Condenser NISSAN TEANA 2008 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2574 of 5121

REFRIGERATION SYSTEM

HA-5

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

FUNCTION DIAGNOSIS

REFRIGERATION SYSTEM

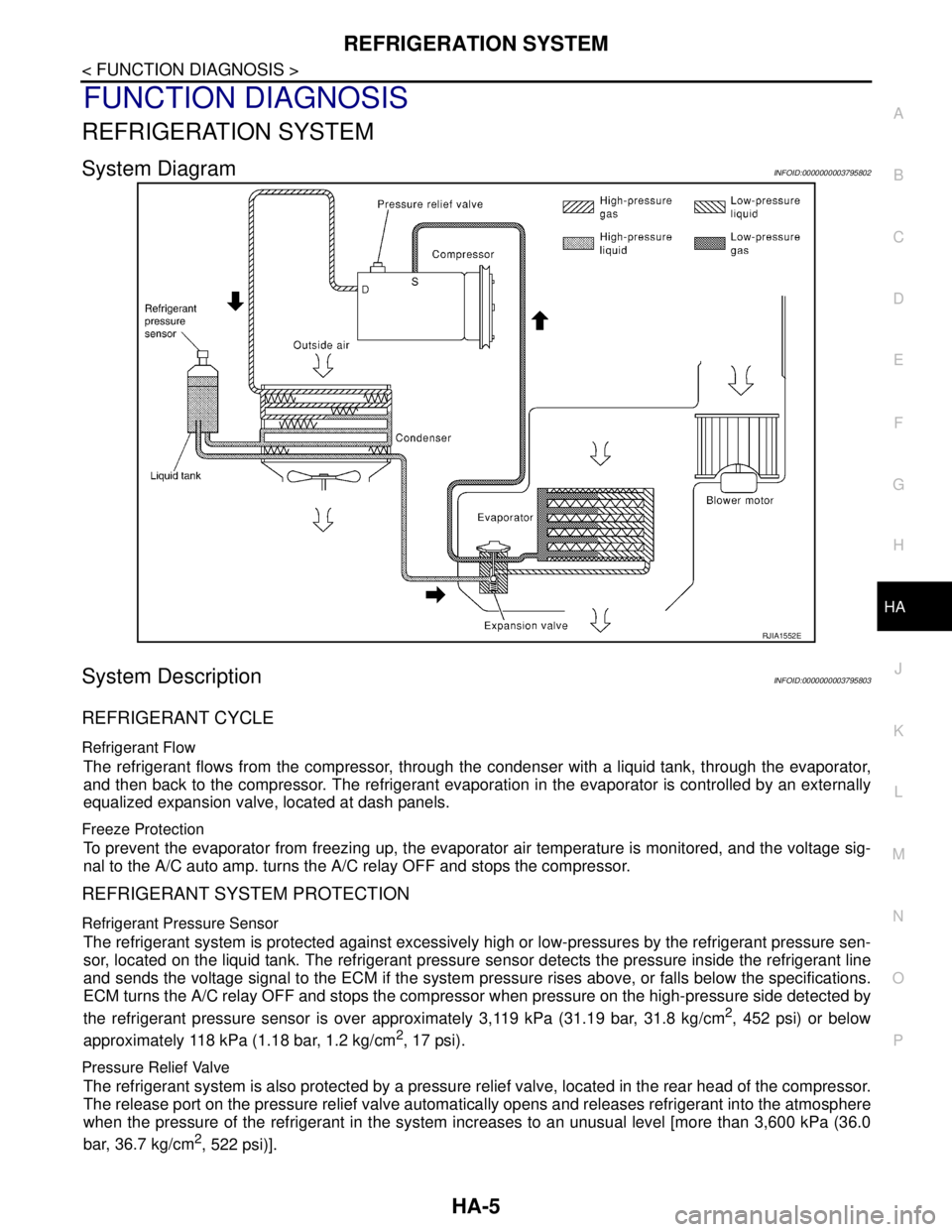

System DiagramINFOID:0000000003795802

System DescriptionINFOID:0000000003795803

REFRIGERANT CYCLE

Refrigerant Flow

The refrigerant flows from the compressor, through the condenser with a liquid tank, through the evaporator,

and then back to the compressor. The refrigerant evaporation in the evaporator is controlled by an externally

equalized expansion valve, located at dash panels.

Freeze Protection

To prevent the evaporator from freezing up, the evaporator air temperature is monitored, and the voltage sig-

nal to the A/C auto amp. turns the A/C relay OFF and stops the compressor.

REFRIGERANT SYSTEM PROTECTION

Refrigerant Pressure Sensor

The refrigerant system is protected against excessively high or low-pressures by the refrigerant pressure sen-

sor, located on the liquid tank. The refrigerant pressure sensor detects the pressure inside the refrigerant line

and sends the voltage signal to the ECM if the system pressure rises above, or falls below the specifications.

ECM turns the A/C relay OFF and stops the compressor when pressure on the high-pressure side detected by

the refrigerant pressure sensor is over approximately 3,119 kPa (31.19 bar, 31.8 kg/cm

2, 452 psi) or below

approximately 118 kPa (1.18 bar, 1.2 kg/cm

2, 17 psi).

Pressure Relief Valve

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

The release port on the pressure relief valve automatically opens and releases refrigerant into the atmosphere

when the pressure of the refrigerant in the system increases to an unusual level [more than 3,600 kPa (36.0

bar, 36.7 kg/cm

2, 522 psi)].

