NISSAN SERENA 1993 Service Repair Manual

SERENA 1993

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57387/w960_57387-0.png

NISSAN SERENA 1993 Service Repair Manual

Trending: fuse box diagram, torque, brake, tire pressure, control motor, length, checking oil

Page 1131 of 1254

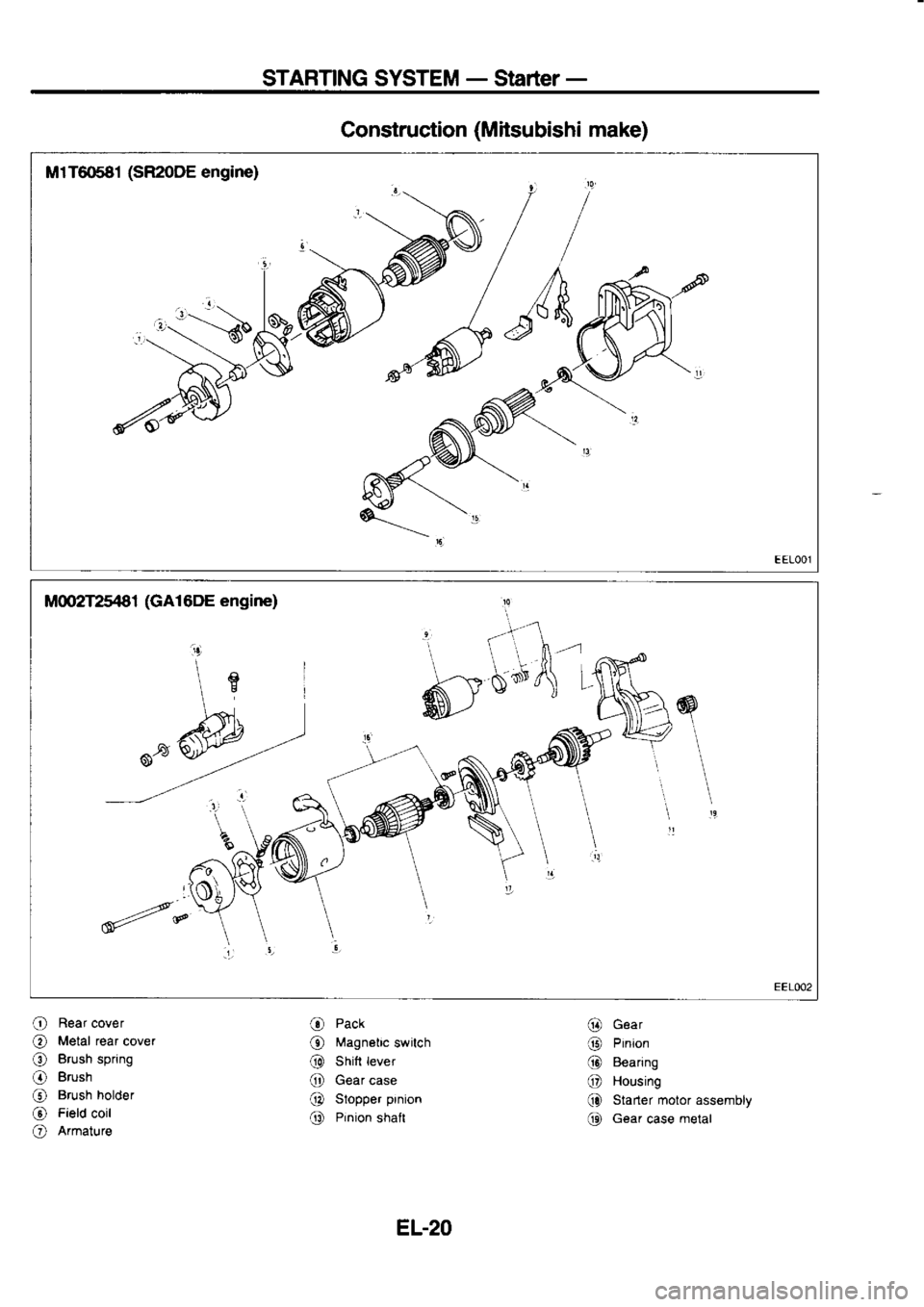

STARTING

SYSTEM -

Starter -

Construction (Mitsubishi

make)

M1T6681 (SR2oDE

engine)

