ABS NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 822 of 5121

BCS

INSPECTION AND ADJUSTMENT

BCS-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L B A

O

P N

CONFIGURATION (BCM) : Configuration listINFOID:0000000003809648

⇔: Items which confirm vehicle specificationsMANUAL SETTING ITEM

NOTE

Items Setting value

AUTO LIGHT WITH —

RR FOG LAMP WITH —

AV C/U WITH ⇔ WITHOUT WITH: With BOSE audio system

WITHOUT: Without BOSE audio system

THEFT ALM AREA MODE3 —

H/L WASHER TIME 1 WITH —

H/L WASHER TIME 2 WITH —

I-KEY WITH —

Key Fob Type MODE10 —

HANDLE LHD —

AUTO SETTING ITEM

NOTE

Items Setting value

H/L BULB DEFAULT —

FR FOG LAMP WITH —

TRANSMISSION AT with ABS —

TR CANCL SW WITHOUT —

TPMS WITHOUT —

AUTO BACK DOOR WITHOUT —

FOG LAMP BULB SINGLE BULB —

D I L M P VA R I AT M O D E 4 —

LIGHT RECOG MODE4 —

FR FOG LOGIC MODE2 —

PANIC ALM TYPE MODE2 —

HAZARD SW TYPE MODE1 —

BCM AC CONTROL MODE1 —

RAIN SENSOR WITHOUT —

FOG ON WITH AUTO LIGHT WITHOUT —

AUTO LOCK&UNLOCK FUNC WITHOUT —

DROP WIP FUNCTION WITHOUT —

SELECTIVE UNLOCK SETTING WITHOUT —

SEAT BLT WARN WITHOUT —

SPEED SNS WIP WITH —

Page 836 of 5121

BCS

DIAGNOSIS SYSTEM (BCM)

BCS-19

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

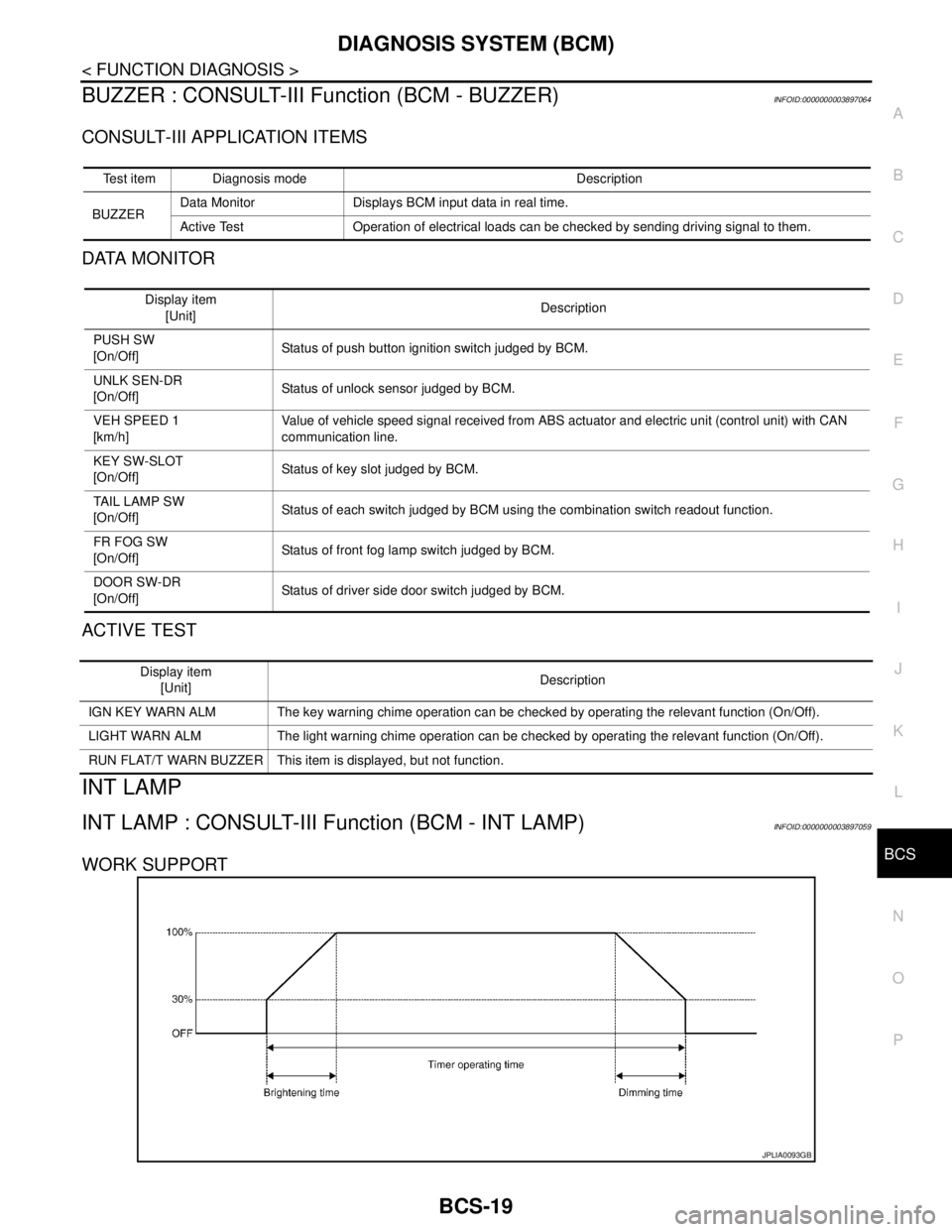

BUZZER : CONSULT-III Function (BCM - BUZZER)INFOID:0000000003897064

CONSULT-III APPLICATION ITEMS

DATA MONITOR

ACTIVE TEST

INT LAMP

INT LAMP : CONSULT-III Function (BCM - INT LAMP)INFOID:0000000003897059

WORK SUPPORT

Test item Diagnosis mode Description

BUZZERData Monitor Displays BCM input data in real time.

Active Test Operation of electrical loads can be checked by sending driving signal to them.

Display item

[Unit]Description

PUSH SW

[On/Off]Status of push button ignition switch judged by BCM.

UNLK SEN-DR

[On/Off]Status of unlock sensor judged by BCM.

VEH SPEED 1

[km/h]Value of vehicle speed signal received from ABS actuator and electric unit (control unit) with CAN

communication line.

KEY SW-SLOT

[On/Off]Status of key slot judged by BCM.

TAIL LAMP SW

[On/Off]Status of each switch judged by BCM using the combination switch readout function.

FR FOG SW

[On/Off]Status of front fog lamp switch judged by BCM.

DOOR SW-DR

[On/Off]Status of driver side door switch judged by BCM.

Display item

[Unit]Description

IGN KEY WARN ALM The key warning chime operation can be checked by operating the relevant function (On/Off).

LIGHT WARN ALM The light warning chime operation can be checked by operating the relevant function (On/Off).

RUN FLAT/T WARN BUZZER This item is displayed, but not function.

JPLIA0093GB

Page 843 of 5121

BCS-26

< FUNCTION DIAGNOSIS >

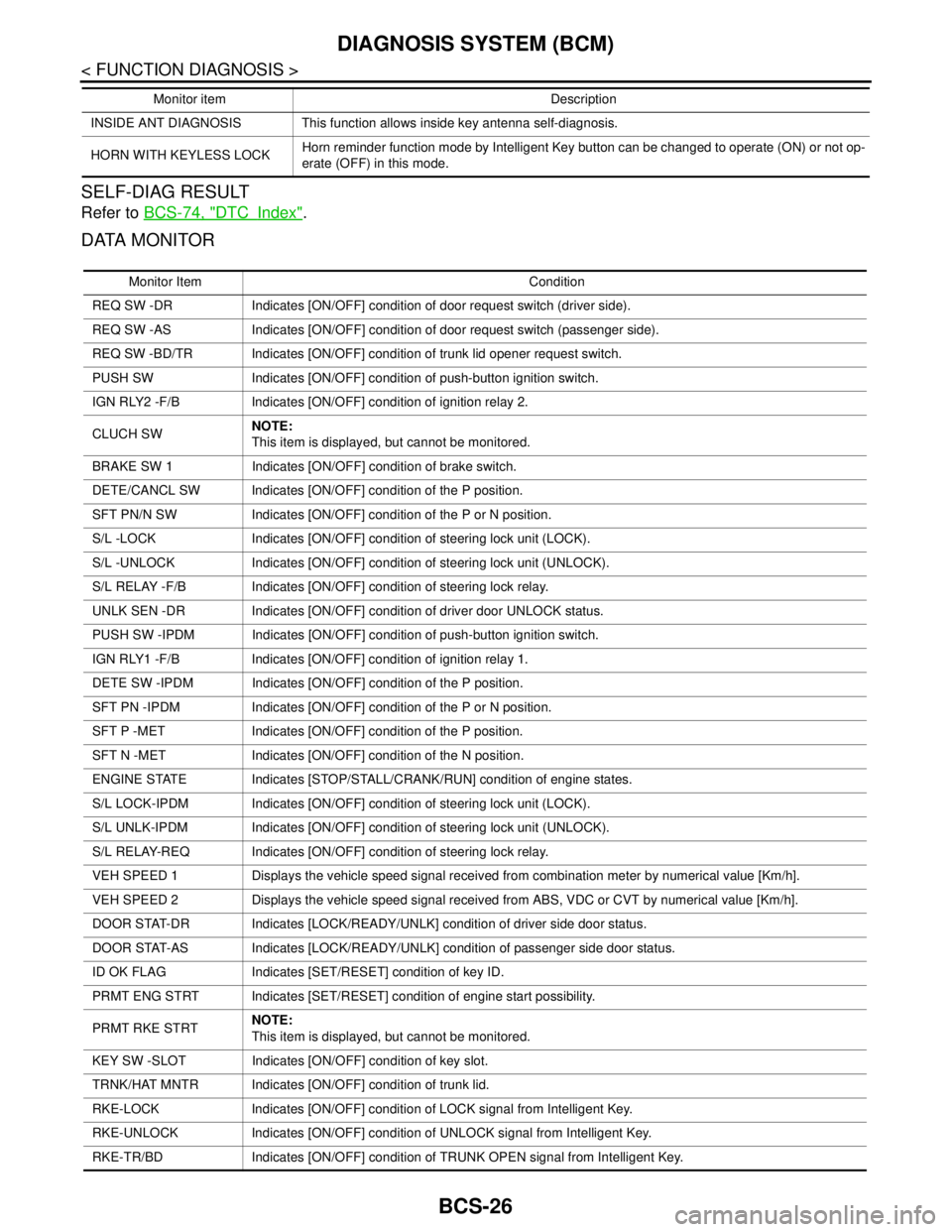

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to BCS-74, "DTCIndex".

DATA MONITOR

INSIDE ANT DIAGNOSIS This function allows inside key antenna self-diagnosis.

HORN WITH KEYLESS LOCKHorn reminder function mode by Intelligent Key button can be changed to operate (ON) or not op-

erate (OFF) in this mode. Monitor item Description

Monitor Item Condition

REQ SW -DR Indicates [ON/OFF] condition of door request switch (driver side).

REQ SW -AS Indicates [ON/OFF] condition of door request switch (passenger side).

REQ SW -BD/TR Indicates [ON/OFF] condition of trunk lid opener request switch.

PUSH SW Indicates [ON/OFF] condition of push-button ignition switch.

IGN RLY2 -F/B Indicates [ON/OFF] condition of ignition relay 2.

CLUCH SWNOTE:

This item is displayed, but cannot be monitored.

BRAKE SW 1 Indicates [ON/OFF] condition of brake switch.

DETE/CANCL SW Indicates [ON/OFF] condition of the P position.

SFT PN/N SW Indicates [ON/OFF] condition of the P or N position.

S/L -LOCK Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L -UNLOCK Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY -F/B Indicates [ON/OFF] condition of steering lock relay.

UNLK SEN -DR Indicates [ON/OFF] condition of driver door UNLOCK status.

PUSH SW -IPDM Indicates [ON/OFF] condition of push-button ignition switch.

IGN RLY1 -F/B Indicates [ON/OFF] condition of ignition relay 1.

DETE SW -IPDM Indicates [ON/OFF] condition of the P position.

SFT PN -IPDM Indicates [ON/OFF] condition of the P or N position.

SFT P -MET Indicates [ON/OFF] condition of the P position.

SFT N -MET Indicates [ON/OFF] condition of the N position.

ENGINE STATE Indicates [STOP/STALL/CRANK/RUN] condition of engine states.

S/L LOCK-IPDM Indicates [ON/OFF] condition of steering lock unit (LOCK).

S/L UNLK-IPDM Indicates [ON/OFF] condition of steering lock unit (UNLOCK).

S/L RELAY-REQ Indicates [ON/OFF] condition of steering lock relay.

VEH SPEED 1 Displays the vehicle speed signal received from combination meter by numerical value [Km/h].

VEH SPEED 2 Displays the vehicle speed signal received from ABS, VDC or CVT by numerical value [Km/h].

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of driver side door status.

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status.

ID OK FLAG Indicates [SET/RESET] condition of key ID.

PRMT ENG STRT Indicates [SET/RESET] condition of engine start possibility.

PRMT RKE STRTNOTE:

This item is displayed, but cannot be monitored.

KEY SW -SLOT Indicates [ON/OFF] condition of key slot.

TRNK/HAT MNTR Indicates [ON/OFF] condition of trunk lid.

RKE-LOCK Indicates [ON/OFF] condition of LOCK signal from Intelligent Key.

RKE-UNLOCK Indicates [ON/OFF] condition of UNLOCK signal from Intelligent Key.

RKE-TR/BD Indicates [ON/OFF] condition of TRUNK OPEN signal from Intelligent Key.

