CVT NISSAN TEANA 2014 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3421 of 4801

![NISSAN TEANA 2014 Owners Manual

PCS-72

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F2 IGNITION RELAY

B26F2 IGNITION RELAY

DTC LogicINFOID:0000000009461653

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF D NISSAN TEANA 2014 Owners Manual

PCS-72

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F2 IGNITION RELAY

B26F2 IGNITION RELAY

DTC LogicINFOID:0000000009461653

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF D](/img/5/57390/w960_57390-3420.png)

PCS-72

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F2 IGNITION RELAY

B26F2 IGNITION RELAY

DTC LogicINFOID:0000000009461653

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON under the following conditions, and wait for 2 seconds or more.

- CVT selector lever is in the P (park) or N (neutral) position.

- Do not depress brake pedal.

2. Perform self diagnostic result.

Is DTC B26F2 detected?

YES >> Go to PCS-72, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461654

Regarding Wiring Diagram information, refer to PCS-44, "Wiring Diagram".

1. CHECK SELF DIAGNOSTIC RESULT FOR IPDM E/R

1. Perform self diagnostic result for IPDM E/R.

2. Erase DTCs.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Perform self diagnostic result for IPDM E/R.

Are any DTCs detected?

YES >> Refer to PCS-20, "DTC Index".

NO >> GO TO 2.

2.CHECK IGNITION RELAY-1 CONTROL SIGNAL (IPDM E/R)

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E63.

3. Check voltage between IPDM E/R connector E63 terminal 43 and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> GO TO 3.

3.CHECK IGNITION RELAY-1 CONTROL SIGNAL CIRCUIT

1. Disconnect BCM connector M18.

2. Check voltage between IPDM E/R connector E63 terminal 43 and ground.

CONSULT Display DTC detectin g condition Possible cause

IGN RELAY ON

[B26F2] BCM transmits the ignition relay control signal, but

does not receive ignition switch ON signal (CAN)

from IPDM E/R. • Harness or connectors

•BCM

• IPDM E/R

IPDM E/R Ground Condition Vo l ta g e

(Approx.)

Connector Terminal

E63 43 — Ignition: OFF 0V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3423 of 4801

![NISSAN TEANA 2014 Owners Manual

PCS-74

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F6 BCM

B26F6 BCM

DTC LogicINFOID:0000000009461655

DTC DETECTION LOGIC

NOTE:

• If DTC B26F6 is displayed with DTC U1000, first perform NISSAN TEANA 2014 Owners Manual

PCS-74

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F6 BCM

B26F6 BCM

DTC LogicINFOID:0000000009461655

DTC DETECTION LOGIC

NOTE:

• If DTC B26F6 is displayed with DTC U1000, first perform](/img/5/57390/w960_57390-3422.png)

PCS-74

< DTC/CIRCUIT DIAGNOSIS >[POWER DISTRIBUTION SYSTEM]

B26F6 BCM

B26F6 BCM

DTC LogicINFOID:0000000009461655

DTC DETECTION LOGIC

NOTE:

• If DTC B26F6 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

PCS-56, "DTC Logic"

.

• If DTC B26F6 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to PCS-57, "DTC Logic"

.

DTC CONFIRMATION PROCEDURE

1.PERFORM SELF DIAGNOSTIC RESULT

1. Turn ignition switch ON under the following conditions, and wait for 2 seconds or more.

- CVT selector lever is in the P (park) or N (neutral) position.

- Do not depress brake pedal.

2. Perform self diagnostic result.

Is DTC B26F6 detected?

YES >> Go to PCS-74, "Diagnosis Procedure".

NO >> Inspection End.

Diagnosis ProcedureINFOID:0000000009461656

Regarding Wiring Diagram information, refer to PCS-44, "Wiring Diagram".

1. CHECK SELF DIAGNOSTIC RESULT FOR IPDM E/R

Perform self diagnostic result for IPDM E/R.

Are any DTCs detected?

YES >> Refer to PCS-20, "DTC Index".

NO >> GO TO 2

2. CHECK IGNITION RELAY-1 POWER SUPPLY (IPDM E/R)

Check voltage between IPDM E/R connector E63 terminal 43 and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> GO TO 3.

3. CHECK IGNITION RELAY-1 POWER SUPPLY (BCM)

Check voltage between BCM connector M18 terminal 70 and ground.

CONSULT Display DTC Detectio n Condition Possible Cause

BCM

[B26F6] Ignition relay ON signal is not transmitted from IPDM

E/R (CAN) when BCM turn s ignition relay ON. BCM

IPDM E/R

Ground Condition Vo l ta g e

(Approx.)

Connector Terminal

E63 43 — Ignition: OFF 0V

Ignition: ON Battery voltage

BCM Ground Condition Vo l ta g e

(Approx.)

