mileage NISSAN TEANA 2008 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 3197 of 5121

PERIODIC MAINTENANCE

MA-9

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

NOTE:

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

(1) Periodic maintenance is not required. However, if valve noise increases, check valve clearance.

(2) Replace the drive belt if found damaged or if the auto belt tensioner reading reaches the maximum limit.

(3) Use Genuine NISSAN Engine Coolant or equivalent in its quality, in order to avoid possible aluminum corrosion within

the engine cooling system caused by the use of non-genuine coolant.

First replace at 90,000 km (54,000 miles), then every 60,000 km (36,000 miles). Perform "I" (Checking the mixture ratio and

correcting the mixture ratio if necessary) at the middle of replacement interval.

(4) Fuel filter is maintenance-free. For service procedures, refer to FL section.

(5) Replace spark plug when the spark plug gap exceeds 1.4 mm (0.055 in) even if within specified periodic replacement

mileage.

CHASSIS AND BODY MAINTENANCE

(Annual Mileage > 30,000 km/year)

Abbreviations: I = Inspect and correct or replace as necessary, R = Replace, L = Lubricate.

Fuel and EVAP vapor lines I IMA-18,

MA-22

Air cleaner filterRRMA-18

Fuel filter (In-tank type)See

NOTE (4)—

Positive crankcase ventilation (PCV) system I I I IMA-21

Spark-plugs (Iridium-tipped type)See

NOTE (5)R R RRRRRRMA-20

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Refer-

ence

page Perform at number of kilometers (miles) basis

only.km x

1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at number of kilometers (miles)

basis only.km x 1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Underhood and under vehicle

Headlamp aiming I I I IMA-23

,

MA-27

Brake system and fluid (For level &

leaks)IIIIMA-38,

MA-37

Brake fluidRRMA-38

Brake booster vacuum hoses, connec-

tions & check valveIIBR-12

Power steering fluid & lines (For level &

leaks)IIIIMA-40

CVT fluid (For level & leaks)See

NOTE (1)IIIIMA-32,

MA-34

Steering gear & linkage, axle & suspen-

sion parts, & front drive shafts IIMA-39,

MA-40

,

MA-41

Exhaust systemIIMA-32

Brake pads, rotors & other brake com-

ponentsIIIIMA-38,

BR-13

,

BR-15

Foot brake & parking brake (For free

play, stroke & operation)IIIIBR-6,

PB-2

Page 3198 of 5121

MA-10

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, inspect CVT fluid deterioration

with Consult-III every 90,000 km (54,000 miles), then change CVT fluid NS-2 if necessary. (Refer to TM-204, "

CONSULT-III

Function (TRANSMISSION)" for RE0F10A, TM-37, "CONSULT-III Function (TRANSMISSION)" for RE0F09B.) And if Consult-III

is not available, change (do not just inspect) CVT fluid NS-2 every 90,000 km (54,000 miles). Using transmission fluid other

than Genuine NISSAN CVT Fluid NS-2 will damage the CVT, which is not covered by the warranty.

(2) Inspect once per year.

Maintenance items with “ ” should be performed more frequently according to “Maintenance Under Severe Driving Condi-

tions”.

