washer fluid NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 917 of 5121

BRAKE PIPINGBR-21

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT : Removal and InstallationINFOID:0000000003811188

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strong ly pull out the brake hoses and tubes.

Cover open end of brake tub es and hoses when disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

2. Align the brake hose pin to the projection (A) of the brake caliper assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

FRONT : InspectionINFOID:0000000003811189

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80 kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

1. ABS actuator and electric unit (con-

trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0099ZZ

Page 919 of 5121

BRAKE PIPINGBR-23

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

REAR : Removal and InstallationINFOID:0000000003811192

REMOVAL

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Remove tires.

2. Drain brake fluid. Refer to BR-9, "

Draining".

3. Loosen the flare nut with a flare nut wrenc h and separate the brake tube from the hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never sharply bend, twist or strongly pull the brake hoses and tubes.

Cover the open end of brake tubes and hoses wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose from the vehicle.

INSTALLATION

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse copper washer.

2. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

3. Connect the hose to the brake tube, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake hose

to the bracket with the lock plate.

CAUTION:

Check that the brake hoses and tubes are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

REAR : InspectionINFOID:0000000003811193

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785N (80

kg, 177 lb) and hold down the pedal for approximately 5

seconds with the engine running. Check for any fluid leakage.

CAUTION:

