display NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2629 of 5121

HAC-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HAC

A

B

HAC

N

O P

CONTENTS

HEATER & AIR CONDITIONING CONTROL SYSTEM

WITHOUT 7 INCH DISPLAY

BASIC INSPECTION ....... .............................

6

DIAGNOSIS AND REPAIR WORKFLOW ..... .....6

Work Flow ........................................................... ......6

INSPECTION AND ADJUSTMENT .....................8

Description & Inspection ..................................... ......8

Temperature Setting Trimmer .................................10

Foot Position Setting Trimmer .................................10

Inlet Port Memory Function (FRE) ..........................11

Inlet Port Memory Function (REC) ..........................11

FUNCTION DIAGNOSIS ..............................12

COMPRESSOR CONTROL FUNCTION ........ ....12

Description .......................................................... ....12

Fail-Safe ..................................................................13

Component Part Location .......................................13

Component’s Role ...................................................15

AUTOMATIC AIR CONDITIONER SYSTEM .....17

System Diagram .................................................. ....17

System Description .................................................17

Component Part Location .......................................24

Component Description ...........................................26

MODE DOOR CONTROL SYSTEM ...................28

System Diagram .................................................. ....28

System Description .................................................28

AIR MIX DOOR CONTROL SYSTEM ................30

System Diagram .................................................. ....30

System Description .................................................30

INTAKE DOOR CONTROL SYSTEM ................32

System Diagram .................................................. ....32

System Description .................................................32

BLOWER MOTOR CONTROL SYSTEM ...........34

System Diagram .................................................. ....34

System Description .................................................34

MAGNET CLUTCH CONTROL SYSTEM .........36

System Diagram .................................................. ....36

System Description ..................................................36

CAN COMMUNICATION SYSTEM ...................37

System Description ..................................................37

DIAGNOSIS SYSTEM (HVAC) .........................38

CONSULT-III Function ............................................38

COMPONENT DIAGNOSIS .........................42

U1000 CAN COMM CIRCUIT ...........................42

Description ........................................................... ....42

DTC Logic ................................................................42

Diagnosis Procedure ..............................................42

U1010 CONTROL UNIT (CAN) .........................43

Description ...............................................................43

DTC Logic ................................................................43

Diagnosis Procedure ...............................................43

B257B, B257C AMBIENT SENSOR .................44

Description ...............................................................44

DTC Logic ................................................................44

Diagnosis Procedure ...............................................45

Component Inspection .............................................46

B2578, B2579 IN-VEHICLE SENSOR ..............47

Description ...............................................................47

DTC Logic ................................................................47

Diagnosis Procedure ...............................................48

Component Inspection .............................................49

B2581, B2582 INTAKE SENSOR .....................50

Description ...............................................................50

DTC Logic ................................................................50

Diagnosis Procedure ...............................................50

Component Inspection .............................................51

B2630, B2631 SUNLOAD SENSOR .................53

Description ...............................................................53

Page 2630 of 5121

HAC-2

DTC Logic ...............................................................53

Diagnosis Procedure ..............................................54

Component Inspection ............................................55

B2632, B2633 AIR MIX DOOR MOTOR

(DRIVER SIDE) ..................................................

56

Description ..............................................................56

DTC Logic ...............................................................56

Diagnosis Procedure ..............................................57

B2634, B2635 AIR MIX DOOR MOTOR (PAS-

SENGER SIDE) ..................................................

58

Description ..............................................................58

DTC Logic ...............................................................58

Diagnosis Procedure ..............................................59

B2636, B2637, B2638, B2639, B2654, B2655

MODE DOOR MOTOR ......................................

60

Description ..............................................................60

DTC Logic ...............................................................60

Diagnosis Procedure ..............................................61

B263D B263E, B263F, B2656 INTAKE DOOR

MOTOR ..............................................................