O Rear

cover

O Metal

rear

cover

O Brush

spring

O Brush

@ Brush

holder

@ Field

coil

O Armature O

Pack

@ Magnetic

switch

@ Shitt

lever

@ Gear

case

@ Stopper

prnion

@ Pinion

shalt @

Gear

'rt Hrnron

@ Bearing

@ Housing

(} Starter motor

assembly

(t Gear case metal

EL-20

Page 1132 of 1254

STARTING

SYSTEM -

Stader-

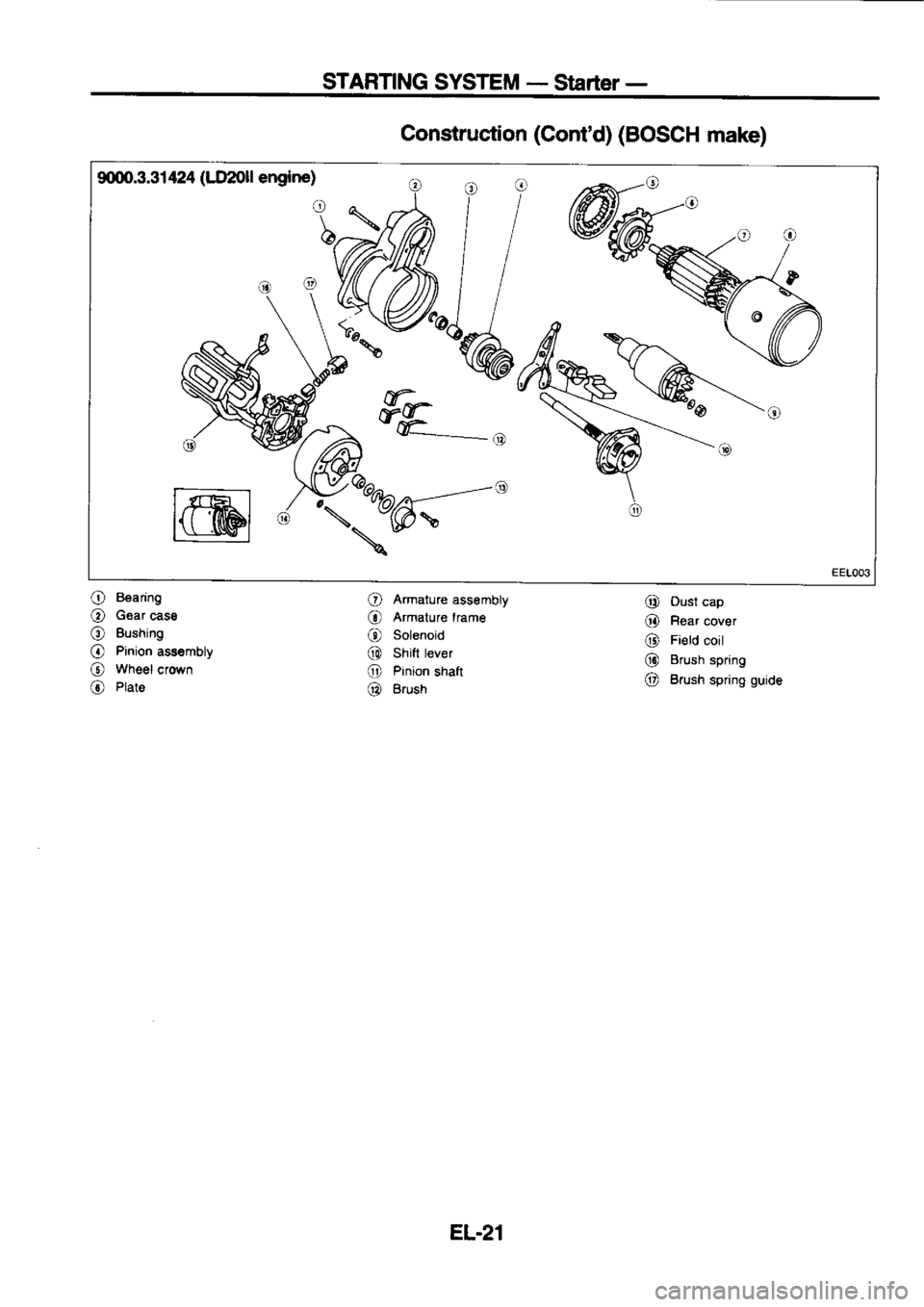

9q)0.3.31 424 (LlI2Oll

engine)

wk

w$ FF.-,

@ /K:b@;-" I@----.*

Construction

(Cont'd)

(BOSCH

make)

O Armature

assembly

@ Dust

cap

O Bearing

O Gear

cass

O Bushing

O Pinion

ass€mbty

@ wheel

crown

O Plate @

Armature

lrame

@ Solenoid

@ shitt

tever

O Pinion

shatt

@ Brush @

Rear

cover

@ Field

coil

@ Brush

spring

O Brush

spring guide

EL.21

Page 1133 of 1254

STARTING

SYSTEM _

StArtEr _

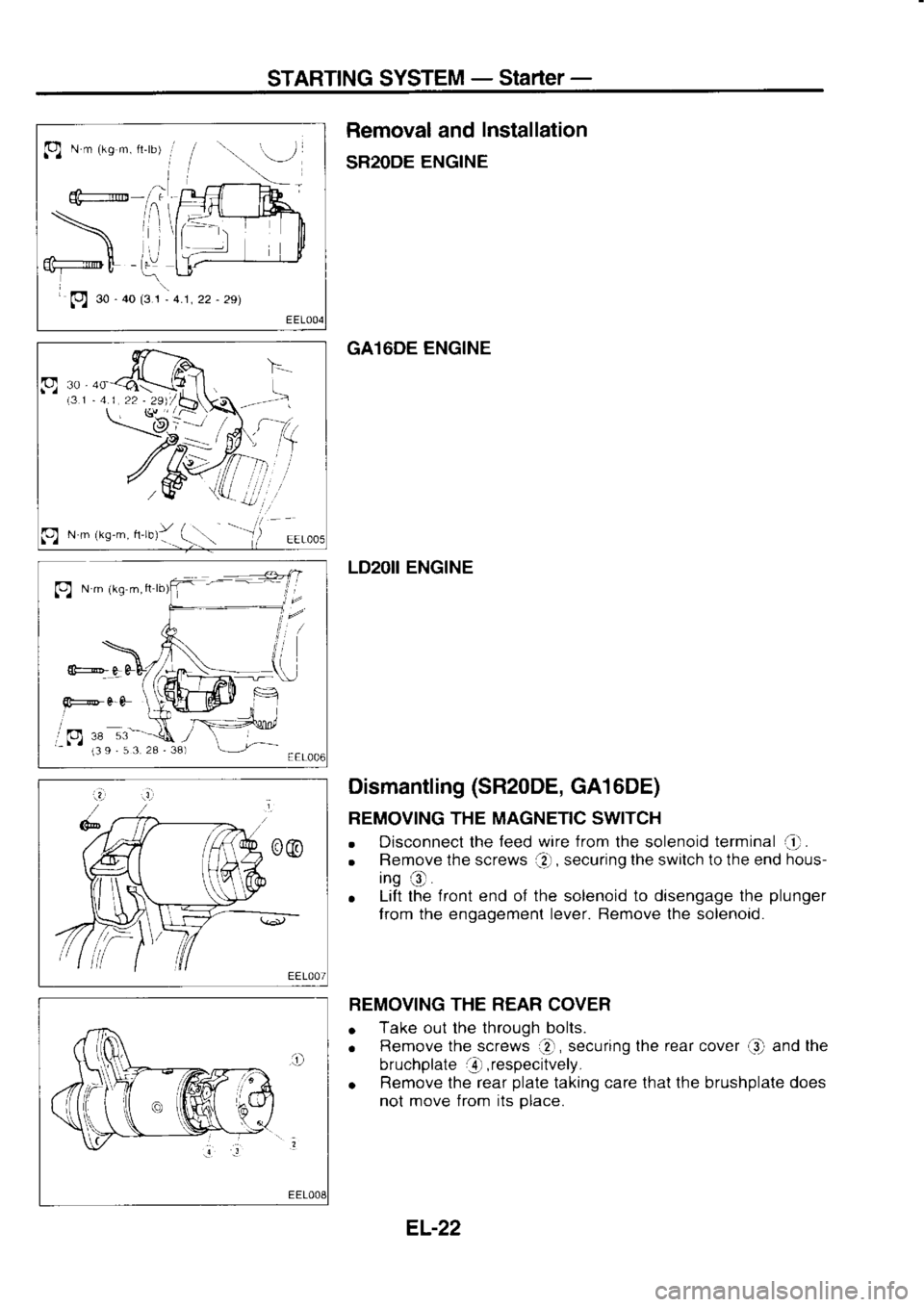

Bemoval and Installation

SR2ODE ENGINE

GA16DE ENGINE

LD2OII ENGINE

p

N

m

1rs-m. h.ru1y

(

Dismantling (SR20DE,

GA1 6DE)

REMOVING THE MAGNETIC SWITCH

o Disconnect

the feed

wire irom

the solenoid terminal

af .

. Remove

the screws

if , securing

the switch to the end hous-

ing O

o Lift

the front

end of the

solenoid to

disengage the plunger

from the engagemenl lever. Remove the solenoid.

BEMOVING THE REAR COVER

o Take

out the through bolts.

o Remove

the screws

@, securing

the rear

cover

Q and

the

bruchplate i!

, respecitvely.

o Remove

the rear plate

taking care lhat the

brushplate does

not move f rom its place.

EL-22

Page 1134 of 1254

STARTING

SYSTEM _

Starter _

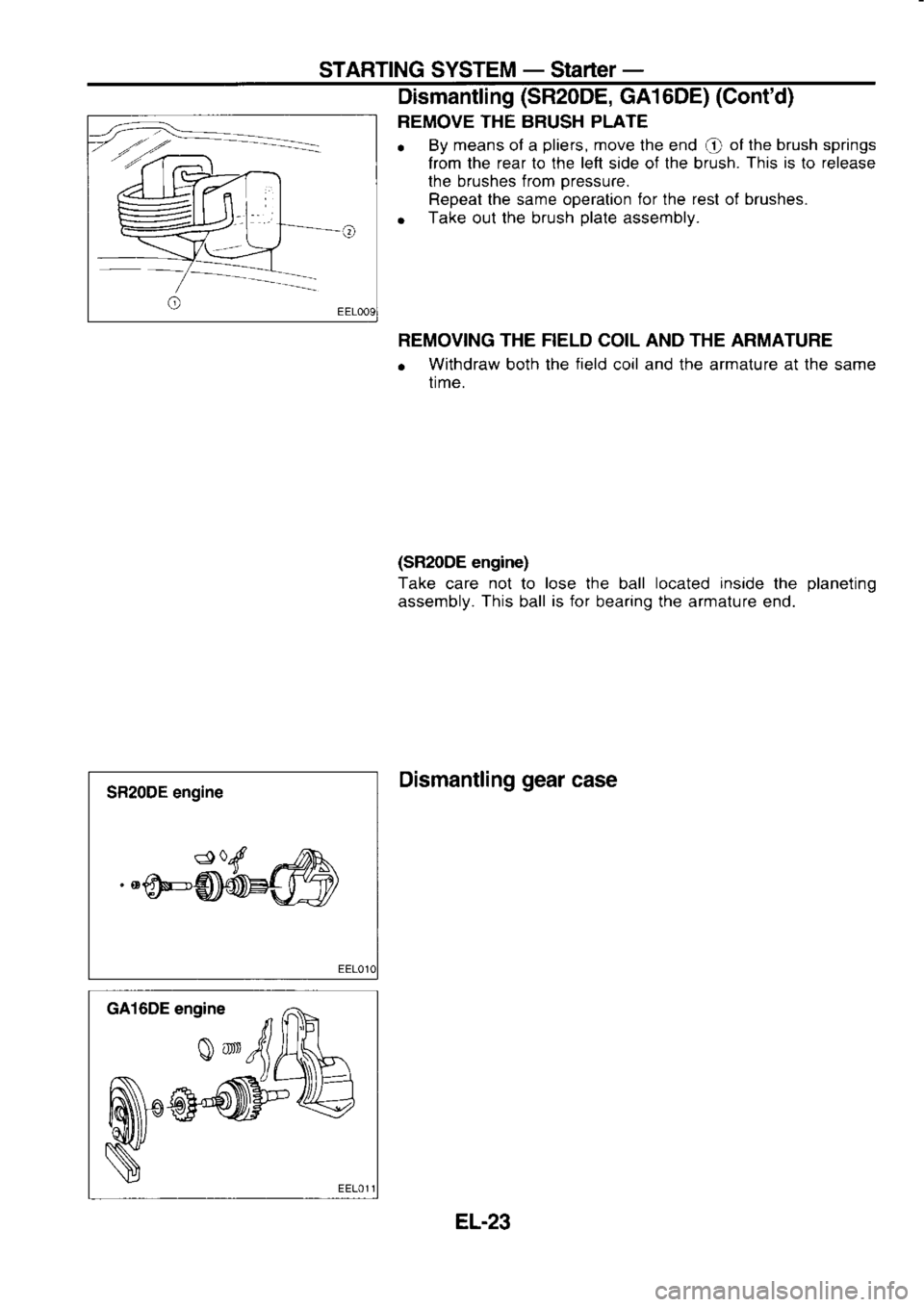

Dismantling (SR20DE,

GA1 6DE) (Cont'd)

REMOVE THE BRUSH PLATE

o By

means of a pliers,

move the end

@ of

the brush springs

Irom the rear lo the left side of the brush. This

is

to release

the brushes from pressure.

Repeat the same operation for

the rest

of brushes.

o Take

out the brush plate

assembly.

REMOVING THE FIELD COIL AND THE ARMATURE

o Withdraw

both the field

coil and the armature at the same

time.

(SMODE engine)

Take care not

to lose

the ball located

inside

the planeting

assembly. This ball is

for

bearing the armature end.

