height adjustment NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 902 of 5121

BR-6

< ON-VEHICLE MAINTENANCE >

BRAKE PEDAL

ON-VEHICLE MAINTENANCE

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000003811172

INSPECTION

Brake Pedal Height

Check the brake pedal height (H1) between the dash lower panel (1)

and the brake pedal upper surface.

CAUTION:

Remove the floor trim.

Stop Lamp Switch and ASCD Brake Switch

Check the clearance (C) between stopper rubber (1) and stop lamp

switch and ASCD brake switch (2) threaded end.

CAUTION:

The stop lamp must be turned off when the brake pedal is

released.

NOTE:

Pull the brake pedal pad to make the clearance between stopper

rubber and stop lamp switch and ASCD brake switch threaded end.

Brake Pedal Play

Press the brake pedal. Check the brake pedal play (A).

Depressed Brake Pedal Height

Check the brake pedal height (H2) between the dash lower panel (1)

and the brake pedal upper surface when depressing the brake pedal

at 490 N (50 kg, 110 lb) while turning engine ON.

CAUTION:

Remove the floor trim.Standard

H

1: Refer to BR-45, "Brake

Pedal".

JPFIA0065ZZ

Standard

C : Refer to BR-45, "

Brake

Pedal".

JPFIA0122ZZ

Standard

A : Refer to BR-45, "

Brake

Pedal".

JPFIA0121ZZ

Standard

H

2: Refer to BR-45, "Brake

Pedal".

