NISSAN SERENA 1993 Service Repair Manual

SERENA 1993

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57387/w960_57387-0.png

NISSAN SERENA 1993 Service Repair Manual

Trending: warning, roof, low oil pressure, wheel bolts, belt, USB port, check engine light

Page 1141 of 1254

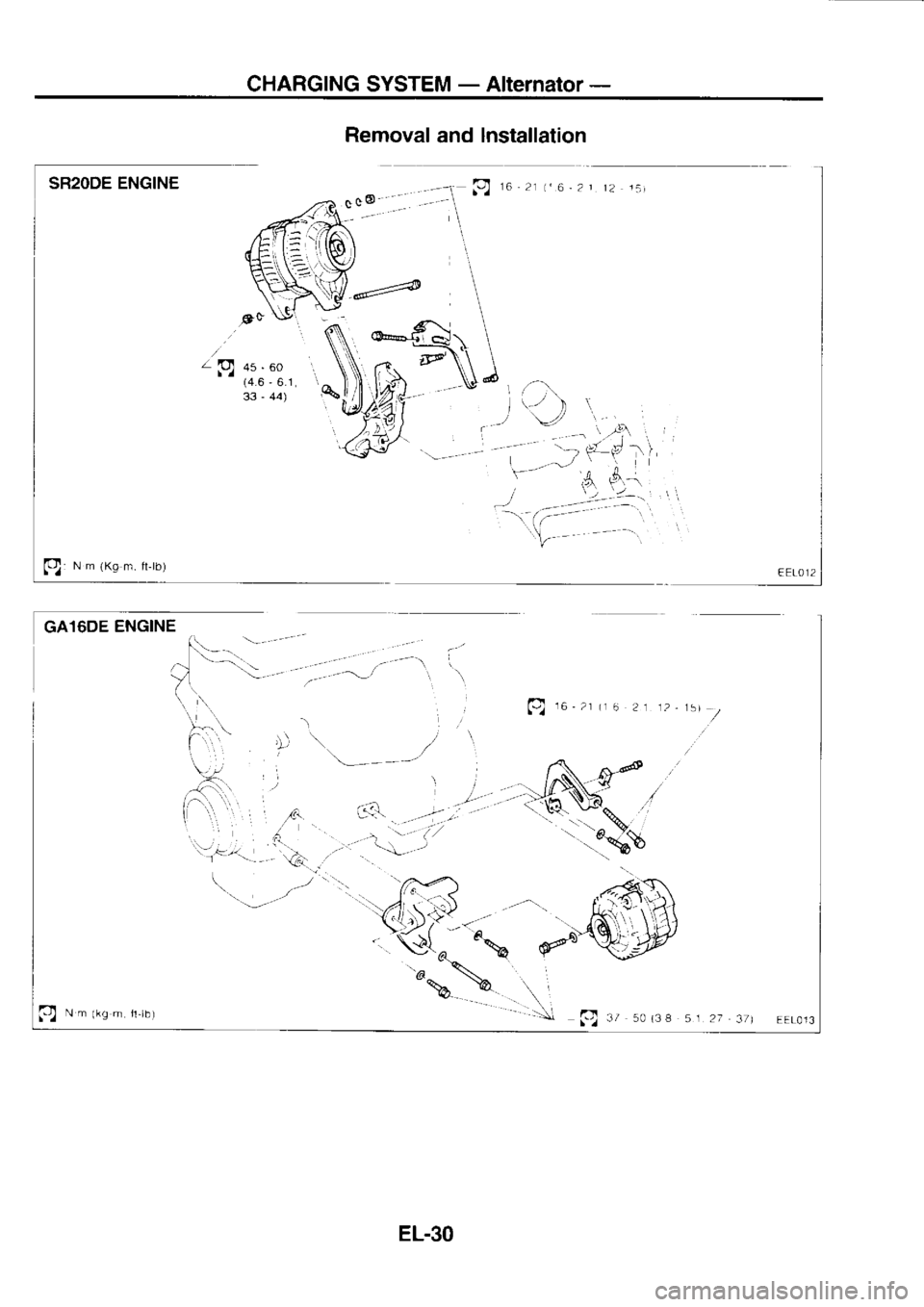

CHARGING

SYSTEM _

Alternator _

Removal and lnstallation

SR2ODE ENGINE

fq: N

m

{Ko m. tl-lb)

GA16DE ENGINE pl

ro :r t.6-p1

12 i,,i

."-"'-E

Z|o! as. so

(4.6 ,

6.1

33 -

44)

r?)

--'-.! Q re-zr

t1

6 21 1p,i5t

//

t) Nm

rr.tjm a,b)

