check engine light NISSAN TEANA 2008 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2032 of 5121

EXL-3

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

TAIL LAMP CIRCUIT .........................................74

Component Function Check ....................................74

Diagnosis Procedure ...............................................74

LICENSE PLATE LAMP CIRCUIT .....................76

Component Function Check ....................................76

Diagnosis Procedure ...............................................76

REAR FOG LAMP CIRCUIT ..............................77

Component Function Check ....................................77

Diagnosis Procedure ...............................................77

HEADLAMP SYSTEM ........................................79

Wiring Diagram - HEADLAMP - ..............................79

AUTO LIGHT SYSTEM ......................................83

Wiring Diagram - AUTO LIGHT SYSTEM - .............83

FRONT FOG LAMP SYSTEM ............................87

Wiring Diagram - FRONT FOG LAMP - ..................87

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM ..................................................

90

Wiring Diagram - TURN AND HAZARD WARN-

ING LAMPS - ..........................................................

90

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ................................................

95

Wiring Diagram - PARKING, LICENSE PLATE

AND TAIL LAMPS - .................................................

95

STOP LAMP .......................................................99

Wiring Diagram - STOP LAMP - .............................99

BACK-UP LAMP ..............................................102

Wiring Diagram - BACK-UP LAMP - .....................102

REAR FOG LAMP SYSTEM ............................105

Wiring Diagram - REAR FOG LAMP - ..................105

ECU DIAGNOSIS .......................................108

BCM (BODY CONTROL MODULE) .................108

Reference Value ...................................................108

Wiring Diagram - BCM - ........................................131

Fail-safe ................................................................137

DTC Inspection Priority Chart .............................139

DTC Index ............................................................140

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ...............

142

Reference Value ...................................................142

Wiring Diagram - IPDM E/R - ................................150

Fail-safe ................................................................153

DTC Index ............................................................155

AUTO LEVELIZER CONTROL UNIT ...............156

Reference Value ...................................................156

Wiring Diagram — HEADLAMP AIMING CON-

TROL SYSTEM — ................................................

158

Fail-safe ................................................................161

DTC Inspection Priority Chart ...............................162

DTC Index .............................................................163

SYMPTOM DIAGNOSIS ............................164

EXTERIOR LIGHTING SYSTEM SYMPTOMS .164

Symptom Table .....................................................164

NORMAL OPERATING CONDITION .............167

Description .............................................................167

BOTH SIDE HEADLAMPS (HI) ARE NOT

TURNED ON ...................................................

168

Description .............................................................168

Diagnosis Procedure .............................................168

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ...................................................

169

Description .............................................................169

Diagnosis Procedure .............................................169

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON .....................

170

Description .............................................................170

Diagnosis Procedure .............................................170

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ...................................................

171

Description .............................................................171

Diagnosis Procedure .............................................171

PRECAUTION ............................................172

PRECAUTIONS ...............................................172

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...............................................................

172

Precautions For Xenon Headlamp Service ...........172

ON-VEHICLE MAINTENANCE ..................173

HEADLAMP AIMING ADJUSTMENT .............173

Description .............................................................173

Aiming Adjustment Procedure (Low Beam) ...........174

Aiming Adjustment Procedure (High Beam) ..........175

FRONT FOG LAMP AIMING ADJUSTMENT .178

Description .............................................................178

Aiming Adjustment Procedure ...............................178

ON-VEHICLE REPAIR ...............................180

FRONT COMBINATION LAMP ......................180

Exploded View .......................................................180

Removal and Installation .......................................181

Replacement .........................................................181

Disassembly and Assembly ...................................182

FRONT FOG LAMP ........................................183

Exploded View .......................................................183

Removal and Installation .......................................183

Replacement .........................................................183

Page 2034 of 5121

EXL-5

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) ............................

224

IPDM E/R (INTELLIGENT POWER DISTRIBU-

TION MODULE ENGINE ROOM) : Diagnosis Pro-

cedure ...................................................................

224

EXTERIOR LAMP FUSE ..................................226

Description ............................................................226

Diagnosis Procedure .............................................226

HEADLAMP (HI) CIRCUIT ...............................227

Component Function Check ..................................227

Diagnosis Procedure .............................................227

HEADLAMP (LO) CIRCUIT ..............................229

Component Function Check ..................................229

Diagnosis Procedure .............................................229

FRONT FOG LAMP CIRCUIT ..........................231

Component Function Check ..................................231

Diagnosis Procedure .............................................231

PARKING LAMP CIRCUIT ...............................233

Component Function Check ..................................233

Diagnosis Procedure .............................................233

TURN SIGNAL LAMP CIRCUIT .......................235

Description ............................................................235

Component Function Check ..................................235

Diagnosis Procedure .............................................235

OPTICAL SENSOR ..........................................238

Description ............................................................238

Component Function Check ..................................238

Diagnosis Procedure .............................................238

HAZARD SWITCH ............................................241

Component Function Check ..................................241

Diagnosis Procedure .............................................241

TAIL LAMP CIRCUIT .......................................243

Component Function Check ..................................243

Diagnosis Procedure .............................................243

LICENSE PLATE LAMP CIRCUIT ...................245

Component Function Check ..................................245

Diagnosis Procedure .............................................245

REAR FOG LAMP CIRCUIT ............................246

Component Function Check ..................................246

Diagnosis Procedure .............................................246

HEADLAMP SYSTEM ......................................248

Wiring Diagram - HEADLAMP - ............................248

AUTO LIGHT SYSTEM ....................................252

Wiring Diagram - AUTO LIGHT SYSTEM - ...........252

HEADLAMP AIMING CONTROL SYSTEM

(MANUAL) ........................................................

256

Description ............................................................256

Wiring Diagram - HEADLAMP AIMING CON-

TROL SYSTEM (MANUAL) - .................................

256

Component Inspection ...........................................257

FRONT FOG LAMP SYSTEM .........................259

Wiring Diagram - FRONT FOG LAMP - ................259

TURN SIGNAL AND HAZARD WARNING

LAMP SYSTEM ...............................................

262

Wiring Diagram - TURN AND HAZARD WARN-

ING LAMPS - .........................................................

262

PARKING, LICENSE PLATE AND TAIL

LAMPS SYSTEM ............................................

267

Wiring Diagram - PARKING, LICENSE PLATE

AND TAIL LAMPS - ...............................................

267

STOP LAMP ....................................................271

Wiring Diagram - STOP LAMP - ............................271

BACK-UP LAMP .............................................274

Wiring Diagram - BACK-UP LAMP - ......................274

REAR FOG LAMP SYSTEM ...........................277

Wiring Diagram - REAR FOG LAMP - ...................277

ECU DIAGNOSIS .......................................280

BCM (BODY CONTROL MODULE) ...............280

Reference Value ....................................................280

Wiring Diagram - BCM - ........................................303

Fail-safe .................................................................309

DTC Inspection Priority Chart .............................311

DTC Index .............................................................312

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ..............

314

Reference Value ....................................................314

Wiring Diagram - IPDM E/R - ................................322

Fail-safe .................................................................325

DTC Index .............................................................327

SYMPTOM DIAGNOSIS ............................328

EXTERIOR LIGHTING SYSTEM SYMPTOMS .328

Symptom Table .....................................................328

BOTH SIDE HEADLAMPS (HI) ARE NOT

TURNED ON ...................................................

331

Description .............................................................331

Diagnosis Procedure .............................................331

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ...................................................

332

Description .............................................................332

Diagnosis Procedure .............................................332

PARKING, LICENSE PLATE AND TAIL

LAMPS ARE NOT TURNED ON .....................

333

Description .............................................................333

Diagnosis Procedure .............................................333

Page 2089 of 5121

![NISSAN TEANA 2008 Owners Manual EXL-60

< COMPONENT DIAGNOSIS >[XENON TYPE]

HEADLAMP LEVELIZER CIRCUIT

HEADLAMP LEVELIZER CIRCUIT

DescriptionINFOID:0000000003774349

The headlamp levelizer adjusts the headlamp light axis upward and do NISSAN TEANA 2008 Owners Manual EXL-60

< COMPONENT DIAGNOSIS >[XENON TYPE]

HEADLAMP LEVELIZER CIRCUIT

HEADLAMP LEVELIZER CIRCUIT

DescriptionINFOID:0000000003774349

The headlamp levelizer adjusts the headlamp light axis upward and do](/img/5/57391/w960_57391-2088.png)

EXL-60

< COMPONENT DIAGNOSIS >[XENON TYPE]

HEADLAMP LEVELIZER CIRCUIT

HEADLAMP LEVELIZER CIRCUIT

DescriptionINFOID:0000000003774349

The headlamp levelizer adjusts the headlamp light axis upward and downward with the aiming motor inte-

grated in the front combination lamp.

Component Function CheckINFOID:0000000003774350

1.CHECK HEADLAMP LEVELIZER OPERATION

CONSULT-III ACTIVE TEST

1. Start the engine.

2. Turn the lighting switch 2ND.

3. Select “LAMP TEST” of HEADLAMP LEVELIZER active test item.

4. With operating the test item, check the light axis operation.

Is the operation normal?

YES >> Headlamp levelizer circuit is normal.

NO >> Refer to EXL-60, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003774351

1.CHECK AIMING MOTOR DRIVE SIGNAL OUTPUT

CONSULT-III ACTIVE TEST

1. Start the engine.

2. Turn the light switch 2ND.

3. Select “LAMP TEST” of HEADLAMP LEVELIZER active test item.

4. With operating the test items, check the voltage between the auto levelizer control unit harness connector

and the ground.

Is the measurement value normal?

YES >> GO TO 2.

Fixed at 0 V>>GO TO 3.

Fixed at battery voltage>>GO TO 4.

2.CHECK AIMING MOTOR DRIVE OPEN CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect auto levelizer control unit connector and headlamp aiming motor connector.

3. Check continuity between auto levelizer control unit harness connector and the headlamp aiming motor

harness connector.

Te s t i t e m

Light axis operation

LAMP TEST

MIN Moves the light axis to the highest position.

MID Moves the light axis to the initial position.

MAX Moves the light axis to the lowest position.

Te r m i n a l s

Te s t i t e m

Voltag e

(Approx.) (+) (−)

Auto levelizer control

unit

GroundLAMP TEST

Connector Terminal

C8 7MIN 1.4 V

MID 6.3 V

MAX 9.3 V

Page 2207 of 5121

![NISSAN TEANA 2008 Owners Manual EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, re NISSAN TEANA 2008 Owners Manual EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, re](/img/5/57391/w960_57391-2206.png)

EXL-178

< ON-VEHICLE MAINTENANCE >[XENON TYPE]

FRONT FOG LAMP AIMING ADJUSTMENT

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003773617

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the lug-

gage room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

Turn the aiming adjusting screw for adjustment.

For the position and direction of the adjusting screw, refer to the

figure.

NOTE:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment ProcedureINFOID:0000000003773618

1. Place the screen.

NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front fog lamp center and the

screen.

3. Start the engine. Illuminate the front fog lamp.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

4. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the hor-

izontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

A: UP

B: DOWN

JPLIA1086ZZ

JPLIA0008ZZ

Page 2370 of 5121

![NISSAN TEANA 2008 Owners Manual FRONT FOG LAMP AIMING ADJUSTMENT

EXL-341

< ON-VEHICLE MAINTENANCE >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003894358

PREPARATION BEFOR NISSAN TEANA 2008 Owners Manual FRONT FOG LAMP AIMING ADJUSTMENT

EXL-341

< ON-VEHICLE MAINTENANCE >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003894358

PREPARATION BEFOR](/img/5/57391/w960_57391-2369.png)

FRONT FOG LAMP AIMING ADJUSTMENT

EXL-341

< ON-VEHICLE MAINTENANCE >[HALOGEN TYPE]

C

D

E

F

G

H

I

J

K

MA

B

EXL

N

O

P

FRONT FOG LAMP AIMING ADJUSTMENT

DescriptionINFOID:0000000003894358

PREPARATION BEFORE ADJUSTING

NOTE:

For details, refer to the regulations in your own country.

Before performing aiming adjustment, check the following.

Adjust the tire pressure to the specification.

Fill with fuel, engine coolant and each oil.

Maintain the unloaded vehicle condition. (Remove luggage from the passenger compartment and the lug-

gage room.)

NOTE:

Do not remove the temporary tire, jack and on-vehicle tool.

Wipe out dirt on the headlamp.

CAUTION:

Never use organic solvent (thinner, gasoline etc.)

Ride alone on the driver seat.

AIMING ADJUSTMENT SCREW

Turn the aiming adjusting screw for adjustment.

For the position and direction of the adjusting screw, refer to the

figure.

NOTE:

A screwdriver or hexagonal wrench [6 mm (0.24 in)] can be used

for adjustment.

Aiming Adjustment ProcedureINFOID:0000000003894359

1. Place the screen.

NOTE:

Stop the vehicle facing the wall.

Place the board on a plain road vertically.

2. Face the vehicle with the screen. Maintain 10 m (32.8 ft) between the front fog lamp center and the

screen.

3. Start the engine. Illuminate the front fog lamp.

CAUTION:

Never cover the lens surface with a tape etc. The lens is made of resin.

NOTE:

Shut off the headlamp light with the board to prevent from illuminating the adjustment screen.

4. Adjust the cutoff line height (A) with the aiming adjustment screw so that the distance (X) between the hor-

izontal center line of front fog lamp (H) and (A) becomes 200 mm (7.87 in).

Front fog lamp light distribution on the screen

A: UP

B: DOWN

JPLIA1086ZZ

JPLIA0008ZZ

Page 2511 of 5121

GI-18

< HOW TO USE THIS MANUAL >

TERMINOLOGY

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor

EGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel trim FT ***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection controlNEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Page 2529 of 5121

GI-36

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the system for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

Connectors not fully seated.

Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

Wires laying across brackets or moving components.

Loose, dirty or corroded ground wires.

Wires routed too close to hot components.

To inspect components under the hood, start by verifying the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previously explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under seating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

The customer's concern may occur during hot weather or after car

has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the

component with a heat gun or equivalent.

CAUTION:

Do not heat components above 60°C (140°).

If incident occurs while heating the unit, either replace or properly

insulate the component.

FREEZING

SGI839

SGI842

Page 2577 of 5121

HA-8

< SYMPTOM DIAGNOSIS >

REFRIGERATION SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

REFRIGERATION SYSTEM SYMPTOMS

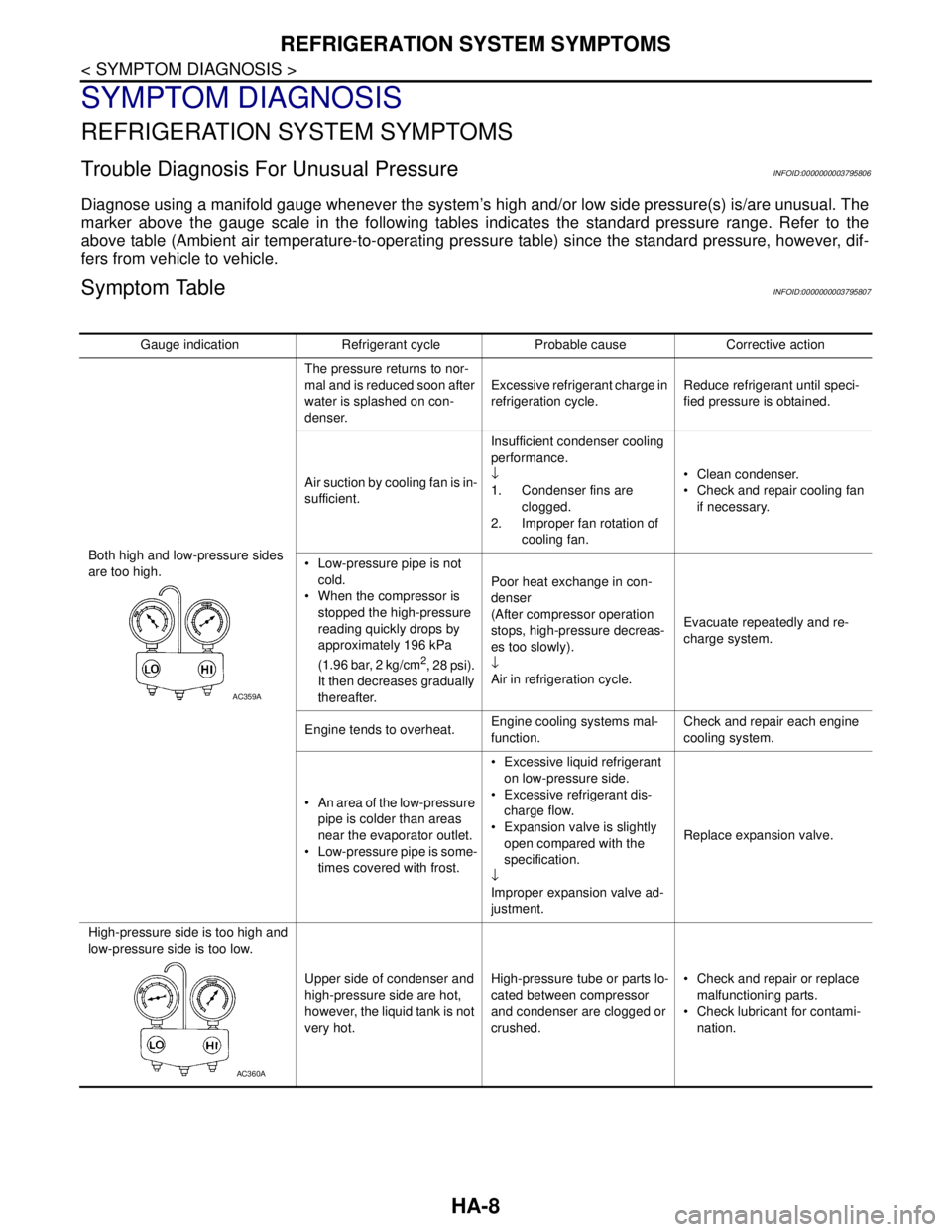

Trouble Diagnosis For Unusual PressureINFOID:0000000003795806

Diagnose using a manifold gauge whenever the system’s high and/or low side pressure(s) is/are unusual. The

marker above the gauge scale in the following tables indicates the standard pressure range. Refer to the

above table (Ambient air temperature-to-operating pressure table) since the standard pressure, however, dif-

fers from vehicle to vehicle.

Symptom TableINFOID:0000000003795807

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure sides

are too high.The pressure returns to nor-

mal and is reduced soon after

water is splashed on con-

denser.Excessive refrigerant charge in

refrigeration cycle.Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient.Insufficient condenser cooling

performance.

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fan. Clean condenser.

Check and repair cooling fan

if necessary.

Low-pressure pipe is not

cold.

When the compressor is

stopped the high-pressure

reading quickly drops by

approximately 196 kPa

(1.96 bar, 2 kg/cm

2, 28 psi).

It then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly).

↓

Air in refrigeration cycle.Evacuate repeatedly and re-

charge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair each engine

cooling system.

An area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

Low-pressure pipe is some-

times covered with frost. Excessive liquid refrigerant

on low-pressure side.

Excessive refrigerant dis-

charge flow.

Expansion valve is slightly

open compared with the

specification.

↓

Improper expansion valve ad-

justment.Replace expansion valve.

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, the liquid tank is not

very hot.High-pressure tube or parts lo-

cated between compressor

and condenser are clogged or

crushed. Check and repair or replace

malfunctioning parts.

Check lubricant for contami-

nation.

AC359A

AC360A

Page 2601 of 5121

HA-32

< ON-VEHICLE MAINTENANCE >

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

InspectionINFOID:0000000003795981

CHECKING SYSTEM FOR LEAKAGES USING THE FLUORESCENT LEAK DETECTOR

1. Check A/C system for leakages using the UV lamp and safety goggles (SST: J-42220) in a low sunlight

area (area without windows preferable). Illuminate all components, fittings and lines. The dye appears as

a bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leakage.

2. Use an adjustable mirror or wipe the area with a clean shop rag or cloth, with the UV lamp for dye residue

if the suspected area is difficult to see.

3. Remove any residual dye using dye cleaner (SST: J-43872) to prevent future misdiagnosis after the leak-

age is repaired.

4. Perform a system performance check and verify the leakage repair with an approved electrical leak detec-

tor.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This may also cause false readings

and may damage the detector.

DYE INJECTION

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (SST: J-41459).

3. Connect the injector tool to the A/C low-pressure side service valve.

4. Start the engine. Then switch A/C ON.

5. Inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye through the low-pressure service valve using dye

injector tool (SST: J-41459) (refer to the manufacture’s operating instructions) when the A/C operating

(compressor running).

6. Disconnect the injector tool from the service valve with the engine still running.

CAUTION:

Be careful when replacing the A/C system or a component, pour the dye directly into the open sys-

tem connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leakage size, operating conditions and location of the leakage, it may take from minutes to days for the

dye to penetrate a leakage and become visible.

8. Attach a blue label if necessary.

Page 2637 of 5121

![NISSAN TEANA 2008 Owners Manual INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE s NISSAN TEANA 2008 Owners Manual INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE s](/img/5/57391/w960_57391-2636.png)

INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE switch. FRE indicator is turned ON.

3. Listen for the intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

the FRE when the DEF is selected.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Intake door system malfunction: HAC-64, "

Diagnosis Procedure".

5.CHECK A/C SWITCH

1. Press the A/C switch.

2. The A/C switch indicator is turned ON.

Confirm that the compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

YES >> GO TO 6.

NO >> Magnet clutch system malfunction: HAC-72, "

Diagnosis Procedure".

6.CHECK WITH TEMPERATURE SETTING LOWERED

1. Operate the compressor.

2. Operate the temperature control switch (driver side) and lower the temperature setting to 18°C (60°F).

3. Check that the cool air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Insufficient cooling: HAC-88, "

Inspection procedure".

7.CHECK WITH TEMPERATURE SETTING RAISED

1. Operate the temperature control switch (driver side) and raise the temperature setting to 32°C (90°F) after

warming up the engine.

2. Check that the warm air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Insufficient heating: HAC-91, "

Inspection procedure".

8.CHECK LEFT AND RIGHT VENTILATION TEMPERATURE SEPARATELY CONTROL SYSTEM FUNC-

TION

1. Press the DUAL switch, and then check that “DUAL” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the discharge air temperature (driver

side) changes.

3. Operate the temperature control switch (passenger side). Check that the discharge air temperature (pas-

senger side) changes.

4. Press the DUAL switch, and then check that the temperature setting (LH/RH) is unified to the driver side

temperature setting.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

9.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the fan speed or outlet changes (the dis-

charge air temperature or fan speed varies depending on the ambient temperature, in-vehicle tempera-

ture, and temperature setting).

Is the inspection result normal?

YES >> GO TO 10.

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.