouble

Shooting Chart in the Wheels and Tires section for

possible causes and renew the faulty components.

Badly worn tires should be renewed prior to

having the wheel alignment checked.

TO CHECK AND ADJUST TOE OUT

NOTE: The following procedures are only a

temporary measure. Th e vehicle should be

referred to a specialis t suspension work-

shop or authorized dealer for accurate

measurement and adjustment.

(1) Position the vehicle on a level floor and

bounce the vehicle several tim es to settle the suspen-

sion. (2) Move the vehicle forward approximately 5

meters, with the front wheels straight ahead, to settle

the tires and suspension to the normal running

position.

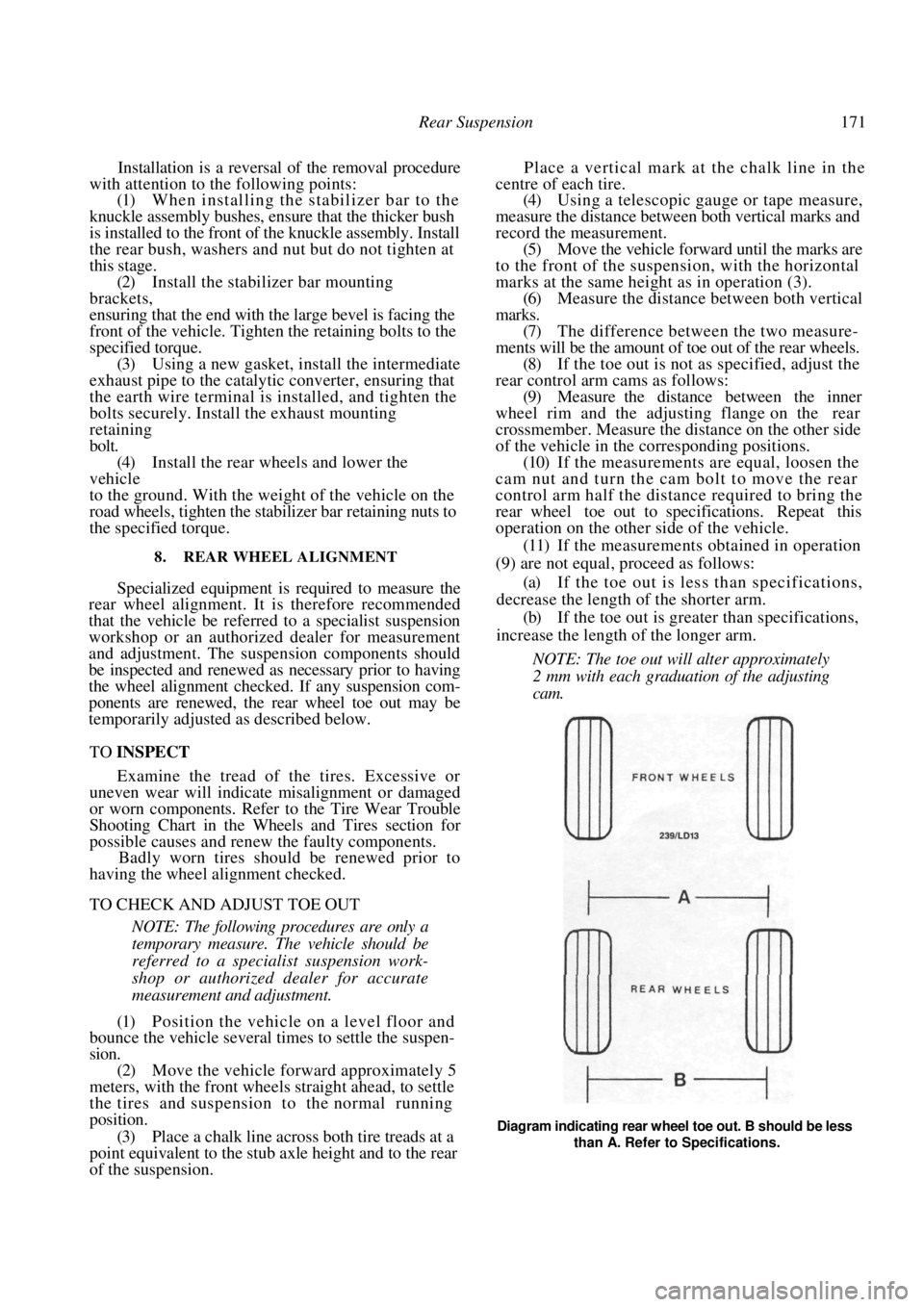

(3) Place a chalk line across both tire treads at a

point equivalent to the stub axle height and to the rear

of the suspension. Place a vertical mark at the chalk line in the

centre of each tire.

(4) Using a telescopic gauge or tape measure,

measure the distance between both vertical marks and

record the measurement. (5) Move the vehicle forward until the marks are

to the front of the suspen sion, with the horizontal

marks at the same height as in operation (3). (6) Measure the distance between both vertical

marks. (7) The difference between the two measure-

ments will be the amount of toe out of the rear wheels. (8) If the toe out is not as specified, adjust the

rear control arm cams as follows: (9) Measure the distance between the inner

wheel rim and the adjusting flange on the rear

crossmember. Measure the distance on the other side

of the vehicle in the corresponding positions. (10) If the measurements are equal, loosen the

cam nut and turn the cam bolt to move the rear

control arm half the distance required to bring the

rear wheel toe out to specifications. Repeat this

operation on the other side of the vehicle.

(11) If the measurements obtained in operation

(9) are not equal, proceed as follows:

(a) If the toe out is less than specifications,

decrease the length of the shorter arm.

(b) If the toe out is greater than specifications,

increase the length of the longer arm.

NOTE: The toe out will alter approximately

2 mm with each graduation of the adjusting

cam.

Diagram indicating rear wheel toe out. B should be less than A. Refer to Specifications.