f) rz

so (38

s r

27 37r EEL0]3

EL-30

Page 1142 of 1254

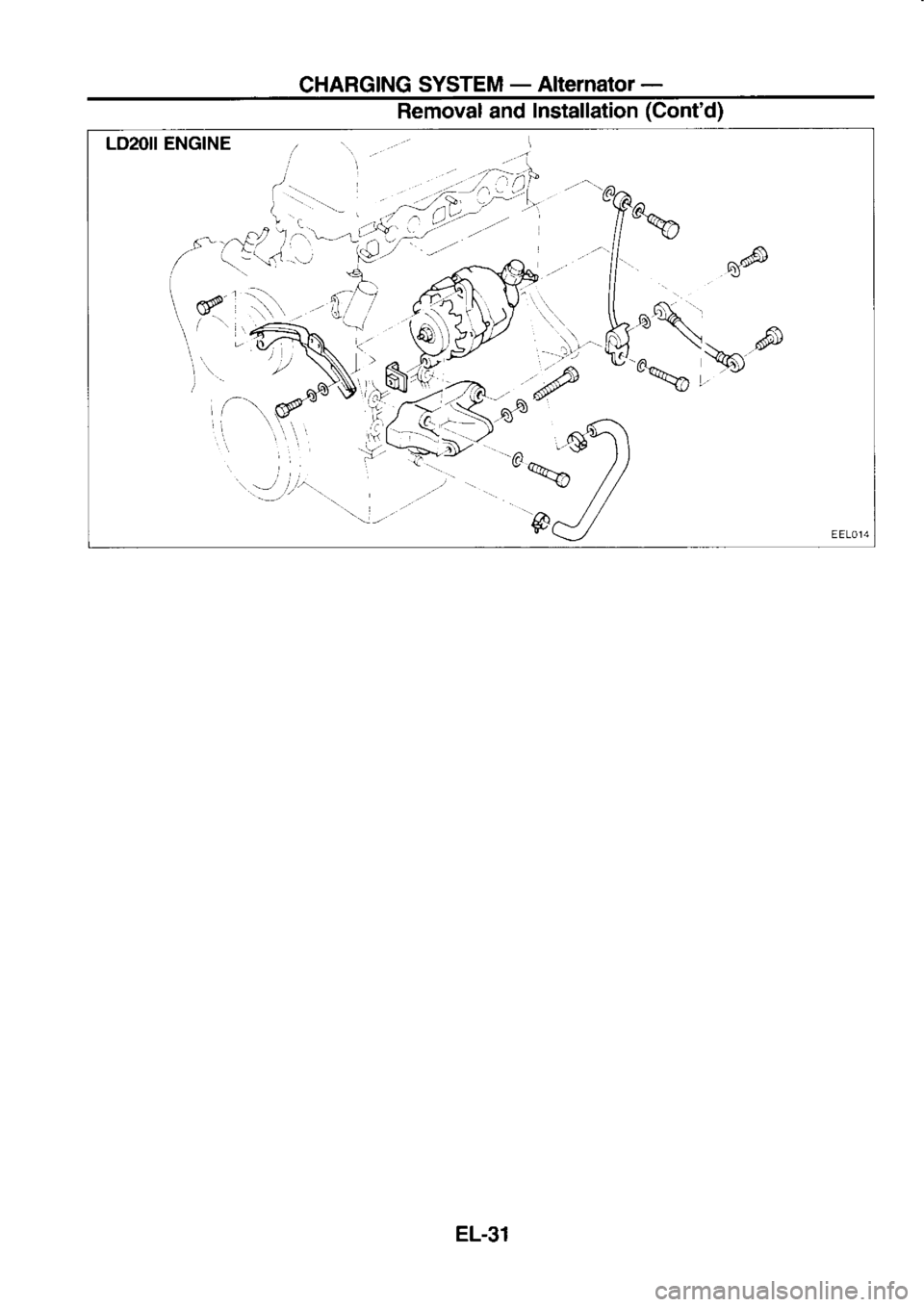

CHARGING

SYSTEM _

Alternator _

Removal and Installation (Cont'd)

EL-31

Page 1143 of 1254

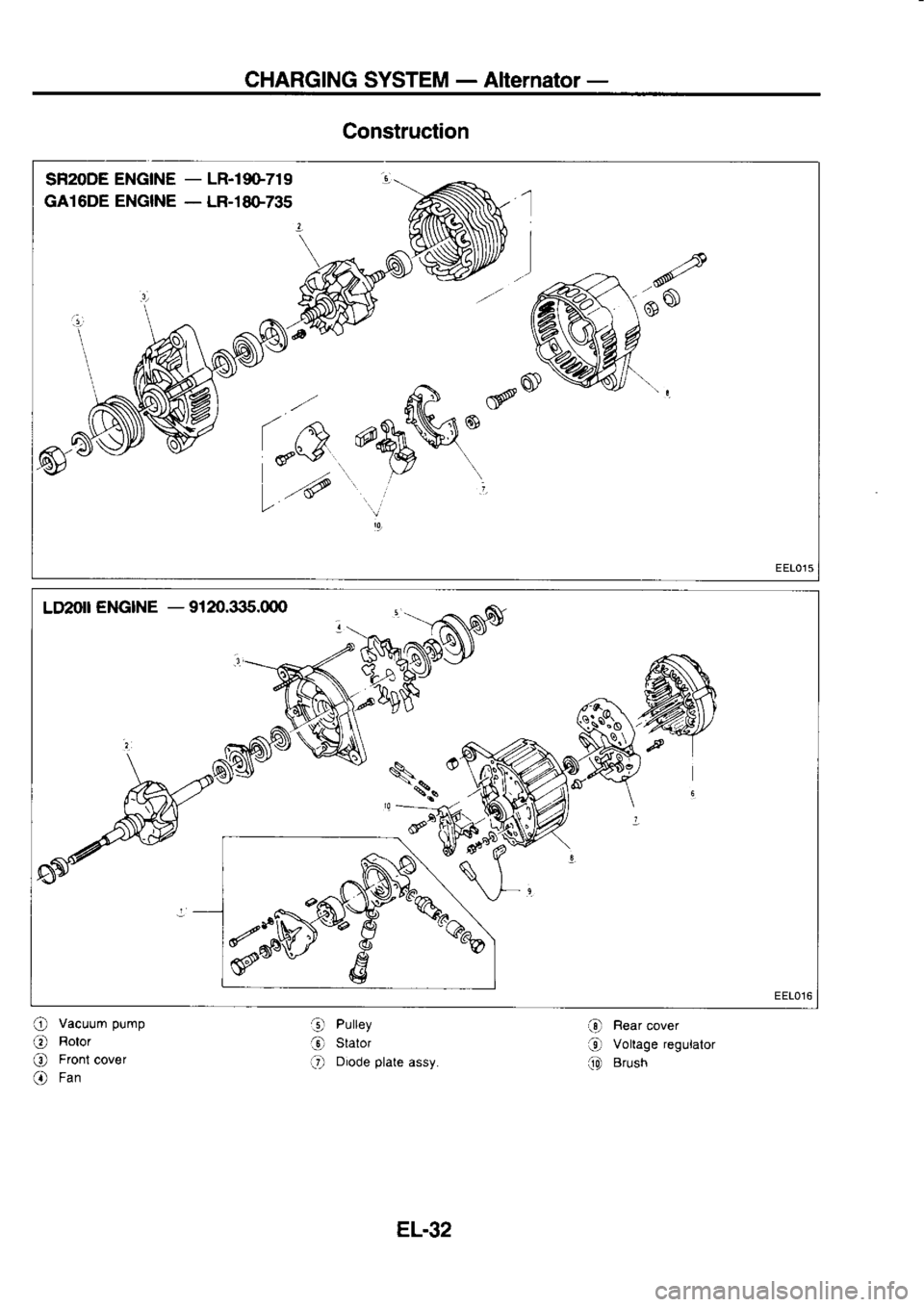

CHARGING

SYSTEM -

Alternator -

Construction

SF2ODE ENGINE _

LR.19O-719

GA16DE ENGINE _

LR-18G735

(n.eu'r6

,"d *>d0

@shM* (v\

".Y\ \.

