Ioni NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1122 of 5121

![NISSAN TEANA 2008 Service Manual CHG-24

< ON-VEHICLE REPAIR >

ALTERNATOR

3. Remove alternator pulley, using alternator pulley adaptor (A)

[SST:KV10118200].

ASSEMBLY

Rear Bearing

CAUTION:

Never reuse rear bearing. Replace with a new NISSAN TEANA 2008 Service Manual CHG-24

< ON-VEHICLE REPAIR >

ALTERNATOR

3. Remove alternator pulley, using alternator pulley adaptor (A)

[SST:KV10118200].

ASSEMBLY

Rear Bearing

CAUTION:

Never reuse rear bearing. Replace with a new](/img/5/57391/w960_57391-1121.png)

CHG-24

< ON-VEHICLE REPAIR >

ALTERNATOR

3. Remove alternator pulley, using alternator pulley adaptor (A)

[SST:KV10118200].

ASSEMBLY

Rear Bearing

CAUTION:

Never reuse rear bearing. Replace with a new one.

Never lubricate rear bearing outer race.

Rear bracket assembly Installation

1. Fit brush assembly, diode assembly, regulator assembly and

stator.

2. Push brushed up with fingers and install them to rotor.

NOTE:

Take care not damage slip ring sliding surface.

InspectionINFOID:0000000003860541

ALTERNATOR PULLEY INSPECTION

Perform the following.

Make sure that alternator pulley does not rattle.

Make sure that alternator pulley nut is tight.

JSMIA0063ZZ

SKIB4529E

SKIB4530E

Page 1131 of 5121

CO-8

< ON-VEHICLE MAINTENANCE >

ENGINE COOLANT

ON-VEHICLE MAINTENANCE

ENGINE COOLANT

InspectionINFOID:0000000003793166

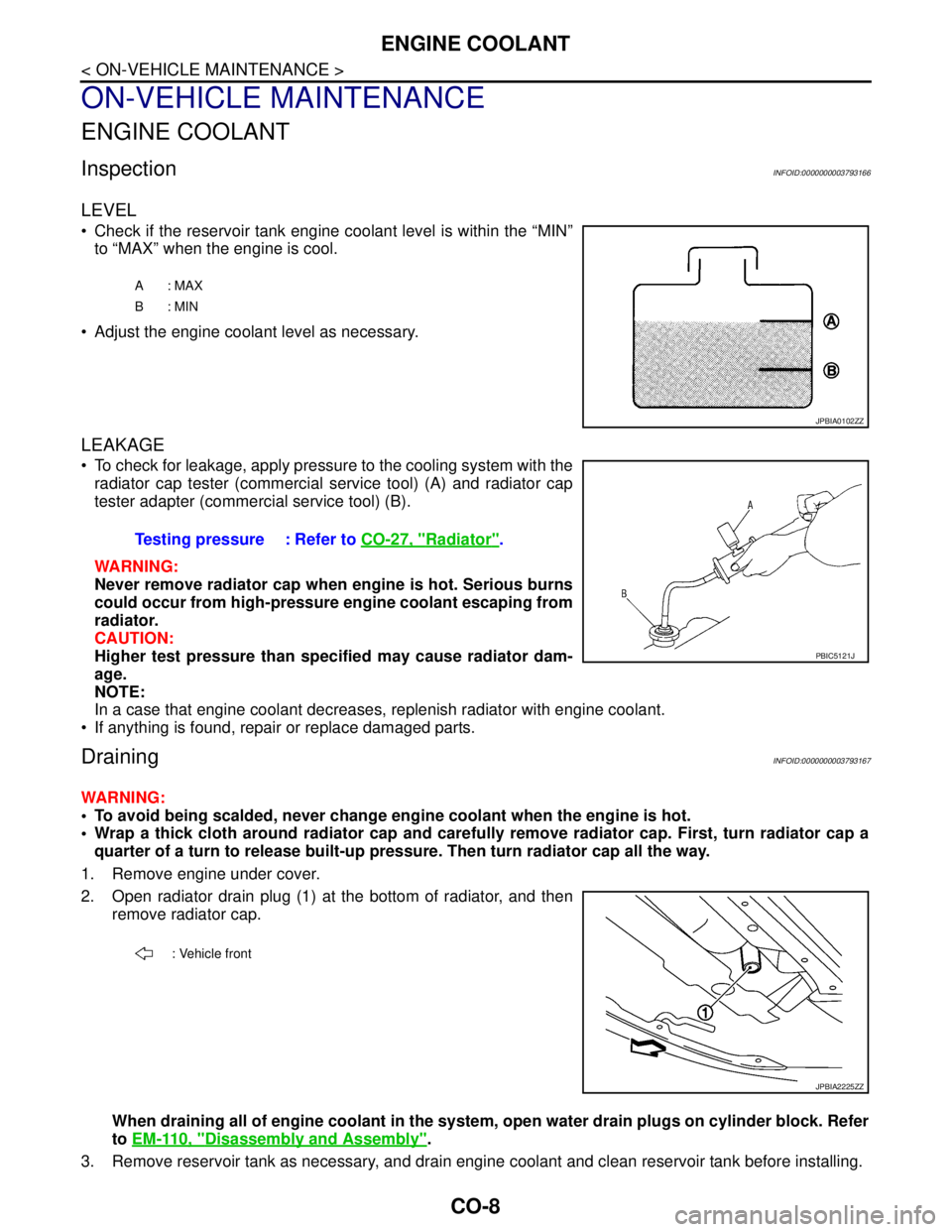

LEVEL

Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” when the engine is cool.

Adjust the engine coolant level as necessary.

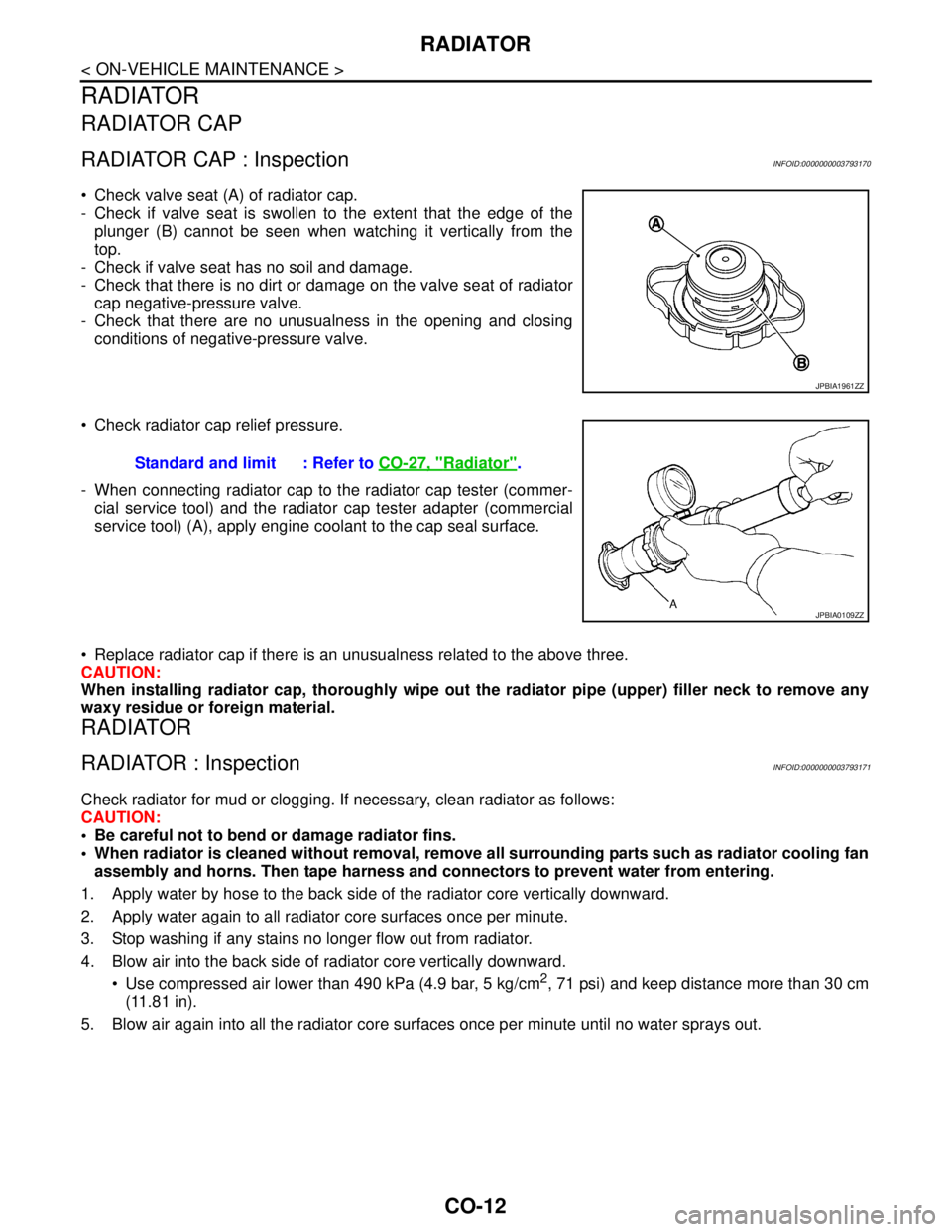

LEAKAGE

To check for leakage, apply pressure to the cooling system with the

radiator cap tester (commercial service tool) (A) and radiator cap

tester adapter (commercial service tool) (B).

WARNING:

Never remove radiator cap when engine is hot. Serious burns

could occur from high-pressure engine coolant escaping from

radiator.

CAUTION:

Higher test pressure than specified may cause radiator dam-

age.

NOTE:

In a case that engine coolant decreases, replenish radiator with engine coolant.

If anything is found, repair or replace damaged parts.

DrainingINFOID:0000000003793167

WARNING:

To avoid being scalded, never change engine coolant when the engine is hot.

Wrap a thick cloth around radiator cap and carefully remove radiator cap. First, turn radiator cap a

quarter of a turn to release built-up pressure. Then turn radiator cap all the way.

1. Remove engine under cover.

2. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

When draining all of engine coolant in the system, open water drain plugs on cylinder block. Refer

to EM-110, "

Disassembly and Assembly".

3. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

A: MAX

B: MIN

JPBIA0102ZZ

Testing pressure : Refer to CO-27, "Radiator".

PBIC5121J

: Vehicle front

JPBIA2225ZZ

Page 1135 of 5121

CO-12

< ON-VEHICLE MAINTENANCE >

RADIATOR

RADIATOR

RADIATOR CAP

RADIATOR CAP : InspectionINFOID:0000000003793170

Check valve seat (A) of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger (B) cannot be seen when watching it vertically from the

top.

- Check if valve seat has no soil and damage.

- Check that there is no dirt or damage on the valve seat of radiator

cap negative-pressure valve.

- Check that there are no unusualness in the opening and closing

conditions of negative-pressure valve.

Check radiator cap relief pressure.

- When connecting radiator cap to the radiator cap tester (commer-

cial service tool) and the radiator cap tester adapter (commercial

service tool) (A), apply engine coolant to the cap seal surface.

Replace radiator cap if there is an unusualness related to the above three.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator pipe (upper) filler neck to remove any

waxy residue or foreign material.

RADIATOR

RADIATOR : InspectionINFOID:0000000003793171

Check radiator for mud or clogging. If necessary, clean radiator as follows:

CAUTION:

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as radiator cooling fan

assembly and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.81 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

JPBIA1961ZZ

Standard and limit : Refer to CO-27, "Radiator".

JPBIA0109ZZ

Page 1136 of 5121

RADIATOR

CO-13

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

ON-VEHICLE REPAIR

RADIATOR

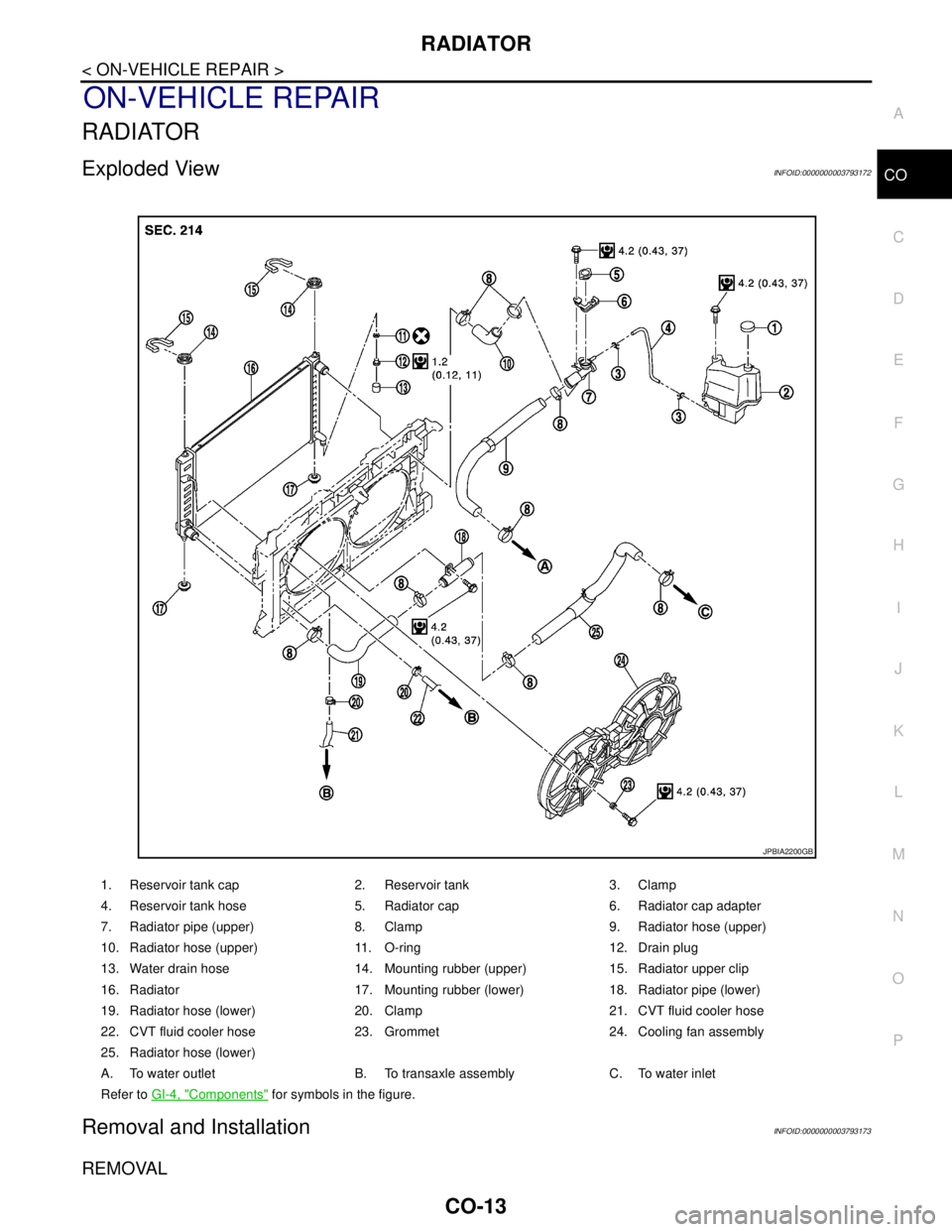

Exploded ViewINFOID:0000000003793172

Removal and InstallationINFOID:0000000003793173

REMOVAL

1. Reservoir tank cap 2. Reservoir tank 3. Clamp

4. Reservoir tank hose 5. Radiator cap 6. Radiator cap adapter

7. Radiator pipe (upper) 8. Clamp 9. Radiator hose (upper)

10. Radiator hose (upper) 11. O-ring 12. Drain plug

13. Water drain hose 14. Mounting rubber (upper) 15. Radiator upper clip

16. Radiator 17. Mounting rubber (lower) 18. Radiator pipe (lower)

19. Radiator hose (lower) 20. Clamp 21. CVT fluid cooler hose

22. CVT fluid cooler hose 23. Grommet 24. Cooling fan assembly

25. Radiator hose (lower)

A. To water outlet B. To transaxle assembly C. To water inlet

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2200GB

Page 1138 of 5121

RADIATOR

CO-15

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

InspectionINFOID:0000000003793174

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant and CVT fluid.

Page 1139 of 5121

CO-16

< ON-VEHICLE REPAIR >

COOLING FAN

COOLING FAN

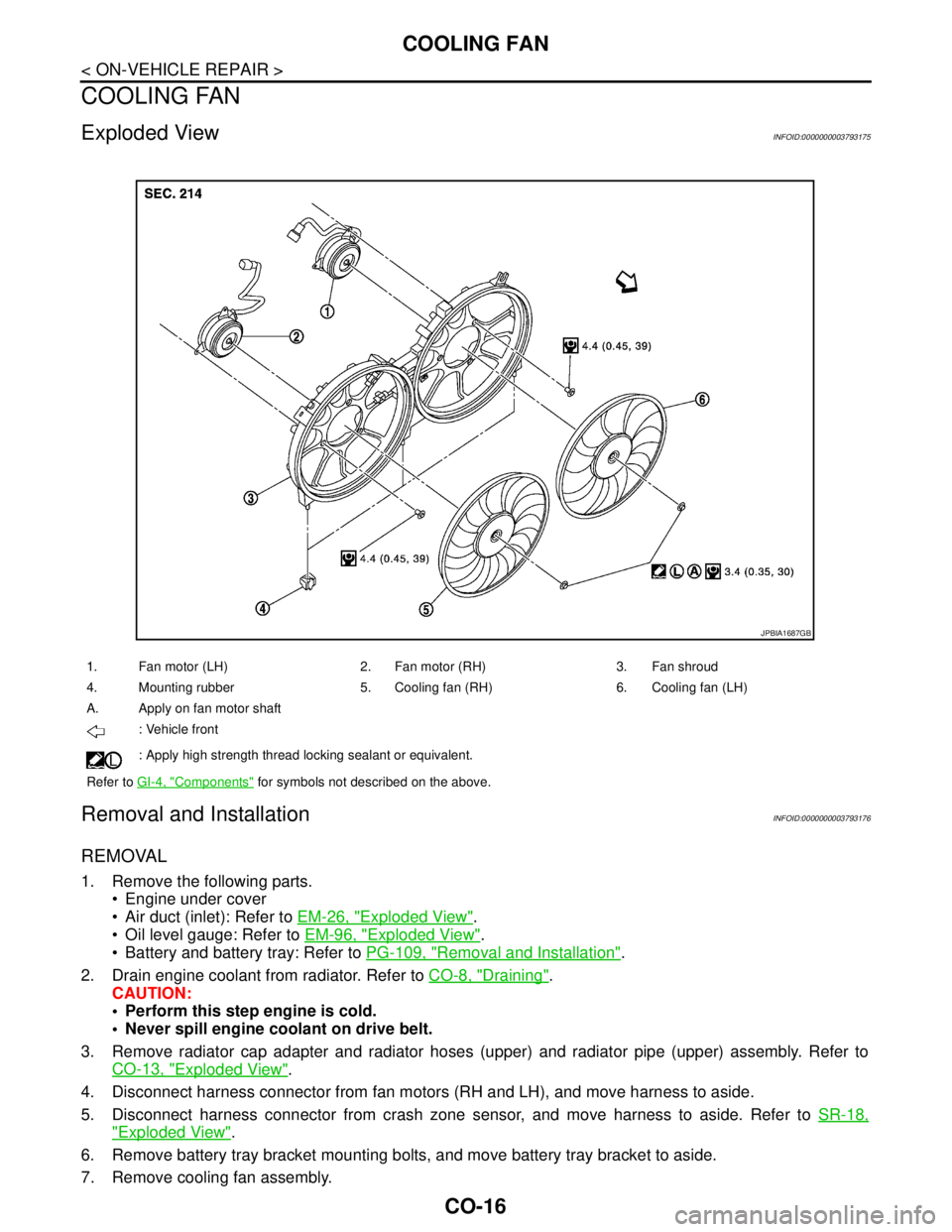

Exploded ViewINFOID:0000000003793175

Removal and InstallationINFOID:0000000003793176

REMOVAL

1. Remove the following parts.

Engine under cover

Air duct (inlet): Refer to EM-26, "

Exploded View".

Oil level gauge: Refer to EM-96, "

Exploded View".

Battery and battery tray: Refer to PG-109, "

Removal and Installation".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step engine is cold.

Never spill engine coolant on drive belt.

3. Remove radiator cap adapter and radiator hoses (upper) and radiator pipe (upper) assembly. Refer to

CO-13, "

Exploded View".

4. Disconnect harness connector from fan motors (RH and LH), and move harness to aside.

5. Disconnect harness connector from crash zone sensor, and move harness to aside. Refer to SR-18,

"Exploded View".

6. Remove battery tray bracket mounting bolts, and move battery tray bracket to aside.

7. Remove cooling fan assembly.

1. Fan motor (LH) 2. Fan motor (RH) 3. Fan shroud

4. Mounting rubber 5. Cooling fan (RH) 6. Cooling fan (LH)

A. Apply on fan motor shaft

: Vehicle front

: Apply high strength thread locking sealant or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPBIA1687GB

Page 1140 of 5121

COOLING FAN

CO-17

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

CAUTION:

Be careful not to damage or scratch on radiator core.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Only use genuine parts for cooling fan mounting bolt and observe the specified torque (to prevent

radiator from being damaged).

NOTE:

Cooling fans are controlled by ECM. For details, refer to EC-60, "

System Diagram".

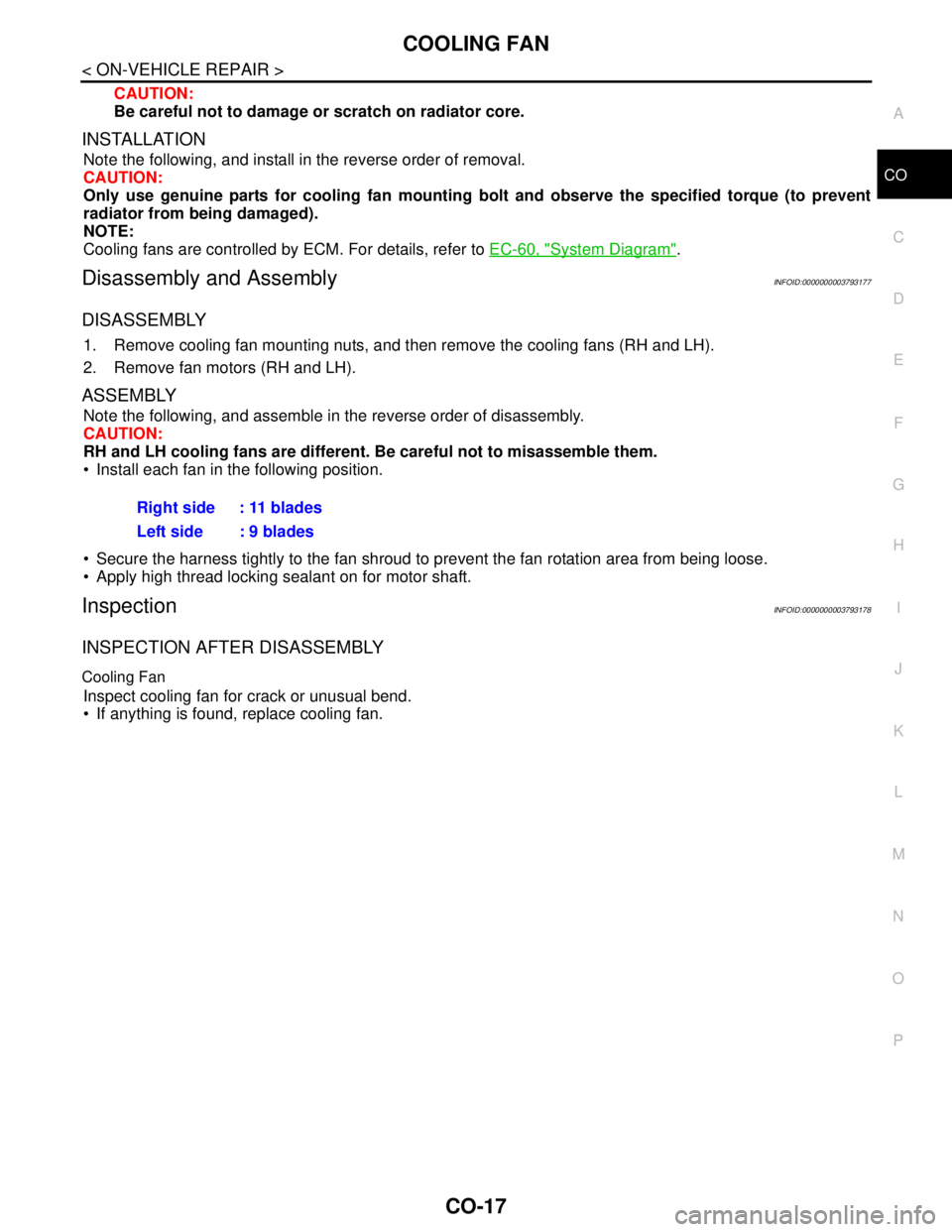

Disassembly and AssemblyINFOID:0000000003793177

DISASSEMBLY

1. Remove cooling fan mounting nuts, and then remove the cooling fans (RH and LH).

2. Remove fan motors (RH and LH).

ASSEMBLY

Note the following, and assemble in the reverse order of disassembly.

CAUTION:

RH and LH cooling fans are different. Be careful not to misassemble them.

Install each fan in the following position.

Secure the harness tightly to the fan shroud to prevent the fan rotation area from being loose.

Apply high thread locking sealant on for motor shaft.

InspectionINFOID:0000000003793178

INSPECTION AFTER DISASSEMBLY

Cooling Fan

Inspect cooling fan for crack or unusual bend.

If anything is found, replace cooling fan.Right side : 11 blades

Left side : 9 blades

Page 1141 of 5121

CO-18

< ON-VEHICLE REPAIR >

WATER PUMP

WATER PUMP

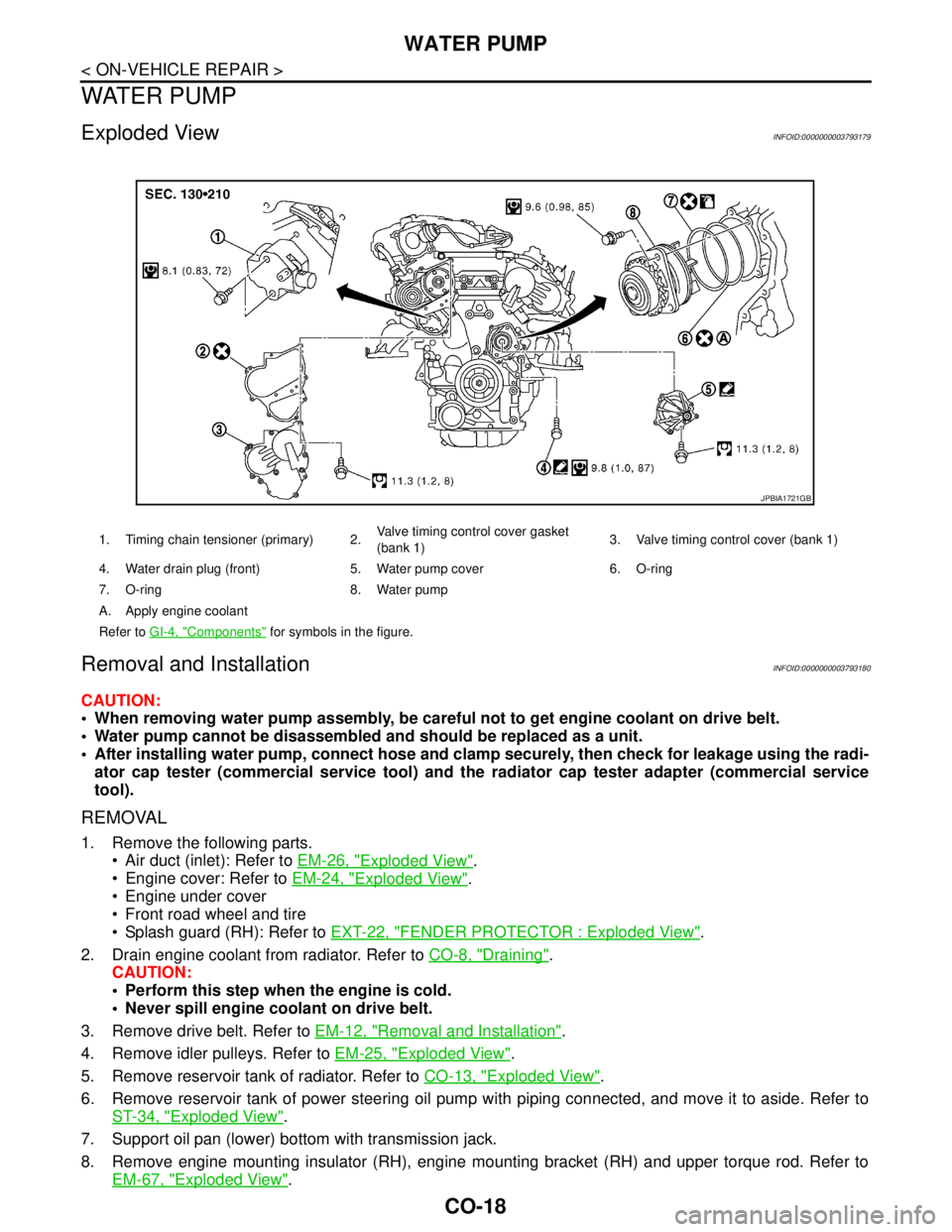

Exploded ViewINFOID:0000000003793179

Removal and InstallationINFOID:0000000003793180

CAUTION:

When removing water pump assembly, be careful not to get engine coolant on drive belt.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, connect hose and clamp securely, then check for leakage using the radi-

ator cap tester (commercial service tool) and the radiator cap tester adapter (commercial service

tool).

REMOVAL

1. Remove the following parts.

Air duct (inlet): Refer to EM-26, "

Exploded View".

Engine cover: Refer to EM-24, "

Exploded View".

Engine under cover

Front road wheel and tire

Splash guard (RH): Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

3. Remove drive belt. Refer to EM-12, "

Removal and Installation".

4. Remove idler pulleys. Refer to EM-25, "

Exploded View".

5. Remove reservoir tank of radiator. Refer to CO-13, "

Exploded View".

6. Remove reservoir tank of power steering oil pump with piping connected, and move it to aside. Refer to

ST-34, "

Exploded View".

7. Support oil pan (lower) bottom with transmission jack.

8. Remove engine mounting insulator (RH), engine mounting bracket (RH) and upper torque rod. Refer to

EM-67, "

Exploded View".

1. Timing chain tensioner (primary) 2.Valve timing control cover gasket

(bank 1)3. Valve timing control cover (bank 1)

4. Water drain plug (front) 5. Water pump cover 6. O-ring

7. O-ring 8. Water pump

A. Apply engine coolant

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1721GB

Page 1144 of 5121

WATER PUMP

CO-21

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

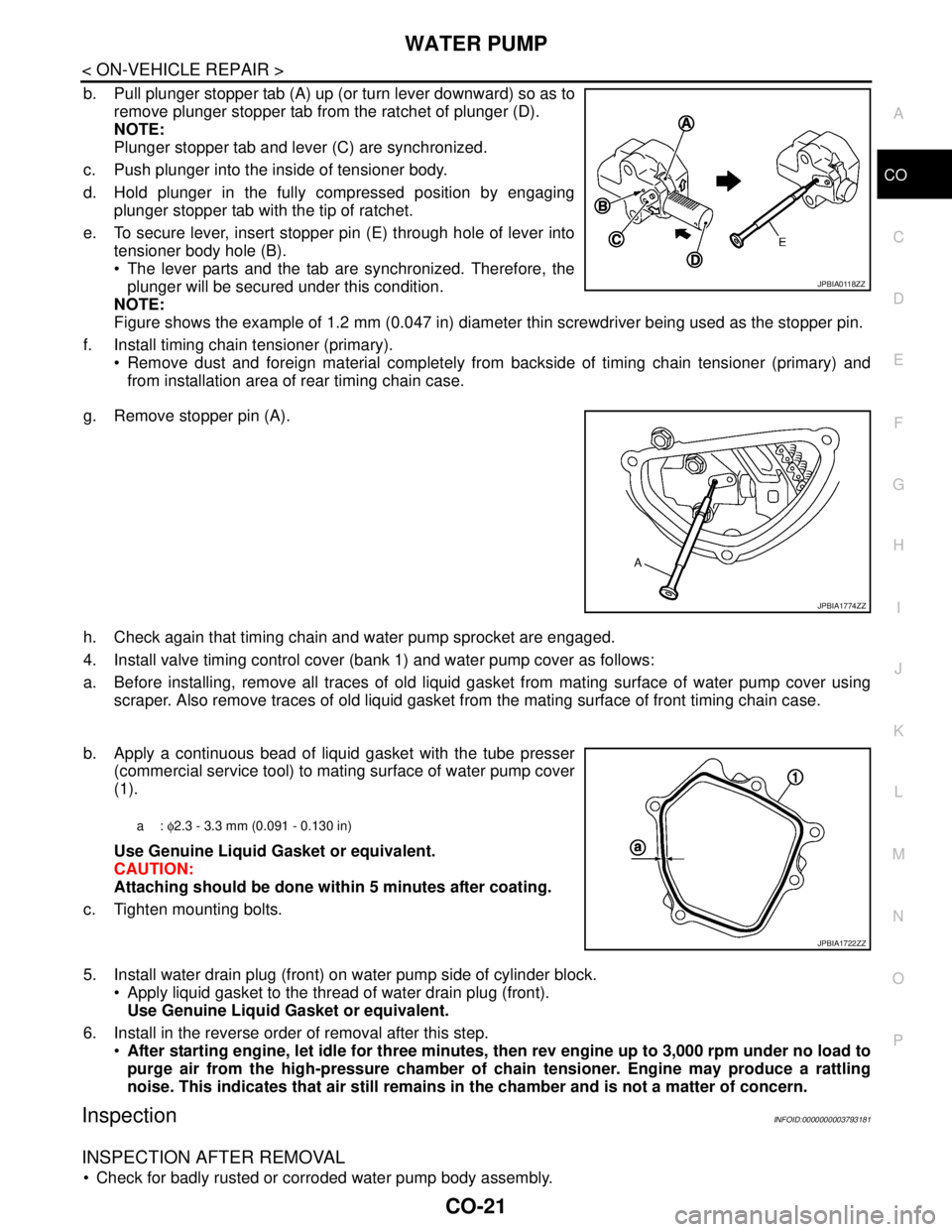

b. Pull plunger stopper tab (A) up (or turn lever downward) so as to

remove plunger stopper tab from the ratchet of plunger (D).

NOTE:

Plunger stopper tab and lever (C) are synchronized.

c. Push plunger into the inside of tensioner body.

d. Hold plunger in the fully compressed position by engaging

plunger stopper tab with the tip of ratchet.

e. To secure lever, insert stopper pin (E) through hole of lever into

tensioner body hole (B).

The lever parts and the tab are synchronized. Therefore, the

plunger will be secured under this condition.

NOTE:

Figure shows the example of 1.2 mm (0.047 in) diameter thin screwdriver being used as the stopper pin.

f. Install timing chain tensioner (primary).

Remove dust and foreign material completely from backside of timing chain tensioner (primary) and

from installation area of rear timing chain case.

g. Remove stopper pin (A).

h. Check again that timing chain and water pump sprocket are engaged.

4. Install valve timing control cover (bank 1) and water pump cover as follows:

a. Before installing, remove all traces of old liquid gasket from mating surface of water pump cover using

scraper. Also remove traces of old liquid gasket from the mating surface of front timing chain case.

b. Apply a continuous bead of liquid gasket with the tube presser

(commercial service tool) to mating surface of water pump cover

(1).

Use Genuine Liquid Gasket or equivalent.

CAUTION:

Attaching should be done within 5 minutes after coating.

c. Tighten mounting bolts.

5. Install water drain plug (front) on water pump side of cylinder block.

Apply liquid gasket to the thread of water drain plug (front).

Use Genuine Liquid Gasket or equivalent.

6. Install in the reverse order of removal after this step.

After starting engine, let idle for three minutes, then rev engine up to 3,000 rpm under no load to

purge air from the high-pressure chamber of chain tensioner. Engine may produce a rattling

noise. This indicates that air still remains in the chamber and is not a matter of concern.

InspectionINFOID:0000000003793181

INSPECTION AFTER REMOVAL

Check for badly rusted or corroded water pump body assembly.

JPBIA0118ZZ

JPBIA1774ZZ

a: φ2.3 - 3.3 mm (0.091 - 0.130 in)

JPBIA1722ZZ

Page 1146 of 5121

WATER INLET AND THERMOSTAT ASSEMBLY

CO-23

< ON-VEHICLE REPAIR >

C

D

E

F

G

H

I

J

K

L

MA

CO

N

P O

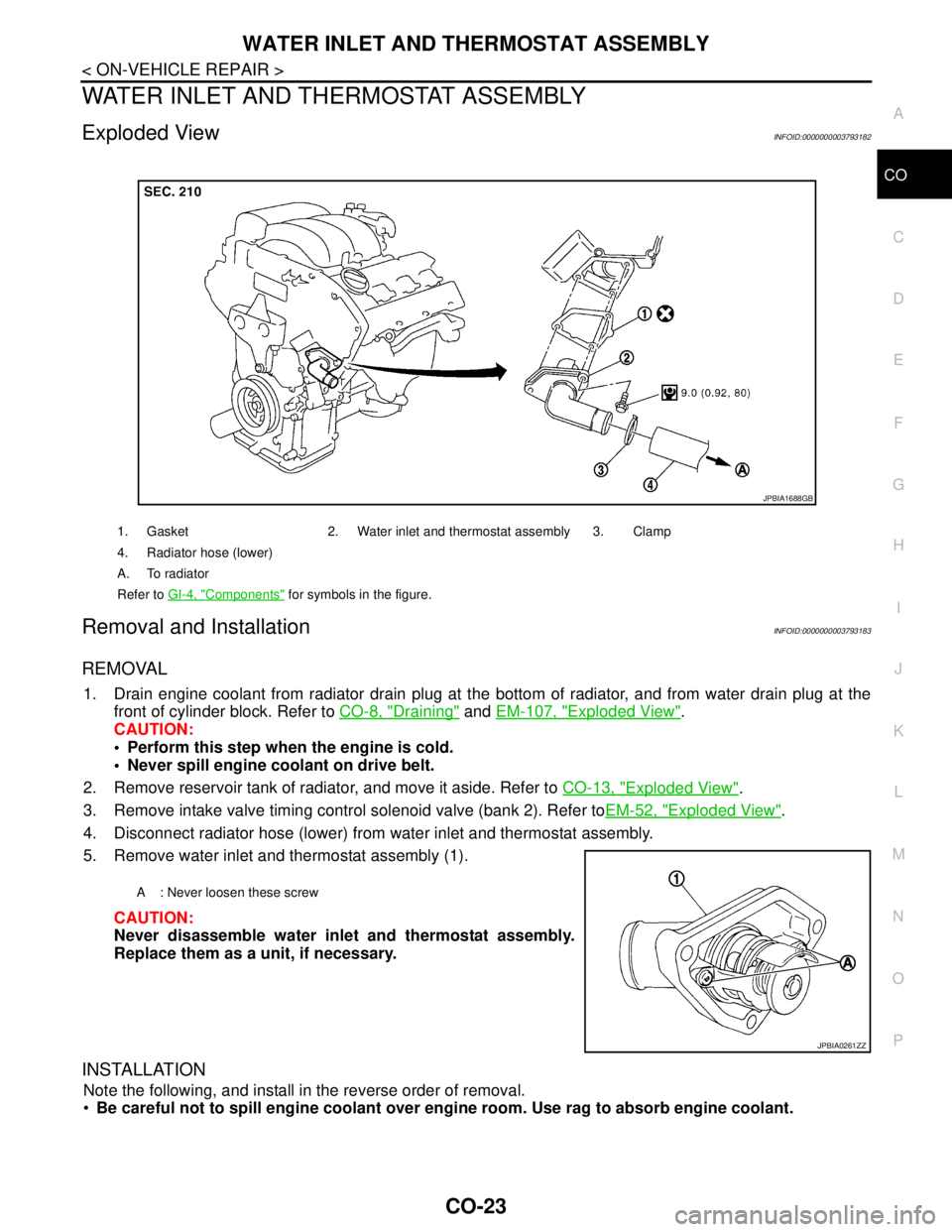

WATER INLET AND THERMOSTAT ASSEMBLY

Exploded ViewINFOID:0000000003793182

Removal and InstallationINFOID:0000000003793183

REMOVAL

1. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-8, "

Draining" and EM-107, "Exploded View".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belt.

2. Remove reservoir tank of radiator, and move it aside. Refer to CO-13, "

Exploded View".

3. Remove intake valve timing control solenoid valve (bank 2). Refer toEM-52, "

Exploded View".

4. Disconnect radiator hose (lower) from water inlet and thermostat assembly.

5. Remove water inlet and thermostat assembly (1).

CAUTION:

Never disassemble water inlet and thermostat assembly.

Replace them as a unit, if necessary.

INSTALLATION

Note the following, and install in the reverse order of removal.

Be careful not to spill engine coolant over engine room. Use rag to absorb engine coolant.

1. Gasket 2. Water inlet and thermostat assembly 3. Clamp

4. Radiator hose (lower)

A. To radiator

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA1688GB

A : Never loosen these screw

JPBIA0261ZZ