Page 852 of 5121

BCS

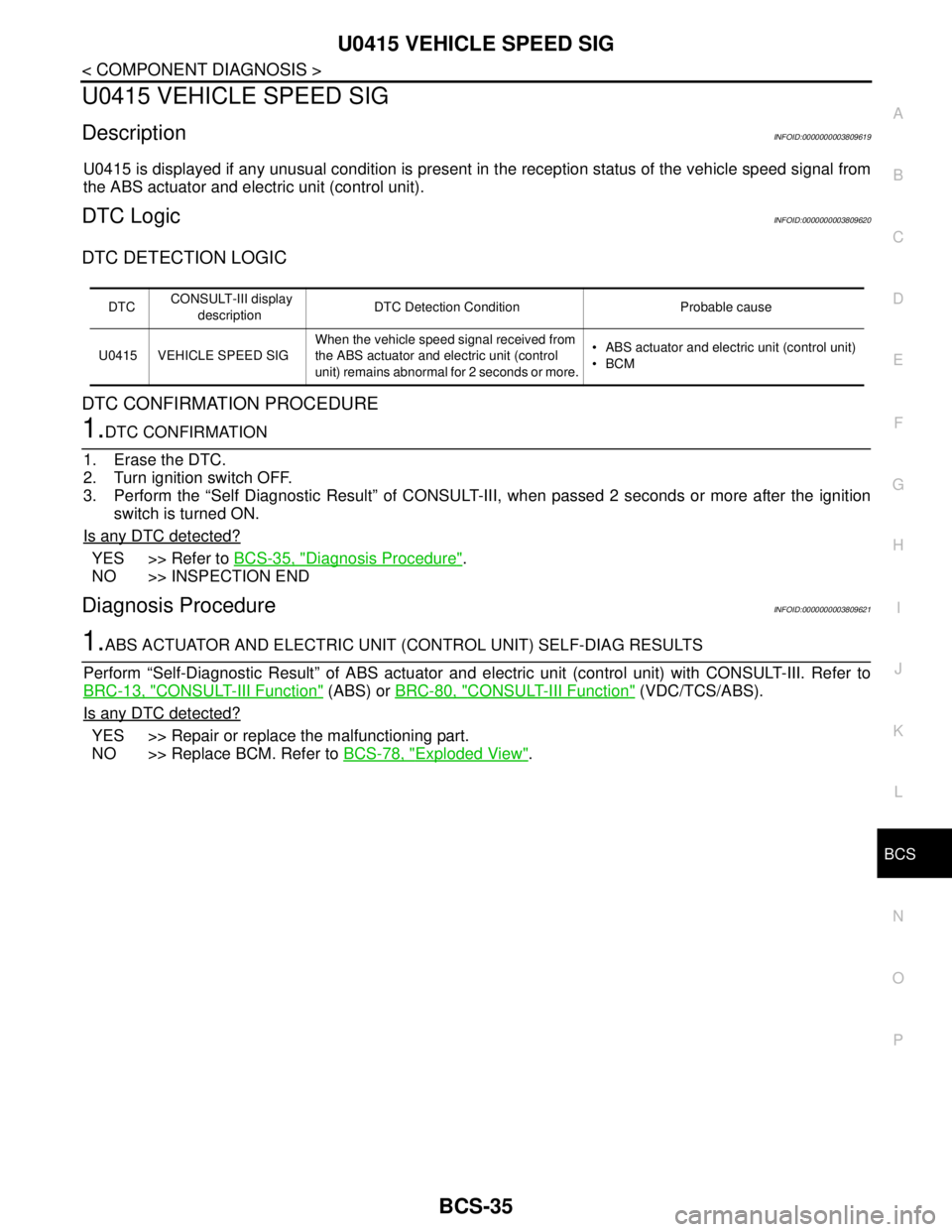

U0415 VEHICLE SPEED SIG

BCS-35

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

U0415 VEHICLE SPEED SIG

DescriptionINFOID:0000000003809619

U0415 is displayed if any unusual condition is present in the reception status of the vehicle speed signal from

the ABS actuator and electric unit (control unit).

DTC LogicINFOID:0000000003809620

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.DTC CONFIRMATION

1. Erase the DTC.

2. Turn ignition switch OFF.

3. Perform the “Self Diagnostic Result” of CONSULT-III, when passed 2 seconds or more after the ignition

switch is turned ON.

Is any DTC detected?

YES >> Refer to BCS-35, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003809621

1.ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAG RESULTS

Perform “Self-Diagnostic Result” of ABS actuator and electric unit (control unit) with CONSULT-III. Refer to

BRC-13, "

CONSULT-III Function" (ABS) or BRC-80, "CONSULT-III Function" (VDC/TCS/ABS).

Is any DTC detected?

YES >> Repair or replace the malfunctioning part.

NO >> Replace BCM. Refer to BCS-78, "

Exploded View".

DTC CONSULT-III display

descriptionDTC Detection Condition Probable cause

U0415 VEHICLE SPEED SIGWhen the vehicle speed signal received from

the ABS actuator and electric unit (control

unit) remains abnormal for 2 seconds or more. ABS actuator and electric unit (control unit)

