Its control NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 172 of 4801

![NISSAN TEANA 2014 User Guide

BRC-26

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

SYSTEM

• Wheel spin status of drive wheel is detected by wheel sensor of 4

wheels. Engine output and transmission shift status is controlled

so that slip NISSAN TEANA 2014 User Guide

BRC-26

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

SYSTEM

• Wheel spin status of drive wheel is detected by wheel sensor of 4

wheels. Engine output and transmission shift status is controlled

so that slip](/img/5/57390/w960_57390-171.png)

BRC-26

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

SYSTEM

• Wheel spin status of drive wheel is detected by wheel sensor of 4

wheels. Engine output and transmission shift status is controlled

so that slip rate of drive wheels is in appropriate level. When wheel

spin occurs on drive wheel, ABS actuator and electric unit (control

unit) perform brake force control of LH and RH drive wheels (apply

brake force by increasing brake fluid pressure of drive wheel) and

decrease engine torque by engine torque control. Wheel spin

amount decreases. Engine torque is controlled to appropriate

level.

• TCS function can be switched to non-operational status (OFF) by operating VDC OFF switch. In this case, VDC OFF indicator lamp

turns ON.

• SLIP indicator lamp blinks while TCS function is in operation and

indicates to the driver that the function is in operation.

• CONSULT can be used to diagnose the system.

• Fail-safe function is adopted. When a malfunction occurs in TCS

function, the control is sus pended for VDC function and TCS func-

tion. However, ABS function and EBD function operate normally.

Refer to BRC-41, "Fail-safe"

.

INPUT SIGNAL AND OUTPUT SIGNAL

Major signal transmission between each unit via communication lines is shown in the following table.

JPFIC0139GB

Component Signal description

ECM Transmits the following signals to ABS actuator and electric unit (control unit) via CAN commu-

nication.

• Accelerator pedal position signal

• Engine speed signal

• Target throttle position signal

TCM Transmits the current gear positi

on signal to ABS actuator and el ectric unit (control unit) via

CAN communication.

Steering angle sensor Transmits the steering angle sensor signal to ABS actuator and electric unit (control unit) via

CAN communication.

Combination meter Transmits the following signals to ABS actuator and electric unit (control unit) via CAN commu-

nication.

• Brake fluid level switch signal

• Parking brake switch signal

Receives the following signals from ABS actuator and electric unit (control unit) via CAN com-

munication.

• VDC OFF indicator lamp signal

• SLIP indicator lamp signal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 173 of 4801

![NISSAN TEANA 2014 User Guide

SYSTEMBRC-27

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VDC/TCS/ABS : ABS FunctionINFOID:0000000009463755

SYSTEM DIAGRAM

• By preventing wheel lock through brake force NISSAN TEANA 2014 User Guide

SYSTEMBRC-27

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VDC/TCS/ABS : ABS FunctionINFOID:0000000009463755

SYSTEM DIAGRAM

• By preventing wheel lock through brake force](/img/5/57390/w960_57390-172.png)

SYSTEMBRC-27

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VDC/TCS/ABS : ABS FunctionINFOID:0000000009463755

SYSTEM DIAGRAM

• By preventing wheel lock through brake force (brake flui d pressure) control that is electronically controlled by

detecting wheel speed during braking, stability during em ergency braking is improved so that obstacles can

be avoided by steering operation.

• During braking, control units calculate wheel speeds , and transmit pressure increase, hold or decrease sig-

nals to actuator portion according to wheel slip status.

• The following effects are obtained by preventing wheel lock during braking.

- Vehicle tail slip is prevented during braking when driving straight.

- Understeer and oversteer tendencie s are moderated during brak-

ing while cornering.

- Obstacles may be easily bypassed by steering operation during

braking.

• CONSULT can be used to diagnose the system.

• Fail-safe function is adopted. When a malfunction occurs in ABS

function, the control is suspended for VDC function, TCS function

and ABS function. However, EBD function operates normally.

Refer to BRC-29, "VDC/TCS/ABS : Fail-safe"

.

