display NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 11 of 5121

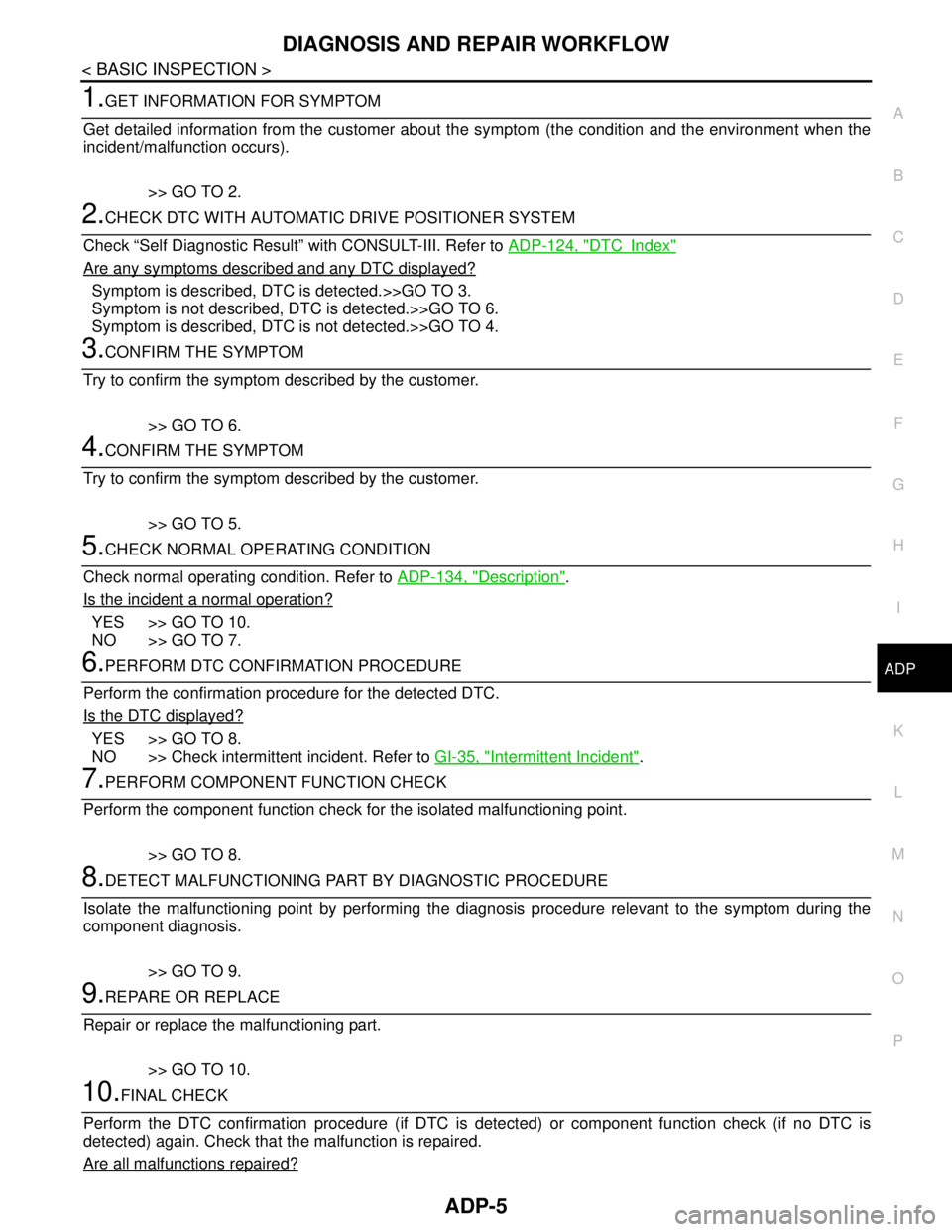

DIAGNOSIS AND REPAIR WORKFLOW

ADP-5

< BASIC INSPECTION >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

1.GET INFORMATION FOR SYMPTOM

Get detailed information from the customer about the symptom (the condition and the environment when the

incident/malfunction occurs).

>> GO TO 2.

2.CHECK DTC WITH AUTOMATIC DRIVE POSITIONER SYSTEM

Check “Self Diagnostic Result” with CONSULT-III. Refer to ADP-124, "

DTCIndex"

Are any symptoms described and any DTC displayed?

Symptom is described, DTC is detected.>>GO TO 3.

Symptom is not described, DTC is detected.>>GO TO 6.

Symptom is described, DTC is not detected.>>GO TO 4.

3.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 6.

4.CONFIRM THE SYMPTOM

Try to confirm the symptom described by the customer.

>> GO TO 5.

5.CHECK NORMAL OPERATING CONDITION

Check normal operating condition. Refer to ADP-134, "

Description".

Is the incident a normal operation?

YES >> GO TO 10.

NO >> GO TO 7.

6.PERFORM DTC CONFIRMATION PROCEDURE

Perform the confirmation procedure for the detected DTC.

Is the DTC displayed?

YES >> GO TO 8.

NO >> Check intermittent incident. Refer to GI-35, "

Intermittent Incident".

7.PERFORM COMPONENT FUNCTION CHECK

Perform the component function check for the isolated malfunctioning point.

>> GO TO 8.

8.DETECT MALFUNCTIONING PART BY DIAGNOSTIC PROCEDURE

Isolate the malfunctioning point by performing the diagnosis procedure relevant to the symptom during the

component diagnosis.

>> GO TO 9.

9.REPARE OR REPLACE

Repair or replace the malfunctioning part.

>> GO TO 10.

10.FINAL CHECK

Perform the DTC confirmation procedure (if DTC is detected) or component function check (if no DTC is

detected) again. Check that the malfunction is repaired.

Are all malfunctions repaired?

