battery NISSAN PULSAR 1987 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1987, Model line: PULSAR, Model: NISSAN PULSAR 1987Pages: 238, PDF Size: 28.91 MB

Page 196 of 238

196 Electrical System

Check the specific gravity in each cell with a hydro-

meter.

Check the battery electrolyte level and re-

plenish as necessary. Remove the filler cap s from the battery.

Follow the battery charger manufacturers

instructions. (3) Should the battery fail to operate satisfacto-

rily after charging, it is recommended that it be taken

to a workshop with the necessary equipment to per-

form a load test. Load testing, when performed in

conjunction with the specific gravity tests described

above will give an accurate indication of the service-

ability of the battery.

7. ALTERNATOR

Special Equipment Required

To Test On Vehicle - Voltmeter, 100-0-100

amp ammeter, ohmmeter

To Dismantle — 200 watt soldering iron,

bearing

puller, press

To Assemble — 200 watt soldering iron

DESCRIPTION

Two types of alternator are installed to the range

of vehicles covered by this manual, either Hitachi or

Bosch. In the alternator, the field and pole shoe assembly

is the moving part and it is shaped to form the rotor.

Since only a low amperage current flows between the

slip rings on the rotor shaft and the brushes, wear on

the brushes and slip rings is very slight and mainte-

nance is reduced to a minimum. The output current is generated in the fixed stator

windings and is a three phase alternating current

(AC). The stator windings are wound on a laminated

soft iron former, star connected and installed between

the end brackets. As it is not possible to charge a storage battery

with alternating current, it is necessary to rectify the

output of the stator windings to direct current (DC). This is done by a bank of diodes mounted within the

alternator slip ring end bracket.

The output of the alternator is governed by the

regulator and the built in ch aracteristics of the alter-

nator.

The regulator and brush holder assembly on

Hitachi alternators is mounted within the alternator

on the slip ring end bracket side. On Bosch

alternators

the regulator and brush holder unit is mounted to the

outside of the slip ring end bracket. An electrical cut out unit is not necessary with the

alternator charging system as the diodes prevent a

reverse current flow through the alternator.

SERVICE PRECAUTIONS

Ensure that the battery is connected with the

correct polarity to earth. Refer to Specifications.

Do not short out or ground any terminals

common to the charging circuit. Always disconnect the battery before con-

necting a battery charger.

If a booster battery is used, always connect it

in a parallel circuit i.e. positive to positive ( + to + )

and negative to negative (- to -) to maintain a 12

volt supply. Never disconnect the battery or terminals in

the charging circuit while the engine is running. Regularly check that the alternator drive belt

tension is as specified. Refer to the Engine Tune-up

section.

Keep the battery terminals clean and all

electrical connections tight. Disconnect the battery and alternator when

electric welding on the vehicle.

TO TEST ON VEHICLE If the charge indicator lamp stays on after the

engine has been started and run at approximately

1 000 rpm, carry out the following tests. Stop the engine.

Check the condition and adjustment of the

alternator drive belt. Clean the battery terminals, tighten all elec-

trical connections, check the wiring for shorts to earth

and/or bridged circuits. Ensure that the battery is fully

charged. If the battery is discharged charge it or

replace it with one fully charged. Start the engine and allow it to run until

normal operating temperature is reached.

Stop the engine and disconnect the negative

battery terminal.

Remove the nut and washer from the alter-

nator output terminal (B +) and disconnect the alter-

nator output lead. Connect one lead of an ammeter to the

alternator output terminal and the other lead to the

lead removed from the output terminal. Connect the negative battery terminal and

connect a voltmeter across the battery terminals.

Page 197 of 238

Electrical System 197

Switch on all lamps and allow them to

illuminate for approximately five minutes to reduce

the charge of the battery and to apply a load to the

circuit.

Start the engine and gradually increase the

speed to approximately 2 500 rpm. The reading on

the ammeter should be approximately 75% of the

rated output of the altern ator. See Specifications.

Switch off all the lamps and run the engine at

1 500-2 000 rpm until the indicated charge is below

10 amps. The voltmeter should now read in excess of

13.6 volts.

NOTE: Should the alternator fail to reach

the specific output, the unit will have to be

removed and overhauled or a replacement

unit installed.

Should the voltage reading be above or

below Specifications, the regulator will have

to be renewed.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

On 1.8 liter engines, remove the bolt secur-

ing the air cleaner intake duct and remove the air

cleaner intake duct. Drain the radiator by releasing the radiator

drain plug, located at the bottom of the radiator and

allow the coolant level to fall below the thermostat

housing level. NOTE: Refer to the Cooling and Heating

Systems section when refilling the radiator

coolant to its correct l

evel, failure to do so

could result in severe damage to engine

components.

Remove the retaining bolts securing the

thermostat housing, disconnect the hose from the

radiator and remove the thermostat housing and

radiator hose from the vehicle. Using a socket and extension bar, remove the

bolt securing the alternator to the drive belt tensioning

bar located under the alternator. On vehicles not equipped with air condition-

ing, remove the front splash guard from under the

front of the vehicle and remove the bolt securing the

alternator to the drive belt tensioning bar. Loosen the upper mounting bolts, slacken

the alternator drive belt and remove it from the

alternator pulley.

While supporting the alternator, remove the

upper mounting bolts and remove the alternator from

the vehicle. Installation is a reversal of the removal procedure

with attention to the following points:

Do not over tension the drive belt. Refer

to

the Engine Tune-up section for the correct belt

adjusting procedure. Ensure that the wiring and connectors are

securely located on the alternator.

