service indicator NISSAN TEANA 2008 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 1 of 5121

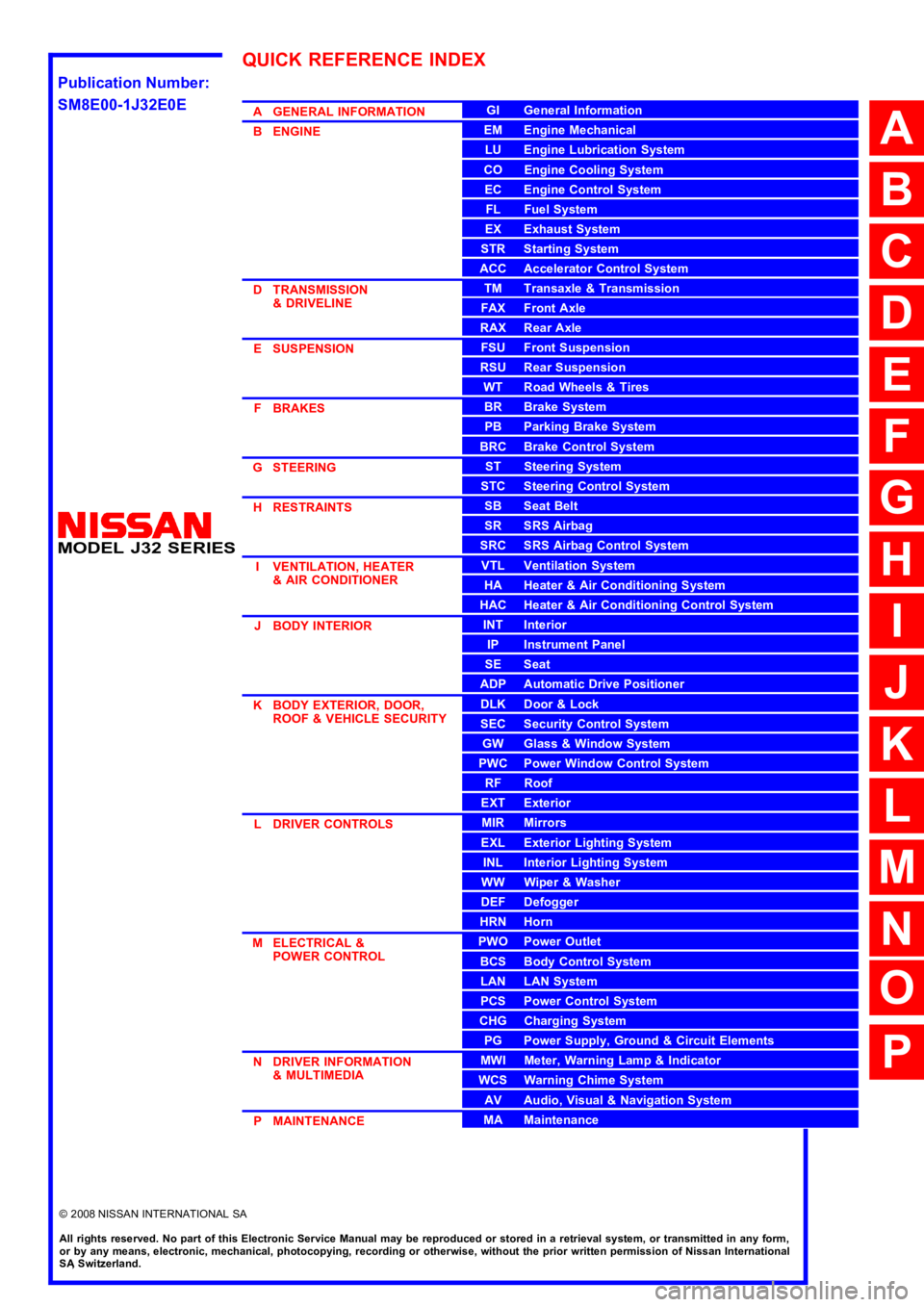

MODEL J32 SERIES

© 2008 NISSAN INTERNATIONAL SA

Allrightsreserved.NopartofthisElectronicServiceManualmaybereproducedorstoredinaretrievalsystem,ortransmittedinanyform,or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan InternationalSA, Switzerland.

AGENERALINFORMATION

BENGINE

DTRANSMISSION&DRIVELINE

ESUSPENSION

FBRAKES

GSTEERING

HRESTRAINTS

IVENTILATION,HEATER&AIRCONDITIONER

JBODYINTERIOR

KBODYEXTERIOR,DOOR,ROOF&VEHICLESECURITY

LDRIVERCONTROLS

MELECTRICAL&POWERCONTROL

NDRIVERINFORMATION&MULTIMEDIA

PMAINTENANCE

GIGeneralInformation

EMEngineMechanical

LUEngineLubricationSystem

COEngineCoolingSystem

ECEngineControlSystem

FLFuelSystem

EXExhaustSystem

STRStartingSystem

ACCAcceleratorControlSystem

TMTransaxle &Transmission

FAXFrontAxle

RAXRearAxle

FSUFrontSuspension

RSURearSuspension

WTRoadWheels &Tires

BRBrakeSystem

PBParkingBrakeSystem

BRCBrakeControlSystem

STSteeringSystem

STCSteeringControlSystem

SBSeatBelt

SRSRSAirbag

SRCSRSAirbagControlSystem

VTLVentilationSystem

HAHeater &AirConditioningSystem

HACHeater &AirConditioningControlSystem

INTInterior

IPInstrumentPanel

SESeat

ADPAutomaticDrivePositioner

DLKDoor &Lock

SECSecurityControlSystem

GWGlass &WindowSystem

PWCPowerWindowControlSystem

RFRoof

EXTExterior

MIRMirrors

EXLExteriorLightingSystem

INLInteriorLightingSystem

WWWiper &Washer

DEFDefogger

HRNHorn

PWOPowerOutlet

BCSBodyControlSystem

LANLANSystem

PCSPowerControlSystem

CHGChargingSystem

PGPowerSupply,Ground&CircuitElements

MWIMeter,WarningLamp&Indicator

WCSWarningChimeSystem

AVAudio,Visual&NavigationSystem

MAMaintenance

QUICKREFERENCEINDEX

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

M

Publication Number:

SM8E00-1J32E0E

Page 840 of 5121

BCS

DIAGNOSIS SYSTEM (BCM)

BCS-23

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

WIPER

WIPER : CONSULT-III Function (BCM - WIPER)INFOID:0000000003897063

WORK SUPPORT

*:Factory setting

NOTE:

When performed “RESET SETTING VALUE” on “Work Support (BCM - BCM)”, set “WIPER SPEED SETTING” on “Work Support (BCM

-WIPER)” to “On”.

DATA MONITOR

ACTIVE TEST

RR FOG LAMPOn Outputs the voltage to turn the rear fog lamp ON.

Transmits the rear fog lamp status signal to the combination meter with

CAN communication to turn the rear fog lamp indicator lamp ON.

Off Stops the voltage to turn the rear fog lamp OFF.

Stops the rear fog lamp status signal transmission.

DAYTIME RUNNING LIGHTOn

NOTE:

The item is indicated, but cannot be tested.

Off

CORNERING LAMPRH

NOTE:

The item is indicated, but cannot be tested. LH

Off

ILL DIM SIGNALOn

NOTE:

The item is indicated, but cannot be tested.

Off Test item Operation Description

Service item Setting item Description

WIPER SPEED

SETTINGOn*With vehicle speed

(Front wiper intermittent time linked with the vehicle speed and wiper intermittent dial position)

OffWithout vehicle speed

(Front wiper intermittent time linked with the wiper intermittent dial position)

Monitor Item

[Unit]Description

PUSH SW

[Off/On]The switch status input from push-button ignition switch.

VEH SPEED 1

[km/h]Displays the value of the vehicle speed signal received from combination meter with CAN communication.

FR WIPER HI

[Off/On]

Status of each switch judged by BCM using the combination switch reading function FR WIPER LOW

[Off/On]

FR WASHER SW

[Off/On]

FR WIPER INT

[Off/On]

FR WIPER STOP

[Off/On]Displays the status of the front wiper stop position signal received from IPDM E/R with CAN communication.

INT VOLUME

[1 − 7] Status of each switch judged by BCM using the combination switch reading function

H/L WASH SW

[Off/On]Status of the switch input from headlamp washer switch

Page 846 of 5121

BCS

DIAGNOSIS SYSTEM (BCM)

BCS-29

< FUNCTION DIAGNOSIS >

C

D

E

F

G

H

I

J

K

L B A

O

P N

When performed “RESET SETTING VALUE” on “Work Support (BCM - BCM)”, set “WIPER SPEED SETTING” on “Work Support (BCM

- WIPER)” to “On”.