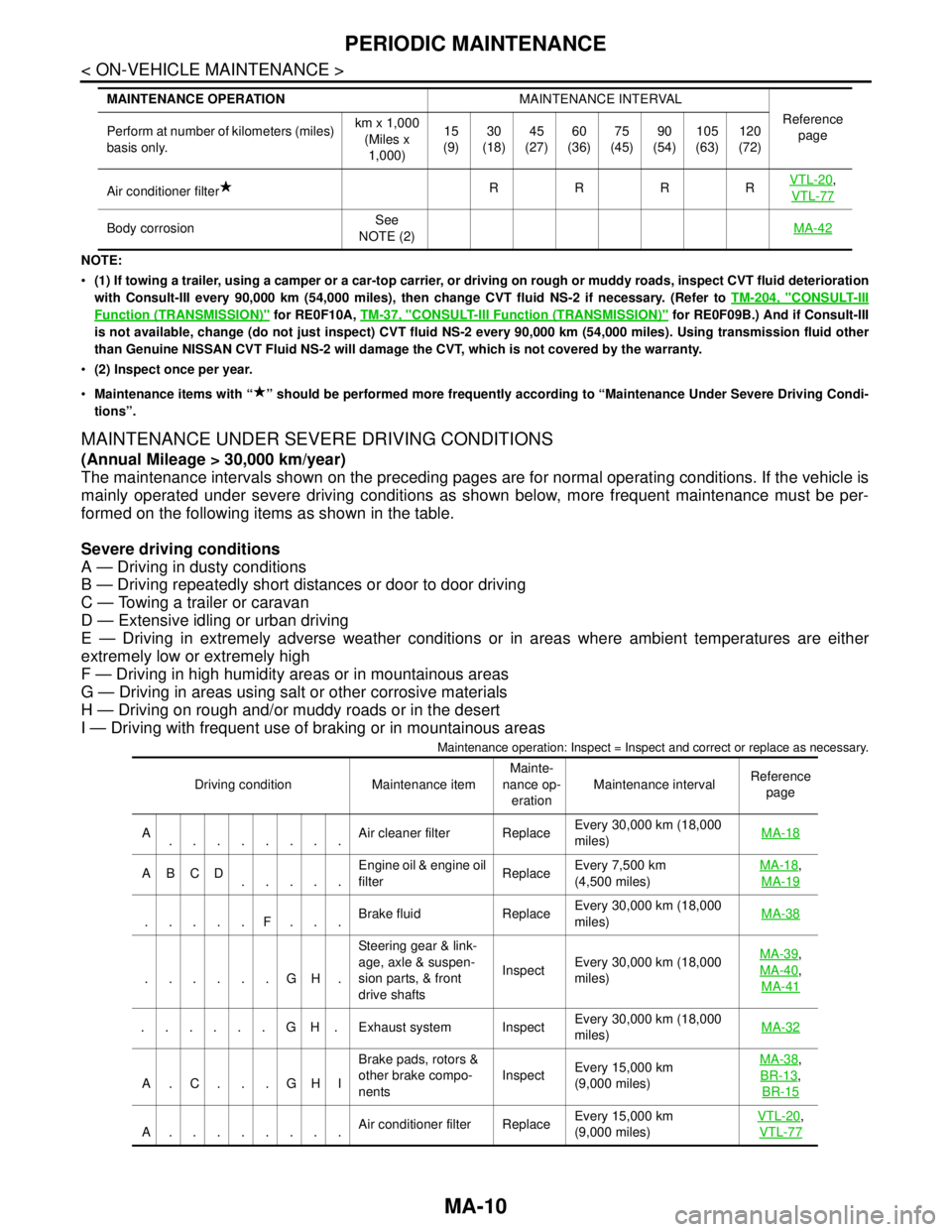

MAINTENANCE UNDER SEVERE DRIVING CONDITIONS

(Annual Mileage > 30,000 km/year)

The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle is

mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving in dusty conditions

B — Driving repeatedly short distances or door to door driving

C — Towing a trailer or caravan

D — Extensive idling or urban driving

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

Maintenance operation: Inspect = Inspect and correct or replace as necessary.

Air conditioner filterRRRRVTL-20,

VTL-77

Body corrosionSee

NOTE (2)MA-42

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

page Perform at number of kilometers (miles)

basis only.km x 1,000

(Miles x

1,000)15

(9)30

(18)45

(27)60

(36)75

(45)90

(54)105

(63)120

(72)