INPUT SIGNAL AND OUTPUT SIGNAL

ALFIA0297GB

JPFIC0140GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 175 of 4801

![NISSAN TEANA 2014 User Guide

SYSTEMBRC-29

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

• During braking, control unit portion compares slight slip on front and rear wheels by wheel sensor signal, tr NISSAN TEANA 2014 User Guide

SYSTEMBRC-29

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

• During braking, control unit portion compares slight slip on front and rear wheels by wheel sensor signal, tr](/img/5/57390/w960_57390-174.png)

SYSTEMBRC-29

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

• During braking, control unit portion compares slight slip on front and rear wheels by wheel sensor signal, transmits drive signal to

actuator portion when rear wheel sl ip exceeds front wheel slip for

the specified value or more, and controls rear wheel brake force

(brake fluid pressure) so that increase of rear wheel slip is pre-

vented and slips on front wheel and rear wheel are nearly equal-

ized. ABS control is applied when slip on each wheel increases

and wheel speed is the threshold value of ABS control or less.

• CONSULT can be used to diagnose the system.

• Fail-safe function is adopted. When a malfunction occurs in EBD function, the control is suspended for VDC function, TCS function,

ABS function and EBD function. Refer to BRC-29, "VDC/TCS/ABS

: Fail-safe".

INPUT SIGNAL AND OUTPUT SIGNAL

Major signal transmission between each unit via communication lines is shown in the following table.

VDC/TCS/ABS : Fail-safeINFOID:0000000009463757

VDC AND TCS FUNCTIONS

VDC warning lamp in combination meter turns ON when a malfunction occurs in system [ABS actuator and

electric unit (control unit)]. The control is su spended for VDC and TCS functions. However, ABS and EBD

functions operate normally.

ABS FUNCTION

ABS warning lamp and SLIP indicator lamp in combination meter turn ON when a malfunction occurs in sys-

tem [ABS actuator and electric unit (control unit)]. The control is suspended for VDC, TCS and ABS functions.

However, EBD functions operate normally.

EBD FUNCTION

ABS warning lamp, brake warning lamp and SLIP indicator lamp in combination meter turn ON when a mal-

function occurs in system [ABS actuator and electric unit (control unit)]. The control is suspended for VDC,

TCS, ABS and EBD functions.

JPFIC0143GB

Component Signal description

Combination meter Receives the following signals from ABS actuator and electric unit (control unit) via CAN com-

munication.

• ABS warning lamp signal

• Brake warning lamp signal

• SLIP indicator lamp signal

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 182 of 4801

![NISSAN TEANA 2014 User Guide

BRC-36

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

ACTIVE TEST

The active test is used to determine and identify details of a malfunction, NISSAN TEANA 2014 User Guide

BRC-36

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

ACTIVE TEST

The active test is used to determine and identify details of a malfunction,](/img/5/57390/w960_57390-181.png)

BRC-36

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

DIAGNOSIS SYSTEM [

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)]

ACTIVE TEST

The active test is used to determine and identify details of a malfunction, based on self-diagnosis test results

and data obtained in the DATA MONITOR. In response to instructions from CONSULT, instead of those from

ABS actuator and electric unit (control unit) on the vehicle, a drive signal is sent to the actuator to check its

operation.

CAUTION:

• Never perform ACTIVE TEST while driving the vehicle.

• Always bleed air from brake system before active test.

• Never perform active test when system is malfunctioning.

NOTE:

• When active test is performed while depressing the pedal, the pedal depressing stroke may change. This is not a malfunction.

• “TEST IS STOPPED” is displayed approx. 10 seconds after operation start.

• When performing active test again after “TEST IS STOPPED” is displayed, select “BACK”.

• ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON during active test. This is not a malfunction.

ABS IN Valve and ABS OUT Valve

When “Up”, “Keep” or “Down” is selected on display sc reen, the following items are displayed when system is

normal.

*: Immediately after being selected, status is “O n”. Status changes to “Off” after approx. 2 seconds.

ABS IN Valve (ACT) and ABS OUT Valve (ACT)

When “Up”, “ACT UP” or “ACT KEEP” is selected on di splay screen, the following items are displayed when

system is normal.

Test item Display Item Display

Up Keep Down

FR RH SOL FR RH IN SOL Off On* On*

FR RH OUT SOL Off Off On*

FR LH SOL FR LH IN SOL Off On* On*

FR LH OUT SOL Off Off On*

RR RH SOL RR RH IN SOL Off On* On*

RR RH OUT SOL Off Off On*

RR LH SOL RR LH IN SOL Off On* On*

RR LH OUT SOL Off Off On*

Test item Display Item Display

Up ACT UP ACT KEEP

FR RH SOLENOID

(ACT) FR RH IN SOL Off Off Off

FR RH OUT SOL Off Off Off

CV1 Off Off Off

CV2 Off On* On*

FR LH SOLENOID

(ACT) FR LH IN SOL Off Off Off

FR LH OUT SOL Off Off Off

CV1 Off On* On*

CV2 Off Off Off

RR RH SOLENOID

(ACT) RR RH IN SOL Off Off Off

RR RH OUT SOL Off Off Off

CV1 Off On* On*

CV2 Off Off Off

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 206 of 4801

![NISSAN TEANA 2014 User Guide

BRC-60

< BASIC INSPECTION >[VDC/TCS/ABS]

CONFIGURATION [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)]

CONFIGURATION [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL

UNIT)]

Work ProcedureINFOID:000000000946 NISSAN TEANA 2014 User Guide

BRC-60

< BASIC INSPECTION >[VDC/TCS/ABS]

CONFIGURATION [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)]

CONFIGURATION [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL

UNIT)]

Work ProcedureINFOID:000000000946](/img/5/57390/w960_57390-205.png)

BRC-60

< BASIC INSPECTION >[VDC/TCS/ABS]

CONFIGURATION [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)]

CONFIGURATION [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL

UNIT)]

Work ProcedureINFOID:0000000009463769

CAUTION:

• Use “Manual Configuration” only when “TYPE ID” of ABS actuator an d electric unit (control unit)

cannot be read.

• After configuration, turn the ignition switch from OFF to ON and check that the VDC warning lamp

turns OFF after staying illuminated for approximately two seconds.

• If an error occurs during configurat ion, start over from the beginning.

1.CHECKING TYPE ID (1)

Use FAST (service parts catalogue) to search ABS ac tuator and electric unit (control unit) of the applicable

vehicle and find “Type ID”.

Is

“Type ID” displayed?

YES >> Print out “Type ID” and GO TO 2.

NO >> “Configuration” is not required for ABS actuat or and electric unit (control unit). Replace in the

usual manner. Refer to BRC-128, "Removal and Installation"

.

2.CHECKING TYPE ID (2)

CONSULT Configuration

1. Select “Before Replace ECU” of “Read/Write Configuration”.

2. Check that “Type ID” is displayed on the CONSULT screen.

Is

“Type ID” displayed?

YES >> GO TO 3.

NO >> GO TO 7.

3.VERIFYING TYPE ID (1)

CONSULT Configuration

Compare a “Type ID” displayed on the CONSULT screen with the one searched by using FAST (service parts

catalogue) to check that these “Type ID” agree with each other.

NOTE:

For the “Type ID” searched by using FA ST (service parts catalog), use the last five digits of the “Type ID”.

>> GO TO 4.

4.SAVING TYPE ID

CONSULT Configuration

Save “Type ID” on CONSULT.

>> GO TO 5.

5.REPLACING ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) (1)

Replace ABS actuator and electric unit (control unit). Refer to BRC-128, "Removal and Installation"

.

CAUTION:

Never perform the following work items:

• Air bleeding

>> GO TO 6.

6.WRITING (AUTOMATIC WRITING)

CONSULT Configuration

1. Select “After Replace ECU” of “R e/programming, Configuration” or that of “Read / Write Configuration”.

2. Select the “Type ID” agreeing with the one stored on CONSULT and the one searched by using FAST (service parts catalogue) to write the “Type ID” in to the ABS actuator and electric unit (control unit).

NOTE:

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 207 of 4801

![NISSAN TEANA 2014 User Guide

CONFIGURATION [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)]

BRC-61

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

For the “Type ID” searched by using FAST (service parts NISSAN TEANA 2014 User Guide

CONFIGURATION [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)]

BRC-61

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

For the “Type ID” searched by using FAST (service parts](/img/5/57390/w960_57390-206.png)

CONFIGURATION [ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)]

BRC-61

< BASIC INSPECTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

For the “Type ID” searched by using FAST (service parts catalog), use the last five digits of the “Type ID”.

>> GO TO 9.

7.REPLACING ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) (2)

Replace ABS actuator and electric unit (control unit). Refer to BRC-128, "Removal and Installation"

.

CAUTION:

Never perform the following work items:

• Air bleeding

>> GO TO 8.

8.WRITING (MANUAL WRITING)

CONSULT Configuration

1. Select “Manual Configuration”.

2. Select the “Type ID” searched by using FAST (service parts catalogue) to write the “Type ID” into the ABS

actuator and electric unit (control unit).

NOTE:

For the “Type ID” searched by using FAST (service parts catalog), use the last five digits of the “Type ID”.

>> GO TO 9.

9.VERIFYING TYPE ID (2)

Compare “Type ID” written into the ABS actuator and el ectric unit (control unit) with the one searched by using

FAST (service parts catalogue) to check that these “Type ID” agree with each other.

NOTE:

For the “Type ID” searched by using FAST (service parts catalog), use the last five digits of the “Type ID”.

>> GO TO 10.

10.CHECKING VDC WARNING LAMP

1. Turn the ignition switch OFF.

2. Turn the ignition switch ON and check that the VDC warning lamp turns OFF after staying illuminated for

approximately two seconds.

CAUTION:

Never start the engine.

Is the inspection result normal?

YES >> GO TO 11.

NO >> Perform the self-diagnosis of “ABS”. Refer to BRC-33, "CONSULT Function (ABS)"

.

11 .PERFORMING SUPPLEMENTARY WORK

1. Perform the air bleeding. Refer to BR-14, "Bleeding Brake System"

.

2. Perform the self-diagnosis of all systems.

3. Erase self-diagnosis results.

>> End of work.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 212 of 4801

![NISSAN TEANA 2014 User Guide

BRC-66

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1101, C1102, C1103,

C1104 WHEEL SENSOR

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair the circuit.

7.CHECK WIRING HARNESS FO R SHORT BE NISSAN TEANA 2014 User Guide

BRC-66

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1101, C1102, C1103,

C1104 WHEEL SENSOR

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair the circuit.

7.CHECK WIRING HARNESS FO R SHORT BE](/img/5/57390/w960_57390-211.png)

BRC-66

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1101, C1102, C1103,

C1104 WHEEL SENSOR

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair the circuit.

7.CHECK WIRING HARNESS FO R SHORT BETWEEN CIRCUITS

Check continuity between wheel sensor harness connector terminals of suspect wheel.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair the circuit.

8.CHECK WIRING HARNESS FOR OPEN CIRCUIT

Check continuity between ABS actuator and electric unit (control unit) connector E54 and wheel sensor con-

nector of wheel with DTC.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair the circuit.

9.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between ABS actuator and electric uni t (control unit) harness connector E54 terminal and

ground.

Front LH E19 1

—No

2

Front RH E11 1

2

Rear LH C2 1

2

Rear RH C3 1

2

Wheel Sensor (+) (-) Continuity

Wheel Connector Terminal Terminal

Front LH E19

12No

Front RH E41

Rear LH C2

Rear RH C3

Wheel sensor ABS actuator and electric unit (c

ontrol unit) Wheel sensor Continuity

Connector Terminal Connector Terminal

Ye s

Front LH

E548

E19 2

19 1

Front RH 4

E41 2

16 1

Rear LH 18

C2 2

31 1

Rear RH 29

C3 2

17 1

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 380 of 4801

CHG

SERVICE DATA AND SPECIFICATIONS (SDS)CHG-35

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

B

A

O P

N

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

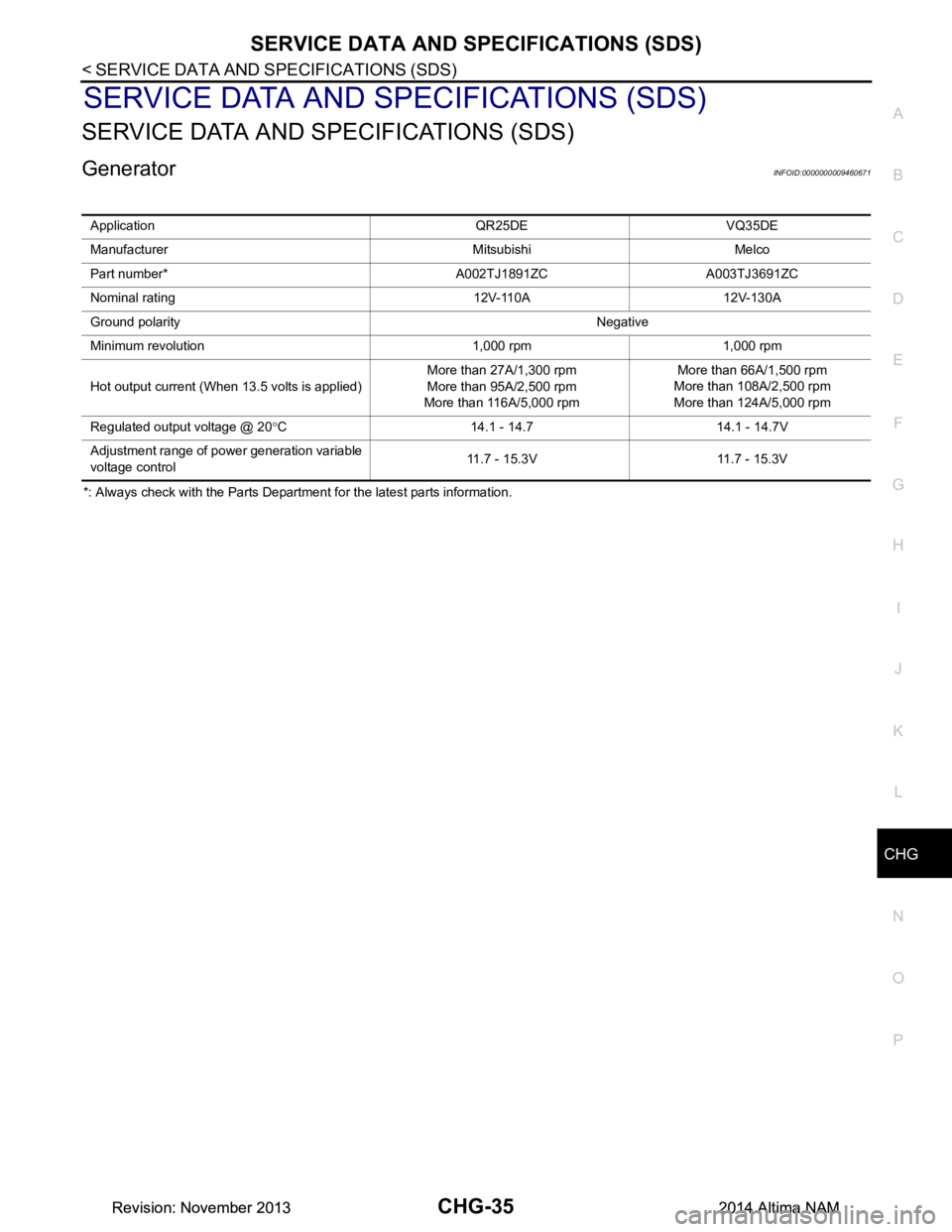

GeneratorINFOID:0000000009460671

*: Always check with the Parts Department for the latest parts information. Application QR25DE VQ35DE

Manufacturer Mitsubishi Melco

Part number* A002TJ1891ZC A003TJ3691ZC

Nominal rating 12V-110A 12V-130A

Ground polarity Negative

Minimum revolution 1,000 rpm 1,000 rpm

Hot output current (When 13.5 volts is applied) More than 27A/1,300 rpm

More than 95A/2,500 rpm

More than 116A/5,000 rpm More than 66A/1,500 rpm

More than 108A/2,500 rpm

More than 124A/5,000 rpm

Regulated output voltage @ 20 °C 14.1 - 14.7 14.1 - 14.7V

Adjustment range of power generation variable

voltage control 11.7 - 15.3V 11.7 - 15.3V

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 425 of 4801

![NISSAN TEANA 2014 User Guide

WATER PUMPCO-45

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

4. Remove cowl top extension. Refer to

EXT-24, "Removal and Installation".

5. Remove the front road wheel and t NISSAN TEANA 2014 User Guide

WATER PUMPCO-45

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

4. Remove cowl top extension. Refer to

EXT-24, "Removal and Installation".

5. Remove the front road wheel and t](/img/5/57390/w960_57390-424.png)

WATER PUMPCO-45

< REMOVAL AND INSTALLATION > [VQ35DE]

C

D E

F

G H

I

J

K L

M A

CO

NP

O

4. Remove cowl top extension. Refer to

EXT-24, "Removal and Installation".

5. Remove the front road wheel and tire (RH). Refer to WT-55, "Adjustment"

.

6. Remove the fender protector (RH). Refer to EXT-26, "FENDER PROTECTOR : Removal and Installation"

.

7. Drain coolant from the radiator. Refer to CO-36, "Changing Engine Coolant"

.

CAUTION:

Perform when the engine is cold.

8. Disconnect coolant reservoir hose and remove coolant reservoir tank. Refer to CO-40, "Exploded View"

.

9. Drain the power steering fluid reservoir. Refer to ST-30, "Draining and Refilling"

.

10. Remove the power steering oil pump. Refer to ST-38, "Removal and Installation"

.

11. Support engine and remove the RH engine insulator and bracket. Refer to EM-220, "Exploded View"

.

12. Set No. 1 cylinder at TDC on its compression stroke. • Align pointer with TDC mark on crankshaft pulley.

13. Remove drive belt. Refer to EM-134, "Removal and Installation"

.

14. Remove the drive belt auto-tensioner assembly. Refer to EM-135, "Removal and Installation of Drive Belt

Auto-tensioner".

15. Remove water drain plug (A) and copper sealing washer (B) to drain coolant from engine.

CAUTION:

Do not reuse copper sealing washers.

16. Disconnect RH valve timing control connectors and remo ve valve timing control cover (bank 1). Refer to

EM-182, "Exploded View"

.

17. Remove water pump cover. Refer to CO-44, "Exploded View"

.

18. Remove the timing chain tensioner (primary) as follows:

a. Pull the lever (C) down to release the plunger stopper tab (B).

b. Insert the stopper pin A into the tensioner body hole to hold the lever (C) and keep the plunger stopper tab (B) released.

NOTE:

An allen wrench [(1.2 mm (0.047 in)] is used for a stopper pin A

as an example.

c. Compress the plunger (D) into the tensioner body (1) by press- ing the slack guide (2).

d. Keep the slack guide (2) pressed and lock the plunger (D) in by pushing the stopper pin A through the lever (C) and into the

chain tensioner body hole.

e. Remove timing chain tensioner bolts and then remove the timing chain tensioner. CAUTION:

Be careful not to drop timing chain te nsioner bolts inside timing chain case.

19. Remove the three water pump bolts (A). Make a gap between water pump sprocket (1) and timing chain, by carefully turning

crankshaft pulley (2) counterclockwise until timing chain loosens

on water pump sprocket (1).

