roof NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1 of 5121

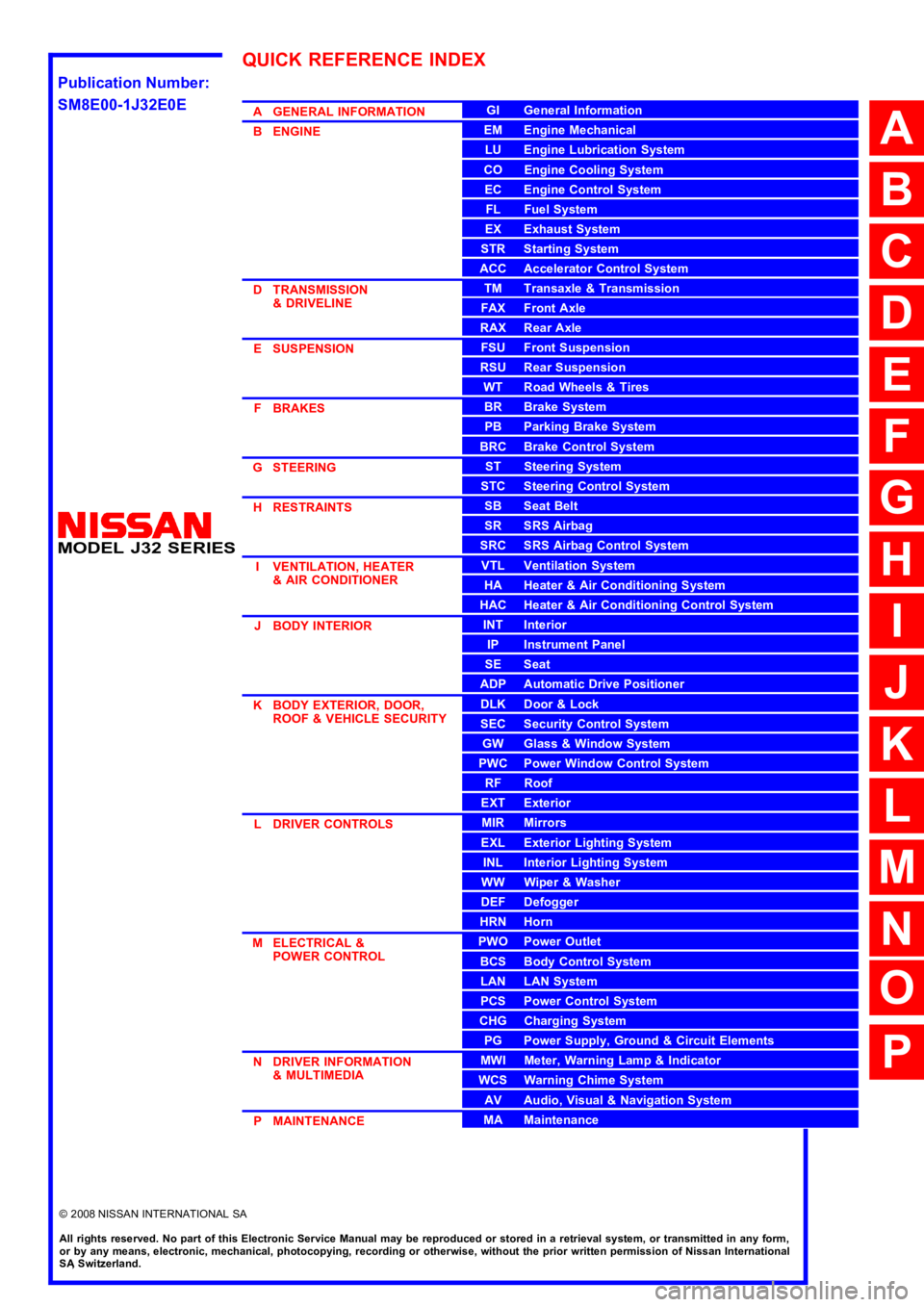

MODEL J32 SERIES

© 2008 NISSAN INTERNATIONAL SA

Allrightsreserved.NopartofthisElectronicServiceManualmaybereproducedorstoredinaretrievalsystem,ortransmittedinanyform,or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan InternationalSA, Switzerland.