Connector Terminal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3473 of 4801

PG

HARNESSPG-41

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B

A

O P

N

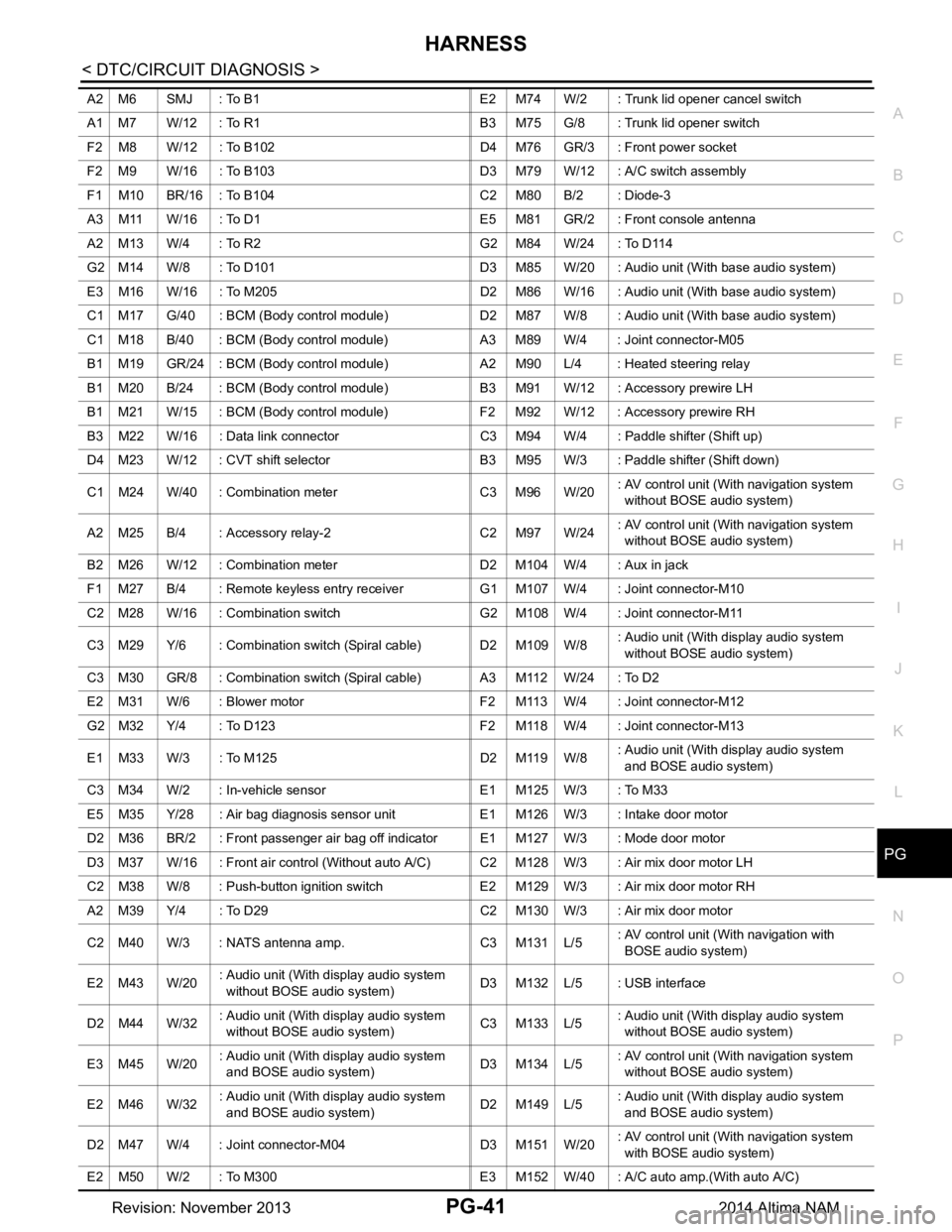

A2 M6 SMJ : To B1 E2 M74 W/2 : Trunk lid opener cancel switch

A1 M7 W/12 : To R1 B3 M75 G/8 : Trunk lid opener switch

F2 M8 W/12 : To B102 D4 M76 GR/3 : Front power socket

F2 M9 W/16 : To B103 D3 M79 W/12 : A/C switch assembly

F 1 M 1 0 B R / 1 6 : T o B 1 0 4 C 2 M 8 0 B / 2 : D i o d e - 3

A3 M11 W/16 : To D1 E5 M81 GR/2 : Front console antenna

A 2 M 1 3 W / 4 : T o R 2 G 2 M 8 4 W / 2 4 : T o D 1 1 4

G2 M14 W/8 : To D101 D3 M85 W/20 : Audio unit (With base audio system)

E3 M16 W/16 : To M205 D2 M86 W/16 : Audio unit (With base audio system)

C1 M17 G/40 : BCM (Body control module) D2 M87 W/8 : Audio unit (With base audio system)

C1 M18 B/40 : BCM (Body control module) A3 M89 W/4 : Joint connector-M05

B1 M19 GR/24 : BCM (Body control module) A2 M90 L/4 : Heated steering relay

B1 M20 B/24 : BCM (Body control module) B3 M91 W/12 : Accessory prewire LH

B1 M21 W/15 : BCM (Body control module) F2 M92 W/12 : Accessory prewire RH

B3 M22 W/16 : Data link connector C3 M94 W/4 : Paddle shifter (Shift up)

D4 M23 W/12 : CVT shift selector B3 M95 W/3 : Paddle shifter (Shift down)

C1 M24 W/40 : Combination meter C3 M96 W/20 : AV control unit (With navigation system

without BOSE audio system)

A2 M25 B/4 : Accessory relay-2 C2 M97 W/24 : AV control unit (With navigation system

without BOSE audio system)

