fuel pressure NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 924 of 5121

BR-28

< ON-VEHICLE REPAIR >

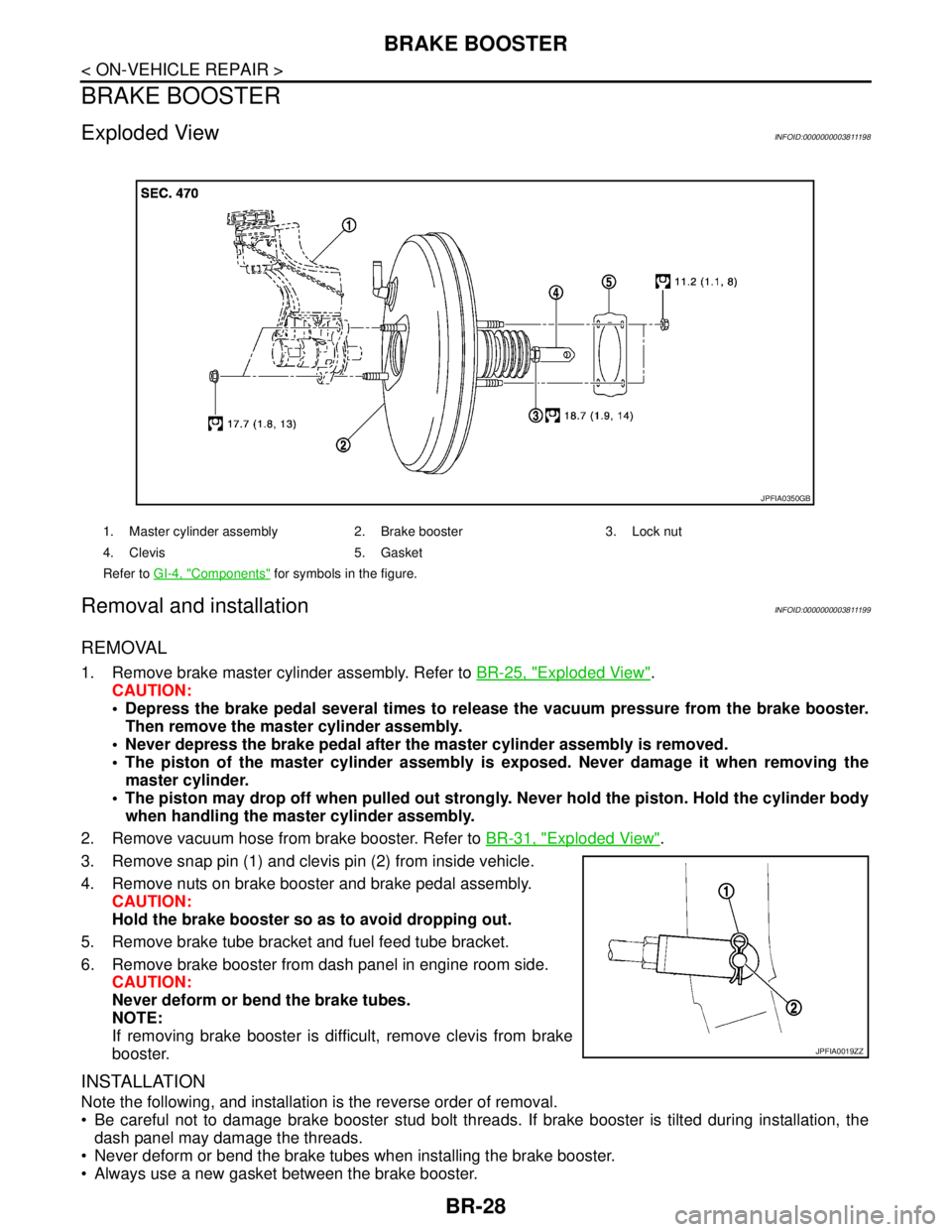

BRAKE BOOSTER

BRAKE BOOSTER

Exploded ViewINFOID:0000000003811198

Removal and installationINFOID:0000000003811199

REMOVAL

1. Remove brake master cylinder assembly. Refer to BR-25, "Exploded View".

CAUTION:

Depress the brake pedal several times to release the vacuum pressure from the brake booster.

Then remove the master cylinder assembly.

Never depress the brake pedal after the master cylinder assembly is removed.

The piston of the master cylinder assembly is exposed. Never damage it when removing the

master cylinder.

The piston may drop off when pulled out strongly. Never hold the piston. Hold the cylinder body

when handling the master cylinder assembly.

2. Remove vacuum hose from brake booster. Refer to BR-31, "

Exploded View".

3. Remove snap pin (1) and clevis pin (2) from inside vehicle.

4. Remove nuts on brake booster and brake pedal assembly.

CAUTION:

Hold the brake booster so as to avoid dropping out.