IMMU

IMMU : CONSULT-III Function (BCM - IMMU)INFOID:0000000003897057

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

DATA MONITOR

ACTIVE TEST

BATTERY SAVER

BATTERY SAVER : CONSULT-III Function (BCM - BATTERY SAVER)INFOID:0000000003897060

WORK SUPPORT

*: Factory setting

DATA MONITOR

Diagnosis mode Function Description

DATA MONITOR The BCM input/output signals are displayed.

ACTIVE TEST The signals used to activate each device are forcibly supplied from BCM.

Monitor item Content

CONFRM ID ALL

Indicates [YET] at all time.

Switches to [DONE] when a registered Intelligent Key is inserted into the key slot. CONFIRM ID4

CONFIRM ID3

CONFIRM ID2

CONFIRM ID1

TP 4

Indicates the number of ID which has been registered. TP 3

TP 2

TP 1

PUSH SW Indicates [ON/OFF] condition of push-button ignition switch.

KEY SW -SLOT Indicates [ON/OFF] condition of key slot.

Test item Description

THEFT INDThis test is able to check security indicator lamp operation.

The lamp will be turned on when “ON” on CONSULT-III screen touched.

Service item Setting item Setting

BATTERY SAVER SETOn* With the exterior lamp battery saver function

Off Without the exterior lamp battery saver function

ROOM LAMP BAT SAV SETOn* With the interior room lamp battery saver function

Off Without the interior room lamp battery saver function

ROOM LAMP TIMER SETMODE 1* 30 min.

Sets the interior room lamp battery saver timer operating

time.

MODE 2 60 min.

Page 1472 of 5121

![NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

EC-11

< BASIC INSPECTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

INSPECTION AND ADJUSTMENT

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000 NISSAN TEANA 2008 Service Manual INSPECTION AND ADJUSTMENT

EC-11

< BASIC INSPECTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

INSPECTION AND ADJUSTMENT

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000](/img/5/57391/w960_57391-1471.png)

INSPECTION AND ADJUSTMENT

EC-11

< BASIC INSPECTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

INSPECTION AND ADJUSTMENT

BASIC INSPECTION

BASIC INSPECTION : Special Repair RequirementINFOID:0000000003856444

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Head lamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no

load.

6. Check that no DTC is displayed with CONSULT-III or GST.

Are any DTCs detected?

YES >> GO TO 2.

NO >> GO TO 3.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3

3.CHECK TARGET IDLE SPEED

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Page 1563 of 5121

![NISSAN TEANA 2008 Service Manual EC-102

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000003856502

INTRODUCTION

The ECM has an on board diagno NISSAN TEANA 2008 Service Manual EC-102

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000003856502

INTRODUCTION

The ECM has an on board diagno](/img/5/57391/w960_57391-1562.png)

EC-102

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

Diagnosis DescriptionINFOID:0000000003856502

INTRODUCTION

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emission-related diagnostic information including:

The above information can be checked using procedures listed in the table below.

×: Applicable —: Not applicable

*: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator MI on the instrument panel illuminates when the same malfunction is detected in two

consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode. (Refer to EC-386, "

Fail

safe".)

TWO TRIP DETECTION LOGIC

When a malfunction is detected for the first time, 1st trip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MI will not illuminate at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MI illuminates. The MI illuminates at the same time the DTC is stored. <2nd trip>

The “trip” in the “Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed during

vehicle operation. Specific on board diagnostic items will cause the ECM to illuminate or blink the MI, and

store DTC and Freeze Frame data, even in the 1st trip, as shown below.

×: Applicable —: Not applicable

DTC AND FREEZE FRAME DATA

DTC and 1st Trip DTC

Emission-related diagnostic information Diagnostic service

Diagnostic Trouble Code (DTC) Service $03 of ISO 15031-5

Freeze Frame data Service $02 of ISO 15031-5

System Readiness Test (SRT) code Service $01 of ISO 15031-5

1st Trip Diagnostic Trouble Code (1st Trip DTC) Service $07 of ISO 15031-5

1st Trip Freeze Frame data —

Test values and Test limits Service $06 of ISO 15031-5

Calibration ID Service $09 of ISO 15031-5

DTC 1st trip DTCFreeze

Frame data1st trip Freeze

Frame dataSRT code SRT status Test value

CONSULT-III×× × × × ×—

GST×× ×—×××

ECM××*— — —×—

ItemsMI DTC 1st trip DTC

1st trip 2nd trip

1st trip

displaying2nd trip

displaying1st trip

displaying2nd trip

display-

ing BlinkingIlluminat-

edBlinkingIlluminat-

ed

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0306 is

being detected×———— —×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0306 is

being detected——×——×——

One trip detection diagnoses (Re-

fer to EC-389, "

DTCIndex".)—×——×———

Except above — — —×—××—

Page 1568 of 5121

![NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-107

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O How to Display SRT Status

WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMAT NISSAN TEANA 2008 Service Manual ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-107

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O How to Display SRT Status

WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMAT](/img/5/57391/w960_57391-1567.png)

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-107

< FUNCTION DIAGNOSIS >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O How to Display SRT Status

WITH CONSULT-III

Selecting “SRT STATUS” in “DTC CONFIRMATION” mode with CONSULT-III.

For items whose SRT codes are set, “CMPLT” is displayed on the CONSULT-III screen; for items whose SRT

codes are not set, “INCMP” is displayed.

NOTE:

Though displayed on the CONSULT-III screen, “HO2S HTR” is not SRT item.

WITH GST

Selecting Service $01 with GST (Generic Scan Tool)

MALFUNCTION INDICATOR (MI)

Description

The MI is located on the instrument panel.

1. The MI will illuminate when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MI does not illuminate, check MI circuit. Refer to EC-346,

"Component Function Check".

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

On Board Diagnostic System Function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode I — Bulb Check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check MI circuit. Refer to EC-

346, "Component Function Check".

Diagnostic Test Mode I — Malfunction Warning

SAT652J

Diagnostic Test

ModeKEY and ENG.

Sta tusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MI bulb for damage (blown, open

circuit, etc.).

If the MI does not come on, check MI circuit.

Engine running MALFUNCTION

WARNINGWhen a malfunction is detected twice in two consecutive

driving cycles (two trip detection logic), the MI will illuminate

to inform the driver that a malfunction has been detected.

The following malfunctions will illuminate or blink the MI in

the 1st trip.

Misfire (Possible three way catalyst damage)

One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Page 1866 of 5121

![NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INF NISSAN TEANA 2008 Service Manual PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INF](/img/5/57391/w960_57391-1865.png)

PRECAUTIONS

EC-405

< PRECAUTION >[VQ25DE, VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003960684

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precautions For Xenon Headlamp ServiceINFOID:0000000003856878

WARNING:

Comply with the following warnings to prevent any serious accident.

Disconnect the battery cable (negative terminal) or the power supply fuse before installing, remov-

ing, or touching the xenon headlamp (bulb included). The xenon headlamp contains high-voltage

generated parts.

Never work with wet hands.

Check the xenon headlamp ON-OFF status after assembling it to the vehicle. Never turn the xenon

headlamp ON in other conditions. Connect the power supply to the vehicle-side connector.

(Turning it ON outside the lamp case may cause fire or visual impairments.)

Never touch the bulb glass immediately after turning it OFF. It is extremely hot.

CAUTION:

Comply with the following cautions to prevent any error and malfunction.

Install the xenon bulb securely. (Insufficient bulb socket installation may melt the bulb, the connec-

tor, the housing, etc. by high-voltage leakage or corona discharge.)

Never perform HID circuit inspection with a tester.

Never touch the xenon bulb glass with hands. Never put oil and grease on it.

Dispose of the used xenon bulb after packing it in thick vinyl without breaking it.

Never wipe out dirt and contamination with organic solvent (thinner, gasoline, etc.).

Precaution for Procedure without Cowl Top CoverINFOID:0000000003856879

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnostic (OBD) System of Engine and CVTINFOID:0000000003856880

The ECM has an on board diagnostic system. It will illuminate the malfunction indicator MI to warn the driver of

a malfunction causing emission deterioration.

PIIB3706J

Page 1994 of 5121

CYLINDER BLOCK

EM-119

< DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

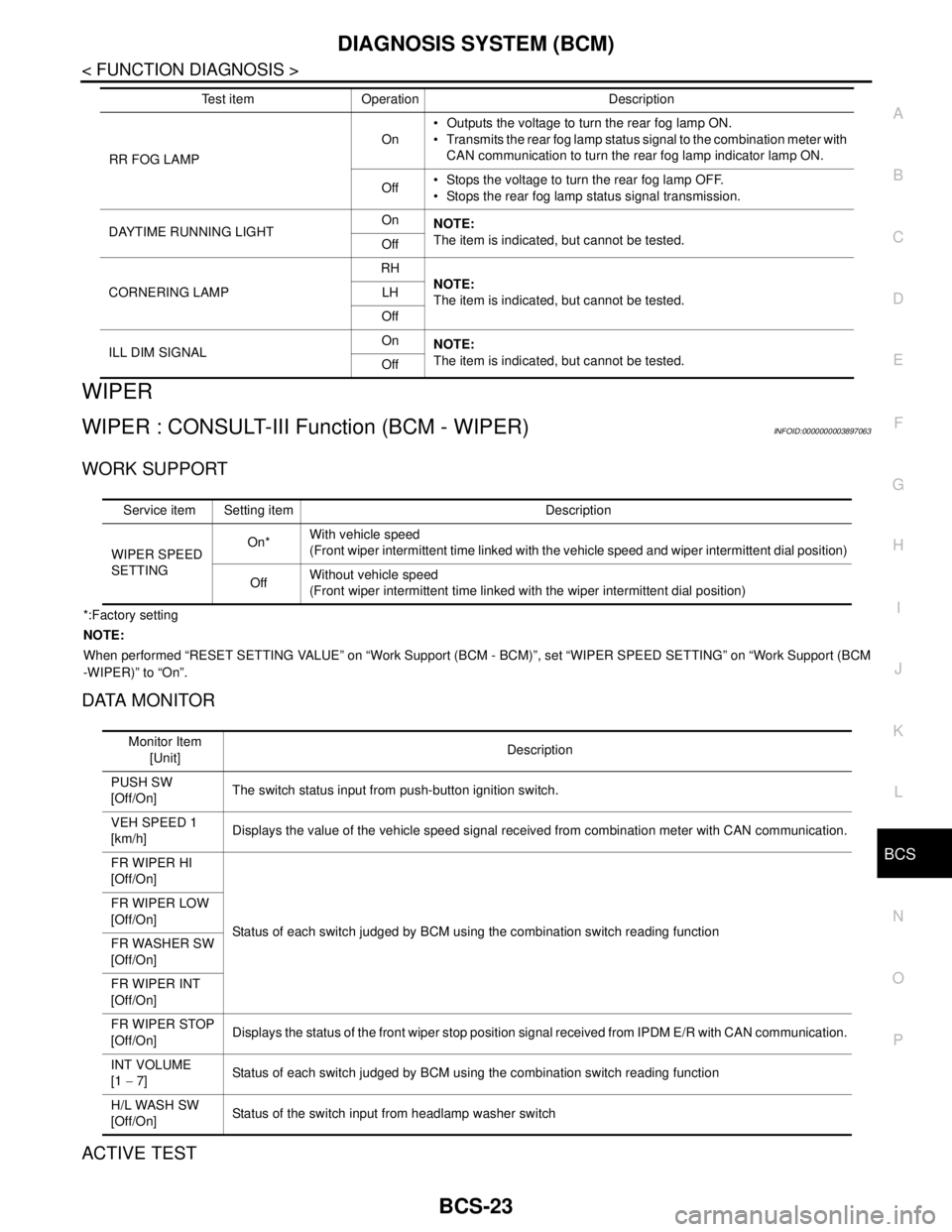

Install drive plate (2) and reinforcement plate (3) as shown in

the figure.

Holding ring gear with the pulley holder (commercial service

tool).

Tighten mounting bolts crosswise over several times.

InspectionINFOID:0000000003802295

CRANKSHAFT END PLAY

Measure the clearance between thrust bearings and crankshaft

arm when crankshaft is moved fully forward or backward with a dial

indicator.

If the measured value exceeds the limit, replace thrust bearings,

and measure again. If it still exceeds the limit, replace crankshaft

also.

CONNECTING ROD SIDE CLEARANCE

Measure the side clearance between connecting rod and crank-

shaft arm with a feeler gauge (A).

If the measured value exceeds the limit, replace connecting rod,

and measure again. If it still exceeds the limit, replace crankshaft

also.

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter

Measure the inner diameter of piston pin hole with an inside

micrometer (A).

Piston Pin Outer Diameter

1 : Ring gear

4 : Pilot converter

5 : Crankshaft

A : Rounded

: Engine front

JPBIA0212ZZ

Standard and limit : Refer to EM-143, "CylinderBlock".

EMQ0196D

Standard and limit : Refer to EM-143, "CylinderBlock".

JPBIA0536ZZ

Standard : Refer to EM-143, "CylinderBlock".

JPBIA0217ZZ

Page 2012 of 5121

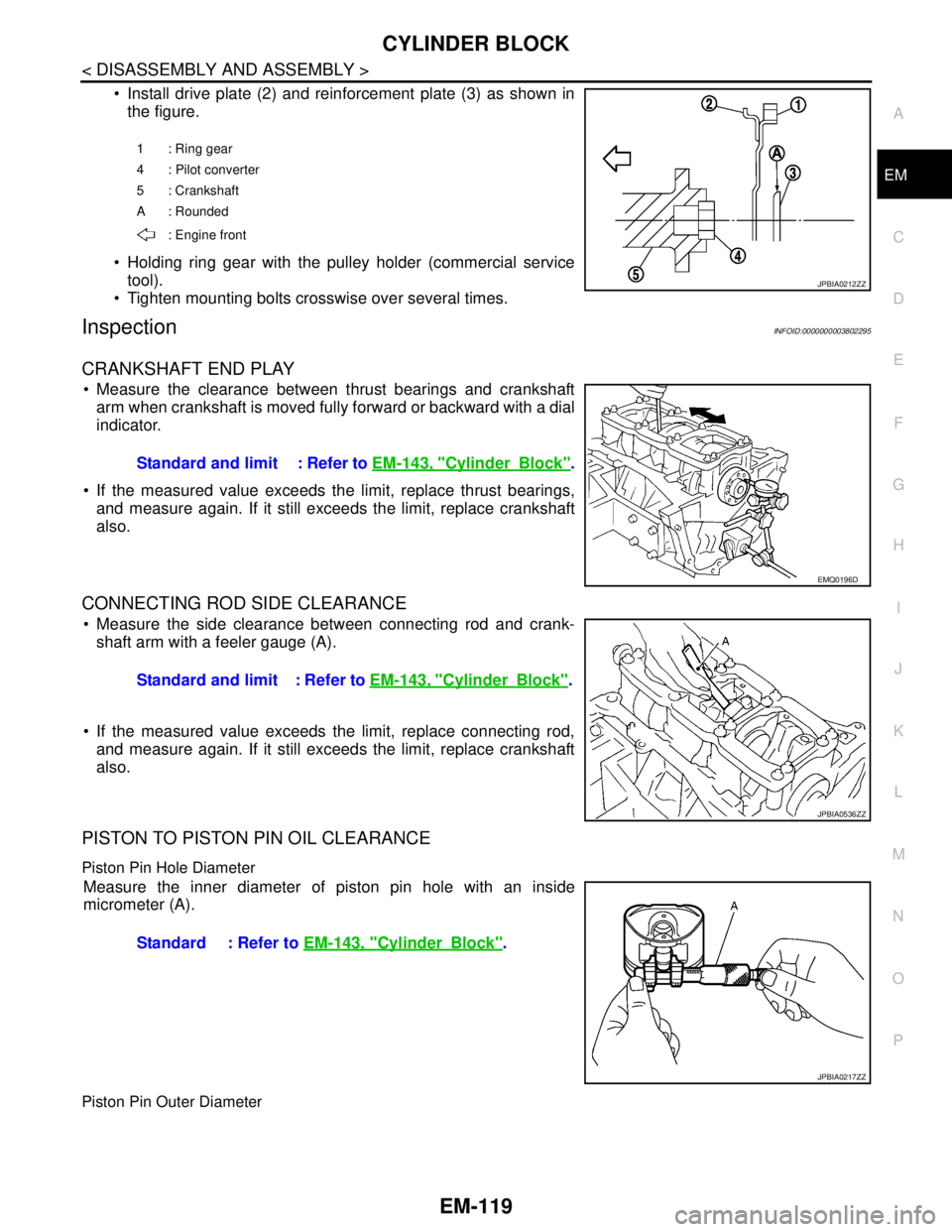

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-137

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

I

J

K

L

MA

EM

N

P O

*1: Cam wear limit

*

2: Total indicator reading

VA LV E L I F T E R

Unit: mm (in)

VALVE CLEARANCE

Unit: mm (in)

*: Approximately 80°C (176°F)

AVAILABLE VALVE LIFTER

VQ25DE

Unit: mm (in)

Camshaft sprocket runout [TIR*2]— 0.15 (0.0059)

SEM671

ItemsStandard

VQ25DE VQ35DE

Valve lifter outer diameterIntake 33.980 - 33.990 (1.3378 - 1.3382)

33.980 - 33.990 (1.3378 - 1.3382)

Exhaust 29.977 - 29.987 (1.1802 - 1.1806)

Valve lifter hole diameterIntake 34.000 - 34.016 (1.3386 - 1.3392)

34.000 - 34.016 (1.3386 - 1.3392)

Exhaust 29.997 - 30.013 (1.1810 - 1.1816)

Valve lifter clearance 0.010 - 0.036 (0.0004 - 0.0014)

Items Cold Hot* (reference data)

Intake 0.26 - 0.34 (0.010 - 0.013) 0.304 - 0.416 (0.012 - 0.016)

Exhaust 0.29 - 0.37 (0.011 - 0.015) 0.308 - 0.432 (0.012 - 0.017)

Intake Exhaust

Identification (stamped) mark Thickness Identification (stamped) mark Thickness

788P 7.88 (0.3102) 666U 6.66 (0.2622)

790P 7.90 (0.3110) 668U 6.68 (0.2630)

792P 7.92 (0.3118) 670U 6.70 (0.2638)

794P 7.94 (0.3126) 672U 6.72 (0.2646)

796P 7.96 (0.3134) 674U 6.74 (0.2654)

798P 7.98 (0.3142) 676U 6.76 (0.2661)

800P 8.00 (0.3150) 678U 6.78 (0.2669)

802P 8.02 (0.3157) 680U 6.80 (0.2677)

804P 8.04 (0.3165) 682U 6.82 (0.2685)

806P 8.06 (0.3173) 684U 6.84 (0.2693)

808P 8.08 (0.3181) 686U 6.86 (0.2701)

810P 8.10 (0.3189) 688U 6.88 (0.2709)

Page 2021 of 5121

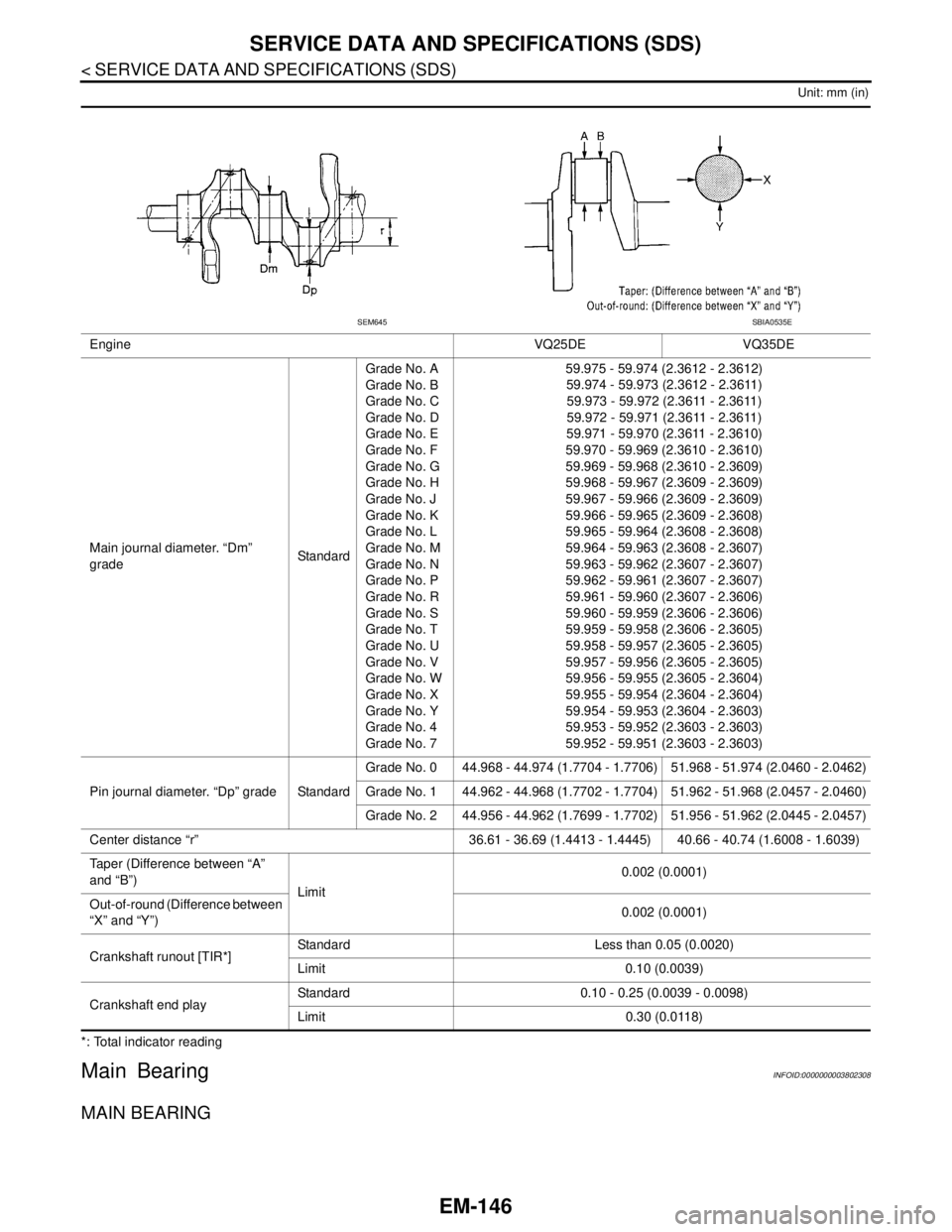

EM-146

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

*: Total indicator reading

Main BearingINFOID:0000000003802308

MAIN BEARING

Engine VQ25DE VQ35DE

Main journal diameter. “Dm”

gradeStandardGrade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 4

Grade No. 759.975 - 59.974 (2.3612 - 2.3612)

59.974 - 59.973 (2.3612 - 2.3611)

59.973 - 59.972 (2.3611 - 2.3611)

59.972 - 59.971 (2.3611 - 2.3611)

59.971 - 59.970 (2.3611 - 2.3610)

59.970 - 59.969 (2.3610 - 2.3610)

59.969 - 59.968 (2.3610 - 2.3609)

59.968 - 59.967 (2.3609 - 2.3609)

59.967 - 59.966 (2.3609 - 2.3609)

59.966 - 59.965 (2.3609 - 2.3608)

59.965 - 59.964 (2.3608 - 2.3608)

59.964 - 59.963 (2.3608 - 2.3607)

59.963 - 59.962 (2.3607 - 2.3607)

59.962 - 59.961 (2.3607 - 2.3607)

59.961 - 59.960 (2.3607 - 2.3606)

59.960 - 59.959 (2.3606 - 2.3606)

59.959 - 59.958 (2.3606 - 2.3605)

59.958 - 59.957 (2.3605 - 2.3605)

59.957 - 59.956 (2.3605 - 2.3605)

59.956 - 59.955 (2.3605 - 2.3604)

59.955 - 59.954 (2.3604 - 2.3604)

59.954 - 59.953 (2.3604 - 2.3603)

59.953 - 59.952 (2.3603 - 2.3603)

59.952 - 59.951 (2.3603 - 2.3603)

Pin journal diameter. “Dp” grade StandardGrade No. 0 44.968 - 44.974 (1.7704 - 1.7706) 51.968 - 51.974 (2.0460 - 2.0462)

Grade No. 1 44.962 - 44.968 (1.7702 - 1.7704) 51.962 - 51.968 (2.0457 - 2.0460)

Grade No. 2 44.956 - 44.962 (1.7699 - 1.7702) 51.956 - 51.962 (2.0445 - 2.0457)

Center distance “r” 36.61 - 36.69 (1.4413 - 1.4445) 40.66 - 40.74 (1.6008 - 1.6039)

Taper (Difference between “A”

and “B”)

Limit0.002 (0.0001)

Out-of-round (Difference between

“X” and “Y”)0.002 (0.0001)

Crankshaft runout [TIR*]Standard Less than 0.05 (0.0020)

Limit 0.10 (0.0039)

Crankshaft end playStandard 0.10 - 0.25 (0.0039 - 0.0098)

Limit 0.30 (0.0118)

SEM645SBIA0535E