63

Description ..............................................................63

DTC Logic ...............................................................63

Diagnosis Procedure ..............................................64

POWER SUPPLY AND GROUND CIRCUIT .....65

A/C AUTO AMP. .......................................................65

A/C AUTO AMP. : Diagnosis Procedure ................65

A/C CONTROL ..........................................................65

A/C CONTROL : Diagnosis Procedure ...................65

A/C DISPLAY ............................................................66

A/C DISPLAY : Diagnosis Procedure .....................66

A/C AUTO AMP. ................................................67

Description ..............................................................67

Component Function Check ...................................67

Diagnosis Procedure ..............................................67

BLOWER MOTOR .............................................68

Description ..............................................................68

Component Function Check .................................68

Diagnosis Procedure ..............................................68

Component Inspection ............................................71

MAGNET CLUTCH ............................................72

Description ..............................................................72

Component Function Check ...................................72

Diagnosis Procedure ..............................................72

A/C CONTROL SIGNAL CIRCUIT ....................74

Diagnosis Procedure ..............................................74

ECU DIAGNOSIS ........................................75

A/C AUTO AMP. ................................................75

Reference Value .....................................................75

Wiring Diagram - AIR CONDITIONER CONTROL

SYSTEM - ...............................................................

77

Fail-Safe ..................................................................84

DTC Inspection Priority Chart ...............................85

DTC Index ...............................................................85

SYMPTOM DIAGNOSIS ............................87

AIR CONDITIONER CONTROL ........................87

Diagnosis Chart By Symptom .................................87

INSUFFICIENT COOLING .................................88

Description ..............................................................88

Inspection procedure ..............................................88

INSUFFICIENT HEATING .................................91

Description ..............................................................91

Inspection procedure ..............................................91

NOISE ................................................................94

Description ..............................................................94

Inspection procedure ..............................................94

MEMORY FUNCTION DOES NOT OPERATE ...96

Description ..............................................................96

Inspection procedure ..............................................96

PRECAUTION ............................................97

PRECAUTIONS .................................................97

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

97

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

97

Precaution for Procedure without Cowl Top Cover ...98

Precautions For Xenon Headlamp Service .............98

Working with HFC-134a (R-134a) ...........................98

General Refrigerant Precaution ..............................99

Refrigerant Connection ...........................................99

Service Equipment ................................................101

COMPRESSOR ................................................104

General Precautions .............................................104

FLUORESCENT LEAK DETECTOR ................105

General Precautions .............................................105

WITH 7 INCH DISPLAY

BASIC INSPECTION .................................

106

DIAGNOSIS AND REPAIR WORKFLOW ........106

Work Flow .............................................................106

INSPECTION AND ADJUSTMENT ..................108

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM ..................................................................

108

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM : Description & Inspection .....................

108

WITHOUT INTELLIGENT AIR CONDITIONER

SYSTEM : Temperature Setting Trimmer .............

110

Page 2634 of 5121

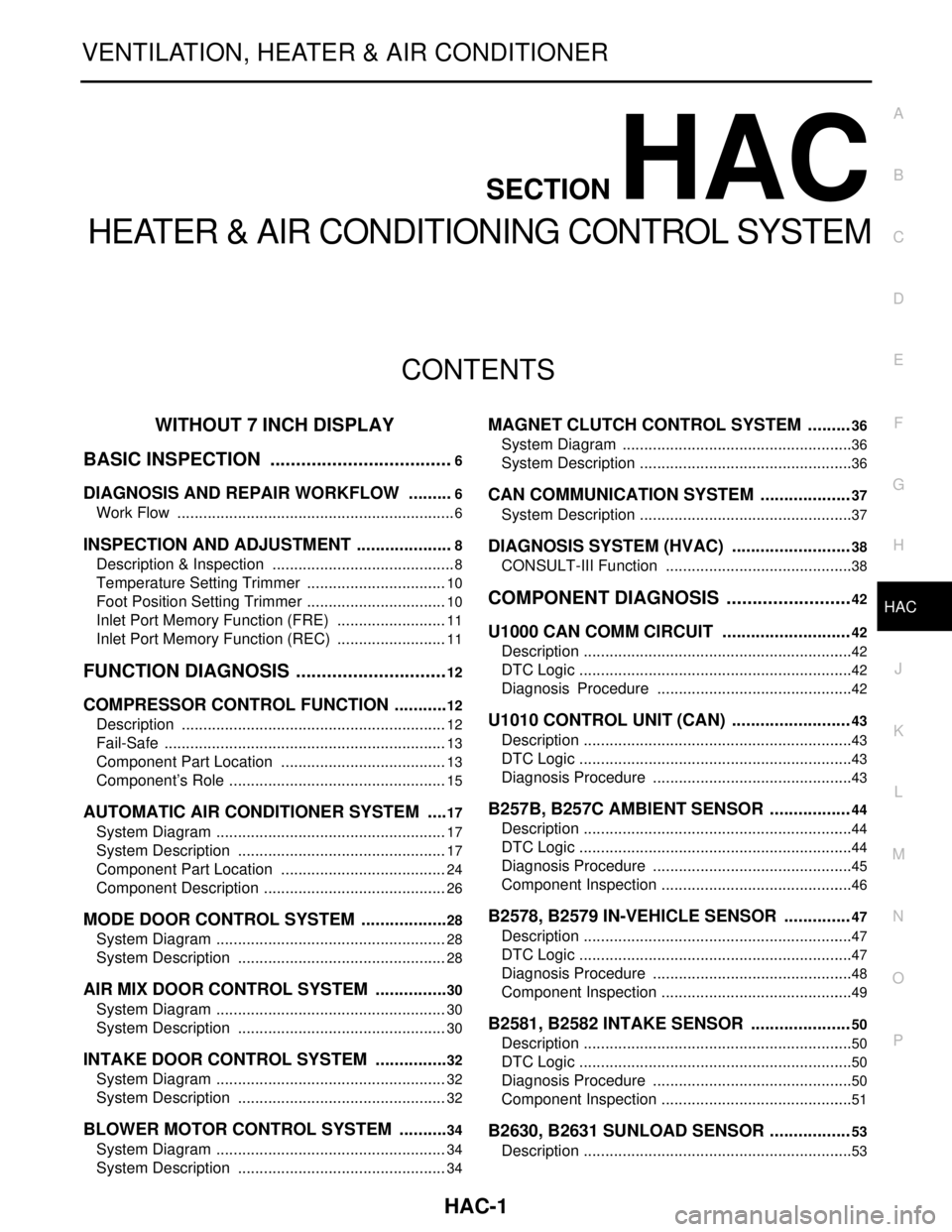

![NISSAN TEANA 2008 Service Manual HAC-6

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003846290

OVERALL SEQUENCE

*1: Refer to HAC-85, " NISSAN TEANA 2008 Service Manual HAC-6

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003846290

OVERALL SEQUENCE

*1: Refer to HAC-85, "](/img/5/57391/w960_57391-2633.png)

HAC-6

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work FlowINFOID:0000000003846290

OVERALL SEQUENCE

*1: Refer to HAC-85, "DTC Index".

*2: Refer to HAC-87, "

Diagnosis Chart By Symptom".

DETAILED FLOW

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

>> GO TO 2.

2.VERIFY SYMPTOM

Verify the symptom with operational check based on the information obtained from the customer. Refer to

HAC-8, "

Description & Inspection".

>> GO TO 3.