1. ABS actuator and electric unit (con- trol unit) 2. Front disc brake 3. Master cylinder assembly

4. Brake booster 5. Connector 6. Rear disc brake

A. Brake tube B. Brake hose : Flare nut

: Union bolt

JPFIA0012ZZ

Page 932 of 5121

BR-36

< ON-VEHICLE REPAIR >

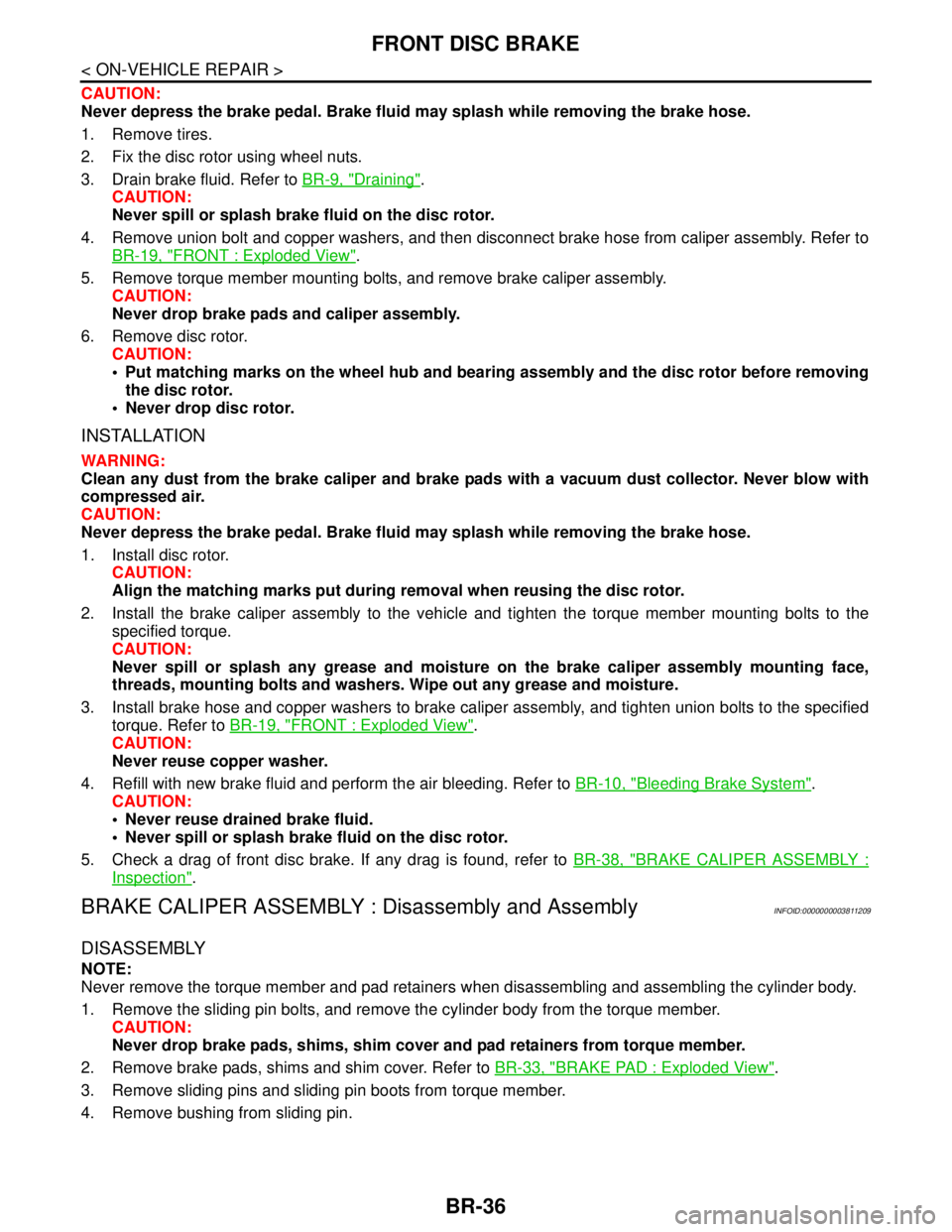

FRONT DISC BRAKE

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers, and then disconnect brake hose from caliper assembly. Refer to

BR-19, "

FRONT : Exploded View".

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-19, "

FRONT : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check a drag of front disc brake. If any drag is found, refer to BR-38, "

BRAKE CALIPER ASSEMBLY :

Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811209

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts, and remove the cylinder body from the torque member.

CAUTION:

Never drop brake pads, shims, shim cover and pad retainers from torque member.

2. Remove brake pads, shims and shim cover. Refer to BR-33, "

BRAKE PAD : Exploded View".