Driving condition Maintenance itemMainte-

nance op-

erationMaintenance intervalReference

page

A

........Air cleaner filter ReplaceEvery 30,000 km (18,000

miles) MA-18

ABCD

.....Engine oil & engine oil

filter ReplaceEvery 7,500 km

(4,500 miles) MA-18,

MA-19

.....F...Brake fluid ReplaceEvery 30,000 km (18,000

miles) MA-38

......GH.Steering gear & link-

age, axle & suspen-

sion parts, & front

drive shaftsInspectEvery 30,000 km (18,000

miles) MA-39

,

MA-40

,

MA-41

......GH.Exhaust system InspectEvery 30,000 km (18,000

miles)MA-32

A.C. . .GHIBrake pads, rotors &

other brake compo-

nentsInspectEvery 15,000 km

(9,000 miles) MA-38

,

BR-13

,

BR-15

A........Air conditioner filter ReplaceEvery 15,000 km

(9,000 miles) VTL-20

,

VTL-77

Page 3272 of 5121

MWI-18

< FUNCTION DIAGNOSIS >

METER SYSTEM

FUEL GAUGE : Component Description

INFOID:0000000003792526

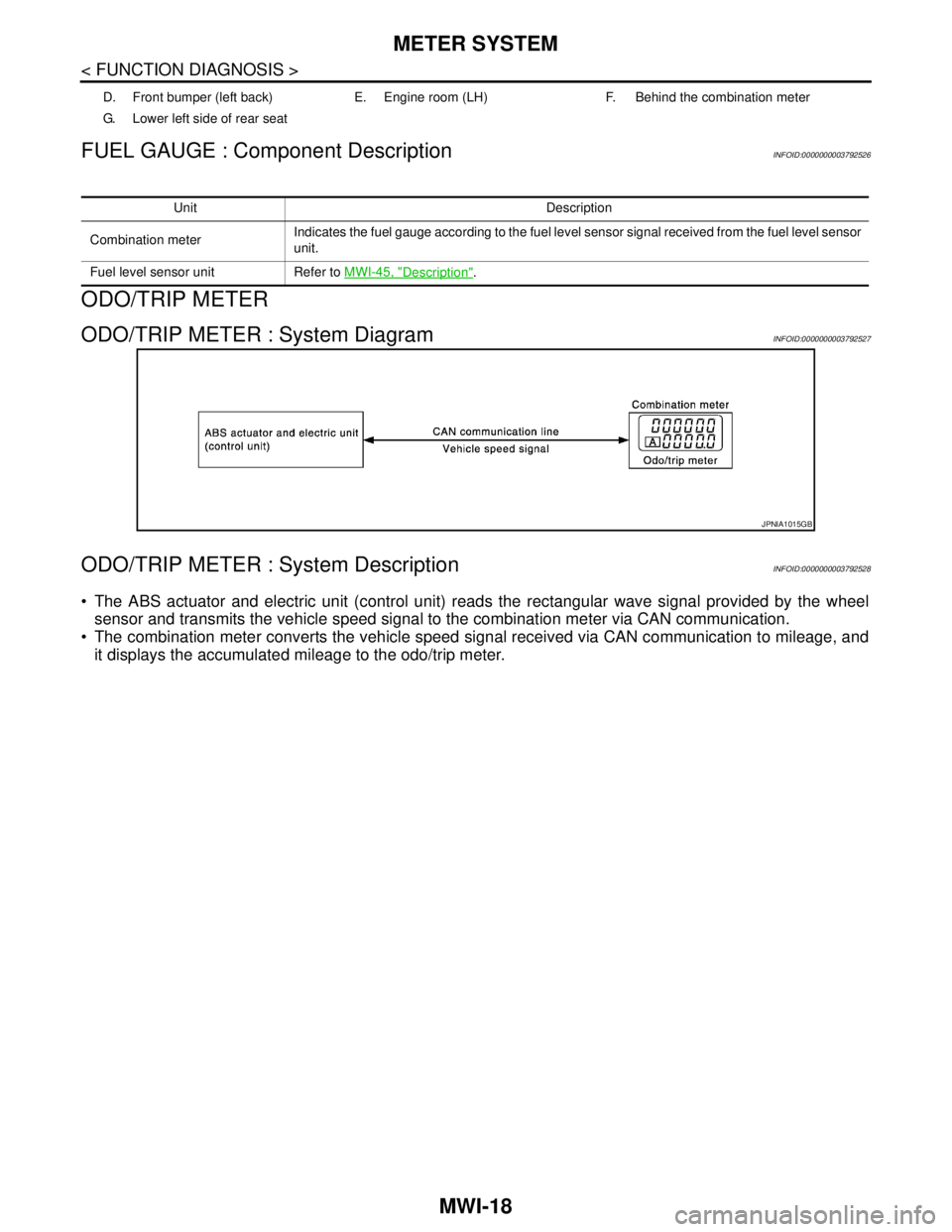

ODO/TRIP METER

ODO/TRIP METER : System DiagramINFOID:0000000003792527

ODO/TRIP METER : System DescriptionINFOID:0000000003792528

The ABS actuator and electric unit (control unit) reads the rectangular wave signal provided by the wheel

sensor and transmits the vehicle speed signal to the combination meter via CAN communication.

The combination meter converts the vehicle speed signal received via CAN communication to mileage, and

it displays the accumulated mileage to the odo/trip meter.

D. Front bumper (left back) E. Engine room (LH) F. Behind the combination meter

G. Lower left side of rear seat

Unit Description

Combination meterIndicates the fuel gauge according to the fuel level sensor signal received from the fuel level sensor

unit.

Fuel level sensor unit Refer to MWI-45, "

Description".