Page 172 of 238

172

BRAKES

SPECIFICATIONS

Type:

Except Pulsar/Vector GL from

July 1989 and Astra models ... Four wheel disc

Pulsar/Vector GL from

July 1989 and Astra models —

Front...............................................................Disc

Rear..............................................................Drum

Operation:

Footbrake ............... Vacuum assisted diagonally

split dual hydraulic

Handbrake................ Mechanical on rear wheels

Fluid type ...........................................................Dot 4

Master cylinder:

Make ........................................................ Girlock

Bore diameter —

Large .................................................... 25.40 mm

Small .................................................... 20.64 mm

Front disc brakes:

Caliper bore diameter ........................... 48.1 mm

Disc diameter ........................................ 240 mm

Disc thickness, minimum ......................... 16 mm

Disc runout, maximum ......................... 0.07 mm

Disc pad thickness, minimum ....................2 mm

Rear disc pads:

Caliper bore diameter ......................... 30.16 mm

Disc diameter ........................................ 234 mm

Disc thickness, minimum ...........................9 mm

Disc runout, maximum .......................... 0.07 mm

Disc pad thickness, minimum ....................2 mm

Rear drum brakes:

Wheel cylinder bore diameter ............ 15.87 mm

Drum diameter, maximum ............... 204.50 mm

Drum out of round, maximum.............. 0.03 mm

Drum runout, maximum ........................ 0.05 mm

Brake lining wear limit ........................... 1.5 mm

TORQUE WRENCH SETTINGS

Brake pedal bracket to body........................... 11 Nm

Brake pedal pivot bolt ..................................... 11 Nm

Brake servo unit to body................................. I I N m

Brake servo unit to master cylinder ............... 11 Nm

Pressure differential piston plug ...................... 12 Nm

Proportioning valve plug................................. 27 Nm

Caliper anchor plate bolts ............................... 52 Nm

Caliper guide bolts .......................................... 31 Nm

Brake hose to caliper....................................... 34 Nm

Handbrake cable bracket bolt ......................... 49 Nm

Handbrake lever to body ................................ 11 Nm

Cable clamp to body....................................... 11 Nm

Cam lever nut.................................................. 49 Nm

1. BRAKES TROUBLE SHOOTING

BRAKE PEDAL HARD

(1) Seized caliper piston or wheel cylinder: Over-

haul the caliper or wheel cylinder.

(2) Seized master cylinder piston: Overhaul the

master cylinder. (3) Seized pedal pivot: Rectify or renew the

pedal pivot shaft and bushes. (4) Restricted brake line: Remove the restriction

or renew the brake line.

(5) Vacuum servo system inoperative: Check

and repair the servo system.

NOTE: The vacuum servo system can be

checked as follows: With the engine

switched off, pump the brake pedal several

times to deplete any vacuum in the system.

With the engine still switched off, press

down firmly on the brake pedal and hold it

there noting the position and pressure re-

quired. Start the engine. If the servo unit is

operating correctly, the brake pedal will sink

slightly and the pressure required to hold it

may reduce. If the pedal does not sink

slightly when the engine is started, check the

vacuum supply to the servo unit. If vacuum

is reaching the brake servo unit, the unit can

be considered inoperative.

BRAKE DRAG

(1) Clogged master cylinder ports: Clean the

master cylinder and the fluid reservoir. Renew the

brake fluid. (2) Seized caliper piston or wheel cylinder: Over-

haul the caliper or wheel cylinder.

(3) Seized handbrake linkage: Free up or renew

the linkage.

Page 179 of 238

Brakes 179

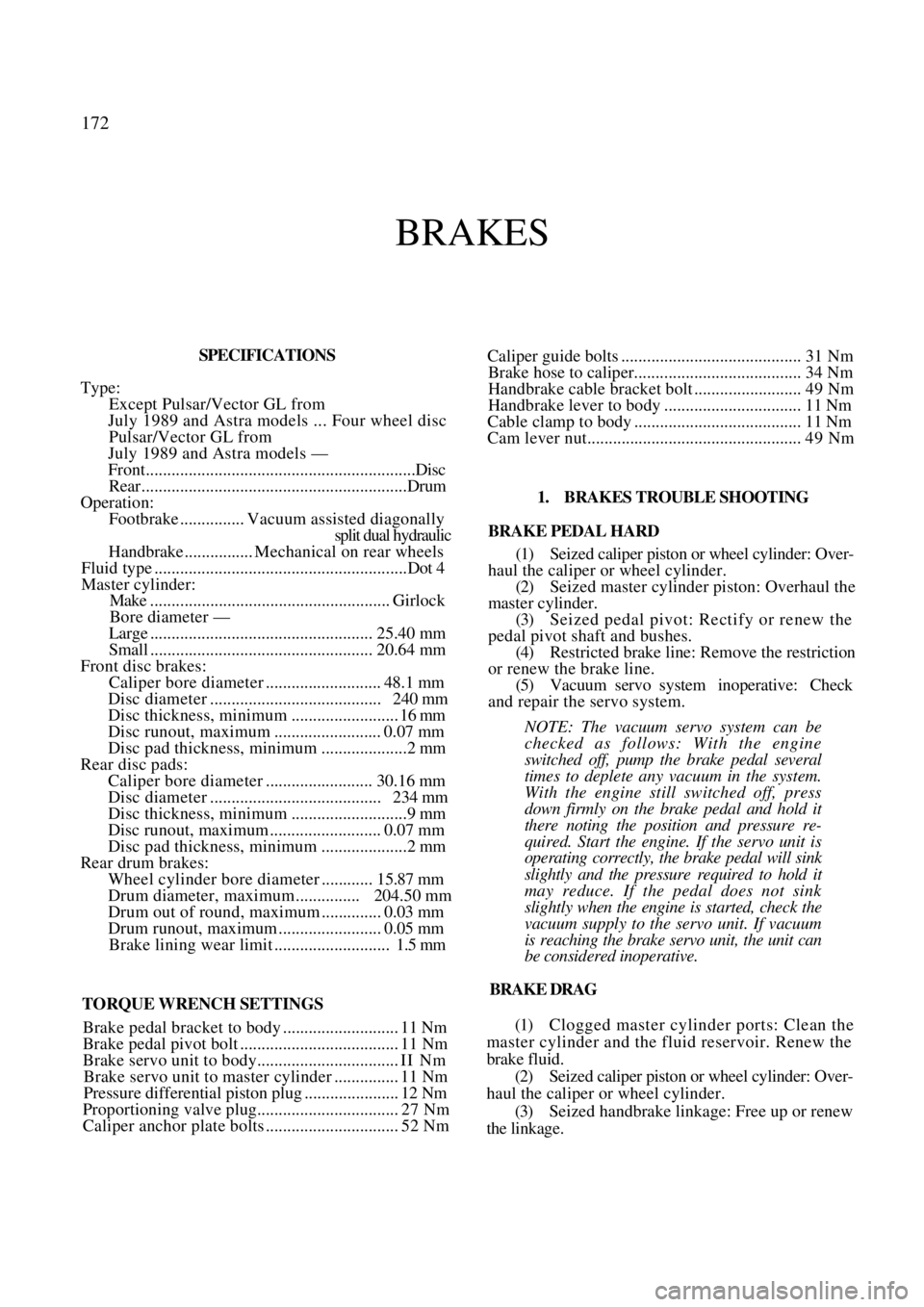

Installed view of the front brake pads, spring clips and shims.

NOTE: Do not drain all the fluid from the

reservoir or it will be necessary to bleed the

hydraulic system. The fluid is drained from

the reservoir to prevent overflow when the

caliper piston is pushed back into the caliper

bore to facilitate pad renewal.