Page 15 of 5121

INSPECTION AND ADJUSTMENT

ADP-9

< BASIC INSPECTION >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

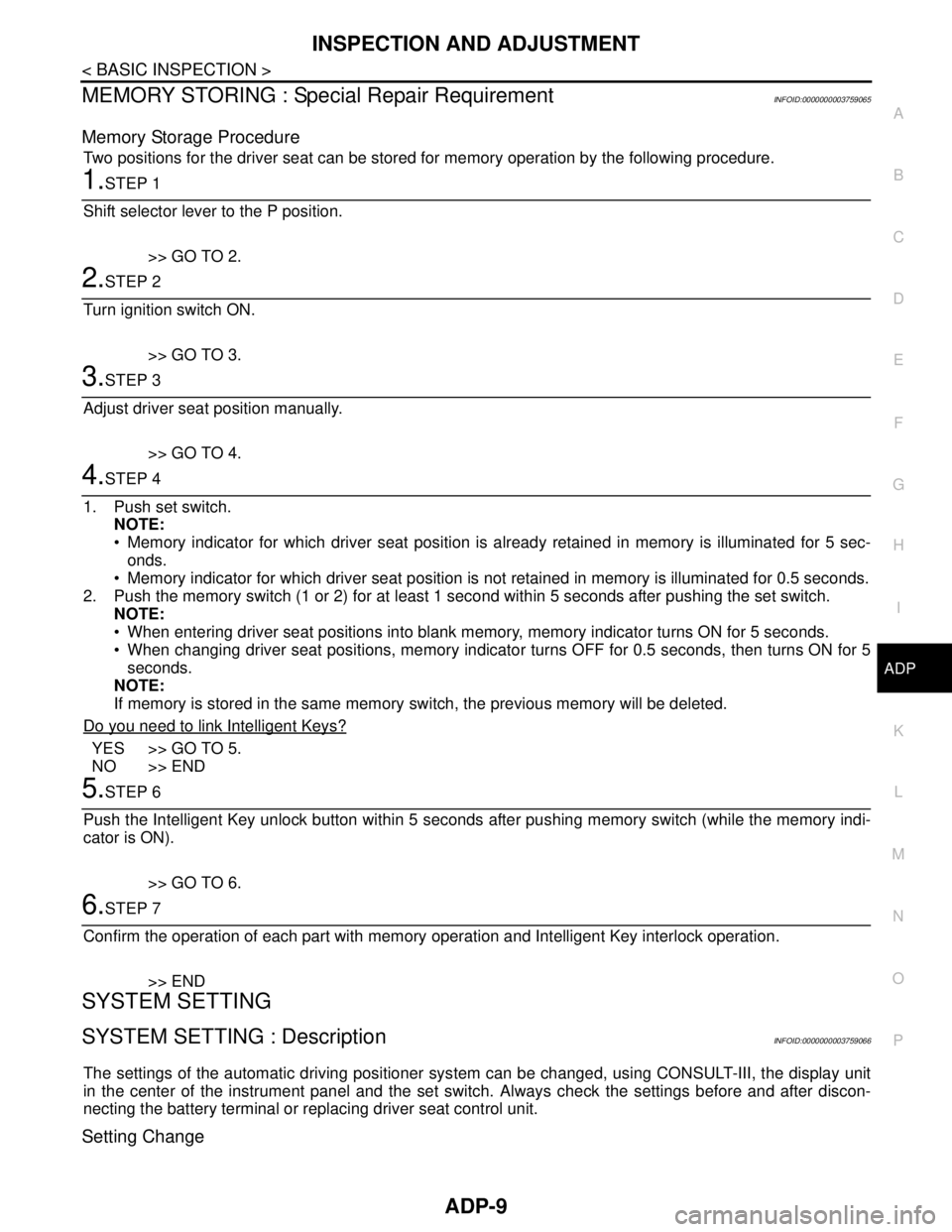

MEMORY STORING : Special Repair RequirementINFOID:0000000003759065

Memory Storage Procedure

Two positions for the driver seat can be stored for memory operation by the following procedure.

1.STEP 1

Shift selector lever to the P position.

>> GO TO 2.

2.STEP 2

Turn ignition switch ON.

>> GO TO 3.

3.STEP 3

Adjust driver seat position manually.

>> GO TO 4.

4.STEP 4

1. Push set switch.

NOTE:

Memory indicator for which driver seat position is already retained in memory is illuminated for 5 sec-

onds.

Memory indicator for which driver seat position is not retained in memory is illuminated for 0.5 seconds.

2. Push the memory switch (1 or 2) for at least 1 second within 5 seconds after pushing the set switch.

NOTE:

When entering driver seat positions into blank memory, memory indicator turns ON for 5 seconds.

When changing driver seat positions, memory indicator turns OFF for 0.5 seconds, then turns ON for 5

seconds.

NOTE:

If memory is stored in the same memory switch, the previous memory will be deleted.

Do you need to link Intelligent Keys?

YES >> GO TO 5.

NO >> END

5.STEP 6

Push the Intelligent Key unlock button within 5 seconds after pushing memory switch (while the memory indi-

cator is ON).

>> GO TO 6.

6.STEP 7

Confirm the operation of each part with memory operation and Intelligent Key interlock operation.

>> END

SYSTEM SETTING

SYSTEM SETTING : DescriptionINFOID:0000000003759066

The settings of the automatic driving positioner system can be changed, using CONSULT-III, the display unit

in the center of the instrument panel and the set switch. Always check the settings before and after discon-

necting the battery terminal or replacing driver seat control unit.