JPNIA1015GB

Page 3274 of 5121

MWI-20

< FUNCTION DIAGNOSIS >

METER SYSTEM

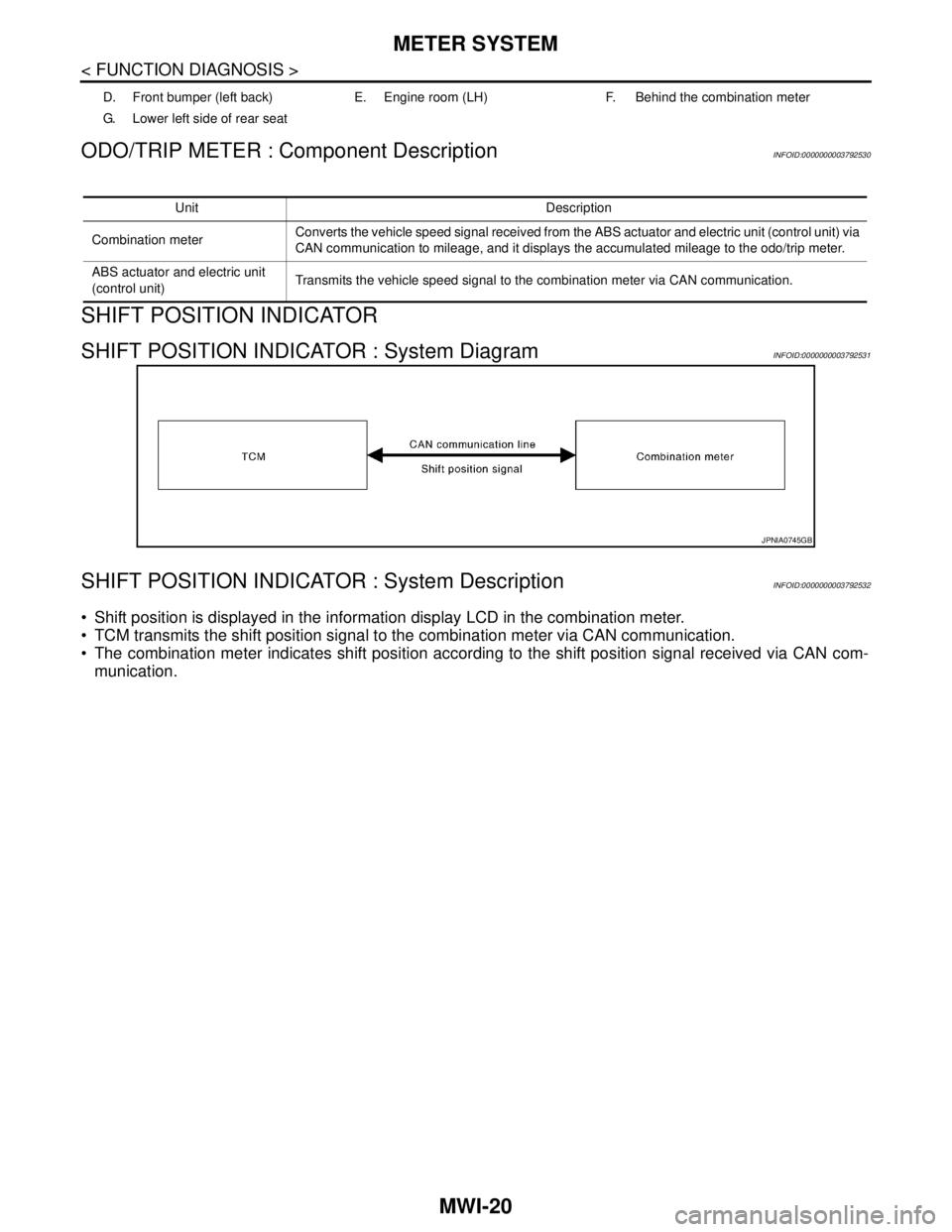

ODO/TRIP METER : Component Description

INFOID:0000000003792530

SHIFT POSITION INDICATOR

SHIFT POSITION INDICATOR : System DiagramINFOID:0000000003792531

SHIFT POSITION INDICATOR : System DescriptionINFOID:0000000003792532

Shift position is displayed in the information display LCD in the combination meter.

TCM transmits the shift position signal to the combination meter via CAN communication.

The combination meter indicates shift position according to the shift position signal received via CAN com-

munication.

