Ccu NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4883 of 5121

![NISSAN TEANA 2008 Service Manual VTL-72

< PRECAUTION >[WITH 7 INCH DISPLAY]

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003894454

CAUTION:

The A/C system contains a fluorescent leak detectio NISSAN TEANA 2008 Service Manual VTL-72

< PRECAUTION >[WITH 7 INCH DISPLAY]

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003894454

CAUTION:

The A/C system contains a fluorescent leak detectio](/img/5/57391/w960_57391-4882.png)

VTL-72

< PRECAUTION >[WITH 7 INCH DISPLAY]

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

General PrecautionsINFOID:0000000003894454

CAUTION:

The A/C system contains a fluorescent leak detection dye used for locating refrigerant leakages. An

ultraviolet (UV) lamp is required to illuminate the dye when inspecting for leakages.

Wear always fluorescence enhancing UV safety goggles to protect eyes and enhance the visibility of

the fluorescent dye.

The fluorescent dye leak detector is not a replacement for an electrical leak detector (SST). The fluo-

rescent dye leak detector should be used in conjunction with an electrical leak detector (SST) to pin-

point refrigerant leakages.

Read and follow all manufacture’s operating instructions and precautions prior to performing the

work for the purpose of safety and customer’s satisfaction.

A compressor shaft seal should not necessarily be repaired because of dye seepage. The compres-

sor shaft seal should only be repaired after confirming the leakage with an electrical leak detector

(SST).

Remove always any remaining dye from the leakage area after repairs are completed to avoid a mis-

diagnosis during a future service.

Never allow dye to come into contact with painted body panels or interior components. Clean imme-

diately with the approved dye cleaner if dye is spilled. Fluorescent dye left on a surface for an

extended period of time cannot be removed.

Never spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

Never use more than one refrigerant dye bottle (1/4 ounce /7.4 cc) per A/C system.

Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A/C systems are different. Never use

HFC-134a (R-134a) leak detection dye in CFC-12 (R-12) A/C system, or CFC-12 (R-12) leak detection

dye in HFC-134a (R-134a) A/C system, or A/C system damage may result.

The fluorescent properties of the dye remains for three or more years unless a compressor malfunc-

tion occurs.

IDENTIFICATION

NOTE:

Vehicles with factory installed fluorescent dye have a green label.

Vehicles without factory installed fluorescent dye have a blue label.

IDENTIFICATION LABEL FOR VEHICLE

Vehicles with factory installed fluorescent dye have the identification label on the front side of hood.

Page 4884 of 5121

![NISSAN TEANA 2008 Service Manual PREPARATION

VTL-73

< PREPARATION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003894466

HFC-134a (R-134a) Service Tool and Equipmen NISSAN TEANA 2008 Service Manual PREPARATION

VTL-73

< PREPARATION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003894466

HFC-134a (R-134a) Service Tool and Equipmen](/img/5/57391/w960_57391-4883.png)

PREPARATION

VTL-73

< PREPARATION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000003894466

HFC-134a (R-134a) Service Tool and Equipment Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another: refrigerant/lubricant contamination occurs and

compressor malfunction may result.

Tool number

(SPX-North America No.)

Tool nameDescription

Recovery/recycling/recharging

equipment (ACR4)Function: Refrigerant recovery, recycling

and recharging

Electrical leak detectorPower supply:

DC 12 V (Cigarette lighter)

(J-43926)

Refrigerant dye leak detection

kit

Kit includes:

(J-42220)

UV lamp and UV safety goggles

(J-41459)

HFC-134a (R-134a) dye injector

Use with J-41447, 1/4 ounce

bottle

(J-41447)

HFC-134a (R-134a) fluorescent

leak detection dye

(Box of 24, 1/4 ounce bottles)

(J-43872)

Refrigerant dye cleanerPower supply:

DC 12 V (Battery terminal)

RJIA0195E

SHA705EB

ZHA200H

Page 4886 of 5121

![NISSAN TEANA 2008 Service Manual PREPARATION

VTL-75

< PREPARATION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

PCommercial Service ToolINFOID:0000000003894468

Sealant or/and LubricantINFOID:0000000003894469

HFC-134a (R-134a) NISSAN TEANA 2008 Service Manual PREPARATION

VTL-75

< PREPARATION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

PCommercial Service ToolINFOID:0000000003894468

Sealant or/and LubricantINFOID:0000000003894469

HFC-134a (R-134a)](/img/5/57391/w960_57391-4885.png)

PREPARATION

VTL-75

< PREPARATION >[WITH 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

VTL

N

O

PCommercial Service ToolINFOID:0000000003894468

Sealant or/and LubricantINFOID:0000000003894469

HFC-134a (R-134a) Service Tool and Equipment Never mix HFC-134a (R-134a) refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/

or its lubricant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Never use adapters that convert one size fitting to another: refrigerant/lubricant contamination occurs and

compressor malfunction may result.

Service couplers

High-pressure side coupler

Low-pressure side couplerHose fitting to service hose:

M14 x 1.5 fitting is optional or permanently

attached.

Refrigerant weight scaleFor measuring of refrigerant

Fitting size: Thread size

1/2

″-16 ACME

Va c u u m p u m p

(Including the isolator valve)Capacity:

Air displacement: 4 CFM

Micron rating: 20 microns

Oil capacity: 482 g (17 oz.)

Fitting size: Thread size

1/2

″-16 ACME Tool number

(SPX-North America No.)