3. Remove sliding pins and sliding pin boots from torque member.

4. Remove bushing from sliding pin.

Page 938 of 5121

BR-42

< ON-VEHICLE REPAIR >

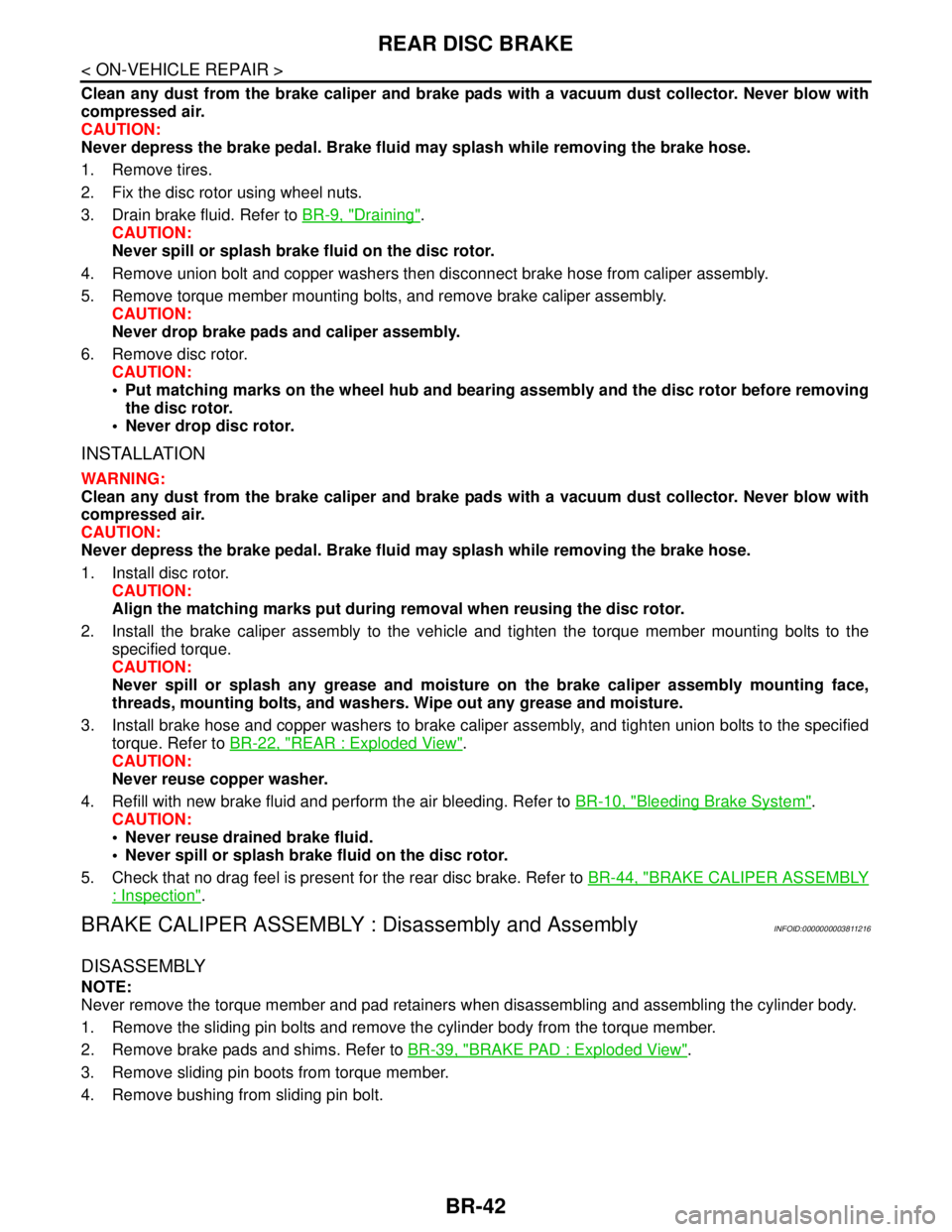

REAR DISC BRAKE

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Remove tires.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-9, "

Draining".

CAUTION:

Never spill or splash brake fluid on the disc rotor.

4. Remove union bolt and copper washers then disconnect brake hose from caliper assembly.

5. Remove torque member mounting bolts, and remove brake caliper assembly.

CAUTION:

Never drop brake pads and caliper assembly.

6. Remove disc rotor.

CAUTION:

Put matching marks on the wheel hub and bearing assembly and the disc rotor before removing

the disc rotor.

Never drop disc rotor.

INSTALLATION

WARNING:

Clean any dust from the brake caliper and brake pads with a vacuum dust collector. Never blow with

compressed air.

CAUTION:

Never depress the brake pedal. Brake fluid may splash while removing the brake hose.

1. Install disc rotor.

CAUTION:

Align the matching marks put during removal when reusing the disc rotor.

2. Install the brake caliper assembly to the vehicle and tighten the torque member mounting bolts to the

specified torque.

CAUTION:

Never spill or splash any grease and moisture on the brake caliper assembly mounting face,

threads, mounting bolts, and washers. Wipe out any grease and moisture.

3. Install brake hose and copper washers to brake caliper assembly, and tighten union bolts to the specified

torque. Refer to BR-22, "

REAR : Exploded View".

CAUTION:

Never reuse copper washer.

4. Refill with new brake fluid and perform the air bleeding. Refer to BR-10, "

Bleeding Brake System".

CAUTION:

Never reuse drained brake fluid.

Never spill or splash brake fluid on the disc rotor.

5. Check that no drag feel is present for the rear disc brake. Refer to BR-44, "

BRAKE CALIPER ASSEMBLY

: Inspection".

BRAKE CALIPER ASSEMBLY : Disassembly and AssemblyINFOID:0000000003811216

DISASSEMBLY

NOTE:

Never remove the torque member and pad retainers when disassembling and assembling the cylinder body.

1. Remove the sliding pin bolts and remove the cylinder body from the torque member.

2. Remove brake pads and shims. Refer to BR-39, "

BRAKE PAD : Exploded View".