.' .i,

,9

LII20[ ENGINE -

9120.335.000

@ Rear

cover

O Voltage

regulator

f,Q Brush

.9

Pulley

O stator

O Diode

plate

assy.

EL.32

O

Vacuum

pump

O Rotor

(D Front cover

@ Fan

Page 1144 of 1254

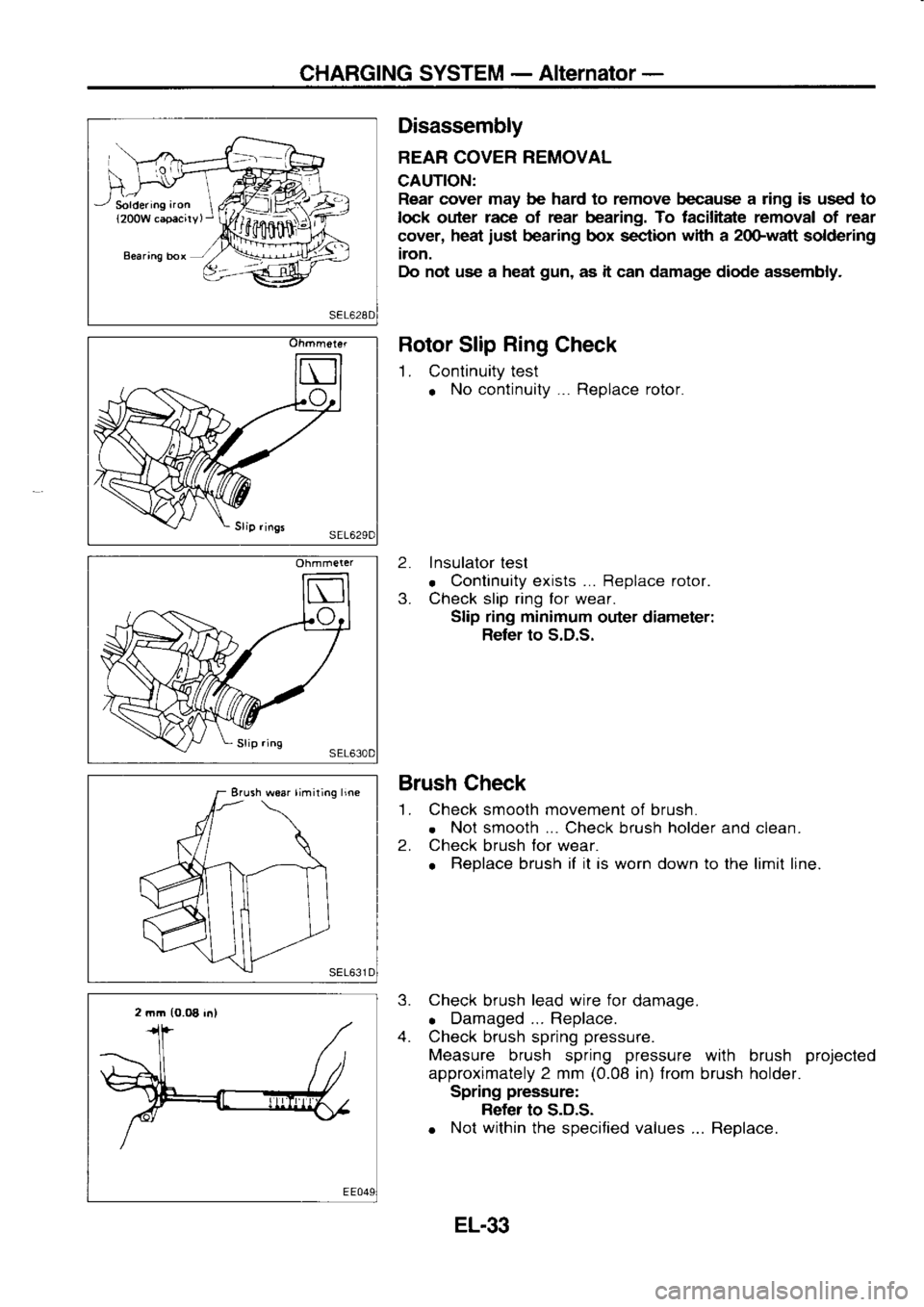

CHARGING

SYSTEM -

Alternator -

Soldering aron

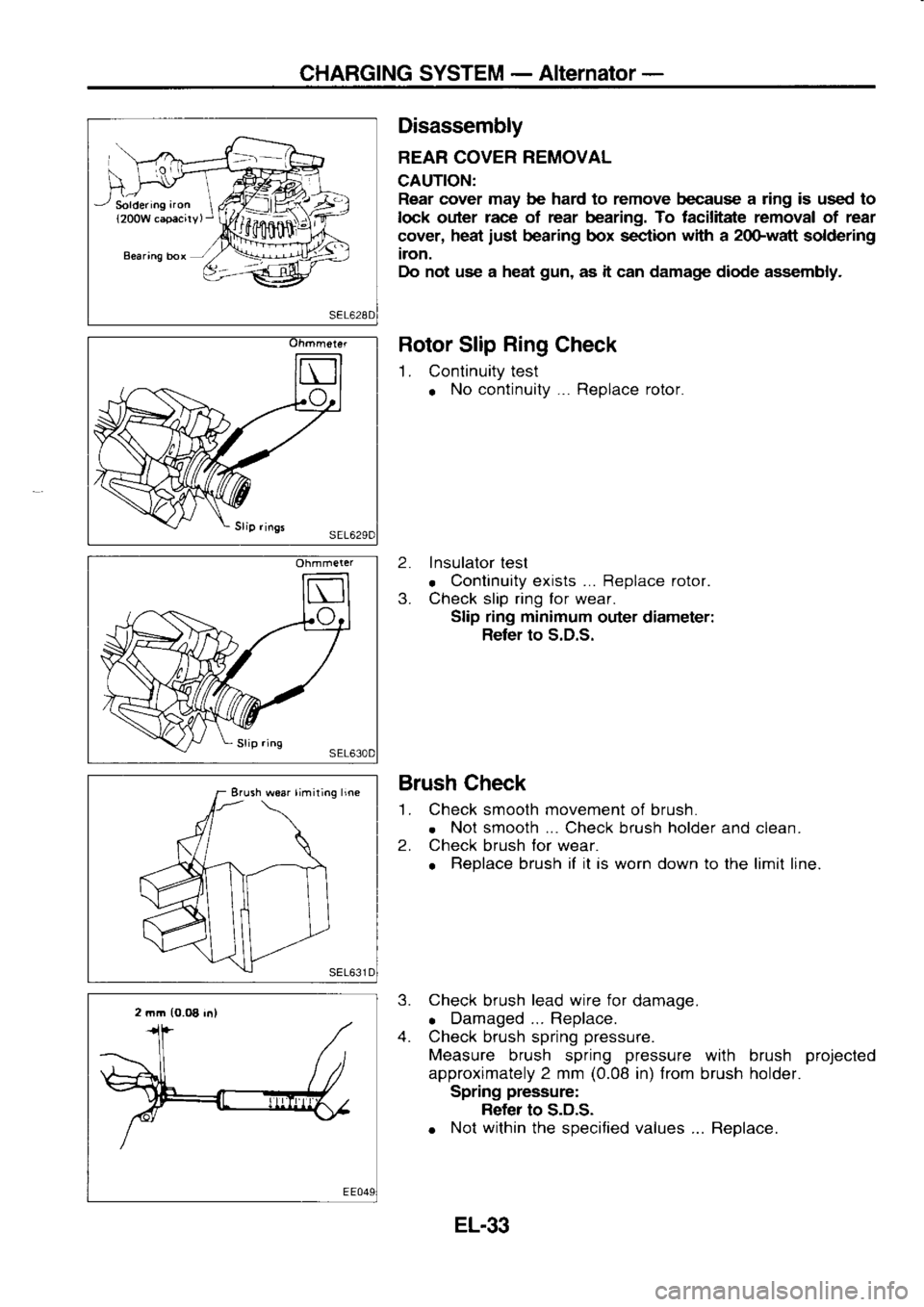

{200W capacirv, Disassembly

BEAR COVER REMOVAL

CAUTION: Rear cover may be hard to remove because a ring is used to

lock outer race

of rear bearing. To facilitate removal of rear

cover, heat

iust bearing

box section with

a 2oGwatt

soldering

iron.

Do not use a heat gun,

as it can damage diode assembly.

Rotor Slip Ring

Check

1. Continuity test

o No

continuity... Replace rotor.

2. Insulator

test

. Continuity

exists ... Replace rotor.

3. Check slip ring for wear.

Slip ring minimum

outer diameter:

Refer to S.D.S.

Brush Check

'L Check smooth movement

of brush.

. Not

smooth ...

Check brush holder

and clean.

2. Check

brush for

wear.

o Replace

brush if

it

is worn down to the limit line.

3. Check

brush lead

wire for

damage.

o Damaged...

Replace.

4. Check brush spring pressure.

Measure brush spring pressure

with brush projected

approximately 2 mm (0.08

in) from

brush holder.

Spring pressure:

Refer to S.D.S.

o Not

within

the specified values ... Replace.

Ohmmeter

Erush woar limiting

line

2 mm (0.O8

in)