AGENERALINFORMATION

BENGINE

DTRANSMISSION&DRIVELINE

ESUSPENSION

FBRAKES

GSTEERING

HRESTRAINTS

IVENTILATION,HEATER&AIRCONDITIONER

JBODYINTERIOR

KBODYEXTERIOR,DOOR,ROOF&VEHICLESECURITY

LDRIVERCONTROLS

MELECTRICAL&POWERCONTROL

NDRIVERINFORMATION&MULTIMEDIA

PMAINTENANCE

GIGeneralInformation

EMEngineMechanical

LUEngineLubricationSystem

COEngineCoolingSystem

ECEngineControlSystem

FLFuelSystem

EXExhaustSystem

STRStartingSystem

ACCAcceleratorControlSystem

TMTransaxle &Transmission

FAXFrontAxle

RAXRearAxle

FSUFrontSuspension

RSURearSuspension

WTRoadWheels &Tires

BRBrakeSystem

PBParkingBrakeSystem

BRCBrakeControlSystem

STSteeringSystem

STCSteeringControlSystem

SBSeatBelt

SRSRSAirbag

SRCSRSAirbagControlSystem

VTLVentilationSystem

HAHeater &AirConditioningSystem

HACHeater &AirConditioningControlSystem

INTInterior

IPInstrumentPanel

SESeat

ADPAutomaticDrivePositioner

DLKDoor &Lock

SECSecurityControlSystem

GWGlass &WindowSystem

PWCPowerWindowControlSystem

RFRoof

EXTExterior

MIRMirrors

EXLExteriorLightingSystem

INLInteriorLightingSystem

WWWiper &Washer

DEFDefogger

HRNHorn

PWOPowerOutlet

BCSBodyControlSystem

LANLANSystem

PCSPowerControlSystem

CHGChargingSystem

PGPowerSupply,Ground&CircuitElements

MWIMeter,WarningLamp&Indicator

WCSWarningChimeSystem

AVAudio,Visual&NavigationSystem

MAMaintenance

QUICKREFERENCEINDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM8E00-1J32E0E

Page 1217 of 5121

DLK-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION DLK

A

B

DLK

N

O P

CONTENTS

DOOR & LOCK

WITH INTELLIGE NT KEY SYSTEM

BASIC INSPECTION ....... .............................

7

DIAGNOSIS AND REPAIR WORKFLOW ..... .....7

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT ....................10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ....

10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ................................

10

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .....

10

FUNCTION DIAGNOSIS .. ............................11

POWER DOOR LOCK SYSTEM .................... ....11

System Diagram .................................................. ....11

System Description .................................................11

Component Parts Location ....................................12

Component Description ..........................................12

INTELLIGENT KEY SYSTEM ............................14

INTELLIGENT KEY SYSTEM ...................................14

INTELLIGENT KEY SYSTEM : System Diagram ....14

INTELLIGENT KEY SYSTEM : System Descrip-

tion ..........................................................................

14

INTELLIGENT KEY SYSTEM :

Component Parts Location ....................................

15

INTELLIGENT KEY SYSTEM :

Component Description ..........................................

16

DOOR LOCK FUNCTION ...................................... ....16

DOOR LOCK FUNCTION : System Diagram .........17

DOOR LOCK FUNCTION : System Description .....17

DOOR LOCK FUNCTION :

Component Parts Location ....................................

19

DOOR LOCK FUNCTION :

Component Description ..........................................

20

TRUNK OPEN FUNCTION .................................... ....20

TRUNK OPEN FUNCTION : System Diagram ........21

TRUNK OPEN FUNCTION : System Description ....21

TRUNK OPEN FUNCTION :

Component Parts Location ....................................

23

TRUNK OPEN FUNCTION :

Component Description ..........................................

24

REMOTE KEYLESS ENTRY FUNCTION ..................24

REMOTE KEYLESS ENTRY FUNCTION : Sys-

tem Diagram ........................................................ ....

25

REMOTE KEYLESS ENTRY FUNCTION : Sys-

tem Description ........................................................