RJIA1552E

Page 2575 of 5121

HA-6

< FUNCTION DIAGNOSIS >

REFRIGERATION SYSTEM

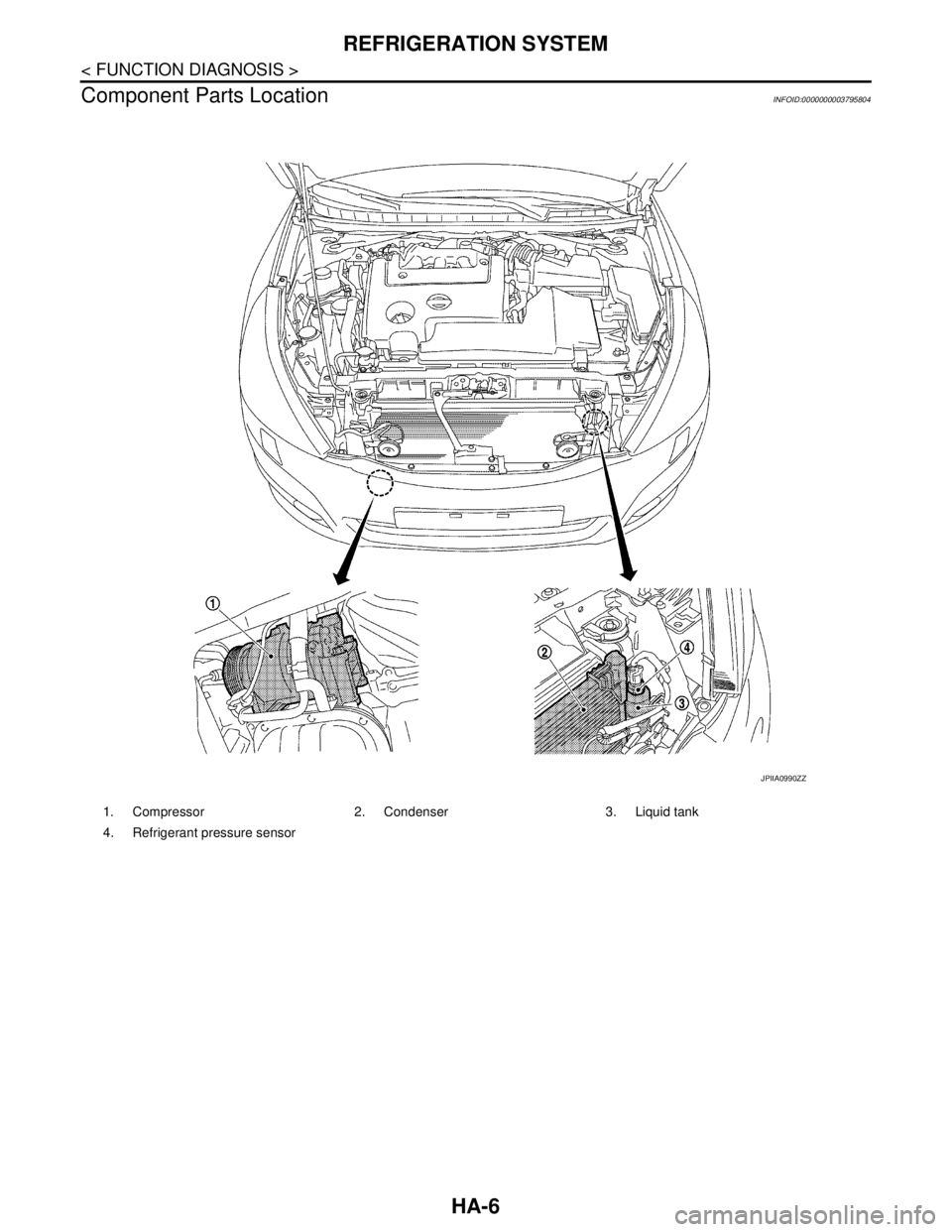

Component Parts Location

INFOID:0000000003795804

1. Compressor 2. Condenser 3. Liquid tank

4. Refrigerant pressure sensor

JPIIA0990ZZ

Page 2576 of 5121

REFRIGERATION SYSTEM

HA-7

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

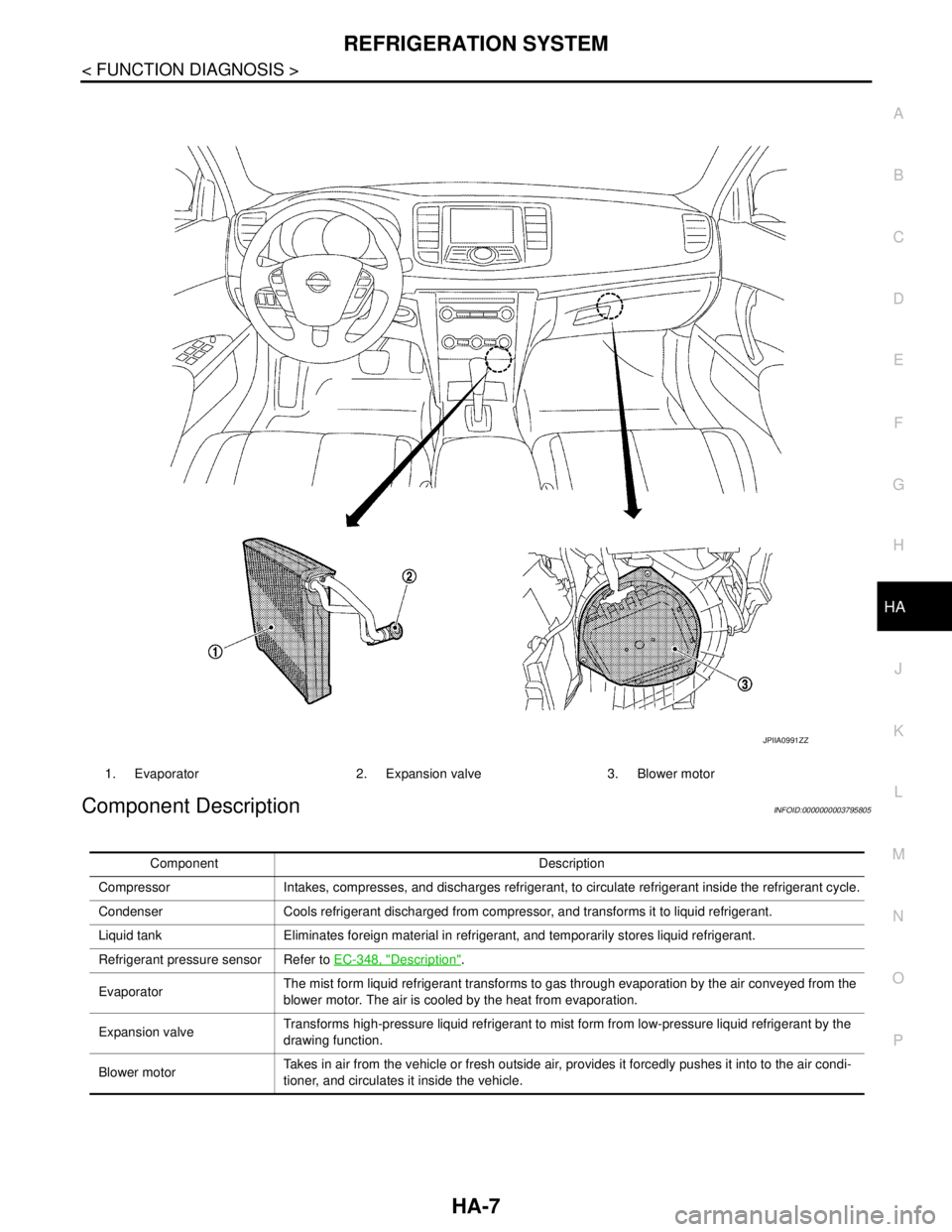

Component DescriptionINFOID:0000000003795805

1. Evaporator 2. Expansion valve 3. Blower motor

JPIIA0991ZZ

Component Description

Compressor Intakes, compresses, and discharges refrigerant, to circulate refrigerant inside the refrigerant cycle.

Condenser Cools refrigerant discharged from compressor, and transforms it to liquid refrigerant.

Liquid tank Eliminates foreign material in refrigerant, and temporarily stores liquid refrigerant.

Refrigerant pressure sensor Refer to EC-348, "

Description".

EvaporatorThe mist form liquid refrigerant transforms to gas through evaporation by the air conveyed from the

blower motor. The air is cooled by the heat from evaporation.

Expansion valveTransforms high-pressure liquid refrigerant to mist form from low-pressure liquid refrigerant by the

drawing function.

Blower motorTakes in air from the vehicle or fresh outside air, provides it forcedly pushes it into to the air condi-

tioner, and circulates it inside the vehicle.