(4) Remove the lower guide bolt and rotate the

caliper body upwards, pivoting on the upper guide

bolt.

(5) Remove the brake pad assemblies from the

anchor plate. (6) Noting the installed positions, remove the

spring clips from the anchor plate and the shims from

the brake pads.

(7) Squarely push the piston into its bore in the

caliper body. If necessary, us e a G clamp to push the

piston into the caliper b ody. Check for fluid leaks

from the calip er body.

(8) If necessary, check the disc runout and

thickness as described under the Brake Disc heading.

(9) Ensure that the guide bolts move freely in the

anchor plate and that the dust boots are in good

condition. (10) Install the brake pads, shims and spring

clips

in the position noted on removal. (11) Rotate the caliper body downwards, to re-

turn to its original position. Lubricate the lower guide

bolt with suitable grease. In stall and tighten the guide

bolt to the specified torque. (12) Repeat the procedure on the opposite front

brake assembly. (13) Replenish the master cylinder reservoir with the recommended fluid to the correct level and pump

the brake pedal several times to locate the disc pads.

(14)

Install the front wheels and lower the

vehicle

to the ground. (15) Road lest the vehicle and check for correct

brake operation.

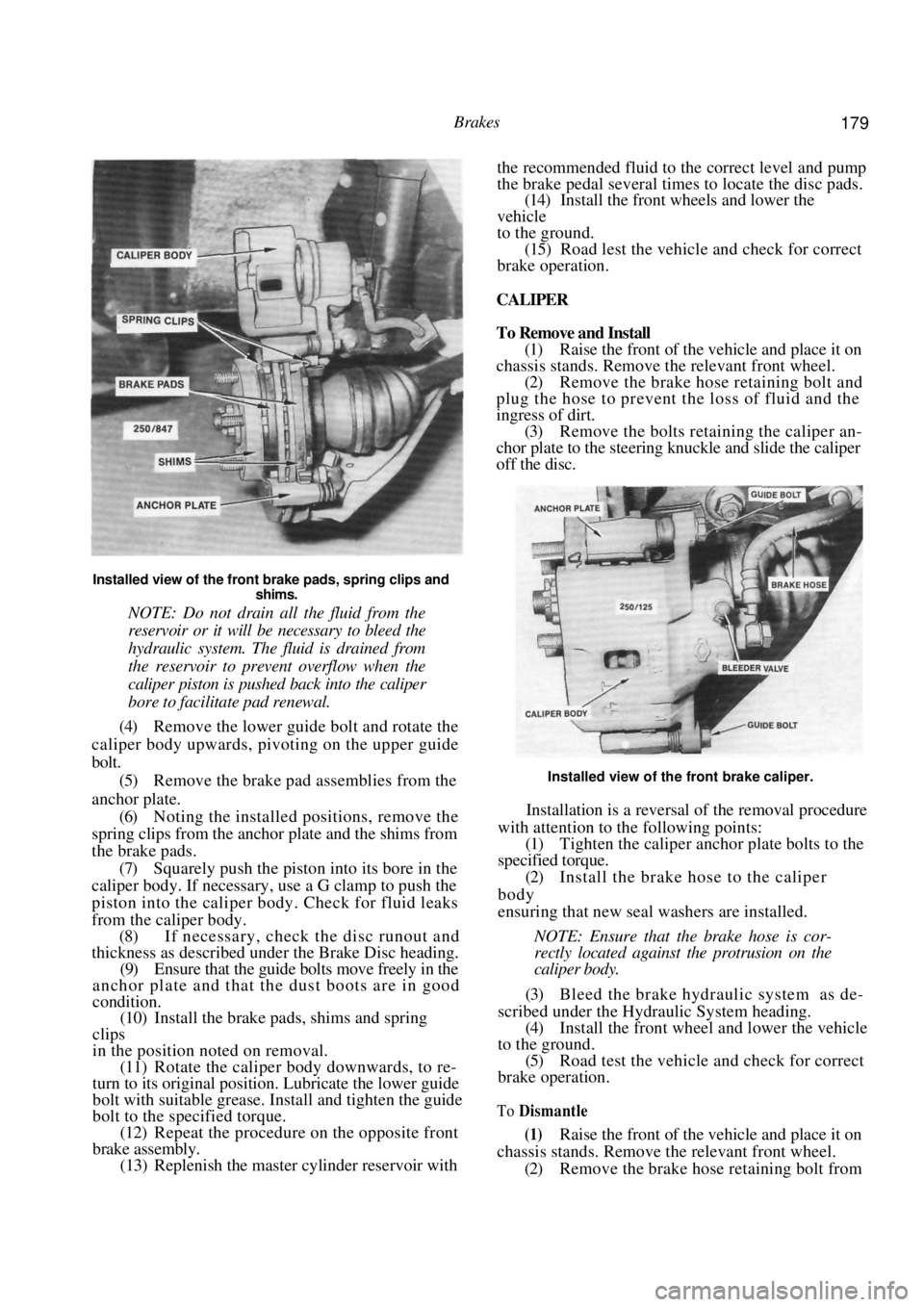

CALIPER

To Remove and Install

(1) Raise the front of the vehicle and place it on

chassis stands. Remove the relevant front wheel. (2) Remove the brake hose retaining bolt and

plug the hose to prevent the loss of fluid and the

ingress of dirt. (3) Remove the bolts retaining the caliper an-

chor plate to the steering knuckle and slide the caliper

off the disc.

Installed view of the front brake caliper.

Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the caliper anch or plate bolts to the

specified torque.

(2) Install the brake hose to the caliper

body

ensuring that new seal washers are installed.

NOTE: Ensure that the brake hose is cor-

rectly located against the protrusion on the

caliper body.

(3) Bleed the brake hydraulic system as de-

scribed under the Hydraulic System heading. (4) Install the fron t wheel and lower the vehicle

to the ground. (5) Road test the vehicle and check for correct

brake operation.