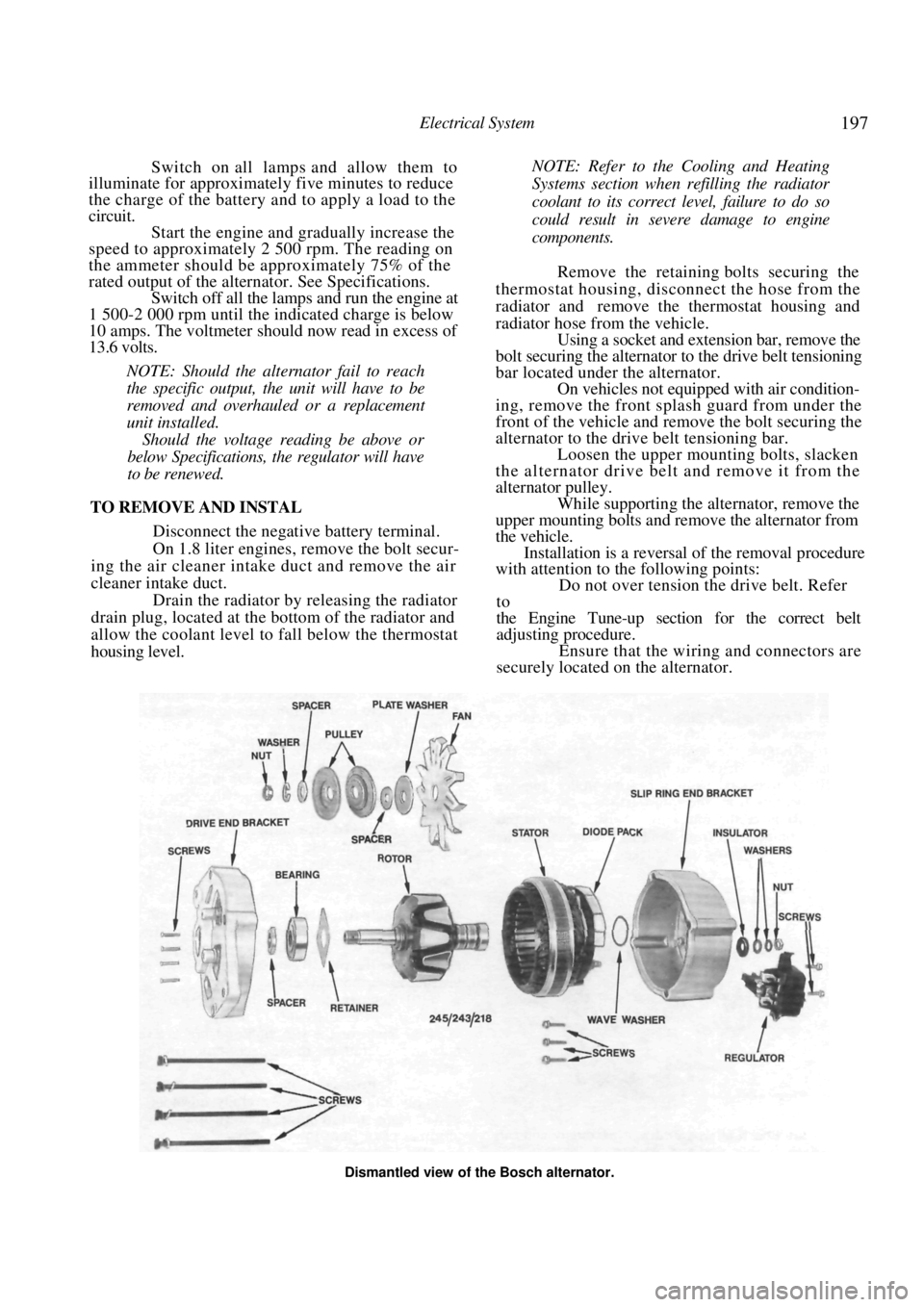

Dismantled view of the Bosch alternator.

Page 200 of 238

200 Electrical System

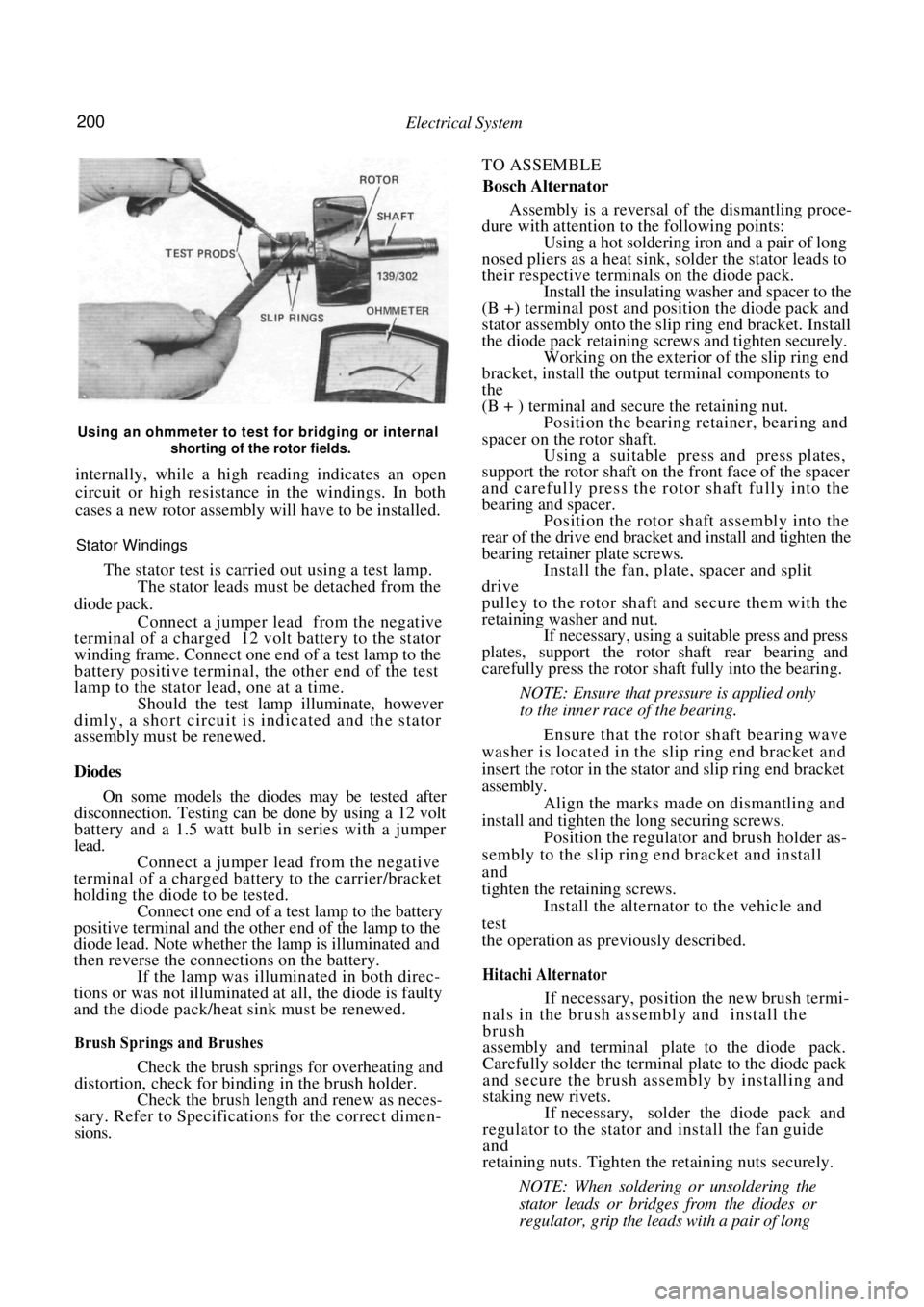

Using an ohmmeter to test for bridging or internal shorting of the rotor fields.

internally, while a high reading indicates an open

circuit or high resistance in the windings. In both

cases a new rotor assembly will have to be installed.

Stator Windings

The stator test is carried out using a test lamp.

The stator leads must be detached from the

diode pack.

Connect a jumper lead from the negative

terminal of a charged 12 volt battery to the stator

winding frame. Connect one en d of a test lamp to the

battery positive terminal, the other end of the test

lamp to the stator lead, one at a time. Should the test lamp illuminate, however

dimly, a short circuit is indicated and the stator

assembly must be renewed.

Diodes

On some models the diod es may be tested after

disconnection. Testing can be done by using a 12 volt

battery and a 1.5 watt bulb in series with a jumper

lead.

Connect a jumper lead from the negative

terminal of a charged battery to the carrier/bracket

holding the diode to be tested. Connect one end of a test lamp to the battery

positive terminal and the other end of the lamp to the

diode lead. Note whether the lamp is illuminated and

then reverse the connections on the battery. If the lamp was illuminated in both direc-

tions or was not illuminated at all, the diode is faulty

and the diode pack/heat sink must be renewed.

Brush Springs and Brushes

Check the brush spring s for overheating and

distortion, check for binding in the brush holder.

Check the brush length and renew as neces-

sary. Refer to Specifications for the correct dimen-

sions. TO ASSEMBLE

Bosch Alternator

Assembly is a reversal of the dismantling proce-

dure with attention to the following points:

Using a hot soldering iron and a pair of long

nosed pliers as a heat sink, solder the stator leads to

their respective terminals on the diode pack. Install the insulating washer and spacer to the

(B +) terminal post and position the diode pack and

stator assembly onto the slip ring end bracket. Install

the diode pack retaining screws and tighten securely. Working on the exterior of the slip ring end

bracket, install the output terminal components to

the

(B + ) terminal and secure the retaining nut.

Position the bearing retainer, bearing and

spacer on the rotor shaft. Using a suitable press and press plates,

support the rotor sh aft on the front face of the spacer

and carefully press the rotor shaft fully into the

bearing and spacer. Position the rotor shaft assembly into the

rear of the drive end bracket and install and tighten the

bearing retainer plate screws. Install the fan, plate, spacer and split

drive

pulley to the rotor shaft and secure them with the

retaining washer and nut. If necessary, using a suitable press and press

plates, support the rotor shaft rear bearing and

carefully press the rotor shaft fully into the bearing.

NOTE: Ensure that pressure is applied only

to the inner race of the bearing.

Ensure that the rotor shaft bearing wave

washer is located in the slip ring end bracket and

insert the rotor in the stator and slip ring end bracket

assembly. Align the marks made on dismantling and

install and tighten the long securing screws.

Position the regulator and brush holder as-

sembly to the slip ring end bracket and install

and

tighten the retaining screws. Install the alternator to the vehicle and

test

the operation as prev iously described.

Hitachi Alternator

If necessary, position the new brush termi-

nals in the brush assembly and install the

brush

assembly and terminal plate to the diode pack.

Carefully solder the terminal plate to the diode pack

and secure the brush assembly by installing and

staking new rivets.

If necessary, solder the diode pack and

regulator to the stator and install the fan guide

and

retaining nuts. Tighten the retaining nuts securely.

NOTE: When soldering or unsoldering the

stator leads or bridges from the diodes or

regulator, grip the leads with a pair of long

Page 201 of 238

Electrical System 201

nosed pliers. This will safeguard the diodes

by transferring any excess heat to the jaws of

the pliers.

Using a suitable drift, install the bearing into

the drive end bracket, install the retainer plate and

screws. Tighten the screws securely. Using a suitable press and press plates, install

the bearing to the slip ring end of the rotor shaft.

Ensure that pressure is ex erted only on the inner race

and that the stop ring groove is nearest to the sl i p

rings. Ensure that the rotor sh aft rear bearing stop

ring is positioned so that the protruding part of the

ring is located in the deepest part of the groove. Install the stator, diode pack and

regulator

assembly to the slip ring e nd bracket. Install the

retaining nuts and washers and tighten securely. Install the nut and insulator to the terminal

and tighten securely. Using a piece of wire, hold the brushes in a

retracted position. Hold the drive end bracket in a soft jawed

vice and install the rotor shaft assembly to the drive

end bracket. Install the pulley, retaining nut and washer to

the rotor shaft and tighten the retaining nut to the

specified torque. Apply a heated 200 watt soldering iron to the

slip ring end bracket at the bearing mounting boss for

3-4 minutes to heat the bracket and allow the

installation of the rotor shaft rear bearing. Aligning the marks made on dismantling and

ensuring that the rotor sh aft rear bearing retaining

ring protrusion is located in the deepest part of its

groove, install the rotor/stator assembly to the slip ring

end bracket.

Remove the brush retr acting wire from the

alternator, ensure that the alternator component

marks are aligned, install the retaining through bolts

and tighten them securely. Check the alternator rotor for smooth oper-

ation and install the al ternator to the vehicle

as

previously described.

Check the alternator operation on the vehicle

as previously described.

8. STARTER MOTOR

Special Equipment Required:

To Renew Brushes — Soldering iron

To Renew Armature Bearings — Bearing puller

DESCRIPTION

Two types of starter motors are installed to the

range of vehicles covere d by this manual, either

Hitachi or Bosch.

The starter motor is the induced pole type with

four brushes and four pole shoes with field coils.

A solenoid switch is attached to the starter drive

end bracket. The solenoid plunger is connected to

the overrunning clutch and drive pinion assembly

through a lever and pivot arrangement.

When the solenoid windings are energized, the

plunger acting on the lever and pivot engages the drive

pinion with the flywheel ri ng gear and at the same

time closes the switch supplying power from the

positive lead of the battery to the starter motor field

coils and armature to operate the motor.