5. Remove brake tube bracket and fuel feed tube bracket.

6. Remove brake booster from dash panel in engine room side.

CAUTION:

Never deform or bend the brake tubes.

NOTE:

If removing brake booster is difficult, remove clevis from brake

booster.

INSTALLATION

Note the following, and installation is the reverse order of removal.

Be careful not to damage brake booster stud bolt threads. If brake booster is tilted during installation, the

dash panel may damage the threads.

Never deform or bend the brake tubes when installing the brake booster.

Always use a new gasket between the brake booster.

1. Master cylinder assembly 2. Brake booster 3. Lock nut

4. Clevis 5. Gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPFIA0350GB

JPFIA0019ZZ

Page 1012 of 5121

![NISSAN TEANA 2008 Service Manual TCS

BRC-71

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS

System DiagramINFOID:0000000003767312

System DescriptionINFOID:0000000003766890

Traction Control System is a funct NISSAN TEANA 2008 Service Manual TCS

BRC-71

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS

System DiagramINFOID:0000000003767312

System DescriptionINFOID:0000000003766890

Traction Control System is a funct](/img/5/57391/w960_57391-1011.png)

TCS

BRC-71

< FUNCTION DIAGNOSIS >[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

TCS

System DiagramINFOID:0000000003767312

System DescriptionINFOID:0000000003766890

Traction Control System is a function that electronically controls engine torque, brake fluid pressure and

CVT shift position to ensure the optimum slippage ratio at drive wheels by computing wheel speed signals

from 4 wheel sensors. When ABS actuator and electric unit (control unit) detects a spin at drive wheels (rear

wheels), it compares wheel speed signals from all 4 wheels. At this time, LH and RH rear brake fluid pres-

sure are controlled, while fuel being cut to engine and throttle valve being closed to reduce engine torque by

the control unit. Further more, throttle position is continuously controlled to ensure the optimum engine

torque at all times.

During TCS operation, TCS informs driver of system operation by flashing SLIP indicator lamp.

Electrical system diagnosis by CONSULT-III is available.

JSFIA0259GB

Page 1466 of 5121

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA

N

O

P

P2122, P2123 APP SENSOR ...........................304

Description ............................................................304

DTC Logic .............................................................304

Diagnosis Procedure .............................................304

Component Inspection ..........................................306

Special Repair Requirement .................................306

P2127, P2128 APP SENSOR ...........................307

Description ............................................................307

DTC Logic .............................................................307

Diagnosis Procedure .............................................307

Component Inspection ..........................................309

Special Repair Requirement .................................310

P2135 TP SENSOR ..........................................311

Description ............................................................311

DTC Logic .............................................................311

Diagnosis Procedure .............................................311

Component Inspection ..........................................313

Special Repair Requirement .................................313

P2138 APP SENSOR .......................................314

Description ............................................................314

DTC Logic .............................................................314

Diagnosis Procedure .............................................314

Component Inspection ..........................................316

Special Repair Requirement .................................317

P2A00, P2A03 A/F SENSOR 1 ........................318

Description ............................................................318

DTC Logic .............................................................318

Diagnosis Procedure .............................................319

ASCD BRAKE SWITCH ...................................321

Description ............................................................321

Component Function Check ..................................321

Diagnosis Procedure .............................................321

Component Inspection (ASCD Brake Switch) .......322

ASCD INDICATOR ...........................................323

Description ............................................................323

Component Function Check ..................................323

Diagnosis Procedure .............................................323

COOLING FAN .................................................324

Description ............................................................324

Component Function Check ..................................324

Diagnosis Procedure .............................................324

Component Inspection (Cooling Fan Motor) .........327

Component Inspection (Cooling Fan Relay) .........328

ELECTRICAL LOAD SIGNAL .........................329

Description ............................................................329

Component Function Check ..................................329

Diagnosis Procedure .............................................329

ELECTRONIC CONTROLLED ENGINE

MOUNT .............................................................

331

Description ............................................................331

Component Function Check ..................................331

Diagnosis Procedure .............................................331

Component Inspection ...........................................332

FUEL INJECTOR ............................................334

Description .............................................................334

Component Function Check ..................................334

Diagnosis Procedure .............................................334

Component Inspection ...........................................336

FUEL PUMP ....................................................337

Description .............................................................337

Component Function Check ..................................337

Diagnosis Procedure .............................................337

Component Inspection (Fuel Pump) ......................340

Component Inspection (Condenser) ......................340

IGNITION SIGNAL ..........................................341

Description .............................................................341

Component Function Check ..................................341

Diagnosis Procedure .............................................341

Component Inspection (Ignition Coil with Power

Transistor) .............................................................

344

Component Inspection (Condenser) ......................345

MALFUNCTION INDICATOR .........................346

Description .............................................................346

Component Function Check ..................................346

Diagnosis Procedure .............................................346

POSITIVE CRANKCASE VENTILATION .......347

Description .............................................................347

Component Inspection ...........................................347

REFRIGERANT PRESSURE SENSOR ..........348

Description .............................................................348

Component Function Check ..................................348

Diagnosis Procedure .............................................348

VARIABLE INDUCTION AIR SYSTEM ..........351

Description .............................................................351

Component Function Check (VQ35DE engine) .....351

Component Function Check (VQ25DE engine) .....353

Diagnosis Procedure (VQ35DE engine) ................353

Diagnosis Procedure (VQ25DE engine) ................355

ECU DIAGNOSIS .......................................357

ECM .................................................................357

Reference Value ....................................................357

Wiring Diagram—ENGINE CONTROL SYS-

TEM— ...................................................................

371

Fail safe .................................................................386

DTC Inspection Priority Chart .............................388

DTC Index .............................................................389

How to Set SRT Code ........................................392

Test Value and Test Limit ...................................394

SYMPTOM DIAGNOSIS ............................400

ENGINE CONTROL SYSTEM SYMPTOMS ...400

Symptom Table .....................................................400

NORMAL OPERATING CONDITION .............404

Page 1467 of 5121

EC-6

Description .............................................................404

PRECAUTION ............................................405

PRECAUTIONS ...............................................405

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

405

Precautions For Xenon Headlamp Service ...........405

Precaution for Procedure without Cowl Top Cover ..405

On Board Diagnostic (OBD) System of Engine

and CVT ................................................................

405

General Precautions ..............................................406

PREPARATION ..........................................410

PREPARATION ...............................................410

Special Service Tools ............................................410

Commercial Service Tools .....................................410

ON-VEHICLE MAINTENANCE .................411

FUEL PRESSURE ............................................411

Inspection ..............................................................411

ON-VEHICLE REPAIR ..............................413

EVAPORATIVE EMISSION SYSTEM ..............413

Inspection ..............................................................413

SERVICE DATA AND SPECIFICATIONS

(SDS) .........................................................

414

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

414

Idle Speed .............................................................414

Ignition Timing .......................................................414

Calculated Load Value ..........................................414

Mass Air Flow Sensor ...........................................414

Page 1481 of 5121

![NISSAN TEANA 2008 Service Manual EC-20

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM

System Description

INFOID:0000000003856462

ECM performs various controls such as fuel injection control and ignition timing control.

NISSAN TEANA 2008 Service Manual EC-20

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM

System Description

INFOID:0000000003856462

ECM performs various controls such as fuel injection control and ignition timing control.](/img/5/57391/w960_57391-1480.png)

EC-20

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM

System Description

INFOID:0000000003856462

ECM performs various controls such as fuel injection control and ignition timing control.

Component Parts LocationINFOID:0000000003856463

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1483 of 5121

![NISSAN TEANA 2008 Service Manual EC-22

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft position sensor (PHASE)

(bank 1)

: Vehi NISSAN TEANA 2008 Service Manual EC-22

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft position sensor (PHASE)

(bank 1)

: Vehi](/img/5/57391/w960_57391-1482.png)

EC-22

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ENGINE CONTROL SYSTEM

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft position sensor (PHASE)

(bank 1)

: Vehicle front

1. Refrigerant pressure sensor 2. Battery current sensor

: Vehicle front

1. ECM 2. Fuel pump fuse 3. IPDM E/R

: Vehicle front

JMBIA1378ZZ

JMBIA1379ZZ

PBIB1686E

Page 1486 of 5121

![NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM

EC-25

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component DescriptionINFOID:0000000003856464

1. Fuel level sensor unit and fuel pump

harness connect NISSAN TEANA 2008 Service Manual ENGINE CONTROL SYSTEM

EC-25

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component DescriptionINFOID:0000000003856464

1. Fuel level sensor unit and fuel pump

harness connect](/img/5/57391/w960_57391-1485.png)

ENGINE CONTROL SYSTEM

EC-25

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component DescriptionINFOID:0000000003856464

1. Fuel level sensor unit and fuel pump

harness connector2. Fuel pressure regulator 3. Fuel level sensor unit and fuel pump

: Vehicle front

JMBIA1385ZZ

Component Reference

A/F sensor 1EC-163, "

Description"

A/F sensor 1 heaterEC-140, "Description"

Accelerator pedal position sensorEC-304, "Description"

ASCD brake switchEC-273, "Description"

ASCD steering switchEC-270, "Description"

Battery current sensorEC-258, "Description"

Camshaft position sensor (PHASE)EC-222, "Description"

Crankshaft position sensor (POS)EC-218, "Description"

Cooling fan motorEC-324, "Description"

Electric throttle control actuatorEC-302, "Description"

Electronic controlled engine mountEC-331, "Description"

Engine coolant temperature sensorEC-157, "Description"

EVAP canister purge volume control solenoid valveEC-231, "Description"

Fuel injectorEC-334, "Description"

Fuel pumpEC-337, "Description"

Heated oxygen sensor 2EC-178, "Description"

Heated oxygen sensor 2 heaterEC-143, "Description"

Ignition coil with power transistorEC-341, "Description"

Intake air temperature sensorEC-154, "Description"

Intake valve timing control solenoid valveEC-146, "Description"

Knock sensorEC-215, "Description"

Mass air flow sensorEC-149, "Description"

PCV valveEC-347, "Description"

Power steering pressure sensorEC-236, "Description"

Power valves 1 and 2EC-351, "Description"

Refrigerant pressure sensorEC-348, "Description"

Stop lamp switchEC-291, "Description"

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE engine)EC-245, "Description"

Throttle control motorEC-300, "Description"

Page 1489 of 5121

![NISSAN TEANA 2008 Service Manual EC-28

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

MULTIPORT FUEL INJECTION SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM throug NISSAN TEANA 2008 Service Manual EC-28

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

MULTIPORT FUEL INJECTION SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM throug](/img/5/57391/w960_57391-1488.png)

EC-28

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

MULTIPORT FUEL INJECTION SYSTEM

*1: This sensor is not used to control the engine system under normal conditions.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from the crankshaft position sensor (POS), camshaft position

sensor (PHASE) and the mass air flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

During warm-up

When starting the engine

During acceleration

Hot-engine operation

When selector lever is changed from N to D

High-load, high-speed operation

During high engine speed operation

Sensor Input Signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Intake air temperature sensor Intake air temperature

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

TCM (VQ35DE engine)

Park/neutral position (PNP) switch (VQ25DE engine)Gear position

Battery

Battery voltage*

3

Knock sensor Engine knocking condition

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

BCM

Air conditioner operation*2

ABS actuator and electric unit (control unit)

Vehicle speed*2

Page 1492 of 5121

![NISSAN TEANA 2008 Service Manual MULTIPORT FUEL INJECTION SYSTEM

EC-31

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857771

1. Intake valve timing control solenoid

va NISSAN TEANA 2008 Service Manual MULTIPORT FUEL INJECTION SYSTEM

EC-31

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857771

1. Intake valve timing control solenoid

va](/img/5/57391/w960_57391-1491.png)

MULTIPORT FUEL INJECTION SYSTEM

EC-31

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Component Parts LocationINFOID:0000000003857771

1. Intake valve timing control solenoid

valve (bank 1)2. Intake valve timing control solenoid

valve (bank 2)3. Electronic controlled engine mount

control solenoid valve

4. Fuel injector (bank 2) 5. Cooling fan motor-2 6. A/F sensor 1 (bank 2)

7. Ignition coil (with power transistor)

and spark plug (bank 2)8. Camshaft position sensor (PHASE)

(bank 2)9. Crankshaft position sensor (POS)

10. Engine coolant temperature sensor 11. Cooling fan motor-1 12. ECM

13. Refrigerant pressure sensor 14. Battery current sensor 15. IPDM E/R

16. Mass air flow sensor (with intake air

temperature sensor)17. Electric throttle control actuator 18. Power valve actuator 2 (VQ35DE

models)

19. EVAP canister purge volume control

solenoid valve20. Camshaft position sensor (PHASE)

(bank 1)21. Ignition coil (with power transistor)

and spark plug (bank 1)

22. A/F sensor 1 (bank 1) 23. Fuel injector (bank 1) 24. VIAS control solenoid valve 1 and 2

(VQ35DE models)

25. Power valve actuator 1

JMBIA1373ZZ

Page 1494 of 5121

![NISSAN TEANA 2008 Service Manual MULTIPORT FUEL INJECTION SYSTEM

EC-33

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaf NISSAN TEANA 2008 Service Manual MULTIPORT FUEL INJECTION SYSTEM

EC-33

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaf](/img/5/57391/w960_57391-1493.png)

MULTIPORT FUEL INJECTION SYSTEM

EC-33

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1. Crankshaft position sensor (POS) 2. Camshaft position sensor (PHASE)

(bank 2)3. Camshaft position sensor (PHASE)

(bank 1)

: Vehicle front

1. Refrigerant pressure sensor 2. Battery current sensor

: Vehicle front

1. ECM 2. Fuel pump fuse 3. IPDM E/R

: Vehicle front

JMBIA1378ZZ

JMBIA1379ZZ

PBIB1686E