25

REMOTE KEYLESS ENTRY FUNCTION :

Component Parts Location ....................................

27

REMOTE KEYLESS ENTRY FUNCTION :

Component Description ..........................................

28

KEY REMINDER FUNCTION ................................ ....28

KEY REMINDER FUNCTION : System Descrip-

tion ...........................................................................

28

KEY REMINDER FUNCTION :

Component Parts Location ....................................

30

WARNING FUNCTION .......................................... ....31

WARNING FUNCTION : System Description ..........31

WARNING FUNCTION :

Component Parts Location ................................ ....

36

TRUNK OPEN FUNCTION ...............................38

System Diagram ......................................................38

System Description ..................................................38

Component Parts Location ....................................38

Component Description ..........................................39

FUEL FILLER LID OPENER .............................40

Component Parts Location ......................................40

DIAGNOSIS SYSTEM (BCM) ...........................41

COMMON ITEM ..................................................... ....41

Page 1400 of 5121

![NISSAN TEANA 2008 Service Manual DLK-184

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Inspection Procedure

INFOID:0000000003941378

Refer to Table of Contents for specific component removal an NISSAN TEANA 2008 Service Manual DLK-184

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Inspection Procedure

INFOID:0000000003941378

Refer to Table of Contents for specific component removal an](/img/5/57391/w960_57391-1399.png)

DLK-184

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Inspection Procedure

INFOID:0000000003941378

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insulated with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

Page 2390 of 5121

EXT-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION EXT

A

B

EXT

N

O P

CONTENTS

EXTERIOR

SYMPTOM DIAGNOSIS ..... ..........................2

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

2

Work Flow ........................................................... ......2

Inspection Procedure ................................................4

Diagnostic Worksheet ...............................................6

PRECAUTION ...............................................8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

8

Precaution for Procedure without Cowl Top Cover ......9

Precaution for Work ..................................................9

PREPARATION ...........................................10

PREPARATION .............................................. ....10

Commercial Service Tools ................................. ....10

ON-VEHICLE REPAIR .................................11

FRONT BUMPER ........................................... ....11

Exploded View .................................................... ....11

Removal and Installation .........................................12

REAR BUMPER .................................................15

Exploded View .................................................... ....15

Removal and Installation .........................................16

FRONT GRILLE .................................................18

Exploded View .................................................... ....18

Removal and Installation .........................................18

COWL TOP .........................................................20

Exploded View .................................................... ....20

Removal and Installation .........................................20

FENDER PROTECTOR ......................................22

FENDER PROTECTOR ......................................... ....22

FENDER PROTECTOR : Exploded View ...............22

FENDER PROTECTOR : Removal and Installa-

tion ...........................................................................

22

REAR WHEEL HOUSE PROTECTOR .................. ....23

REAR WHEEL HOUSE PROTECTOR : Exploded

View .........................................................................

24

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation ........................................................

24

CENTER MUD GUARD .....................................26

Exploded View .........................................................26

Removal and Installation .........................................26

FLOOR SIDE FAIRING .....................................28

Exploded View .........................................................28

Removal and Installation .........................................28

ROOF SIDE MOLDING .....................................29

Exploded View .........................................................29

Removal and Installation .........................................29

DRIP MOLDING ................................................32

Exploded View .........................................................32

Removal and Installation .........................................32

DOOR OUTSIDE MOLDING .............................33

Exploded View .........................................................33

Removal and Installation .........................................33

DOOR PARTING SEAL ....................................35

Exploded View .........................................................35

Removal and Installation .........................................35

SIDE GUARD MOLDING ..................................36

Component Parts Location .................................. ....36

Removal and Installation .........................................36

TRUNK LID FINISHER ......................................38

Exploded View .........................................................38

Removal and Installation .........................................38

Page 2393 of 5121

EXT-4

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Check that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000003941540

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Never use silicone spray to isolate a squeak or rattle. If the area is saturated with silicone, the recheck

of repair becomes impossible.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the following:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. Usually insulate the areas with felt cloth tape or insulator foam blocks to repair the

noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition look for the following:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Page 2418 of 5121

ROOF SIDE MOLDING

EXT-29

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

ROOF SIDE MOLDING

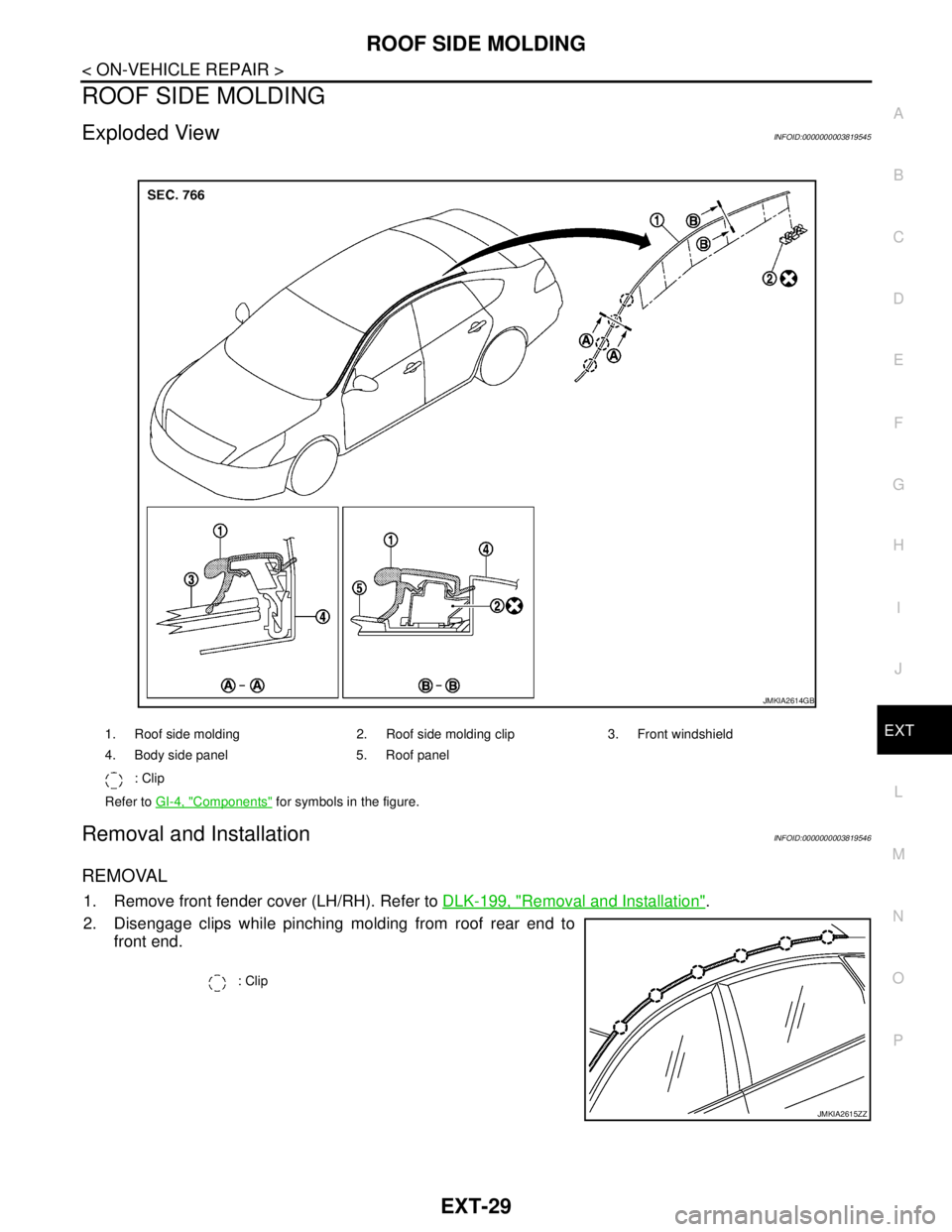

Exploded ViewINFOID:0000000003819545

Removal and InstallationINFOID:0000000003819546