Setting Change

Page 16 of 5121

ADP-10

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

×: Applicable

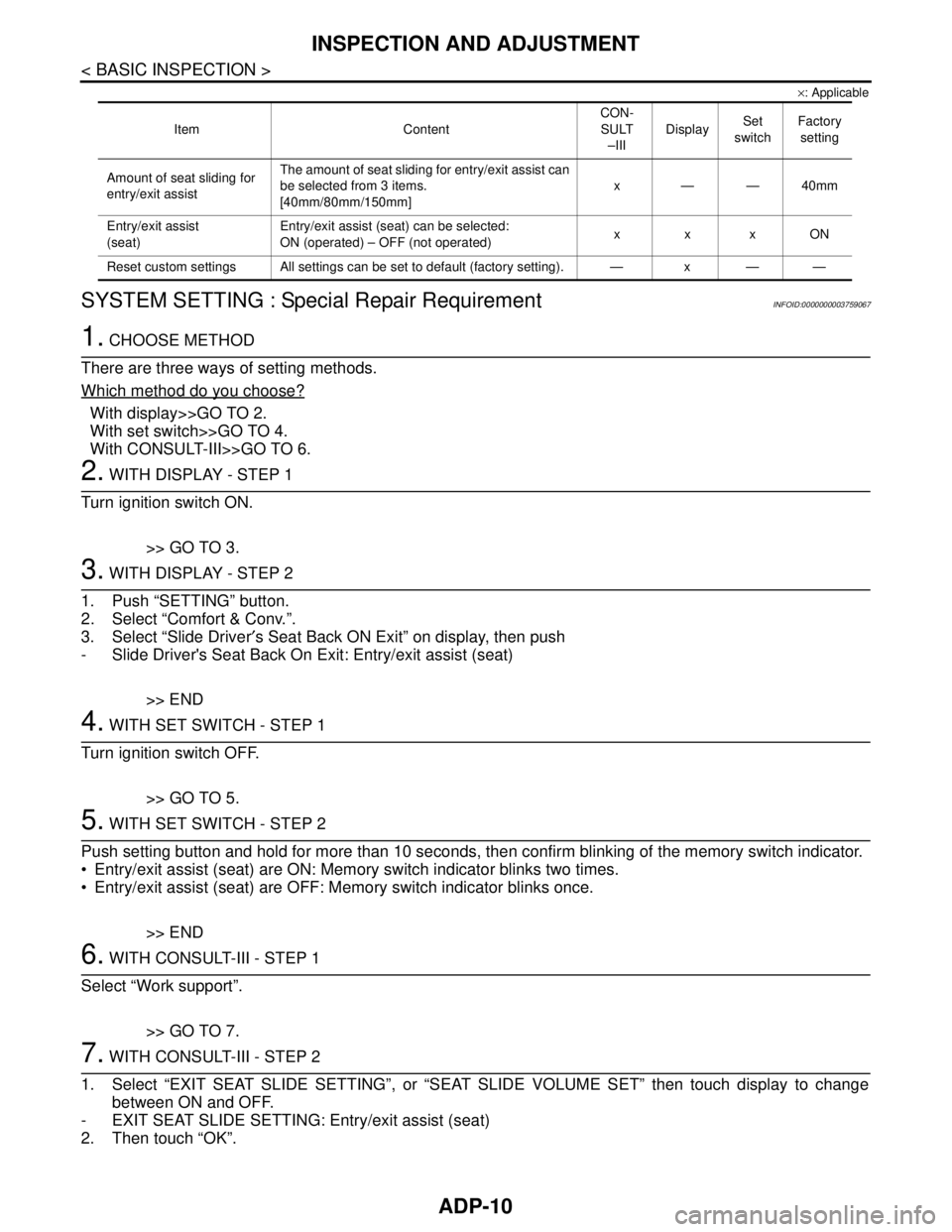

SYSTEM SETTING : Special Repair RequirementINFOID:0000000003759067

1. CHOOSE METHOD

There are three ways of setting methods.

Which method do you choose?

With display>>GO TO 2.

With set switch>>GO TO 4.

With CONSULT-III>>GO TO 6.

2. WITH DISPLAY - STEP 1

Turn ignition switch ON.

>> GO TO 3.

3. WITH DISPLAY - STEP 2

1. Push “SETTING” button.

2. Select “Comfort & Conv.”.

3. Select “Slide Driver′s Seat Back ON Exit” on display, then push

- Slide Driver's Seat Back On Exit: Entry/exit assist (seat)

>> END

4. WITH SET SWITCH - STEP 1

Turn ignition switch OFF.

>> GO TO 5.

5. WITH SET SWITCH - STEP 2

Push setting button and hold for more than 10 seconds, then confirm blinking of the memory switch indicator.

Entry/exit assist (seat) are ON: Memory switch indicator blinks two times.

Entry/exit assist (seat) are OFF: Memory switch indicator blinks once.

>> END

6. WITH CONSULT-III - STEP 1

Select “Work support”.

>> GO TO 7.

7. WITH CONSULT-III - STEP 2

1. Select “EXIT SEAT SLIDE SETTING”, or “SEAT SLIDE VOLUME SET” then touch display to change

between ON and OFF.

- EXIT SEAT SLIDE SETTING: Entry/exit assist (seat)

2. Then touch “OK”.

Item ContentCON-

SULT

–IIIDisplaySet

switchFactory

setting

Amount of seat sliding for

entry/exit assistThe amount of seat sliding for entry/exit assist can

be selected from 3 items.

[40mm/80mm/150mm]x——40mm

Entry/exit assist

(seat)Entry/exit assist (seat) can be selected:

ON (operated) – OFF (not operated)xxxON

Reset custom settings All settings can be set to default (factory setting). — x — —

Page 21 of 5121

AUTOMATIC DRIVE POSITIONER SYSTEM

ADP-15

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

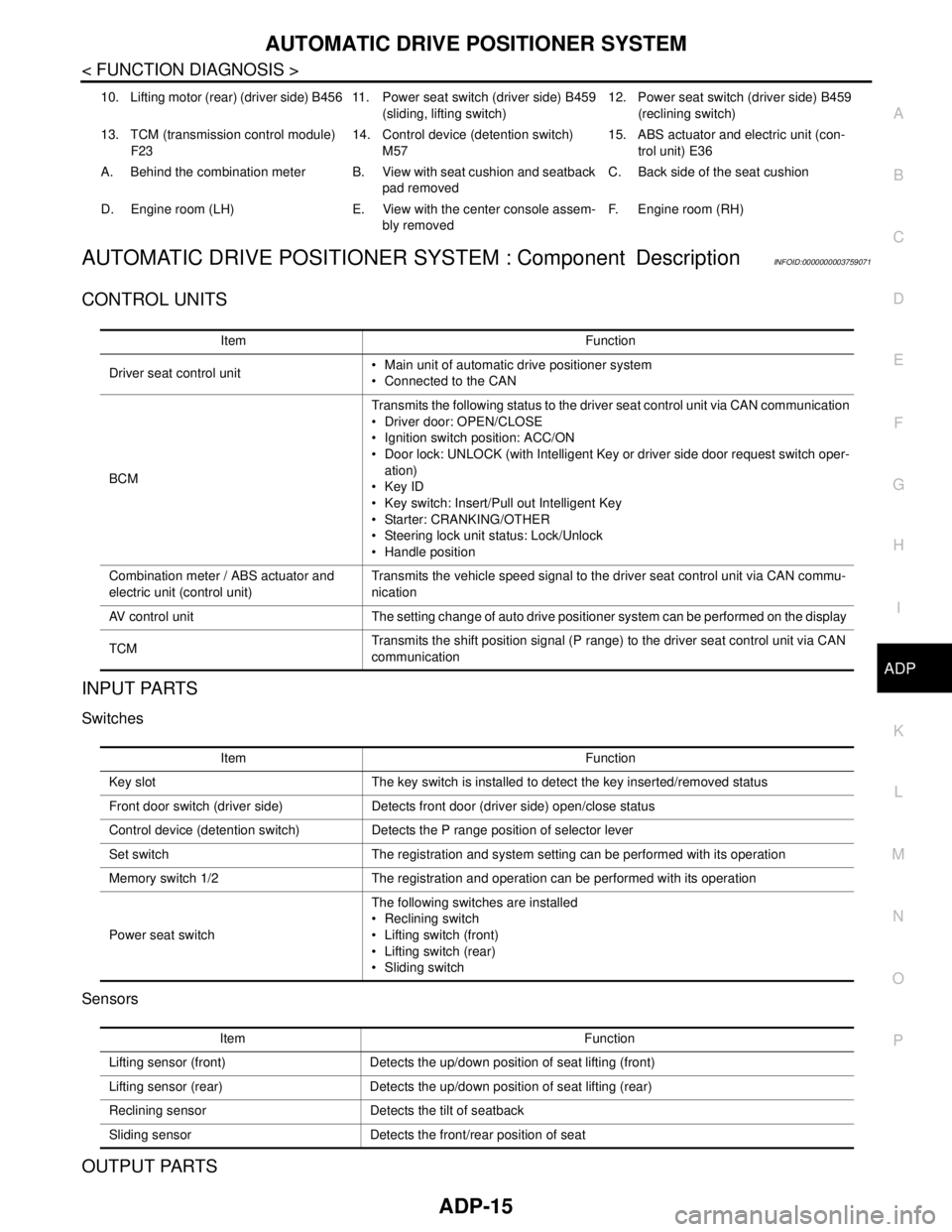

AUTOMATIC DRIVE POSITIONER SYSTEM : Component DescriptionINFOID:0000000003759071

CONTROL UNITS

INPUT PARTS

Switches

Sensors

OUTPUT PARTS

10. Lifting motor (rear) (driver side) B456 11. Power seat switch (driver side) B459

(sliding, lifting switch)12. Power seat switch (driver side) B459

(reclining switch)