B2 M26 W/12 : Combination meter D2 M104 W/4 : Aux in jack

F1 M27 B/4 : Remote keyless entry receiver G1 M107 W/4 : Joint connector-M10

C2 M28 W/16 : Combination switch G2 M108 W/4 : Joint connector-M11

C3 M29 Y/6 : Combination switch (Spiral cable) D2 M109 W/8 : Audio unit (With display audio system

without BOSE audio system)

C3 M30 GR/8 : Combination switch (Spiral cable) A3 M112 W/24 : To D2

E2 M31 W/6 : Blower motor F2 M113 W/4 : Joint connector-M12

G2 M32 Y/4 : To D123 F2 M118 W/4 : Joint connector-M13

E1 M33 W/3 : To M125 D2 M119 W/8 : Audio unit (With display audio system

and BOSE audio system)

C3 M34 W/2 : In-vehicle sensor E1 M125 W/3 : To M33

E5 M35 Y/28 : Air bag diagnosis sensor unit E1 M126 W/3 : Intake door motor

D2 M36 BR/2 : Front passenger air bag off indicator E1 M127 W/3 : Mode door motor

D3 M37 W/16 : Front air control (Without auto A/C) C2 M128 W/3 : Air mix door motor LH

C2 M38 W/8 : Push-button ignition switch E2 M129 W/3 : Air mix door motor RH

A2 M39 Y/4 : To D29 C2 M130 W/3 : Air mix door motor

C2 M40 W/3 : NATS antenna amp. C3 M131 L/5 : AV control unit (With navigation with

BOSE audio system)

E 2 M 4 3 W / 2 0 : Audio unit (With display audio system

without BOSE audio system) D3 M132

L/5 : USB interface

D 2 M 4 4 W / 3 2 : Audio unit (With display audio system

without BOSE audio system) C3 M133 L/5

: Audio unit (With display audio system

without BOSE audio system)

E 3 M 4 5 W / 2 0 : Audio unit (With display audio system

and BOSE audio system) D3 M134

L/5 : AV control unit (With navigation system

without BOSE audio system)

E 2 M 4 6 W / 3 2 : Audio unit (With display audio system

and BOSE audio system) D2 M149

L/5 : Audio unit (With display audio system

and BOSE audio system)

D2 M47 W/4 : Joint connector-M04 D3 M151 W/20 : AV control unit (With navigation system

with BOSE audio system)

E2 M50 W/2 : To M300 E3 M152 W/40 : A/C auto amp.(With auto A/C)

