clock setting NISSAN PULSAR 1987 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 79 of 238

Cooling and Heating Systems 79

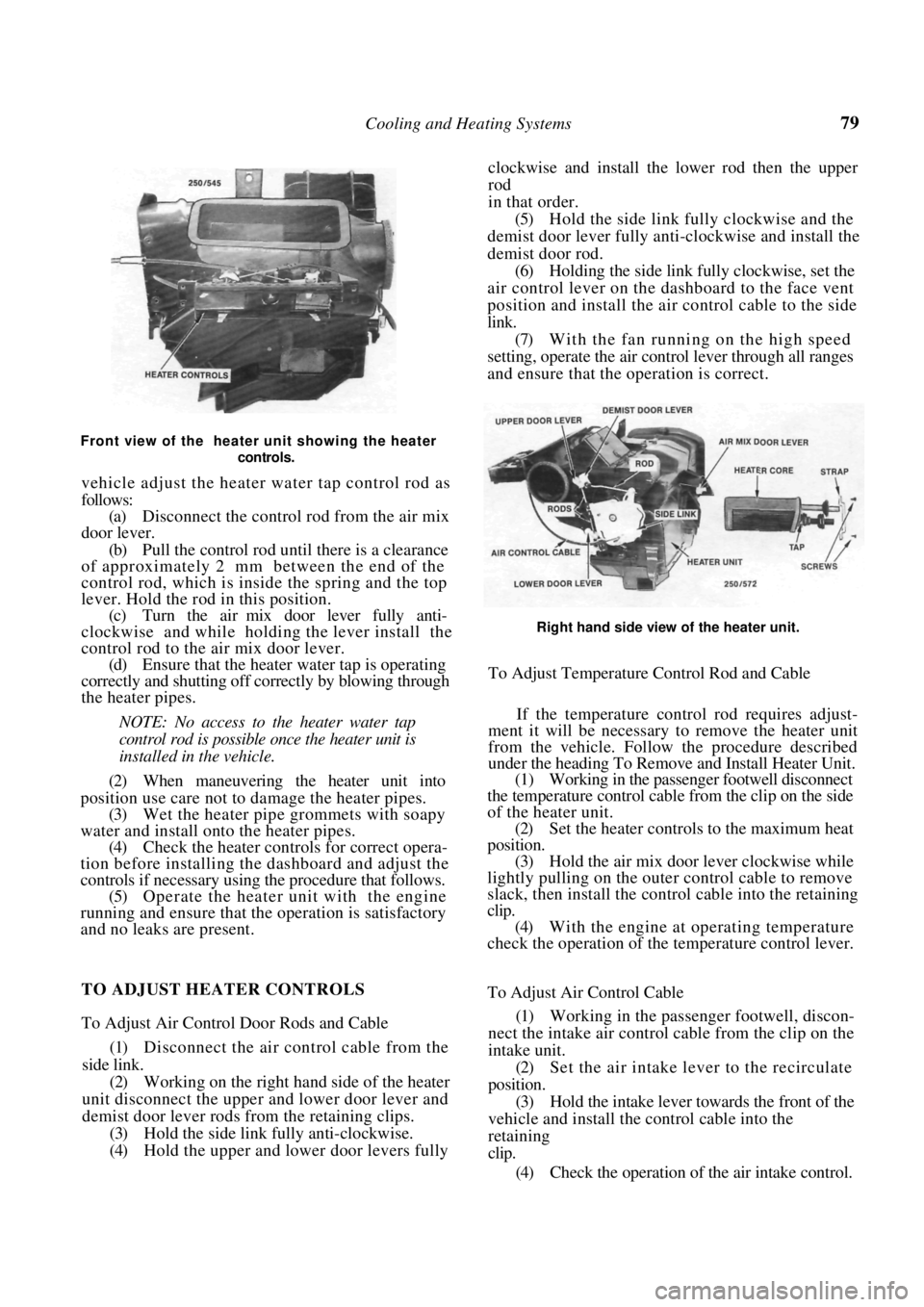

Front view of the heater unit showing the heater controls.

vehicle adjust the heater water tap control rod as

follows:

(a) Disconnect the control rod from the air mix

door lever.

(b) Pull the control rod un til there is a clearance

of approximately 2 mm between the end of the

control rod, which is inside the spring and the top

lever. Hold the rod in this position.

(c) Turn the air mix door lever fully anti-

clockwise and while holding the lever install the

control rod to the air mix door lever. (d) Ensure that the heater water tap is operating

correctly and shutting off correctly by blowing through

the heater pipes.

NOTE: No access to the heater water tap

control rod is possible once the heater unit is

installed in the vehicle.

(2) When maneuvering the heater unit into

position use care not to damage the heater pipes. (3) Wet the heater pipe grommets with soapy

water and install onto the heater pipes. (4) Check the heater controls for correct opera-

tion before installing the dashboard and adjust the

controls if necessary using the procedure that follows. (5) Operate the heater unit with the engine

running and ensure that the operation is satisfactory

and no leaks are present. clockwise and install the lower rod then the upper

rod

in that order.

(5)

Hold the side link fully clockwise and the

demist door lever fully anti-clockwise and install the

demist door rod. (6) Holding the side link fully clockwise, set the

air control lever on the dashboard to the face vent

position and install the air control cable to the side

link. (7) With the fan running on the high speed

setting, operate the air cont rol lever through all ranges

and ensure that the operation is correct.

Right hand side view of the heater unit.

To Adjust Temperature Control Rod and Cable

If the temperature control rod requires adjust-

ment it will be necessary to remove the heater unit

from the vehicle. Follow the procedure described

under the heading To Remove and Install Heater Unit.

(1) Working in the passenger footwell disconnect

the temperature control cable from the clip on the side

of the heater unit. (2) Set the heater controls to the maximum heat

position. (3) Hold the air mix door lever clockwise while

lightly pulling on the outer control cable to remove

slack, then install the control cable into the retaining

clip.

(4) With the engine at operating temperature

check the operation of the temperature control lever.

TO ADJUST HEATER CONTROLS

To Adjust Air Control Door Rods and Cable

(1) Disconnect the air control cable from the

side link. (2) Working on the right hand side of the heater

unit disconnect the upper and lower door lever and

demist door lever rods from the retaining clips.

(3) Hold the side link fully anti-clockwise.

(4) Hold the upper and lower door levers fully To Adjust Air Control Cable

(1)

Working in the passeng er footwell, discon-

nect the intake air control cable from the clip on the

intake unit. (2) Set the air intake lever to the recirculate

position. (3) Hold the intake lever to wards the front of the

vehicle and install the control cable into the

retaining

clip.

(4) Check the operation of the air intake control.

Page 82 of 238

82

FUEL AND ENGINE MANAGEMENT

CAUTION: To prevent severe electrical shock, extreme care must be taken when

working on or near the electronic ignition system as dangerous high tension voltages

are produced in both the primary and secondary circuits. See the text fo\

r

precautionary notes.

SPECIFICATIONS

FUEL INJECTION

Type:

1.6 liter engine .................................. Single point

1.8 liter engine................................... Multi point

FUEL PUMP

Type ................................................................ Electric

Pressure at idle:

1.6 liter engine ..................................... 62-90 kPa

1.8 liter engine ................................ 190-230 kPa

FUEL FILTER

Type ................................................ Inline, disposable

AIR FILTER

Type ................................... Disposable paper element

DISTRIBUTOR

Make ........................................................ Delco Remy

Advance contro l .......................................... Electronic

Rotation of rotor .................................. Anti-clockwise

Firing order....................................................1 -3-4-2

ADJUSTMENTS

Base idle speed ..................................... 550-650 rpm

Ignition timing.......................................... 10° BTDC

TORQUE WRENCH SETTINGS

Throttle body nuts.......................................... 10 Nm

*Throttle body bolts ........................................ 12 Nm

*Fuel hose fittings............................................ 35 Nm

Fuel rail bolts ....................................................8 Nm

Fuel tank drain plug ........................................ 24 Nm

Coolant temperature sensor ............................ 12 Nm

Oxygen sensor .................................................. 40 Nm

MAT sensor..................................................... 14 Nm

*1.6 liter engine

l . 8 liter engine

1. FUEL AND ENGINE MANAGEMENT

TROUBLE SHOOTING

NOTE: The following Trouble Shooting pro-

cedures are basic checks only. If these pro-

cedures fail to locate the fault, refer to the

System Diagnosis and Adjustments heading

for more thorough testing.

Prior to performing any of the following

operations, refer to the Service Precautions

and Procedures heading.

ENGINE WILL NOT START OR HARD TO

START

(1) Water in the fuel: Dr ain the fuel from the

system and renew the fuel filter.

(2) Fault in the power supply: Check the battery,

fusible links and fuses. Check for clean, secure con-

nections, particularly the earth connections. Check the

EG1 and fuel pump relays.

NOTE: If the fuel pump relay fails, power

will be supplied to the fuel pump via the oil

pressure switch. When starting the engine,

Check that the MAP sensor hose is not blocked or split

and ensure that all electrical connections are clean and

secure.