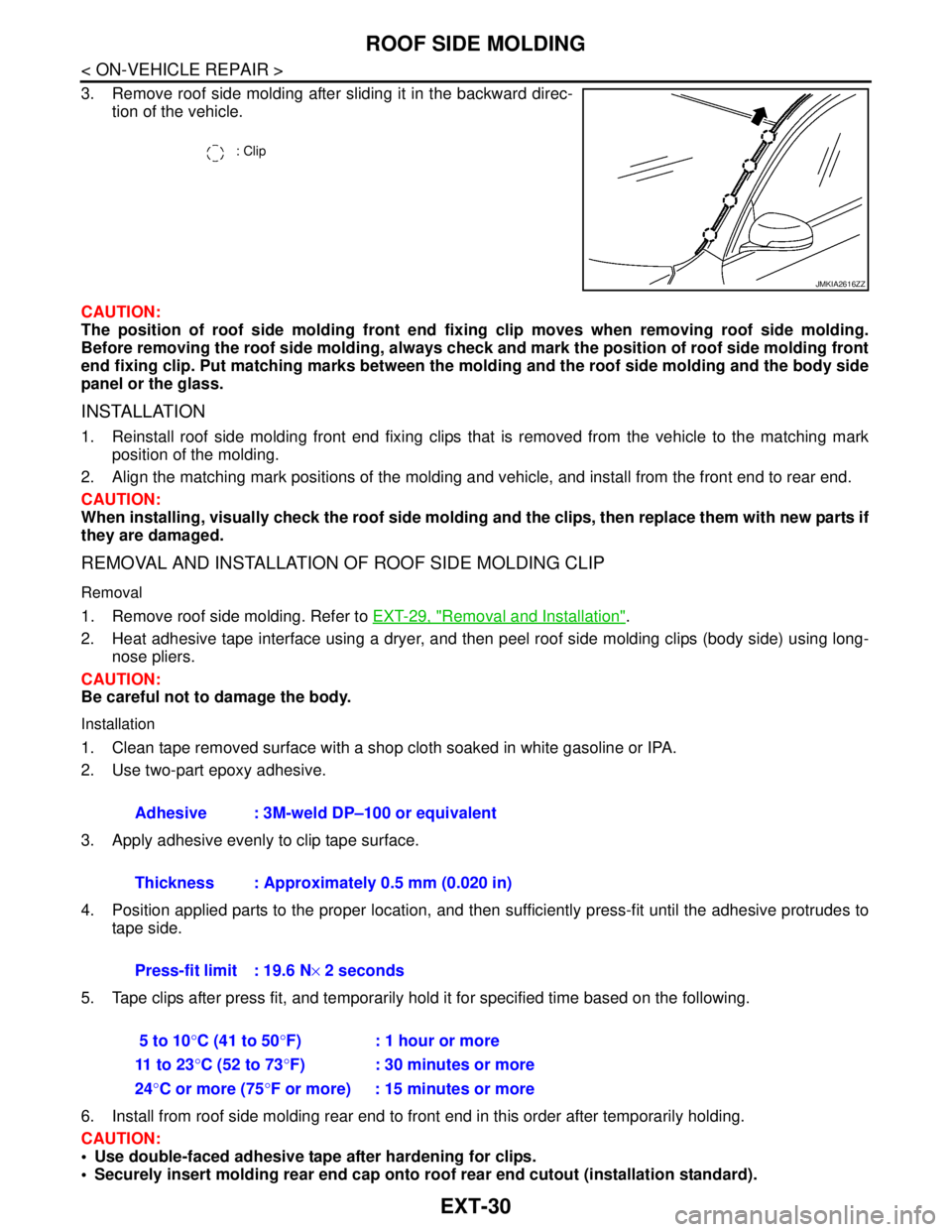

REMOVAL

1. Remove front fender cover (LH/RH). Refer to DLK-199, "Removal and Installation".

2. Disengage clips while pinching molding from roof rear end to

front end.