Revision: November 20132014 Altima NAM

Page 3474 of 4801

PG-42

< DTC/CIRCUIT DIAGNOSIS >

HARNESS

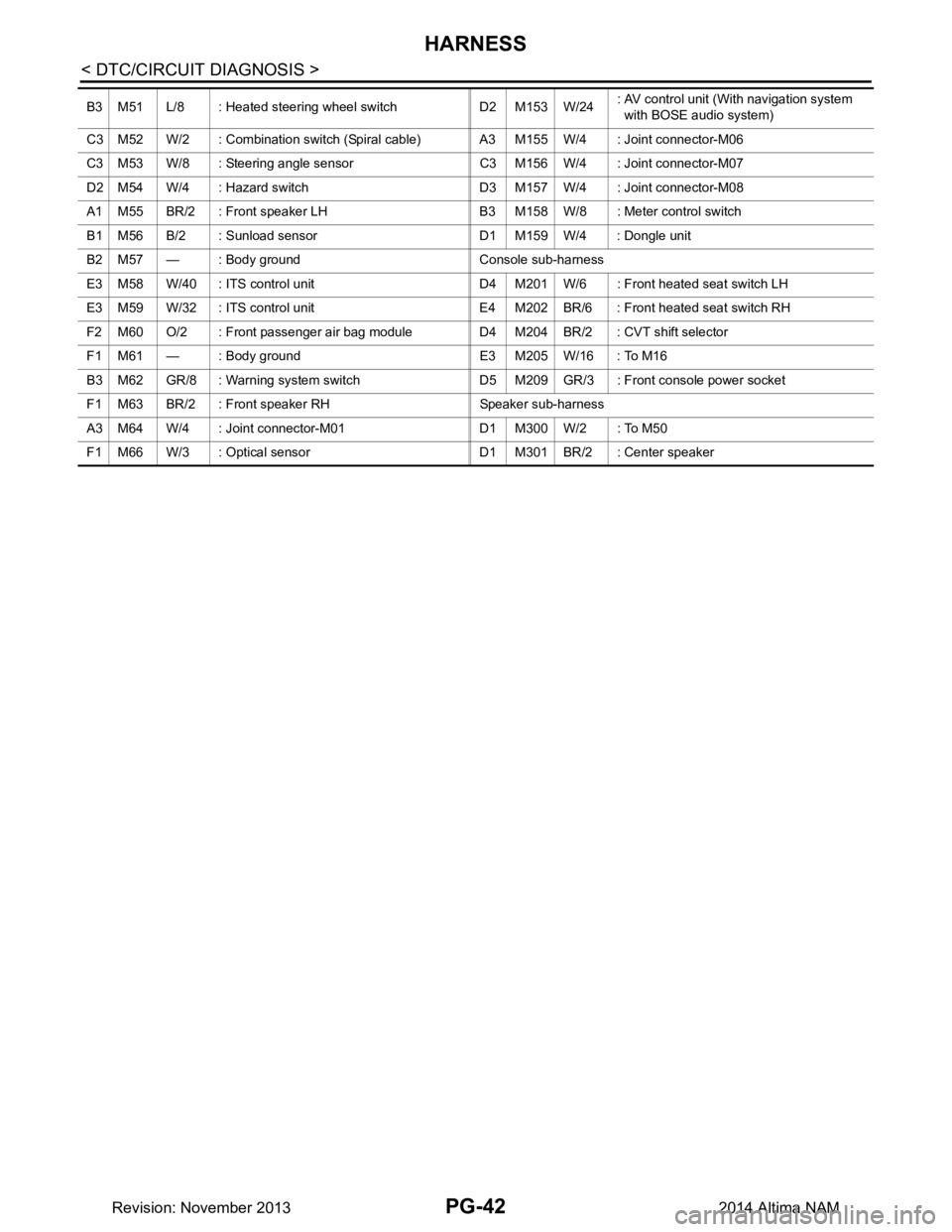

B3 M51 L/8 : Heated steering wheel switch D2 M153 W / 2 4: AV control unit (With navigation system

with BOSE audio system)