JPFIA0068ZZ

Page 903 of 5121

BRAKE PEDAL

BR-7

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

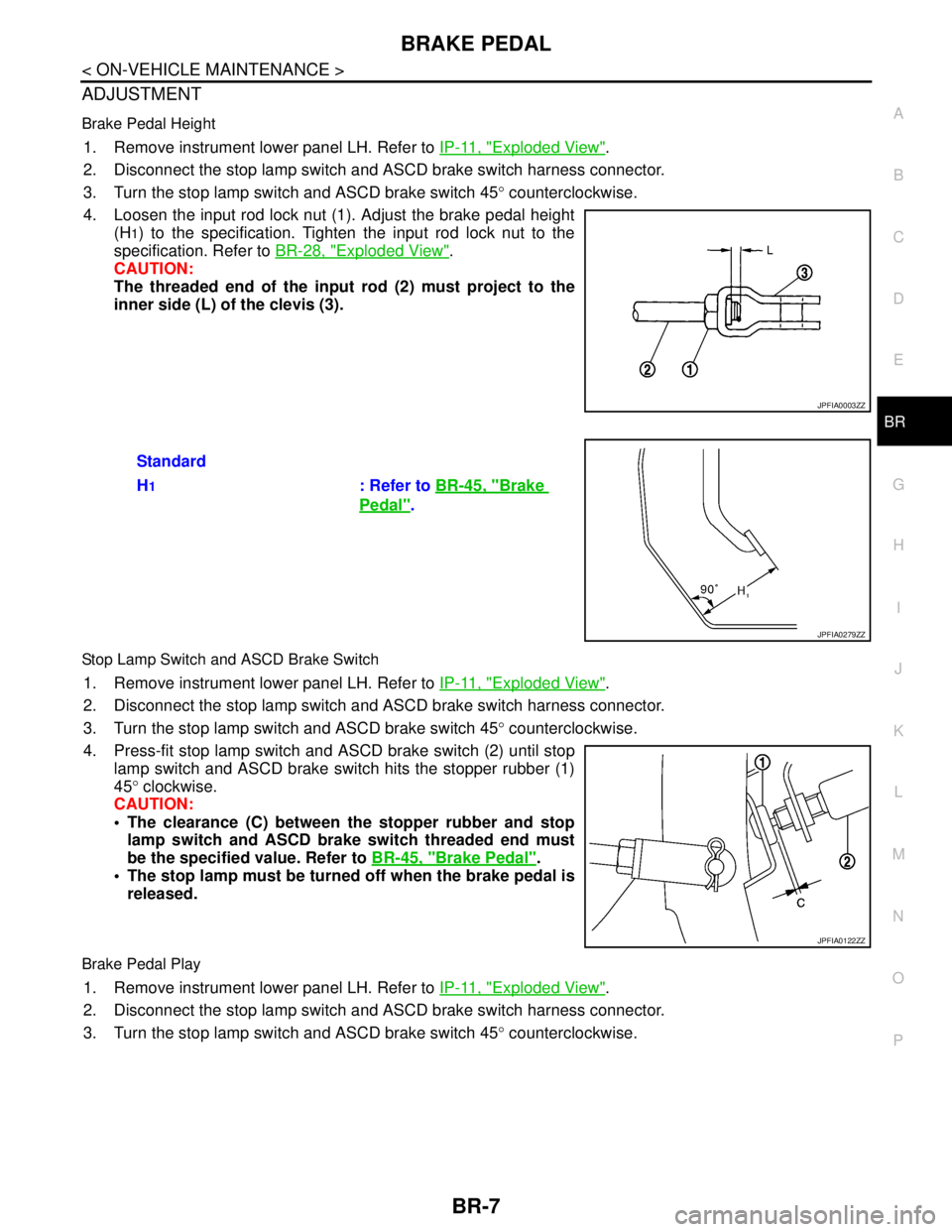

ADJUSTMENT

Brake Pedal Height

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connector.

3. Turn the stop lamp switch and ASCD brake switch 45° counterclockwise.

4. Loosen the input rod lock nut (1). Adjust the brake pedal height

(H

1) to the specification. Tighten the input rod lock nut to the

specification. Refer to BR-28, "

Exploded View".

CAUTION:

The threaded end of the input rod (2) must project to the

inner side (L) of the clevis (3).

Stop Lamp Switch and ASCD Brake Switch

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connector.

3. Turn the stop lamp switch and ASCD brake switch 45° counterclockwise.

4. Press-fit stop lamp switch and ASCD brake switch (2) until stop

lamp switch and ASCD brake switch hits the stopper rubber (1)

45° clockwise.

CAUTION:

The clearance (C) between the stopper rubber and stop

lamp switch and ASCD brake switch threaded end must

be the specified value. Refer to BR-45, "

Brake Pedal".

The stop lamp must be turned off when the brake pedal is

released.

Brake Pedal Play

1. Remove instrument lower panel LH. Refer to IP-11, "Exploded View".

2. Disconnect the stop lamp switch and ASCD brake switch harness connector.

3. Turn the stop lamp switch and ASCD brake switch 45° counterclockwise.

JPFIA0003ZZ

Standard

H

1: Refer to BR-45, "Brake

Pedal".

JPFIA0279ZZ

JPFIA0122ZZ

Page 1409 of 5121

![NISSAN TEANA 2008 Service Manual HOOD

DLK-193

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Front grille: Refer to EXT-18, "Removal and Installation".

INSTALLATION

Install in the reverse order NISSAN TEANA 2008 Service Manual HOOD

DLK-193

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Front grille: Refer to EXT-18, "Removal and Installation".

INSTALLATION

Install in the reverse order](/img/5/57391/w960_57391-1408.png)

HOOD

DLK-193

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Front grille: Refer to EXT-18, "Removal and Installation".

INSTALLATION

Install in the reverse order of removal.

CAUTION:

After installing, perform hood fitting adjustment. Refer to DLK-193, "

HOOD ASSEMBLY : Adjust-

ment".

After installing, perform front washer nozzle and tube inspection and adjustment. Refer to WW-102,

"Inspection and Adjustment".

HOOD ASSEMBLY : AdjustmentINFOID:0000000003813385

Check the clearance and the surface height between hood and each part visually and by touching. (Fitting

standard dimension in the table below should be satisfied.

If the clearance and the surface height are out of specification, adjust them according to the procedures

shown below.

Unit: mm (in)

1. Remove hood lock and adjust the height by rotating hood bumper rubber (side, lower) until hood becomes

1 to1.5 mm (0.039 to 0.059 in) lower than fender.

2. Temporarily tighten hood lock assembly, and position by engaging it with hood striker. Check hood lock

and striker for looseness and adjust the clearance and evenness with striker to satisfy the specification.

3. Adjust A and B shown in the figure to the following value with hood's own weight by dropping it from

approximately 200 mm (7.874 in) height or by pressing hood lightly [approximately 29 N (3.0 kg, 6.5 lb)].

4. After adjustment, tighten lock bolts to the specified torque.

HOOD HINGE

Portion StandardDifference

(RH/LH, MAX)

Hood – Front bumper

fasciaA – A D Clearance3.7 – 8.3

(0.146 – 0.315)2.0

(0.079)

Hood – Front combina-

tion lampB – B E Clearance2.4 – 6.8

(0.094 – 0.268)2.5

(0.098)

Hood – Front fender C – CF Clearance3.1 – 6.1

(0.122 – 0.240)2.0

(0.079)

G Surface height−1.5 – 1.5

(−0.059 – 0.059)—

1. Hood striker 2. Primary latch 3. Secondary striker

4. Secondary latch

A : 20.0 mm (0.787 in)

B : 6.8 mm (0.268 in)

JMKIA2399ZZ

Page 1419 of 5121

![NISSAN TEANA 2008 Service Manual FRONT DOOR

DLK-203

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

After i NISSAN TEANA 2008 Service Manual FRONT DOOR

DLK-203

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

After i](/img/5/57391/w960_57391-1418.png)

FRONT DOOR

DLK-203

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

After installation, perform the fitting adjustment. Refer to DLK-203, "

DOOR ASSEMBLY : Adjust-

ment".

After installation, apply touch-up paint (the body color) onto the head of door hinge mounting nuts.

DOOR ASSEMBLY : AdjustmentINFOID:0000000003813396

Check the clearance and surface height between front door and each part by visually and touching.

If the clearance and the surface height are out of specification, adjust them according to the procedures

shown below.

Unit: mm (in)

1. Remove front fender. Refer to DLK-199, "Removal and Installation".

2. Loosen door hinge mounting nuts on door side.

3. Adjust the surface height of front door according to the fitting standard dimension.

4. Temporarily tighten door hinge mounting nuts on door side.

5. Loosen door hinge mounting bolts on body side.

6. Raise front door at rear end to adjust clearance of the front door according to the fitting standard dimen-

sion.

7. After adjustment tighten bolts and nuts to the specified torque.

8. Install front fender. Refer to DLK-199, "

Removal and Installation".

DOOR STRIKER ADJUSTMENT

Adjust door striker so that it becomes parallel with door lock insertion direction.

DOOR STRIKER

DOOR STRIKER : Exploded ViewINFOID:0000000003819380

Portion Clearance Surface height

Front fender – Front door A – A 2.6 – 4.6 (0.102 – 0.181)−1.0 – 1.0 (−0.039 – 0.039)

Front door – Rear door B – B 3.6 – 5.6 (0.142 – 0.220)−1.0 – 1.0 (−0.039 – 0.039)

JMKIA2384ZZ

Page 1425 of 5121

![NISSAN TEANA 2008 Service Manual REAR DOOR

DLK-209

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

After in NISSAN TEANA 2008 Service Manual REAR DOOR

DLK-209

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

After in](/img/5/57391/w960_57391-1424.png)

REAR DOOR

DLK-209

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

Check door hinge rotating part for poor lubrication. If necessary, apply body grease.

After installation, perform the fitting adjustment. Refer to DLK-209, "

DOOR ASSEMBLY : Adjust-

ment".

After installation, apply touch-up paint (the body color) onto the head of door hinge mounting nuts.

DOOR ASSEMBLY : AdjustmentINFOID:0000000003813405

Check the clearance and surface height between rear door and each part by visually and touching.

If the clearance and surface height are out of specification, adjust them according to the procedures shown

below.

Unit: mm (in)

1. Remove center pillar lower garnish. Refer to INT-39, "Removal and Installation".

2. Loosen door hinge mounting nuts on door side.

3. Adjust the surface height of rear door according to the fitting standard dimension.

4. Temporarily tighten door hinge mounting nuts on door side.

5. Loosen door hinge mounting nuts and bolts on body side.

6. Raise rear door at rear end to adjust clearance of the rear door according to the fitting standard dimen-

sion.

7. After adjustment, tighten bolts and nuts to the specified torque.

8. Install center pillar lower garnish. Refer to INT-39, "

Removal and Installation".

DOOR STRIKER ADJUSTMENT

Adjust door striker so that it becomes parallel with door lock insertion direction.

DOOR STRIKER

DOOR STRIKER : Exploded ViewINFOID:0000000003819605

Portion Clearance Surface height

Front door – Rear door B – B 3.6 – 5.6 (0.142 – 0.220) -1.0 – 1.0 (-0.039 – 0.039)

Rear door – Body side outer C – C 2.6 – 4.6 (0.102 – 0.181) -1.0 – 1.0 (-0.039 – 0.039)

JMKIA2385ZZ

Page 1431 of 5121

![NISSAN TEANA 2008 Service Manual TRUNK LID

DLK-215

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

TRUNK LID ASSEMBLY : AdjustmentINFOID:0000000003813414

Check the clearance and surface height betw NISSAN TEANA 2008 Service Manual TRUNK LID

DLK-215

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

TRUNK LID ASSEMBLY : AdjustmentINFOID:0000000003813414

Check the clearance and surface height betw](/img/5/57391/w960_57391-1430.png)

TRUNK LID

DLK-215

< ON-VEHICLE REPAIR >[WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

DLK

N

O

P

TRUNK LID ASSEMBLY : AdjustmentINFOID:0000000003813414

Check the clearance and surface height between trunk lid and each part by visually and touching.

If the clearance and surface height are out of specification, adjust them according to the procedures shown

below.

Unit: mm (in)

1. Loosen trunk lid hinge mounting bolts (trunk lid side).

2. Remove trunk rear finisher. Refer to INT-57, "

Removal and Installation".

3. Loosen trunk lid striker mounting bolts.

4. Lift up trunk lid approximately 100 – 150 mm (3.937 – 5.906 in) height then close it lightly and check that it

is engaged firmly with trunk lid closed.

5. Check the clearance and surface height.

6. Finally tighten trunk lid hinge and trunk lid striker.

7. Install trunk rear finisher. Refer to INT-57, "

Removal and Installation".

TRUNK LID STRIKER ADJUSTMENT

Adjust trunk lid striker so that it becomes parallel with trunk lid lock insertion direction.

TRUNK LID STRIKER

Portion StandardDifference

(RH/LH, MAX)

Trunk lid – Body side outer A – AD Clearance2.5 – 4.5

(0.098 – 0.177)1.0 (0.039)

ESurface

height−1.5 – 0.5

(−0.059 – 0.020)1.4 (0.055)

Trunk lid – Rear combina-

tion lampB – BF Clearance2.9 – 6.5

(0.114 – 0.256)2.0 (0.079)

GSurface

height−2.3 – 1.3

(−0.091 – 0.051)2.0 (0.079)

Trunk lid – Rear bumper fas-

ciaC – C H Clearance5.0 – 9.0

(0.197 – 0.354)—

Page 2039 of 5121

![NISSAN TEANA 2008 Service Manual EXL-10

< BASIC INSPECTION >[XENON TYPE]

INSPECTION AND ADJUSTMENT

SENSOR INITIALIZE : Description

INFOID:0000000003774311

HEADLAMP AIMING CONTROL SYSTEM

Perform the sensor initialize when installing, NISSAN TEANA 2008 Service Manual EXL-10

< BASIC INSPECTION >[XENON TYPE]

INSPECTION AND ADJUSTMENT

SENSOR INITIALIZE : Description

INFOID:0000000003774311

HEADLAMP AIMING CONTROL SYSTEM

Perform the sensor initialize when installing,](/img/5/57391/w960_57391-2038.png)

EXL-10

< BASIC INSPECTION >[XENON TYPE]

INSPECTION AND ADJUSTMENT

SENSOR INITIALIZE : Description

INFOID:0000000003774311

HEADLAMP AIMING CONTROL SYSTEM

Perform the sensor initialize when installing, removing and replacing the auto levelizer control unit and sus-

pension components.

SENSOR INITIALIZE : Special Repair Requirement (HEADLAMP AIMING CONTROL

SYSTEM)

INFOID:0000000003774312

1.VEHICLE CONDITION CHECK

1. Park the vehicle in the straight-forward position.

2. Unload the vehicle (no passenger aboard).

>> GO TO 2.

2.SENSOR INITIALIZE

CONSULT-III WORK SUPPORT

1. Select "SENSOR INITIALIZE" of HEADLAMP LEVELIZER work support item.

2. Select "START".

3. When "INITIALIZE COMPLETE", select "END".

CAUTION:

If "INITIALIZE NOT DONE" is indicated, auto levelizer control unit detects that the sensor lever sig-

nal changes. The sensor initialize is cancelled. In this case, turn the ignition switch OFF to prevent

the vehicle from the height change. Perform the sensor initialize again.

Is the sensor initialize completed?

YES >> GO TO 3.

NO >> Perform the sensor initialize again.

3.SELF-DIAGNOSIS RESULT CHECK

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected.

Is any DTC detected?

YES >> GO TO 2.

NO >> Sensor initialize completed

Page 2204 of 5121

![NISSAN TEANA 2008 Service Manual HEADLAMP AIMING ADJUSTMENT

EXL-175

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Low beam distribution on the screen

Unit: mm (in)

Aiming Adjustment Procedure (High Beam)INFO NISSAN TEANA 2008 Service Manual HEADLAMP AIMING ADJUSTMENT

EXL-175

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Low beam distribution on the screen

Unit: mm (in)

Aiming Adjustment Procedure (High Beam)INFO](/img/5/57391/w960_57391-2203.png)

HEADLAMP AIMING ADJUSTMENT

EXL-175

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Low beam distribution on the screen

Unit: mm (in)

Aiming Adjustment Procedure (High Beam)INFOID:0000000003827917

1. Place the screen.

NOTE:

Stop the vehicle at the perpendicular angle to the wall.

Set the screen so that it is perpendicular to a level load surface.

JSLIA0030ZZ

A. Aiming adjustment area

B. Elbow point

C. Headlamp center

H. Horizontal center line of headlamp

V. Vertical center line of headlamp

C. Vertical center line of headlamp H. Horizontal center line of headlamp L. Distance from headlamp center to screen

X. Aiming adjustment area

(lateral)Y. Aiming adjustment area

(Vertical)

Distance from headlamp center to screen (L) : 10m (32.8 ft)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center height)Lateral direction (X)

(Right and left side from headlamp centerline)

Highest light axis 100 (3.94)

0-100 (3.94) Target light axis 120 (4.72)

Lowest light axis 150 (5.91)

JPLIA1062ZZ

Page 2206 of 5121

![NISSAN TEANA 2008 Service Manual HEADLAMP AIMING ADJUSTMENT

EXL-177

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Unit: mm (in)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center NISSAN TEANA 2008 Service Manual HEADLAMP AIMING ADJUSTMENT

EXL-177

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Unit: mm (in)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center](/img/5/57391/w960_57391-2205.png)

HEADLAMP AIMING ADJUSTMENT

EXL-177

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

Unit: mm (in)

Aiming adjustment area

Vertical direction (Y)

(Lower side from headlamp center height)Lateral direction (X)

(Right and left side from headlamp centerline)

Highest light axis 106 (4.17)

0-100 (3.94) Target light axis 120 (4.72)

Lowest light axis 164 (6.46)

Page 2207 of 5121

![NISSAN TEANA 2008 Service Manual EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, re NISSAN TEANA 2008 Service Manual EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, re](/img/5/57391/w960_57391-2206.png)

EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the lug-

gage room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

Turn the aiming adjusting screw for adjustment.

For the position and direction of the adjusting screw, refer to the

figure.

NOTE:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment ProcedureINFOID:0000000003773618

1. Place the screen.

NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front fog lamp center and the

screen.

3. Start the engine. Illuminate the front fog lamp.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

4. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the hor-

izontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

A: UP

B: DOWN

JPLIA1086ZZ

JPLIA0008ZZ