Dismantling gear

case

SR20DE engine

EL-23

Page 1135 of 1254

STARTING

SYSTEM _

Starter _

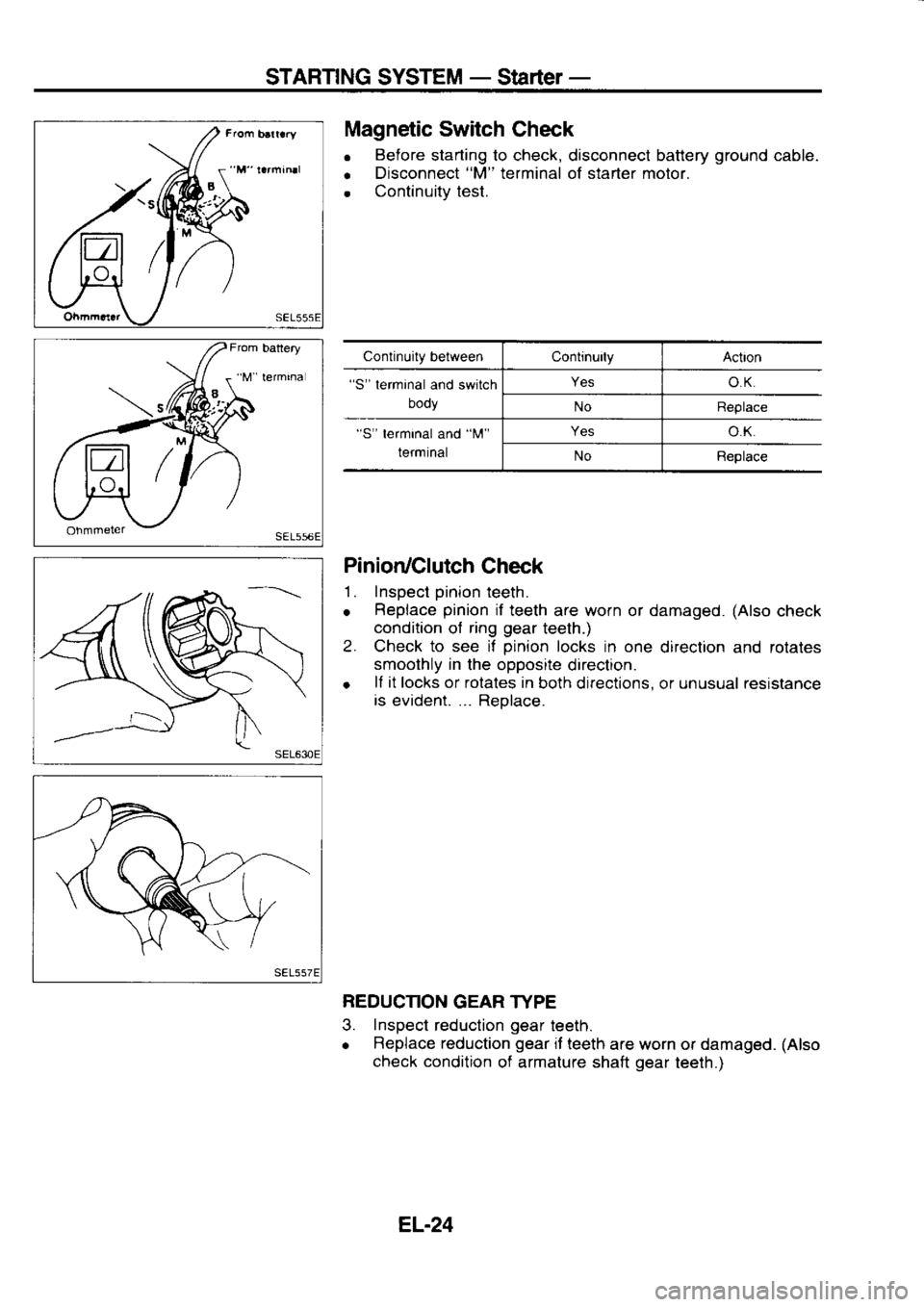

Magnetic Switch

Check

Before starting to check, disconnecl battery ground

cable.

Disconnect "M"

terminal of starter motor.

Continuitv test.

Pinion/Clutch Check

1. Inspect pinion

teeth.

o Replace pinion

if teeth are worn or damaged. (Also

check

condition of ring gear

teeth.)

2. Check to see if pinion

locks in one

direction and rotates

smoothly in

the opposite

direction.

o lf

it

locks or rotales in

both directions,

or unusual

resistance

is evident. ... Reolace.

REDUCTION GEAR TYPE

3. Inspect

reduction gear

teeth.

o Replace

reduction gear

it teeth are worn or damaged. (Also

check condition

of armalure shaft gear

teeth.)

Continuily

between Continurty

Action

"S" lerminal and switch

DOOy Yes

o.K.

No Replace

"S" terminal and "l\,t"

terminal Yes

o.K.

No Replace

EL.24

Page 1136 of 1254

STARTING

SYSTEM _

Starter _

Srush spring Brush

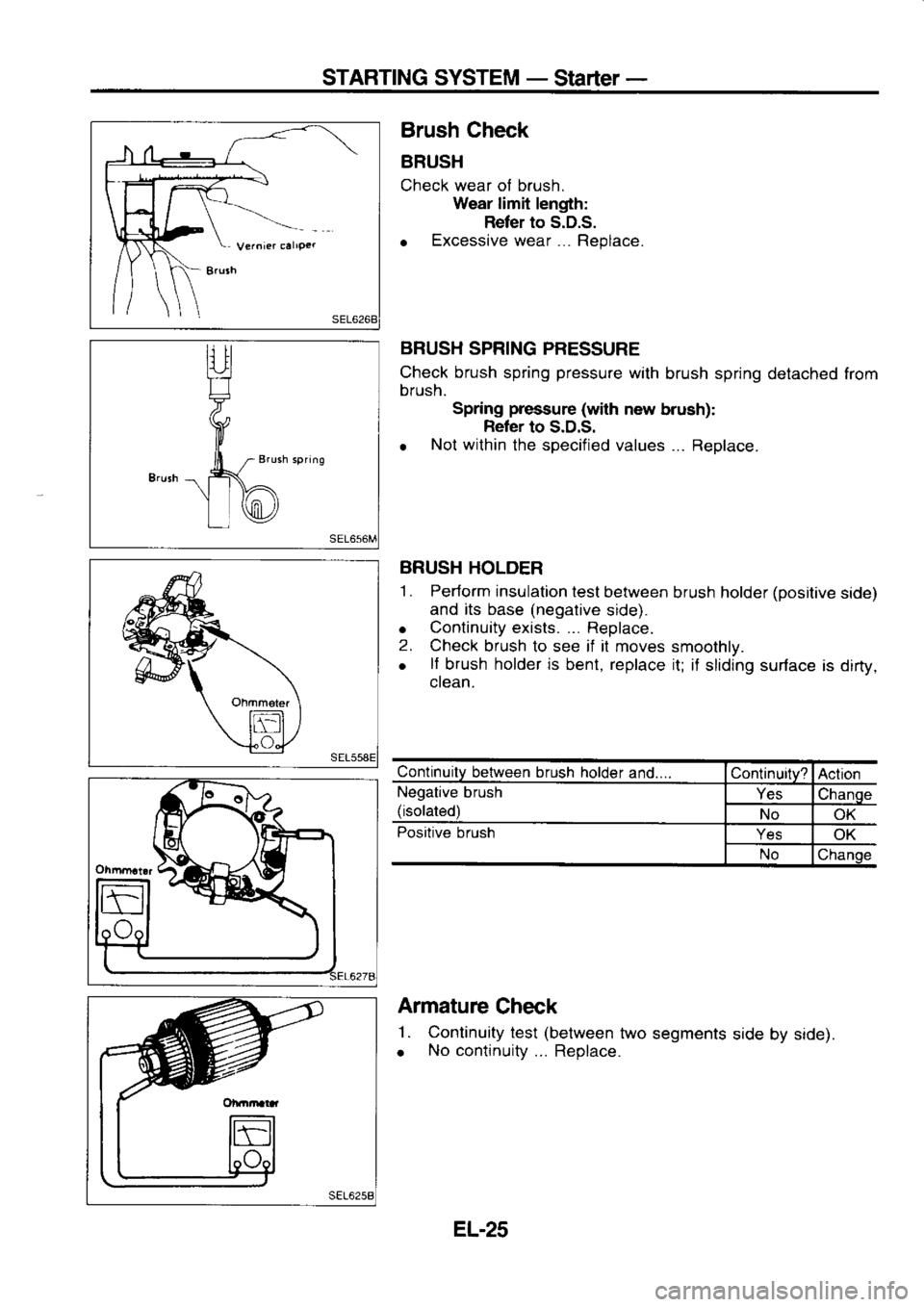

Check

BRUSH

Check wear of brush.

Wear limit

length:

Refer to S.D.S.

o Excessive

wear...

Replace.

BRUSH SPRING PRESSURE

Check brush

spring pressure

with brush spring

detached from

brush.

Spring pressure

(with

new brush):

Refer to S.D.S.

o Not

within

the specified

values... Replace.

BRUSH HOLDER

1 . Perform

insulation test

between brush holder (positive

side)

and its base (negative

side).

Continuity exists. ... Replace.

Check brush to see if il moves

smoothlv.

lf brush holder is

bent. replace

it: if

sliding surface is dirty.

ctean.

ilv between brush holder

and....

Negative brush

rsolat

Positive brush

Armature Check

1 .

Continuity test (between

two segments side by side).

o No

continuiw...

Reolace.

2.

EL-25

Page 1137 of 1254

STARTING

SYSTEM _

StaTteT _

Vnniar ctlipar Armature

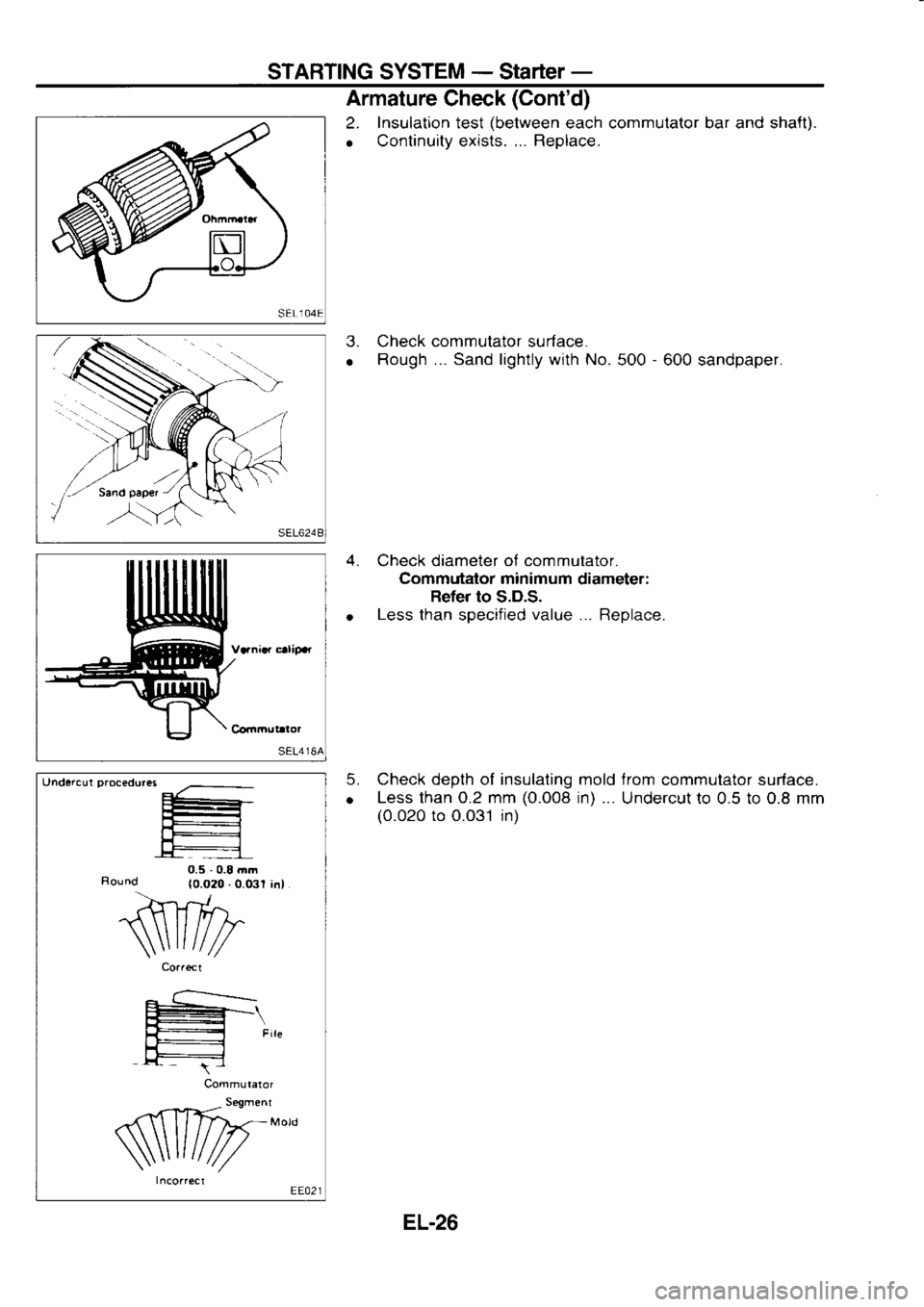

Check (Cont'd)

2. Insulatron test (between

each commutator bar and shafl).

o Continuity

exrsts. ... Replace.

3. Check commutator surface.

o Rough

... Sand lightly with No.500 -

600 sandpaper.

Check diameter ol commutator.

Commutator minimum

diameter:

Refer to S.D.S.

Less than specified value...

Replace.

5. Check depth of insulating mold irom

commutator suriace.

o Less

than 0.2 mm (0.008

in) ...

Undercut to 0.5 to 0.8 mm

(0.020 to 0.031 in)

Undercut

procedures

Round IO.O2O. O.

-->-

^/

r{\\il rr,

\\\

'//// Correc!

Sr F, te

rF:=

E1.26

Page 1138 of 1254

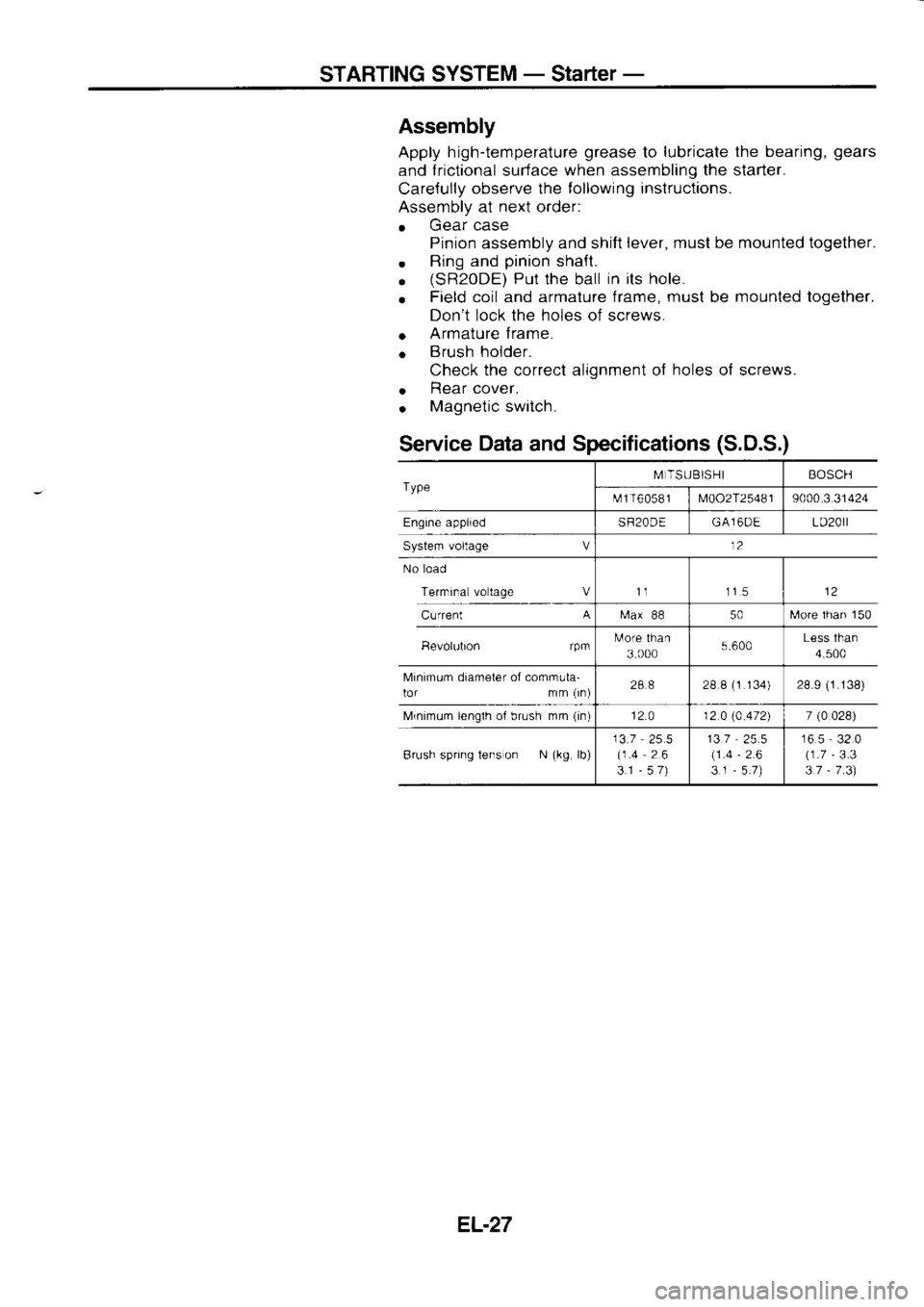

STARTING

SYSTEM -

Starter -

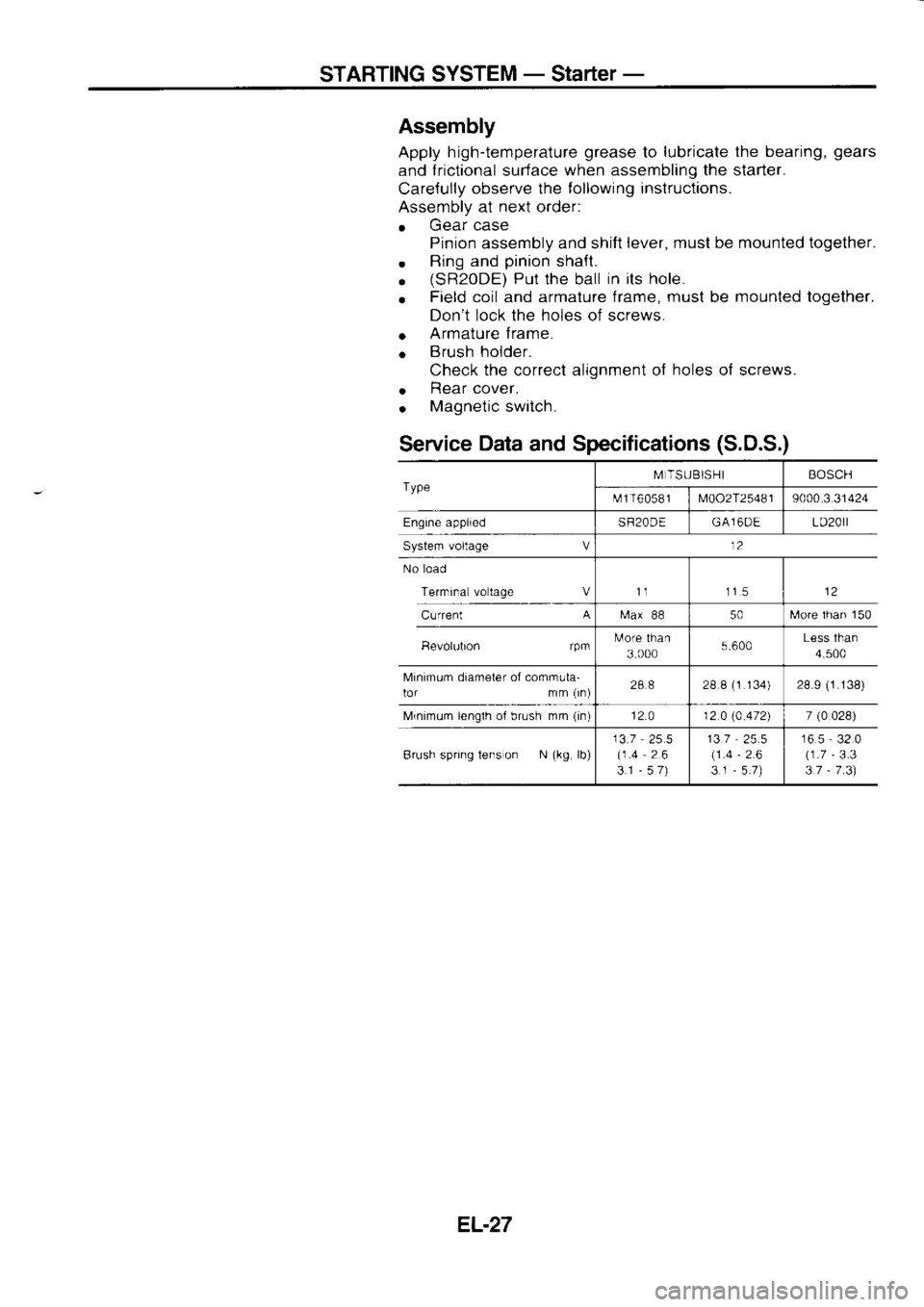

Assembly

Apply h igh-temperature grease

to lubricate

the bearing, gears

and frictional

surface when

assembling the starter.

Care{ully observe

the following inslructions.

Assembly at next

order:

. Gear

case

Pinion assembly and shift lever,

musl be mounted together.

. Ring

and pinion

shaft.

. (sR20DE)

Put the ball in

its hole.

o Field

coil and armature frame, must

be mounted

together.

Don't lock the holes of screws.

o Armature

f rame.

o Brush

holder.

Check the correct alignment of holes

of screws.

o Rear

cover.

. Magnetic

switch.

Service Data

and Specifications (S.D.S.)

Type M

TSUBISHI BOSCH

t\.rf 1 T6

05 8 I

M002T25481 9000.3

31424

Engine applied SR20DEGA16DE LD20rl

System voltage V 12

No load

Terrnrna voltage Vt1 115

Current A

[ra.x

88 50[,,lore

lhan 150

Bevolubon rpmtulore

than

3 000 5.600Less

than

4,500

Minimum diameter of comrnula-

lor mm (rn) 288

28 8 (1

134) 28.9 (1.138)

Mrnimum lenglh of brush mm (in)

12.0 12 0 (4.472)

7 (0

028)

Brush spring tens on N (kg,

lb) 13.7

25.5

(1.4 26

3.1 -57) 137

(1 .4

3.1 -

2.6 16.5

32.0

(1.7 -

3.3

3.7 -

7 .3)

EL.27

Page 1139 of 1254

CHARGING

SYSTEM

Wiring Diagram

t

o

z

E

o

ffi

dd

EE

'H

-Fr Fl-1

Etr

F

t44

@

t-.t-.]

-H

t-f1

t-t-1

H

t:]-

F;

ll r-.

9t I

[!J0

r.g?

c

c

E

3

c

rr,

(E/

8sF

," fsl

EF+

ai_ A

z

.

o

cD

f)

^l

t9E

.6\F

tsF

@+

A.r-

\sl'-Y

@

taA.

r?r r

€_llD

@# ra$ d@

SoS *@

*- :

|r

At-- -------r

lln 6 -l

il' a 'l

frt6 lEt I

-l -:? J

-=:' !!

9! o

3 6; .9

;;p !F

;'; P F 9

;;::v:l

6 i,

ofo)to6

n -

HHI'::IP:

ooo(,

0a

v1 0 )u

urr!

it:

I

.<

,,!f_

"Ll

o

tr

o

v)Z

@@@@@@ec

EL.28

Page 1140 of 1254

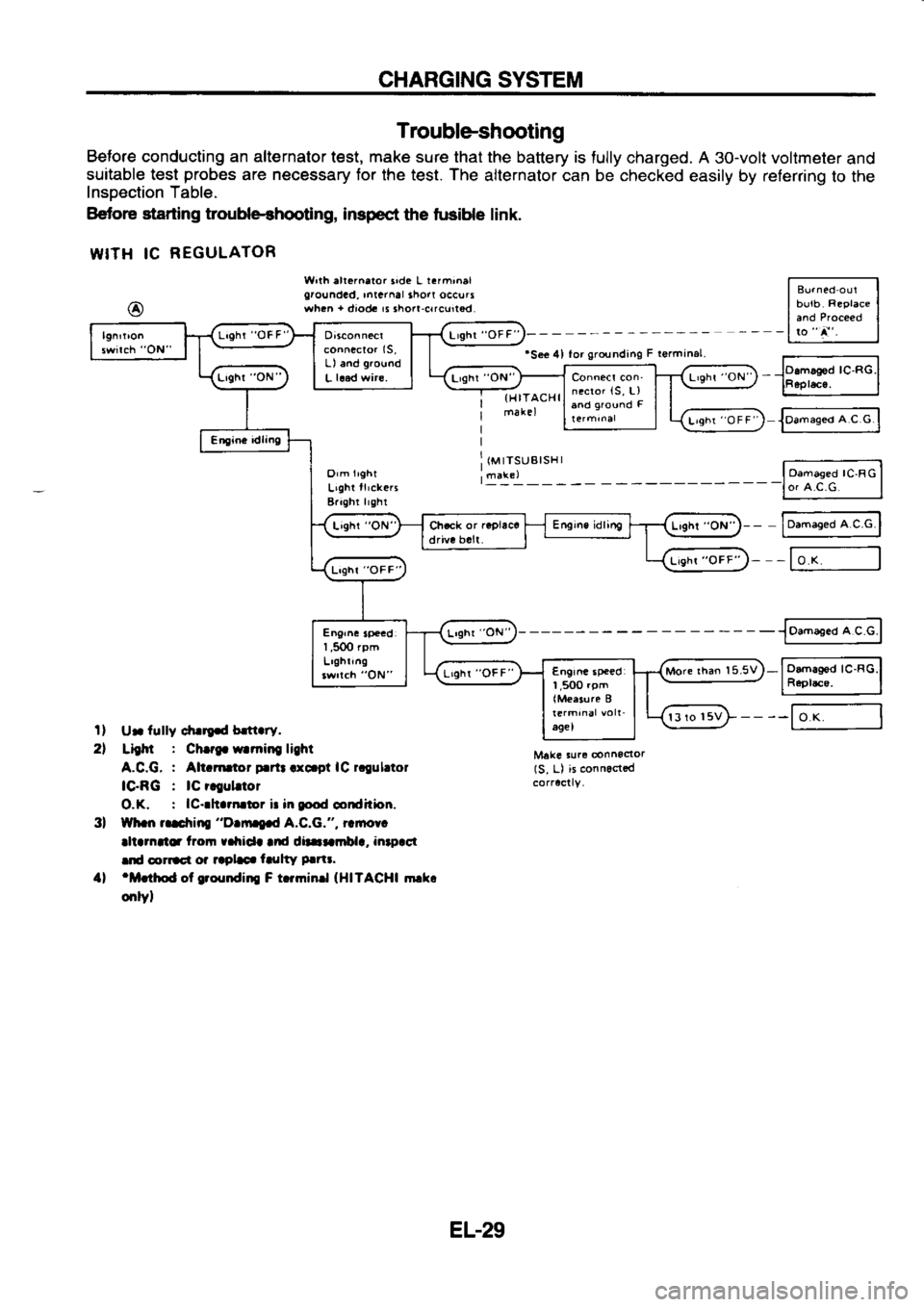

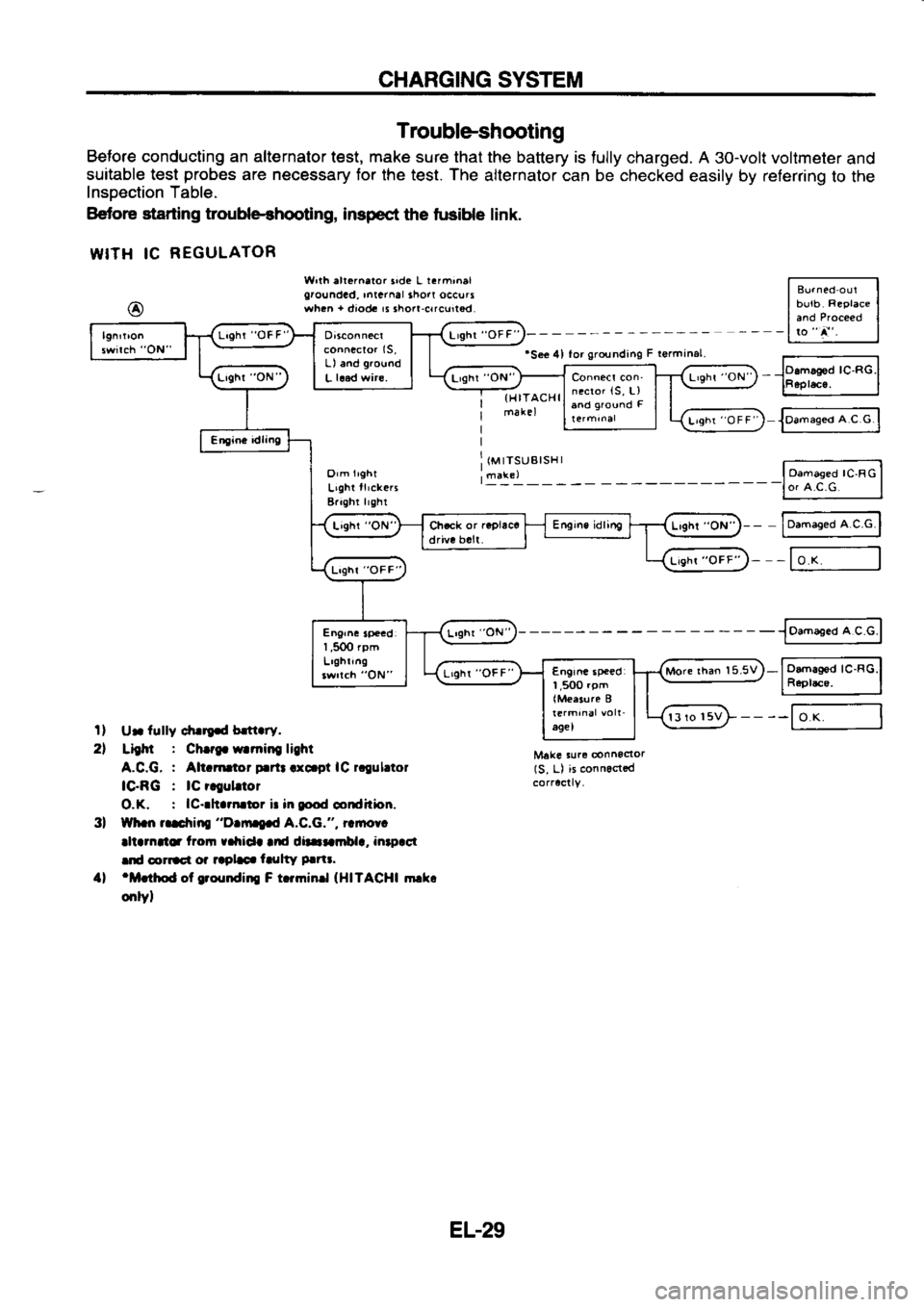

CHARGING

SYSTEM

Troubleshooting

Before conducting an alternator

test, make sure that the

battery is fully charged. A

3o-volt voltmeter

and

suitable test probes

are necessary

for the test. The

alternator can be checked

easily by relerring

to the

Insoection Table.

Betore starting troubleshooting,

inspec,t the fusible link.

WITH IC REGULATOR

l/Vrrh.lt.rn.to. iid. L r.rm;nel

groundad, Intcrnal 3ho7t occuri

whln +

diod. ri

3hoit-crrcurtod. |;;;;-l

I burb

Repl.ce

I

I end

Proceed

I

- -l'."r-"

I

\--6;;"*;l

,/

lRepleco. I

) F"-"r""

"c;:l

E."*;;I

- -lo,

a.c.c I

- F;"d"-l

--F* _-l

-@

D-|;;;d'cnc'l

/

lR6elacs. I

---l;* __l

'SGe

4l lor grounding F

termrnel.

(H ITACH I

1)

2l Ur

lully

dr.n d brtr.ty.

Light :

Cbrgt wrming light

A.C.G. :

Alt.nrator p.rtr

ax6pt lC

lrguhtot

IC.RG :

lC r.!ul

or

O.K. : lC-rhrrtt.tor

it in good

@ndhbn.

Wbn r.aafiing

"O.nrqad A.C.G.", rar|oy!

allarnatc tron

r.lrida

||td ditaaxmbla, intpasr

|rrd corrrct or

aapLc. fasltY prn!.

'Mrthod of ero{Ddirt F

t.rmin.l

{HITACHI mrkc

onlyl Make

suro connodor

(S, L) is

connocted

3)

4) More

than 15.5V

13 ro l5V

EL-29

Trending: steering, oil pressure, tires, check engine light, tire pressure, air condition, low oil pressure

![NISSAN SERENA 1993 Service Repair Manual CHARGING

SYSTEM

Wiring Diagram

t

o

z

E

o

ffi

dd

EE

H

-Fr Fl-1

Etr

F

t44

@

t-.t-.]

-H

t-f1

t-t-1

H

t:]-

F;

ll r-.

9t I

[!J0

r.g?

c

c

E

3

c

rr,

(E/

8sF

," fsl

EF+

ai_ A

z

.

o

cD

f)

^l

t9E

.6\F

ts NISSAN SERENA 1993 Service Repair Manual CHARGING

SYSTEM

Wiring Diagram

t

o

z

E

o

ffi

dd

EE

H

-Fr Fl-1

Etr

F

t44

@

t-.t-.]

-H

t-f1

t-t-1

H

t:]-

F;

ll r-.

9t I

[!J0

r.g?

c

c

E

3

c

rr,

(E/

8sF

," fsl

EF+

ai_ A

z

.

o

cD

f)

^l

t9E

.6\F

ts](/img/5/57387/w960_57387-1138.png)