D. Front bumper (left back) E. Engine room (LH) F. Behind the combination meter

G. Lower left side of rear seat

Unit Description

Combination meterConverts the vehicle speed signal received from the ABS actuator and electric unit (control unit) via

CAN communication to mileage, and it displays the accumulated mileage to the odo/trip meter.

ABS actuator and electric unit

(control unit)Transmits the vehicle speed signal to the combination meter via CAN communication.

JPNIA0745GB

Page 3286 of 5121

MWI-32

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

DIAGNOSIS SYSTEM (METER)

Diagnosis DescriptionINFOID:0000000003792550

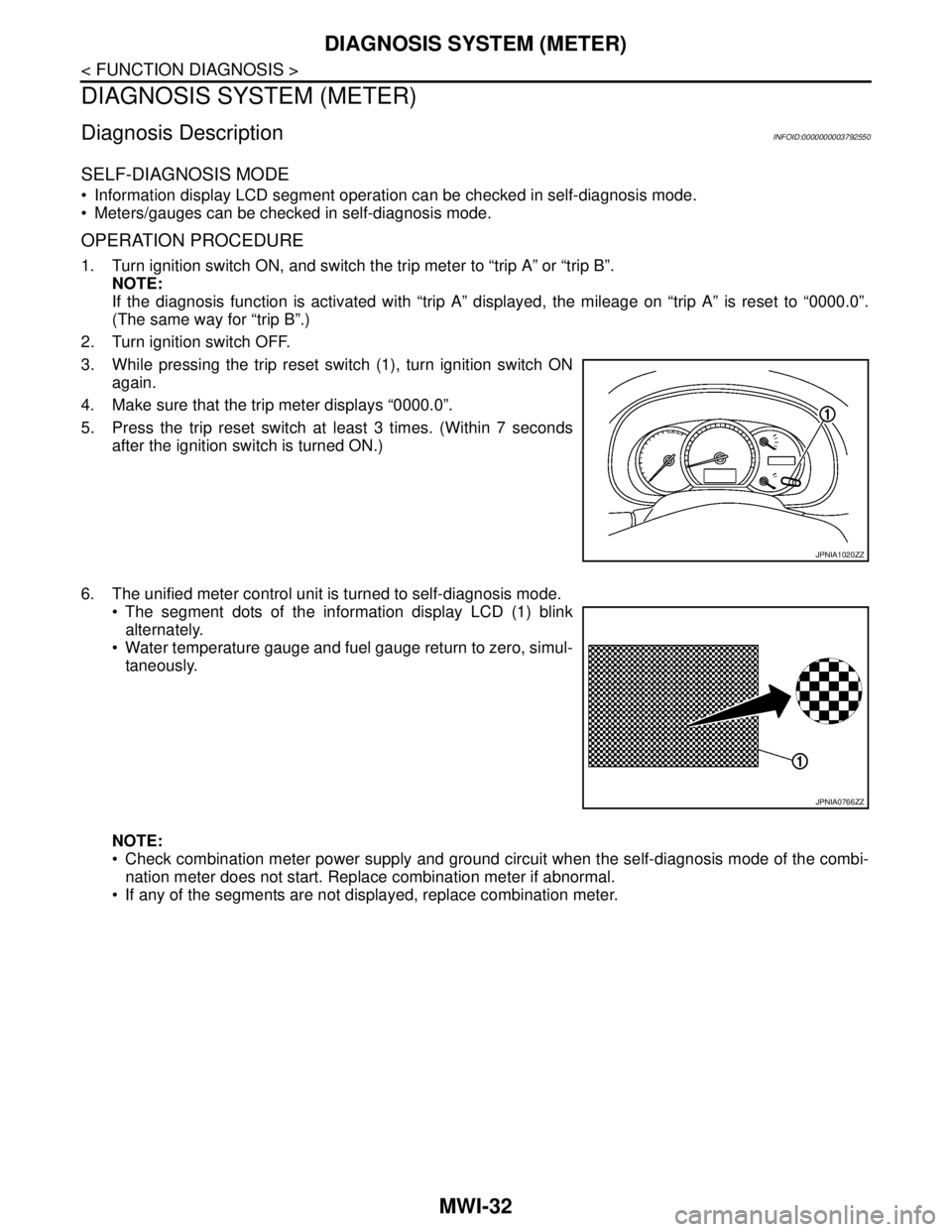

SELF-DIAGNOSIS MODE

Information display LCD segment operation can be checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