EL.33

Page 1145 of 1254

CHARGING

SYSTEM -

Alternator -

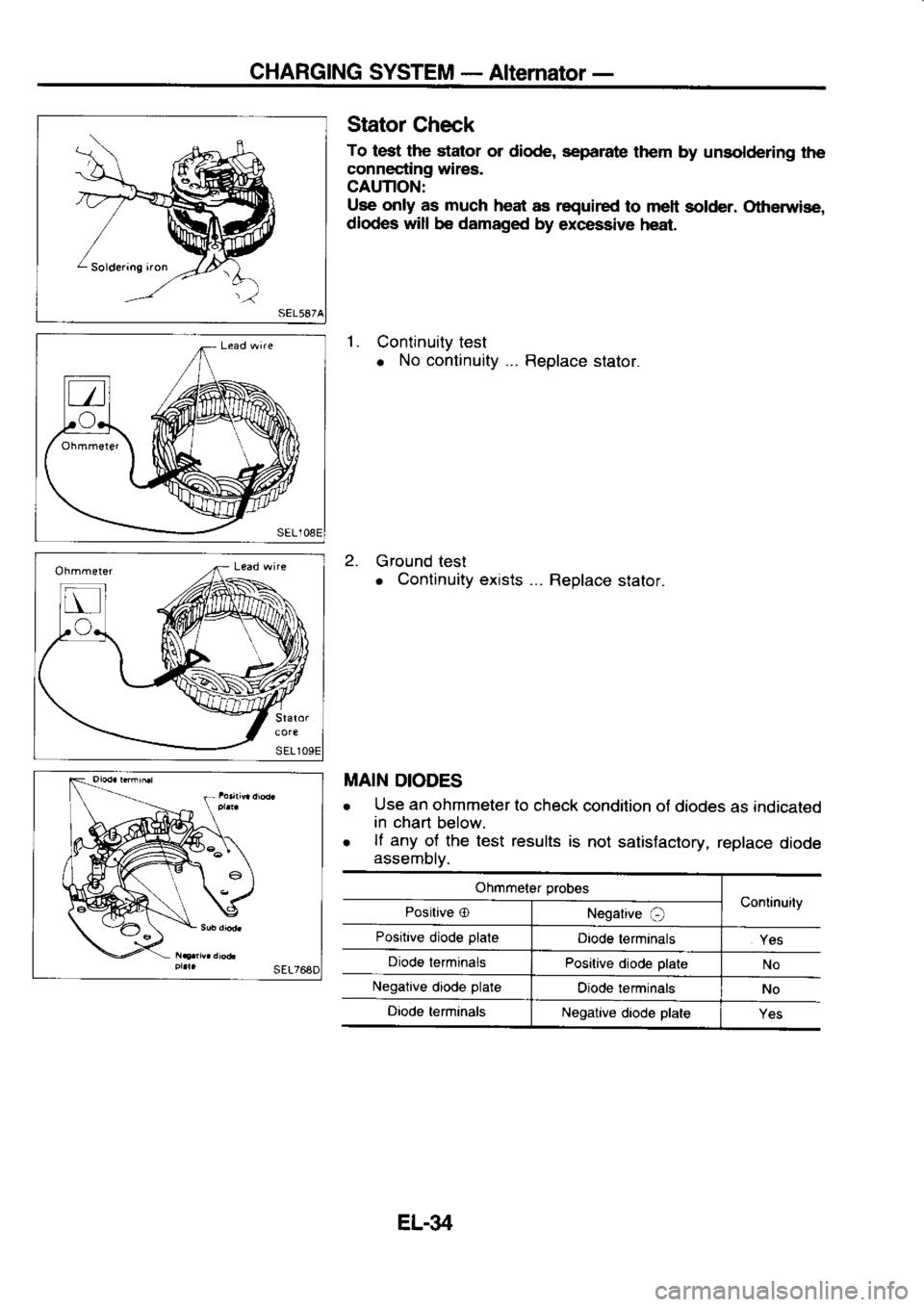

Stator Check

To test the stator

or diode, separate

them by unsoldering

the

connecting wires.

CAUTION:

Use only

as much heat

as required

to melt solder. Otherwise,

diodes will

be damaged

by excessive heat.

1 .

Continuity test

o No

continuity... Replace stator.

2. Ground test

o Continuity

exists... Replace stator.

MAIN DIODES

r Use

an ohmmeter

to check

condition of

diodes as indicated

in chart

below.

o lf

any

of the test results

is not satisfactory,

replace diode

assembly.

Ohmmeter probes

Continuity

Positive O

Negative

O

Positive diode plale

Diode terminals

Yes

Diode lerminals Positive diode plate

No

Negalive diode plate

Oiode terminals

No

Oiode terminals

Negative

diode plate

Yes

EL-34

Page 1146 of 1254

CHARGING

SYSTEM -

Altemator -

Crolin .nia|| ,Dod.l

Brurh litt

rvira Stator

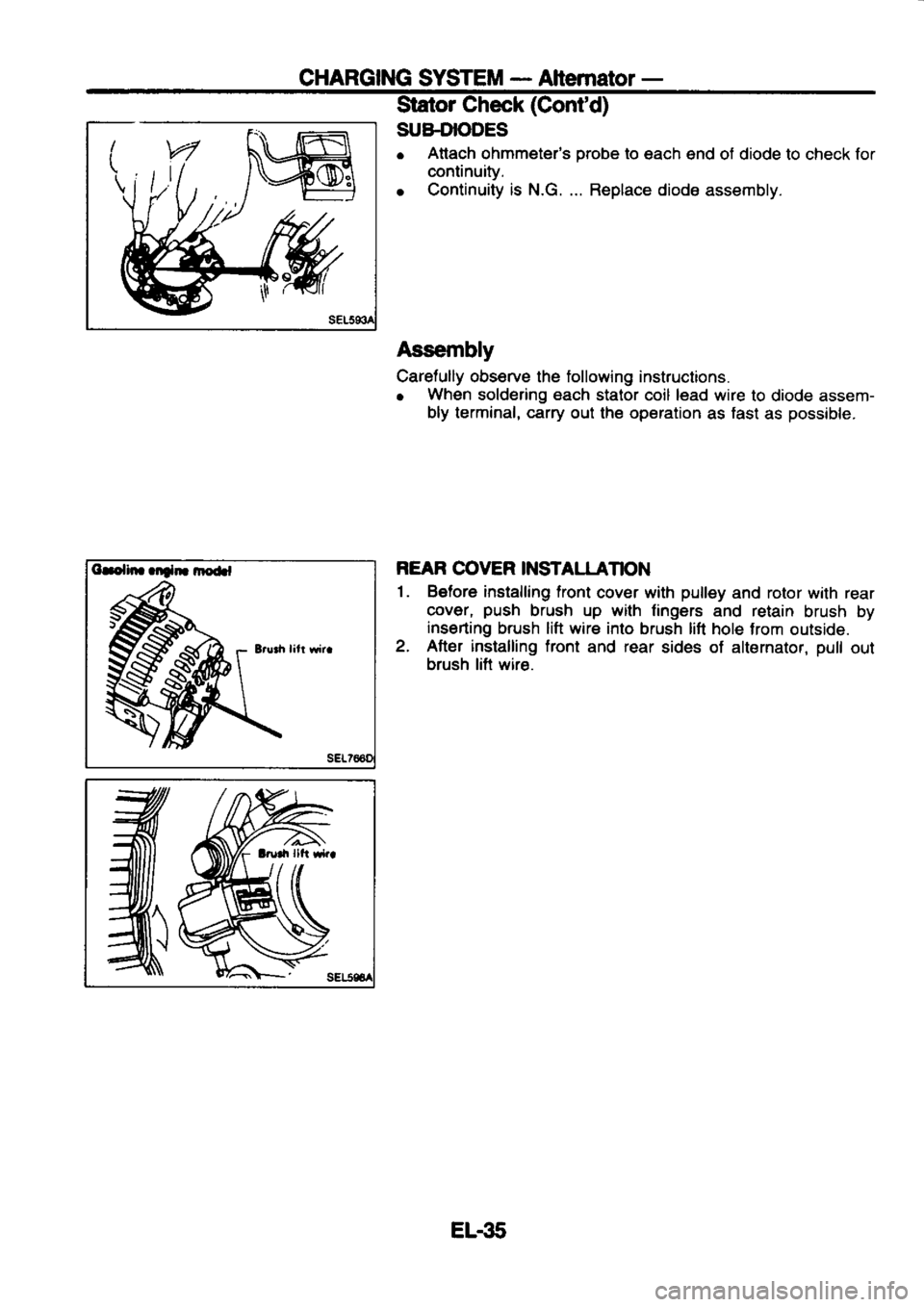

Check (Gont'd)

SUB-DIODES

o Attach

ohmmeter's orobe to

€ach end of diode to check for

continuity.

o Continuity

is N.G. ... Replace diode

assembly.

Assembly

Carefully observe the following instructions.

o When

soldering each

stator coil lead wire

to diode assem-

bly terminal, carry

oul lhe operation

as fast

as possible.

REAR COVER INSTALLATION

1. Before installing front

cover with pulley

and rotor with rear

cover, push

brush up with lingers

and retain

brush by

inserting brush lift wire

into brush lift

hole lrom outside.

2. After installing front

and rear

sides of

alternator, pull

out

brush lift wire.

EL€5

Page 1147 of 1254

CHARGING

SYSTEM -

Alternator -

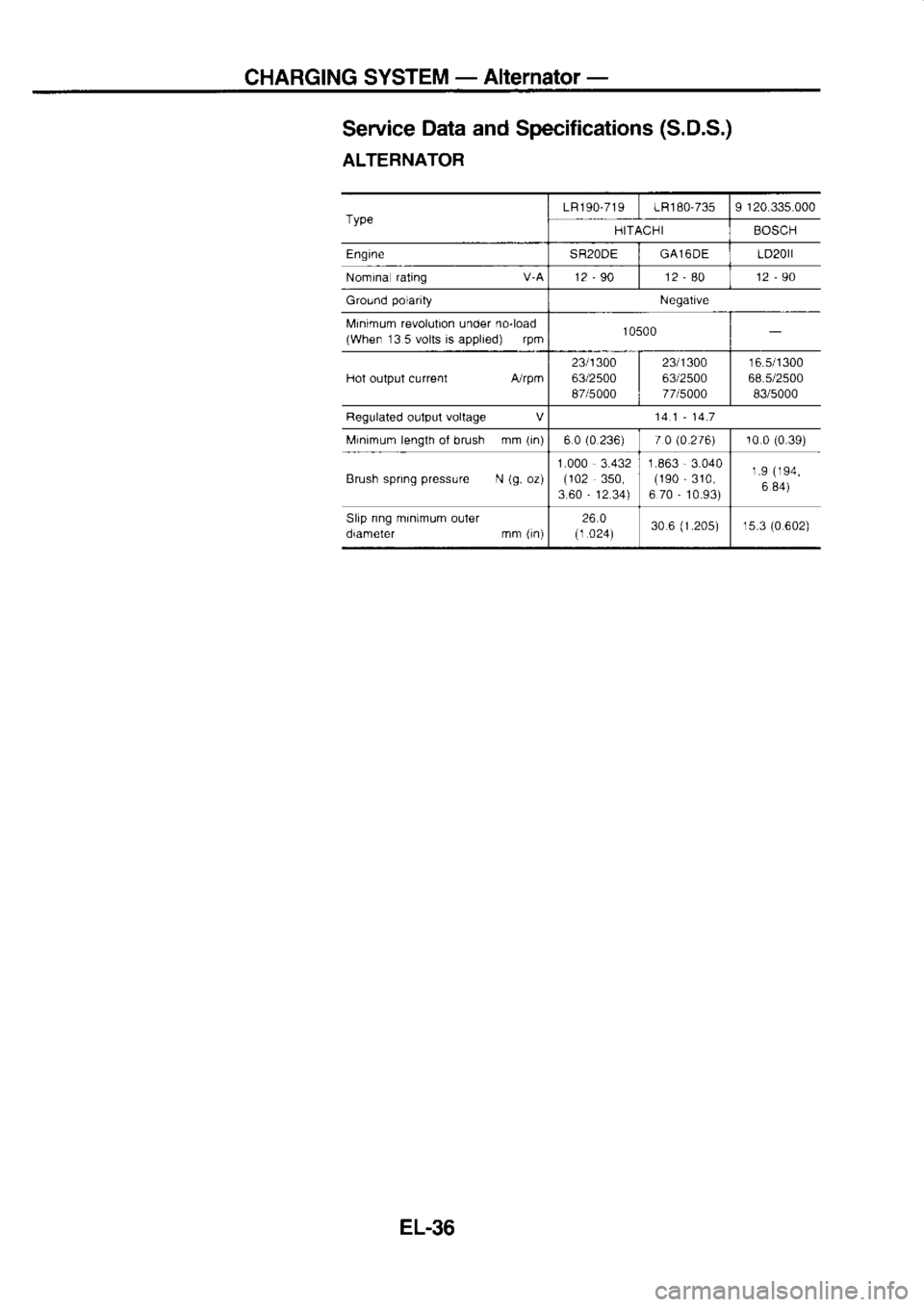

Service Data

and Specifications (S.D.S.)

ALTERNATOR

Type LR190-719

1R180-735I 120.335.000

HITACHI BOSCH

Engine SR2ODEGAl6DE LD20rl

Nomina rating

V-A12-90 12 -

80 12-90

Ground polarity

Negalrve

l\,4inimum revolution

under no-load

(When 13 5 volts

is

applred) rpm 10500

Hot output current A./rpm234300

63/2500

87/5000 2311300

63/2500

77l5000 16.5/1300

68.5/2500 B3/5000

Regulated oulpul vollage

V 14.114.7

Minimum length ot brush mm (in)

6 0 (0

236) t

010.276) 10

0

{0.39)

Brush spring pressure

N (9,

oz) 1.000

3.432

(102 350,

3.60 -

12.34) 1.863

3.040

(1S0 -

310,

6 70 -

10.93) 1.9

(194,

6 84)

Slip nng

minimum

outer

orameler mm (1n) 26.0

(1 024) 30

6 (1.20s)

1s.3 (0

602)

E1.36

Page 1148 of 1254

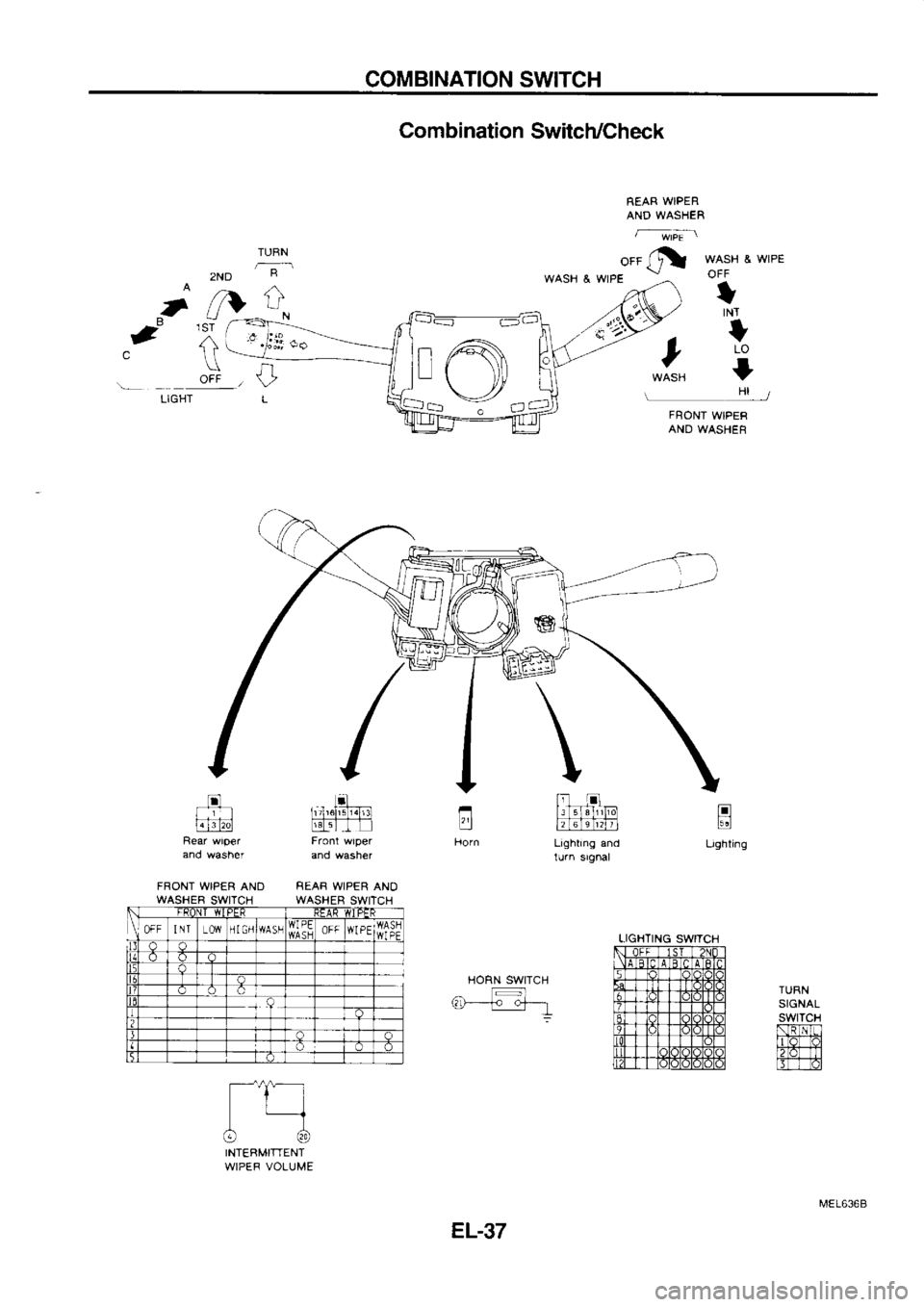

COMBINATION

SWITCH

Combination Switch/Check

REAR WIPER

AND WASHER

-wrpEa

TURN

a; --r

Lf o"fr

WASH

& WIPE

OFF

tINT

t LO

I Ht /

u

e 1ST

^ t\

OFF ,

LIGHT FNONT WIPER

AND WASHEF

FRONT WIPER AND

WASHER SWITCH a]

I ii

,6iGT,

.td

tq-Tfll

REAR WIPER AND

WASHER SWITCH til

l-l

l, L6le L,rtr I

Lrghtrng and

rurn srgnal

HORN SWITCH

TURN

SIGNAL

swtTcH

NmNn

llo ol

f2TdTm

ETT r0l

I

l-1

tGt

INTERMITTENT

wlPEF VOLUME in,A

ll

tl { \\1t F

-r- // L

\-:=/

;*-a o a-Lj

PER

OFF

I NT

I]I GH WIPE

OFFWIPE

LIGHTING SWITCH

EL-37

Page 1149 of 1254

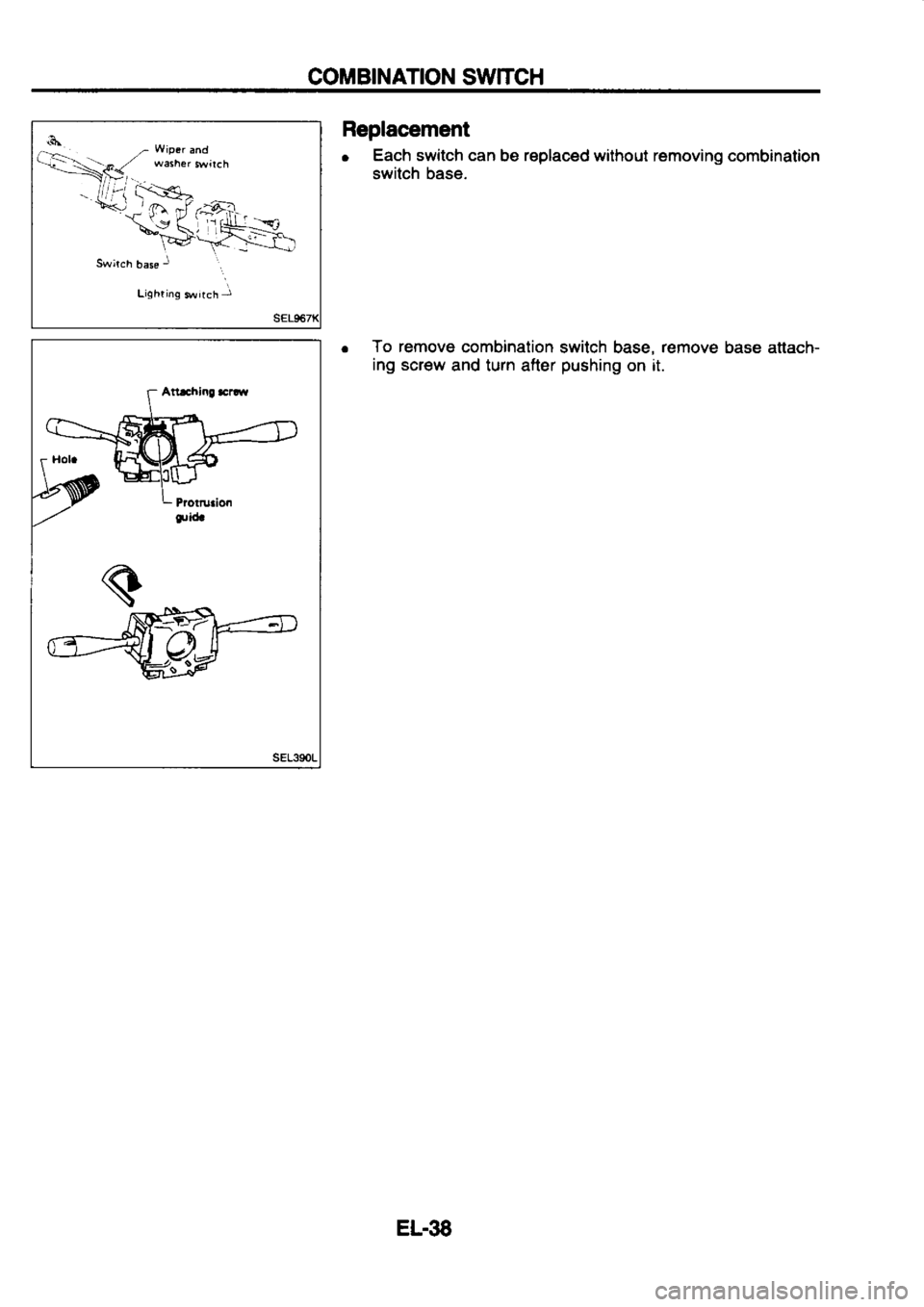

COMBINATION

SWTCH

SEL39OL Replacement

o Each

switch can

be replaced

without removing combination

switch base.

r To

remove

combination switch base, remove

base anach-

ing screw

