brake rotor NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 897 of 5121

BR-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BR

A

B

BR

N

O P

CONTENTS

BRAKE SYSTEM

SYMPTOM DIAGNOSIS ..... ..........................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

3

NVH Troubleshooting Chart ................................ ......3

PRECAUTION ...............................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Brake System ....................................5

ON-VEHICLE MAINTENANCE .....................6

BRAKE PEDAL .............................................. .....6

Inspection and Adjustment .................................. ......6

BRAKE FLUID .....................................................9

Inspection ............................................................ ......9

Draining .....................................................................9

Refilling .....................................................................9

Bleeding Brake System ...........................................10

BRAKE MASTER CYLINDER ........................ ....11

Inspection ............................................................ ....11

BRAKE BOOSTER ............................................12

Inspection ............................................................ ....12

FRONT DISC BRAKE .................................... ....13

BRAKE PAD .......................................................... ....13

BRAKE PAD : Inspection and Adjustment ..............13

DISC ROTOR ......................................................... ....13

DISC ROTOR : Inspection and Adjustment ............13

REAR DISC BRAKE ...................................... ....15

BRAKE PAD .......................................................... ....15

BRAKE PAD : Inspection and Adjustment ...............15

DISC ROTOR ......................................................... ....15

DISC ROTOR : Inspection and Adjustment .............15

ON-VEHICLE REPAIR .................................17

BRAKE PEDAL ................................ .................17

Exploded View ..................................................... ....17

Removal and Installation .........................................17

Inspection and Adjustment ......................................18

BRAKE PIPING ................................ .................19

FRONT ................................................................... ....19

FRONT : Exploded View .........................................19

FRONT : Hydraulic Piping .......................................20

FRONT : Removal and Installation ..........................21

FRONT : Inspection .................................................21

REAR ..................................................................... ....22

REAR : Exploded View ............................................22

REAR : Hydraulic Piping ..........................................22

REAR : Removal and Installation ............................23

REAR : Inspection ...................................................23

BRAKE MASTER CYLINDER ..........................25

Exploded View .........................................................25

Removal and Installation .........................................25

Disassembly and Assembly .....................................26

Inspection ................................................................27

BRAKE BOOSTER ...........................................28

Exploded View ..................................................... ....28

Removal and installation .........................................28

Inspection and Adjustment ......................................29

VACUUM LINES ...............................................31

Exploded View .........................................................31

Removal and Installation .........................................31

Inspection ................................................................31

Page 899 of 5121

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

BR-3

< SYMPTOM DIAGNOSIS >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

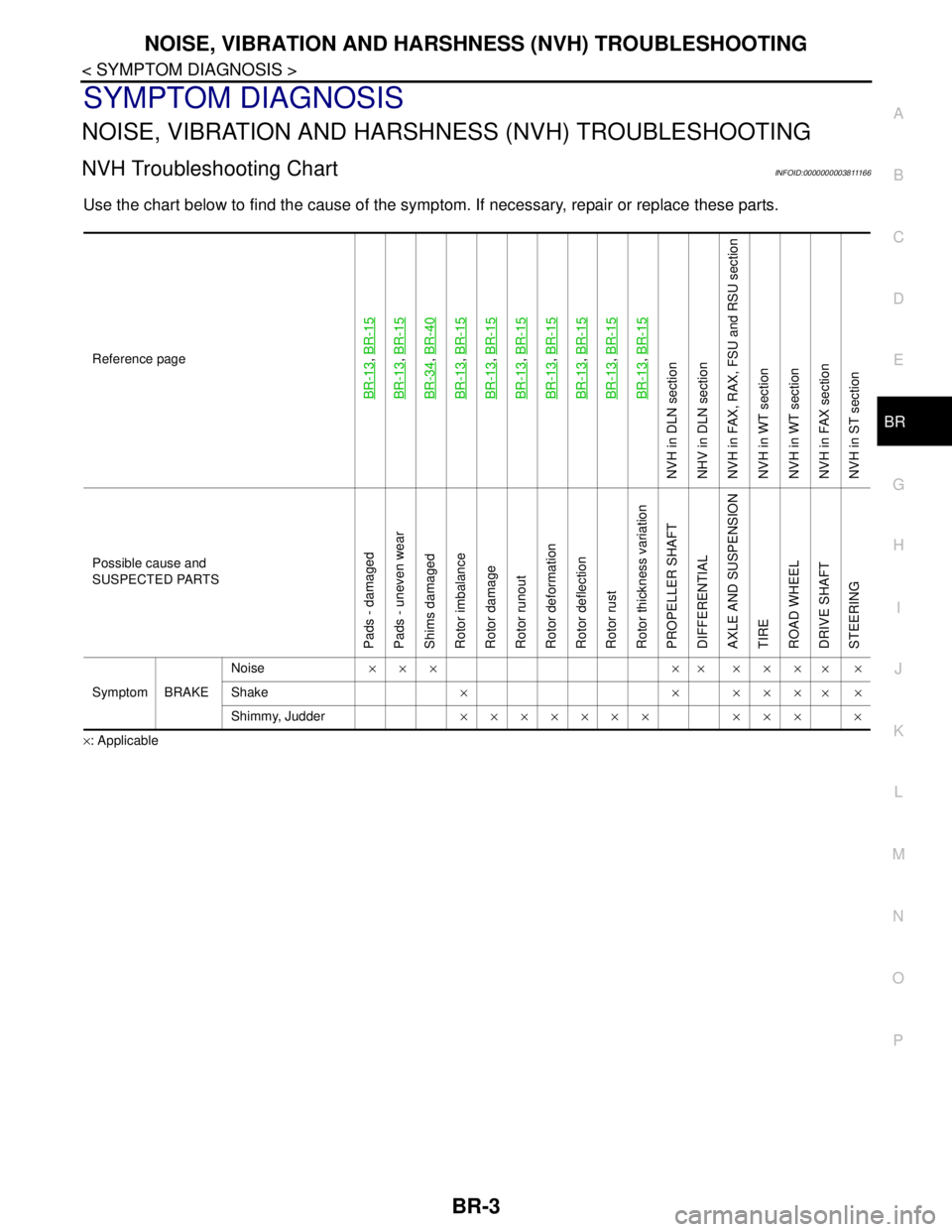

NVH Troubleshooting ChartINFOID:0000000003811166

Use the chart below to find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

BR-13

, BR-15

BR-13

, BR-15

BR-34

, BR-40

BR-13

, BR-15

BR-13

, BR-15

BR-13

, BR-15

BR-13

, BR-15

BR-13

, BR-15

BR-13

, BR-15

BR-13

, BR-15

NVH in DLN section

NHV in DLN section

NVH in FAX, RAX, FSU and RSU section

NVH in WT section

NVH in WT section

NVH in FAX section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKENoise××× ×× ×××

××

Shake×××××

××

Shimmy, Judder××××××× ××× ×

Page 901 of 5121

PRECAUTIONS

BR-5

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

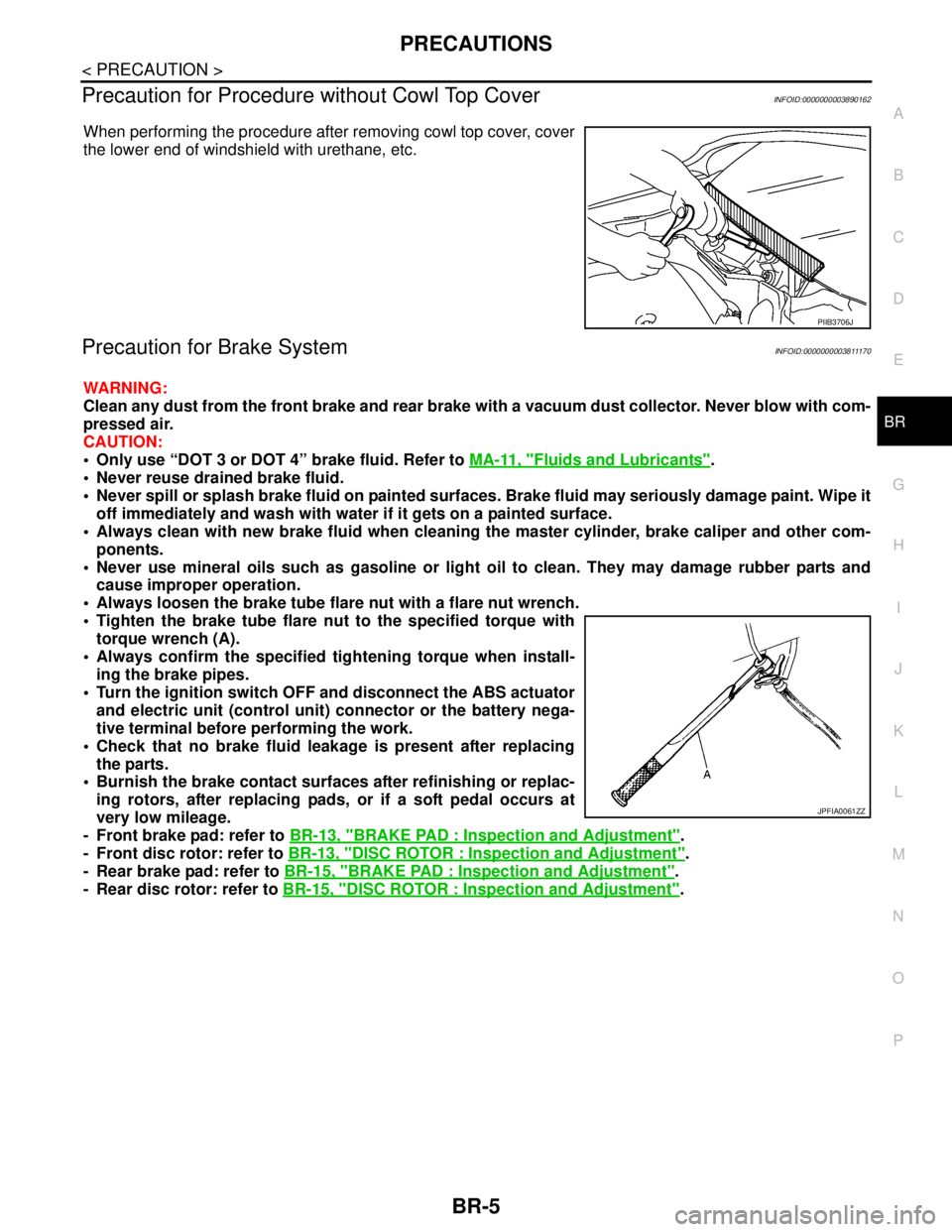

Precaution for Procedure without Cowl Top CoverINFOID:0000000003890162

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003811170

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

Only use “DOT 3 or DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other com-

ponents.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with

torque wrench (A).

Always confirm the specified tightening torque when install-

ing the brake pipes.

Turn the ignition switch OFF and disconnect the ABS actuator

and electric unit (control unit) connector or the battery nega-

tive terminal before performing the work.

Check that no brake fluid leakage is present after replacing

the parts.

Burnish the brake contact surfaces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

- Front brake pad: refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0061ZZ

Page 909 of 5121

FRONT DISC BRAKE

BR-13

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

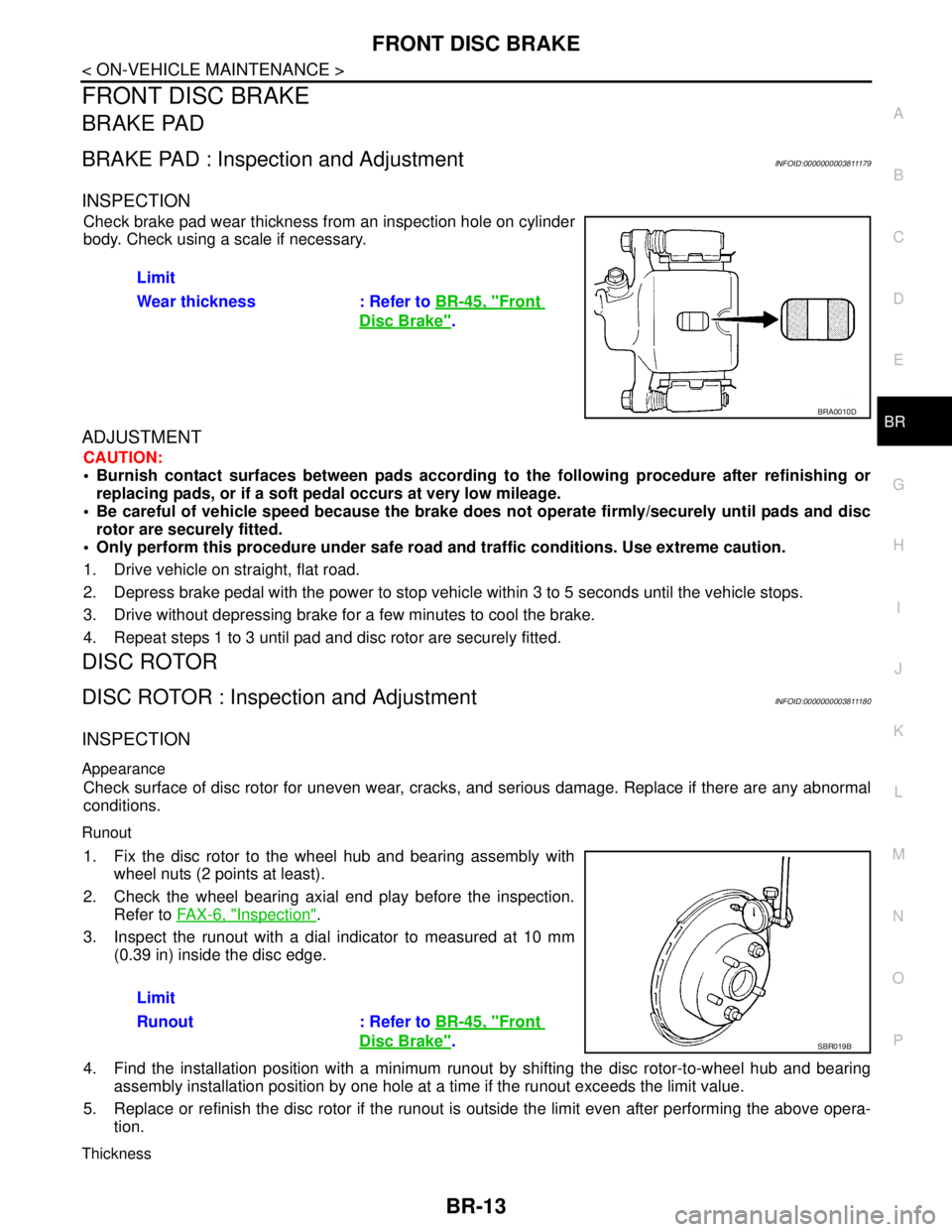

BRAKE PAD : Inspection and AdjustmentINFOID:0000000003811179

INSPECTION

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and AdjustmentINFOID:0000000003811180

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

Runout

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

Refer to FA X - 6 , "

Inspection".

3. Inspect the runout with a dial indicator to measured at 10 mm

(0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5. Replace or refinish the disc rotor if the runout is outside the limit even after performing the above opera-

tion.

Thickness

Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

BRA0010D

Limit

Runout : Refer to BR-45, "

Front

Disc Brake".SBR019B

Page 910 of 5121

BR-14

< ON-VEHICLE MAINTENANCE >

FRONT DISC BRAKE

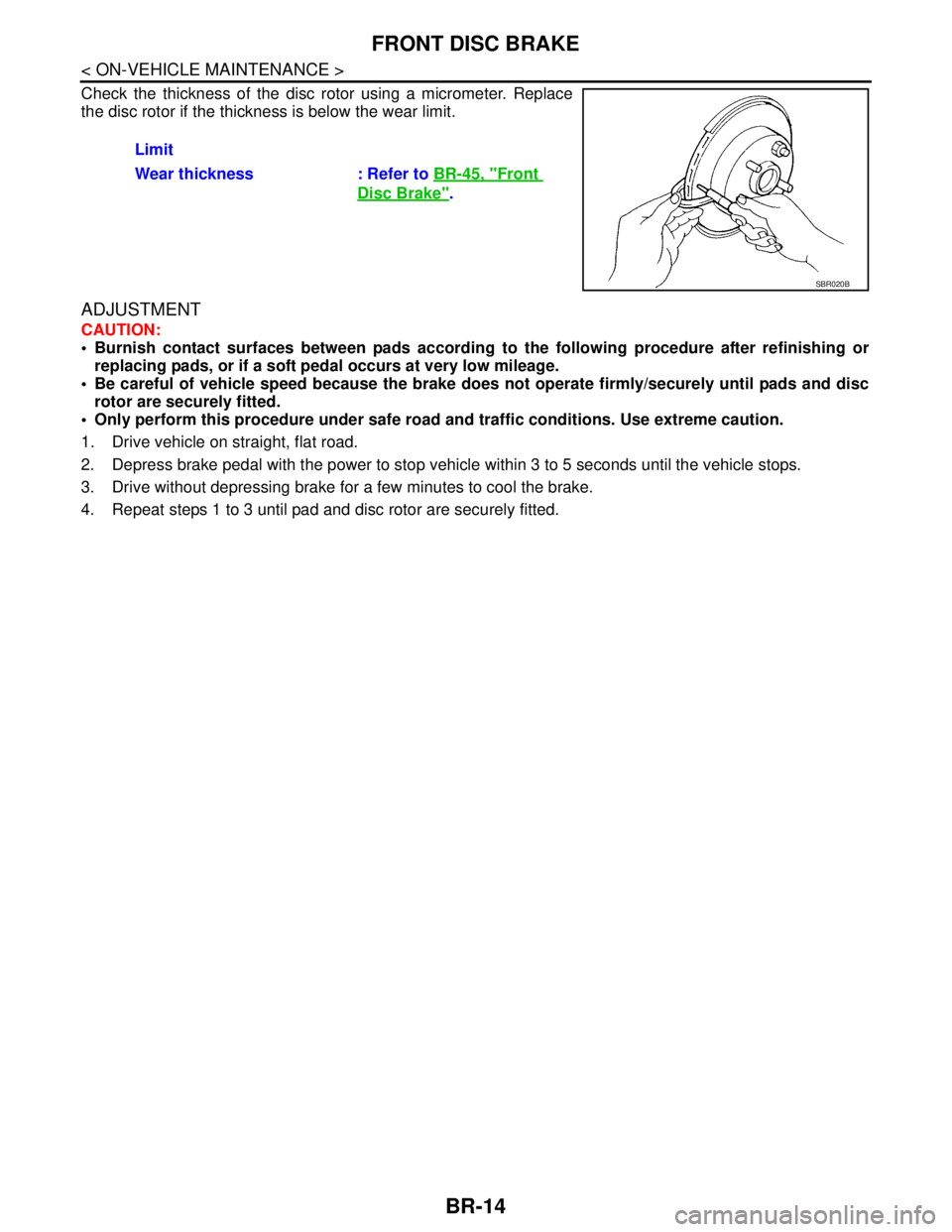

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Front

Disc Brake".

SBR020B

Page 911 of 5121

REAR DISC BRAKE

BR-15

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

BRAKE PAD

BRAKE PAD : Inspection and AdjustmentINFOID:0000000003811181

INSPECTION

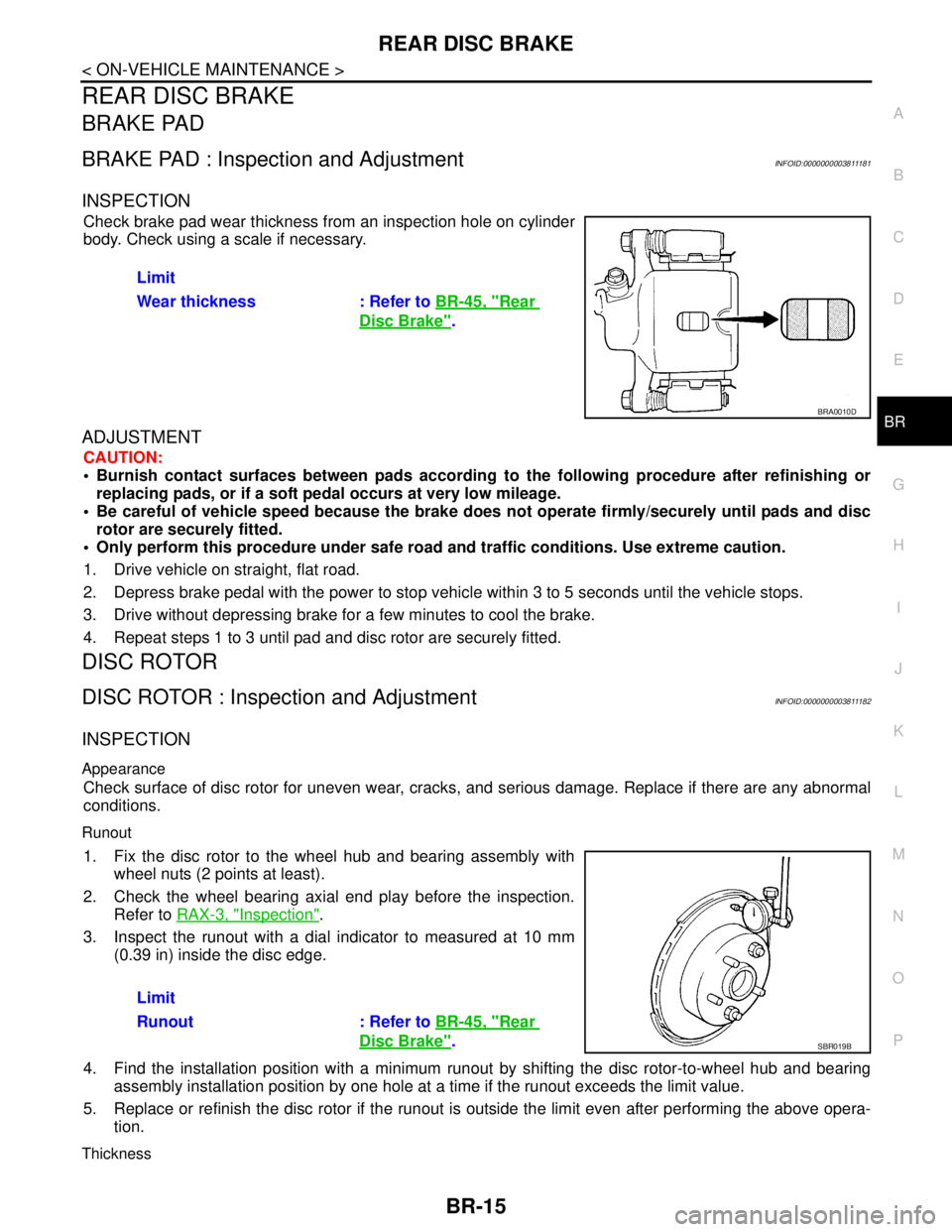

Check brake pad wear thickness from an inspection hole on cylinder

body. Check using a scale if necessary.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

DISC ROTOR

DISC ROTOR : Inspection and AdjustmentINFOID:0000000003811182

INSPECTION

Appearance

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are any abnormal

conditions.

Runout

1. Fix the disc rotor to the wheel hub and bearing assembly with

wheel nuts (2 points at least).

2. Check the wheel bearing axial end play before the inspection.

Refer to RAX-3, "

Inspection".

3. Inspect the runout with a dial indicator to measured at 10 mm

(0.39 in) inside the disc edge.

4. Find the installation position with a minimum runout by shifting the disc rotor-to-wheel hub and bearing

assembly installation position by one hole at a time if the runout exceeds the limit value.

5. Replace or refinish the disc rotor if the runout is outside the limit even after performing the above opera-

tion.

Thickness

Limit

Wear thickness : Refer to BR-45, "

Rear

Disc Brake".

BRA0010D

Limit

Runout : Refer to BR-45, "

Rear

Disc Brake".SBR019B

Page 912 of 5121

BR-16

< ON-VEHICLE MAINTENANCE >

REAR DISC BRAKE

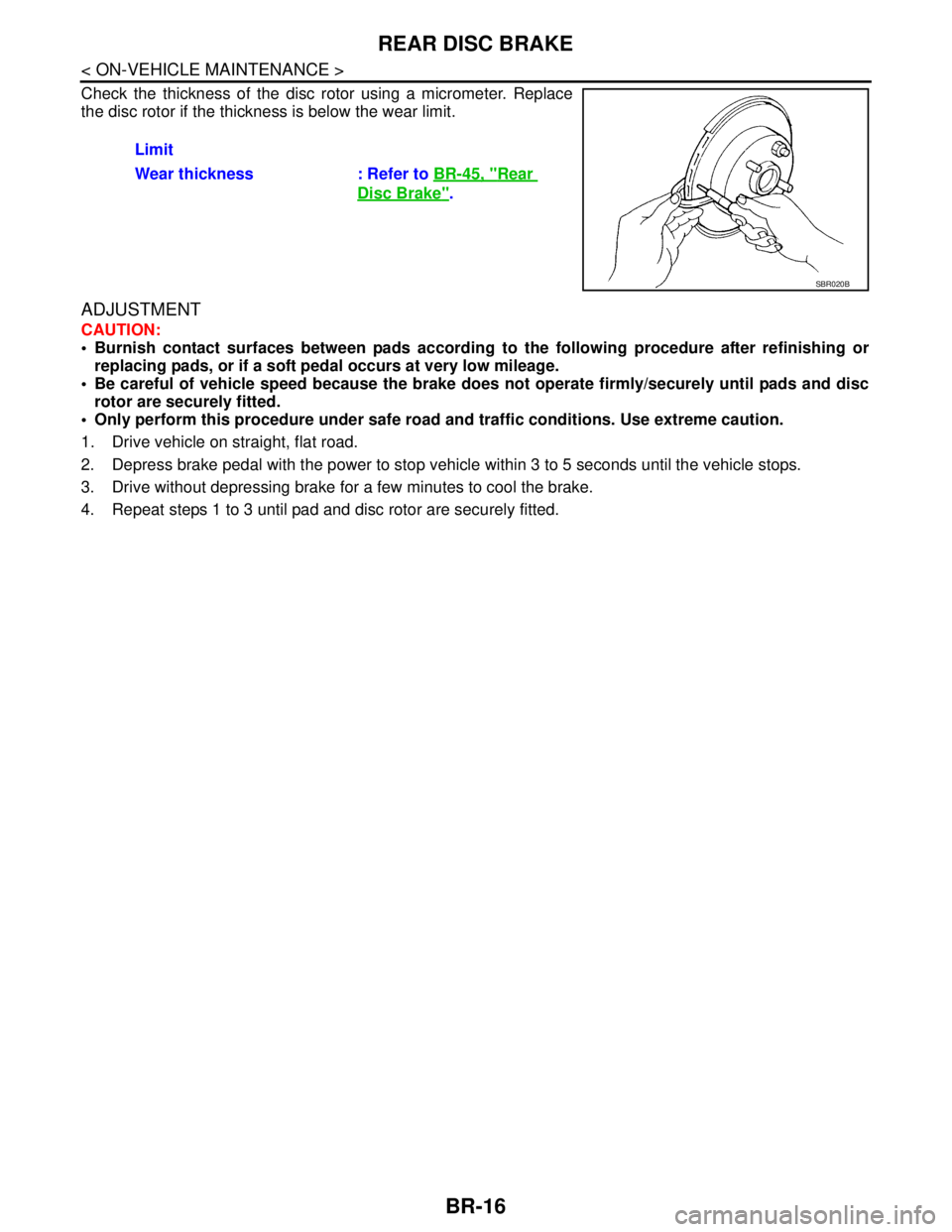

Check the thickness of the disc rotor using a micrometer. Replace

the disc rotor if the thickness is below the wear limit.

ADJUSTMENT

CAUTION:

Burnish contact surfaces between pads according to the following procedure after refinishing or

replacing pads, or if a soft pedal occurs at very low mileage.

Be careful of vehicle speed because the brake does not operate firmly/securely until pads and disc

rotor are securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.Limit

Wear thickness : Refer to BR-45, "

Rear

Disc Brake".

SBR020B

Page 929 of 5121

FRONT DISC BRAKE

BR-33

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

FRONT DISC BRAKE

BRAKE PAD

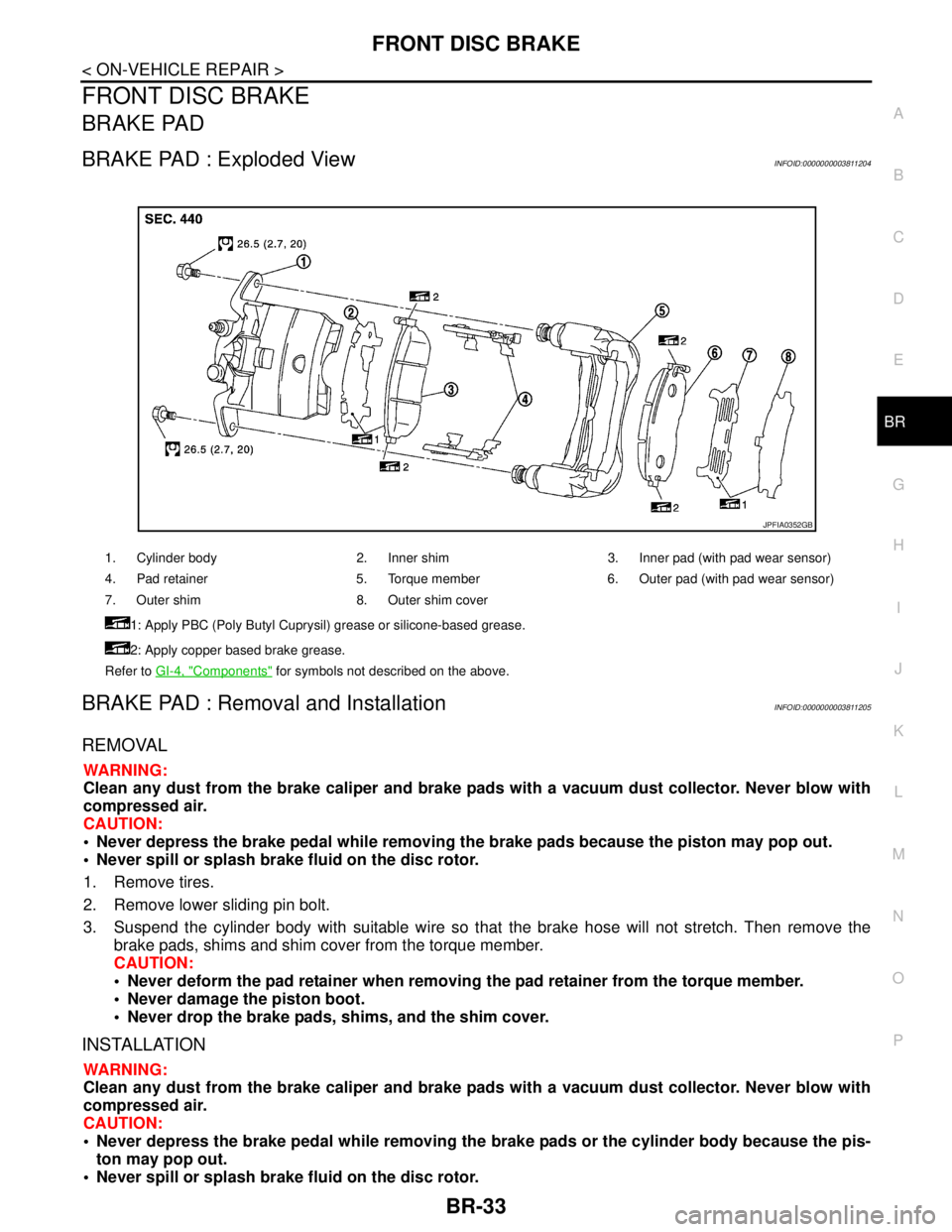

BRAKE PAD : Exploded ViewINFOID:0000000003811204

BRAKE PAD : Removal and InstallationINFOID:0000000003811205

REMOVAL

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads because the piston may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Remove tires.

2. Remove lower sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch. Then remove the

brake pads, shims and shim cover from the torque member.

CAUTION:

Never deform the pad retainer when removing the pad retainer from the torque member.

Never damage the piston boot.

Never drop the brake pads, shims, and the shim cover.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal while removing the brake pads or the cylinder body because the pis-

ton may pop out.

Never spill or splash brake fluid on the disc rotor.

1. Cylinder body 2. Inner shim 3. Inner pad (with pad wear sensor)

4. Pad retainer 5. Torque member 6. Outer pad (with pad wear sensor)

7. Outer shim 8. Outer shim cover

1: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

2: Apply copper based brake grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0352GB

Page 932 of 5121

BR-36

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers, and then disconnect brake hose from caliper assembly. Refer to

BR-19, "

FRONT : Exploded View".

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-19, "

FRONT : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check a drag of front disc brake. If any drag is found, refer to BR-38, "

BRAKE CALIPER ASSEMBLY :

Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811209

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts, and remove the cylinder body from the torque member.

CAUTION:

Never drop brake pads, shims, shim cover and pad retainers from torque member.

2. Remove brake pads, shims and shim cover. Refer to BR-33, "

BRAKE PAD : Exploded View".

3. Remove sliding pins and sliding pin boots from torque member.

4. Remove bushing from sliding pin.

Page 934 of 5121

BR-38

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

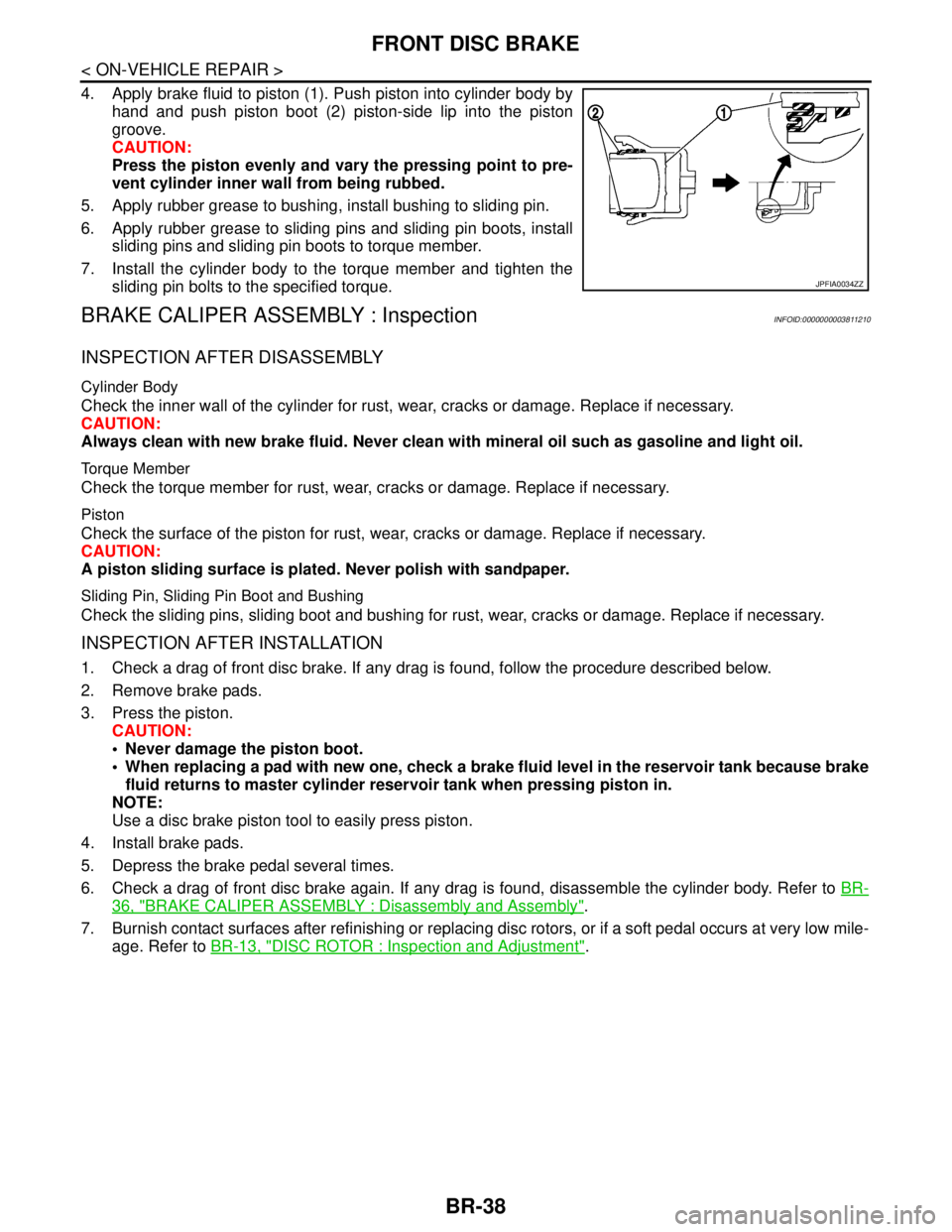

4. Apply brake fluid to piston (1). Push piston into cylinder body by

hand and push piston boot (2) piston-side lip into the piston

groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to bushing, install bushing to sliding pin.

6. Apply rubber grease to sliding pins and sliding pin boots, install

sliding pins and sliding pin boots to torque member.

7. Install the cylinder body to the torque member and tighten the

sliding pin bolts to the specified torque.

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000003811210

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of the cylinder for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

Always clean with new brake fluid. Never clean with mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage. Replace if necessary.

Piston

Check the surface of the piston for rust, wear, cracks or damage. Replace if necessary.

CAUTION:

A piston sliding surface is plated. Never polish with sandpaper.

Sliding Pin, Sliding Pin Boot and Bushing

Check the sliding pins, sliding boot and bushing for rust, wear, cracks or damage. Replace if necessary.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any drag is found, follow the procedure described below.

2. Remove brake pads.

3. Press the piston.

CAUTION:

Never damage the piston boot.

When replacing a pad with new one, check a brake fluid level in the reservoir tank because brake

fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

4. Install brake pads.

5. Depress the brake pedal several times.

6. Check a drag of front disc brake again. If any drag is found, disassemble the cylinder body. Refer to BR-

36, "BRAKE CALIPER ASSEMBLY : Disassembly and Assembly".

7. Burnish contact surfaces after refinishing or replacing disc rotors, or if a soft pedal occurs at very low mile-

age. Refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

JPFIA0034ZZ