13. TCM (transmission control module)

F2314. Control device (detention switch)

M5715. ABS actuator and electric unit (con-

trol unit) E36

A. Behind the combination meter B. View with seat cushion and seatback

pad removedC. Back side of the seat cushion

D. Engine room (LH) E. View with the center console assem-

bly removedF. Engine room (RH)

Item Function

Driver seat control unit Main unit of automatic drive positioner system

Connected to the CAN

BCMTransmits the following status to the driver seat control unit via CAN communication

Driver door: OPEN/CLOSE

Ignition switch position: ACC/ON

Door lock: UNLOCK (with Intelligent Key or driver side door request switch oper-

ation)

Key ID

Key switch: Insert/Pull out Intelligent Key

Starter: CRANKING/OTHER

Steering lock unit status: Lock/Unlock

Handle position

Combination meter / ABS actuator and

electric unit (control unit)Transmits the vehicle speed signal to the driver seat control unit via CAN commu-

nication

AV control unit The setting change of auto drive positioner system can be performed on the display

TCMTransmits the shift position signal (P range) to the driver seat control unit via CAN

communication

Item Function

Key slot The key switch is installed to detect the key inserted/removed status

Front door switch (driver side) Detects front door (driver side) open/close status

Control device (detention switch) Detects the P range position of selector lever

Set switch The registration and system setting can be performed with its operation

Memory switch 1/2 The registration and operation can be performed with its operation

Power seat switchThe following switches are installed

Reclining switch

Lifting switch (front)

Lifting switch (rear)

Sliding switch

Item Function

Lifting sensor (front) Detects the up/down position of seat lifting (front)

Lifting sensor (rear) Detects the up/down position of seat lifting (rear)

Reclining sensor Detects the tilt of seatback

Sliding sensor Detects the front/rear position of seat

Page 41 of 5121

DIAGNOSIS SYSTEM (DRIVER SEAT CONTROL UNIT)

ADP-35

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

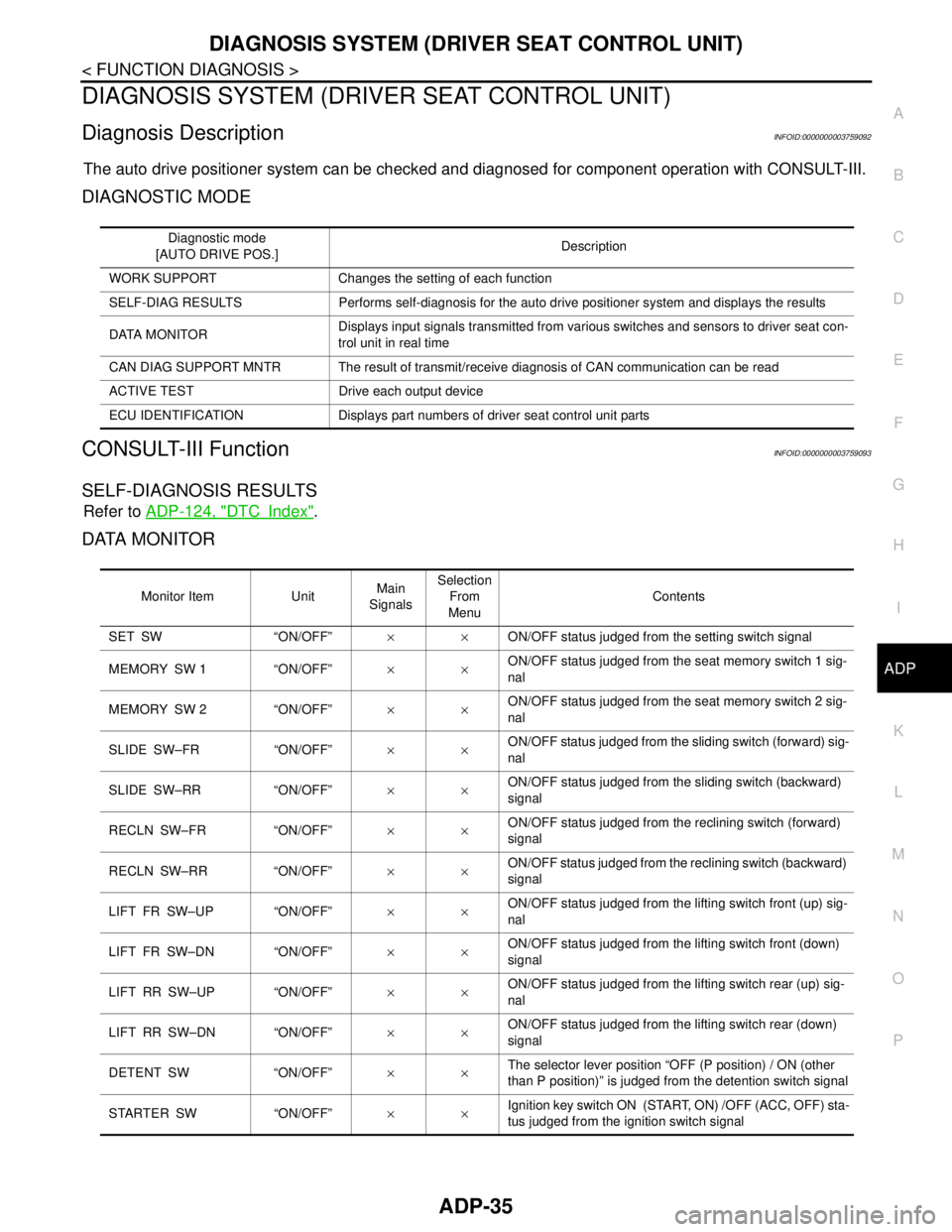

DIAGNOSIS SYSTEM (DRIVER SEAT CONTROL UNIT)

Diagnosis DescriptionINFOID:0000000003759092

The auto drive positioner system can be checked and diagnosed for component operation with CONSULT-III.

DIAGNOSTIC MODE

CONSULT-III FunctionINFOID:0000000003759093

SELF-DIAGNOSIS RESULTS

Refer to ADP-124, "DTCIndex".

DATA MONITOR

Diagnostic mode

[AUTO DRIVE POS.]Description

WORK SUPPORT Changes the setting of each function

SELF-DIAG RESULTS Performs self-diagnosis for the auto drive positioner system and displays the results

DATA MONITORDisplays input signals transmitted from various switches and sensors to driver seat con-

trol unit in real time

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read

ACTIVE TEST Drive each output device

ECU IDENTIFICATION Displays part numbers of driver seat control unit parts

Monitor Item UnitMain

SignalsSelection

From

MenuContents

SET SW “ON/OFF”××ON/OFF status judged from the setting switch signal

MEMORY SW 1 “ON/OFF”××ON/OFF status judged from the seat memory switch 1 sig-

nal

MEMORY SW 2 “ON/OFF”××ON/OFF status judged from the seat memory switch 2 sig-

nal

SLIDE SW–FR “ON/OFF”××ON/OFF status judged from the sliding switch (forward) sig-

nal

SLIDE SW–RR “ON/OFF”××ON/OFF status judged from the sliding switch (backward)

signal

RECLN SW–FR “ON/OFF”××ON/OFF status judged from the reclining switch (forward)

signal

RECLN SW–RR “ON/OFF”××ON/OFF status judged from the reclining switch (backward)

signal

LIFT FR SW–UP “ON/OFF”××ON/OFF status judged from the lifting switch front (up) sig-

nal

LIFT FR SW–DN “ON/OFF”××ON/OFF status judged from the lifting switch front (down)

signal

LIFT RR SW–UP “ON/OFF”××ON/OFF status judged from the lifting switch rear (up) sig-

nal

LIFT RR SW–DN “ON/OFF”××ON/OFF status judged from the lifting switch rear (down)

signal

DETENT SW “ON/OFF”××The selector lever position “OFF (P position) / ON (other

than P position)” is judged from the detention switch signal

STARTER SW “ON/OFF”××Ignition key switch ON (START, ON) /OFF (ACC, OFF) sta-

tus judged from the ignition switch signal

Page 42 of 5121

ADP-36

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (DRIVER SEAT CONTROL UNIT)

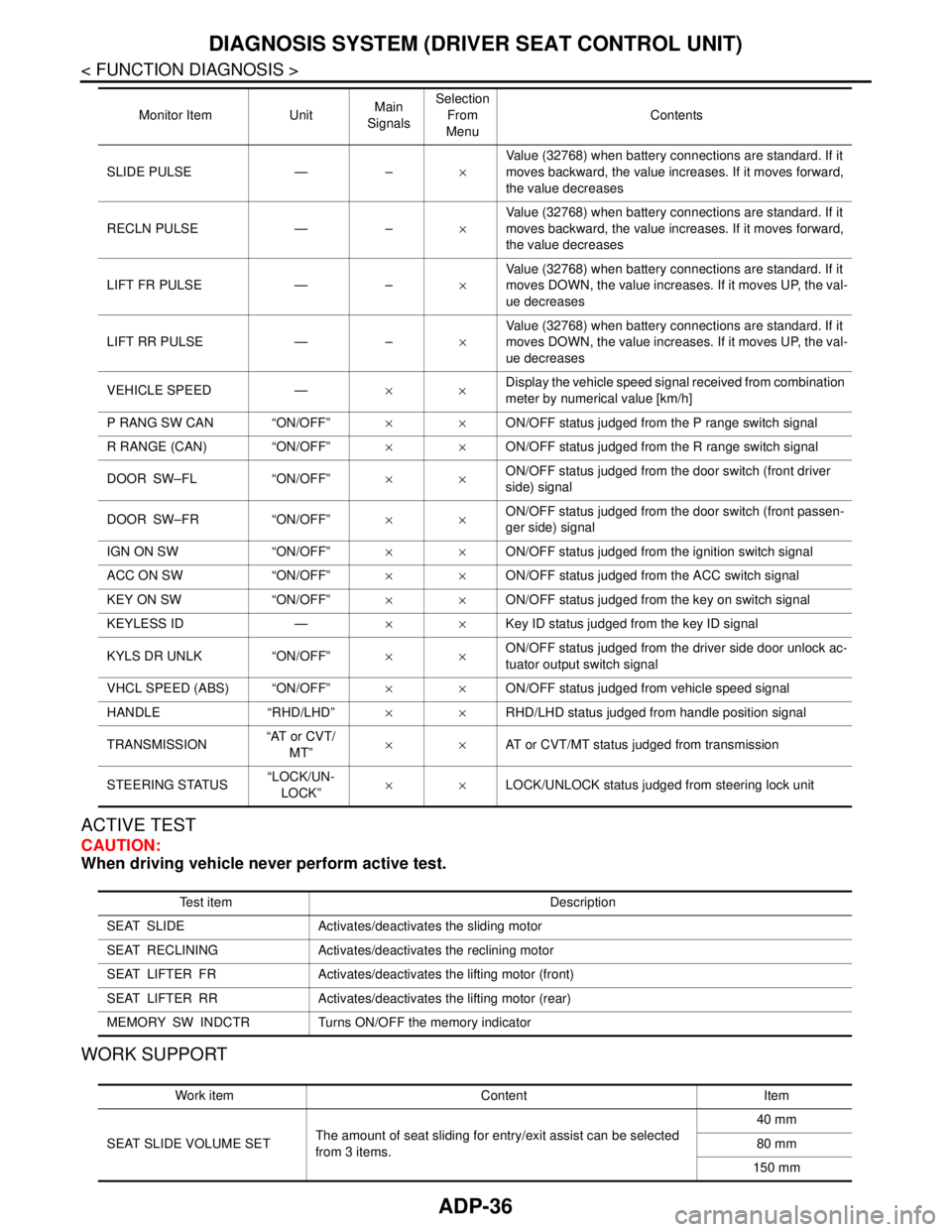

ACTIVE TEST

CAUTION:

When driving vehicle never perform active test.

WORK SUPPORT

SLIDE PULSE — –×Value (32768) when battery connections are standard. If it

moves backward, the value increases. If it moves forward,

the value decreases

RECLN PULSE — –×Value (32768) when battery connections are standard. If it

moves backward, the value increases. If it moves forward,

the value decreases

LIFT FR PULSE — –×Value (32768) when battery connections are standard. If it

moves DOWN, the value increases. If it moves UP, the val-

ue decreases

LIFT RR PULSE — –×Value (32768) when battery connections are standard. If it

moves DOWN, the value increases. If it moves UP, the val-

ue decreases

VEHICLE SPEED —××Display the vehicle speed signal received from combination

meter by numerical value [km/h]

P RANG SW CAN “ON/OFF”××ON/OFF status judged from the P range switch signal

R RANGE (CAN) “ON/OFF”××ON/OFF status judged from the R range switch signal

DOOR SW–FL “ON/OFF”××ON/OFF status judged from the door switch (front driver

side) signal

DOOR SW–FR “ON/OFF”××ON/OFF status judged from the door switch (front passen-

ger side) signal

IGN ON SW “ON/OFF”××ON/OFF status judged from the ignition switch signal

ACC ON SW “ON/OFF”××ON/OFF status judged from the ACC switch signal

KEY ON SW “ON/OFF”××ON/OFF status judged from the key on switch signal

KEYLESS ID —××Key ID status judged from the key ID signal

KYLS DR UNLK “ON/OFF”××ON/OFF status judged from the driver side door unlock ac-

tuator output switch signal

VHCL SPEED (ABS) “ON/OFF”××ON/OFF status judged from vehicle speed signal

HANDLE “RHD/LHD”××RHD/LHD status judged from handle position signal

TRANSMISSION“AT or CVT/

MT”××AT or CVT/MT status judged from transmission

STEERING STATUS“LOCK/UN-

LOCK”××LOCK/UNLOCK status judged from steering lock unit Monitor Item UnitMain

SignalsSelection

From

MenuContents

Test item Description

SEAT SLIDE Activates/deactivates the sliding motor

SEAT RECLINING Activates/deactivates the reclining motor

SEAT LIFTER FR Activates/deactivates the lifting motor (front)

SEAT LIFTER RR Activates/deactivates the lifting motor (rear)

MEMORY SW INDCTR Turns ON/OFF the memory indicator

Work item Content Item

SEAT SLIDE VOLUME SETThe amount of seat sliding for entry/exit assist can be selected

from 3 items.40 mm

80 mm

150 mm

Page 46 of 5121

ADP-40

< COMPONENT DIAGNOSIS >

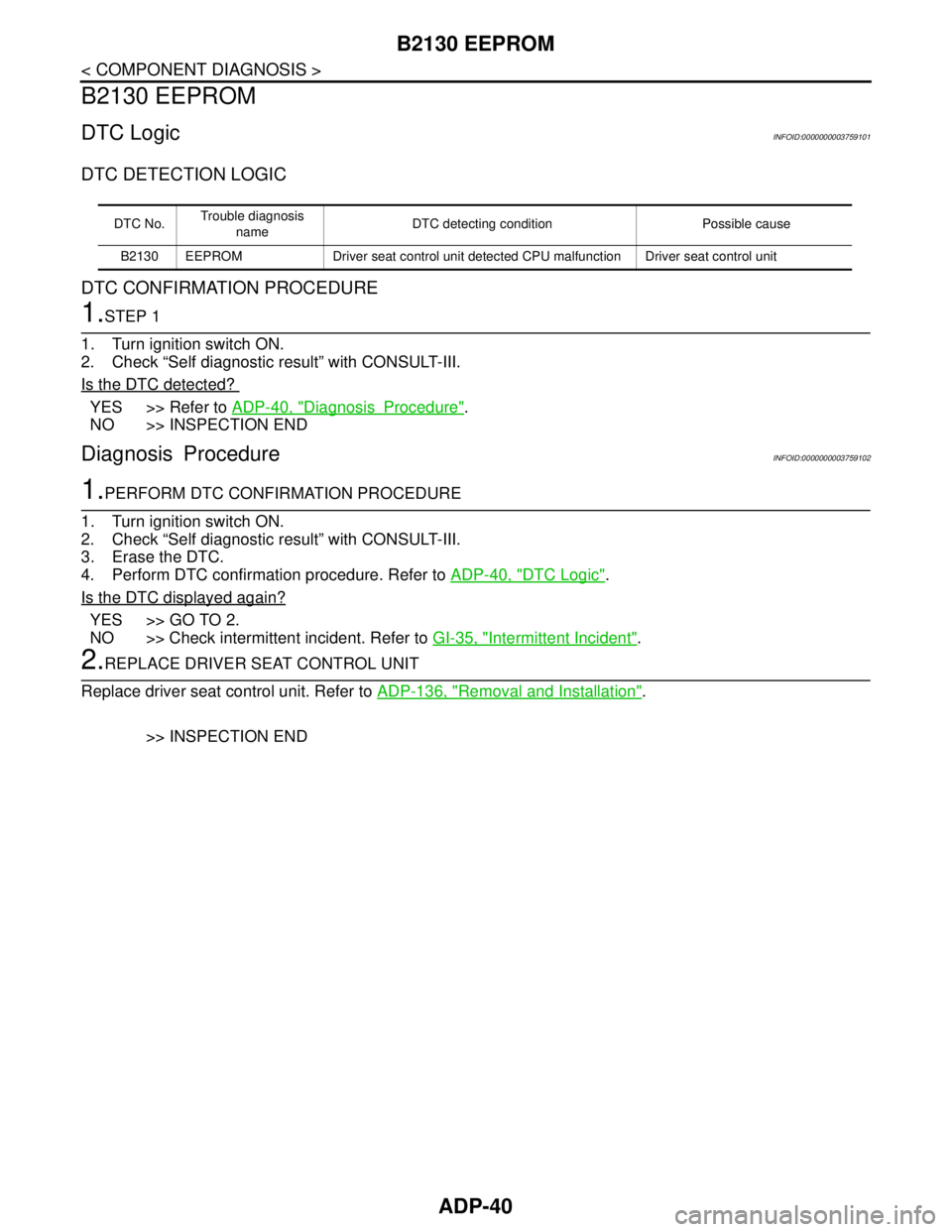

B2130 EEPROM

B2130 EEPROM

DTC LogicINFOID:0000000003759101

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to ADP-40, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003759102

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-40, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> Check intermittent incident. Refer to GI-35, "

Intermittent Incident".

2.REPLACE DRIVER SEAT CONTROL UNIT

Replace driver seat control unit. Refer to ADP-136, "

Removal and Installation".

>> INSPECTION END

DTC No.Trouble diagnosis

nameDTC detecting condition Possible cause

B2130 EEPROM Driver seat control unit detected CPU malfunction Driver seat control unit