3. Remove sliding pin boots from torque member.

4. Remove bushing from sliding pin bolt.

Page 2498 of 5121

HOW TO USE THIS MANUAL

GI-5

< HOW TO USE THIS MANUAL >

C

D

E

F

G

H

I

J

K

L

MB

GI

N

O

P

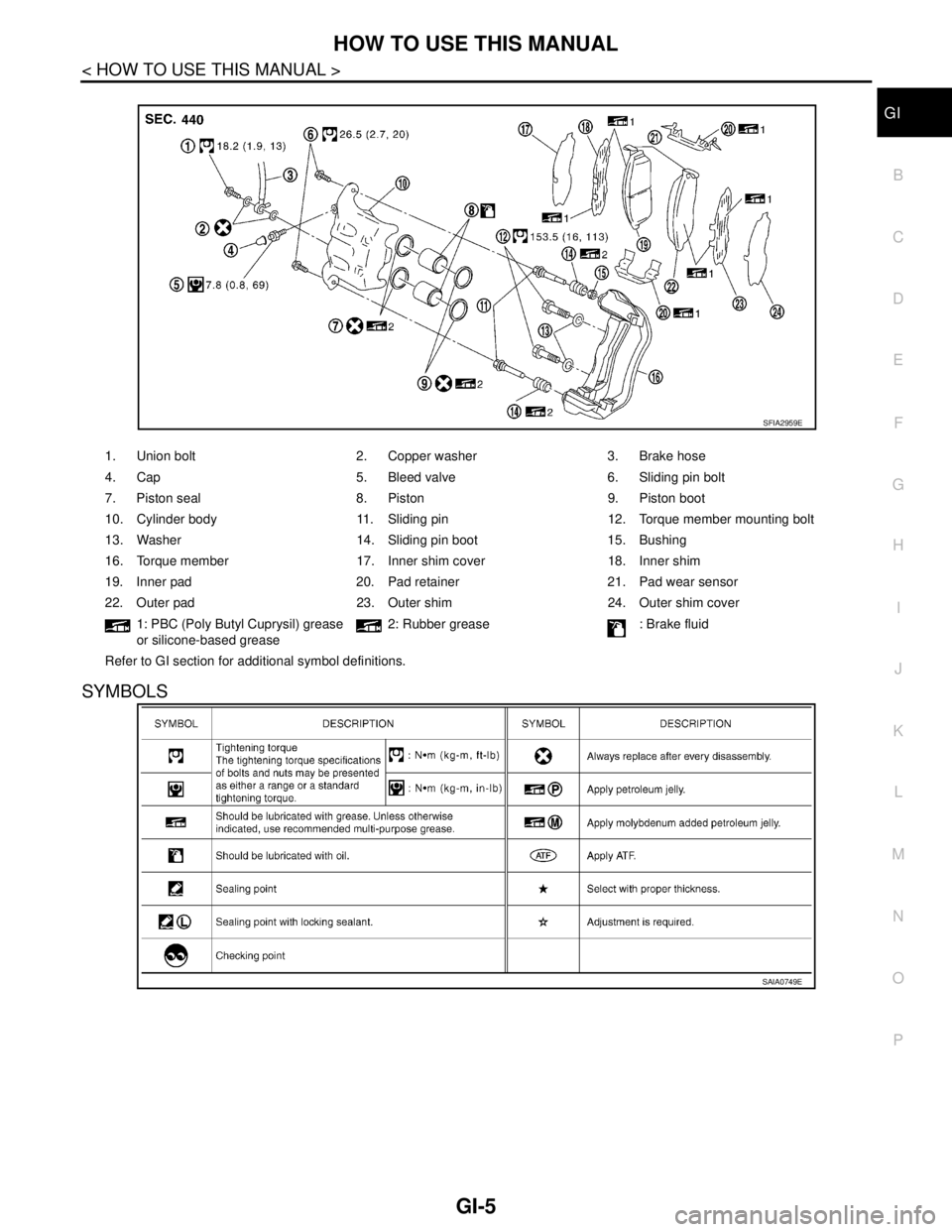

SYMBOLS

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Page 2519 of 5121

GI-26

< PRECAUTION >

PRECAUTIONS

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of drained oil or the solvent used for cleaning parts in an

appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended

special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems,

check all affected lines for leaks.

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

SEF289H

SGI233

PBIC0190E

SGI234

Page 2601 of 5121

HA-32

< ON-VEHICLE MAINTENANCE >

FLUORESCENT LEAK DETECTOR

FLUORESCENT LEAK DETECTOR

InspectionINFOID:0000000003795981

CHECKING SYSTEM FOR LEAKAGES USING THE FLUORESCENT LEAK DETECTOR

1. Check A/C system for leakages using the UV lamp and safety goggles (SST: J-42220) in a low sunlight

area (area without windows preferable). Illuminate all components, fittings and lines. The dye appears as

a bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leakage.

2. Use an adjustable mirror or wipe the area with a clean shop rag or cloth, with the UV lamp for dye residue

if the suspected area is difficult to see.

3. Remove any residual dye using dye cleaner (SST: J-43872) to prevent future misdiagnosis after the leak-

age is repaired.

4. Perform a system performance check and verify the leakage repair with an approved electrical leak detec-

tor.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This may also cause false readings

and may damage the detector.

DYE INJECTION

(This procedure is only necessary when recharging the system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool (SST: J-41459).

3. Connect the injector tool to the A/C low-pressure side service valve.

4. Start the engine. Then switch A/C ON.

5. Inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye through the low-pressure service valve using dye

injector tool (SST: J-41459) (refer to the manufacture’s operating instructions) when the A/C operating

(compressor running).

6. Disconnect the injector tool from the service valve with the engine still running.

CAUTION:

Be careful when replacing the A/C system or a component, pour the dye directly into the open sys-

tem connection and proceed with the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leakage size, operating conditions and location of the leakage, it may take from minutes to days for the

dye to penetrate a leakage and become visible.

