display NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4748 of 5121

![NISSAN TEANA 2008 Service Manual TCM

TM-275

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

ECU DIAGNOSIS

TCM

Reference ValueINFOID:0000000003806487

VALUES ON THE DIAGNOSIS TOOL

Item name Condition Display value (App NISSAN TEANA 2008 Service Manual TCM

TM-275

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

ECU DIAGNOSIS

TCM

Reference ValueINFOID:0000000003806487

VALUES ON THE DIAGNOSIS TOOL

Item name Condition Display value (App](/img/5/57391/w960_57391-4747.png)

TCM

TM-275

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

ECU DIAGNOSIS

TCM

Reference ValueINFOID:0000000003806487

VALUES ON THE DIAGNOSIS TOOL

Item name Condition Display value (Approx.)

VSP SENSOR During drivingApproximately matches the speedometer

reading.

ESTM VSP SIG During drivingApproximately matches the speedometer

reading.

PRI SPEED SEN During driving (lock-up ON) Approximately matches the engine speed.

ENG SPEED SIG Engine running Closely matches the tachometer reading.

SEC HYDR SEN “N” position idle 1.0 V

PRI HYDR SEN “N” position idle 0.7 – 3.5 V

ATF TEMP SEN*When CVT fluid temperature is 20°C (68°F) 2.0 V

When CVT fluid temperature is 80°C (176°F) 1.0 V

VIGN SEN Ignition switch: ON Battery voltage

VEHICLE SPEED During drivingApproximately matches the speedometer

reading.

PRI SPEED During driving (lock-up ON) Approximately matches the engine speed.

SEC SPEED During driving45 X Approximately matches the speedom-

eter reading.

ENG SPEED Engine running Closely matches the tachometer reading.

GEAR RATIO During driving 2.34 – 0.39

ACC PEDAL OPENReleased accelerator pedal - Fully depressed acceler-

ator pedal0.0/8 – 8.0/8

SEC PRESS “N” position idle 1.3 MPa

STM STEP During driving−20 step – 190 step

ISOLT1Lock-up “OFF” 0.0 A

Lock-up “ON” 0.7 A

ISOLT2Release foot from the accelerator pedal. 0.8 A

Press the accelerator pedal all the way down. 0.0 A

ISOLT3 Secondary pressure low - Secondary pressure high 0.8 – 0.0 A

SOLMON1Lock-up “OFF” 0.0 A

Lock-up “ON” 0.7 A

SOLMON2“N” position idle 0.8 A

When stalled 0.3 – 0.6 A

SOLMON3“N” position idle 0.6 – 0.7 A

When stalled 0.4 – 0.6 A

P POSITION SWSelector lever in “P” position On

Other than the above position. Off

R POSITION SWSelector lever in “R” position On

Other than the above position. Off

N POSITION SWSelector lever in “N“ position On

Other than the above position. Off

Page 4749 of 5121

![NISSAN TEANA 2008 Service Manual TM-276

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

*Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-301, "ATFTEMP COUNT

Conversion Table".

TERMINAL LA NISSAN TEANA 2008 Service Manual TM-276

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

*Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-301, "ATFTEMP COUNT

Conversion Table".

TERMINAL LA](/img/5/57391/w960_57391-4748.png)

TM-276

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

*Means CVT fluid temperature. Convert numerical values for actual fluid temperature °C (°F). Refer to TM-301, "ATFTEMP COUNT

Conversion Table".

TERMINAL LAYOUT

D POSITION SWSelector lever in “D” position On

Other than the above position. Off

L POSITION SWSelector lever in “L” position On

Other than the above position. Off

BRAKE SWDepressed brake pedal On

Released brake pedal Off

FULL SWFully depressed accelerator pedal On

Released accelerator pedal Off

IDLE SWReleased accelerator pedal On

Fully depressed accelerator pedal Off

SPORT MODE SWWhile pushing sport mode switch On

Other conditions Off

INDLRNGSelector lever in “L” position On

When setting selector lever to other positions. Off

INDDRNGSelector lever in “D” position On

When setting selector lever to other positions. Off

INDNRNGSelector lever in “N“ position On

When setting selector lever to other positions. Off

INDRRNGSelector lever in “R” position On

When setting selector lever to other positions. Off

INDPRNGSelector lever in “P” position On

When setting selector lever to other positions. Off

SPORT MODE INDWhen sport mode On

Other conditions Off

SMCOIL A During driving Changes On ⇔ Off.

SMCOIL B During driving Changes On ⇔ Off.

SMCOIL C During driving Changes On ⇔ Off.

SMCOIL D During driving Changes On ⇔ Off.

LUSEL SOL OUTSelector lever in “P” and “N” positions On

Wait at least for 5 seconds with the selector lever in “R”

and “D” positionsOff

LUSEL SOL MONSelector lever in “P” and “N” positions On

Wait at least for 5 seconds with the selector lever in “R”

and “D” positionsOff

ABS ONABS operate On

Other conditions Off

RANGESelector lever in “N” and “P” position N·P

Selector lever in “R” position R

Selector lever in “D” position D

Selector lever in “L” position L Item name Condition Display value (Approx.)

Page 4757 of 5121

![NISSAN TEANA 2008 Service Manual TM-284

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

Output Speed Sensor (Secondary Speed Sensor)

The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

out NISSAN TEANA 2008 Service Manual TM-284

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

Output Speed Sensor (Secondary Speed Sensor)

The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

out](/img/5/57391/w960_57391-4756.png)

TM-284

< ECU DIAGNOSIS >[CVT: RE0F10A]

TCM

Output Speed Sensor (Secondary Speed Sensor)

The shift pattern is changed in accordance with throttle position when an unexpected signal is sent from the

output speed sensor (secondary speed sensor) to the TCM. The manual mode is inhibited, and the transaxle

is put in “D”.

Input Speed Sensor (Primary Speed Sensor)

The shift pattern is changed in accordance with throttle position and secondary speed (vehicle speed) when

an unexpected signal is sent from the input speed sensor (primary speed sensor) to the TCM. The manual

mode is inhibited, and the transaxle is put in “D”.

PNP Switch

If an unexpected signal is sent from the PNP switch to the TCM, the transaxle is put in “D”.

CVT Fluid Temperature Sensor

If an unexpected signal is sent from the CVT fluid temperature sensor to the TCM, the gear ratio in use before

receiving the unexpected signal is maintained or the gear ratio is controlled to keep engine speed under 5000

rpm.

Transmission Fluid Pressure Sensor A (Secondary Pressure Sensor)

If an unexpected signal is sent from the transmission fluid pressure sensor A (secondary pressure sensor) to

the TCM, the secondary pressure feedback control is stopped and the offset value obtained before the non-

standard condition occurs is used to control line pressure.

If transmission fluid pressure sensor A (secondary pressure sensor) error signal is input to TCM, secondary

pressure feedback control stops, but line pressure is controlled normally.

Pressure Control Solenoid A (Line Pressure Solenoid valve)

If an unexpected signal is sent from the solenoid to the TCM, the pressure control solenoid A (line pressure

solenoid valve) is turned OFF to achieve the maximum fluid pressure.

Pressure Control Solenoid B (Secondary Pressure Solenoid valve)

If an unexpected signal is sent from the solenoid to the TCM, the pressure control solenoid B (secondary pres-

sure solenoid valve) is turned OFF to achieve the maximum fluid pressure.

Torque Converter Clutch Solenoid valve

If an unexpected signal is sent from the solenoid to the TCM, the torque converter clutch solenoid valve is

turned OFF to cancel the lock-up.

Step Motor

If an unexpected signal is sent from the step motor to the TCM, the step motor coil phases “A” through “D” are

all turned OFF to hold the gear ratio used just before the non-standard condition occurred.

CVT Lock-up Select Solenoid valve

If an unexpected signal is sent from the solenoid to the TCM, the CVT lock-up select solenoid valve is turned

OFF to cancel the lock-up.

TCM Power Supply (Memory Back-up)

Transaxle assembly is protected by limiting the engine torque when the memory back-up power supply (for

controlling) from the battery is not supplied to TCM. Normal status is restored when turning the ignition switch

OFF to ON after the normal power supply.

DTC Inspection Priority ChartINFOID:0000000003806490

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to TM-208

.

DTC IndexINFOID:0000000003806491

NOTE:

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 4758 of 5121

![NISSAN TEANA 2008 Service Manual TCM

TM-285

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN CO NISSAN TEANA 2008 Service Manual TCM

TM-285

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN CO](/img/5/57391/w960_57391-4757.png)

TCM

TM-285

< ECU DIAGNOSIS >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

If DTC “U1000 CAN COMM CIRCUIT” is displayed with other DTCs, first perform the trouble diagnosis

for “DTC U1000 CAN COMMUNICATION LINE”. Refer to TM-208

.

*1: These numbers are prescribed by ISO 15031-6.

*2: Refer to TM-202, "

Diagnosis Description". DTC

*1

Items

(CONSULT-III screen terms)Reference MI*2, “ENGINE” with

CONSULT-III or

GSTCONSULT-III only

“TRANSMISSION”

— P0703 BRAKE SW/CIRCTM-210

P0705 P0705 PNP SW/CIRCTM-213

P0710 P0710 ATF TEMP SEN/CIRCTM-216

P0715 P0715 INPUT SPD SEN/CIRCTM-218

P0720 P0720 VEH SPD SEN/CIR ATTM-222

— P0725 ENGINE SPEED SIGTM-226

— P0730 BELT DAMGTM-228

P0740 P0740 TCC SOLENOID/CIRCTM-230

P0744 P0744 A/T TCC S/V FNCTNTM-232

P0745 P0745 L/PRESS SOL/CIRCTM-234

P0746 P0746 PRS CNT SOL/A FCTNTM-236

P0776 P0776 PRS CNT SOL/B FCTNTM-238

P0778 P0778 PRS CNT SOL/B CIRCTM-240

P0840 P0840 TR PRS SENS/A CIRCTM-242

— P0841 PRESS SEN/FNCTNTM-245

— P0868 SEC/PRESS DOWNTM-247

— P1701 TCM-POWER SUPPLYTM-249

— P1705 TP SEN/CIRC A/TTM-252

— P1722 ESTM VEH SPD SIGTM-253

— P1723 CVT SPD SEN/FNCTNTM-255

— P1726 ELEC TH CONTROLTM-257

P1740 P1740 LU-SLCT SOL/CIRCTM-258

— P1745 L/PRESS CONTROLTM-260

P1777 P1777 STEP MOTR CIRCTM-261

P1778 P1778 STEP MOTR/FNCTM-264

U1000 U1000 CAN COMM CIRCUITTM-208

— U1010 CONTROL UNIT (CAN)TM-209

Page 4773 of 5121

![NISSAN TEANA 2008 Service Manual TM-300

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Turn ignition switch OFF and disconnect negative battery

cable before connecting or disconnecting the TCM harness

connector. Because battery voltage is NISSAN TEANA 2008 Service Manual TM-300

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Turn ignition switch OFF and disconnect negative battery

cable before connecting or disconnecting the TCM harness

connector. Because battery voltage is](/img/5/57391/w960_57391-4772.png)

TM-300

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Turn ignition switch OFF and disconnect negative battery

cable before connecting or disconnecting the TCM harness

connector. Because battery voltage is applied to TCM even if

ignition switch is turned OFF.

When connecting or disconnecting pin connectors into or

from TCM, do not damage pin terminals (bend or break).

Check that there are not any bends or breaks on TCM pin ter-

minal, when connecting pin connectors.

Perform TCM input/output signal inspection and check

whether TCM functions normally or not before replacing TCM.

Refer to TM-275, "

Reference Value".

Perform “DTC Confirmation Procedure” after performing each

TROUBLE DIAGNOSIS.

If the repair is completed the DTC should not be displayed in

the “DTC Confirmation Procedure”.

Always use the specified brand of CVT fluid. Refer to MA-11, "

Flu-

ids and Lubricants".

Use lint-free paper, not cloth rags, during work.

Dispose of the waste oil using the methods prescribed by law, ordi-

nance, etc. after replacing the CVT fluid.

Service Notice or PrecautionINFOID:0000000003806500

OBD SELF-DIAGNOSIS

CVT self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the Malfunction Indicator (MI). Refer to the table on TM-204, "

CONSULT-III Function

(TRANSMISSION)" for the indicator used to display each self-diagnostic result.

The self-diagnostic results indicated by the MI are automatically stored in both the ECM and TCM memories.

Always perform the procedure on TM-202, "

Diagnosis Description" to complete the repair and avoid

unnecessary blinking of the MIL.

For details of OBD, refer to EC-102, "

Diagnosis Description".

SEF289H

SEF291H

MEF040DA

SAT652J

Page 4783 of 5121

![NISSAN TEANA 2008 Service Manual TM-310

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

ROAD TEST

ROAD TEST

DescriptionINFOID:0000000003806508

DESCRIPTION

The purpose of the test is to determine the overall performance of

CVT and analyze NISSAN TEANA 2008 Service Manual TM-310

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

ROAD TEST

ROAD TEST

DescriptionINFOID:0000000003806508

DESCRIPTION

The purpose of the test is to determine the overall performance of

CVT and analyze](/img/5/57391/w960_57391-4782.png)

TM-310

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

ROAD TEST

ROAD TEST

DescriptionINFOID:0000000003806508

DESCRIPTION

The purpose of the test is to determine the overall performance of

CVT and analyze causes of problems.

The road test consists of the following three parts:

1. “Check Before Engine Is Started” TM-310

.

2. “Check at Idle” TM-311

.

3. “Cruise Test” TM-312

.

Before the road test, familiarize yourself with all test procedures

and items to check.

Perform tests for all the check items until a malfunction phenome-

non is detected. Perform diagnosis for NG items after the comple-

tion of road tests.

CONSULT-III SETTING PROCEDURE

Using CONSULT-III, perform a cruise test and record the result.

Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “Data Monitor” on “Direct Diagnostic Mode” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to TM-312, "

Cruise Test".

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out.

Check before Engine Is StartedINFOID:0000000003806509

1.CHECK SHIFT POSITION INDICATOR

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Never start engine.)

Has shift position indicator been turned ON for about 2 seconds?

YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.

Refer to TM-204, "

CONSULT-III Function (TRANSMISSION)".

3. Go to TM-311, "

Check at Idle".

SAT786A

SAT496G

Page 4812 of 5121

VTL-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION VTL

A

B

VTL

N

O P

CONTENTS

VENTILATION SYSTEM

WITHOUT 7 INCH DISPLAY

FUNCTION DIAGNOSIS .. .............................

5

SWITCHES AND THEIR CONTROL FUNC-

TION ............................................................... .....

5

System Description ............................................. ......5

AIR DISTRIBUTION ............................................6

System Description ............................................. ......6

PRECAUTION ...............................................7

PRECAUTIONS .............................................. .....7

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

7

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

7

Precaution for Procedure without Cowl Top Cover ......8

Precautions For Xenon Headlamp Service ...............8

Working with HFC-134a (R-134a) .............................8

General Refrigerant Precaution ................................8

Refrigerant Connection .............................................9

Service Equipment ..................................................11

COMPRESSOR .............................................. ....14

General Precautions ........................................... ....14

FLUORESCENT LEAK DETECTOR .................15

General Precautions ........................................... ....15

PREPARATION ...........................................16

PREPARATION .............................................. ....16

Special Service Tool ........................................... ....16

Commercial Service Tool ........................................18

Sealant or/and Lubricant .........................................18

ON-VEHICLE MAINTENANCE ....................20

AIR CONDITIONER FILTER .......................... ....20

Exploded View .................................................... ....20

Removal and Installation ..................................... ....20

Replacement ...........................................................20

ON-VEHICLE REPAIR .................................21

A/C CONTROL ..................................................21

Exploded View ..................................................... ....21

Removal and Installation .........................................21

A/C DISPLAY ....................................................22

Exploded View .........................................................22

Removal and Installation .........................................22

A/C AUTO AMP. ...............................................23

Exploded View .........................................................23

Removal and Installation .........................................23

AMBIENT SENSOR ..........................................24

Exploded View .........................................................24

Removal and Installation .........................................24

IN-VEHICLE SENSOR ......................................25

Exploded View .........................................................25

Removal and Installation .........................................25

SUNLOAD SENSOR .........................................26

Exploded View .........................................................26

Removal and Installation .........................................26

INTAKE SENSOR .............................................27

Exploded View .........................................................27

Removal and Installation .........................................28

BLOWER UNIT .................................................29

Exploded View .........................................................29

Removal and Installation .........................................30

BLOWER MOTOR ............................................32

Exploded View .........................................................32

Removal and Installation .........................................32

INTAKE DOOR MOTOR ...................................33

Exploded View .........................................................33

Page 4813 of 5121

VTL-2

Removal and Installation ........................................33

HEATER & COOLING UNIT ASSEMBLY .........35

Exploded View ........................................................35

Removal and Installation ........................................37

MODE DOOR MOTOR ......................................40

Exploded View ........................................................40

Removal and Installation ........................................40

AIR MIX DOOR MOTOR ....................................41

Exploded View ........................................................41

Removal and Installation ........................................41

HEATER CORE .................................................43

Exploded View ........................................................43

Removal and Installation ........................................44

DUCT AND GRILLE ..........................................45

CENTER VENTILATOR GRILLE ..............................45

CENTER VENTILATOR GRILLE : Exploded View ...45

CENTER VENTILATOR GRILLE : Removal and

Installation ..............................................................

45

SIDE VENTILATOR GRILLE ....................................45

SIDE VENTILATOR GRILLE : Exploded View .......46

SIDE VENTILATOR GRILLE : Removal and In-

stallation .................................................................

46

SIDE DEFROSTER GRILLE .....................................46

SIDE DEFROSTER GRILLE : Exploded View ........47

SIDE DEFROSTER GRILLE : Removal and In-

stallation .................................................................

47

VENTILATOR DUCT .................................................47

VENTILATOR DUCT : Exploded View ...................48

VENTILATOR DUCT : Removal and Installation ....48

SIDE DEFROSTER NOZZLE ....................................49

SIDE DEFROSTER NOZZLE : Exploded View ......49

SIDE DEFROSTER NOZZLE : Removal and In-

stallation .................................................................

49

DEFROSTER NOZZLE .............................................50

DEFROSTER NOZZLE : Exploded View ................50

DEFROSTER NOZZLE : Removal and Installation

...

51

REAR VENTILATOR GRILLE ..................................51

REAR VENTILATOR GRILLE : Exploded View ......52

REAR VENTILATOR GRILLE : Removal and In-

stallation .................................................................

52

REAR VENTILATOR DUCT 1 ...................................52

REAR VENTILATOR DUCT 1 : Exploded View .....53

REAR VENTILATOR DUCT 1 : Removal and In-

stallation .................................................................

53

REAR VENTILATOR DUCT 2 ...................................53

REAR VENTILATOR DUCT 2 : Exploded View .....54

REAR VENTILATOR DUCT 2 : Removal and In-

stallation .................................................................

54

REAR FOOT DUCT 1 ................................................54

REAR FOOT DUCT 1 : Exploded View ..................55

REAR FOOT DUCT 1 : Removal and Installation ...55

REAR FOOT DUCT 2 ................................................56

REAR FOOT DUCT 2 : Exploded View ..................56

REAR FOOT DUCT 2 : Removal and Installation ...56

REAR FOOT DUCT 3 ................................................57

REAR FOOT DUCT 3 : Exploded View ..................58

REAR FOOT DUCT 3 : Removal and Installation ...58

FOOT DUCT ..............................................................59

FOOT DUCT : Exploded View ................................59

FOOT DUCT : Removal and Installation .................60

WITH 7 INCH DISPLAY

FUNCTION DIAGNOSIS ............................

61

SWITCHES AND THEIR CONTROL FUNC-

TION ...................................................................

61

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM ....................................................................

61

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM : System Description ...............................

61

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM ...........................................................................

62

WITH INTELLIGENT AIR CONDITIONER SYS-

TEM : System Description ......................................

62

AIR DISTRIBUTION ..........................................63

System Description .................................................63

PRECAUTION ............................................64

PRECAUTIONS .................................................64

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

64

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

64

Precaution for Procedure without Cowl Top Cover ...65

Precautions For Xenon Headlamp Service .............65

Working with HFC-134a (R-134a) ...........................65

General Refrigerant Precaution ..............................65

Refrigerant Connection ...........................................66

Service Equipment ..................................................68

COMPRESSOR .................................................71

General Precautions ...............................................71

FLUORESCENT LEAK DETECTOR .................72

General Precautions ...............................................72

PREPARATION ..........................................73

PREPARATION .................................................73

Special Service Tool ...............................................73

Commercial Service Tool ........................................75

Sealant or/and Lubricant .........................................75

Page 4816 of 5121

![NISSAN TEANA 2008 Service Manual SWITCHES AND THEIR CONTROL FUNCTION

VTL-5

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

FUNCTION DIAGNOSIS

SWITCHES AND THEIR CONTROL FUNCTION

System DescriptionINFOI NISSAN TEANA 2008 Service Manual SWITCHES AND THEIR CONTROL FUNCTION

VTL-5

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

FUNCTION DIAGNOSIS

SWITCHES AND THEIR CONTROL FUNCTION

System DescriptionINFOI](/img/5/57391/w960_57391-4815.png)

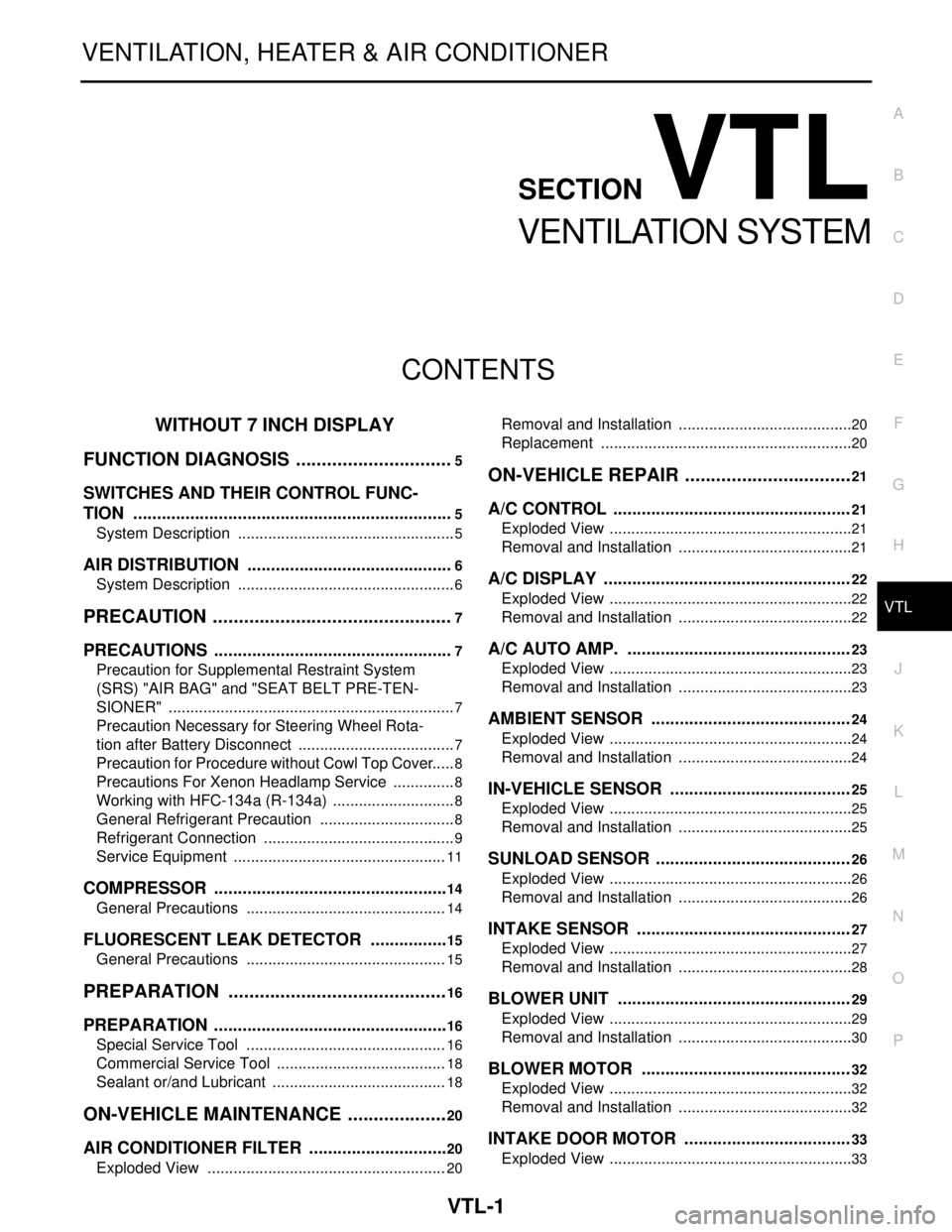

SWITCHES AND THEIR CONTROL FUNCTION

VTL-5

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

FUNCTION DIAGNOSIS

SWITCHES AND THEIR CONTROL FUNCTION

System DescriptionINFOID:0000000003774638

JPIIA0885GB

JSIIA1186GB

Page 4817 of 5121

![NISSAN TEANA 2008 Service Manual VTL-6

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

AIR DISTRIBUTION

AIR DISTRIBUTION

System DescriptionINFOID:0000000003774639

JPIIA0877GB NISSAN TEANA 2008 Service Manual VTL-6

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

AIR DISTRIBUTION

AIR DISTRIBUTION

System DescriptionINFOID:0000000003774639

JPIIA0877GB](/img/5/57391/w960_57391-4816.png)

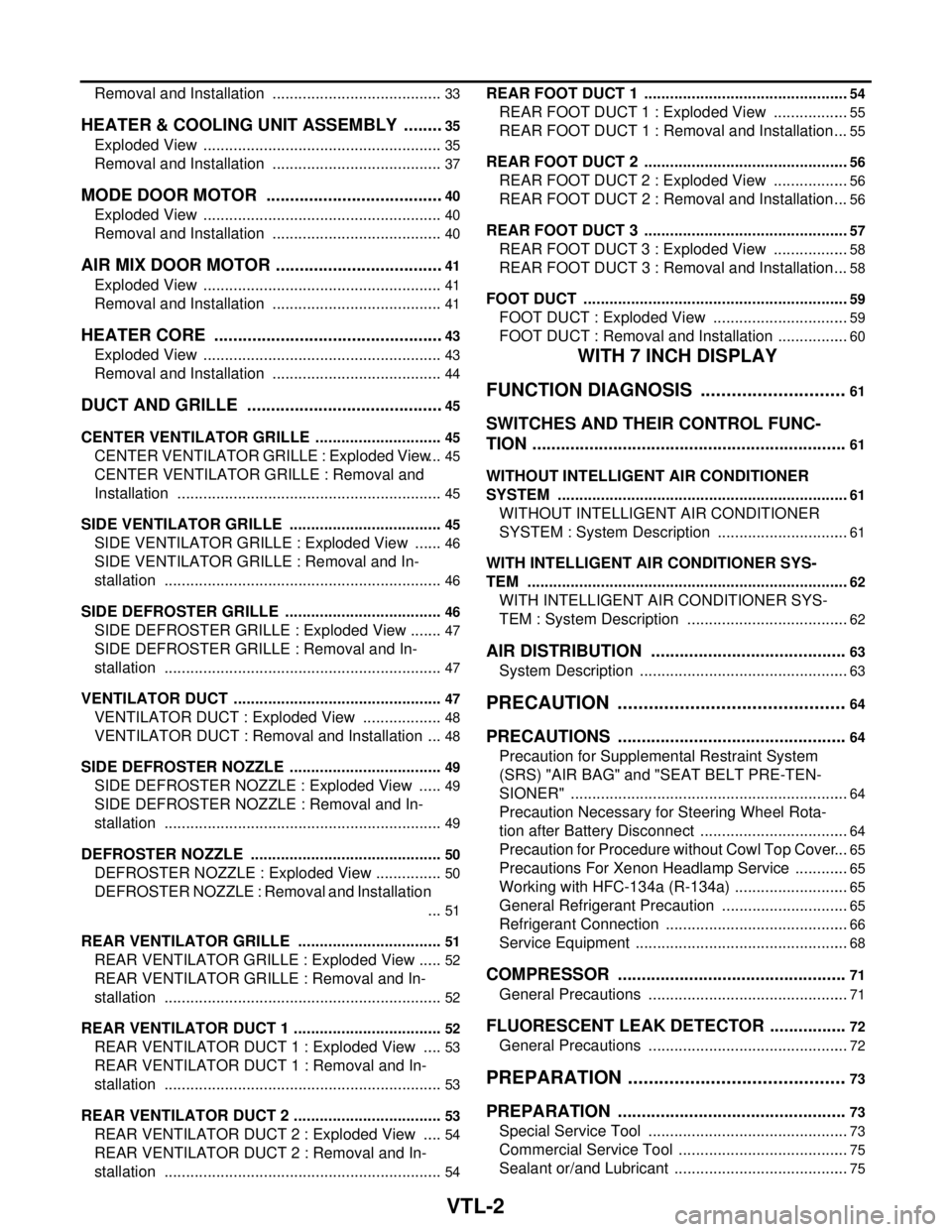

VTL-6

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

AIR DISTRIBUTION

AIR DISTRIBUTION

System DescriptionINFOID:0000000003774639

JPIIA0877GB