Page 47 of 5121

B2112 SLIDING MOTOR

ADP-41

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

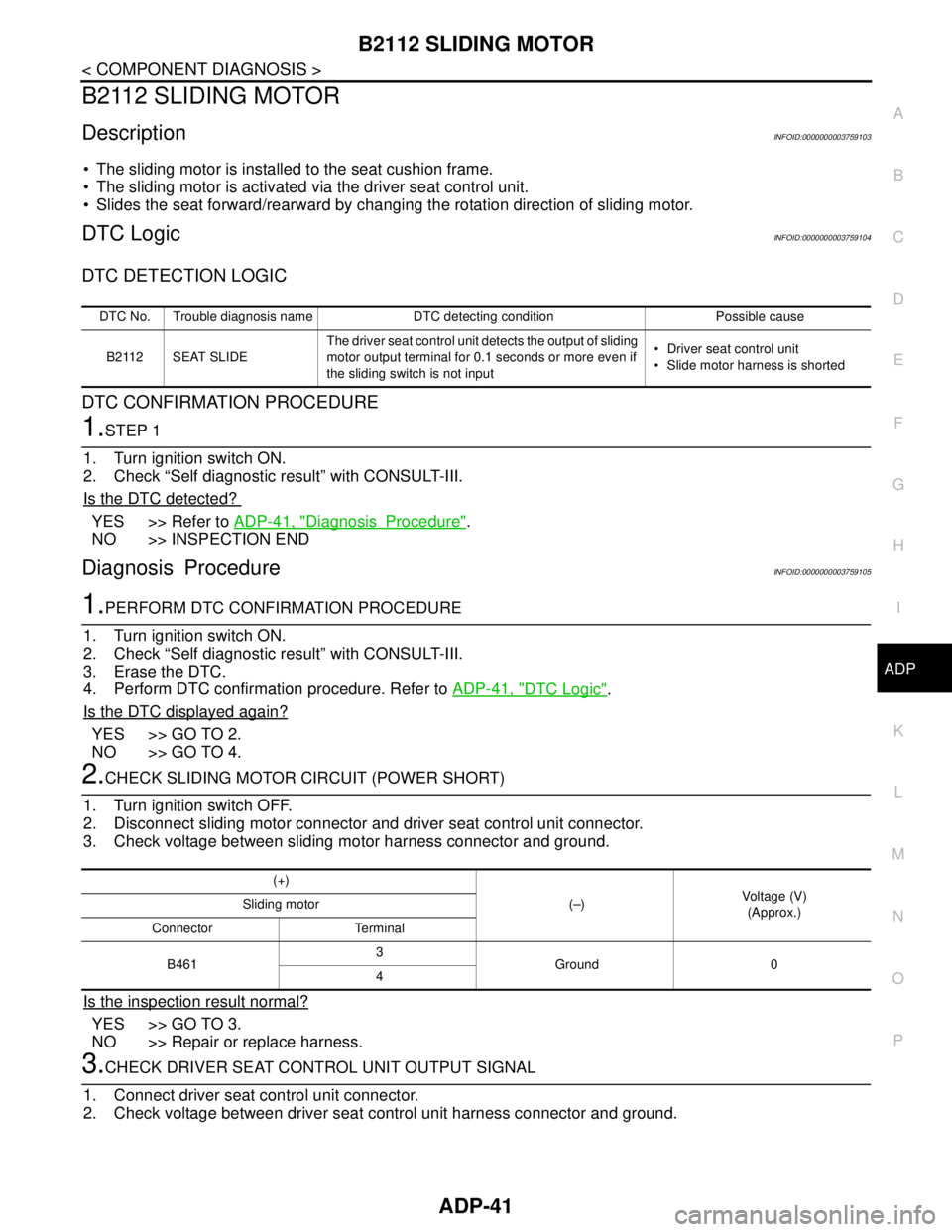

B2112 SLIDING MOTOR

DescriptionINFOID:0000000003759103

The sliding motor is installed to the seat cushion frame.

The sliding motor is activated via the driver seat control unit.

Slides the seat forward/rearward by changing the rotation direction of sliding motor.

DTC LogicINFOID:0000000003759104

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to ADP-41, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003759105

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-41, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK SLIDING MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect sliding motor connector and driver seat control unit connector.

3. Check voltage between sliding motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect driver seat control unit connector.

2. Check voltage between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B2112 SEAT SLIDEThe driver seat control unit detects the output of sliding

motor output terminal for 0.1 seconds or more even if

the sliding switch is not input Driver seat control unit

Slide motor harness is shorted

(+)

(–)Voltage (V)

(Approx.) Sliding motor

Connector Terminal

B4613

Ground 0

4

Page 49 of 5121

B2113 RECLINING MOTOR

ADP-43

< COMPONENT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

MA

B

ADP

N

O

P

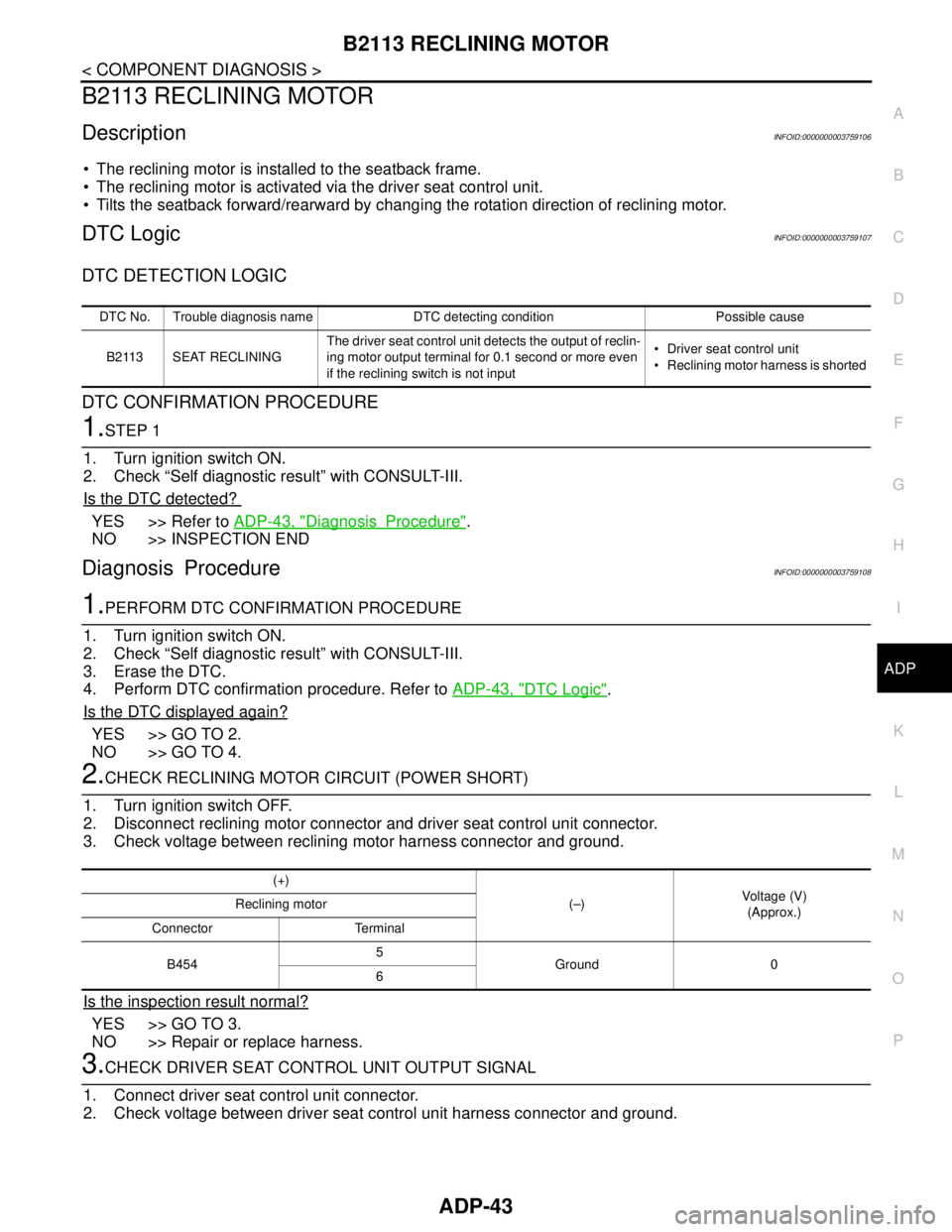

B2113 RECLINING MOTOR

DescriptionINFOID:0000000003759106

The reclining motor is installed to the seatback frame.

The reclining motor is activated via the driver seat control unit.

Tilts the seatback forward/rearward by changing the rotation direction of reclining motor.

DTC LogicINFOID:0000000003759107

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.STEP 1

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

Is the DTC detected?

YES >> Refer to ADP-43, "DiagnosisProcedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000003759108

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON.