: Front

AWBIA1202GB

AWBIA0903ZZ

AWBIA0904ZZ

Revision: November 20132014 Altima NAM

Page 434 of 4801

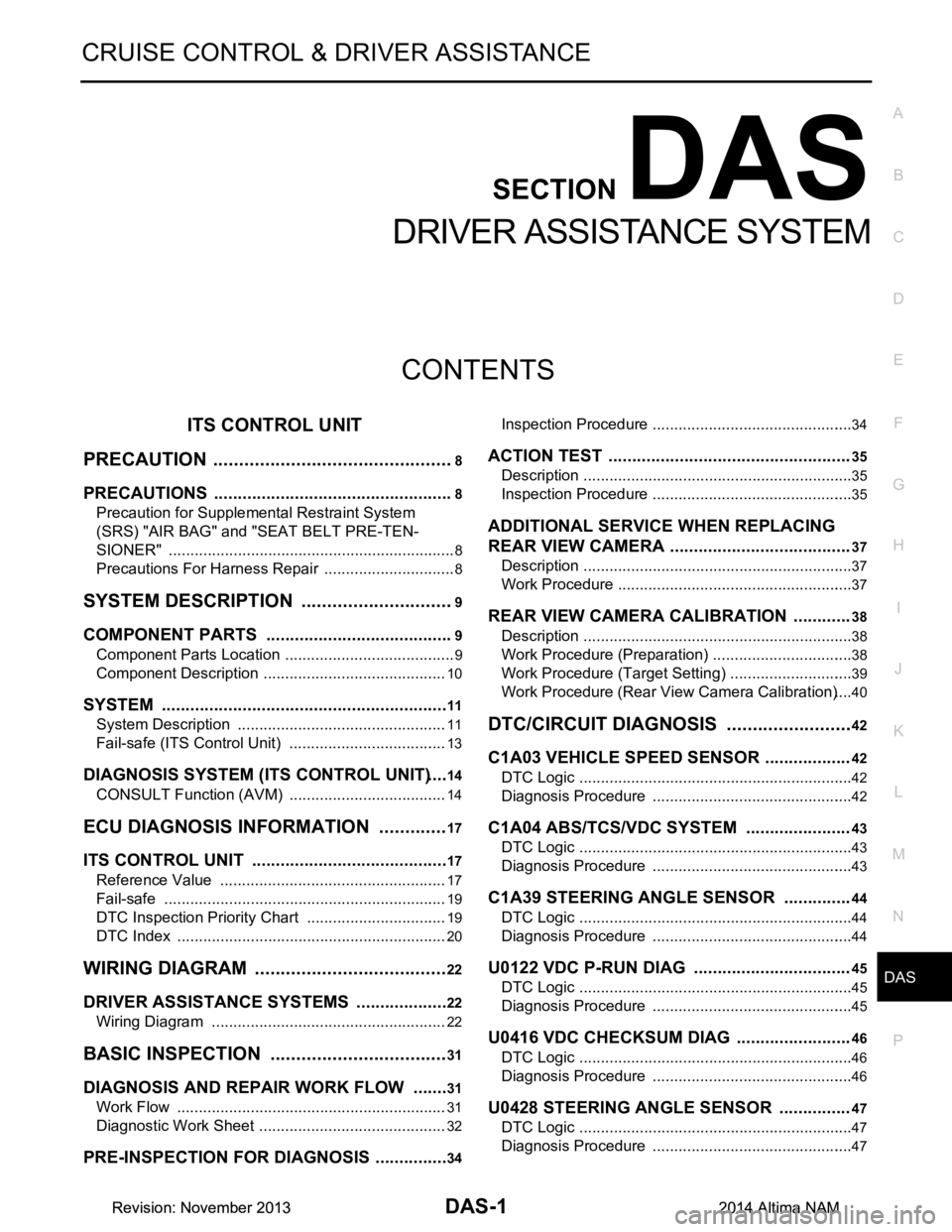

DAS-1

CRUISE CONTROL & DRIVER ASSISTANCE

C

D E

F

G H

I

J

K L

M B

DAS

SECTION DAS

N

P

A

CONTENTS

DRIVER ASSISTANCE SYSTEM

ITS CONTROL UNIT

PRECAUTION ................ ...............................

8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

Precautions For Harness Repair ...............................8

SYSTEM DESCRIPTION . .............................9

COMPONENT PARTS ................................... .....9

Component Parts Location .................................. ......9

Component Description ...........................................10

SYSTEM .............................................................11

System Description ............................................. ....11

Fail-safe (ITS Control Unit) .....................................13

DIAGNOSIS SYSTEM (ITS CONTROL UNIT) ....14

CONSULT Function (AVM) ................................. ....14

ECU DIAGNOSIS INFORMATION ..............17

ITS CONTROL UNIT ...................................... ....17

Reference Value ................................................. ....17

Fail-safe ..................................................................19

DTC Inspection Priority Chart ............................. ....19

DTC Index ........................................................... ....20

WIRING DIAGRAM ......................................22

DRIVER ASSISTANCE SYSTEMS ................ ....22

Wiring Diagram ................................................... ....22

BASIC INSPECTION ...................................31

DIAGNOSIS AND REPAIR WORK FLOW .... ....31

Work Flow ........................................................... ....31

Diagnostic Work Sheet ............................................32

PRE-INSPECTION FOR DIAGNOSIS ................34

Inspection Procedure ........................................... ....34

ACTION TEST ...................................................35

Description ...............................................................35

Inspection Procedure ...............................................35

ADDITIONAL SERVICE WHEN REPLACING

REAR VIEW CAMERA ......................................

37

Description ........................................................... ....37

Work Procedure .......................................................37

REAR VIEW CAMERA CALIBRATION ............38

Description ...............................................................38

Work Procedure (Preparation) .................................38

Work Procedure (Target Setting) .............................39

Work Procedure (Rear View Camera Calibration) ....40

DTC/CIRCUIT DIAGNOSIS .........................42

C1A03 VEHICLE SPEED SENSOR ..................42

DTC Logic ............................................................ ....42

Diagnosis Procedure ...............................................42

C1A04 ABS/TCS/VDC SYSTEM ......................43

DTC Logic ................................................................43

Diagnosis Procedure ...............................................43

C1A39 STEERING ANGLE SENSOR ..............44

DTC Logic ................................................................44

Diagnosis Procedure ...............................................44

U0122 VDC P-RUN DIAG .................................45

DTC Logic ............................................................ ....45

Diagnosis Procedure ...............................................45

U0416 VDC CHECKSUM DIAG ........................46

DTC Logic ................................................................46

Diagnosis Procedure ...............................................46

U0428 STEERING ANGLE SENSOR ...............47

DTC Logic ................................................................47

Diagnosis Procedure ...............................................47

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM