ignition NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 5035 of 5121

FRONT WIPER MOTOR LO CIRCUIT

WW-23

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER MOTOR LO CIRCUIT

Component Function CheckINFOID:0000000003761586

1.CHECK FRONT WIPER LO OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-11, "

Diagnosis Description".

2. Check that the front wiper operates at the LO operation.

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Is front wiper (LO) operation normally?

YES >> Front wiper motor LO circuit is normal.

NO >> Refer to WW-23, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761587

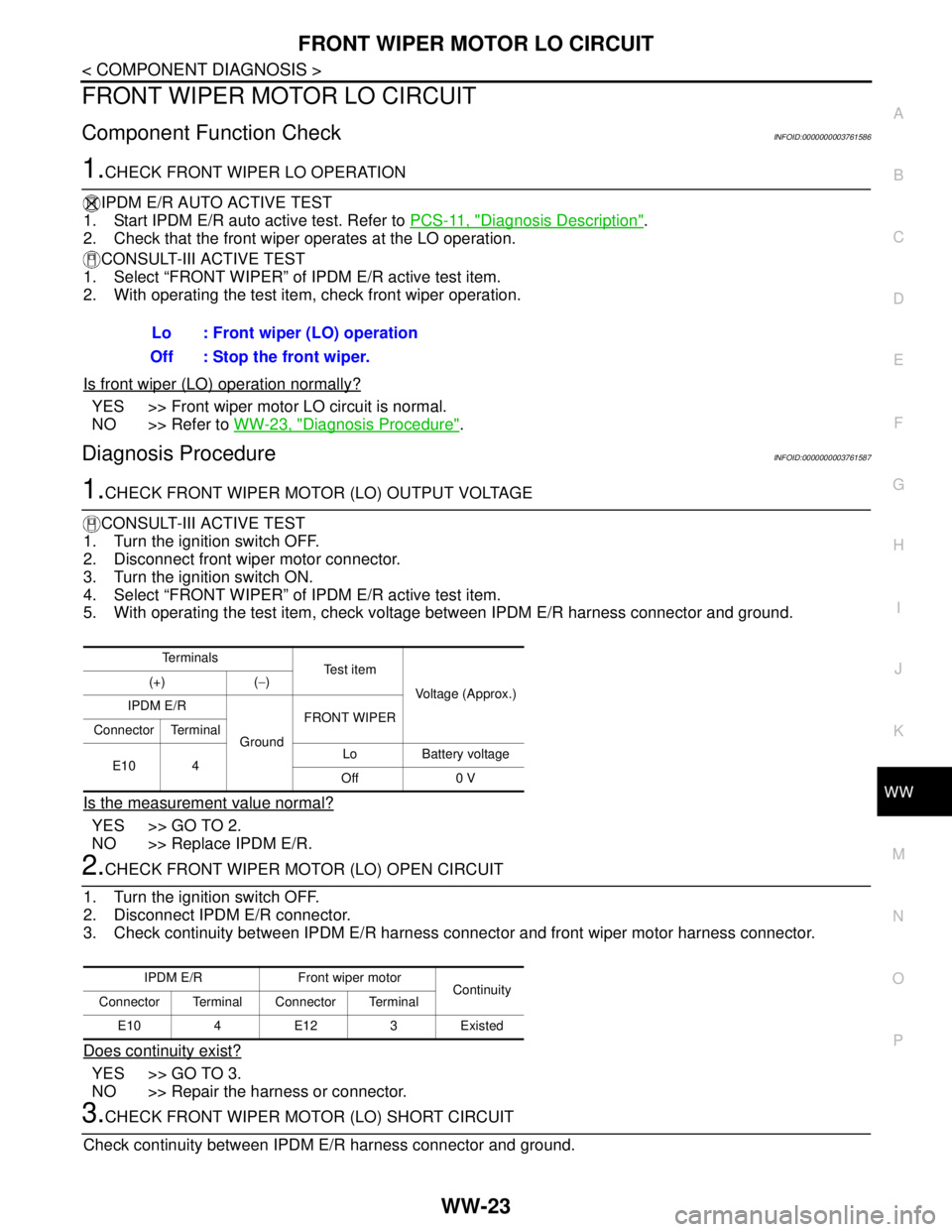

1.CHECK FRONT WIPER MOTOR (LO) OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn the ignition switch ON.

4. Select “FRONT WIPER” of IPDM E/R active test item.

5. With operating the test item, check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 2.

NO >> Replace IPDM E/R.

2.CHECK FRONT WIPER MOTOR (LO) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Does continuity exist?

YES >> GO TO 3.

NO >> Repair the harness or connector.

3.CHECK FRONT WIPER MOTOR (LO) SHORT CIRCUIT

Check continuity between IPDM E/R harness connector and ground.Lo : Front wiper (LO) operation

Off : Stop the front wiper.

Te r m i n a l s

Te s t i t e m

Voltage (Approx.) (+) (−)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E10 4Lo Battery voltage

Off 0 V

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E10 4 E12 3 Existed

Page 5037 of 5121

FRONT WIPER MOTOR HI CIRCUIT

WW-25

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER MOTOR HI CIRCUIT

Component Function CheckINFOID:0000000003761588

1.CHECK FRONT WIPER HI OPERATION

IPDM E/R AUTO ACTIVE TEST

1. Start IPDM E/R auto active test. Refer to PCS-11, "

Diagnosis Description".

2. Check that the front wiper operates at the HI operation.

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Is front wiper (HI) operation normally?

YES >> Front wiper motor HI circuit is normal.

NO >> Refer to WW-25, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761589

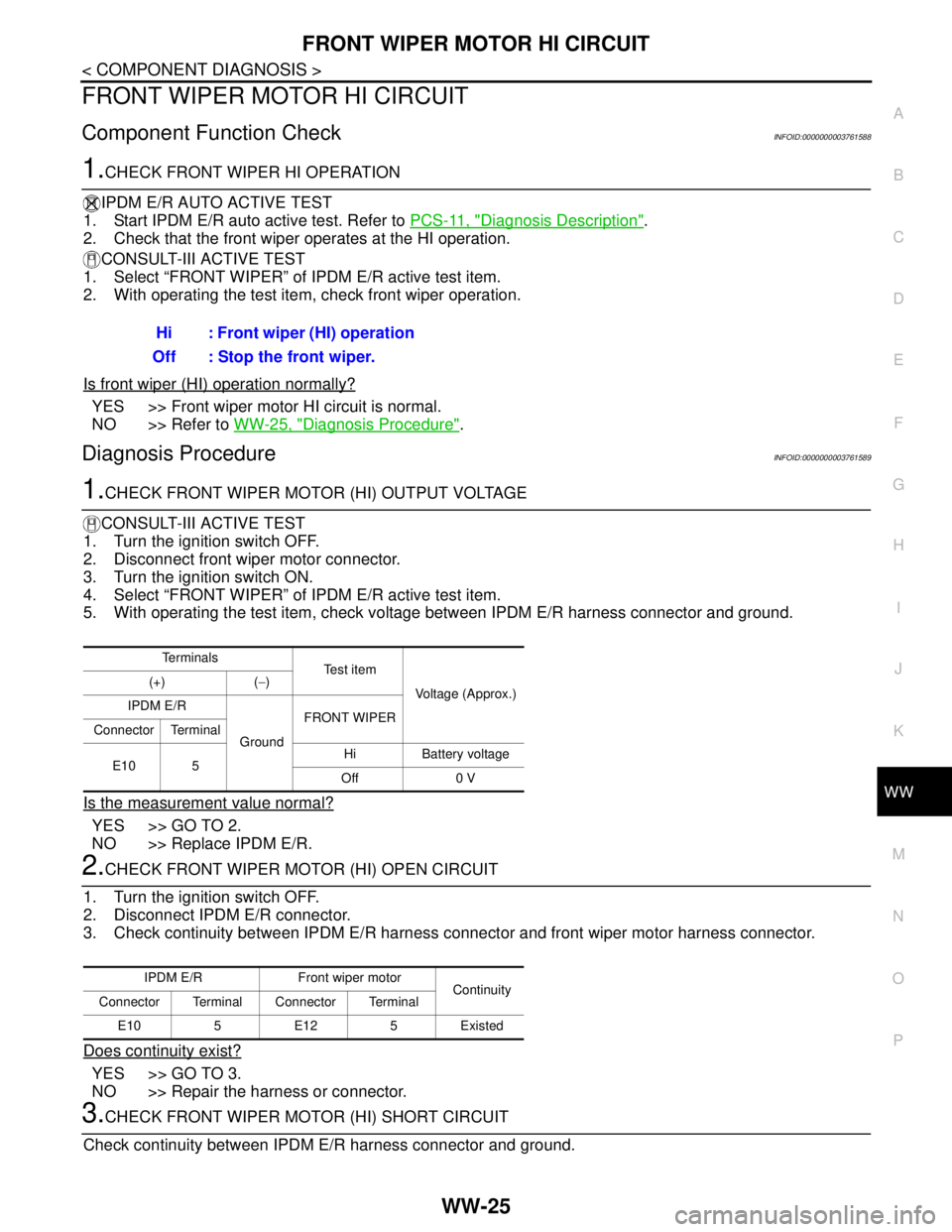

1.CHECK FRONT WIPER MOTOR (HI) OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn the ignition switch ON.

4. Select “FRONT WIPER” of IPDM E/R active test item.

5. With operating the test item, check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 2.

NO >> Replace IPDM E/R.

2.CHECK FRONT WIPER MOTOR (HI) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Does continuity exist?

YES >> GO TO 3.

NO >> Repair the harness or connector.

3.CHECK FRONT WIPER MOTOR (HI) SHORT CIRCUIT

Check continuity between IPDM E/R harness connector and ground.Hi : Front wiper (HI) operation

Off : Stop the front wiper.

Te r m i n a l s

Te s t i t e m

Voltage (Approx.) (+) (−)

IPDM E/R

GroundFRONT WIPER

Connector Terminal

E10 5Hi Battery voltage

Off 0 V

IPDM E/R Front wiper motor

Continuity

Connector Terminal Connector Terminal

E10 5 E12 5 Existed

Page 5039 of 5121

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

WW-27

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER AUTO STOP SIGNAL CIRCUIT

Component Function CheckINFOID:0000000003761590

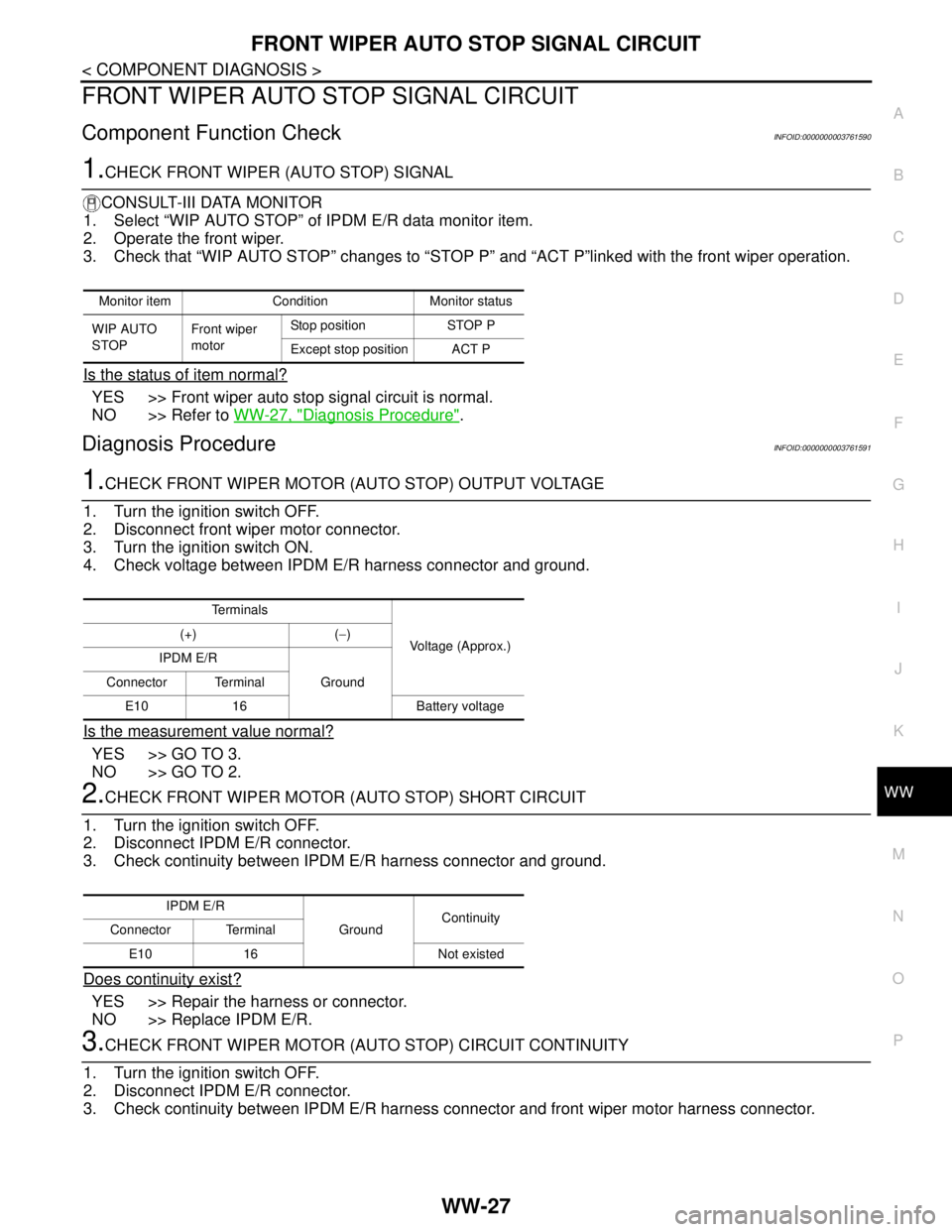

1.CHECK FRONT WIPER (AUTO STOP) SIGNAL

CONSULT-III DATA MONITOR

1. Select “WIP AUTO STOP” of IPDM E/R data monitor item.

2. Operate the front wiper.

3. Check that “WIP AUTO STOP” changes to “STOP P” and “ACT P”linked with the front wiper operation.

Is the status of item normal?

YES >> Front wiper auto stop signal circuit is normal.

NO >> Refer to WW-27, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761591

1.CHECK FRONT WIPER MOTOR (AUTO STOP) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn the ignition switch ON.

4. Check voltage between IPDM E/R harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FRONT WIPER MOTOR (AUTO STOP) SHORT CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and ground.

Does continuity exist?

YES >> Repair the harness or connector.

NO >> Replace IPDM E/R.

3.CHECK FRONT WIPER MOTOR (AUTO STOP) CIRCUIT CONTINUITY

1. Turn the ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

Monitor item Condition Monitor status

WIP AUTO

STOPFront wiper

motorStop position STOP P

Except stop position ACT P

Te r m i n a l s

Voltage (Approx.) (+) (−)

IPDM E/R

Ground Connector Terminal

E10 16 Battery voltage

IPDM E/R

GroundContinuity

Connector Terminal

E10 16 Not existed

Page 5041 of 5121

FRONT WIPER MOTOR GROUND CIRCUIT

WW-29

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

FRONT WIPER MOTOR GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000003761592

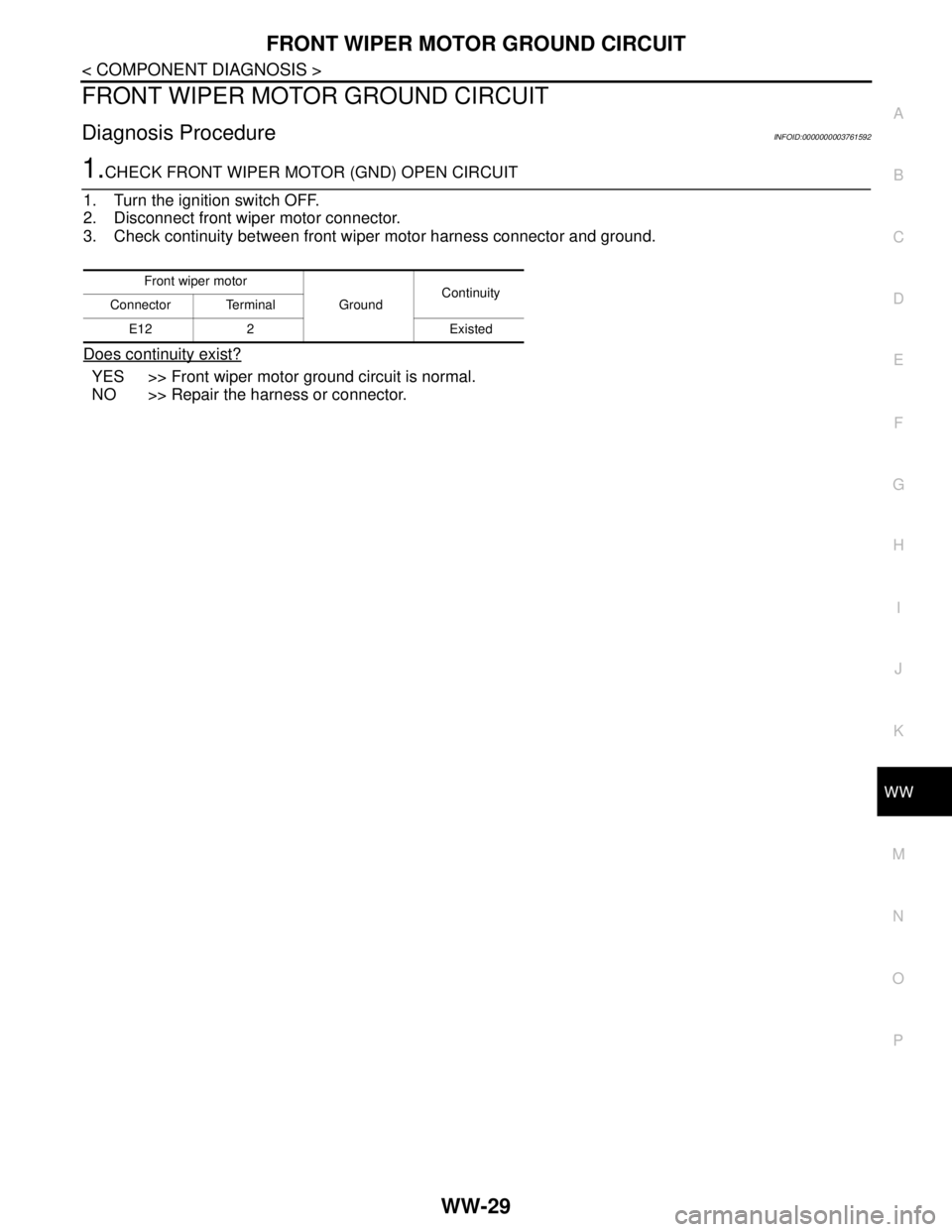

1.CHECK FRONT WIPER MOTOR (GND) OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Check continuity between front wiper motor harness connector and ground.

Does continuity exist?

YES >> Front wiper motor ground circuit is normal.

NO >> Repair the harness or connector.

Front wiper motor

GroundContinuity

Connector Terminal

E12 2 Existed

Page 5042 of 5121

WW-30

< COMPONENT DIAGNOSIS >

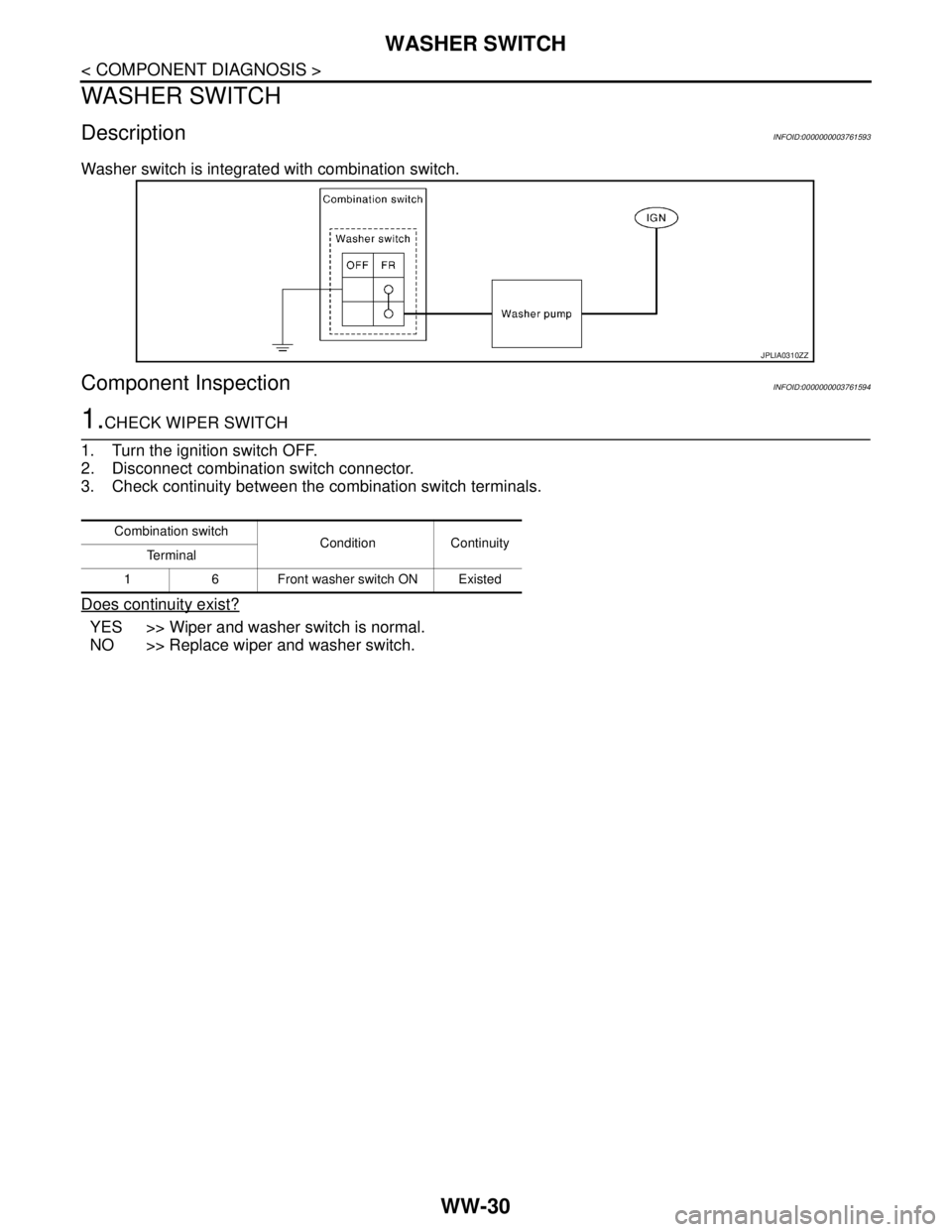

WASHER SWITCH

WASHER SWITCH

DescriptionINFOID:0000000003761593

Washer switch is integrated with combination switch.

Component InspectionINFOID:0000000003761594

1.CHECK WIPER SWITCH

1. Turn the ignition switch OFF.

2. Disconnect combination switch connector.

3. Check continuity between the combination switch terminals.

Does continuity exist?

YES >> Wiper and washer switch is normal.

NO >> Replace wiper and washer switch.

JPLIA0310ZZ

Combination switch

Condition Continuity

Te r m i n a l

1 6 Front washer switch ON Existed

Page 5043 of 5121

HEADLAMP WASHER RELAY

WW-31

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

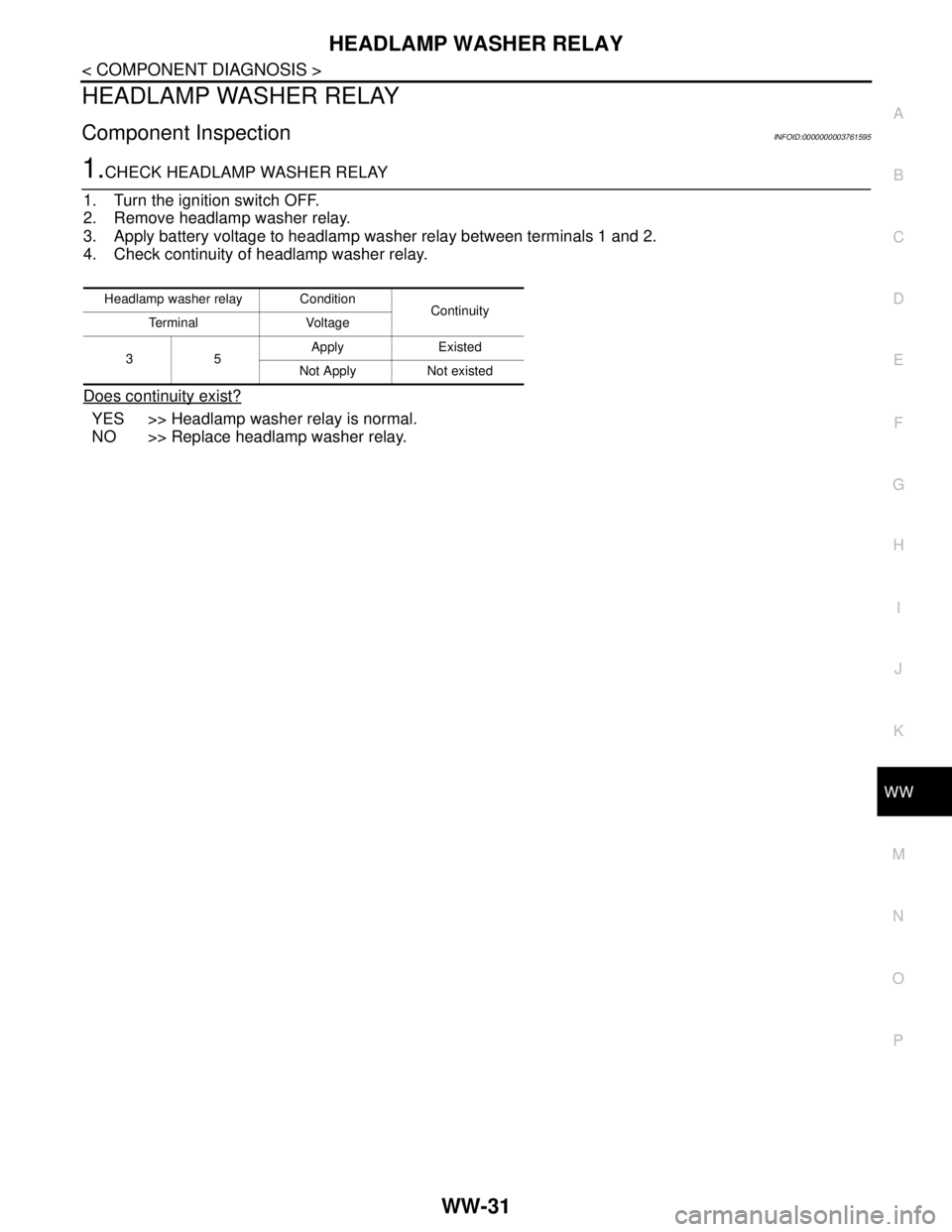

HEADLAMP WASHER RELAY

Component InspectionINFOID:0000000003761595

1.CHECK HEADLAMP WASHER RELAY

1. Turn the ignition switch OFF.

2. Remove headlamp washer relay.

3. Apply battery voltage to headlamp washer relay between terminals 1 and 2.

4. Check continuity of headlamp washer relay.

Does continuity exist?

YES >> Headlamp washer relay is normal.

NO >> Replace headlamp washer relay.

Headlamp washer relay Condition

Continuity

Terminal Voltage

35Apply Existed

Not Apply Not existed

Page 5044 of 5121

WW-32

< COMPONENT DIAGNOSIS >

HEADLAMP WASHER CIRCUIT

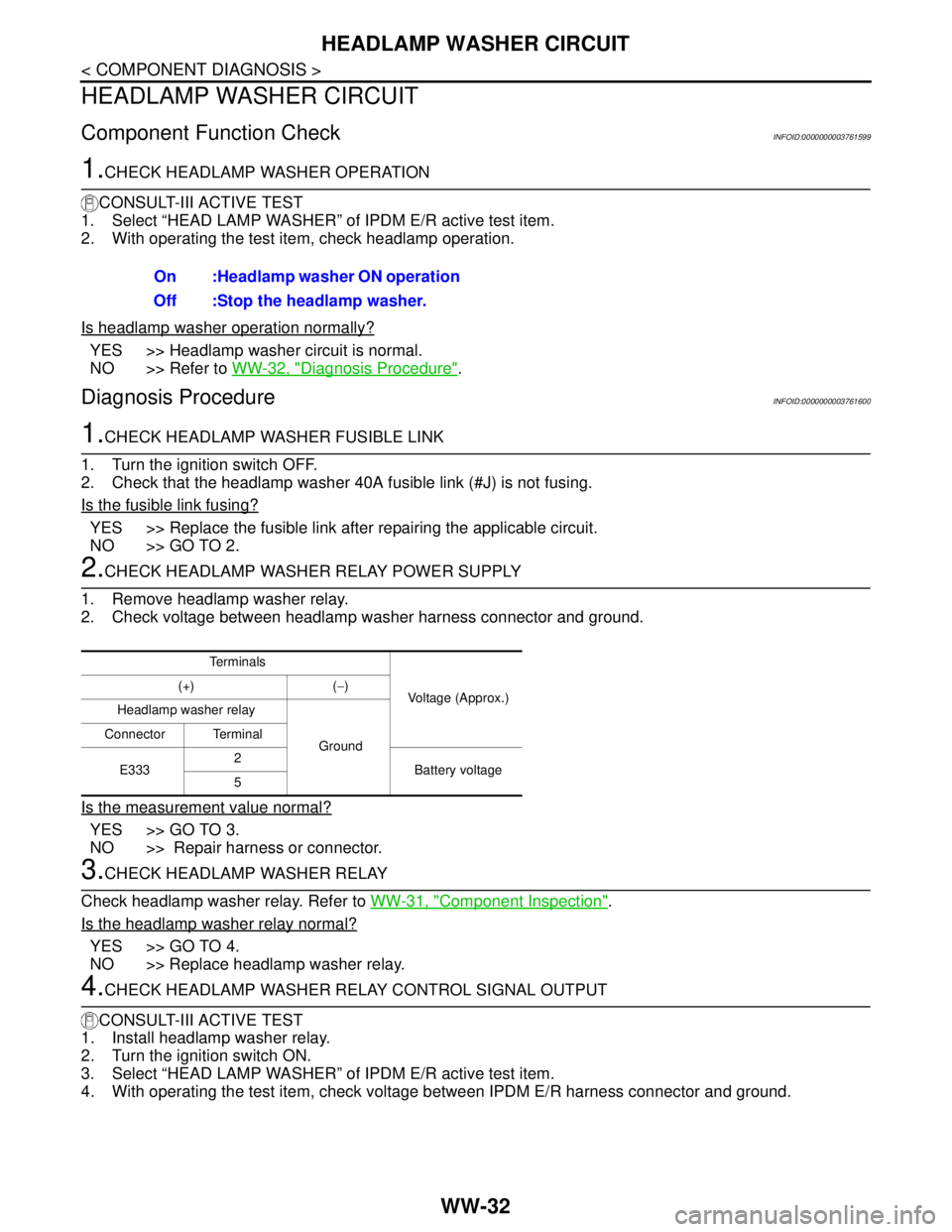

HEADLAMP WASHER CIRCUIT

Component Function CheckINFOID:0000000003761599

1.CHECK HEADLAMP WASHER OPERATION

CONSULT-III ACTIVE TEST

1. Select “HEAD LAMP WASHER” of IPDM E/R active test item.

2. With operating the test item, check headlamp operation.

Is headlamp washer operation normally?

YES >> Headlamp washer circuit is normal.

NO >> Refer to WW-32, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003761600

1.CHECK HEADLAMP WASHER FUSIBLE LINK

1. Turn the ignition switch OFF.

2. Check that the headlamp washer 40A fusible link (#J) is not fusing.

Is the fusible link fusing?

YES >> Replace the fusible link after repairing the applicable circuit.

NO >> GO TO 2.

2.CHECK HEADLAMP WASHER RELAY POWER SUPPLY

1. Remove headlamp washer relay.

2. Check voltage between headlamp washer harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK HEADLAMP WASHER RELAY

Check headlamp washer relay. Refer to WW-31, "

Component Inspection".

Is the headlamp washer relay normal?

YES >> GO TO 4.

NO >> Replace headlamp washer relay.

4.CHECK HEADLAMP WASHER RELAY CONTROL SIGNAL OUTPUT

CONSULT-III ACTIVE TEST

1. Install headlamp washer relay.

2. Turn the ignition switch ON.

3. Select “HEAD LAMP WASHER” of IPDM E/R active test item.

4. With operating the test item, check voltage between IPDM E/R harness connector and ground.On :Headlamp washer ON operation

Off :Stop the headlamp washer.

Te r m i n a l s

Voltage (Approx.) (+) (−)

Headlamp washer relay

Ground Connector Terminal

E3332

Battery voltage

5

Page 5056 of 5121

WW-44

< ECU DIAGNOSIS >

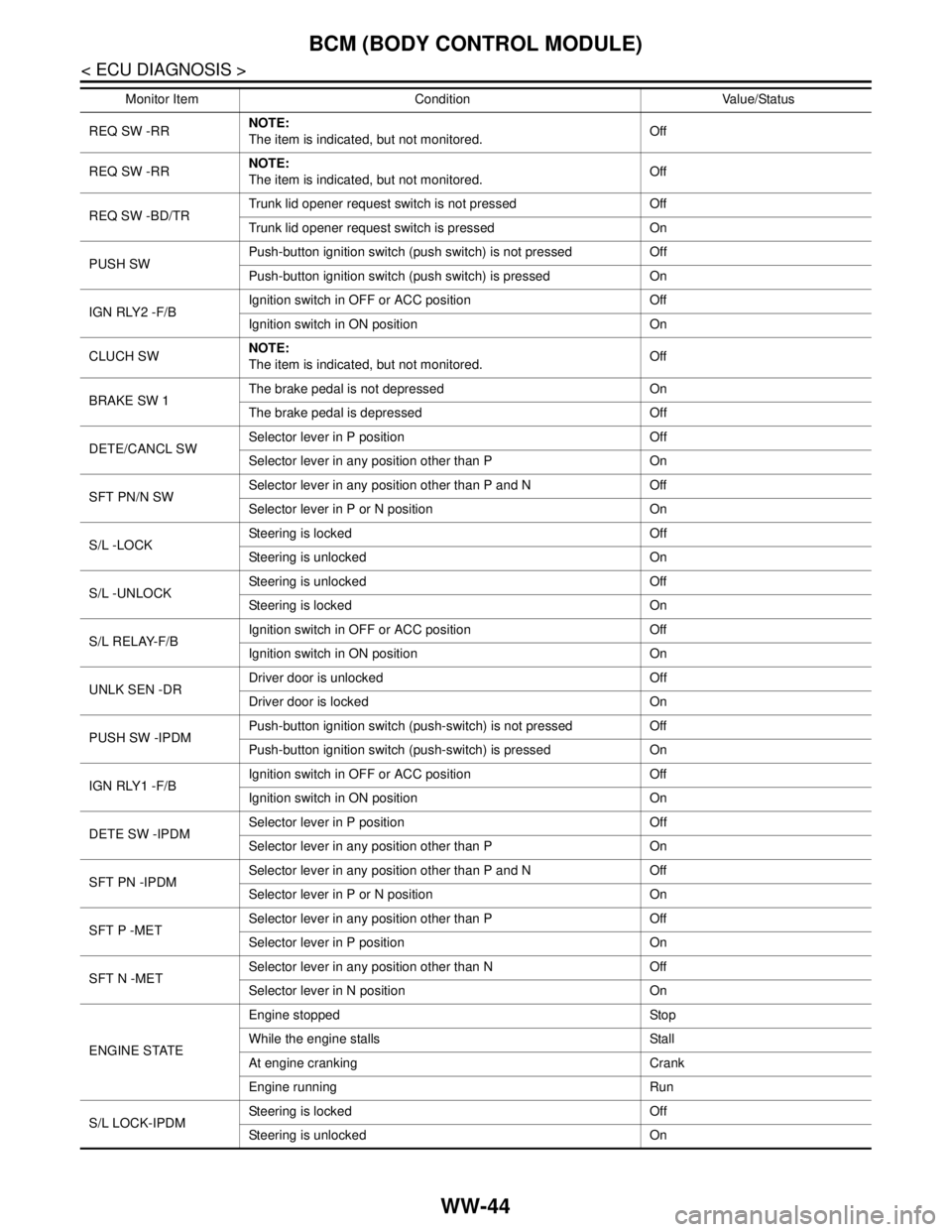

BCM (BODY CONTROL MODULE)

REQ SW -RRNOTE:

The item is indicated, but not monitored. Off

REQ SW -RRNOTE:

The item is indicated, but not monitored. Off

REQ SW -BD/TRTrunk lid opener request switch is not pressed Off

Trunk lid opener request switch is pressed On

PUSH SWPush-button ignition switch (push switch) is not pressed Off

Push-button ignition switch (push switch) is pressed On

IGN RLY2 -F/BIgnition switch in OFF or ACC position Off

Ignition switch in ON position On

CLUCH SWNOTE:

The item is indicated, but not monitored. Off

BRAKE SW 1The brake pedal is not depressed On

The brake pedal is depressed Off

DETE/CANCL SWSelector lever in P position Off

Selector lever in any position other than P On

SFT PN/N SWSelector lever in any position other than P and N Off

Selector lever in P or N position On

S/L -LOCKSteering is locked Off

Steering is unlocked On

S/L -UNLOCKSteering is unlocked Off

Steering is locked On

S/L RELAY-F/BIgnition switch in OFF or ACC position Off

Ignition switch in ON position On

UNLK SEN -DRDriver door is unlocked Off

Driver door is locked On

PUSH SW -IPDMPush-button ignition switch (push-switch) is not pressed Off

Push-button ignition switch (push-switch) is pressed On

IGN RLY1 -F/BIgnition switch in OFF or ACC position Off

Ignition switch in ON position On

DETE SW -IPDMSelector lever in P position Off

Selector lever in any position other than P On

SFT PN -IPDMSelector lever in any position other than P and N Off

Selector lever in P or N position On

SFT P -METSelector lever in any position other than P Off

Selector lever in P position On

SFT N -METSelector lever in any position other than N Off

Selector lever in N position On

ENGINE STATEEngine stopped Stop

While the engine stalls Stall

At engine cranking Crank

Engine running Run

S/L LOCK-IPDMSteering is locked Off

Steering is unlocked On Monitor Item Condition Value/Status

Page 5057 of 5121

BCM (BODY CONTROL MODULE)

WW-45

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

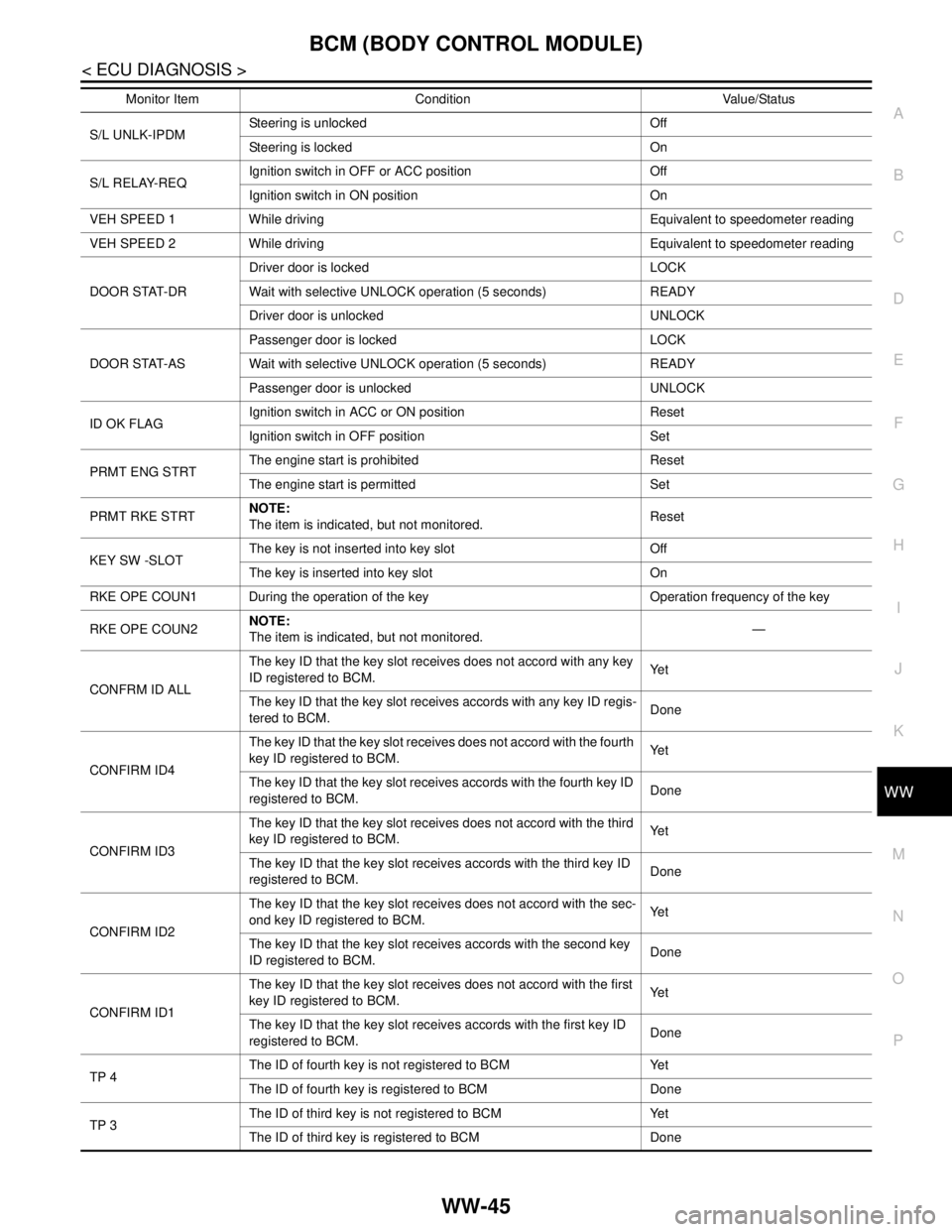

S/L UNLK-IPDMSteering is unlocked Off

Steering is locked On

S/L RELAY-REQIgnition switch in OFF or ACC position Off

Ignition switch in ON position On

VEH SPEED 1 While driving Equivalent to speedometer reading

VEH SPEED 2 While driving Equivalent to speedometer reading

DOOR STAT-DRDriver door is locked LOCK

Wait with selective UNLOCK operation (5 seconds) READY

Driver door is unlocked UNLOCK

DOOR STAT-ASPassenger door is locked LOCK

Wait with selective UNLOCK operation (5 seconds) READY

Passenger door is unlocked UNLOCK

ID OK FLAGIgnition switch in ACC or ON position Reset

Ignition switch in OFF position Set

PRMT ENG STRTThe engine start is prohibited Reset

The engine start is permitted Set

PRMT RKE STRTNOTE:

The item is indicated, but not monitored. Reset

KEY SW -SLOTThe key is not inserted into key slot Off

The key is inserted into key slot On

RKE OPE COUN1 During the operation of the key Operation frequency of the key

RKE OPE COUN2NOTE:

The item is indicated, but not monitored. —

CONFRM ID ALLThe key ID that the key slot receives does not accord with any key

ID registered to BCM.Ye t

The key ID that the key slot receives accords with any key ID regis-

tered to BCM.Done

CONFIRM ID4The key ID that the key slot receives does not accord with the fourth

key ID registered to BCM.Ye t

The key ID that the key slot receives accords with the fourth key ID

registered to BCM.Done

CONFIRM ID3The key ID that the key slot receives does not accord with the third

key ID registered to BCM.Ye t

The key ID that the key slot receives accords with the third key ID

registered to BCM.Done

CONFIRM ID2The key ID that the key slot receives does not accord with the sec-

ond key ID registered to BCM.Ye t

The key ID that the key slot receives accords with the second key

ID registered to BCM.Done

CONFIRM ID1The key ID that the key slot receives does not accord with the first

key ID registered to BCM.Ye t

The key ID that the key slot receives accords with the first key ID

registered to BCM.Done

TP 4The ID of fourth key is not registered to BCM Yet

The ID of fourth key is registered to BCM Done

TP 3The ID of third key is not registered to BCM Yet

The ID of third key is registered to BCM Done Monitor Item Condition Value/Status