and turn after pushing

on rt.

EL.38

Page 1150 of 1254

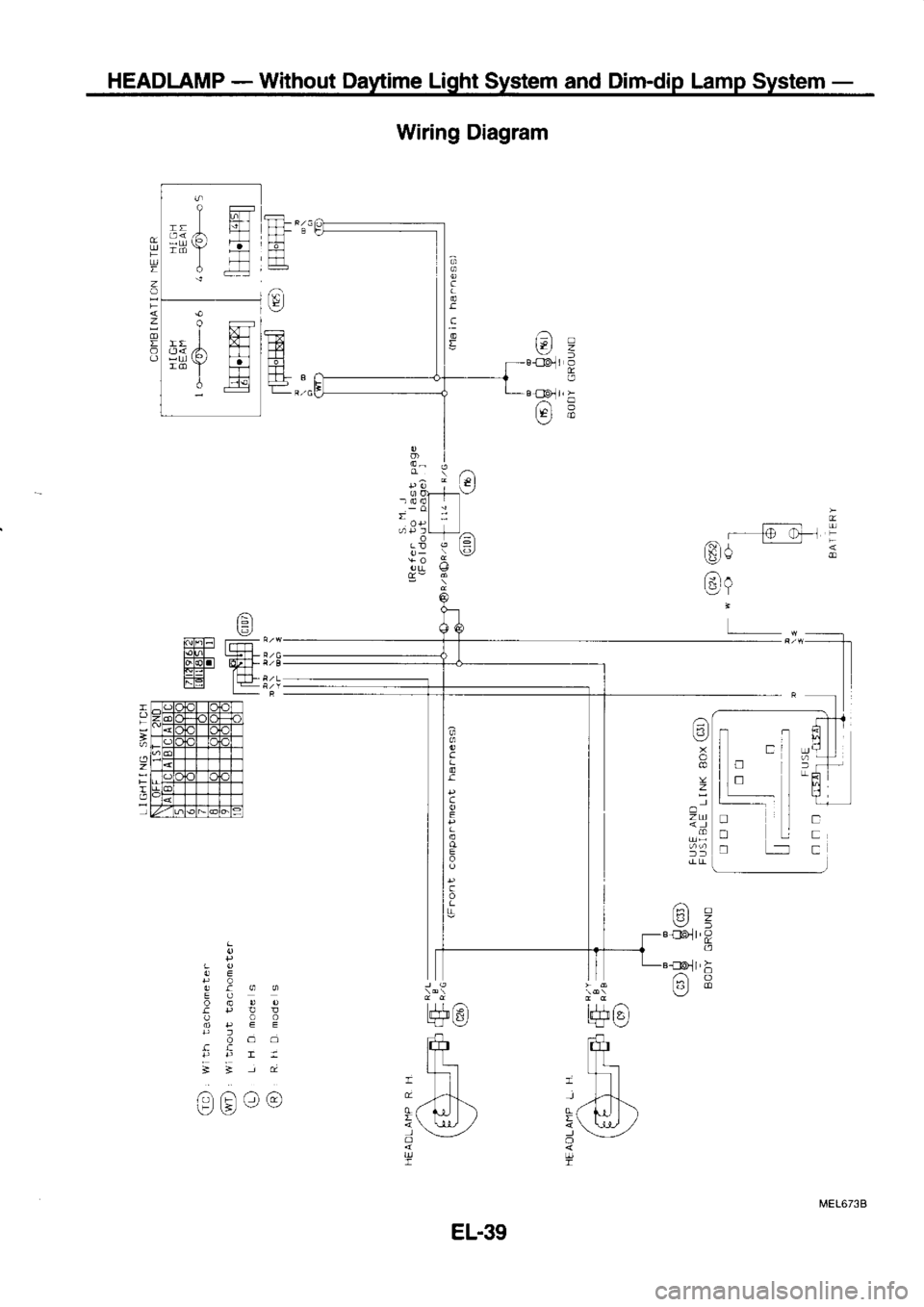

HEADLAMP

-

Without Daytime Light

System and Dim-dip

Lamp System -

ttf

ffi

T.-l

m

G

= ffii

ff-l

E

L Wiring

Diagram

I /-:\

qtrLdl

t=

t-:J!.ll= rT_-

m q4+

L

[-/

z

=

o

ztx

.o11' A

@E

/-,

-

lEl z

aolr, ?

a

al

6i rA r-l 6\

!-rtrr"" tP

q+

1+ +

rf rJl

" --1-tf- '

--.1-t+.

9( t.A.r ) g(

ur )

; \-r-{-/

/ ;

\ll,

,/

3 v

d '\-,--l

fiff II

EL.39

Trending: fuel cap, oil reset, radiator, length, charging, turn signal bulb, wiper blades