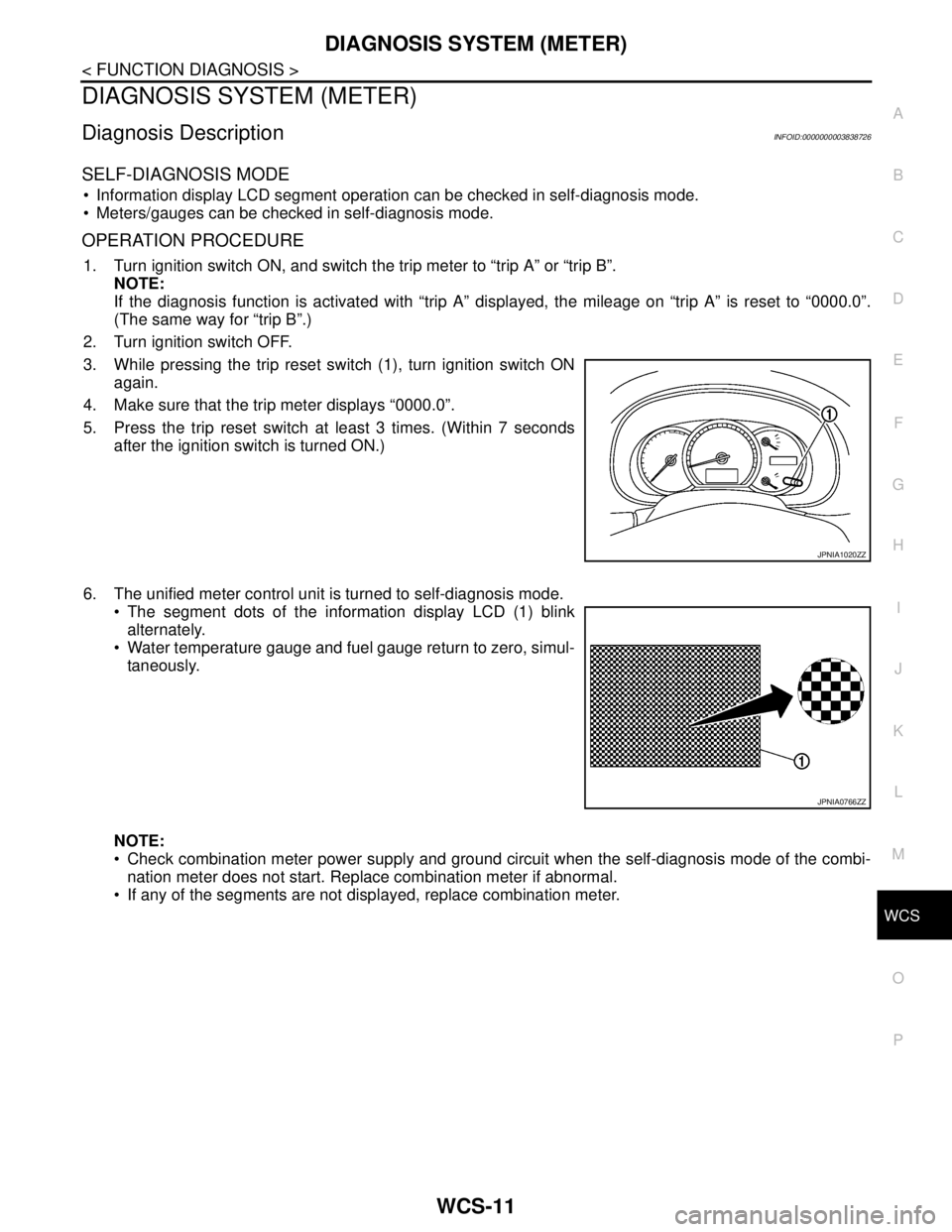

1. Turn ignition switch ON, and switch the trip meter to “trip A” or “trip B”.

NOTE:

If the diagnosis function is activated with “trip A” displayed, the mileage on “trip A” is reset to “0000.0”.

(The same way for “trip B”.)

2. Turn ignition switch OFF.

3. While pressing the trip reset switch (1), turn ignition switch ON

again.

4. Make sure that the trip meter displays “0000.0”.

5. Press the trip reset switch at least 3 times. (Within 7 seconds

after the ignition switch is turned ON.)

6. The unified meter control unit is turned to self-diagnosis mode.

The segment dots of the information display LCD (1) blink

alternately.

Water temperature gauge and fuel gauge return to zero, simul-

taneously.