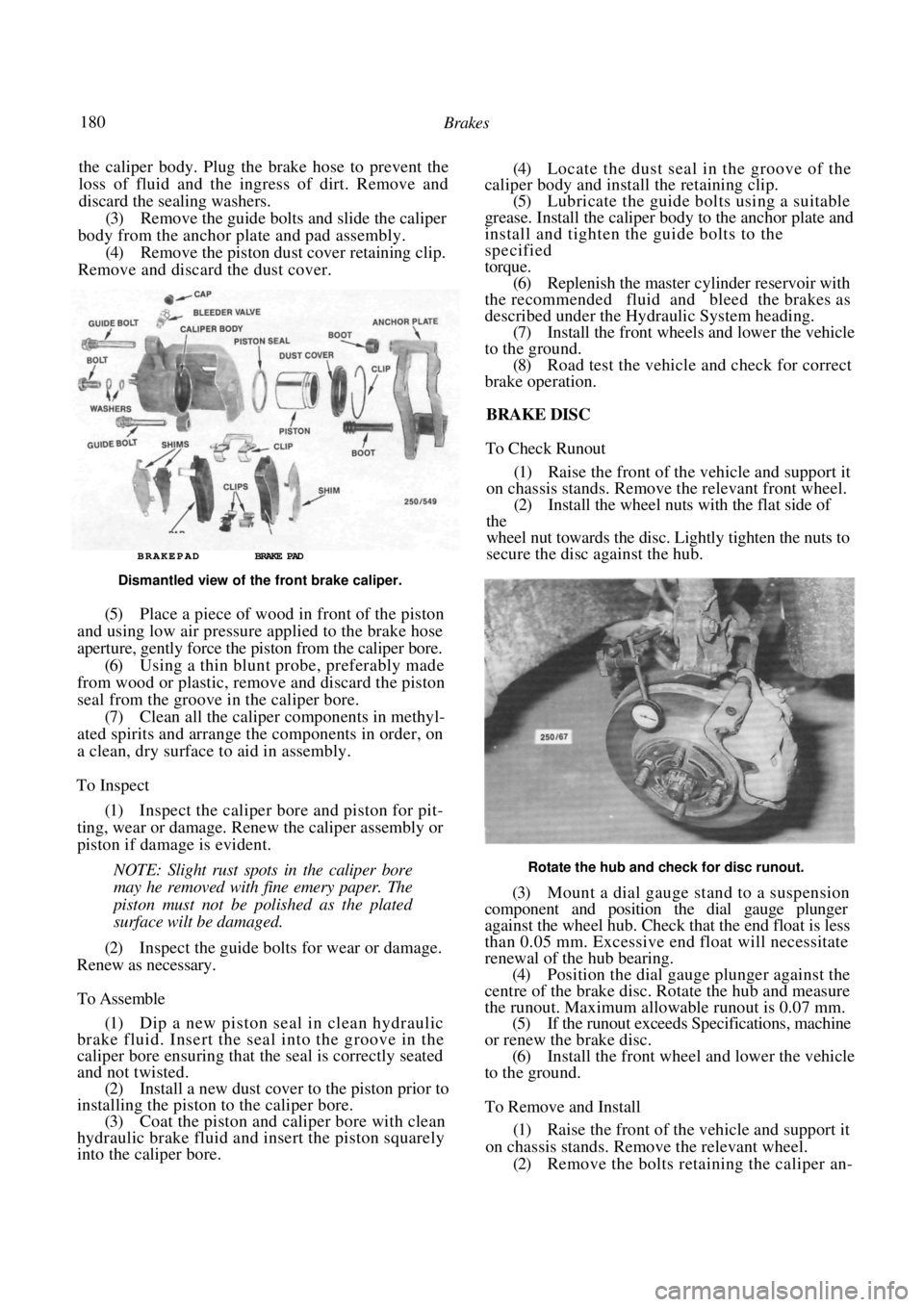

To Dismantle

(1) Raise the front of the vehicle and place it on

chassis stands. Remove the relevant front wheel.

(2) Remove the brake hose retaining bolt from

Page 180 of 238

180 Brakes

the caliper body. Plug the brake hose to prevent the

loss of fluid and the ingress of dirt. Remove and

discard the sealing washers.

(3) Remove the guide bolts and slide the caliper

body from the anchor plate and pad assembly. (4) Remove the piston dust cover retaining clip.

Remove and discard the dust cover.

BRAKEPAD BRAKE PAD

Dismantled view of the front brake caliper.

(5) Place a piece of wood in front of the piston

and using low air pressure applied to the brake hose

aperture, gently force the piston from the caliper bore.

(6) Using a thin blunt probe, preferably made

from wood or plastic, remove and discard the piston

seal from the groove in the caliper bore. (7) Clean all the caliper components in methyl-

ated spirits and arrange the components in order, on

a clean, dry surface to aid in assembly.

To Inspect

(1) Inspect the caliper bore and piston for pit-

ting, wear or damage. Renew the caliper assembly or

piston if damage is evident.

NOTE: Slight rust spots in the caliper bore

may he removed with fine emery paper. The

piston must not be polished as the plated

surface wilt be damaged.

(2) Inspect the guide bolts for wear or damage.

Renew as necessary.

To Assemble

(1) Dip a new piston seal in clean hydraulic

brake fluid. Insert the seal into the groove in the

caliper bore ensuring that the seal is correctly seated

and not twisted.

(2) Install a new dust cover to the piston prior to

installing the piston to the caliper bore. (3) Coat the piston and caliper bore with clean

hydraulic brake fluid and insert the piston squarely

into the caliper bore.

(4) Locate the dust seal in the groove of the

caliper body and install the retaining clip.

(5) Lubricate the guide bolts using a suitable

grease. Install the caliper body to the anchor plate and

install and tighten the guide bolts to the

specified

torque. (6) Replenish the master cylinder reservoir with

the recommended fluid and bleed the brakes as

described under the Hydr aulic System heading.

(7) Install the front wheels and lower the vehicle

to the ground. (8) Road test the vehicle and check for correct

brake operation.

BRAKE DISC

To Check Runout

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the relevant front wheel. (2) Install the wheel nuts with the flat side of

the

wheel nut towards the disc. Lightly tighten the nuts to

secure the disc against the hub.

Rotate the hub and check for disc runout.

(3) Mount a dial gauge stand to a suspension

component and position the dial gauge plunger

against the wheel hub. Check that the end float is less

than 0.05 mm. Excessive e nd float will necessitate

renewal of the hub bearing. (4) Position the dial gauge plunger against the

centre of the brake disc. Ro tate the hub and measure

the runout. Maximum allowable runout is 0.07 mm. (5) If the runout exceeds Specifications, machine

or renew the brake disc. (6) Install the fron t wheel and lower the vehicle

to the ground.

To Remove and Install

(1) Raise the front of the vehicle and support it

on chassis stands. Remove the relevant wheel. (2) Remove the bolts retaining the caliper an-

Page 182 of 238

182 Brakes

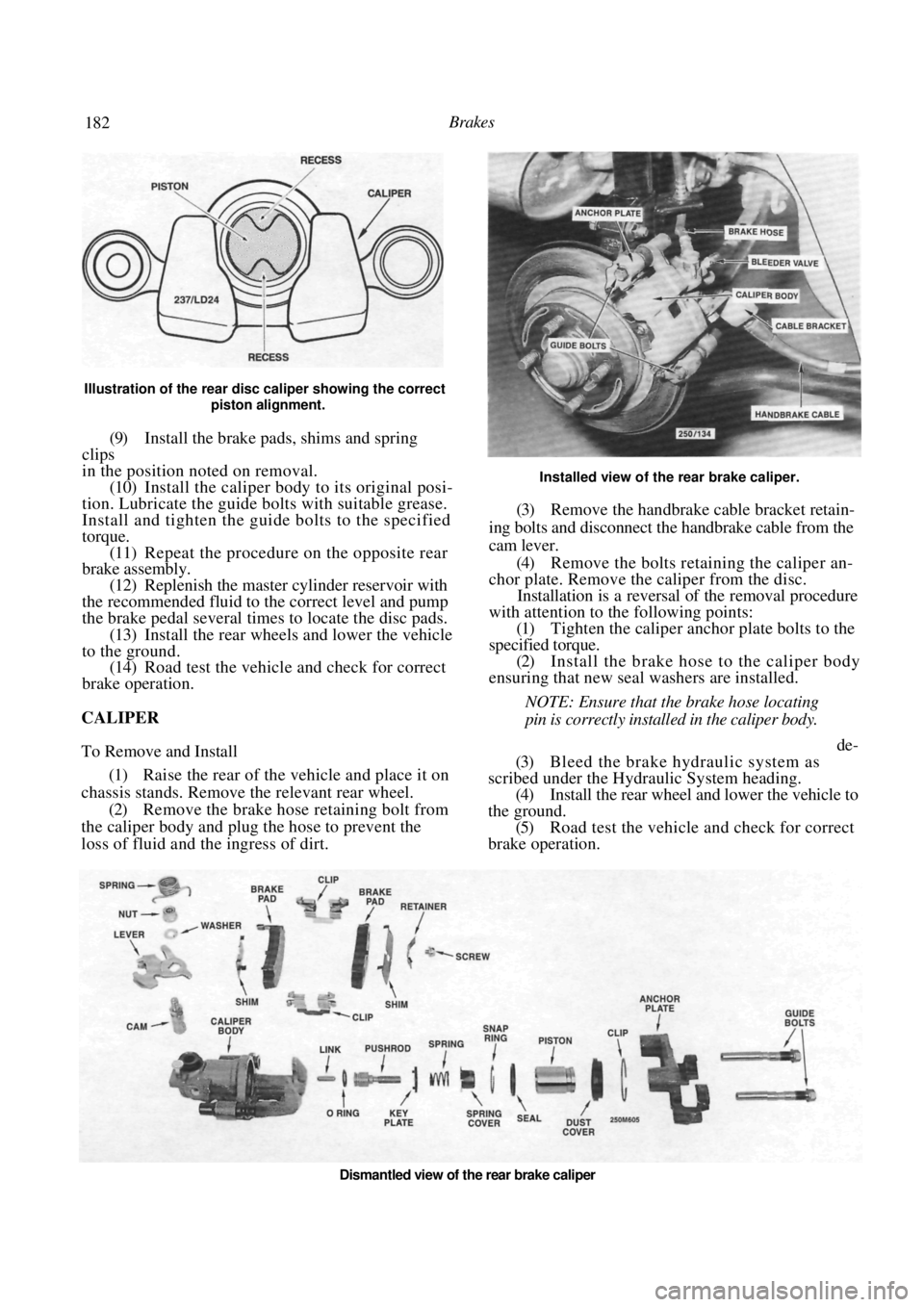

Illustration of the rear disc caliper showing the correct

piston alignment.

(9) Install the brake pads, shims and spring

clips

in the position noted on removal. (10) Install the caliper body to its original posi-

tion. Lubricate the guide bolts with suitable grease.

Install and tighten the guide bolts to the specified

torque. (11) Repeat the procedure on the opposite rear

brake assembly.

(12) Replenish the master cylinder reservoir with

the recommended fluid to the correct level and pump

the brake pedal several times to locate the disc pads. (13) Install the rear wheels and lower the vehicle

to the ground. (14) Road test the vehicle and check for correct

brake operation.

CALIPER

To Remove and Install

(1) Raise the rear of the vehicle and place it on

chassis stands. Remove the relevant rear wheel. (2) Remove the brake hose retaining bolt from

the caliper body and plug the hose to prevent the

loss of fluid and the ingress of dirt.

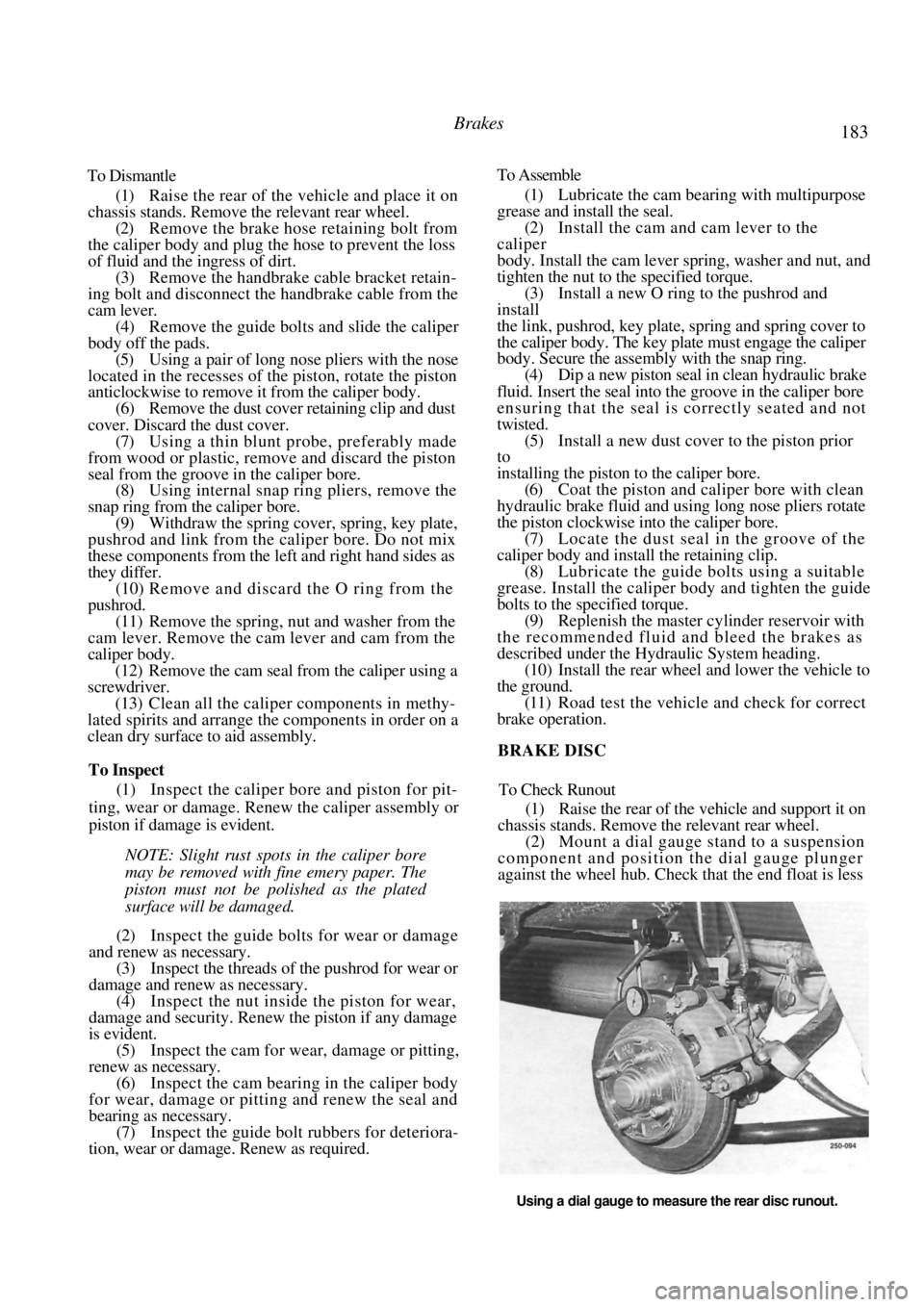

Installed view of the rear brake caliper.

(3) Remove the handbrake cable bracket retain-

ing bolts and disconnect the handbrake cable from the

cam lever. (4) Remove the bolts retaining the caliper an-

chor plate. Remove the caliper from the disc. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the caliper anch or plate bolts to the

specified torque. (2) Install the brake hose to the caliper body

ensuring that new seal washers are installed.

NOTE: Ensure that the brake hose locating

pin is correctly installed in the caliper body.

de-

(3) Bleed the brake hydraulic system as

scribed under the Hydraulic System heading. (4) Install the rear wheel and lower the vehicle to

the ground. (5) Road test the vehicle and check for correct

brake operation.

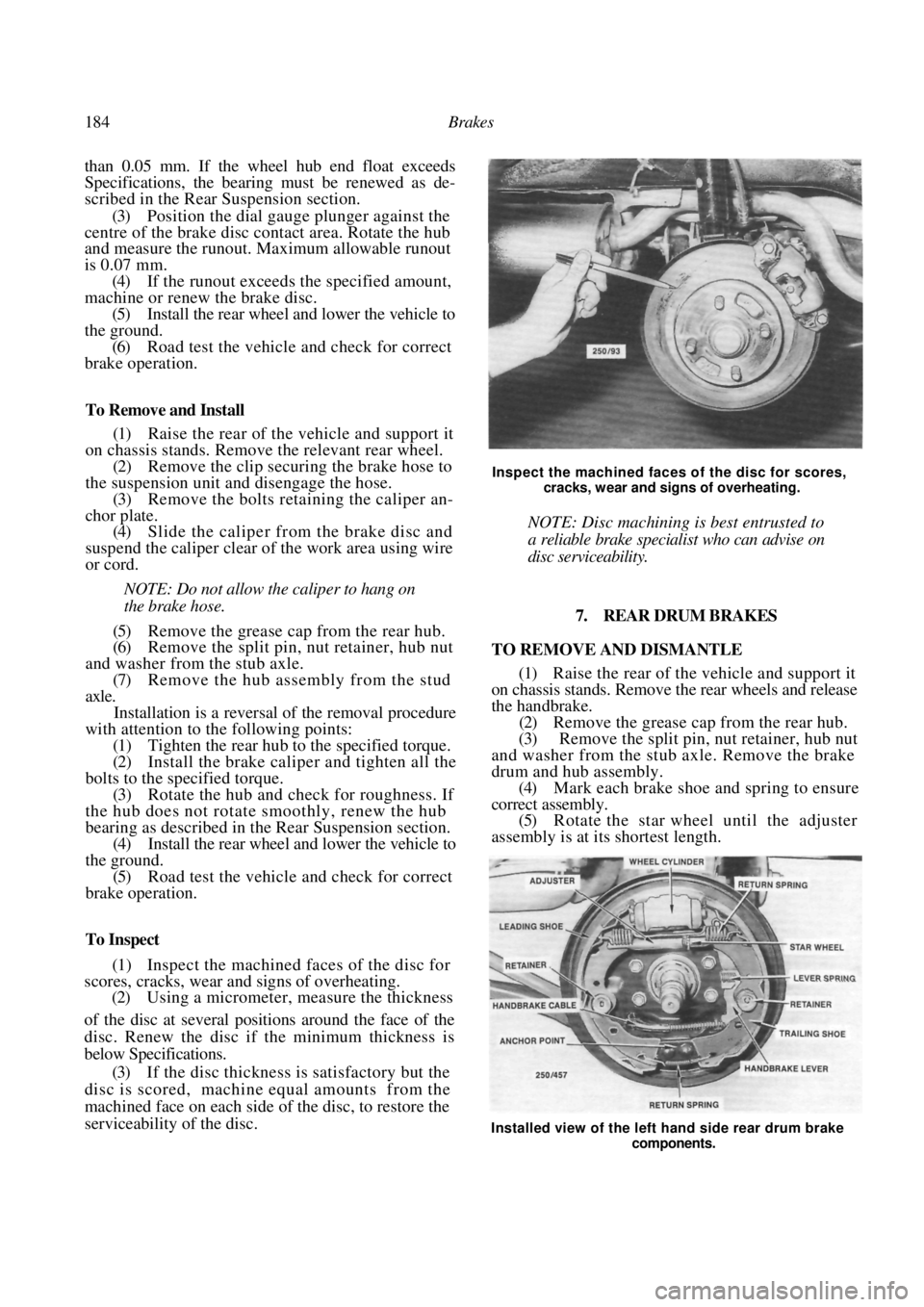

Dismantled view of the rear brake caliper

Page 183 of 238

Brakes 183

To Dismantle

(1) Raise the rear of the vehicle and place it on

chassis stands. Remove the relevant rear wheel.

(2) Remove the brake hose retaining bolt from

the caliper body and plug the hose to prevent the loss

of fluid and the ingress of dirt. (3) Remove the handbrake cable bracket retain-

ing bolt and disconnect the handbrake cable from the

cam lever.

(4) Remove the guide bolts and slide the caliper

body off the pads. (5) Using a pair of long nose pliers with the nose

located in the recesses of the piston, rotate the piston

anticlockwise to remove it from the caliper body.

(6) Remove the dust cover retaining clip and dust

cover. Discard the dust cover. (7) Using a thin blunt probe, preferably made

from wood or plastic, remove and discard the piston

seal from the groove in the caliper bore. (8) Using internal snap ring pliers, remove the

snap ring from the caliper bore. (9) Withdraw the spring cover, spring, key plate,

pushrod and link from the caliper bore. Do not mix

these components from the left and right hand sides as

they differ. (10) Remove and discard the O ring from the

pushrod. (11) Remove the spring, nut and washer from the

cam lever. Remove the cam lever and cam from the

caliper body. (12) Remove the cam seal from the caliper using a

screwdriver.

(13) Clean all the caliper components in methy-

lated spirits and arrange the components in order on a

clean dry surface to aid assembly.

To Inspect

(1) Inspect the caliper bore and piston for pit-

ting, wear or damage. Renew the caliper assembly or

piston if damage is evident.

NOTE: Slight rust spots in the caliper bore

may be removed with fine emery paper. The

piston must not be polished as the plated

surface will be damaged.

(2) Inspect the guide bolts for wear or damage

and renew as necessary.

(3) Inspect the threads of the pushrod for wear or

damage and renew as necessary. (4) Inspect the nut inside the piston for wear,

damage and security. Renew the piston if any damage

is evident. (5) Inspect the cam for wear, damage or pitting,

renew as necessary. (6) Inspect the cam bearing in the caliper body

for wear, damage or pitting and renew the seal and

bearing as necessary. (7) Inspect the guide bolt rubbers for deteriora-

tion, wear or damage. Renew as required. To Assemble

(1)

Lubricate the cam bearing with multipurpose

grease and install the seal. (2) Install the cam and cam lever to the

caliper

body. Install the cam lever spring, washer and nut, and

tighten the nut to the specified torque. (3) Install a new O ring to the pushrod and

install

the link, pushrod, key plate, spring and spring cover to

the caliper body. The key plate must engage the caliper

body. Secure the assembly with the snap ring. (4) Dip a new piston seal in clean hydraulic brake

fluid. Insert the seal into the groove in the caliper bore

ensuring that the seal is correctly seated and not

twisted. (5) Install a new dust cover to the piston prior

to

installing the piston to the caliper bore.

(6) Coat the piston and caliper bore with clean

hydraulic brake fluid and using long nose pliers rotate

the piston clockwise into the caliper bore. (7) Locate the dust seal in the groove of the

caliper body and install the retaining clip.

(8) Lubricate the guide bolts using a suitable

grease. Install the caliper body and tighten the guide

bolts to the specified torque. (9) Replenish the master cylinder reservoir with

the recommended fluid and bleed the brakes as

described under the Hydraulic System heading. (10) Install the rear wheel and lower the vehicle to

the ground. (11) Road test the vehicle and check for correct

brake operation.

BRAKE DISC

To Check Runout

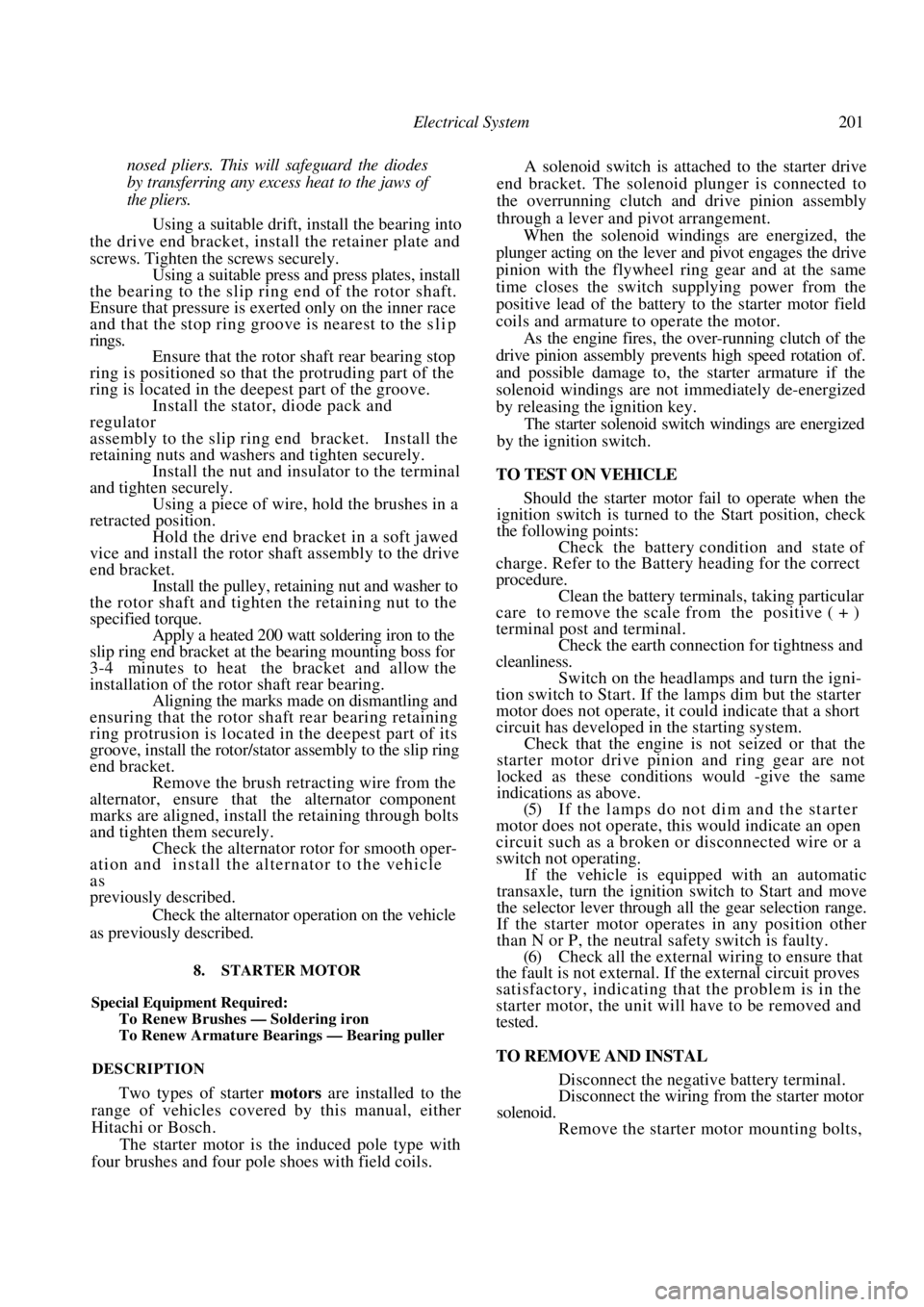

(1) Raise the rear of the vehicle and support it on

chassis stands. Remove the relevant rear wheel.