JSIIA0943GB

Page 2635 of 5121

![NISSAN TEANA 2008 Service Manual DIAGNOSIS AND REPAIR WORKFLOW

HAC-7

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

3.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

Using CONSULT-III, perform “SELF NISSAN TEANA 2008 Service Manual DIAGNOSIS AND REPAIR WORKFLOW

HAC-7

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

3.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

Using CONSULT-III, perform “SELF](/img/5/57391/w960_57391-2634.png)

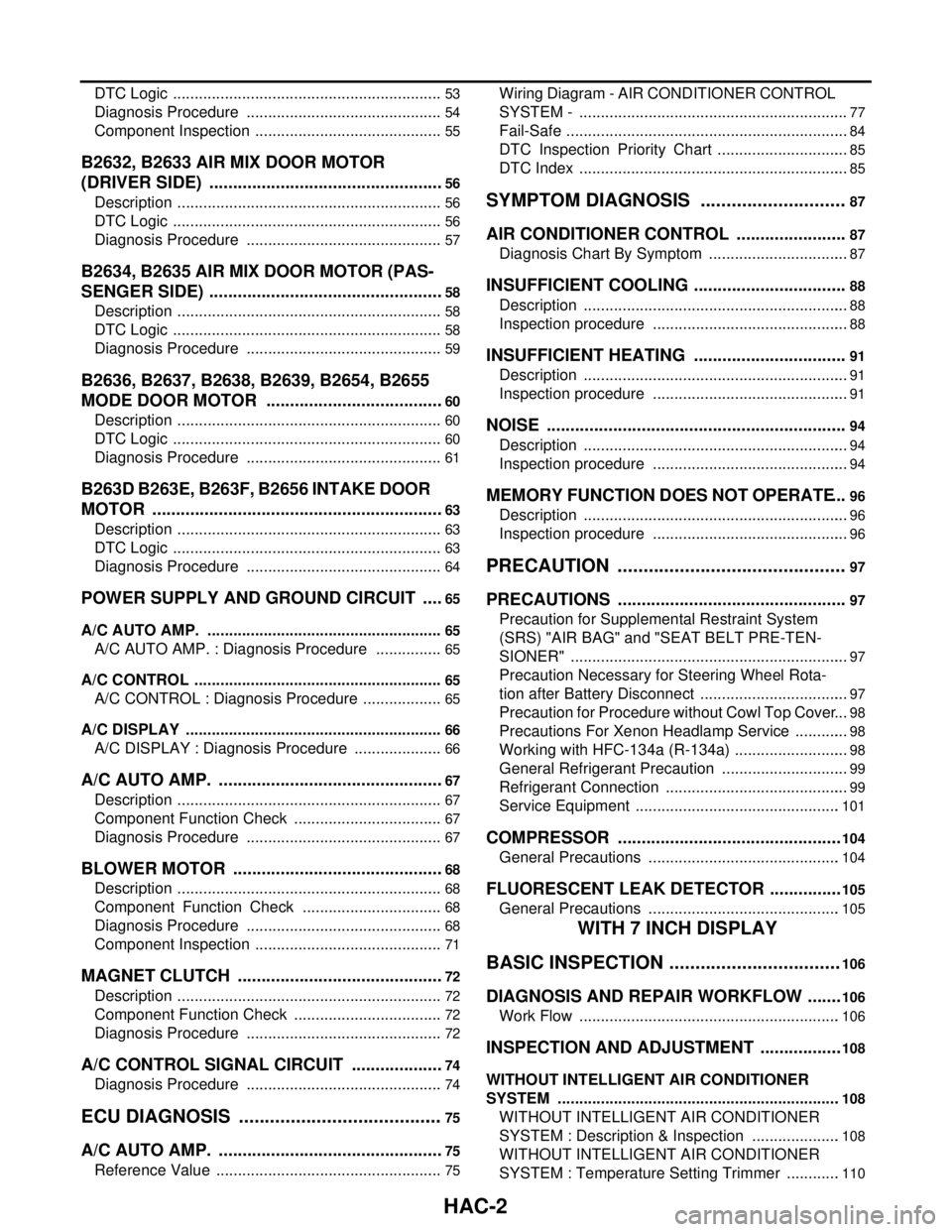

DIAGNOSIS AND REPAIR WORKFLOW

HAC-7

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

3.CHECK WITH SELF-DIAGNOSIS FUNCTION OF CONSULT-III

Using CONSULT-III, perform “SELF-DIAGNOSIS RESULTS” of HVAC. Refer to HAC-85, "

DTC Index".

Are self

-diagnosis results normal?

YES >> GO TO 4.

NO >> GO TO 5.

4.NARROW DOWN THE MALFUNCTIONING PARTS BY SYMPTOM DIAGNOSIS

Perform symptom diagnosis and narrow down the malfunctioning parts. Refer to HAC-87, "

Diagnosis Chart By

Symptom".

>> GO TO 5.

5.REPAIR OR REPLACE MALFUNCTIONING PARTS

Repair or replace malfunctioning parts.

NOTE:

If DTC is displayed, erase DTC after repairing or replacing malfunctioning parts.

>> GO TO 6.

6.FINAL CHECK

Check that the A/C system operates normally.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 3.

Page 2636 of 5121

![NISSAN TEANA 2008 Service Manual HAC-8

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Description & InspectionINFOID:0000000003846291

DESCRIPTION

The purpose of the operational check NISSAN TEANA 2008 Service Manual HAC-8

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Description & InspectionINFOID:0000000003846291

DESCRIPTION

The purpose of the operational check](/img/5/57391/w960_57391-2635.png)

HAC-8

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Description & InspectionINFOID:0000000003846291

DESCRIPTION

The purpose of the operational check is to check that the individual system operates normally.

INSPECTION PROCEDURE

1.CHECK MEMORY FUNCTION

1. Start the engine.

2. Operate the temperature control switch (driver side) and raise the temperature setting to 32°C (90°F).

3. Press the OFF switch.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON.

6. Press the AUTO switch.

7. Check that the temperature setting before turning the ignition switch OFF is stored.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Memory function malfunction: HAC-96, "

Inspection procedure".

2.CHECK BLOWER MOTOR SPEED

1. Start the engine.

2. Operate the fan control dial. Check that the fan speed changes. Check the operation for all fan speeds.

3. Set the fan speed to speed 7.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Blower motor system malfunction: HAC-68, "

Diagnosis Procedure".

3.CHECK DISCHARGE AIR

1. Press the MODE switch and the DEF switch.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-17, "

System

Description".

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

the FRE when DEF is selected.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Mode door system malfunction: HAC-61, "

Diagnosis Procedure". Conditions : Engine running at normal operating temperature

JPIIA0877GB

Page 2637 of 5121

![NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE s NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE s](/img/5/57391/w960_57391-2636.png)

INSPECTION AND ADJUSTMENT

HAC-9

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

4.CHECK INTAKE AIR

1. Press the REC switch. REC indicator is turned ON.

2. Press the FRE switch. FRE indicator is turned ON.

3. Listen for the intake door position change. (Slight change of blower sound can be heard.)

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and the intake door position is at

the FRE when the DEF is selected.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Intake door system malfunction: HAC-64, "

Diagnosis Procedure".

5.CHECK A/C SWITCH

1. Press the A/C switch.

2. The A/C switch indicator is turned ON.

Confirm that the compressor clutch engages (sound or visual inspection).

Is the inspection result normal?

YES >> GO TO 6.

NO >> Magnet clutch system malfunction: HAC-72, "

Diagnosis Procedure".

6.CHECK WITH TEMPERATURE SETTING LOWERED

1. Operate the compressor.

2. Operate the temperature control switch (driver side) and lower the temperature setting to 18°C (60°F).

3. Check that the cool air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Insufficient cooling: HAC-88, "

Inspection procedure".

7.CHECK WITH TEMPERATURE SETTING RAISED

1. Operate the temperature control switch (driver side) and raise the temperature setting to 32°C (90°F) after

warming up the engine.

2. Check that the warm air blows from the outlets.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Insufficient heating: HAC-91, "

Inspection procedure".

8.CHECK LEFT AND RIGHT VENTILATION TEMPERATURE SEPARATELY CONTROL SYSTEM FUNC-

TION

1. Press the DUAL switch, and then check that “DUAL” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the discharge air temperature (driver

side) changes.

3. Operate the temperature control switch (passenger side). Check that the discharge air temperature (pas-

senger side) changes.

4. Press the DUAL switch, and then check that the temperature setting (LH/RH) is unified to the driver side

temperature setting.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

9.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the fan speed or outlet changes (the dis-

charge air temperature or fan speed varies depending on the ambient temperature, in-vehicle tempera-

ture, and temperature setting).

Is the inspection result normal?

YES >> GO TO 10.

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

Page 2638 of 5121

![NISSAN TEANA 2008 Service Manual HAC-10

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

10.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Operate the tempe NISSAN TEANA 2008 Service Manual HAC-10

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

10.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Operate the tempe](/img/5/57391/w960_57391-2637.png)

HAC-10

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

INSPECTION AND ADJUSTMENT

10.CHECK AUTO MODE

1. Press the AUTO switch, and then check that “AUTO” is shown on the display.

2. Operate the temperature control switch (driver side). Check that the fan speed or outlet changes (the dis-

charge air temperature or fan speed varies depending on the ambient temperature, in-vehicle tempera-

ture, and temperature setting).

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to HAC-87, "

Diagnosis Chart By Symptom" and perform the appropriate diagnosis.

Temperature Setting TrimmerINFOID:0000000003846292

DESCRIPTION

If the temperature felt by the customer is different than the air flow temperature controlled by the temperature

setting, the A/C auto amp. control temperature can be adjusted to compensate for the temperature setting.

HOW TO SET

Using CONSULT-III, perform “TEMP SET CORRECT” on “WORK SUPPORT” of HVAC.

NOTE:

When the temperature setting is set to 25.0°C (77°F) and −3.0°C (−6°F), the temperature controlled by A/C

auto amp. is 25.0°C (77°F) −3.0°C (6°F) = 22.0°C (71°F) and the temperature becomes lower than the tem-

perature setting.

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10

V or less, trimmer operation is canceled. Temperature set becomes that of initial condition.

Foot Position Setting TrimmerINFOID:0000000003846293

DESCRIPTION

In the FOOT mode, the air blowing to the DEF can be turned ON/OFF.

HOW TO SET

Using CONSULT-III, perform “BLOW SET” on “WORK SUPPORT” of HVAC.

Work support items Display (°F) Display (°C)

TEMP SET CORRECT63.0

52.5

42.0

31.5

21.0

10.5

0 (initial status) 0 (initial status)

−1−0.5

−2−1.0

−3−1.5

−4−2.0

−5−2.5

−6−3.0

Work support items DisplayDEF door position

Auto control Manual control

BLOW SETMode 1 OPEN CLOSE

Mode 2 (initial status) OPEN OPEN

Mode 3 CLOSE OPEN

Mode 4 CLOSE CLOSE

Page 2639 of 5121

![NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

HAC-11

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the batte NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

HAC-11

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the batte](/img/5/57391/w960_57391-2638.png)

INSPECTION AND ADJUSTMENT

HAC-11

< BASIC INSPECTION >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, trimmer operation is cancelled. Wind distribution rate set becomes that of initial condition.

Inlet Port Memory Function (FRE)INFOID:0000000003846294

DESCRIPTION

If the ignition switch is turned to the OFF position while the FRE switch is set to ON (fresh air intake), “Per-

form the memory” or “Do not perform the memory” of the FRE switch ON (fresh air intake) condition can be

selected.

If “Perform the memory” was set, the FRE switch will be ON (fresh air intake) when turning the ignition switch

to the ON position again.

If “Do not perform the memory” was set, the air inlets will be controlled automatically when turning the igni-

tion switch to the ON position again.

HOW TO SET

Using CONSULT-III, perform “FRE MEMORY SET” on “WORK SUPPORT” of HVAC.

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, the setting of the FRE switch memory function may be cancelled.

Inlet Port Memory Function (REC)INFOID:0000000003846295

DESCRIPTION

If the ignition switch is turned to the OFF position while the REC switch is set to ON (recirculation), “Perform

the memory” or “Do not perform the memory” of the REC switch ON (recirculation) condition can be

selected.

If “Perform the memory” was set, the REC switch will be ON (recirculation) when turning the ignition switch

to the ON position again.

If “Do not perform the memory” was set, the air inlets will be controlled automatically when turning the igni-

tion switch to the ON position again.

HOW TO SET

Using CONSULT-III, perform “REC MEMORY SET” on “WORK SUPPORT” of HVAC.

NOTE:

When the battery cable is disconnected from the negative terminal or when the battery voltage becomes 10 V

or less, the setting of the REC switch memory function may be cancelled.

Work support items Display Setting

FRE MEMORY SETWITHOUT (initial status) Perform the memory of manual FRE

WITH Do not perform the memory of manual FRE (auto control)

Work support items Display Setting

REC MEMORY SETWITHOUT Perform the memory of manual REC

WITH (initial status) Do not perform the memory of manual REC (auto control)

Page 2640 of 5121

![NISSAN TEANA 2008 Service Manual HAC-12

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

COMPRESSOR CONTROL FUNCTION

FUNCTION DIAGNOSIS

COMPRESSOR CONTROL FUNCTION

DescriptionINFOID:0000000003846298

PRINCIPLE OF OPERATION

Compressor is NISSAN TEANA 2008 Service Manual HAC-12

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

COMPRESSOR CONTROL FUNCTION

FUNCTION DIAGNOSIS

COMPRESSOR CONTROL FUNCTION

DescriptionINFOID:0000000003846298

PRINCIPLE OF OPERATION

Compressor is](/img/5/57391/w960_57391-2639.png)

HAC-12

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

COMPRESSOR CONTROL FUNCTION

FUNCTION DIAGNOSIS

COMPRESSOR CONTROL FUNCTION

DescriptionINFOID:0000000003846298

PRINCIPLE OF OPERATION

Compressor is not activated.

Functional circuit diagram

Functional initial inspection chart

CAN (1) : A/C switch signal

: Blower fan motor switch signalCAN (2) : A/C Compressor request signal

RX : A/C switch signal

: Fan ON signal

: Defroster signal

JPIIA0483GB

Control unit Diagnosis ItemLocation

ABCD

A/C auto amp.

“HVAC”Self-diagnosis Yes

Data monitor Yes

Active test Yes Yes

ECM

“ENGINE”Self-diagnosis

(CAN system diagnosis)Ye s

Data monitor Yes Yes

IPDM E/R“IPDM E/R”Self-diagnosis

(CAN system diagnosis)Ye s

Data monitor Yes

Auto active testYe s

Page 2641 of 5121

![NISSAN TEANA 2008 Service Manual COMPRESSOR CONTROL FUNCTION

HAC-13

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

Fail-SafeINFOID:0000000003901219

FAIL-SAFE FUNCTION

If a communication error exists b NISSAN TEANA 2008 Service Manual COMPRESSOR CONTROL FUNCTION

HAC-13

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

Fail-SafeINFOID:0000000003901219

FAIL-SAFE FUNCTION

If a communication error exists b](/img/5/57391/w960_57391-2640.png)

COMPRESSOR CONTROL FUNCTION

HAC-13

< FUNCTION DIAGNOSIS >[WITHOUT 7 INCH DISPLAY]

C

D

E

F

G

H

J

K

L

MA

B

HAC

N

O

P

Fail-SafeINFOID:0000000003901219

FAIL-SAFE FUNCTION

If a communication error exists between the A/C auto amp. and A/C control for 30 seconds or longer, air con-

ditioner is controlled under the following conditions:

Component Part LocationINFOID:0000000003846299

ENGINE COMPARTMENT

Compressor : ON

Air outlet : AUTO

Air inlet : FRE (Fresh)

Blower fan speed : AUTO

Set temperature : Setting before communication error occurs