BCM

Page 889 of 5121

BCS-72

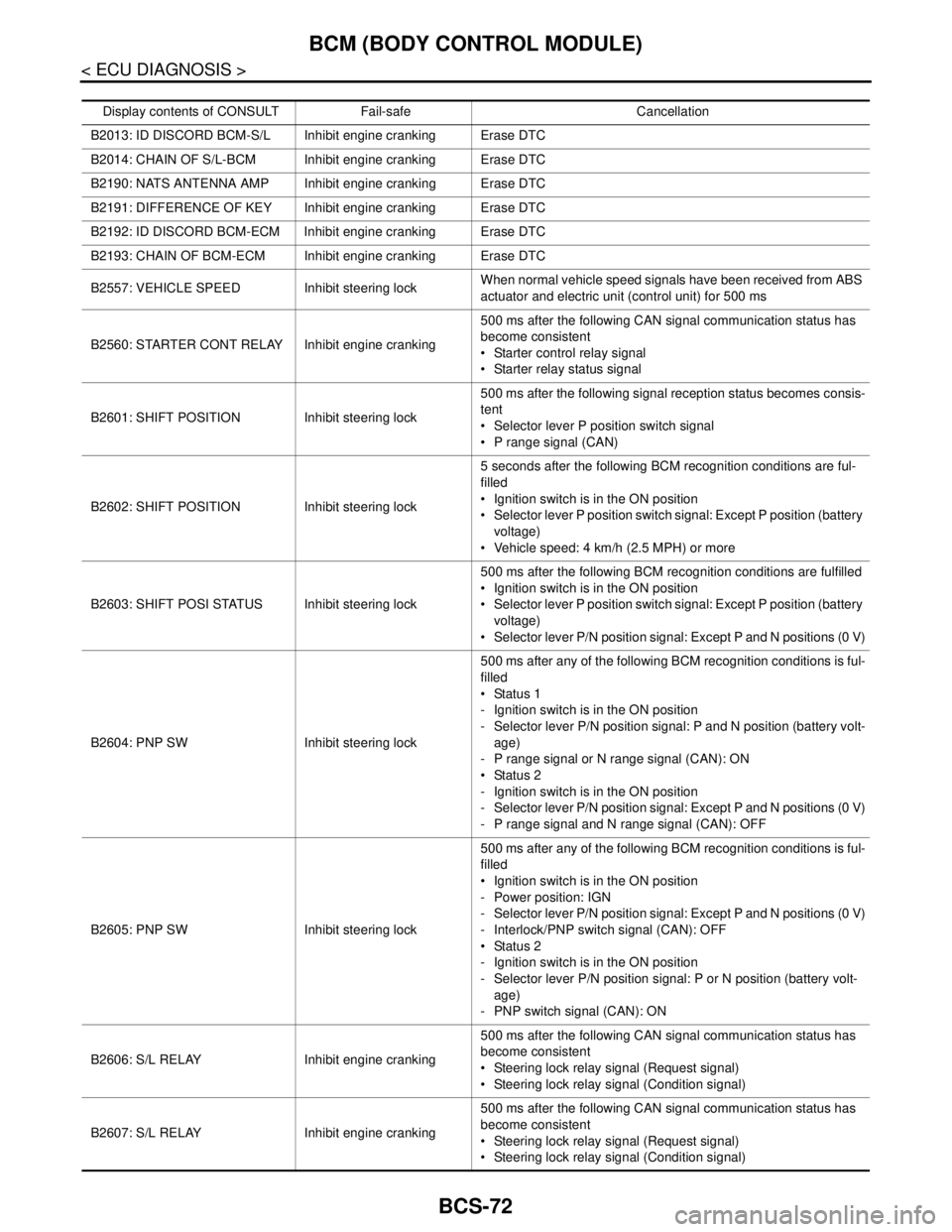

< ECU DIAGNOSIS >

BCM (BODY CONTROL MODULE)

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITION Inhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITION Inhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

Page 901 of 5121

PRECAUTIONS

BR-5

< PRECAUTION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Precaution for Procedure without Cowl Top CoverINFOID:0000000003890162

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000003811170

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector. Never blow with com-

pressed air.

CAUTION:

Only use “DOT 3 or DOT 4” brake fluid. Refer to MA-11, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Always clean with new brake fluid when cleaning the master cylinder, brake caliper and other com-

ponents.

Never use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and

cause improper operation.

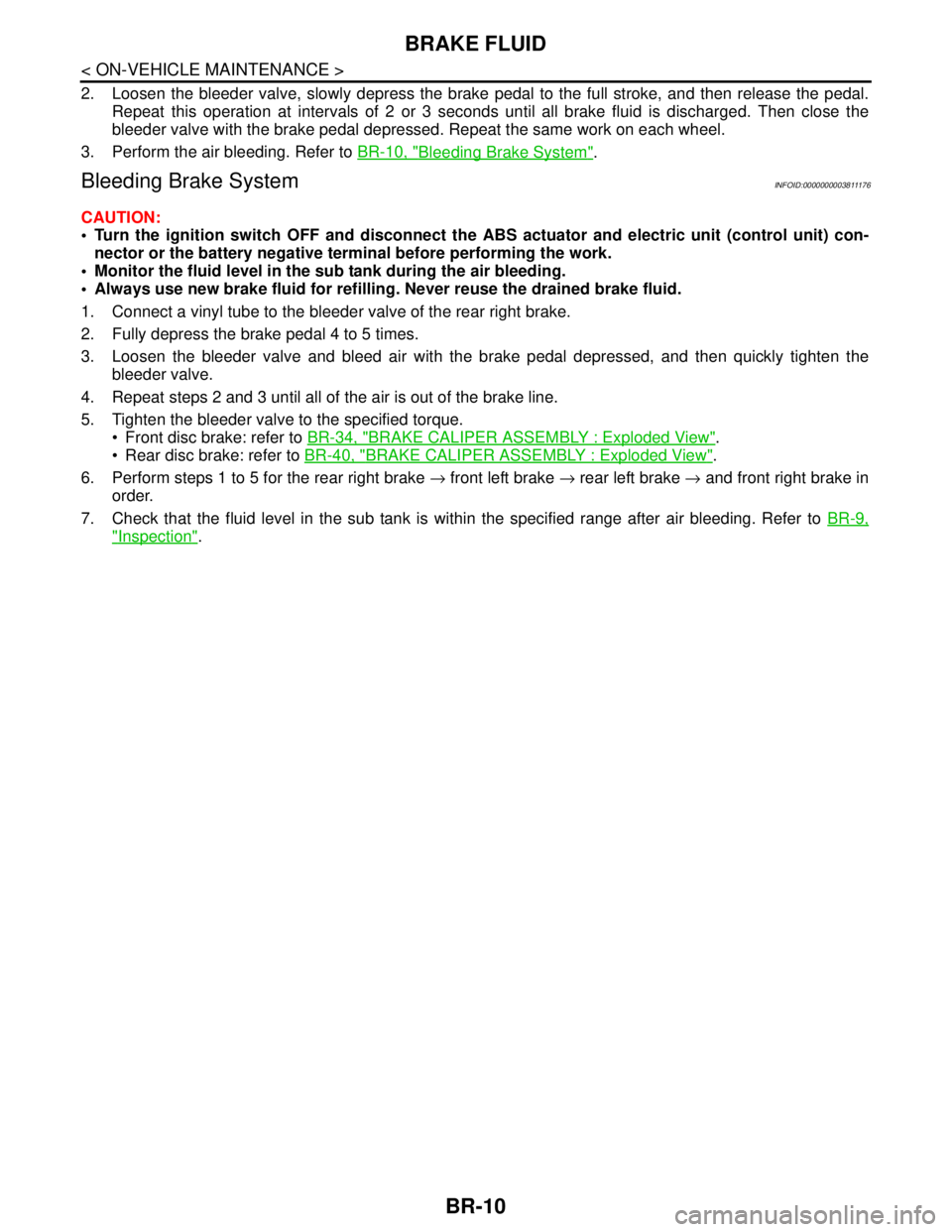

Always loosen the brake tube flare nut with a flare nut wrench.

Tighten the brake tube flare nut to the specified torque with

torque wrench (A).

Always confirm the specified tightening torque when install-

ing the brake pipes.

Turn the ignition switch OFF and disconnect the ABS actuator

and electric unit (control unit) connector or the battery nega-

tive terminal before performing the work.

Check that no brake fluid leakage is present after replacing

the parts.

Burnish the brake contact surfaces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

- Front brake pad: refer to BR-13, "

BRAKE PAD : Inspection and Adjustment".

- Front disc rotor: refer to BR-13, "

DISC ROTOR : Inspection and Adjustment".

- Rear brake pad: refer to BR-15, "

BRAKE PAD : Inspection and Adjustment".

- Rear disc rotor: refer to BR-15, "

DISC ROTOR : Inspection and Adjustment".

PIIB3706J

JPFIA0061ZZ

Page 905 of 5121

BRAKE FLUID

BR-9

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE FLUID

InspectionINFOID:0000000003811173

BRAKE FLUID LEVEL

Check that the fluid level in the sub tank is within the specified

range (MAX – MIN lines).

Visually check for any brake fluid leakage around the sub tank,

reservoir tank and hose.

Check the brake system for any leakage if the fluid level is

extremely low (lower than MIN).

Check the brake system for fluid leakage if the warning lamp

remains illuminated even after the parking brake is released.

BRAKE LINE

1. Check brake line (tubes and hoses) for cracks, deterioration or other damage. Replace any damaged

parts.

2. Check for fluid leakage by fully depressing brake pedal while

engine is running.

CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

DrainingINFOID:0000000003811174

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with water if it gets on a painted surface.

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before draining.

1. Connect a vinyl tube to the bleed valve.

2. Depress the brake pedal and loosen the bleeder valve to gradu-

ally discharge brake fluid.

RefillingINFOID:0000000003811175

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) connec-

tor or the battery negative terminal before refilling.

1. Check that there is no foreign material in the sub tank, and refill with new brake fluid.

CAUTION:

Never reuse drained brake fluid.