1. Roof side molding 2. Roof side molding clip 3. Front windshield

4. Body side panel 5. Roof panel

: Clip

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA2614GB

: Clip

JMKIA2615ZZ

Page 2419 of 5121

EXT-30

< ON-VEHICLE REPAIR >

ROOF SIDE MOLDING

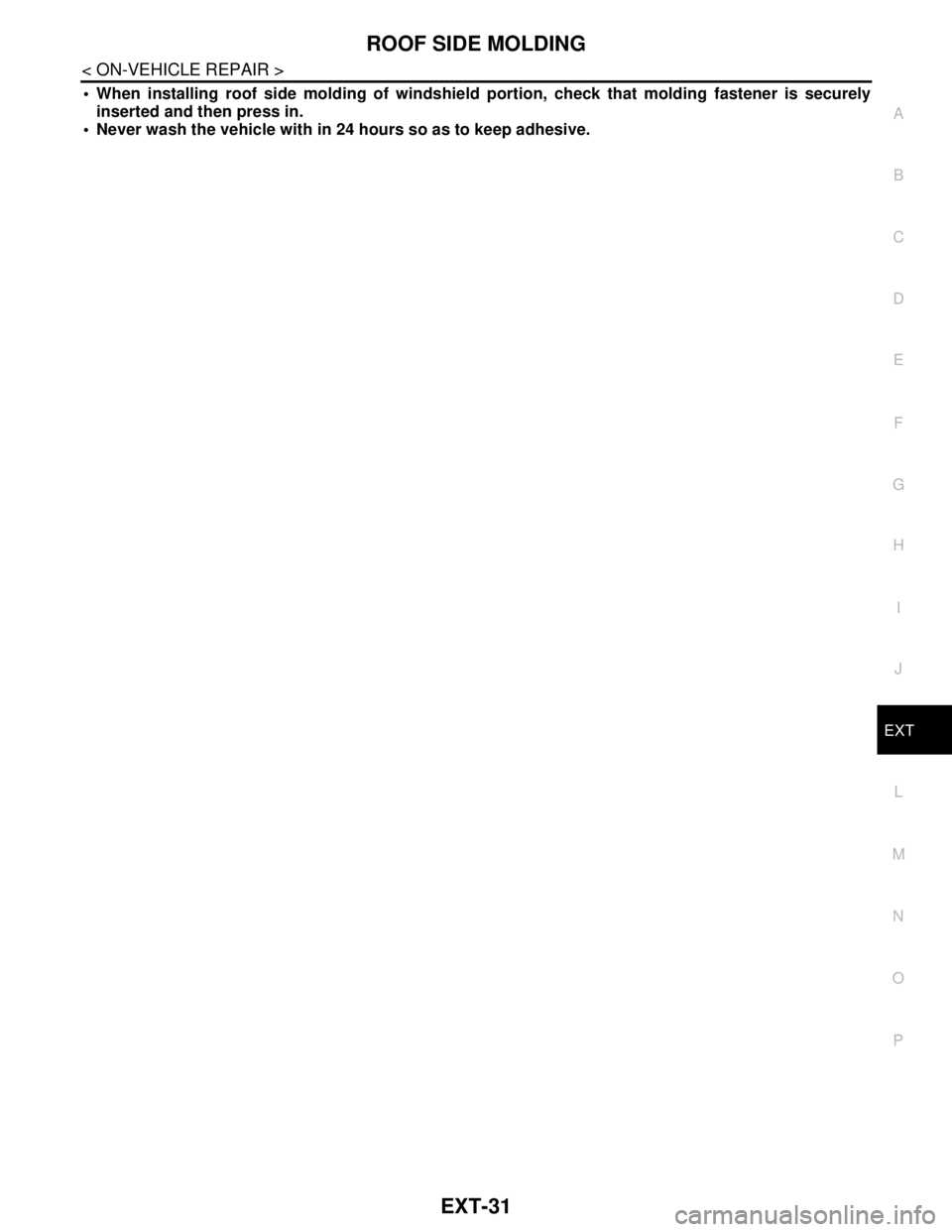

3. Remove roof side molding after sliding it in the backward direc-

tion of the vehicle.

CAUTION:

The position of roof side molding front end fixing clip moves when removing roof side molding.

Before removing the roof side molding, always check and mark the position of roof side molding front

end fixing clip. Put matching marks between the molding and the roof side molding and the body side

panel or the glass.

INSTALLATION

1. Reinstall roof side molding front end fixing clips that is removed from the vehicle to the matching mark

position of the molding.

2. Align the matching mark positions of the molding and vehicle, and install from the front end to rear end.

CAUTION:

When installing, visually check the roof side molding and the clips, then replace them with new parts if

they are damaged.

REMOVAL AND INSTALLATION OF ROOF SIDE MOLDING CLIP

Removal

1. Remove roof side molding. Refer to EXT-29, "Removal and Installation".

2. Heat adhesive tape interface using a dryer, and then peel roof side molding clips (body side) using long-

nose pliers.

CAUTION:

Be careful not to damage the body.

Installation

1. Clean tape removed surface with a shop cloth soaked in white gasoline or IPA.

2. Use two-part epoxy adhesive.

3. Apply adhesive evenly to clip tape surface.

4. Position applied parts to the proper location, and then sufficiently press-fit until the adhesive protrudes to

tape side.

5. Tape clips after press fit, and temporarily hold it for specified time based on the following.

6. Install from roof side molding rear end to front end in this order after temporarily holding.

CAUTION:

Use double-faced adhesive tape after hardening for clips.

Securely insert molding rear end cap onto roof rear end cutout (installation standard).

: Clip

JMKIA2616ZZ

Adhesive : 3M-weld DP–100 or equivalent

Thickness : Approximately 0.5 mm (0.020 in)

Press-fit limit : 19.6 N× 2 seconds

5 to 10°C (41 to 50°F) : 1 hour or more

11 t o 2 3°C (52 to 73°F) : 30 minutes or more

24°C or more (75°F or more) : 15 minutes or more

Page 2420 of 5121

ROOF SIDE MOLDING

EXT-31

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

L

MA

B

EXT

N

O

P

When installing roof side molding of windshield portion, check that molding fastener is securely

inserted and then press in.

Never wash the vehicle with in 24 hours so as to keep adhesive.

Page 2465 of 5121

FL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

General PrecautionsINFOID:0000000003793245

WARNING:

When replacing fuel line parts, be sure to observe the following.

• Put a “CAUTION: FLAMMABLE” sign in the workshop.

Be sure to work in a well ventilated area and furnish workshop with a CO

2 fire extinguisher.

Never smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

Use gasoline required by the regulations for octane number. Refer to GI-29, "

Fuel".

Before removing fuel line parts, perform out the following procedures:

- Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

- Release fuel pressure from the fuel lines. Refer to EC-411, "

Inspection".

- Disconnect the battery cable from the negative terminal.

Always replace O-ring and clamps with new ones.

Never kink or twist tubes when they are being installed.

Never tighten hose clamps excessively to avoid damaging hoses.

After installing tubes, check there is no fuel leakage at connections in the following steps.

- Apply fuel pressure to fuel lines with turning ignition switch “ON” (with engine stopped). Then check

for fuel leakage at connections.

- Start engine and rev it up and check for fuel leakage at connections.

Use only a genuine NISSAN fuel filler cap as a replacement. If an incorrect fuel filler cap is used, the

“MI” may come on.

For servicing “Evaporative Emission System” parts, refer to EC-76, "

System Diagram".