NOTE:

Check combination meter power supply and ground circuit when the self-diagnosis mode of the combi-

nation meter does not start. Replace combination meter if abnormal.

If any of the segments are not displayed, replace combination meter.

JPNIA1020ZZ

JPNIA0766ZZ

Page 4483 of 5121

![NISSAN TEANA 2008 User Guide TM-10

< BASIC INSPECTION >[CVT: RE0F09B]

DIAGNOSIS AND REPAIR WORK FLOW

Stall test. Refer to TM-144, "Inspection and Judgment".

>> GO TO 3.

3.CHECK DTC

1. Check DTC.

2. Perform the following procedu NISSAN TEANA 2008 User Guide TM-10

< BASIC INSPECTION >[CVT: RE0F09B]

DIAGNOSIS AND REPAIR WORK FLOW

Stall test. Refer to TM-144, "Inspection and Judgment".

>> GO TO 3.

3.CHECK DTC

1. Check DTC.

2. Perform the following procedu](/img/5/57391/w960_57391-4482.png)

TM-10

< BASIC INSPECTION >[CVT: RE0F09B]

DIAGNOSIS AND REPAIR WORK FLOW

Stall test. Refer to TM-144, "Inspection and Judgment".

>> GO TO 3.

3.CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is detected.

Record DTC.

Erase DTC. Refer to TM-35, "

Diagnosis Description".

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM DIAGNOSTIC PROCEDURE

Perform “Diagnostic Procedure” for the displayed DTC. Repair detected items.

>> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform “DTC CONFIRMATION PROCEDURE” for the displayed DTC.

Is DTC detected?

YES >> GO TO 4.

NO >> GO TO 6.

6.CHECK SYMPTOM 2

Confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 7.

NO >> INSPECTION END

7.ROAD TEST

Perform “ROAD TEST”. Refer to TM-148, "

Description".

>> GO TO 8.

8.CHECK SYMPTOM 3

Confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 2.

NO >> INSPECTION END

Diagnostic Work SheetINFOID:0000000003848915

INFORMATION FROM CUSTOMER

KEY POINTS

WHAT..... Vehicle & CVT model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequencyo Continuouso Intermittent ( times a day)

Page 4504 of 5121

![NISSAN TEANA 2008 User Guide SHIFT CONTROL SYSTEM

TM-31

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

By limiting the gear range to the lowest position, the strong driving

force and the engine brake can be NISSAN TEANA 2008 User Guide SHIFT CONTROL SYSTEM

TM-31

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

By limiting the gear range to the lowest position, the strong driving

force and the engine brake can be](/img/5/57391/w960_57391-4503.png)

SHIFT CONTROL SYSTEM

TM-31

< FUNCTION DIAGNOSIS >[CVT: RE0F09B]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

By limiting the gear range to the lowest position, the strong driving

force and the engine brake can be secured.

DOWNHILL ENGINE BRAKE CONTROL (AUTO ENGINE BRAKE CONTROL)

When a downhill slope is detected with the accelerator pedal released, the engine brake will be strengthened

up by downshifting so as not to accelerate the vehicle more than necessary.

ACCELERATION CONTROL

According to vehicle speed and a change of accelerator pedal angle, driver's request for acceleration and driv-

ing scene are judged. This function assists improvement in the acceleration feeling by making the engine

speed proportionate to the vehicle speed. And a shift map that can gain a larger driving force is available for

compatibility of mileage with driveability.

Component Parts LocationINFOID:0000000003848938

JPDIA0686GB

JPDIA0747ZZ

Page 4650 of 5121

![NISSAN TEANA 2008 User Guide DIAGNOSIS AND REPAIR WORK FLOW

TM-177

< BASIC INSPECTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Stall test. Refer to TM-306, "Inspection and Judgment".

>> GO TO 3.

3.CHECK DTC

1. Check DTC. NISSAN TEANA 2008 User Guide DIAGNOSIS AND REPAIR WORK FLOW

TM-177

< BASIC INSPECTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Stall test. Refer to TM-306, "Inspection and Judgment".

>> GO TO 3.

3.CHECK DTC

1. Check DTC.](/img/5/57391/w960_57391-4649.png)

DIAGNOSIS AND REPAIR WORK FLOW

TM-177

< BASIC INSPECTION >[CVT: RE0F10A]

C

E

F

G

H

I

J

K

L

MA

B

TM

N

O

P

Stall test. Refer to TM-306, "Inspection and Judgment".

>> GO TO 3.