(2) Mount a dial gauge stand to a suspension

component and position the dial gauge plunger

against the wheel hub. Check that the end float is less

Using a dial gauge to measure the rear disc runout.

Page 184 of 238

184 Brakes

than 0.05 mm. If the wheel hub end float exceeds

Specifications, the bearing must be renewed as de-

scribed in the Rear Suspension section.

(3) Position the dial gauge plunger against the

centre of the brake disc contact area. Rotate the hub

and measure the runout. Ma ximum allowable runout

is 0.07 mm. (4) If the runout exceeds the specified amount,

machine or renew the brake disc. (5) Install the rear wheel and lower the vehicle to

the ground. (6) Road test the vehicle and check for correct

brake operation.

To Remove and Install

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove the relevant rear wheel.

(2) Remove the clip securing the brake hose to

the suspension unit and disengage the hose. (3) Remove the bolts retaining the caliper an-

chor plate. (4) Slide the caliper from the brake disc and

suspend the caliper clear of the work area using wire

or cord.

NOTE: Do not allow the caliper to hang on

the brake hose.

(5) Remove the grease cap from the rear hub.

(6) Remove the split pin, nut retainer, hub nut

and washer from the stub axle. (7) Remove the hub assembly from the stud

axle. Installation is a reversal of the removal procedure

with attention to the following points:

(1) Tighten the rear hub to the specified torque.

(2) Install the brake caliper and tighten all the

bolts to the specified torque. (3) Rotate the hub and check for roughness. If

the hub does not rotate smoothly, renew the hub

bearing as described in the Rear Suspension section. (4) Install the rear wheel and lower the vehicle to

the ground.

(5) Road test the vehicle and check for correct

brake operation.

To Inspect

(1) Inspect the machined faces of the disc for

scores, cracks, wear and signs of overheating. (2) Using a micrometer, measure the thickness

of the disc at several posit ions around the face of the

disc. Renew the disc if the minimum thickness is

below Specifications.

(3) If the disc thickness is satisfactory but the

disc is scored, machine equal amounts from the

machined face on each side of the disc, to restore the

serviceability of the disc.

Inspect the machined faces of the disc for scores,

cracks, wear and signs of overheating.

NOTE: Disc machining is best entrusted to

a reliable brake specialist who can advise on

disc serviceability.

7. REAR DRUM BRAKES

TO REMOVE AND DISMANTLE

(1) Raise the rear of the vehicle and support it

on chassis stands. Remove th e rear wheels and release

the handbrake.

(2) Remove the grease cap from the rear hub.

(3) Remove the split pin, nut retainer, hub nut

and washer from the stub axle. Remove the brake

drum and hub assembly.

(4) Mark each brake shoe and spring to ensure

correct assembly. (5) Rotate the star wheel until the adjuster

assembly is at its shortest length.

Installed view of the left hand side rear drum brake

components.

Page 201 of 238

Electrical System 201

nosed pliers. This will safeguard the diodes

by transferring any excess heat to the jaws of

the pliers.

Using a suitable drift, install the bearing into

the drive end bracket, install the retainer plate and

screws. Tighten the screws securely. Using a suitable press and press plates, install

the bearing to the slip ring end of the rotor shaft.

Ensure that pressure is ex erted only on the inner race

and that the stop ring groove is nearest to the sl i p

rings. Ensure that the rotor sh aft rear bearing stop

ring is positioned so that the protruding part of the

ring is located in the deepest part of the groove. Install the stator, diode pack and

regulator

assembly to the slip ring e nd bracket. Install the

retaining nuts and washers and tighten securely. Install the nut and insulator to the terminal

and tighten securely. Using a piece of wire, hold the brushes in a

retracted position. Hold the drive end bracket in a soft jawed

vice and install the rotor shaft assembly to the drive

end bracket. Install the pulley, retaining nut and washer to

the rotor shaft and tighten the retaining nut to the

specified torque. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the

installation of the rotor shaft rear bearing. Aligning the marks made on dismantling and

ensuring that the rotor sh aft rear bearing retaining

ring protrusion is located in the deepest part of its

groove, install the rotor/stator assembly to the slip ring

end bracket.

Remove the brush retr acting wire from the

alternator, ensure that the alternator component

marks are aligned, install the retaining through bolts

and tighten them securely. Check the alternator rotor for smooth oper-

ation and install the al ternator to the vehicle

as

previously described.

Check the alternator operation on the vehicle

as previously described.

8. STARTER MOTOR

Special Equipment Required:

To Renew Brushes — Soldering iron

To Renew Armature Bearings — Bearing puller

DESCRIPTION

Two types of starter motors are installed to the

range of vehicles covere d by this manual, either

Hitachi or Bosch.

The starter motor is the induced pole type with

four brushes and four pole shoes with field coils.

A solenoid switch is attached to the starter drive

end bracket. The solenoid plunger is connected to

the overrunning clutch and drive pinion assembly

through a lever and pivot arrangement.

When the solenoid windings are energized, the

plunger acting on the lever and pivot engages the drive

pinion with the flywheel ri ng gear and at the same

time closes the switch supplying power from the

positive lead of the battery to the starter motor field

coils and armature to operate the motor.

As the engine fires, the over-running clutch of the

drive pinion assembly prevents high speed rotation of.

and possible damage to, the starter armature if the

solenoid windings are not immediately de-energized

by releasing the ignition key.

The starter solenoid switch windings are energized

by the ignition switch.

TO TEST ON VEHICLE

Should the starter motor fail to operate when the

ignition switch is turned to the Start position, check

the following points:

Check the battery condition and state of

charge. Refer to the Battery heading for the correct

procedure.

Clean the battery terminals, taking particular

care to remove the scale from the positive ( + )

terminal post and terminal. Check the earth connection for tightness and

cleanliness.

Switch on the headlamps and turn the igni-

tion switch to Start. If the lamps dim but the starter

motor does not operate, it could indicate that a short

circuit has developed in the starting system. Check that the engine is not seized or that the

starter motor drive pinion and ring gear are not

locked as these conditions would -give the same

indications as above.

(5) If the lamps do not dim and the starter

motor does not operate, this would indicate an open

circuit such as a broken or disconnected wire or a

switch not operating.

If the vehicle is equipped with an automatic

transaxle, turn the ignition switch to Start and move

the selector lever through all the gear selection range.

If the starter motor operates in any position other

than N or P, the neutral safety switch is faulty.

(6) Check all the external wiring to ensure that

the fault is not external. If the external circuit proves

satisfactory, indicating that the problem is in the

starter motor, the unit will have to be removed and

tested.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Disconnect the wiring from the starter motor

solenoid. Remove the starter motor mounting bolts,