2. Check “Self diagnostic result” with CONSULT-III.

3. Erase the DTC.

4. Perform DTC confirmation procedure. Refer to ADP-43, "

DTC Logic".

Is the DTC displayed again?

YES >> GO TO 2.

NO >> GO TO 4.

2.CHECK RECLINING MOTOR CIRCUIT (POWER SHORT)

1. Turn ignition switch OFF.

2. Disconnect reclining motor connector and driver seat control unit connector.

3. Check voltage between reclining motor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect driver seat control unit connector.

2. Check voltage between driver seat control unit harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B2113 SEAT RECLININGThe driver seat control unit detects the output of reclin-

ing motor output terminal for 0.1 second or more even

if the reclining switch is not input Driver seat control unit

Reclining motor harness is shorted

(+)

(–)Voltage (V)

(Approx.) Reclining motor

Connector Terminal

B4545

Ground 0

6

Page 114 of 5121

ADP-108

< COMPONENT DIAGNOSIS >

BCM (BODY CONTROL MODULE)

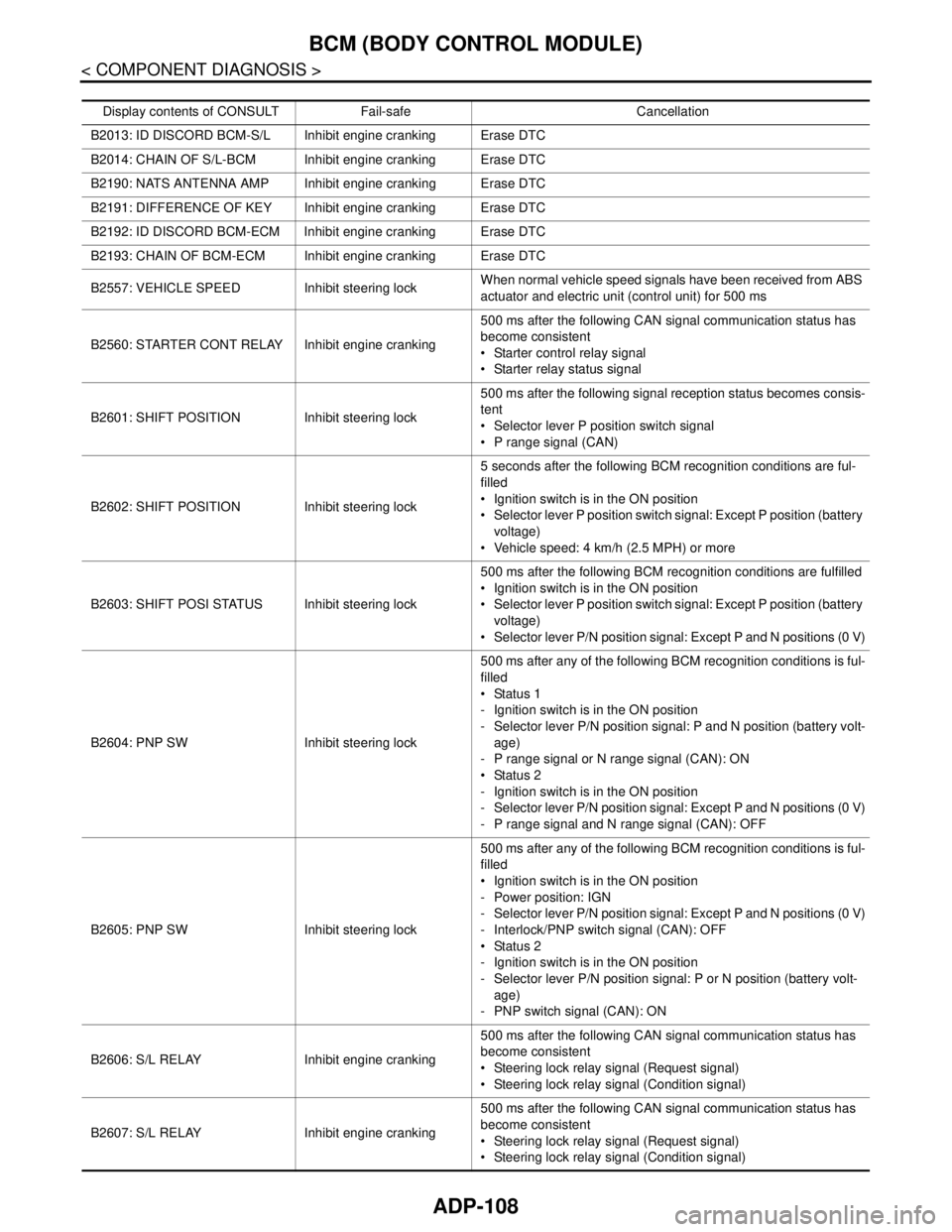

Display contents of CONSULT Fail-safe Cancellation

B2013: ID DISCORD BCM-S/L Inhibit engine cranking Erase DTC

B2014: CHAIN OF S/L-BCM Inhibit engine cranking Erase DTC

B2190: NATS ANTENNA AMP Inhibit engine cranking Erase DTC

B2191: DIFFERENCE OF KEY Inhibit engine cranking Erase DTC

B2192: ID DISCORD BCM-ECM Inhibit engine cranking Erase DTC

B2193: CHAIN OF BCM-ECM Inhibit engine cranking Erase DTC

B2557: VEHICLE SPEED Inhibit steering lockWhen normal vehicle speed signals have been received from ABS

actuator and electric unit (control unit) for 500 ms

B2560: STARTER CONT RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Starter control relay signal

Starter relay status signal

B2601: SHIFT POSITION Inhibit steering lock500 ms after the following signal reception status becomes consis-

tent

Selector lever P position switch signal

P range signal (CAN)

B2602: SHIFT POSITION Inhibit steering lock5 seconds after the following BCM recognition conditions are ful-

filled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Vehicle speed: 4 km/h (2.5 MPH) or more

B2603: SHIFT POSI STATUS Inhibit steering lock500 ms after the following BCM recognition conditions are fulfilled

Ignition switch is in the ON position

Selector lever P position switch signal: Except P position (battery

voltage)

Selector lever P/N position signal: Except P and N positions (0 V)

B2604: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Status 1

- Ignition switch is in the ON position

- Selector lever P/N position signal: P and N position (battery volt-

age)

- P range signal or N range signal (CAN): ON

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: Except P and N positions (0 V)

- P range signal and N range signal (CAN): OFF

B2605: PNP SW Inhibit steering lock500 ms after any of the following BCM recognition conditions is ful-

filled

Ignition switch is in the ON position

- Power position: IGN

- Selector lever P/N position signal: Except P and N positions (0 V)

- Interlock/PNP switch signal (CAN): OFF

Status 2

- Ignition switch is in the ON position

- Selector lever P/N position signal: P or N position (battery volt-

age)

- PNP switch signal (CAN): ON

B2606: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)

B2607: S/L RELAY Inhibit engine cranking500 ms after the following CAN signal communication status has

become consistent

Steering lock relay signal (Request signal)

Steering lock relay signal (Condition signal)