C3 M52 W/2 : Combination switch (Spiral cable) A3 M155 W/4 : Joint connector-M06

C3 M53 W/8 : Steering angle sensor C3 M156 W/4 : Joint connector-M07

D2 M54 W/4 : Hazard switch D3 M157 W/4 : Joint connector-M08

A1 M55 BR/2 : Front speaker LH B3 M158 W/8 : Meter control switch

B1 M56 B/2 : Sunload sensor D1 M159 W/4 : Dongle unit

B2 M57 — : Body ground Console sub-harness

E3 M58 W/40 : ITS control unit D4 M201 W/6 : Front heated seat switch LH

E3 M59 W/32 : ITS control unit E4 M202 BR/6 : Front heated seat switch RH

F2 M60 O/2 : Front passenger air bag module D4 M204 BR/2 : CVT shift selector

F1 M61 — : Body ground E3 M205 W / 1 6 : T o M 1 6

B3 M62 GR/8 : Warning system switch D5 M209 GR/3 : Front console power socket

F1 M63 BR/2 : Front speaker RH Speaker sub-harness

A3 M64 W/4 : Joint connector-M01 D1 M300 W / 2 : T o M 5 0

F1 M66 W/3 : Optical sensor D1 M301 BR/2 : Center speaker

Revision: November 20132014 Altima NAM

Page 3481 of 4801

PG

HARNESSPG-49

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B

A

O P

N

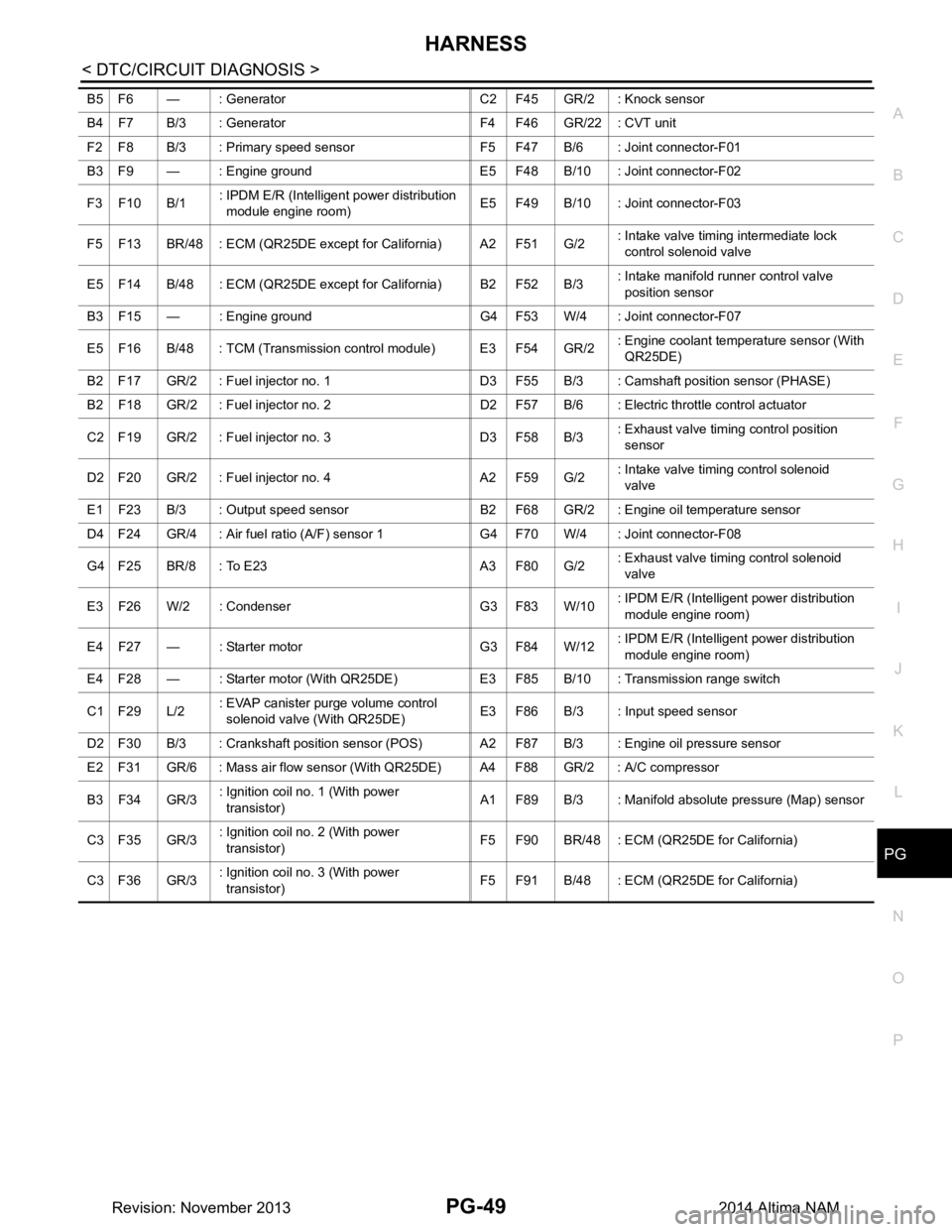

B5 F6 — : Generator C2 F45 GR/2 : Knock sensor

B4 F7 B/3 : Generator F4 F46 GR/22 : CVT unit

F2 F8 B/3 : Primary speed sensor F5 F47 B/6 : Joint connector-F01

B3 F9 — : Engine ground E5 F48 B/10 : Joint connector-F02

F 3 F 1 0 B / 1 : IPDM E/R (Intelligent power distribution

module engine room) E5 F49 B/10 : Joint connector-F03

F 5 F 1 3 B R / 4 8 : E C M ( Q R 2 5 D E e x c e p t f o r C a l i f o r n i a ) A 2 F 5 1 G / 2 : Intake valve timing intermediate lock

control solenoid valve

E5 F14 B/48 : ECM (QR25DE except for California) B2 F52 B/3 : Intake manifold runner control valve

position sensor

B3 F15 — : Engine ground G4 F53 W/4 : Joint connector-F07

E5 F16 B/48 : TCM (Transmission control module) E3 F54 GR/2 : Engine coolant temperature sensor (With

QR25DE)

B2 F17 GR/2 : Fuel injector no. 1 D3 F55 B/3 : Camshaft position sensor (PHASE)

B2 F18 GR/2 : Fuel injector no. 2 D2 F57 B/6 : Electric throttle control actuator

C 2 F 1 9 G R / 2 : F u e l i n j e c t o r n o . 3 D 3 F 5 8 B / 3 : Exhaust valve timing control position

sensor

D 2 F 2 0 G R / 2 : F u e l i n j e c t o r n o . 4 A 2 F 5 9 G / 2 : Intake valve timing control solenoid

valve

E1 F23 B/3 : Output speed sensor B2 F68 GR/2 : Engine oil temperature sensor

D4 F24 GR/4 : Air fuel ratio (A/F) sensor 1 G4 F70 W/4 : Joint connector-F08

G 4 F 2 5 B R / 8 : To E 2 3 A 3 F 8 0 G / 2 : Exhaust valve timing control solenoid

valve

E 3 F 2 6 W / 2 : C o n d e n s e r G 3 F 8 3 W / 1 0 : IPDM E/R (Intelligent power distribution

module engine room)

E 4 F 2 7 — : S t a r t e r m o t o r G 3 F 8 4 W / 1 2 : IPDM E/R (Intelligent power distribution

module engine room)

E4 F28 — : Starter motor (With QR25DE) E3 F85 B/10 : Transmission range switch

C 1 F 2 9 L / 2 : EVAP canister purge volume control

solenoid valve (With QR25DE) E3 F86 B/3 : Input speed sensor

D2 F30 B/3 : Crankshaft position sensor (POS) A2 F87 B/3 : Engine oil pressure sensor

E2 F31 GR/6 : Mass air flow sensor (With QR25DE) A4 F88 GR/2 : A/C compressor

B 3 F 3 4 G R / 3 : Ignition coil no. 1 (With power

transistor) A1 F89 B/3 : Manifold absolute pressure (Map) sensor

C 3 F 3 5 G R / 3 : Ignition coil no. 2 (With power

transistor) F5 F90 BR/48 : ECM (QR25DE for California)

C 3 F 3 6 G R / 3 : Ignition coil no. 3 (With power

transistor) F5 F91 B/48 : ECM (QR25DE for California)