Page 2577 of 5121

HA-8

< SYMPTOM DIAGNOSIS >

REFRIGERATION SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

REFRIGERATION SYSTEM SYMPTOMS

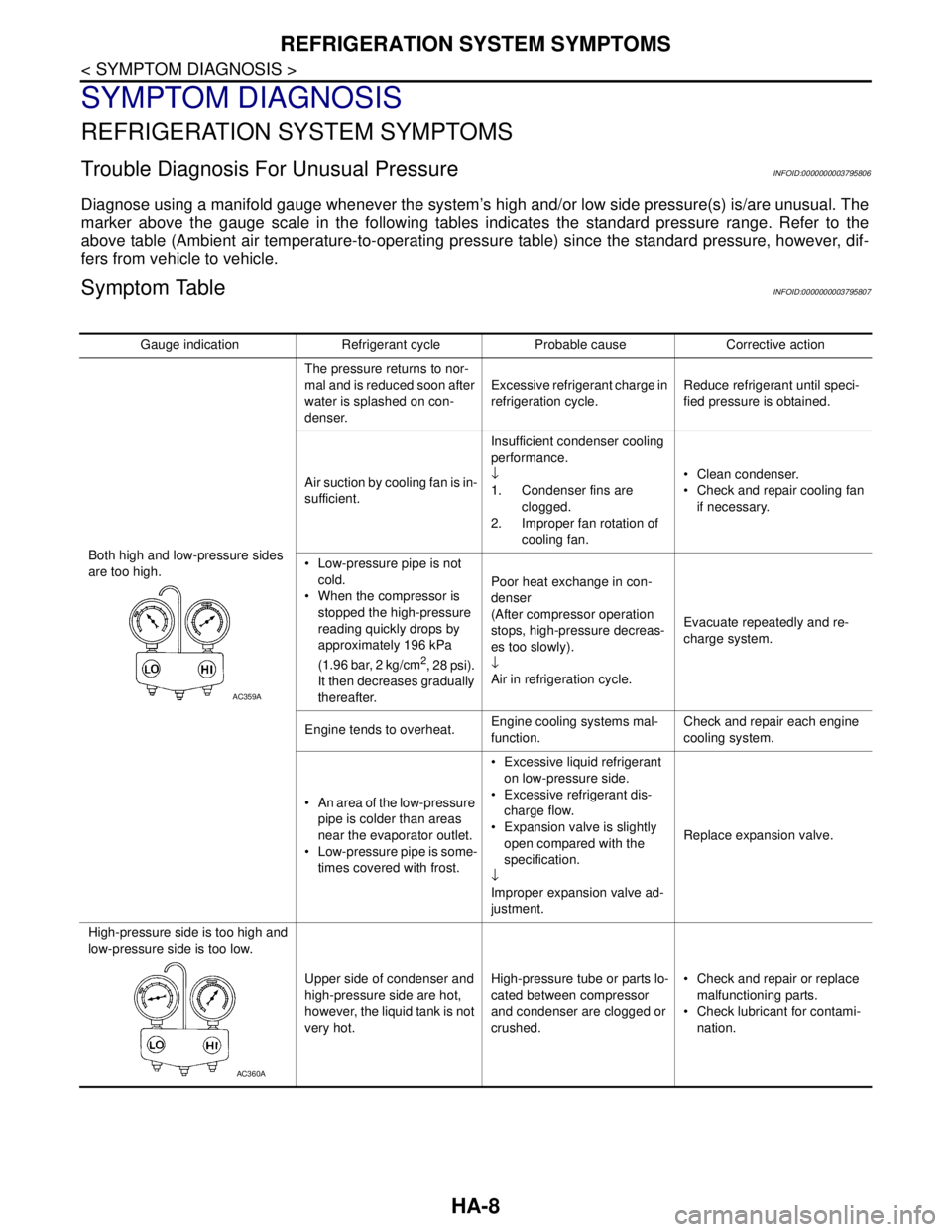

Trouble Diagnosis For Unusual PressureINFOID:0000000003795806

Diagnose using a manifold gauge whenever the system’s high and/or low side pressure(s) is/are unusual. The

marker above the gauge scale in the following tables indicates the standard pressure range. Refer to the

above table (Ambient air temperature-to-operating pressure table) since the standard pressure, however, dif-

fers from vehicle to vehicle.

Symptom TableINFOID:0000000003795807

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure sides

are too high.The pressure returns to nor-

mal and is reduced soon after

water is splashed on con-

denser.Excessive refrigerant charge in

refrigeration cycle.Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling

performance.

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fan. Clean condenser.

Check and repair cooling fan

if necessary.

Low-pressure pipe is not

cold.

When the compressor is

stopped the high-pressure

reading quickly drops by

approximately 196 kPa

(1.96 bar, 2 kg/cm

2, 28 psi).

It then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly).

↓

Air in refrigeration cycle.Evacuate repeatedly and re-

charge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair each engine

cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Low-pressure pipe is some-

times covered with frost. Excessive liquid refrigerant

on low-pressure side.

Excessive refrigerant dis-

charge flow.

Expansion valve is slightly

open compared with the

specification.

↓

Improper expansion valve ad-

justment.Replace expansion valve.

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, the liquid tank is not

very hot.High-pressure tube or parts lo-

cated between compressor

and condenser are clogged or

crushed. Check and repair or replace

malfunctioning parts.

Check lubricant for contami-

nation.

AC359A

AC360A

Page 2584 of 5121

PRECAUTIONS

HA-15

< PRECAUTION >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

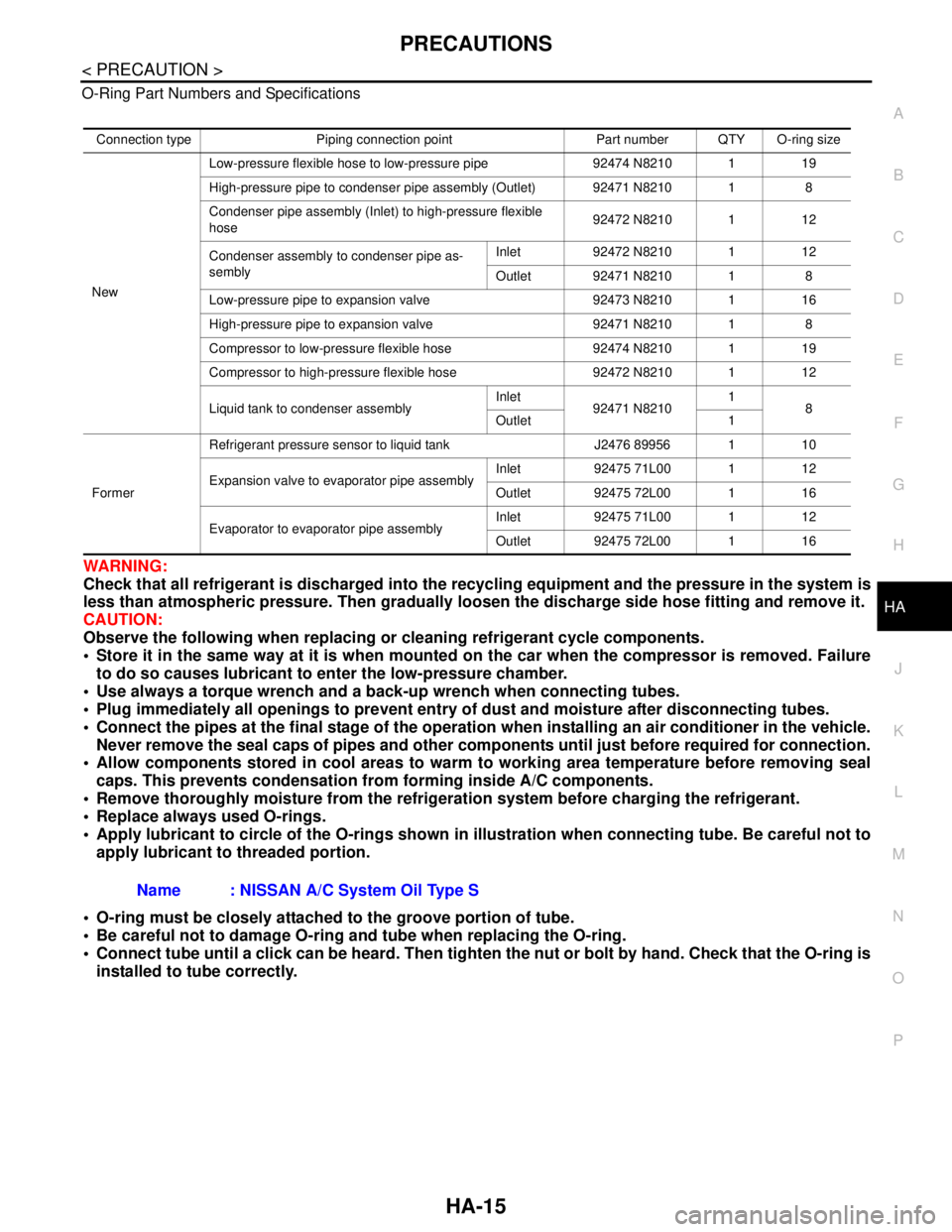

P O-Ring Part Numbers and Specifications

WARNING:

Check that all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

Observe the following when replacing or cleaning refrigerant cycle components.

Store it in the same way at it is when mounted on the car when the compressor is removed. Failure

to do so causes lubricant to enter the low-pressure chamber.

Use always a torque wrench and a back-up wrench when connecting tubes.

Plug immediately all openings to prevent entry of dust and moisture after disconnecting tubes.

Connect the pipes at the final stage of the operation when installing an air conditioner in the vehicle.

Never remove the seal caps of pipes and other components until just before required for connection.

Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

Remove thoroughly moisture from the refrigeration system before charging the refrigerant.

Replace always used O-rings.

Apply lubricant to circle of the O-rings shown in illustration when connecting tube. Be careful not to

apply lubricant to threaded portion.

O-ring must be closely attached to the groove portion of tube.

Be careful not to damage O-ring and tube when replacing the O-ring.

Connect tube until a click can be heard. Then tighten the nut or bolt by hand. Check that the O-ring is

installed to tube correctly.

Connection type Piping connection point Part number QTY O-ring size

NewLow-pressure flexible hose to low-pressure pipe 92474 N8210 1 19

High-pressure pipe to condenser pipe assembly (Outlet) 92471 N8210 1 8

Condenser pipe assembly (Inlet) to high-pressure flexible

hose92472 N8210 1 12

Condenser assembly to condenser pipe as-

semblyInlet 92472 N8210 1 12

Outlet 92471 N8210 1 8

Low-pressure pipe to expansion valve 92473 N8210 1 16

High-pressure pipe to expansion valve 92471 N8210 1 8

Compressor to low-pressure flexible hose 92474 N8210 1 19

Compressor to high-pressure flexible hose 92472 N8210 1 12

Liquid tank to condenser assemblyInlet

92471 N82101

8

Outlet 1

FormerRefrigerant pressure sensor to liquid tank J2476 89956 1 10

Expansion valve to evaporator pipe assemblyInlet 92475 71L00 1 12

Outlet 92475 72L00 1 16

Evaporator to evaporator pipe assemblyInlet 92475 71L00 1 12

Outlet 92475 72L00 1 16

Name : NISSAN A/C System Oil Type S

Page 2597 of 5121

HA-28

< ON-VEHICLE MAINTENANCE >

LUBRICANT

LUBRICANT

Maintenance of Lubricant QuantityINFOID:0000000003795916

The lubricant in the compressor circulates through the system the refrigerant. Add lubricant to compressor

when replacing any component or after a large refrigerant leakage occurred. It is important to maintain the

specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

Lack of lubricant: May lead to a seized compressor.

Excessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

LUBRICANT RETURN OPERATION

Adjust the lubricant quantity according to the test group shown below.

1.CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

A/C system works normally.

There is no evidence of a large amount of lubricant leakage.

CAUTION:

Never perform the lubricant return operation if excessive lubricant leakage is detected.

Is it successful?

YES >> GO TO 2.

NO >> GO TO 3.

2.PERFORM LUBRICANT RETURN OPERATION

1. Start the engine, and set to the following conditions:

- Engine speed: Idling to 1,200 rpm

- A/C switch: ON

- Blower speed: Max. position

- Set temperature: FULL HOT

- Intake position: Recirculation (REC)

2. Perform lubricant return operation for approximately 10 minutes.

3. Stop the engine.

>> GO TO 3.

3.CHECK REPLACEMENT PART

Should the compressor be replaced?

YES >> Refer to HA-29, "Lubricant Adjusting Procedure for Compressor Replacement".

NO >> Refer to HA-28, "

Lubricant Adjusting Procedure for Components Replacement Except Compres-

sor".

Lubricant Adjusting Procedure for Components Replacement Except Compressor

INFOID:0000000003795917

Add the correct amount of lubricant to the system after replacing any of the following major components.

Amount of lubricant to be added:Name : NISSAN A/C System Oil Type S

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m (Imp fl oz.)

Evaporator 75 (2.6) —

Condenser 35 (1.2) —

Liquid tank 10 (0.4) —

Page 2603 of 5121

HA-34

< ON-VEHICLE MAINTENANCE >

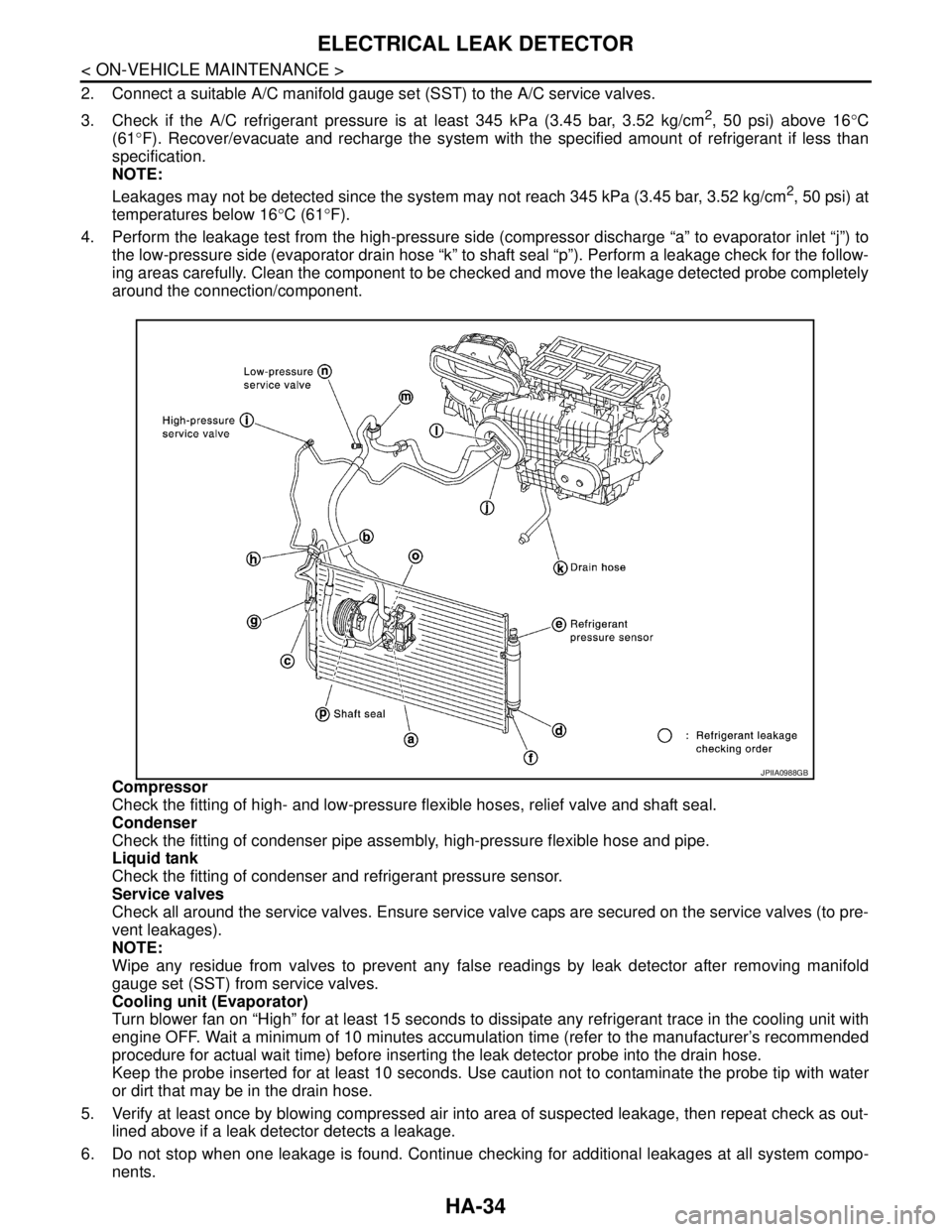

ELECTRICAL LEAK DETECTOR

2. Connect a suitable A/C manifold gauge set (SST) to the A/C service valves.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50 psi) above 16°C

(61°F). Recover/evacuate and recharge the system with the specified amount of refrigerant if less than

specification.

NOTE:

Leakages may not be detected since the system may not reach 345 kPa (3.45 bar, 3.52 kg/cm

2, 50 psi) at

temperatures below 16°C (61°F).

4. Perform the leakage test from the high-pressure side (compressor discharge “a” to evaporator inlet “j”) to

the low-pressure side (evaporator drain hose “k” to shaft seal “p”). Perform a leakage check for the follow-

ing areas carefully. Clean the component to be checked and move the leakage detected probe completely

around the connection/component.

Compressor

Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

Condenser

Check the fitting of condenser pipe assembly, high-pressure flexible hose and pipe.

Liquid tank

Check the fitting of condenser and refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leakages).

NOTE:

Wipe any residue from valves to prevent any false readings by leak detector after removing manifold

gauge set (SST) from service valves.

Cooling unit (Evaporator)

Turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the cooling unit with

engine OFF. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. Verify at least once by blowing compressed air into area of suspected leakage, then repeat check as out-

lined above if a leak detector detects a leakage.

6. Do not stop when one leakage is found. Continue checking for additional leakages at all system compo-

nents.

JPIIA0988GB

Page 2607 of 5121

HA-38

< ON-VEHICLE REPAIR >

LOW-PRESSURE FLEXIBLE HOSE

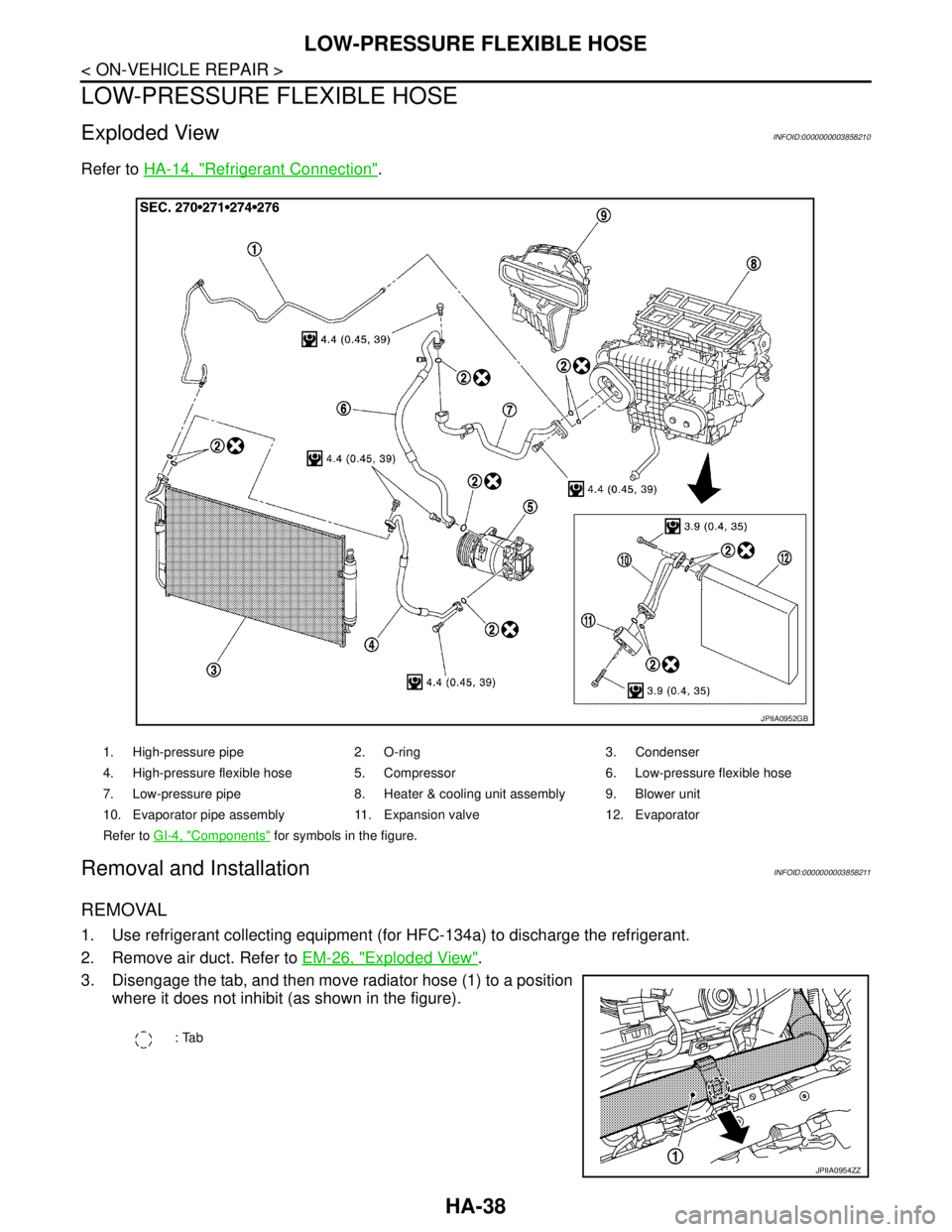

LOW-PRESSURE FLEXIBLE HOSE

Exploded ViewINFOID:0000000003858210

Refer to HA-14, "Refrigerant Connection".

Removal and InstallationINFOID:0000000003858211

REMOVAL

1. Use refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove air duct. Refer to EM-26, "

Exploded View".

3. Disengage the tab, and then move radiator hose (1) to a position

where it does not inhibit (as shown in the figure).

1. High-pressure pipe 2. O-ring 3. Condenser

4. High-pressure flexible hose 5. Compressor 6. Low-pressure flexible hose

7. Low-pressure pipe 8. Heater & cooling unit assembly 9. Blower unit

10. Evaporator pipe assembly 11. Expansion valve 12. Evaporator

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0952GB

: Tab

JPIIA0954ZZ

Page 2609 of 5121

HA-40

< ON-VEHICLE REPAIR >

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE

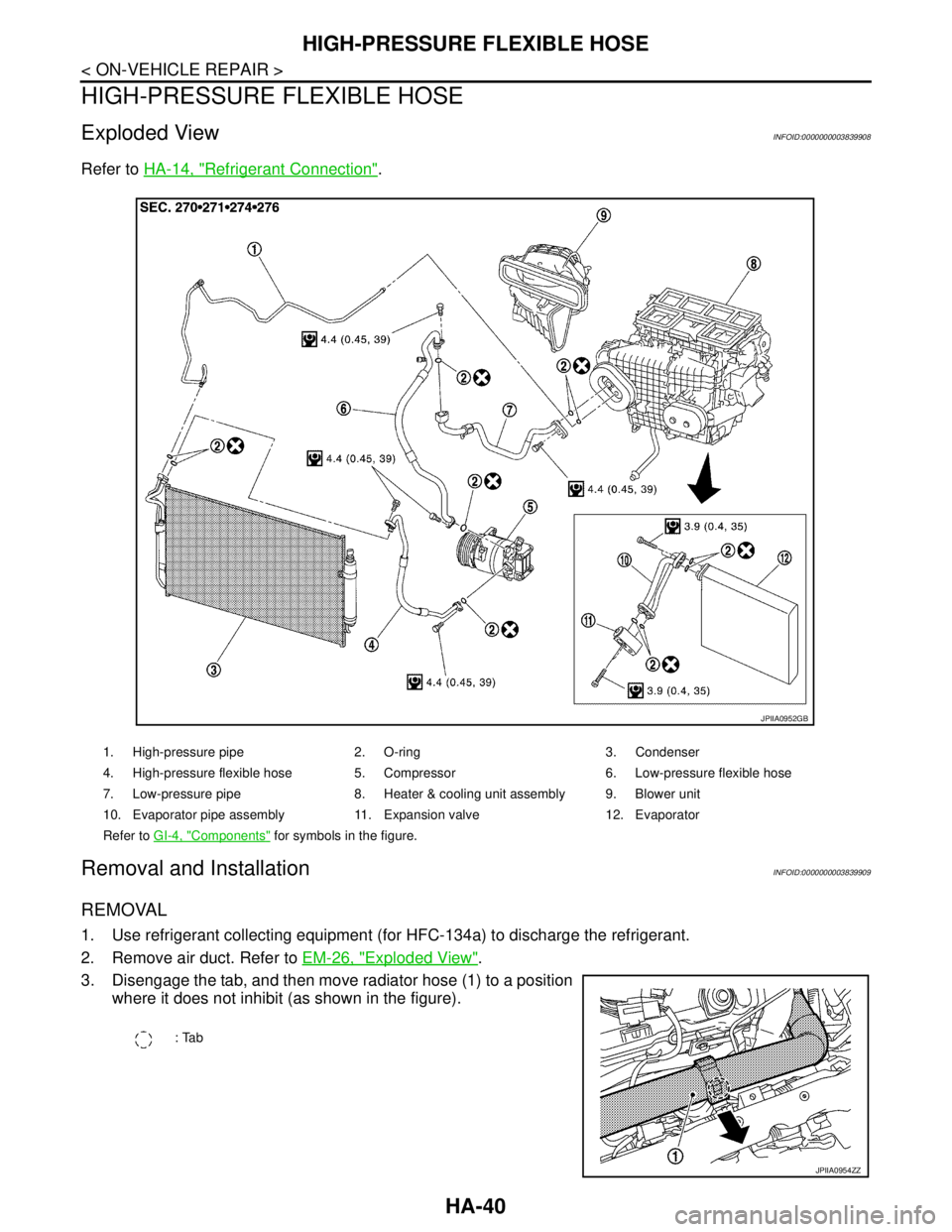

Exploded ViewINFOID:0000000003839908

Refer to HA-14, "Refrigerant Connection".

Removal and InstallationINFOID:0000000003839909

REMOVAL

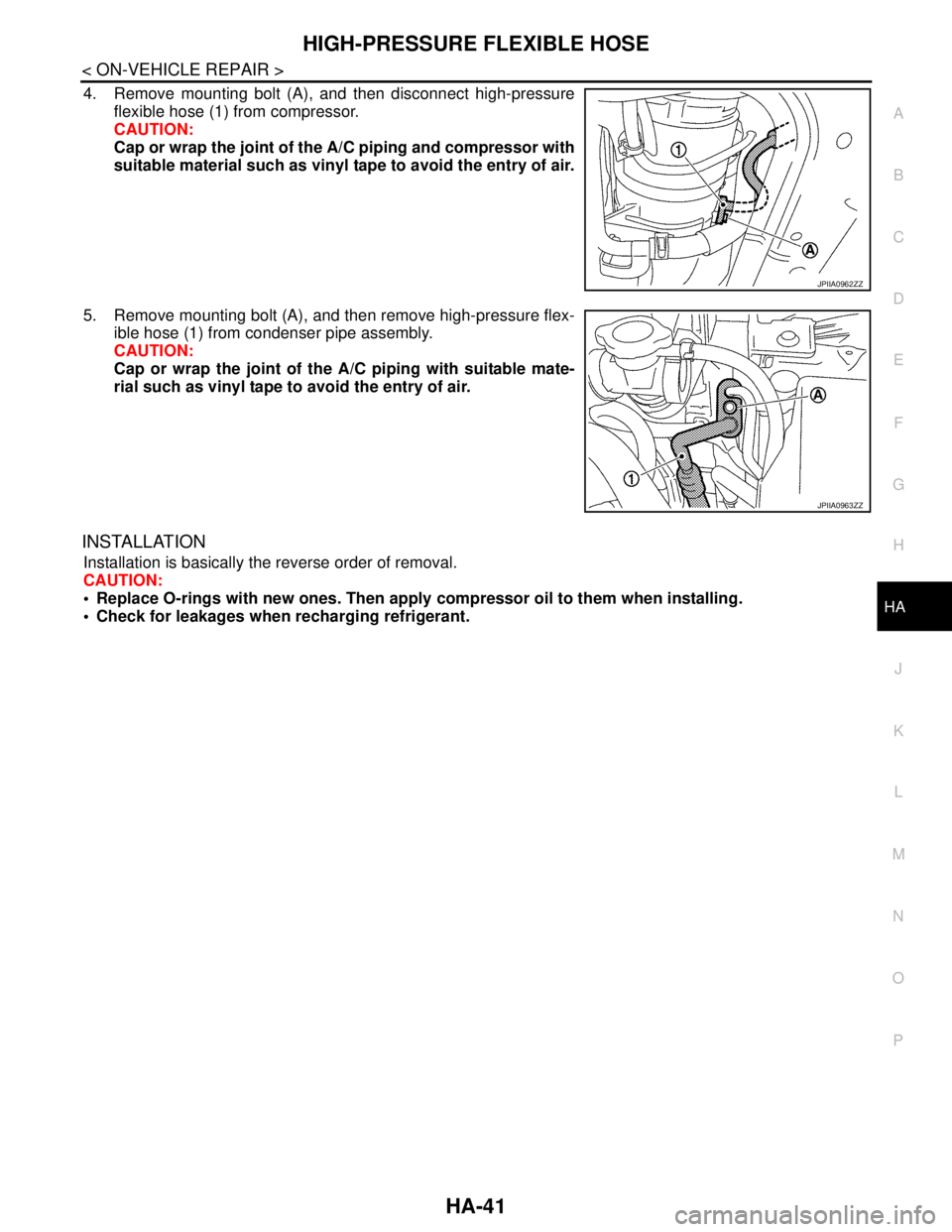

1. Use refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove air duct. Refer to EM-26, "

Exploded View".

3. Disengage the tab, and then move radiator hose (1) to a position

where it does not inhibit (as shown in the figure).

1. High-pressure pipe 2. O-ring 3. Condenser

4. High-pressure flexible hose 5. Compressor 6. Low-pressure flexible hose

7. Low-pressure pipe 8. Heater & cooling unit assembly 9. Blower unit

10. Evaporator pipe assembly 11. Expansion valve 12. Evaporator

Refer to GI-4, "

Components" for symbols in the figure.

JPIIA0952GB

: Tab

JPIIA0954ZZ

Page 2610 of 5121

HIGH-PRESSURE FLEXIBLE HOSE

HA-41

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

J

K

L

MA

B

HA

N

O

P

4. Remove mounting bolt (A), and then disconnect high-pressure

flexible hose (1) from compressor.

CAUTION:

Cap or wrap the joint of the A/C piping and compressor with

suitable material such as vinyl tape to avoid the entry of air.

5. Remove mounting bolt (A), and then remove high-pressure flex-

ible hose (1) from condenser pipe assembly.

CAUTION:

Cap or wrap the joint of the A/C piping with suitable mate-

rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant.

JPIIA0962ZZ

JPIIA0963ZZ