ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2986 of 5121

REAR SUNSHADE SWITCH

INT-9

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

INT

N

O

P

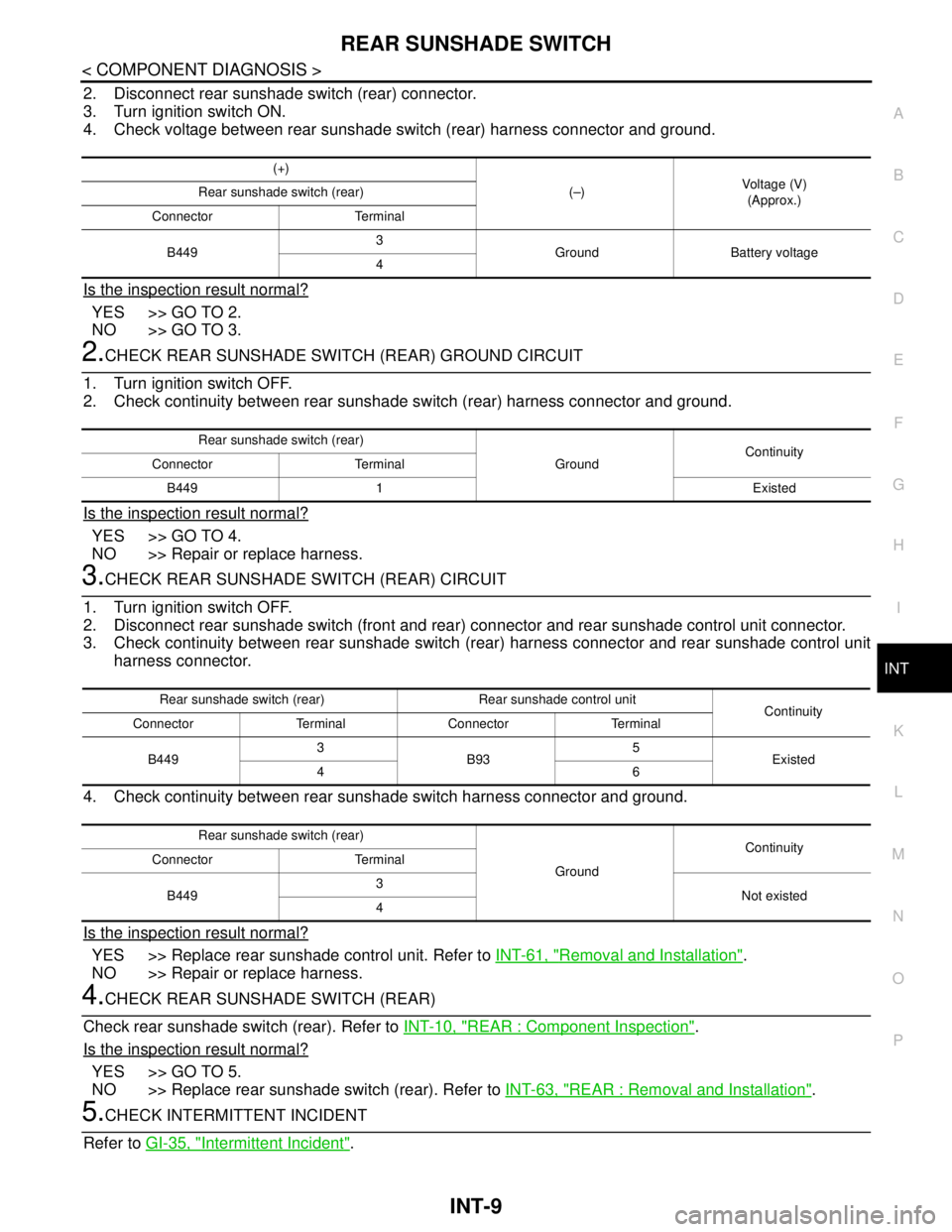

2. Disconnect rear sunshade switch (rear) connector.

3. Turn ignition switch ON.

4. Check voltage between rear sunshade switch (rear) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK REAR SUNSHADE SWITCH (REAR) GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between rear sunshade switch (rear) harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

3.CHECK REAR SUNSHADE SWITCH (REAR) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear sunshade switch (front and rear) connector and rear sunshade control unit connector.

3. Check continuity between rear sunshade switch (rear) harness connector and rear sunshade control unit

harness connector.

4. Check continuity between rear sunshade switch harness connector and ground.

Is the inspection result normal?

YES >> Replace rear sunshade control unit. Refer to INT-61, "Removal and Installation".

NO >> Repair or replace harness.

4.CHECK REAR SUNSHADE SWITCH (REAR)

Check rear sunshade switch (rear). Refer to INT-10, "

REAR : Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace rear sunshade switch (rear). Refer to INT-63, "

REAR : Removal and Installation".

5.CHECK INTERMITTENT INCIDENT

Refer to GI-35, "

Intermittent Incident".

(+)

(–)Voltage (V)

(Approx.) Rear sunshade switch (rear)

Connector Terminal

B4493

Ground Battery voltage

4

Rear sunshade switch (rear)

GroundContinuity

Connector Terminal

B449 1 Existed

Rear sunshade switch (rear) Rear sunshade control unit

Continuity

Connector Terminal Connector Terminal

B4493

B935

Existed

46

Rear sunshade switch (rear)

GroundContinuity

Connector Terminal

B4493

Not existed

4

Page 2987 of 5121

INT-10

< COMPONENT DIAGNOSIS >

REAR SUNSHADE SWITCH

>> INSPECTION END

REAR : Component InspectionINFOID:0000000003819274

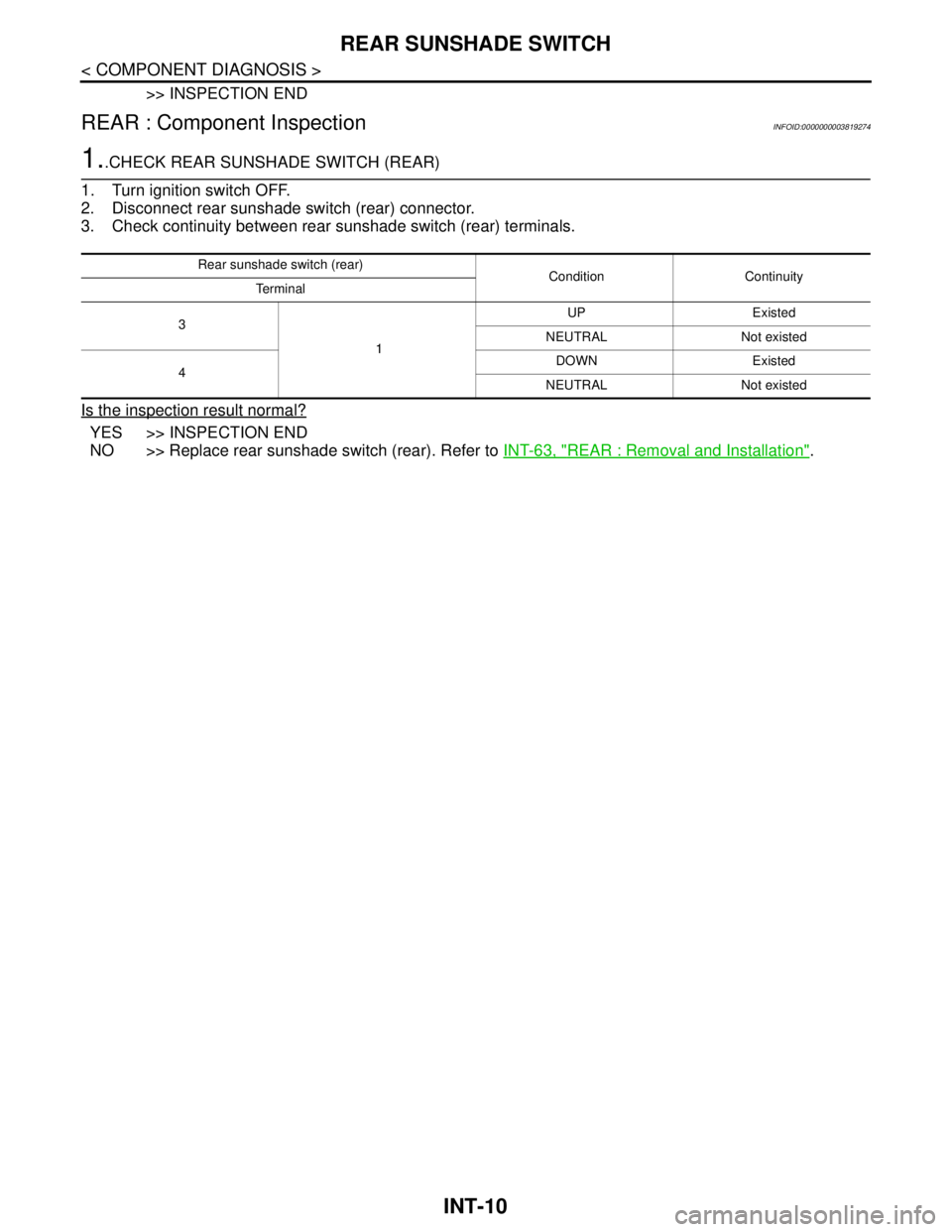

1..CHECK REAR SUNSHADE SWITCH (REAR)

1. Turn ignition switch OFF.

2. Disconnect rear sunshade switch (rear) connector.

3. Check continuity between rear sunshade switch (rear) terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace rear sunshade switch (rear). Refer to INT-63, "

REAR : Removal and Installation".

Rear sunshade switch (rear)

Condition Continuity

Te r m i n a l

3

1UP Existed

NEUTRAL Not existed

4DOWN Existed

NEUTRAL Not existed

Page 2988 of 5121

REAR SUNSHADE MOTOR

INT-11

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

INT

N

O

P

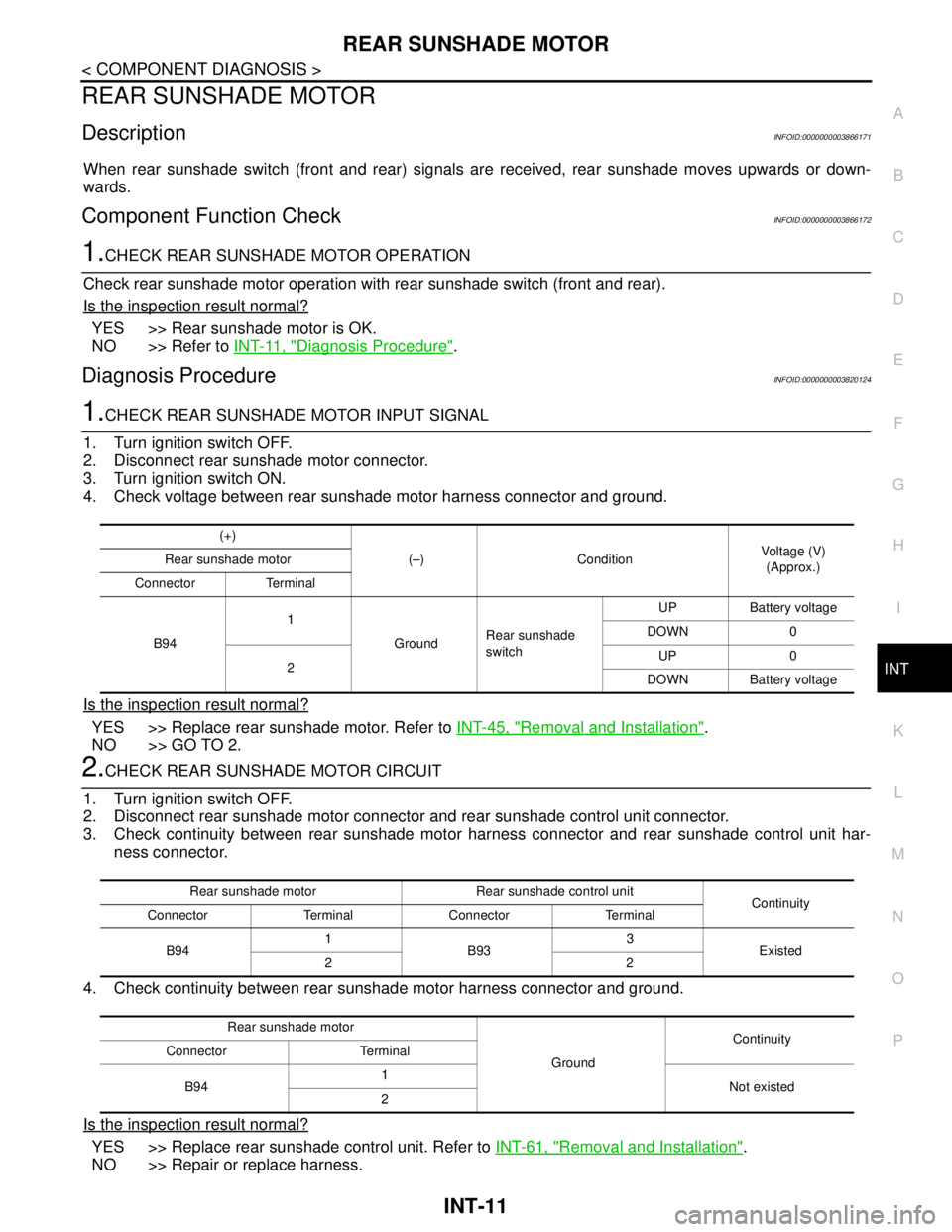

REAR SUNSHADE MOTOR

DescriptionINFOID:0000000003866171

When rear sunshade switch (front and rear) signals are received, rear sunshade moves upwards or down-

wards.

Component Function CheckINFOID:0000000003866172

1.CHECK REAR SUNSHADE MOTOR OPERATION

Check rear sunshade motor operation with rear sunshade switch (front and rear).

Is the inspection result normal?

YES >> Rear sunshade motor is OK.

NO >> Refer to INT-11, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003820124

1.CHECK REAR SUNSHADE MOTOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear sunshade motor connector.

3. Turn ignition switch ON.

4. Check voltage between rear sunshade motor harness connector and ground.

Is the inspection result normal?

YES >> Replace rear sunshade motor. Refer to INT-45, "Removal and Installation".

NO >> GO TO 2.

2.CHECK REAR SUNSHADE MOTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear sunshade motor connector and rear sunshade control unit connector.

3. Check continuity between rear sunshade motor harness connector and rear sunshade control unit har-

ness connector.

4. Check continuity between rear sunshade motor harness connector and ground.

Is the inspection result normal?

YES >> Replace rear sunshade control unit. Refer to INT-61, "Removal and Installation".

NO >> Repair or replace harness.

(+)

(–) ConditionVoltage (V)

(Approx.) Rear sunshade motor

Connector Terminal

B941

GroundRear sunshade

switchUP Battery voltage

DOWN 0

2UP 0

DOWN Battery voltage

Rear sunshade motor Rear sunshade control unit

Continuity

Connector Terminal Connector Terminal

B941

B933

Existed

22

Rear sunshade motor

GroundContinuity

Connector Terminal

B941

Not existed

2

Page 2989 of 5121

INT-12

< COMPONENT DIAGNOSIS >

REVERSE SIGNAL CIRCUIT

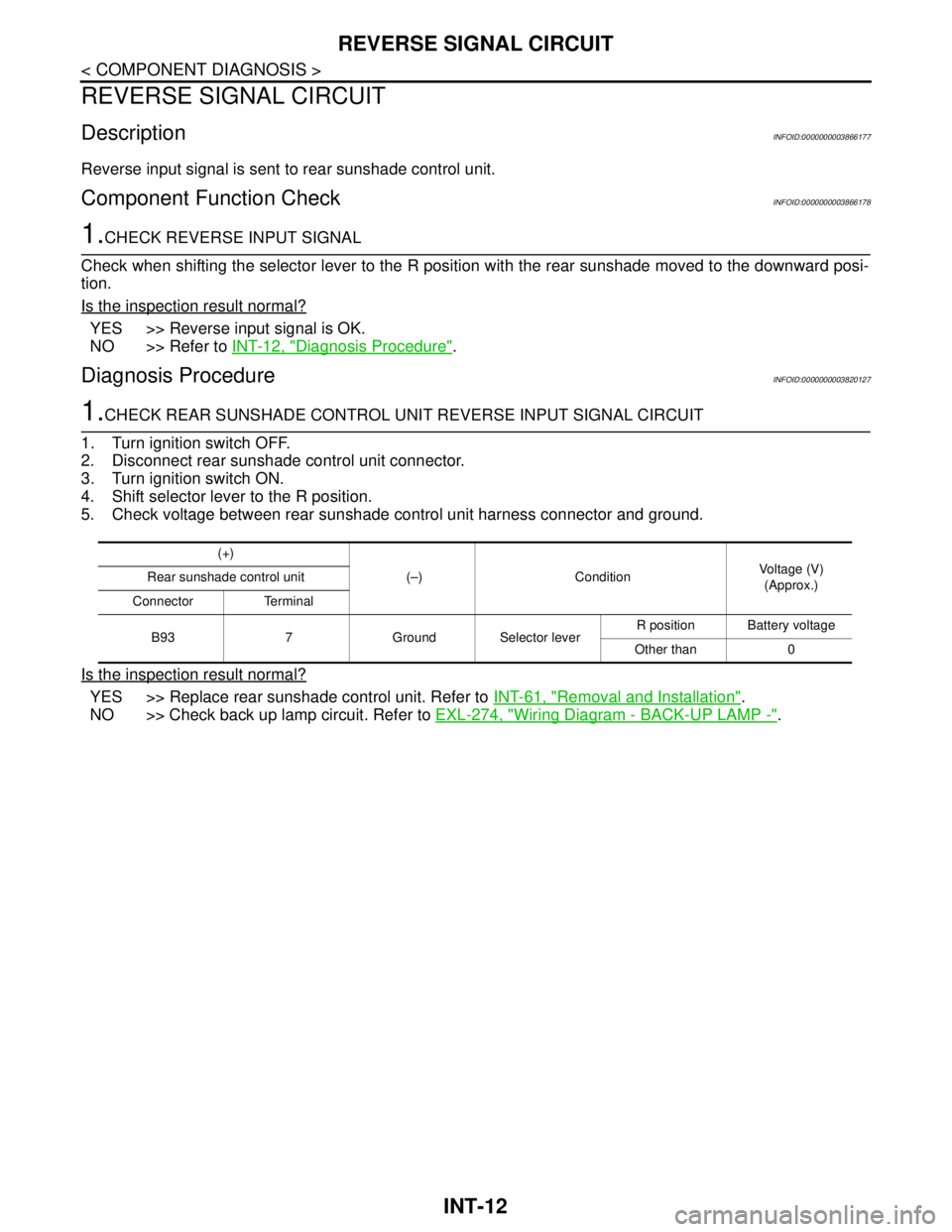

REVERSE SIGNAL CIRCUIT

DescriptionINFOID:0000000003866177

Reverse input signal is sent to rear sunshade control unit.

Component Function CheckINFOID:0000000003866178

1.CHECK REVERSE INPUT SIGNAL

Check when shifting the selector lever to the R position with the rear sunshade moved to the downward posi-

tion.

Is the inspection result normal?

YES >> Reverse input signal is OK.

NO >> Refer to INT-12, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003820127

1.CHECK REAR SUNSHADE CONTROL UNIT REVERSE INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear sunshade control unit connector.

3. Turn ignition switch ON.

4. Shift selector lever to the R position.

5. Check voltage between rear sunshade control unit harness connector and ground.

Is the inspection result normal?

YES >> Replace rear sunshade control unit. Refer to INT-61, "Removal and Installation".

NO >> Check back up lamp circuit. Refer to EXL-274, "

Wiring Diagram - BACK-UP LAMP -".

(+)

(–) ConditionVoltage (V)

(Approx.) Rear sunshade control unit

Connector Terminal

B93 7 Ground Selector leverR position Battery voltage

Other than 0

Page 2990 of 5121

REAR SUNSHADE CONTROL UNIT

INT-13

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

INT

N

O

P

ECU DIAGNOSIS

REAR SUNSHADE CONTROL UNIT

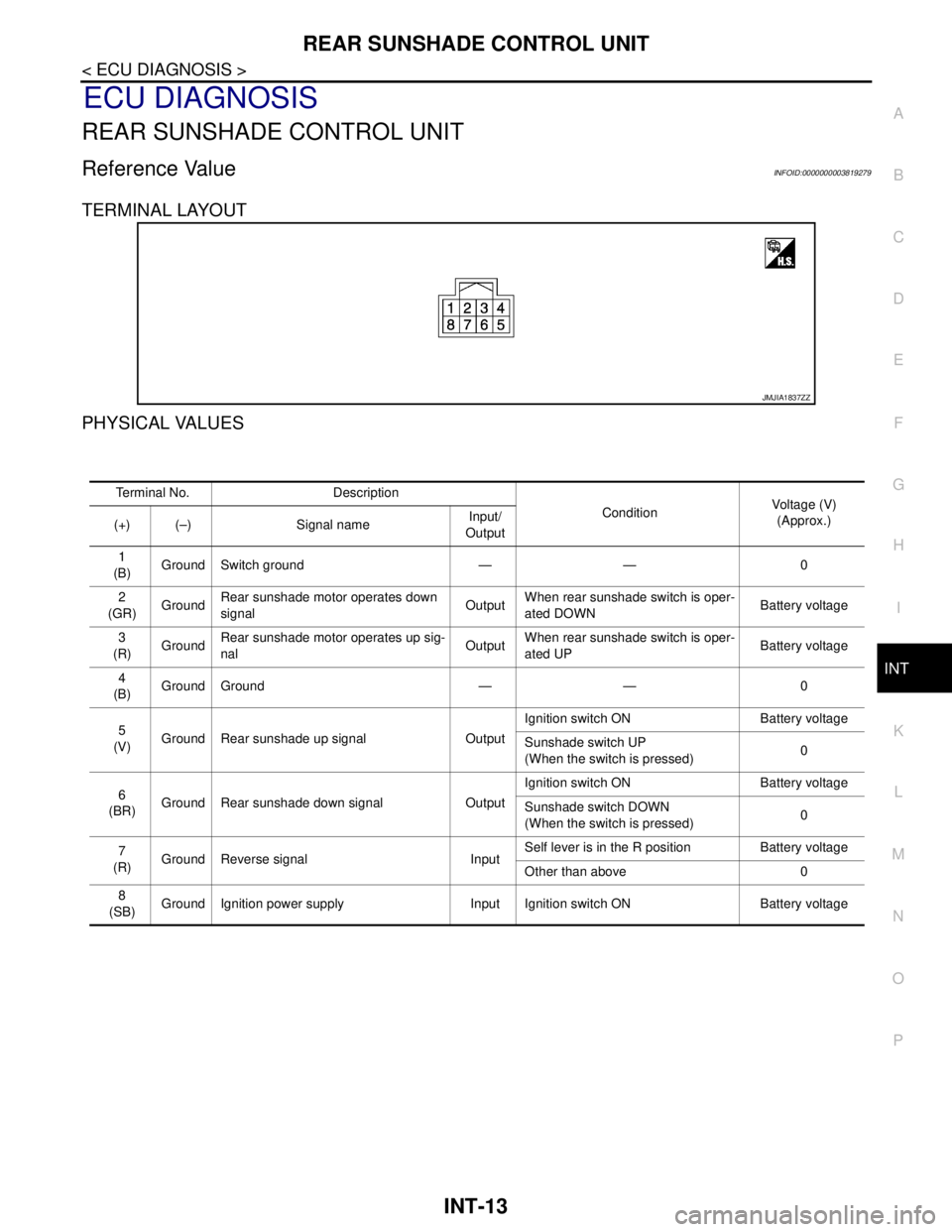

Reference ValueINFOID:0000000003819279

TERMINAL LAYOUT

PHYSICAL VALUES

JMJIA1837ZZ

Terminal No. Description

ConditionVoltage (V)

(Approx.)

(+) (–) Signal nameInput/

Output

1

(B)Ground Switch ground — — 0

2

(GR)GroundRear sunshade motor operates down

signalOutputWhen rear sunshade switch is oper-

ated DOWNBattery voltage

3

(R)GroundRear sunshade motor operates up sig-

nalOutputWhen rear sunshade switch is oper-

ated UPBattery voltage

4

(B)Ground Ground — — 0

5

(V)Ground Rear sunshade up signal OutputIgnition switch ON Battery voltage

Sunshade switch UP

(When the switch is pressed)0

6

(BR)Ground Rear sunshade down signal OutputIgnition switch ON Battery voltage

Sunshade switch DOWN

(When the switch is pressed)0

7

(R)Ground Reverse signal InputSelf lever is in the R position Battery voltage

Other than above 0

8

(SB)Ground Ignition power supply Input Ignition switch ON Battery voltage

Page 3004 of 5121

PRECAUTIONS

INT-27

< PRECAUTION >

C

D

E

F

G

H

I

K

L

MA

B

INT

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003819210

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIRBAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003819211

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Page 3048 of 5121

IP-8

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003819818

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003819825

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

PrecautionINFOID:0000000003751401

Disconnect both battery cables in advance.

Disconnect air bag system line in advance.

Never tamper with or force air bag lid open, as this may adversely affect air bag performance.

Be careful not to scratch pad and other parts.

When removing or disassembling any part, be careful not to damage or deform it. Protect parts, which may

get in the way with a shop cloth.

When removing parts with a screwdriver or other tool, cover the tool surface by vinyl tape to protect parts.

Page 3052 of 5121

IP-12

< ON-VEHICLE REPAIR >

INSTRUMENT PANEL ASSEMBLY

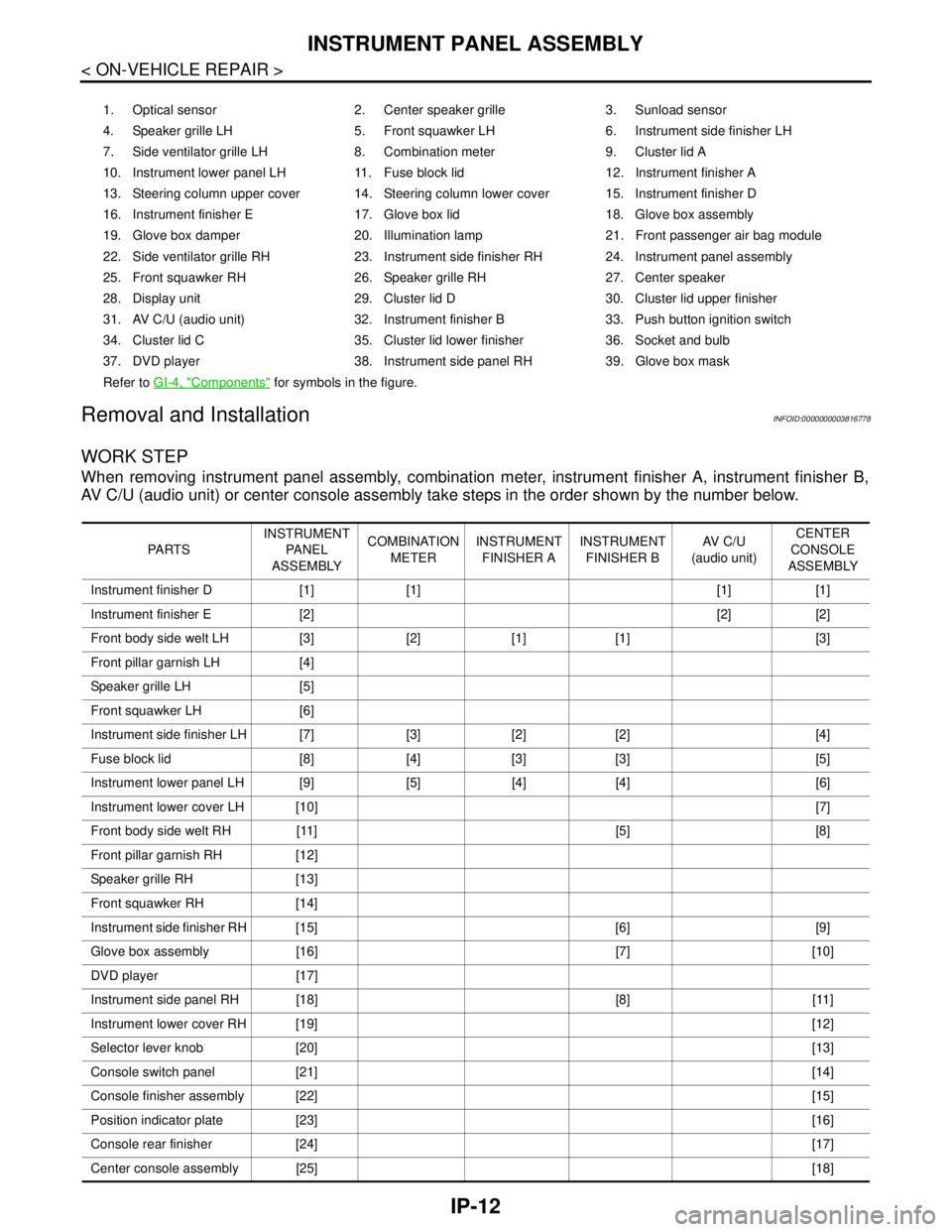

Removal and Installation

INFOID:0000000003816778

WORK STEP

When removing instrument panel assembly, combination meter, instrument finisher A, instrument finisher B,

AV C/U (audio unit) or center console assembly take steps in the order shown by the number below.

1. Optical sensor 2. Center speaker grille 3. Sunload sensor

4. Speaker grille LH 5. Front squawker LH 6. Instrument side finisher LH

7. Side ventilator grille LH 8. Combination meter 9. Cluster lid A

10. Instrument lower panel LH 11. Fuse block lid 12. Instrument finisher A

13. Steering column upper cover 14. Steering column lower cover 15. Instrument finisher D

16. Instrument finisher E 17. Glove box lid 18. Glove box assembly

19. Glove box damper 20. Illumination lamp 21. Front passenger air bag module

22. Side ventilator grille RH 23. Instrument side finisher RH 24. Instrument panel assembly

25. Front squawker RH 26. Speaker grille RH 27. Center speaker

28. Display unit 29. Cluster lid D 30. Cluster lid upper finisher

31. AV C/U (audio unit) 32. Instrument finisher B 33. Push button ignition switch

34. Cluster lid C 35. Cluster lid lower finisher 36. Socket and bulb

37. DVD player 38. Instrument side panel RH 39. Glove box mask

Refer to GI-4, "

Components" for symbols in the figure.

PA R T SINSTRUMENT

PA N E L

ASSEMBLYCOMBINATION

METERINSTRUMENT

FINISHER AINSTRUMENT

FINISHER BAV C / U

(audio unit)CENTER

CONSOLE

ASSEMBLY

Instrument finisher D [1] [1] [1] [1]

Instrument finisher E [2] [2] [2]

Front body side welt LH [3] [2] [1] [1] [3]

Front pillar garnish LH [4]

Speaker grille LH [5]

Front squawker LH [6]

Instrument side finisher LH [7] [3] [2] [2] [4]

Fuse block lid [8] [4] [3] [3] [5]

Instrument lower panel LH [9] [5] [4] [4] [6]

Instrument lower cover LH [10][7]

Front body side welt RH [11] [5] [8]

Front pillar garnish RH [12]

Speaker grille RH [13]

Front squawker RH [14]

Instrument side finisher RH [15] [6] [9]

Glove box assembly [16] [7] [10]

DVD player [17]

Instrument side panel RH [18] [8] [11]

Instrument lower cover RH [19][12]

Selector lever knob [20][13]

Console switch panel [21][14]

Console finisher assembly [22][15]

Position indicator plate [23][16]

Console rear finisher [24][17]

Center console assembly [25][18]

Page 3053 of 5121

![NISSAN TEANA 2008 Service Manual INSTRUMENT PANEL ASSEMBLY

IP-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

[ ]: Number indicates step in removal procedures.

REMOVAL

1. Remove instrument finisher D.

Remove instrument fi NISSAN TEANA 2008 Service Manual INSTRUMENT PANEL ASSEMBLY

IP-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

[ ]: Number indicates step in removal procedures.

REMOVAL

1. Remove instrument finisher D.

Remove instrument fi](/img/5/57391/w960_57391-3052.png)

INSTRUMENT PANEL ASSEMBLY

IP-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

[ ]: Number indicates step in removal procedures.

REMOVAL

1. Remove instrument finisher D.

Remove instrument finisher D (1) fixing clips with remover tool

(A).

Pull back instrument finisher D, and then remove instrument

finisher D.

2. Remove instrument finisher E.

Remove instrument finisher E (1) fixing clips with remover tool

(A).

Pull back instrument finisher E, and then remove instrument

finisher E.

3. Remove front body side welt LH. Refer to INT-39, "

Removal and Installation".

4. Remove front pillar garnish LH. Refer to INT-39, "

Removal and Installation".

Steering wheel [26]

Steering column cover [27] [6] [9]

Combination switch [28] [7] [10]

Spiral cable [29]

Instrument finisher A [30] [8] [5] [11]

Cluster lid A [31] [9] [12]

Combination meter [32] [10]

Cluster lid D [33]

Push button ignition switch [34] [13]

Cluster lid lower finisher [35] [14]

Cluster lid C [36] [15]

Instrument finisher B [16]

AV C/U (audio unit) [37] [3]

Display unit [38]

Center speaker grille [39]

Center speaker [40]

Instrument panel assembly [41]

: Clip

JMJIA1892ZZ

: Clip

JMJIA1893ZZ

Page 3059 of 5121

INSTRUMENT PANEL ASSEMBLY

IP-19

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

K

L

MA

B

IP

N

O

P

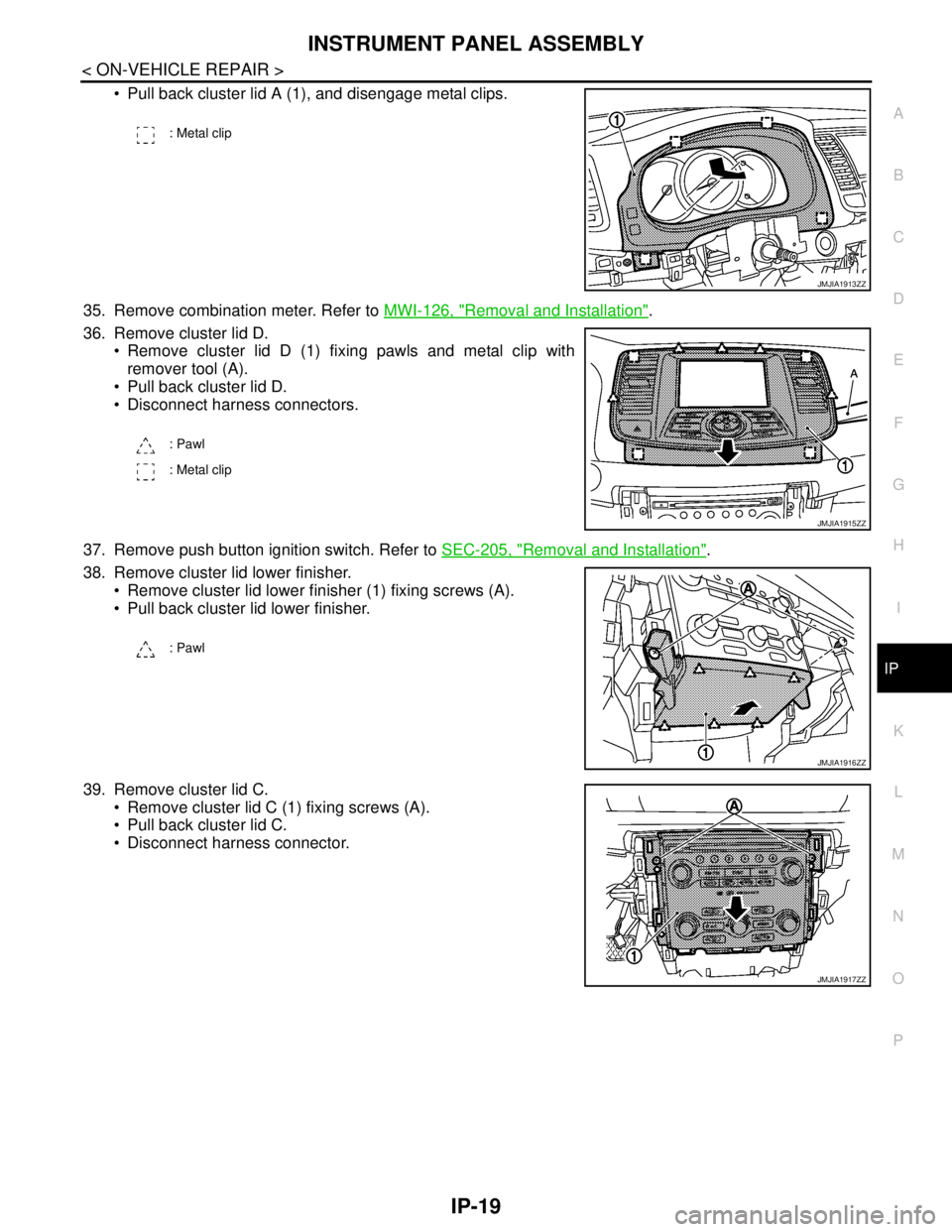

Pull back cluster lid A (1), and disengage metal clips.

35. Remove combination meter. Refer to MWI-126, "

Removal and Installation".

36. Remove cluster lid D.

Remove cluster lid D (1) fixing pawls and metal clip with

remover tool (A).

Pull back cluster lid D.

Disconnect harness connectors.

37. Remove push button ignition switch. Refer to SEC-205, "

Removal and Installation".

38. Remove cluster lid lower finisher.

Remove cluster lid lower finisher (1) fixing screws (A).

Pull back cluster lid lower finisher.

39. Remove cluster lid C.

Remove cluster lid C (1) fixing screws (A).

Pull back cluster lid C.

Disconnect harness connector.

: Metal clip

JMJIA1913ZZ

: Pawl

: Metal clip

JMJIA1915ZZ

: Pawl

JMJIA1916ZZ

JMJIA1917ZZ