JPFIA0007ZZ

SBR389C

BRA0007D

Page 906 of 5121

BR-10

< ON-VEHICLE MAINTENANCE >

BRAKE FLUID

2. Loosen the bleeder valve, slowly depress the brake pedal to the full stroke, and then release the pedal.

Repeat this operation at intervals of 2 or 3 seconds until all brake fluid is discharged. Then close the

bleeder valve with the brake pedal depressed. Repeat the same work on each wheel.

3. Perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

Bleeding Brake SystemINFOID:0000000003811176

CAUTION:

Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) con-

nector or the battery negative terminal before performing the work.

Monitor the fluid level in the sub tank during the air bleeding.

Always use new brake fluid for refilling. Never reuse the drained brake fluid.

1. Connect a vinyl tube to the bleeder valve of the rear right brake.

2. Fully depress the brake pedal 4 to 5 times.

3. Loosen the bleeder valve and bleed air with the brake pedal depressed, and then quickly tighten the

bleeder valve.

4. Repeat steps 2 and 3 until all of the air is out of the brake line.

5. Tighten the bleeder valve to the specified torque.

Front disc brake: refer to BR-34, "

BRAKE CALIPER ASSEMBLY : Exploded View".

Rear disc brake: refer to BR-40, "

BRAKE CALIPER ASSEMBLY : Exploded View".

6. Perform steps 1 to 5 for the rear right brake → front left brake → rear left brake → and front right brake in

order.

7. Check that the fluid level in the sub tank is within the specified range after air bleeding. Refer to BR-9,

"Inspection".

Page 915 of 5121

BRAKE PIPING

BR-19

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

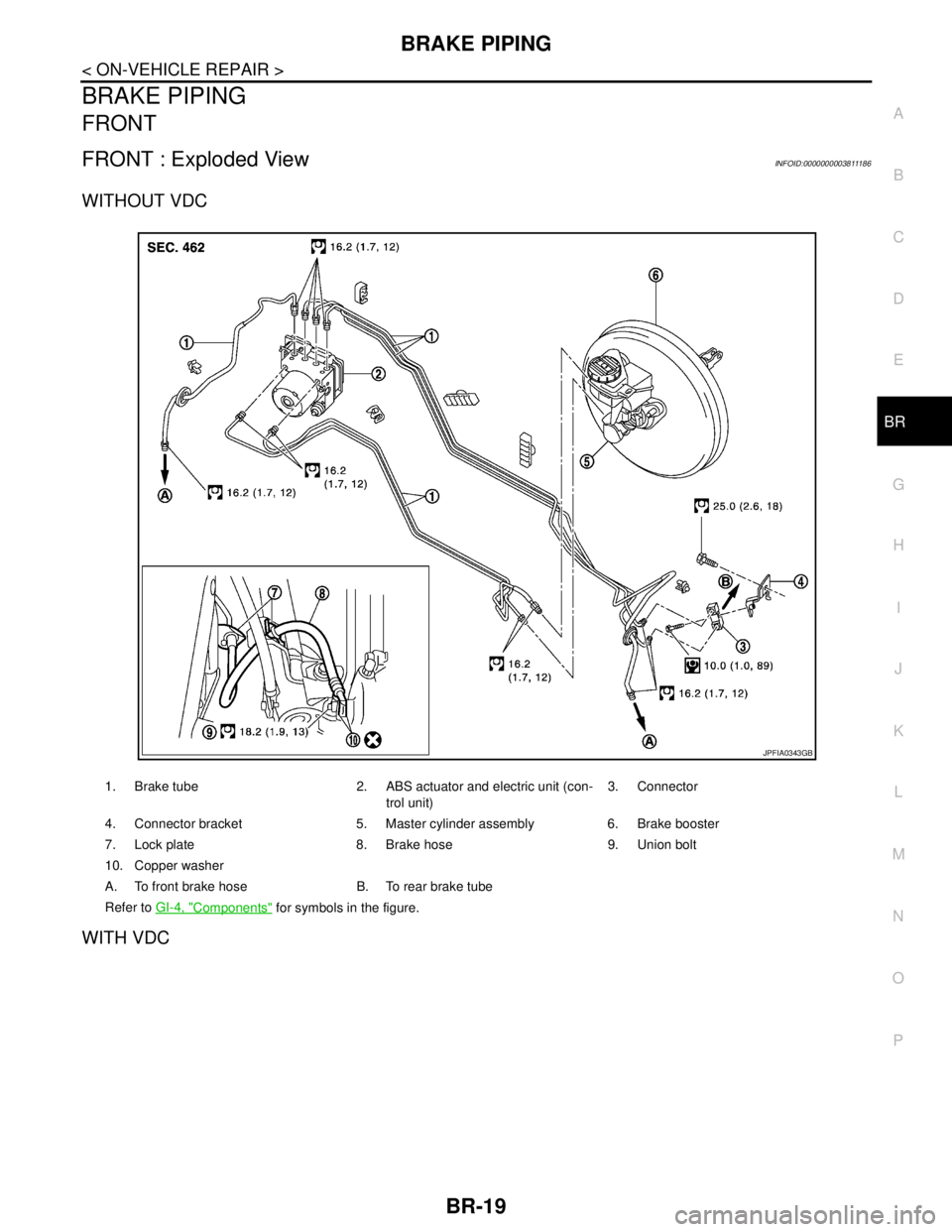

BRAKE PIPING

FRONT

FRONT : Exploded ViewINFOID:0000000003811186

WITHOUT VDC

WITH VDC

1. Brake tube 2. ABS actuator and electric unit (con-

trol unit)3. Connector

4. Connector bracket 5. Master cylinder assembly 6. Brake booster

7. Lock plate 8. Brake hose 9. Union bolt

10. Copper washer

A. To front brake hose B. To rear brake tube

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0343GB

Page 916 of 5121

BR-20

< ON-VEHICLE REPAIR >

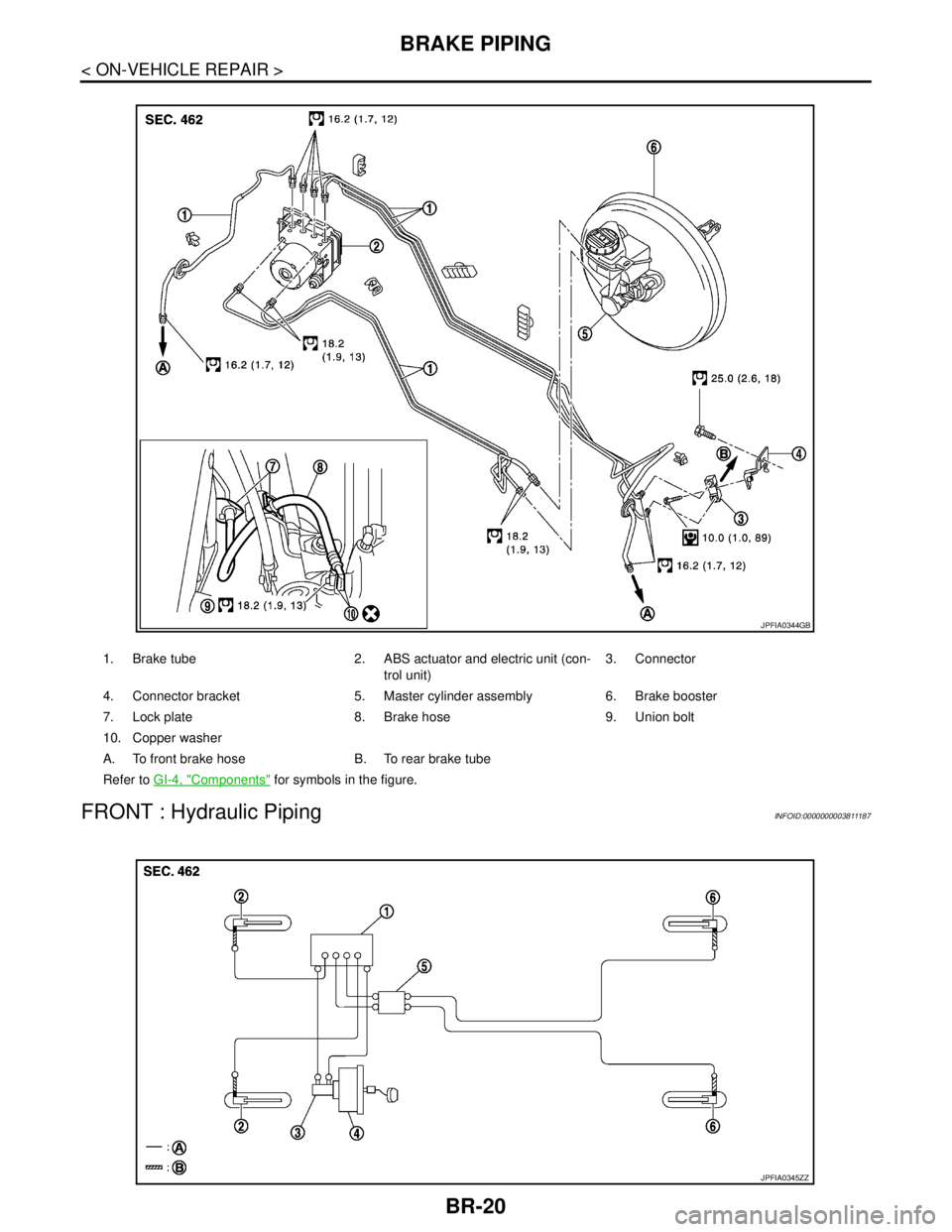

BRAKE PIPING

FRONT : Hydraulic Piping

INFOID:0000000003811187

1. Brake tube 2. ABS actuator and electric unit (con-

trol unit)3. Connector

4. Connector bracket 5. Master cylinder assembly 6. Brake booster

7. Lock plate 8. Brake hose 9. Union bolt

10. Copper washer

A. To front brake hose B. To rear brake tube

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0344GB

JPFIA0345ZZ