Page 5059 of 5121

BCM (BODY CONTROL MODULE)

WW-47

< ECU DIAGNOSIS >

C

D

E

F

G

H

I

J

K

MA

B

WW

N

O

P

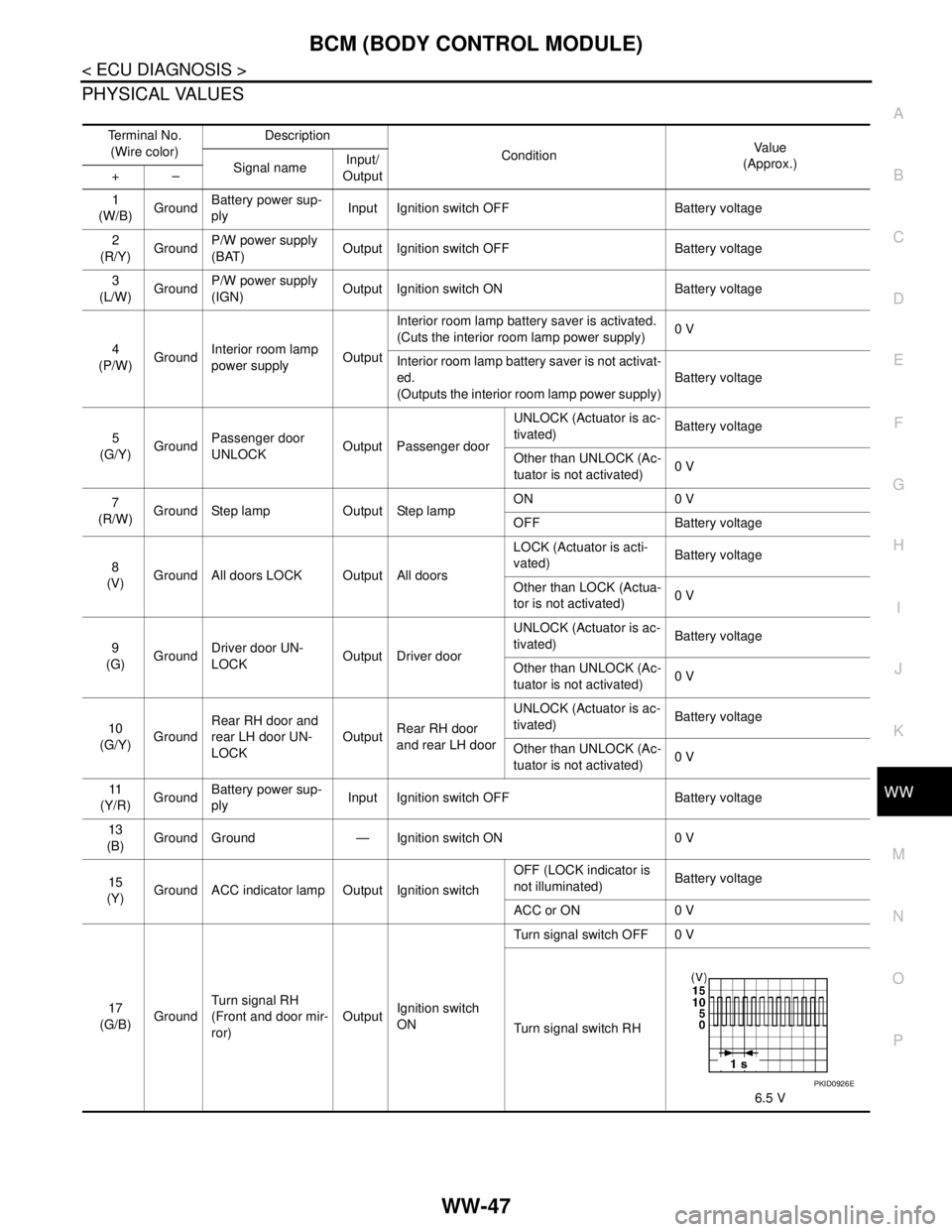

PHYSICAL VALUES

Te r m i n a l N o .

(Wire color)Description

ConditionVa l u e

(Approx.)

Signal nameInput/

Output +–

1

(W/B)GroundBattery power sup-

plyInput Ignition switch OFF Battery voltage

2

(R/Y)GroundP/W power supply

(BAT)Output Ignition switch OFF Battery voltage

3

(L/W)GroundP/W power supply

(IGN)Output Ignition switch ON Battery voltage

4

(P/W)GroundInterior room lamp

power supplyOutputInterior room lamp battery saver is activated.

(Cuts the interior room lamp power supply)0 V

Interior room lamp battery saver is not activat-

ed.

(Outputs the interior room lamp power supply)Battery voltage

5

(G/Y)GroundPassenger door

UNLOCKOutput Passenger doorUNLOCK (Actuator is ac-

tivated)Battery voltage

Other than UNLOCK (Ac-

tuator is not activated)0 V

7

(R/W)Ground Step lamp Output Step lampON 0 V

OFF Battery voltage

8

(V)Ground All doors LOCK Output All doorsLOCK (Actuator is acti-

vated)Battery voltage

Other than LOCK (Actua-

tor is not activated)0 V

9

(G)GroundDriver door UN-

LOCKOutput Driver doorUNLOCK (Actuator is ac-

tivated)Battery voltage

Other than UNLOCK (Ac-

tuator is not activated)0 V

10

(G/Y)GroundRear RH door and

rear LH door UN-

LOCKOutputRear RH door

and rear LH doorUNLOCK (Actuator is ac-

tivated)Battery voltage

Other than UNLOCK (Ac-

tuator is not activated)0 V

11

(Y/R)GroundBattery power sup-

plyInput Ignition switch OFF Battery voltage

13

(B)

Ground Ground — Ignition switch ON 0 V

15

(Y)Ground ACC indicator lamp Output Ignition switchOFF (LOCK indicator is

not illuminated)Battery voltage

ACC or ON 0 V

17

(G/B)GroundTurn signal RH

(Front and door mir-

ror)OutputIgnition switch

ONTurn signal switch OFF 0 V

Turn signal switch RH

6.5 V

PKID0926E