Page 2543 of 5121

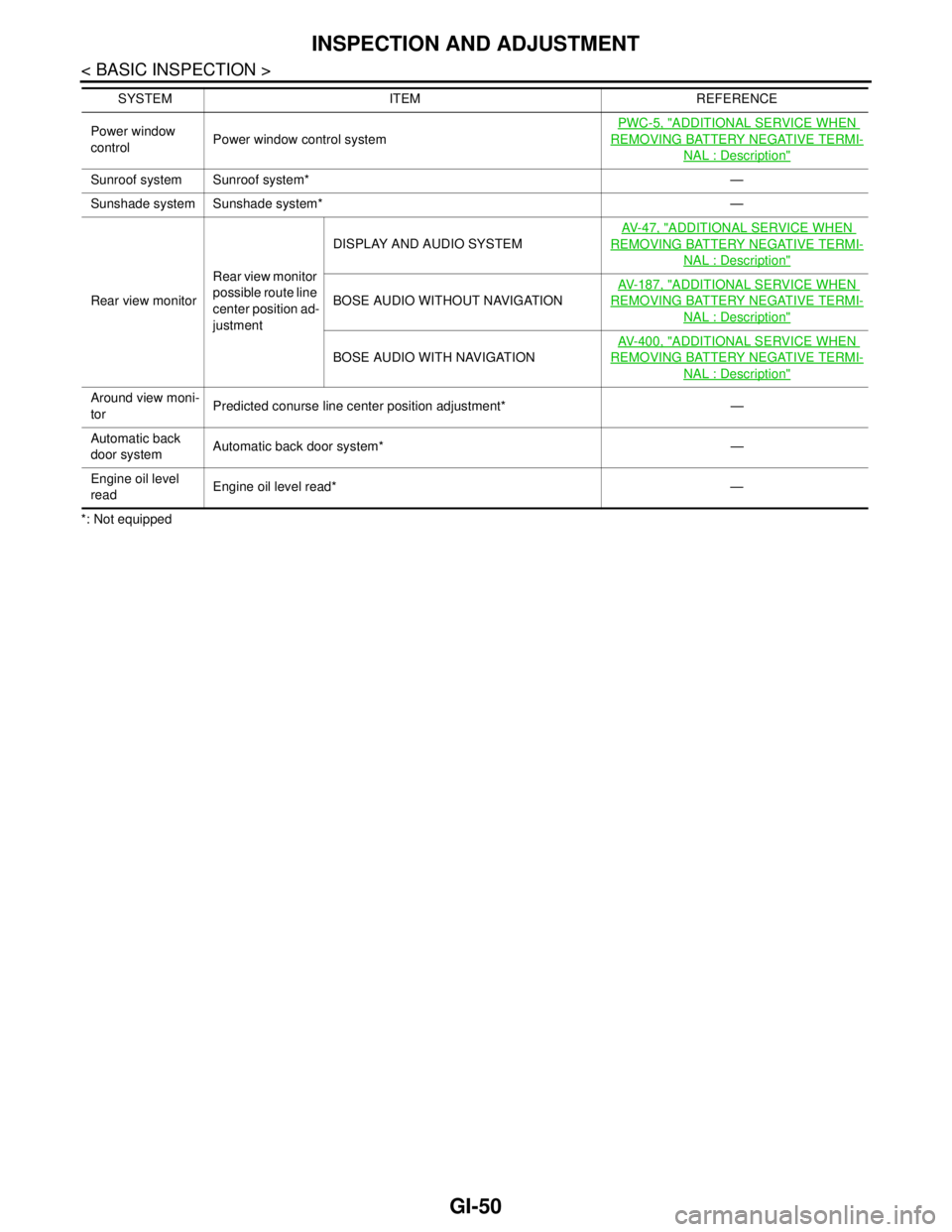

GI-50

< BASIC INSPECTION >

INSPECTION AND ADJUSTMENT

*: Not equippedPower window

controlPower window control systemPWC-5, "

ADDITIONAL SERVICE WHEN

REMOVING BATTERY NEGATIVE TERMI-

NAL : Description"

Sunroof system Sunroof system* —

Sunshade system Sunshade system* —

Rear view monitorRear view monitor

possible route line

center position ad-

justmentDISPLAY AND AUDIO SYSTEMAV- 4 7 , "

ADDITIONAL SERVICE WHEN

REMOVING BATTERY NEGATIVE TERMI-

NAL : Description"

BOSE AUDIO WITHOUT NAVIGATIONAV- 1 8 7 , "

ADDITIONAL SERVICE WHEN

REMOVING BATTERY NEGATIVE TERMI-

NAL : Description"

BOSE AUDIO WITH NAVIGATIONAV- 4 0 0 , "

ADDITIONAL SERVICE WHEN

REMOVING BATTERY NEGATIVE TERMI-

NAL : Description"

Around view moni-

torPredicted conurse line center position adjustment* —

Automatic back

door systemAutomatic back door system* —

Engine oil level

readEngine oil level read* — SYSTEM ITEM REFERENCE