Revision: November 20132014 Altima NAM

Page 3483 of 4801

PG

HARNESSPG-51

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B

A

O P

N

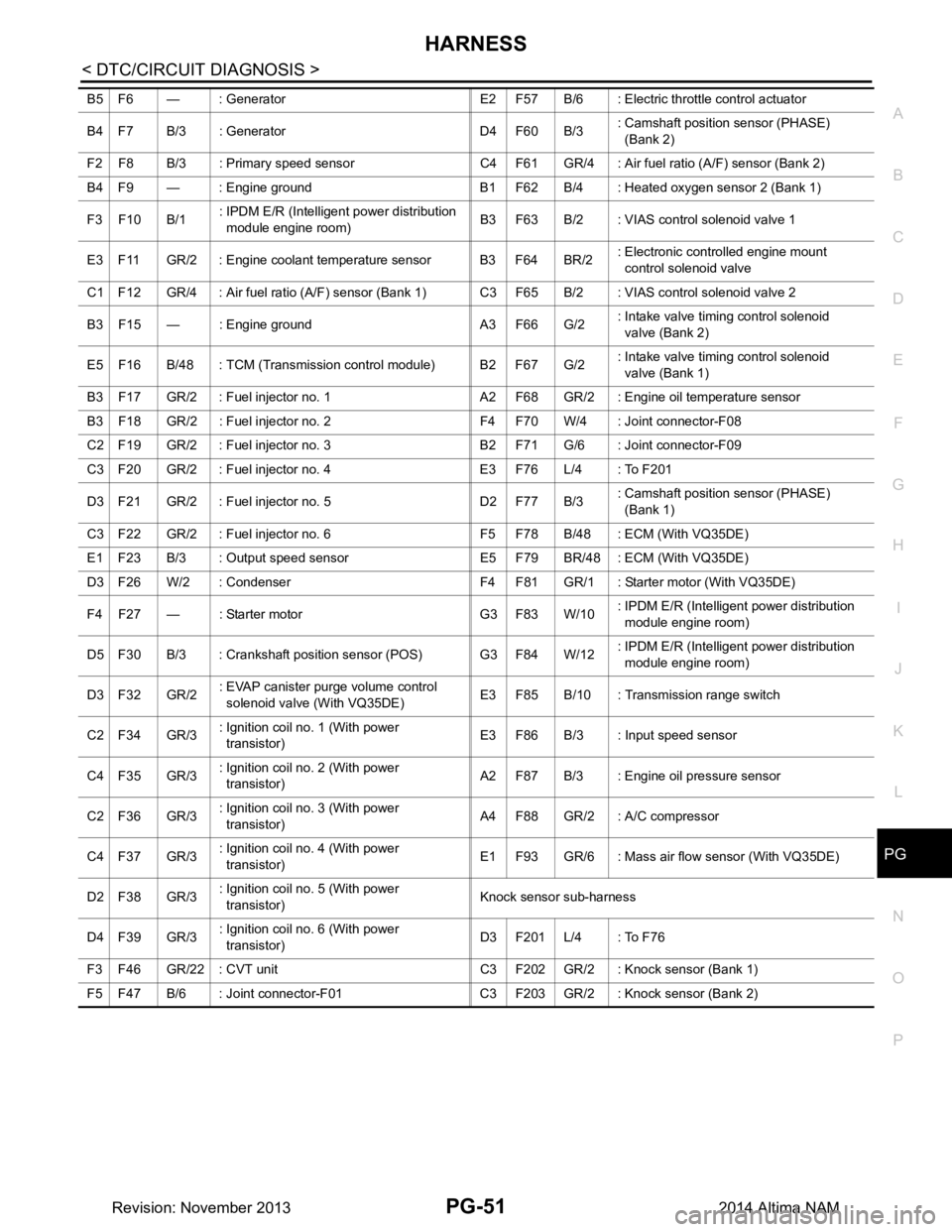

B5 F6 — : Generator E2 F57 B/6 : Electric throttle control actuator

B 4 F 7 B / 3 : G e n e r a t o r D 4 F 6 0 B / 3 : Camshaft position sensor (PHASE)

(Bank 2)

F2 F8 B/3 : Primary speed sensor C4 F61 GR/4 : Air fuel ratio (A/F) sensor (Bank 2)

B4 F9 — : Engine ground B1 F62 B/4 : Heated oxygen sensor 2 (Bank 1)

F 3 F 1 0 B / 1 : IPDM E/R (Intelligent power distribution

module engine room) B3 F63 B/2 : VIAS

control solenoid valve 1

E3 F11 GR/2 : Engine coolant temperature sensor B3 F64 BR/2 : Electronic controlled engine mount

control solenoid valve

C1 F12 GR/4 : Air fuel ratio (A/F) sensor (Ban k 1) C3 F65 B/2 : VIAS control solenoid valve 2

B 3 F 1 5 — : E n g i n e g r o u n d A 3 F 6 6 G / 2 : Intake valve timing control solenoid

valve (Bank 2)

E5 F16 B/48 : TCM (Transmission control module) B2 F67 G/2 : Intake valve timing control solenoid

valve (Bank 1)

B3 F17 GR/2 : Fuel injector no. 1 A2 F68 GR/2 : Engine oil temperature sensor

B3 F18 GR/2 : Fuel injector no. 2 F4 F70 W/4 : Joint connector-F08

C2 F19 GR/2 : Fuel injector no. 3 B2 F71 G/6 : Joint connector-F09

C3 F20 GR/2 : Fuel injector no. 4 E3 F76 L/4 : To F201

D 3 F 2 1 G R / 2 : F u e l i n j e c t o r n o . 5 D 2 F 7 7 B / 3 : Camshaft position sensor (PHASE)

(Bank 1)

C3 F22 GR/2 : Fuel injector no. 6 F5 F78 B/48 : ECM (With VQ35DE)

E1 F23 B/3 : Output speed sensor E5 F79 BR/48 : ECM (With VQ35DE)

D3 F26 W/2 : Condenser F4 F81 GR/1 : Starter motor (With VQ35DE)

F 4 F 2 7 — : S t a r t e r m o t o r G 3 F 8 3 W / 1 0 : IPDM E/R (Intelligent power distribution

module engine room)

D5 F30 B/3 : Crankshaft position sensor (POS) G3 F84 W/12 : IPDM E/R (Intelligent power distribution

module engine room)

D 3 F 3 2 G R / 2 : EVAP canister purge volume control

solenoid valve (With VQ35DE) E3 F85 B/10 : Transmission range switch

C 2 F 3 4 G R / 3 : Ignition coil no. 1 (With power

transistor) E3 F86 B/3 : Input speed sensor

C 4 F 3 5 G R / 3 : Ignition coil no. 2 (With power

transistor) A2 F87 B/3 : Engine oil pressure sensor

C 2 F 3 6 G R / 3 : Ignition coil no. 3 (With power

transistor) A 4 F 8 8 G R / 2 : A / C c o m p r e s s o r

C 4 F 3 7 G R / 3 : Ignition coil no. 4 (With power

transistor) E1 F93 GR/6 : Mass air flow sensor (With VQ35DE)

D 2 F 3 8 G R / 3 : Ignition coil no. 5 (With power

transistor) Knock sensor sub-harness

D 4 F 3 9 G R / 3 : Ignition coil no. 6 (With power

transistor) D 3 F 2 0 1 L / 4 : T o F 7 6

F3 F46 GR/22 : CVT unit C3 F202 GR/2 : Knock sensor (Bank 1)

F5 F47 B/6 : Joint connector-F01 C3 F203 GR/2 : Knock sensor (Bank 2)

Revision: November 20132014 Altima NAM

Page 3701 of 4801

RF-36

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise. Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to RF-37, "Generic Squeak and Rattle Troubleshooting"

.

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISS AN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50 ×50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movemen t is present. Ideal for instrument panel applications.

SILICONE GREASE

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3767 of 4801

SE-18

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or lo cation of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on CVT and A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pi npoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from. Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be

broken or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to SE-18, "Generic Squeak and Rattle Troubleshooting"

.

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-50397) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

• Always check with the Parts Department for the latest parts information.

• The materials contained in the NISSAN Squeak and Rattle Kit (J-50397) are listed on the inside cover of the

kit; and can each be ordered seperately as needed.

• The following materials not found in the kit can also be used to repair squeaks and rattles.

- SILICONE GREASE: Use instead of UHMW tape that will be visible or does not fit. The silicone grease will

only last a few months.

- SILICONE SPRAY: Use when grease cannot be applied.

- DUCT TAPE: Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000009895316

Refer to Table of Contents for specific component removal and installation information.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3780 of 4801

FRONT SEATSE-31

< REMOVAL AND INSTALLATION >

C

D E

F

G H

I

K L

M A

B

SE

N

O P

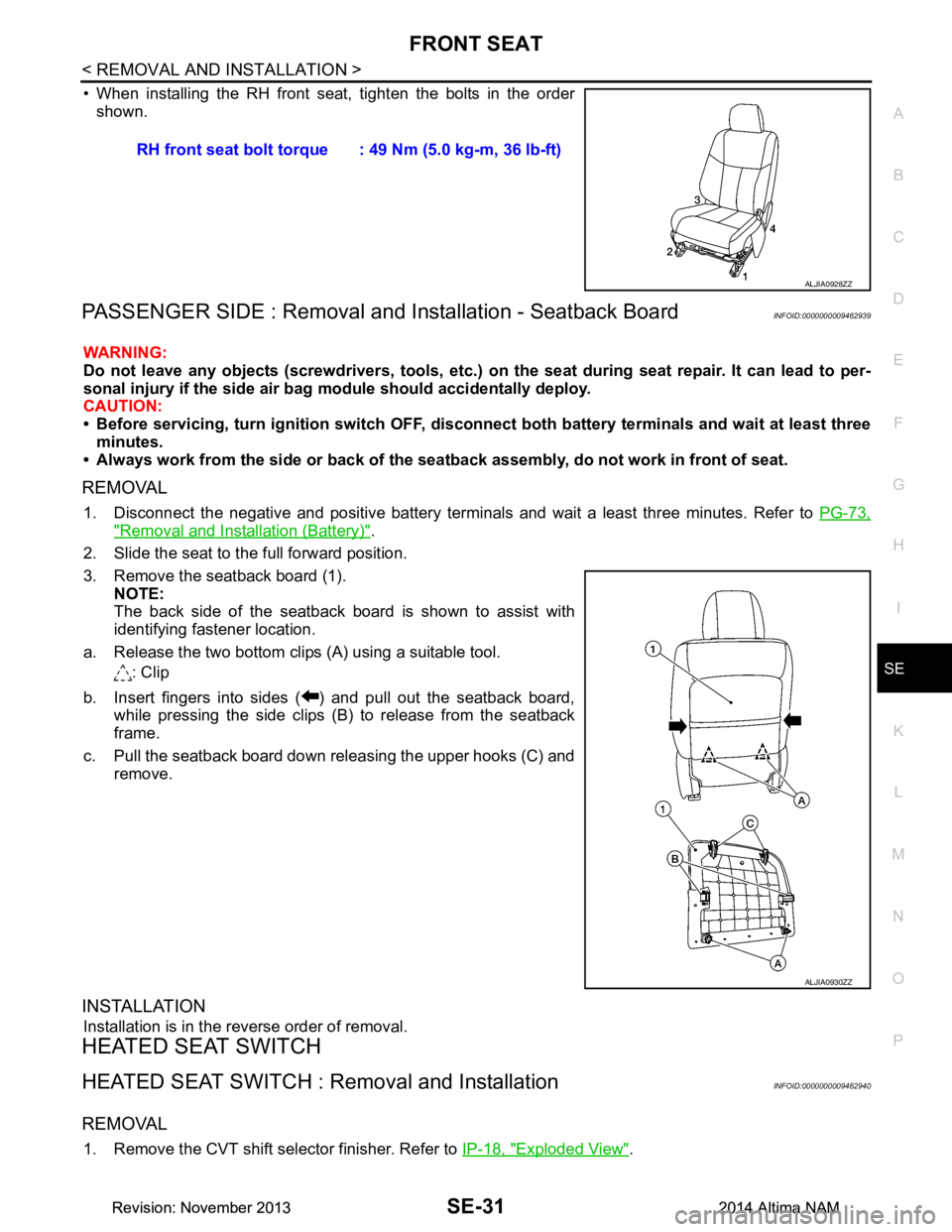

• When installing the RH front seat, tighten the bolts in the order shown.

PASSENGER SIDE : Removal and In stallation - Seatback BoardINFOID:0000000009462939

WARNING:

Do not leave any objects (screwdriver s, tools, etc.) on the seat during seat repair. It can lead to per-

sonal injury if the side air bag module should accidentally deploy.

CAUTION:

• Before servicing, turn ignition swit ch OFF, disconnect both battery terminals and wait at least three

minutes.

• Always work from the side or back of the seat back assembly, do not work in front of seat.

REMOVAL

1. Disconnect the negative and positive battery terminals and wait a least three minutes. Refer to PG-73,

"Removal and Installation (Battery)".

2. Slide the seat to the full forward position.

3. Remove the seatback board (1). NOTE:

The back side of the seatback boar d is shown to assist with

identifying fastener location.

a. Release the two bottom clips (A) using a suitable tool. : Clip

b. Insert fingers into sides ( ) and pull out the seatback board, while pressing the side clips (B) to release from the seatback

frame.

c. Pull the seatback board down releasing the upper hooks (C) and remove.

INSTALLATION

Installation is in the reverse order of removal.

HEATED SEAT SWITCH

HEATED SEAT SWITCH : Removal and InstallationINFOID:0000000009462940

REMOVAL

1. Remove the CVT shift selector finisher. Refer to IP-18, "Exploded View".

RH front seat bolt torque : 49 Nm (5.0 kg-m, 36 lb-ft)

ALJIA0928ZZ

ALJIA0930ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3826 of 4801

SEC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D E

F

G H

I

J

L

M

SECTION SEC

A

B

SEC

N

O P

CONTENTS

SECURITY CONTROL SYSTEM

PRECAUTION ................ ...............................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................8

CVT Shift Selector (Park Position Switch) ................8

BCM ..........................................................................8

ECM ..........................................................................8

IPDM E/R ..................................................................9

NATS Antenna Amp. .................................................9

TCM ..........................................................................9

Combination Meter ....................................................9

Door Switch ...............................................................9

Outside Key Antenna ................................................9

Hood Switch ..............................................................9

Inside Key Antenna ...................................................9

Remote Keyless Entry Receiver ...............................9

Intelligent Key ............................................................9

Push-button Ignition Switch .....................................10

Security Indicator Lamp ...................................... ....10

Starter Control Relay ...............................................10

Starter Relay ...........................................................10

Stop Lamp Switch ...................................................10

Transmission Range Switch ....................................10

Vehicle Information Display .....................................10

SYSTEM .............................................................11

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION ............................................................. ....

11

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION : System Diagram ............................ ....

11

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION : System Description ........................ ....

11

NISSAN VEHICLE IMMOBILIZER SYSTEM-NATS ....13

NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS : System Diagram ..................................... ....

14

NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS : System Description ................................. ....

14

VEHICLE SECURITY SYSTEM .................................16

VEHICLE SECURITY SYSTEM : System Dia-

gram .................................................................... ....

16

VEHICLE SECURITY SYSTEM : System Descrip-

tion ....................................................................... ....

16

DIAGNOSIS SYSTEM (BCM) ...........................20

COMMON ITEM ..................................................... ....20

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) ................................................. ....

20

INTELLIGENT KEY ................................................ ....21

INTELLIGENT KEY : CONSULT Function (BCM -

INTELLIGENT KEY) ........... .....................................

21

THEFT ALM ........................................................... ....24

THEFT ALM : CONSULT Function (BCM - THEFT

ALM) .................................................................... ....

24

IMMU ...................................................................... ....25

IMMU : CONSULT Function (BCM - IMMU) ............25

DIAGNOSIS SYSTEM (IPDM E/R) ...................26

CONSULT Function (IPDM E/R) .............................26

ECU DIAGNOSIS INFORMATION ..............28

ECM, IPDM E/R, BCM .......................................28

List of ECU Reference ......................................... ....28

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM