check engine light NISSAN TEANA 2008 Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 4609 of 5121

![NISSAN TEANA 2008 Workshop Manual TM-136

< PRECAUTION >[CVT: RE0F09B]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003897196

When performing the procedure after removing cowl top cover, cover

the lower end NISSAN TEANA 2008 Workshop Manual TM-136

< PRECAUTION >[CVT: RE0F09B]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003897196

When performing the procedure after removing cowl top cover, cover

the lower end](/img/5/57391/w960_57391-4608.png)

TM-136

< PRECAUTION >[CVT: RE0F09B]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003897196

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000003849068

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal

before any repair or inspection work. The open/short circuit of related switches, sensors, solenoid

valves, etc. will cause the MI to light up.

Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to an open circuit. (Be sure the connector is free from water, grease, dirt,

bent terminals, etc.)

Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MI to light up due to a short circuit.

Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to a malfunction of the EVAP system or fuel injection system, etc.

Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Precaution for TCM and CVT Assembly ReplacementINFOID:0000000003849069

CAUTION:

Check if new data (Unit ID) are entered correctly after replacing CVT assembly and erasing data in

TCM. (Connect CONSULT-III, and then turn ignition switch OFF.)

When replacing CVT assembly or TCM, refer to the pattern table below and erase the EEPROM in the

TCM if necessary.

EEPROM ERASING PATTERNS

Removal and Installation Procedure for CVT Unit ConnectorINFOID:0000000003849070

REMOVAL

PIIB3706J

CVT assembly TCM Erasing EEPROM in TCM Remarks

Replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state. (CVT assembly must be replaced

first.)

Not replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state.

Replaced Not replaced RequiredRequired because data has been written in the EE-

PROM in the TCM and because the TCM cannot write

data from the ROM assembly in the transmission.

Page 4625 of 5121

![NISSAN TEANA 2008 Workshop Manual TM-152

< ON-VEHICLE MAINTENANCE >[CVT: RE0F09B]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003849084

INSPECTION

1. Move selector lever to “P” position, and turn ignition swit NISSAN TEANA 2008 Workshop Manual TM-152

< ON-VEHICLE MAINTENANCE >[CVT: RE0F09B]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003849084

INSPECTION

1. Move selector lever to “P” position, and turn ignition swit](/img/5/57391/w960_57391-4624.png)

TM-152

< ON-VEHICLE MAINTENANCE >[CVT: RE0F09B]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003849084

INSPECTION

1. Move selector lever to “P” position, and turn ignition switch ON (engine stop).

2. Check that selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

check that selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move selector lever and check for excessive effort, sticking, noise or rattle.

4. Check that selector lever stops at each position with the feel of engagement when it is moved through all

the positions. Check that the actual position of selector lever matches the position shown by shift position

indicator and manual lever on the transaxle.

5. The method of operating selector lever to individual positions

correctly should be as shown.

6. When selector button is pressed in “P”, “R”, “N”, “D” or “L” posi-

tion without applying forward/backward force to selector lever,

check button operation for sticking.

7. Check that back-up lamps illuminate only when selector lever is

placed in the “R” position.

8. When in “R” position, check that back-up lamps illuminate even

when the selector lever is pushed toward the “P” position.

CAUTION:

Check the lighting without pressing shift button.

9. Check that back-up lamps do not illuminate when selector lever is pushed toward the “R” position when in

the “P” or “N” position.

CAUTION:

Check the lighting without pressing shift button.

10. Check that the engine can only be started with selector lever in the “P” and “N” positions.

11. Check that transaxle is locked completely in “P” position.

ADJUSTMENT

1. Move selector lever to “ P” position.

CAUTION:

Turn wheels more than 1/4 rotations and apply the park

lock.

2. Loosen the control cable nut (A).

3. Place manual lever (B) to “P” position.

CAUTION:

Never apply any force to manual lever.

4. Tighten the control cable nut. Refer to TM-157, "

Exploded View".

CAUTION:

Fix manual lever when tightening.

JPDIA0343GB

JPDIA0794ZZ

Page 4652 of 5121

![NISSAN TEANA 2008 Workshop Manual INSPECTION AND ADJUSTMENT

TM-179

< BASIC INSPECTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REP NISSAN TEANA 2008 Workshop Manual INSPECTION AND ADJUSTMENT

TM-179

< BASIC INSPECTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REP](/img/5/57391/w960_57391-4651.png)

INSPECTION AND ADJUSTMENT

TM-179

< BASIC INSPECTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

INSPECTION AND ADJUSTMENT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT

ADDITIONAL SERVICE WHEN REPLACING CONTROL UNIT : Service After Replac-

ing TCM and Transaxle Assembly

INFOID:0000000003806346

SERVICE AFTER REPLACING TCM AND TRANSAXLE ASSEMBLY

Perform the applicable service according to the following sheet when replacing TCM or transaxle assembly.

CAUTION:

Never start the engine until the service is completed.

“TCM-POWER SUPPLY [P1701]” may be indicated soon after replacing TCM or transaxle assembly

(after erasing the memory at the pattern B). Restart the self-diagnosis after erasing the self-diagnosis

result. Check that no error is detected.

NOTE:

Old unit means that the unit has been already used for another vehicle.

PATTERN A

1. Shift the selector lever to “P” position after replacing TCM. Turn the ignition switch ON.

2. Check that the shift position indicator in the combination meter turns ON (It indicates approximately 1 or 2

seconds after turning the ignition switch ON.)

Check the following items if the shift position indicator does not turn ON. Repair or replace the shift posi-

tion indicator if necessary.

- The harness between TCM and ROM ASSY in the transaxle assembly is open or shorted.

- Cable disconnected, loosen, or bent from the connector housing.

PATTERN B

1. Turn the ignition switch ON after replacing each part.

2. Start engine.

CAUTION:

Never start driving.

3. Select “Data Monitor” mode for “TRANSMISSION”.

4. Warm up the transaxle assembly until “ATFTEMP COUNT” indicates 47 [approximately 20°C (68°F)] or

more. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

CAUTION:

Never start engine.

6. Select “Self Diagnostic Results” mode for “TRANSMISSION”.

7. Shift the selector lever to “R” position.

8. Depress slightly the accelerator pedal (Pedal angle: 2/8) while depressing the brake pedal.

9. Perform “Erase”.

10. Shift the selector lever to “R” position after replacing TCM. Turn the ignition switch OFF.

11. Wait approximately 10 seconds after turning the ignition switch OFF.

12. Turn the ignition switch ON while shifting the selector lever to “R” position.

CAUTION:

Never start engine.

13. Select “Special Function” mode for “TRANSMISSION”.

14. Check that the value on “CALIBRATION DATA” is the same as the data after erasing “Calibration Data”.

TCM CVT assembly Service pattern

Replace the new unit. Do not replace the unit. “PATTERN A”

Do not replace the unit. Replace either an old unit or new unit.

“PATTERN B”

Replace the old unit.Do not replace the unit.

Replace either an old unit or new unit.

Replace the new unit. Replace either an old unit or new unit. “PATTERN C”

Page 4771 of 5121

![NISSAN TEANA 2008 Workshop Manual TM-298

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003901480

When performing the procedure after removing cowl top cover, cover

the lower end NISSAN TEANA 2008 Workshop Manual TM-298

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003901480

When performing the procedure after removing cowl top cover, cover

the lower end](/img/5/57391/w960_57391-4770.png)

TM-298

< PRECAUTION >[CVT: RE0F10A]

PRECAUTIONS

Precaution for Procedure without Cowl Top Cover

INFOID:0000000003901480

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000003806496

The ECM has an on board diagnostic system. It will light up the Malfunction Indicator Lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal

before any repair or inspection work. The open/short circuit of related switches, sensors, solenoid

valves, etc. will cause the MIL to light up.

Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EVAP system or fuel injection system, etc.

Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Precaution for TCM and CVT Assembly ReplacementINFOID:0000000003806497

CAUTION:

Check if new data (Unit ID) are entered correctly after replacing CVT assembly and erasing data in

TCM. (Connect CONSULT-III, and then turn ignition switch OFF.)

When replacing CVT assembly or TCM, refer to the pattern table below and erase the EEPROM in the

TCM if necessary.

EEPROM ERASING PATTERNS

Removal and Installation Procedure for CVT Unit ConnectorINFOID:0000000003806498

REMOVAL

PIIB3706J

CVT assembly TCM Erasing EEPROM in TCM Remarks

Replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state. (CVT assembly must be replaced

first.)

Not replaced Replaced Not requiredNot required because the EEPROM in the TCM is in

the default state.

Replaced Not replaced RequiredRequired because data has been written in the EE-

PROM in the TCM and because the TCM cannot write

data from the ROM assembly in the transmission.

Page 4787 of 5121

![NISSAN TEANA 2008 Workshop Manual TM-314

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003806512

INSPECTION

1. Place selector lever in “P” position, and turn ignition swi NISSAN TEANA 2008 Workshop Manual TM-314

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003806512

INSPECTION

1. Place selector lever in “P” position, and turn ignition swi](/img/5/57391/w960_57391-4786.png)

TM-314

< ON-VEHICLE MAINTENANCE >[CVT: RE0F10A]

CVT POSITION

CVT POSITION

Inspection and AdjustmentINFOID:0000000003806512

INSPECTION

1. Place selector lever in “P” position, and turn ignition switch ON (engine stop).

2. Check that selector lever can be shifted to other than “P” position when brake pedal is depressed. Also

check that selector lever can be shifted from “P” position only when brake pedal is depressed.

3. Move the selector lever and check for excessive effort, sticking, noise or rattle.

4. Check that selector lever stops at each position with the feel of engagement when it is moved through all

the positions. Check that the actual position of the selector lever matches the position shown by the shift

position indicator and the manual lever on the transaxle.

5. The method of operating the selector lever to individual posi-

tions correctly should be as shown.

6. When selector button is pressed in “P”, “R”, “N”, “D” or “L” posi-

tion without applying forward/backward force to selector lever,

check button operation for sticking.

7. Check that back-up lamps illuminate only when selector lever is

placed in the “R” position.

8. When in “R” position, check that back-up lamps illuminate even

when the selector lever is pushed toward the “P” position.

CAUTION:

Check the lighting without pressing shift button.

9. Check that the back-up lamps do not illuminate when selector lever is pushed toward the “R” position

when in the “P” or “N” position.

CAUTION:

Check the lighting without pressing shift button.

10. Check that the engine can only be started with the selector lever in the “P” and “N” positions.

11. Check that transaxle is locked completely in “P” position.

ADJUSTMENT

1. Place selector lever in “ P” position.

CAUTION:

Turn wheels more than 1/4 rotations and apply the park lock.

2. Loosen nut (A) and place manual lever (B) in “P” position.

CAUTION:

Never apply any force to the manual lever.

3. Tighten nut. Refer to TM-319, "

Exploded View".

CAUTION:

Fix the manual lever when tightening.

JPDIA0343GB

JPDIA0780ZZ

Page 4942 of 5121

WCS-12

< FUNCTION DIAGNOSIS >

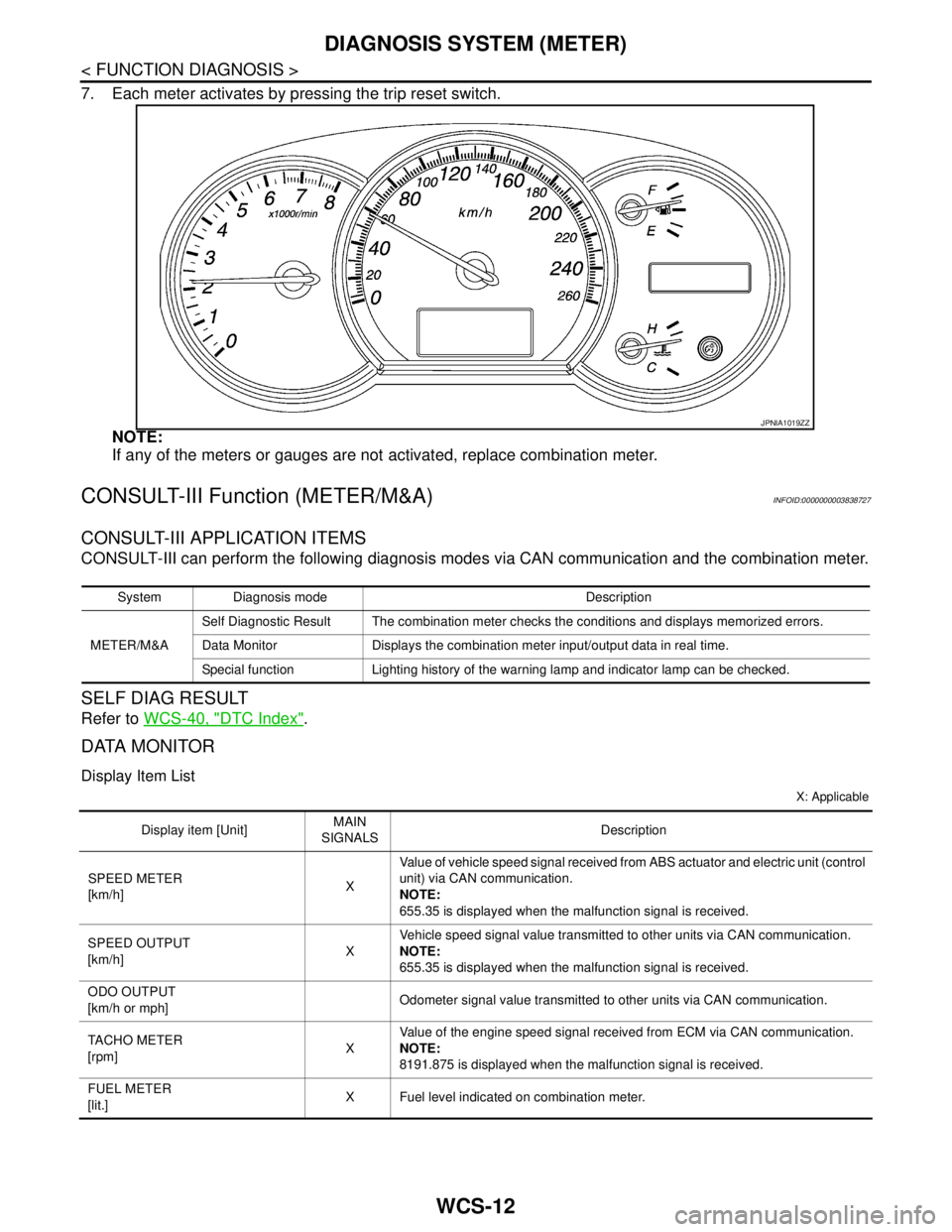

DIAGNOSIS SYSTEM (METER)

7. Each meter activates by pressing the trip reset switch.

NOTE:

If any of the meters or gauges are not activated, replace combination meter.

CONSULT-III Function (METER/M&A)INFOID:0000000003838727

CONSULT-III APPLICATION ITEMS

CONSULT-III can perform the following diagnosis modes via CAN communication and the combination meter.

SELF DIAG RESULT

Refer to WCS-40, "DTC Index".

DATA MONITOR

Display Item List

X: Applicable

JPNIA1019ZZ

System Diagnosis mode Description

METER/M&ASelf Diagnostic Result The combination meter checks the conditions and displays memorized errors.

Data Monitor Displays the combination meter input/output data in real time.

Special function Lighting history of the warning lamp and indicator lamp can be checked.

Display item [Unit]MAIN

SIGNALSDescription

SPEED METER

[km/h]XValue of vehicle speed signal received from ABS actuator and electric unit (control

unit) via CAN communication.

NOTE:

655.35 is displayed when the malfunction signal is received.

SPEED OUTPUT

[km/h]XVehicle speed signal value transmitted to other units via CAN communication.

NOTE:

655.35 is displayed when the malfunction signal is received.

ODO OUTPUT

[km/h or mph]Odometer signal value transmitted to other units via CAN communication.

TACHO METER

[rpm]XValue of the engine speed signal received from ECM via CAN communication.

NOTE:

8191.875 is displayed when the malfunction signal is received.

FUEL METER

[lit.]X Fuel level indicated on combination meter.

Page 4943 of 5121

![NISSAN TEANA 2008 Workshop Manual WCS

DIAGNOSIS SYSTEM (METER)

WCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

W TEMP METER

[°C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NO NISSAN TEANA 2008 Workshop Manual WCS

DIAGNOSIS SYSTEM (METER)

WCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

W TEMP METER

[°C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NO](/img/5/57391/w960_57391-4942.png)

WCS

DIAGNOSIS SYSTEM (METER)

WCS-13

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

W TEMP METER

[°C] XValue of engine coolant temperature signal is received from ECM via CAN com-

munication.

NOTE:

215 is displayed when the malfunction signal is input.

ABS W/L

[On/Off]Status of ABS warning lamp detected from ABS warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

VDC/TCS IND

[On/Off]Status of VDC OFF indicator lamp detected from VDC OFF indicator lamp signal

is received from ABS actuator and electric unit (control unit) via CAN communica-

tion.

SLIP IND

[On/Off]Status of SLIP indicator lamp detected from slip indicator lamp signal received

from ABS actuator and electric unit (control unit) via CAN communication.

BRAKE W/L

[On/Off]Status of brake warning lamp detected from brake warning lamp signal is received

from ABS actuator and electric unit (control unit) via CAN communication.

NOTE:

Displays “Off” if the brake warning lamp is illuminated when the valve check starts,

the parking brake switch is turned ON or the brake fluid level switch is turned ON.

DOOR W/L

[On/Off]Status of door warning detected from door switch signal received from BCM via

CAN communication.

TRUNK/GLAS-H

[On/Off]Status of trunk warning detected from trunk switch signal received from BCM via

CAN communication.

HI-BEAM IND

[On/Off]Status of high beam indicator lamp detected from high beam request signal is re-

ceived from BCM via CAN communication.

TURN IND

[On/Off]Status of turn indicator lamp detected from turn indicator signal is received from

BCM via CAN communication.

FR FOG IND

[On/Off]Status of front fog light indicator lamp detected from front fog light request signal

is received from BCM via CAN communication.

RR FOG IND

[On/Off]Status of rear fog light indicator lamp detected from rear fog light request signal is

received from BCM via CAN communication.

LIGHT IND

[On/Off]Status of light indicator lamp detected from position light request signal is received

from BCM via CAN communication.

OIL W/L

[On/Off]Status of oil pressure warning lamp detected from oil pressure switch signal is re-

ceived from BCM via CAN communication.

MIL

[On/Off] Status of malfunction indicator lamp detected from malfunctioning indicator lamp

signal is received from ECM via CAN communication.

CRUISE IND

[On/Off]Status of CRUISE indicator detected from ASCD status signal is received from

ECM via CAN communication.

SPORT IND

[On/Off]Status of SPORT indicator detected from sport mode switch signal is received

from control device.

4WD W/L

[On/Off]This item is displayed, but cannot be monitored.

4WD LOCK IND

[On/Off]This item is displayed, but cannot be monitored.

FUEL W/L

[On/Off]Low-fuel warning lamp status detected by the identified fuel level.

WASHER W/L

[On/Off]This item is displayed, but cannot be monitored.

KEY G/Y W/L

[On/Off]Status of key warning lamp (G/Y) detected from key warning signal is received

from BCM via CAN communication.

AFS OFF IND

[On/Off]This item is displayed, but cannot be monitored.

LCD

[B&P N, B&P I, ID NG, ROTAT, SFT

P, INSRT, BATT, NO KY,OUTKY, LK

WN]Displays status of Intelligent Key system warning detected from meter display sig-

nal is received from BCM via CAN communication.

Display item [Unit]MAIN

SIGNALSDescription