Tool nameDescription

S-NT202

S-NT200

S-NT203

Tool name Description

Remover toolsRemove clips, pawls, metal clips

PIIB7923J

Page 4933 of 5121

WCS

DIAGNOSIS AND REPAIR WORKFLOW

WCS-3

< BASIC INSPECTION >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

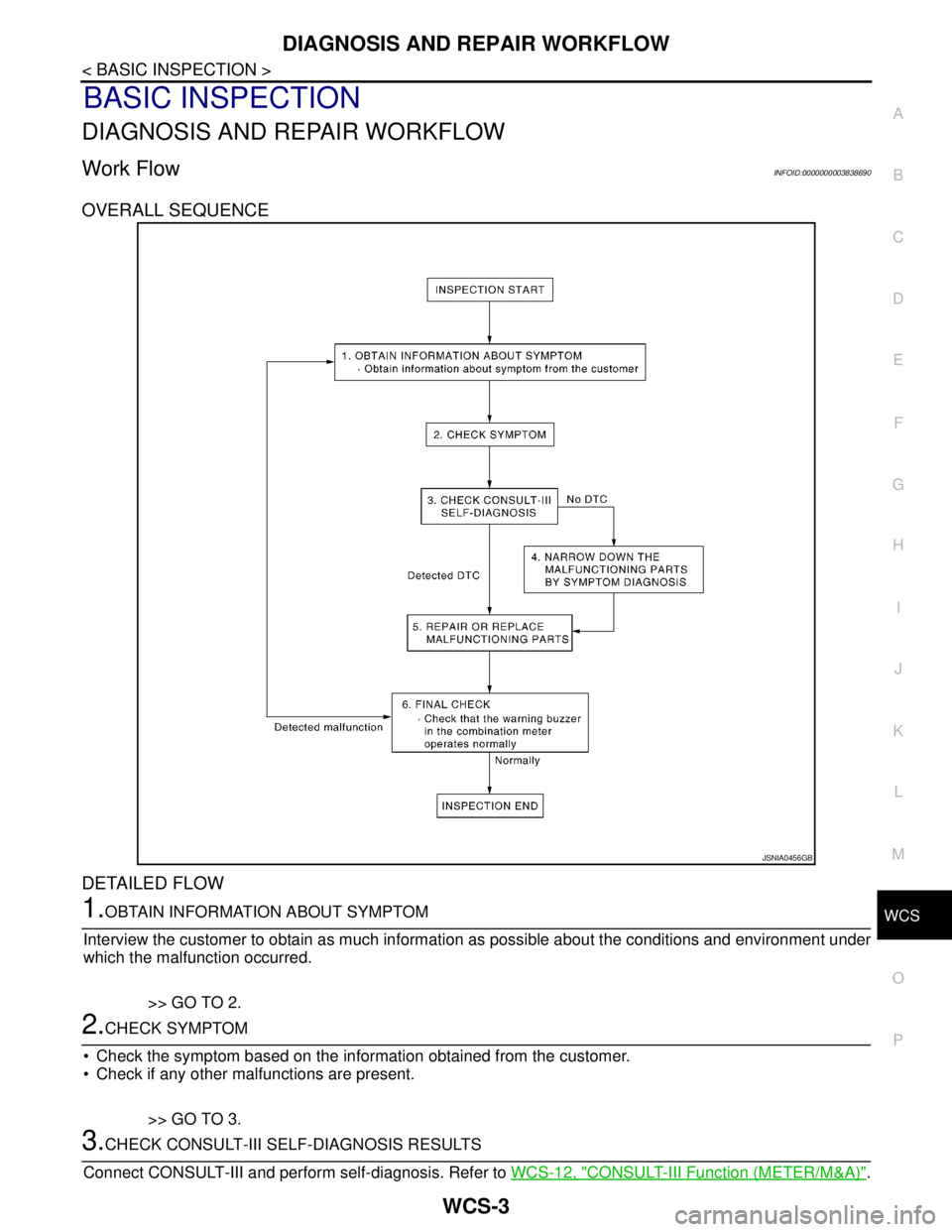

Work FlowINFOID:0000000003838690

OVERALL SEQUENCE

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.CHECK SYMPTOM

• Check the symptom based on the information obtained from the customer.

Check if any other malfunctions are present.

>> GO TO 3.

3.CHECK CONSULT-III SELF-DIAGNOSIS RESULTS

Connect CONSULT-III and perform self-diagnosis. Refer to WCS-12, "

CONSULT-III Function (METER/M&A)".

JSNIA0456GB

Page 5016 of 5121

WW-4

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

>> GO TO 2.

2.SYMPTOM CHECK

Check the symptom from the customer's information.

>> GO TO 3.

3.BASIC INSPECTION

Check the operation of each part. Check that any symptom occurs other than the interviewed symptom.

>> GO TO 4.

4.SELF-DIAGNOSIS WITH CONSULT-III

Perform the self-diagnosis with CONSULT-III. Check that any DTC is detected.

Is any DTC detected?

YES >> GO TO 5.

NO >> GO TO 6.

5.TROUBLE DIAGNOSIS BY DTC

Perform the trouble diagnosis for the detected DTC. Specify the malfunctioning part.

>> GO TO 9.

6.FAIL-SAFE ACTIVATION CHECK

Check that the symptom is applied to the fail-safe activation.

Does the fail-safe activate?

YES >> GO TO 7.

NO >> GO TO 8.

7.SYSTEM DIAGNOSIS

Perform the system diagnosis for the system that the fail-safe activates. Specify the malfunctioning part.

>> GO TO 9.

8.SYMPTOM DIAGNOSIS

Perform the symptom diagnosis. Specify the malfunctioning part.

>> GO TO 9.

9.MALFUNCTION PART REPAIR

Repair or replace the malfunctioning part.

>> GO TO 10.

10.REPAIR CHECK (SELF-DIAGNOSIS WITH CONSULT-III)

Perform the self-diagnosis with CONSULT-III. Check that any DTC is not detected. Erase DTC if DTC is

detected before the repair. Check that DTC is not detected again.

Is any DTC detected?

YES >> GO TO 5.

NO >> GO TO 11.

11 .REPAIR CHECK (OPERATION CHECK)

Check the operation of each part.

Does it operate normally?

YES >> INSPECTION END

NO >> GO TO 3.

Page 5108 of 5121

WW-96

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003761618

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIRBAG” and “SEAT BELT” of this

Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000003761619

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J