As the engine fires, the over-running clutch of the

drive pinion assembly prevents high speed rotation of.

and possible damage to, the starter armature if the

solenoid windings are not immediately de-energized

by releasing the ignition key.

The starter solenoid switch windings are energized

by the ignition switch.

TO TEST ON VEHICLE

Should the starter motor fail to operate when the

ignition switch is turned to the Start position, check

the following points:

Check the battery condition and state of

charge. Refer to the Battery heading for the correct

procedure.

Clean the battery terminals, taking particular

care to remove the scale from the positive ( + )

terminal post and terminal. Check the earth connection for tightness and

cleanliness.

Switch on the headlamps and turn the igni-

tion switch to Start. If the lamps dim but the starter

motor does not operate, it could indicate that a short

circuit has developed in the starting system. Check that the engine is not seized or that the

starter motor drive pinion and ring gear are not

locked as these conditions would -give the same

indications as above.

(5) If the lamps do not dim and the starter

motor does not operate, this would indicate an open

circuit such as a broken or disconnected wire or a

switch not operating.

If the vehicle is equipped with an automatic

transaxle, turn the ignition switch to Start and move

the selector lever through all the gear selection range.

If the starter motor operates in any position other

than N or P, the neutral safety switch is faulty.

(6) Check all the external wiring to ensure that

the fault is not external. If the external circuit proves

satisfactory, indicating that the problem is in the

starter motor, the unit will have to be removed and

tested.

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Disconnect the wiring from the starter motor

solenoid. Remove the starter motor mounting bolts,

Page 206 of 238

206 Electrical System

Install the armature and yoke to the drive end

bracket rotating the drive to align the reduction gears.

Do not use force.

Install the retaining through bolts to the

commutator end bracket and lighten the through bolts

and armature end cover retaining screws securely. Install the solenoid to the drive end bracket,

install the retaining screws and tighten them securely.

Install the brush connector strap and

install

the retaining nut and washer and tighten securely.

9 . IGNITION SYSTEM

The testing and repair procedures for the ignition

system are fully covered in the Fuel and Engine

Management section.

10. STEERING WHEEL

The removal and installation procedures for the

steering wheel and horn pad are fully covered in the

Steering section.

11. SWITCHES AND CONTROLS

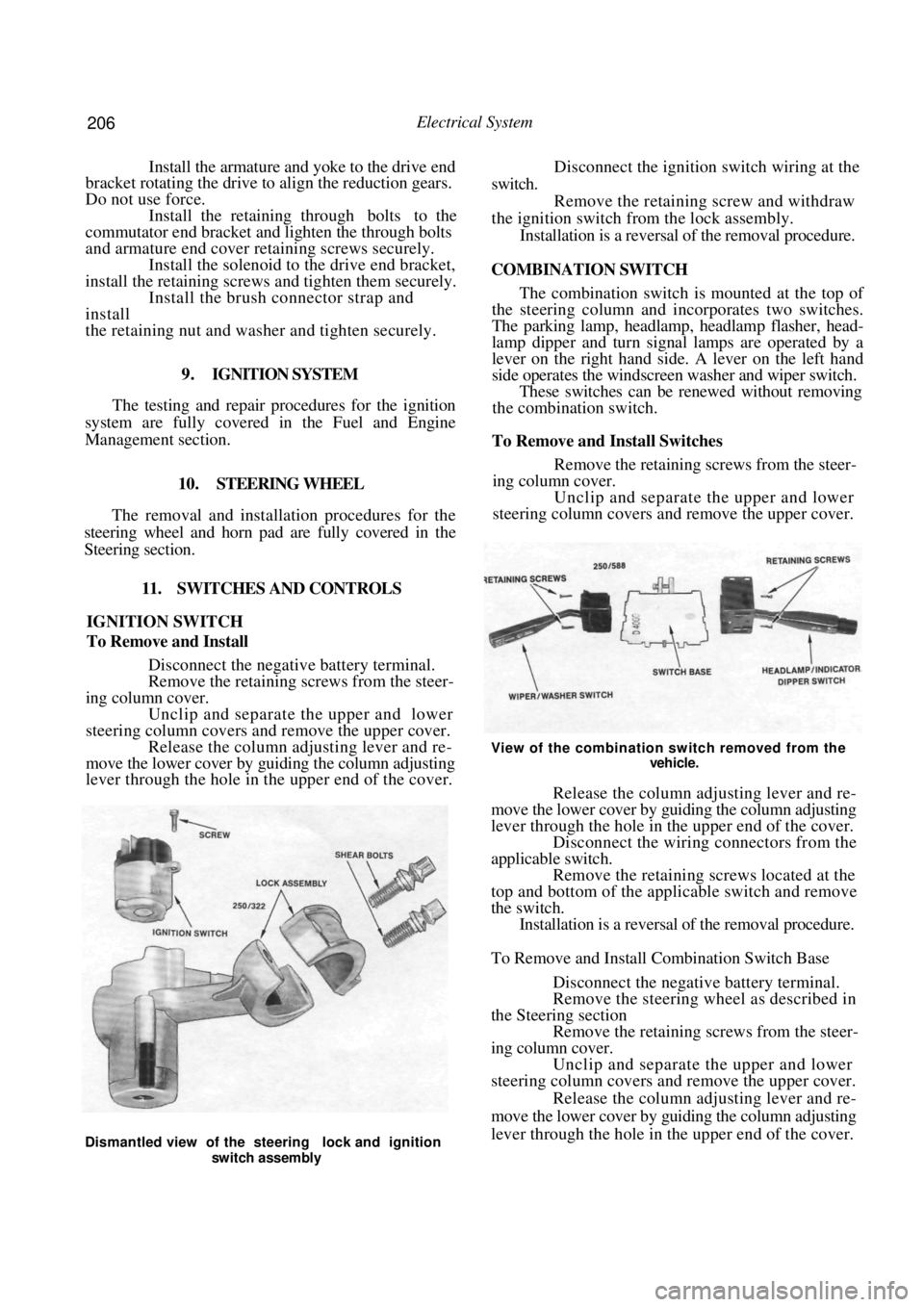

IGNITION SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover. Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Disconnect the ignition switch wiring at the

switch. Remove the retaining screw and withdraw

the ignition switch fr om the lock assembly.

Installation is a reversal of the removal procedure.

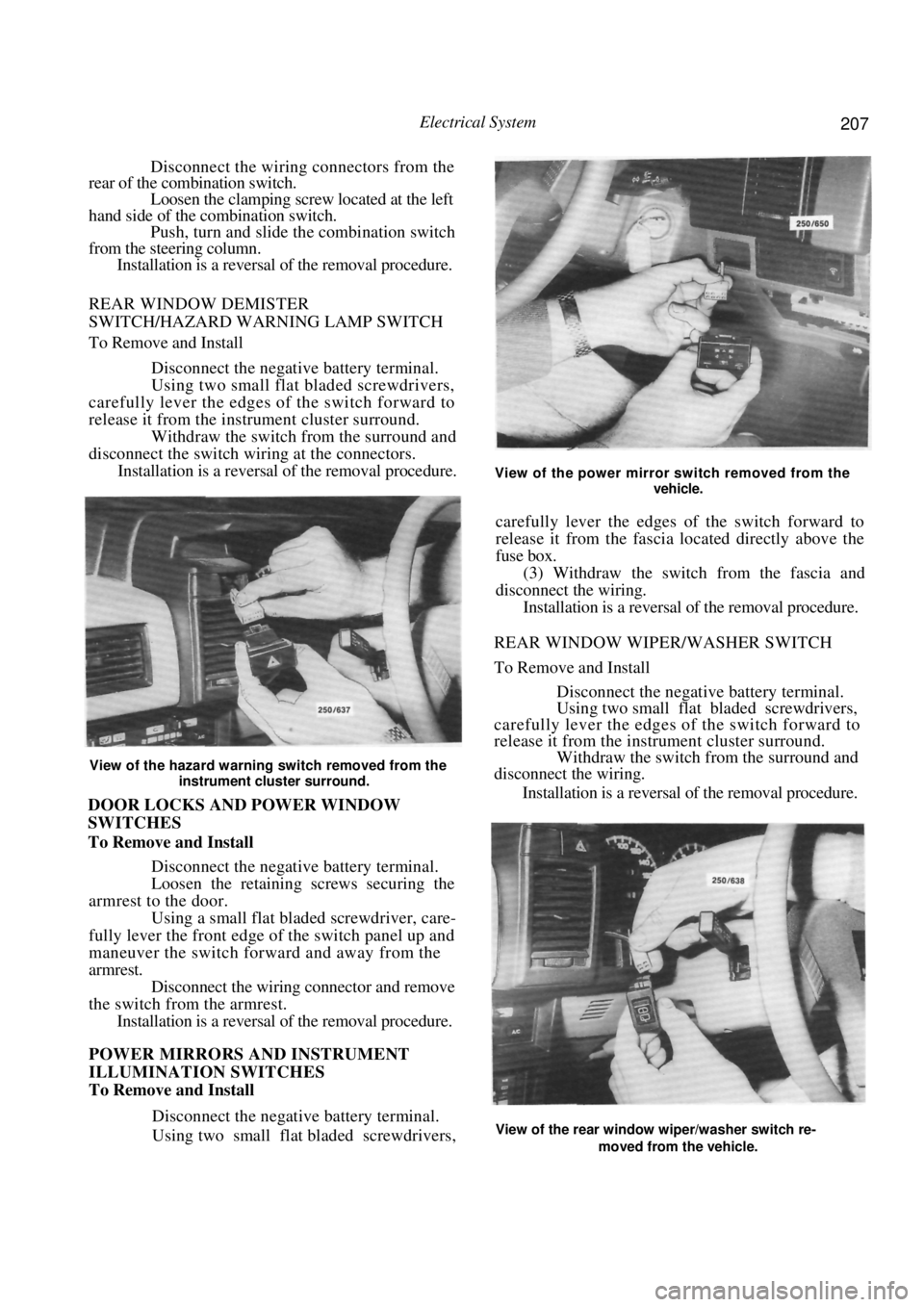

COMBINATION SWITCH

The combination switch is mounted at the top of

the steering column and incorporates two switches.

The parking lamp, headlamp, headlamp flasher, head-

lamp dipper and turn signal lamps are operated by a

lever on the right hand side. A lever on the left hand

side operates the windscreen washer and wiper switch.

These switches can be re newed without removing

the combination switch.

To Remove and Install Switches

Remove the retaining screws from the steer-

ing column cover.

Unclip and separate the upper and lower

steering column covers and remove the upper cover.

View of the combination switch removed from the

vehicle.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover. Disconnect the wiring connectors from the

applicable switch. Remove the retaining screws located at the

top and bottom of the applicable switch and remove

the switch. Installation is a reversal of the removal procedure.

To Remove and Install Combination Switch Base

Disconnect the negative battery terminal.

Remove the steering wheel as described in

the Steering section Remove the retaining screws from the steer-

ing column cover. Unclip and separate the upper and lower

steering column covers and remove the upper cover.

Release the column adjusting lever and re-

move the lower cover by guiding the column adjusting

lever through the hole in the upper end of the cover.

Dismantled view of the steering lock and ignition

switch assembly

Page 207 of 238

Electrical System 207

Disconnect the wiring connectors from the

rear of the combination switch.

Loosen the clamping screw located at the left

hand side of the combination switch. Push, turn and slide the combination switch

from the steering column. Installation is a reversal of the removal procedure.

REAR WINDOW DEMISTER

SWITCH/HAZARD WARNING LAMP SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround.

Withdraw the switch from the surround and

disconnect the switch wiri ng at the connectors.

Installation is a reversal of the removal procedure.

View of the hazard warning switch removed from the

instrument cluster surround.

DOOR LOCKS AND POWER WINDOW

SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Loosen the retaining screws securing the

armrest to the door. Using a small flat bladed screwdriver, care-

fully lever the front edge of the switch panel up and

maneuver the switch forward and away from the

armrest. Disconnect the wiring connector and remove

the switch from the armrest. Installation is a reversal of the removal procedure.

POWER MIRRORS AND INSTRUMENT

ILLUMINATION SWITCHES

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

View of the power mirror switch removed from the

vehicle.

carefully lever the edges of the switch forward to

release it from the fascia lo cated directly above the

fuse box.

(3) Withdraw the switch from the fascia and

disconnect the wiring.

Installation is a reversal of the removal procedure.

REAR WINDOW WIPER/WASHER SWITCH

To Remove and Install

Disconnect the negative battery terminal.

Using two small flat bladed screwdrivers,

carefully lever the edges of the switch forward to

release it from the instrument cluster surround. Withdraw the switch from the surround and

disconnect the wiring.

Installation is a reversal of the removal procedure.

View of the rear window wiper/washer switch re-

moved from the vehicle.

Page 209 of 238

Electrical System 209

12. INSTRUMENT CLUSTER

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the retaining screws from the instru-

ment cluster surround. Carefully withdraw the instrument cluster

surround from the instrument panel sufficiently to

enable the wiring to be disconnected. Remove the

surround from the vehicle.

.

FLEXIBLE PRINTED

CIRCUIT

Rear view of the instrument cluster removed from the

vehicle.

(4) Remove the instrument cluster assembly

retaining screws and gently ease the assembly from the

instrument panel sufficiently to enable the wiring to be

disconnected.

If necessary, remove the instruments as follows:

Carefully depress the retaining clips on the

front lens and remove the front lens. On models equipped with a tachometer, slide

the plastic rib from between the speedometer and the

tachometer. Remove the screws retaining the speedome-

ter and the tachometer or fuel/temperature gauges

from the rear of the instrument cluster.

CLUSTER ASSEMBLY

(d) Withdraw both instruments from the front of

the instrument cluster being careful as these instru-

ments are held by protruding pin terminals.

NOTE: Do not touch the faces of the instru-

ment dials as they mark easily.

(e) On models equipped with a tachometer,

remove the retaining nuts and remove the tempera-

ture and/or the fuel gauge from the cluster assembly.

Installation is a reversal of the removal procedure

ensuring that all electrical connectors are correctly

installed.

13. BLOWER FAN

The removal and installation procedure for the

blower fan is described in the Cooling and Heating

Systems section.

14. RADIO/CASSETTE

TO REMOVE AND INSTAL

Disconnect the negative battery terminal.

Remove the release hole covers on each side

of the radio/cassette.

Dismantled view of the instrument cluster.

Illustration of the radio/cass ette removal tool showing

the required dimensions.

BULB HOLDERS

BULB HOLDERS

Removing the release hole covers from the radio/cas-

sette.

Page 210 of 238

210 Electrical System

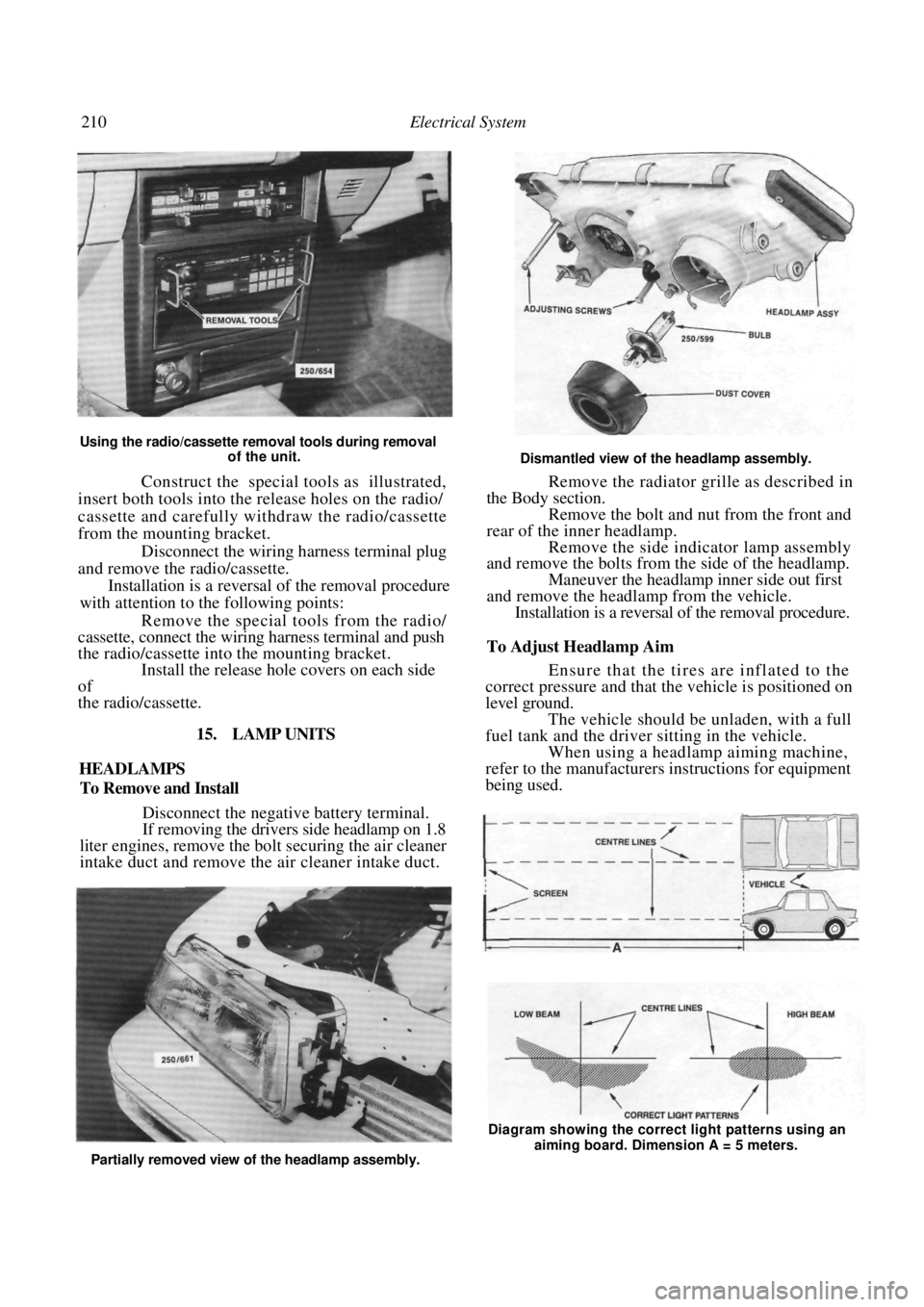

Using the radio/cassette removal tools during removal of the unit.

Construct the special tools as illustrated,

insert both tools into the release holes on the radio/

cassette and carefully withdraw the radio/cassette

from the mounting bracket.

Disconnect the wiring harness terminal plug

and remove the radio/cassette.

Installation is a reversal of the removal procedure

with attention to the following points:

Remove the special tools from the radio/

cassette, connect the wiring harness terminal and push

the radio/cassette into the mounting bracket. Install the release hole covers on each side

of

the radio/cassette.

15. LAMP UNITS

HEADLAMPS

To Remove and Install

Disconnect the negative battery terminal.

If removing the drivers side headlamp on 1.8

liter engines, remove the bo lt securing the air cleaner

intake duct and remove the air cleaner intake duct.

Dismantled view of the headlamp assembly.

Remove the radiator grille as described in

the Body section. Remove the bolt and nut from the front and

rear of the inner headlamp. Remove the side indicator lamp assembly

and remove the bolts from the side of the headlamp.

Maneuver the headlamp inner side out first

and remove the headlamp from the vehicle. Installation is a reversal of the removal procedure.

To Adjust Headlamp Aim

Ensure that the tires are inflated to the

correct pressure and that the vehicle is positioned on

level ground.

The vehicle should be unladen, with a full

fuel tank and the driver sitting in the vehicle. When using a headlamp aiming machine,

refer to the manufacturers instructions for equipment

being used.

Partially removed view of the headlamp assembly. Diagram showing the correct light patterns using an

aiming board. Dimension A = 5 meters.

Page 214 of 238

214 Electrical System

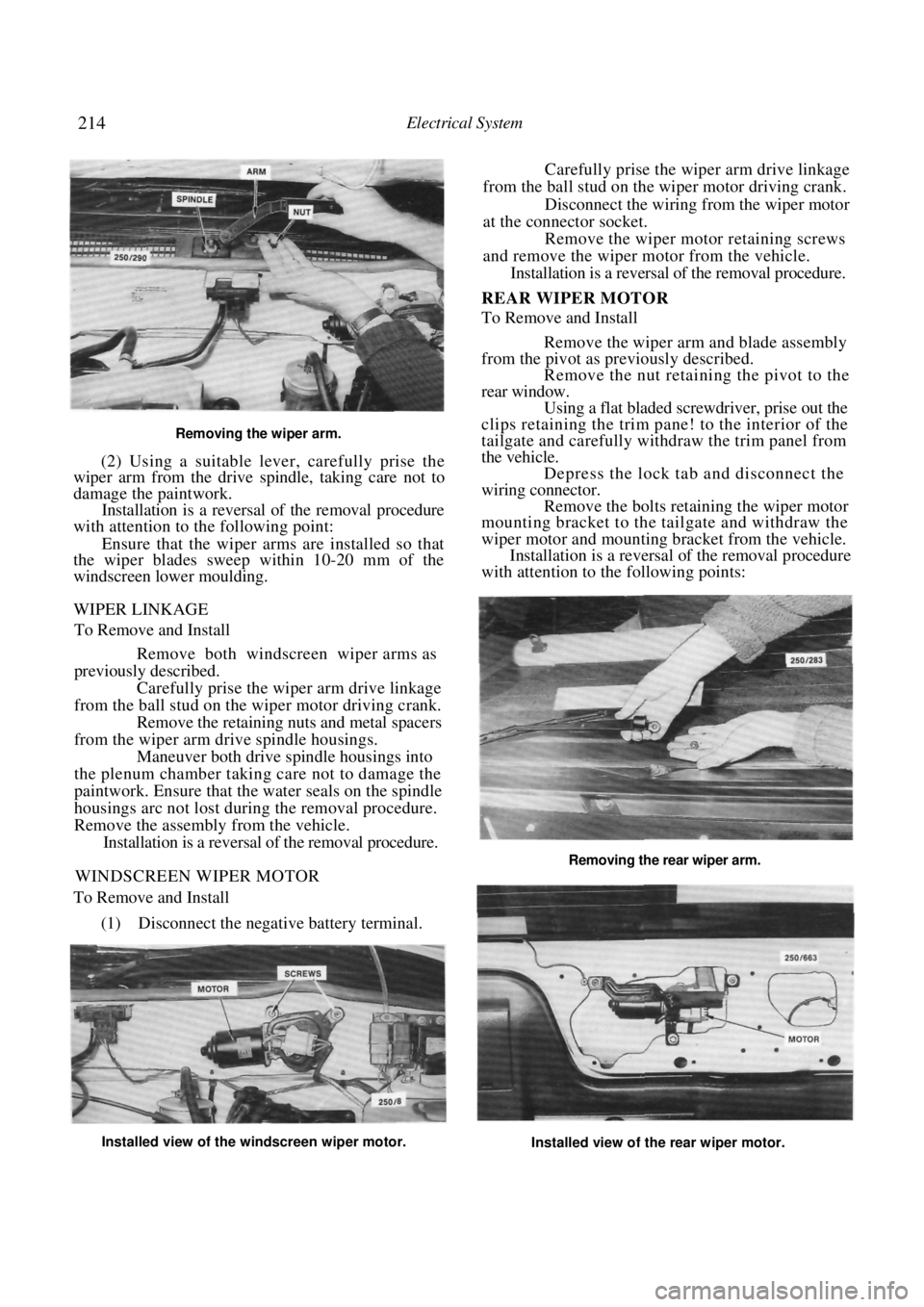

Removing the wiper arm.

(2) Using a suitable lever, carefully prise the

wiper arm from the drive spindle, taking care not to

damage the paintwork.

Installation is a reversal of the removal procedure

with attention to the following point:

Ensure that the wiper arms are installed so that

the wiper blades sweep within 10-20 mm of the

windscreen lower moulding.

WIPER LINKAGE

To Remove and Install

Remove both windscreen wiper arms as

previously described.

Carefully prise the wiper arm drive linkage

from the ball stud on the wiper motor driving crank. Remove the retaining nuts and metal spacers

from the wiper arm dr ive spindle housings.

Maneuver both drive spindle housings into

the plenum chamber taking care not to damage the

paintwork. Ensure that th e water seals on the spindle

housings arc not lost during the removal procedure.

Remove the assembly from the vehicle. Installation is a reversal of the removal procedure.

WINDSCREEN WIPER MOTOR

To Remove and Install

(1) Disconnect the negative battery terminal.

Carefully prise the wiper arm drive linkage

from the ball stud on the wiper motor driving crank.

Disconnect the wiring from the wiper motor

at the connector socket. Remove the wiper motor retaining screws

and remove the wiper motor from the vehicle. Installation is a reversal of the removal procedure.

REAR WIPER MOTOR

To Remove and Install

Remove the wiper arm and blade assembly

from the pivot as previously described. Remove the nut retaining the pivot to the

rear window. Using a flat bladed screwdriver, prise out the

clips retaining the trim pane! to the interior of the

tailgate and carefully wit hdraw the trim panel from

the vehicle. Depress the lock tab and disconnect the

wiring connector. Remove the bolts retaining the wiper motor

mounting bracket to the tailgate and withdraw the

wiper motor and mounting bracket from the vehicle.

Installation is a reversal of the removal procedure

with attention to the following points:

Installed view of the windscreen wiper motor.

Installed view of the rear wiper motor.

Removing the rear wiper arm.

Page 215 of 238

Electrical System 215

Ensure that the wiper motor is in the Park

position before installing the wiper arm. If in doubt,

turn the wiper switch to the Off position and turn the

ignition switch to the On position until the wiper

motor stops.

Install the wiper arm to the pivot so that the

wiper blade is horizontal to the lower edge of the edge

of the rear window when in the Park position.

17. FUSES, FUSIBLE LINKS AND RELAYS

TO CHECK AND RENEW FUSE

NOTE: If a fuse is found to be faulty or

burnt out, use a replacement fuse of the

specified amperage only. The specified amp-

erage is marked on the fuse.

The use of a higher amperage fuse than

that specified could cause damage to the

vehicle wiring harness.

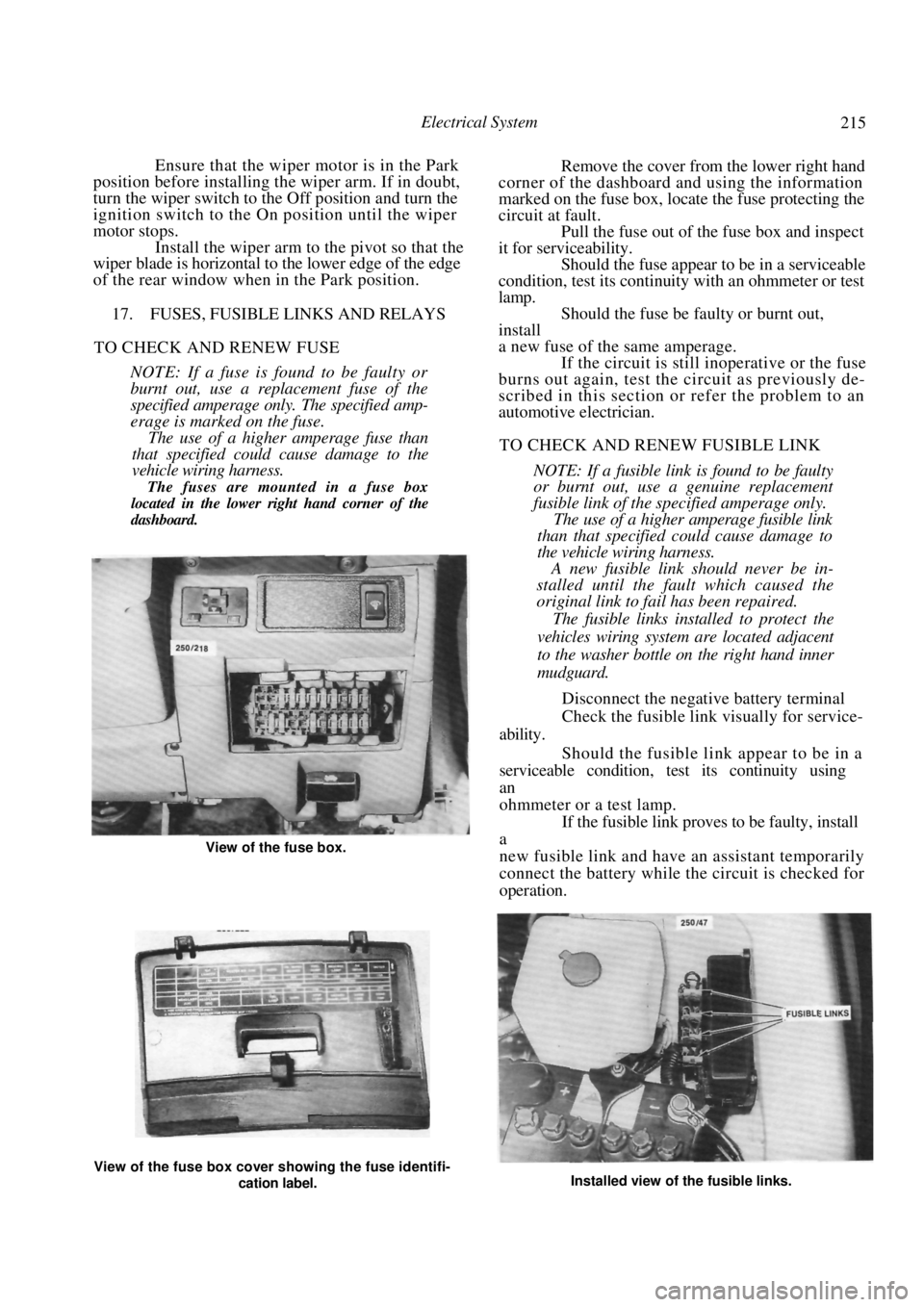

The fuses are mounted in a fuse box

located in the lower right hand corner of the

dashboard.

Remove the cover from the lower right hand

corner of the dashboard and using the information

marked on the fuse box, locate the fuse protecting the

circuit at fault. Pull the fuse out of the fuse box and inspect

it for serviceability.

Should the fuse appear to be in a serviceable

condition, test its continuity with an ohmmeter or test

lamp. Should the fuse be faulty or burnt out,

install

a new fuse of the same amperage. If the circuit is still inoperative or the fuse

burns out again, test the circuit as previously de-

scribed in this section or refer the problem to an

automotive electrician.

TO CHECK AND RENEW FUSIBLE LINK

NOTE: If a fusible link is found to be faulty

or burnt out, use a genuine replacement

fusible link of the specified amperage only.

The use of a higher amperage fusible link

than that specified could cause damage to

the vehicle wiring harness.

A new fusible link should never be in-

stalled until the fault which caused the

original link to fail has been repaired.

The fusible links installed to protect the

vehicles wiring system are located adjacent

to the washer bottle on the right hand inner

mudguard.

Disconnect the negative battery terminal

Check the fusible link visually for service-

ability.

Should the fusible link appear to be in a

serviceable condition, test its continuity using

an

ohmmeter or a test lamp. If the fusible link proves to be faulty, install

a

new fusible link and have an assistant temporarily

connect the battery while the circuit is checked for

operation.

View of the fuse box cover showing the fuse identifi-

cation label. Installed view of the fusible links.

View of the fuse box.