8. Attach a blue label if necessary.

Page 3181 of 5121

ENGINE OIL

LU-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

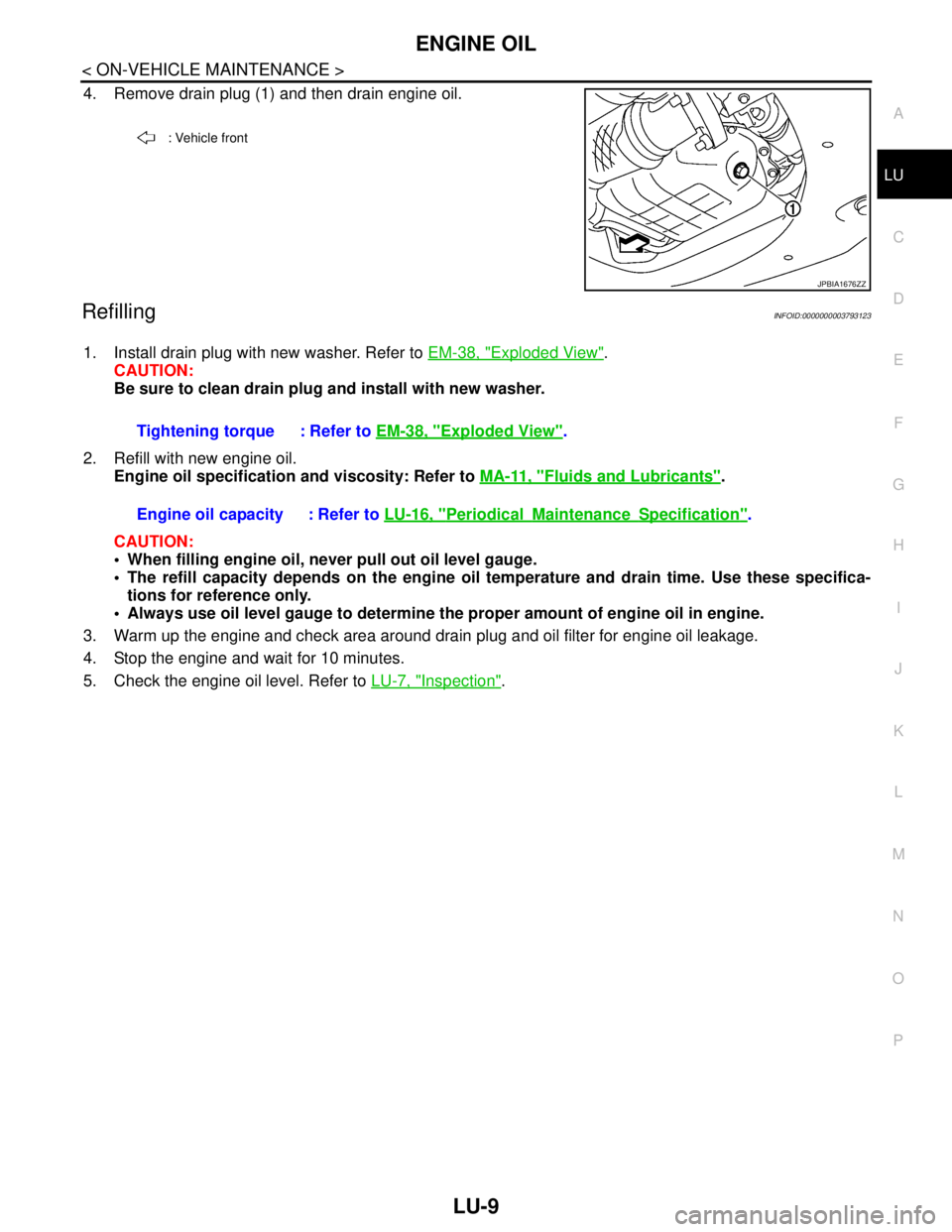

4. Remove drain plug (1) and then drain engine oil.

RefillingINFOID:0000000003793123

1. Install drain plug with new washer. Refer to EM-38, "Exploded View".

CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil.

Engine oil specification and viscosity: Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

When filling engine oil, never pull out oil level gauge.

The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

3. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop the engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "

Inspection".

: Vehicle front

JPBIA1676ZZ

Tightening torque : Refer to EM-38, "Exploded View".

Engine oil capacity : Refer to LU-16, "

PeriodicalMaintenanceSpecification".

Page 3193 of 5121

GENERAL MAINTENANCE

MA-5

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

ON-VEHICLE MAINTENANCE

GENERAL MAINTENANCE

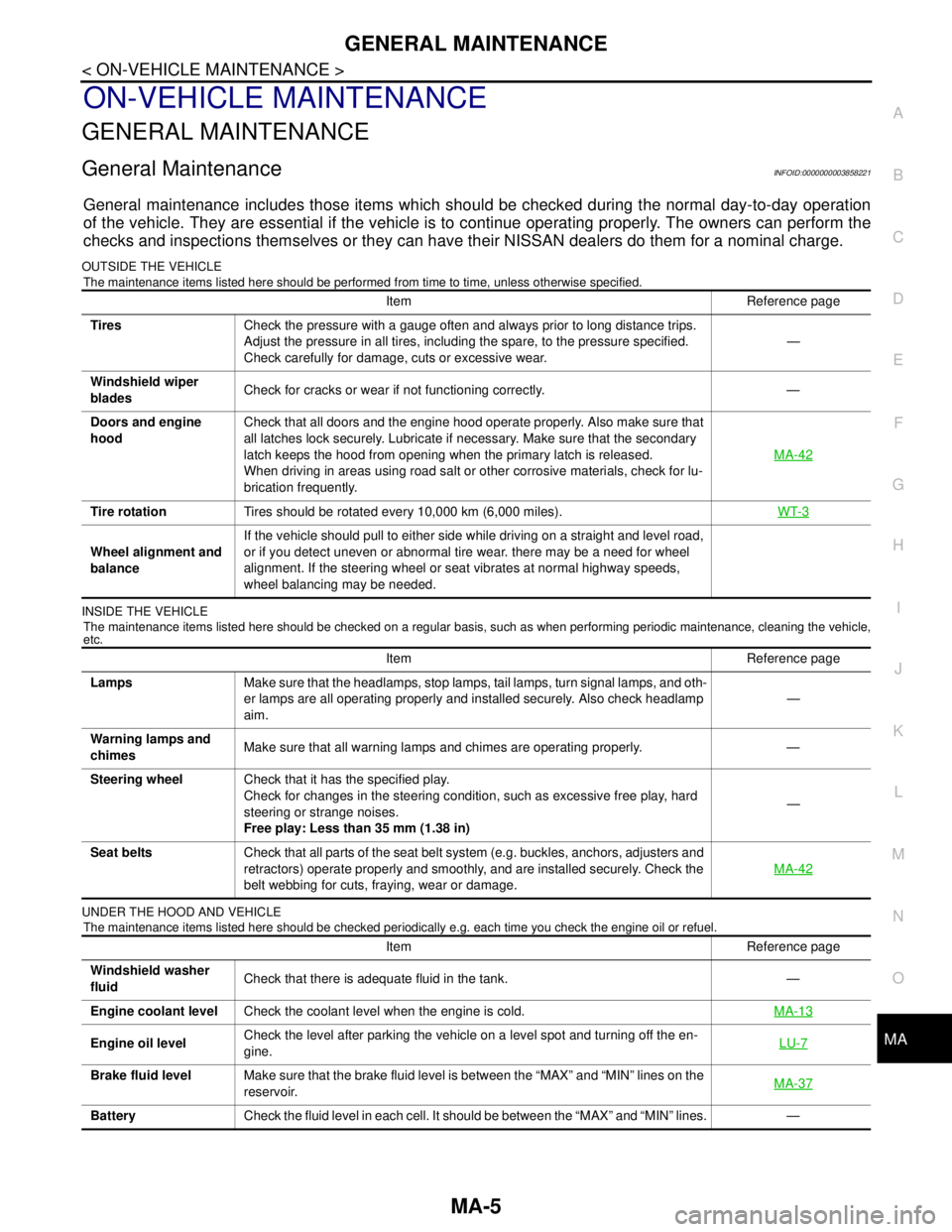

General MaintenanceINFOID:0000000003858221

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

TiresCheck the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors and the engine hood operate properly. Also make sure that

all latches lock securely. Lubricate if necessary. Make sure that the secondary

latch keeps the hood from opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lu-

brication frequently.MA-42

Tire rotationTires should be rotated every 10,000 km (6,000 miles).WT-3

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear. there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim.—

Warning lamps and

chimesMake sure that all warning lamps and chimes are operating properly. —

Steering wheelCheck that it has the specified play.

Check for changes in the steering condition, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.MA-42

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold.MA-13

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the en-

gine.LU-7

Brake fluid levelMake sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir.MA-37

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN” lines. —

Page 3207 of 5121

ENGINE MAINTENANCE

MA-19

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

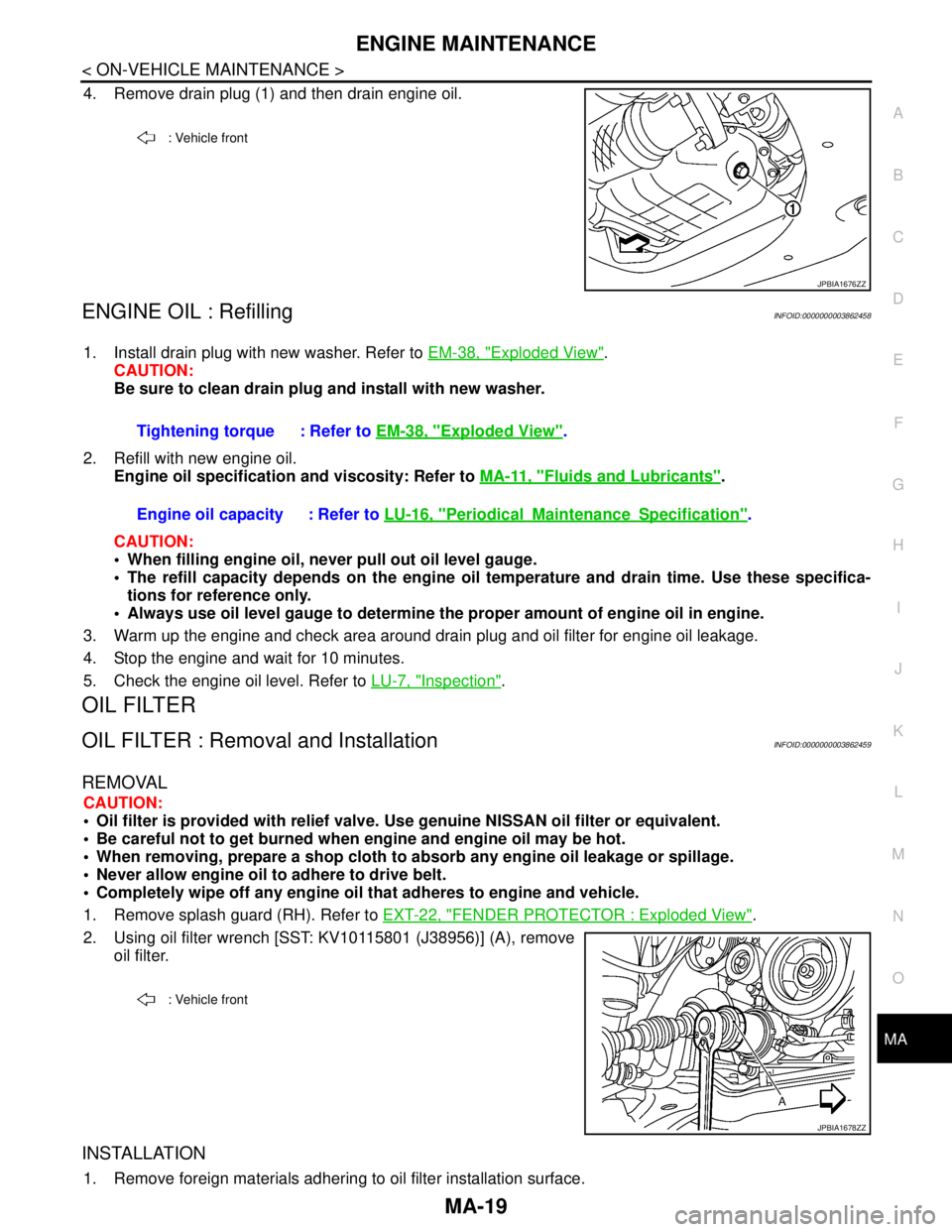

4. Remove drain plug (1) and then drain engine oil.

ENGINE OIL : RefillingINFOID:0000000003862458

1. Install drain plug with new washer. Refer to EM-38, "Exploded View".

CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil.

Engine oil specification and viscosity: Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

When filling engine oil, never pull out oil level gauge.

The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

3. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop the engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "

Inspection".

OIL FILTER

OIL FILTER : Removal and InstallationINFOID:0000000003862459

REMOVAL

CAUTION:

Oil filter is provided with relief valve. Use genuine NISSAN oil filter or equivalent.

Be careful not to get burned when engine and engine oil may be hot.

When removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

Never allow engine oil to adhere to drive belt.

Completely wipe off any engine oil that adheres to engine and vehicle.

1. Remove splash guard (RH). Refer to EXT-22, "

FENDER PROTECTOR : Exploded View".

2. Using oil filter wrench [SST: KV10115801 (J38956)] (A), remove

oil filter.

INSTALLATION

1. Remove foreign materials adhering to oil filter installation surface.

: Vehicle front

JPBIA1676ZZ

Tightening torque : Refer to EM-38, "Exploded View".

Engine oil capacity : Refer to LU-16, "

PeriodicalMaintenanceSpecification".

: Vehicle front

JPBIA1678ZZ