3.CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is detected.

Record DTC.

Erase DTC. Refer to TM-202, "

Diagnosis Description".

Is any DTC detected?

YES >> GO TO 4.

NO >> GO TO 5.

4.PERFORM DIAGNOSTIC PROCEDURE

Perform “Diagnostic Procedure” for the displayed DTC.

>> GO TO 5.

5.PERFORM DTC CONFIRMATION PROCEDURE

Perform “DTC CONFIRMATION PROCEDURE” for the displayed DTC.

Is DTC detected?

YES >> GO TO 4.

NO >> GO TO 6.

6.CHECK SYMPTOM 2

Confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 7.

NO >> INSPECTION END

7.ROAD TEST

Perform “ROAD TEST”. Refer to TM-310, "

Description".

>> GO TO 8.

8.CHECK SYMPTOM 3

Confirm the symptom described by the customer.

Is any malfunction present?

YES >> GO TO 2.

NO >> INSPECTION END

Diagnostic Work SheetINFOID:0000000003806345

INFORMATION FROM CUSTOMER

KEY POINTS

WHAT..... Vehicle & CVT model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Customer name MR/MS Model & Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequencyo Continuouso Intermittent ( times a day)

Page 4671 of 5121

![NISSAN TEANA 2008 User Guide TM-198

< FUNCTION DIAGNOSIS >[CVT: RE0F10A]

SHIFT CONTROL SYSTEM

ACCELERATION CONTROL

According to vehicle speed and a change of accelerator pedal angle, drivers request for acceleration and driv-

in NISSAN TEANA 2008 User Guide TM-198

< FUNCTION DIAGNOSIS >[CVT: RE0F10A]

SHIFT CONTROL SYSTEM

ACCELERATION CONTROL

According to vehicle speed and a change of accelerator pedal angle, drivers request for acceleration and driv-

in](/img/5/57391/w960_57391-4670.png)

TM-198

< FUNCTION DIAGNOSIS >[CVT: RE0F10A]

SHIFT CONTROL SYSTEM

ACCELERATION CONTROL

According to vehicle speed and a change of accelerator pedal angle, driver's request for acceleration and driv-

ing scene are judged. This function assists improvement in the acceleration feeling by making the engine

speed proportionate to the vehicle speed. And a shift map that can gain a larger driving force is available for

compatibility of mileage with driveability.

Component Parts LocationINFOID:0000000003809655

*: Control valve assembly is included in CVT assembly.

NOTE:

The following components are included in control valve assembly (8).

CVT fluid temperature sensor

Torque converter clutch solenoid valve

Line pressure solenoid valve

Step motor

ROM assembly

1. Sport mode switch 2. Shift position indicator 3. SPORT indicator lamp

4. TCM 5. Secondary speed sensor 6. PNP switch

7. Primary speed sensor 8.

Control valve assembly

*9. CVT unit connector

10. Accelerator pedal position sensor

A. Center console B. Combination meter C. Engine room LH

D. CVT assembly E. Accelerator pedal, upper

JPDIA0746ZZ

Page 4941 of 5121

WCS

DIAGNOSIS SYSTEM (METER)

WCS-11

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L

MB A

O

P

DIAGNOSIS SYSTEM (METER)

Diagnosis DescriptionINFOID:0000000003838726

SELF-DIAGNOSIS MODE

Information display LCD segment operation can be checked in self-diagnosis mode.

Meters/gauges can be checked in self-diagnosis mode.

OPERATION PROCEDURE

1. Turn ignition switch ON, and switch the trip meter to “trip A” or “trip B”.

NOTE:

If the diagnosis function is activated with “trip A” displayed, the mileage on “trip A” is reset to “0000.0”.

(The same way for “trip B”.)

2. Turn ignition switch OFF.

3. While pressing the trip reset switch (1), turn ignition switch ON

again.

4. Make sure that the trip meter displays “0000.0”.

5. Press the trip reset switch at least 3 times. (Within 7 seconds

after the ignition switch is turned ON.)

6. The unified meter control unit is turned to self-diagnosis mode.

The segment dots of the information display LCD (1) blink

alternately.

Water temperature gauge and fuel gauge return to zero, simul-

taneously.

NOTE:

Check combination meter power supply and ground circuit when the self-diagnosis mode of the combi-

nation meter does not start. Replace combination meter if abnormal.

If any of the segments are not displayed, replace combination meter.

JPNIA1020ZZ

JPNIA0766ZZ