Pressure NISSAN TEANA 2014 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 68 of 4801

![NISSAN TEANA 2014 User Guide

BCS

BCM (BODY CONTROL MODULE)BCS-53

< ECU DIAGNOSIS INFORMATION > [BCM]

C

D E

F

G H

I

J

K L

B

A

O P

N

B2196: DONGLE UNIT — — —

SEC-90, "Description"

B2198: NATS ANTENNA AMP. — — — SEC-9 NISSAN TEANA 2014 User Guide

BCS

BCM (BODY CONTROL MODULE)BCS-53

< ECU DIAGNOSIS INFORMATION > [BCM]

C

D E

F

G H

I

J

K L

B

A

O P

N

B2196: DONGLE UNIT — — —

SEC-90, "Description"

B2198: NATS ANTENNA AMP. — — — SEC-9](/img/5/57390/w960_57390-67.png)

BCS

BCM (BODY CONTROL MODULE)BCS-53

< ECU DIAGNOSIS INFORMATION > [BCM]

C

D E

F

G H

I

J

K L

B

A

O P

N

B2196: DONGLE UNIT — — —

SEC-90, "Description"

B2198: NATS ANTENNA AMP. — — — SEC-92, "DTC Logic"

B2555: STOP LAMP — — —SEC-94, "DTC Logic"

B2556: PUSH-BTN IGN SW —×— SEC-97, "DTC Logic"

B2557: VEHICLE SPEED — ×— SEC-99, "DTC Logic"

B2560: STARTER CONT RELAY ××—SEC-100, "Description"

B2562: LOW VOLTAGE ×—— BCS-71, "DTC Logic"

B259A: ROOM LAMP FUSE — — — BCS-72, "DTC Logic"

B2601: SHIFT POSITION —×—SEC-101, "DTC Logic"

B2602: SHIFT POSITION — ×—SEC-104, "DTC Logic"

B2603: SHIFT POSI STATUS — ×—SEC-106, "DTC Logic"

B2604: PNP SW — ×—SEC-110, "DTC Logic"

B2605: PNP SW — ×—SEC-113, "DTC Logic"

B2608: STARTER RELAY ××—SEC-116, "DTC Logic"

B260A: IGNITION RELAY ××—PCS-58, "DTC Logic"

B2614: ACC RELAY CIRC — ×— PCS-60, "DTC Logic"

B2615: BLOWER RELAY CIRC — ×— PCS-62, "DTC Logic"

B2616: IGN RELAY CIRC — ×— PCS-64, "DTC Logic"

B2617: STARTER RELAY CIRC ××—SEC-118, "Description"

B2618: BCM ××—PCS-66, "DTC Logic"

B261A: PUSH-BTN IGN SW — ×— PCS-68, "DTC Logic"

B261B: RES ENG RUN — — — DLK-87, "DTC Logic"

B261E: VEHICLE TYPE××

(Turn ON for

15 seconds) —

SEC-120, "Description"

B2621: INSIDE ANTENNA — — — DLK-88, "DTC Logic"

B2622: INSIDE ANTENNA — — —DLK-90, "DTC Logic"

B26F1: IGNITION RELAY — — —PCS-70, "DTC Logic"

B26F2: IGNITION RELAY — — —PCS-72, "DTC Logic"

B26F6: BCM — — —PCS-74, "DTC Logic"

B26FD: SHIFT LOCK SOLENOID — — — DLK-92, "DTC Logic"

B26FE: HOOD SWITCH — — —DLK-95, "DTC Logic"

B26FF: REMOTE KEYLESS ENTRY RE-

CEIVER —— —

DLK-97, "DTC Logic"

C1704: LOW PRESSURE FL — — ×

WT-28, "DTC Logic"

C1705: LOW PRESSURE FR — — ×

C1706: LOW PRESSURE RR — — ×

C1707: LOW PRESSURE RL — — ×

C1708: [NO DATA] FL — — ×

WT-30, "DTC Logic"

C1709: [NO DATA] FR — — ×

C1710: [NO DATA] RR — — ×

C1711: [NO DATA] RL — — ×

CONSULT display Fail-safe

Intelligent Key

warning lamp

ON Tire pressure

monitor warning

lamp ON Reference page

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 69 of 4801

![NISSAN TEANA 2014 User Guide

BCS-54

< ECU DIAGNOSIS INFORMATION >[BCM]

BCM (BODY CONTROL MODULE)

C1712: [CHECKSUM ERR] FL — —

×

WT-33, "DTC Logic"

C1713: [CHECKSUM ERR] FR — — ×

C1714: [CHECKSUM ERR] RR — — ×

C171 NISSAN TEANA 2014 User Guide

BCS-54

< ECU DIAGNOSIS INFORMATION >[BCM]

BCM (BODY CONTROL MODULE)

C1712: [CHECKSUM ERR] FL — —

×

WT-33, "DTC Logic"

C1713: [CHECKSUM ERR] FR — — ×

C1714: [CHECKSUM ERR] RR — — ×

C171](/img/5/57390/w960_57390-68.png)

BCS-54

< ECU DIAGNOSIS INFORMATION >[BCM]

BCM (BODY CONTROL MODULE)

C1712: [CHECKSUM ERR] FL — —

×

WT-33, "DTC Logic"

C1713: [CHECKSUM ERR] FR — — ×

C1714: [CHECKSUM ERR] RR — — ×

C1715: [CHECKSUM ERR] RL — — ×

C1716: [PRESSDATA ERR] FL — — ×

WT-35, "DTC Logic"

C1717: [PRESSDATA ERR] FR — — ×

C1718: [PRESSDATA ERR] RR — — ×

C1719: [PRESSDATA ERR] RL — — ×

C1720: [CODE ERR] FL — — ×

WT-37, "DTC Logic"

C1721: [CODE ERR] FR — — ×

C1722: [CODE ERR] RR — — ×

C1723: [CODE ERR] RL — — ×

C1724: [BATT VOLT LOW] FL — — ×

WT-39, "DTC Logic"

C1725: [BATT VOLT LOW] FR — — ×

C1726: [BATT VOLT LOW] RR — — ×

C1727: [BATT VOLT LOW] RL — — ×

C1729: VHCL SPEED SIG ERR — — ×WT-41, "DTC Logic"

C1730: FLAT TIRE FL — — ×

WT-42, "DTC Logic"

C1731: FLAT TIRE FR — — ×

C1732: FLAT TIRE RR — — ×

C1733: FLAT TIRE RL — — ×

C1734: CONTROL UNIT — — ×WT-44, "DTC Logic"

C1735: IGNTION SIGNAL — — ×WT-46, "DTC Logic"

CONSULT display Fail-safe Intelligent Key

warning lamp

ON Tire pressure

monitor warning

lamp ON Reference page

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 81 of 4801

![NISSAN TEANA 2014 User Guide

BCS-66

< BASIC INSPECTION >[BCM]

INSPECTION AND ADJUSTMENT

CONFIGURATION (BCM) : Configuration list

INFOID:0000000009462025

CAUTION:

Thoroughly read and understand the vehicle specifi cation. Incor NISSAN TEANA 2014 User Guide

BCS-66

< BASIC INSPECTION >[BCM]

INSPECTION AND ADJUSTMENT

CONFIGURATION (BCM) : Configuration list

INFOID:0000000009462025

CAUTION:

Thoroughly read and understand the vehicle specifi cation. Incor](/img/5/57390/w960_57390-80.png)

BCS-66

< BASIC INSPECTION >[BCM]

INSPECTION AND ADJUSTMENT

CONFIGURATION (BCM) : Configuration list

INFOID:0000000009462025

CAUTION:

Thoroughly read and understand the vehicle specifi cation. Incorrect settings may result in abnormal

control of ECU.

⇔ : Items which confirm vehicle specifications MANUAL SETTING ITEM

Items Setting value

AUTO LIGHT WITHOUT ⇔ MODE1 ⇔ MODE2 ⇔ MODE3 ⇔ MODE4 ⇔ MODE5

FR FOG LAMP WITHOUT ⇔ MODE1 ⇔ MODE2

TIRE PRESSURE 220kPa ⇔ 230kPa ⇔ 240kPa

BCM AC CONTROL MODE1 ⇔ MODE2

Key Fob Type ENST/LCK/UNLCK/ALRM

⇔ ENST/LCK/UNLCK/BD/ALRM ⇔

ENST/LCK/UNLCK/TRK/ALRM ⇔ LCK/UNLCK/PBD/ALRM ⇔

LCK/UNLCK/ALRM ⇔ LCK/UNLCK/PBD ⇔ LCK/UNLCK/TRNK ⇔

LCK/UNLCK ⇔ LCK/UNLCK/TRNK/ALRM

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 106 of 4801

BR-10

< BASIC INSPECTION >

BRAKE BOOSTER

BRAKE BOOSTER

InspectionINFOID:0000000009463686

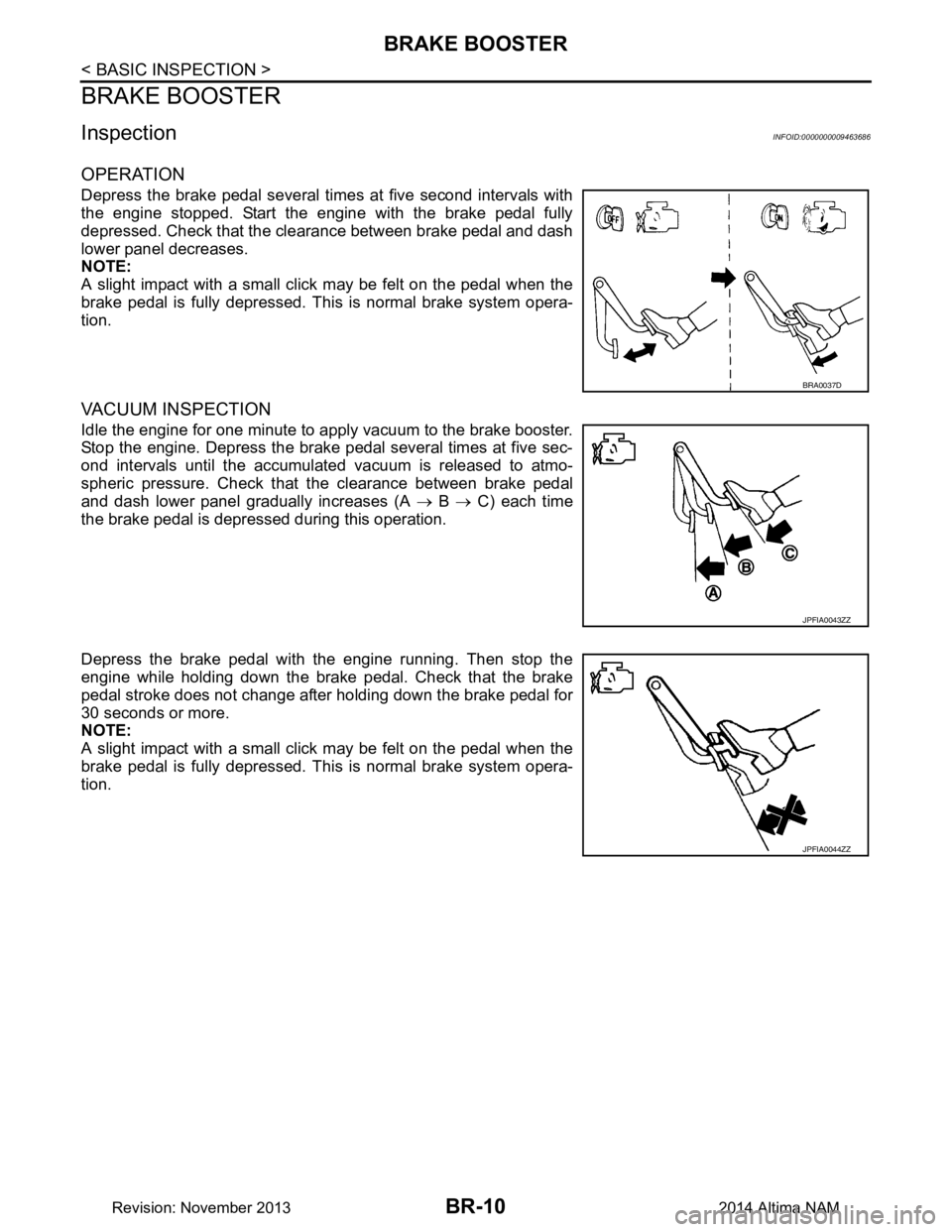

OPERATION

Depress the brake pedal several times at five second intervals with

the engine stopped. Start the engine with the brake pedal fully

depressed. Check that the cl earance between brake pedal and dash

lower panel decreases.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. Th is is normal brake system opera-

tion.

VACUUM INSPECTION

Idle the engine for one minute to apply vacuum to the brake booster.

Stop the engine. Depress the brake pedal several times at five sec-

ond intervals until the accumulated vacuum is released to atmo-

spheric pressure. Check that the clearance between brake pedal

and dash lower panel gradually increases (A → B → C) each time

the brake pedal is depressed during this operation.

Depress the brake pedal with the engine running. Then stop the

engine while holding down the brake pedal. Check that the brake

pedal stroke does not change after holding down the brake pedal for

30 seconds or more.

NOTE:

A slight impact with a small click may be felt on the pedal when the

brake pedal is fully depressed. Th is is normal brake system opera-

tion.

BRA0037D

JPFIA0043ZZ

JPFIA0044ZZ

Revision: November 20132014 Altima NAM

Page 124 of 4801

BR-28

< REMOVAL AND INSTALLATION >

BRAKE BOOSTER

BRAKE BOOSTER

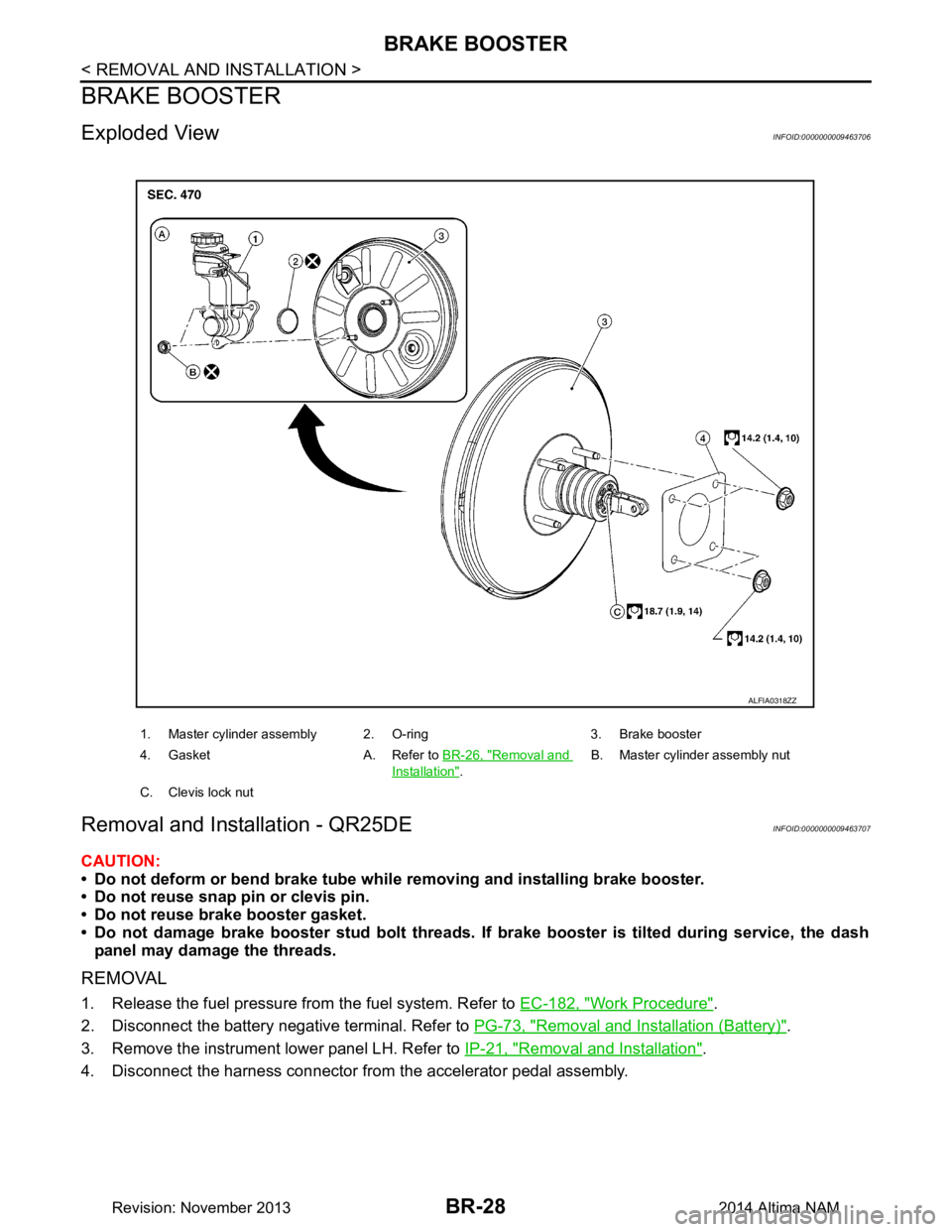

Exploded ViewINFOID:0000000009463706

Removal and Installation - QR25DEINFOID:0000000009463707

CAUTION:

• Do not deform or bend brake tube whil e removing and installing brake booster.

• Do not reuse snap pin or clevis pin.

• Do not reuse brake booster gasket.

• Do not damage brake booster stud bolt threads. If brake booster is tilted during service, the dash

panel may damage the threads.

REMOVAL

1. Release the fuel pressure from the fuel system. Refer to EC-182, "Work Procedure".

2. Disconnect the battery negative terminal. Refer to PG-73, "Removal and Installation (Battery)"

.

3. Remove the instrument lower panel LH. Refer to IP-21, "Removal and Installation"

.

4. Disconnect the harness connector from the accelerator pedal assembly.

1. Master cylinder assembly 2. O-ring 3. Brake booster

4. Gasket A. Refer to BR-26, "Removal and

Installation".B. Master cylinder assembly nut

C. Clevis lock nut

ALFIA0318ZZ

Revision: November 20132014 Altima NAM

Page 125 of 4801

BRAKE BOOSTERBR-29

< REMOVAL AND INSTALLATION >

C

D E

G H

I

J

K L

M A

B

BR

N

O P

5. Remove the snap pin (1) and clevis pin (2) from the brake pedal. CAUTION:

Do not reuse snap pin or clevis pin.

6. Disconnect the harness connectors from the ASCD cancel switch and stop lamp switch.

7. Disconnect the steering column assembly pinch bolt and position the steering column shaft aside. Refer to

ST-33, "Exploded View"

.

8. Remove the brake master cylinder. Refer to BR-26, "Removal and Installation"

.

9. Disconnect the fuel line main connections. Refer to FL-5, "Quick Connector"

.

10. Remove the cowl top. Refer to EXT-24, "Removal and Installation"

.

11. Remove the strut tower bar. Refer to FSU-19, "Exploded View"

.

12. Remove the wiper drive assembly. Refer to WW-64, "Removal and Installation"

.

13. Remove the cowl top extension.

14. Disconnect the vacuum hose from the brake booster.

15. Disconnect the active boost sensor harness connector.

16. Remove brake booster nuts.

17. Remove the brake booster.

18. Remove and discard the brake booster gasket. CAUTION:

Do not reuse brake booster gasket.

INSTALLATION

Installation is in the reverse order of removal.

• Prior to installation, loosen clevis lock nut (1) and adjust input rod (2) to the specified value (B).

• After input rod adjustment (B), temporarily tighten clevis lock nut for installation of brake booster.

• Connect the battery negative terminal. Refer to PG-7, "ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Special Repair Requirement".

Removal and Installation - VQ35DEINFOID:0000000009463708

CAUTION:

• Do not deform or bend brake tube while removing and installing brake booster.

• Do not reuse snap pin or clevis pin.

• Do not reuse brake booster gasket.

• Do not damage brake booster stud bolt threads. If brake booster is tilted during service, the dash

panel may damage the threads.

REMOVAL

1. Release the fuel pressure from the fuel system. Refer to EC-687, "Work Procedure".

JPFIA0019ZZ

Length (B) : Refer to BR-49, "Brake Booster".

ALFIA0299ZZ

Revision: November 20132014 Altima NAM

Page 155 of 4801

![NISSAN TEANA 2014 User Guide

COMPONENT PARTSBRC-9

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000009463742

ABS Actuator and Electric Unit (Control Unit)INFOID:0000000 NISSAN TEANA 2014 User Guide

COMPONENT PARTSBRC-9

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000009463742

ABS Actuator and Electric Unit (Control Unit)INFOID:0000000](/img/5/57390/w960_57390-154.png)

COMPONENT PARTSBRC-9

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

Component DescriptionINFOID:0000000009463742

ABS Actuator and Electric Unit (Control Unit)INFOID:0000000009463743

Electric unit (control unit) is integrated with actuator and comprehensively controls VDC function, TCS func-

tion, ABS function and EBD function.

ELECTRIC UNIT (CONTROL UNIT)

• Brake fluid pressure is controlled according to signals from each sensor.

• If malfunction is detected, t he system enters fail-safe mode.

ACTUATOR

The following components are integrated with ABS actuator.

Pump

Returns the brake fluid reserved in reservoir to master cylinder by reducing pressure.

Motor

Activates the pump according to signals from ABS actuator and electric unit (control unit).

Motor Relay

Operates the motor ON/OFF according to signals fr om ABS actuator and electric unit (control unit).

Actuator Relay (Main Relay)

Operates each valve ON/OFF according to signals fr om ABS actuator and electric unit (control unit).

ABS IN Valve

Switches the fluid pressure line to increase or hold according to signals from control unit.

ABS OUT Valve

Switches the fluid pressure line to increase, hold or decrease according to signals from control unit.

Cut Valve 1, Cut Valve 2

Shuts off the ordinary brake line from master cylinder, when VDC function and TCS function are activated.

7. Rear wheel sensor LH (RH similar) 8. VDC OFF switch 9. Steering angle sensor

(view with steering wheel removed)

10. Parking brake switch 11. Stop lamp switch 12. Combination meter

Component Reference/Function

ABS actuator and electric unit (control unit) BRC-9, "ABS Actuator and Electric Unit (Control Unit)"

Wheel sensorBRC-10, "Wheel Sensor and Sensor Rotor"

Stop lamp switchBRC-10, "Stop Lamp Switch"

Steering angle sensorBRC-10, "Steering Angle Sensor"

Vacuum sensorBRC-10, "Vacuum Sensor"

VDC OFF switchBRC-11, "VDC OFF Switch"

Brake fluid level switchBRC-10, "Brake Fluid Level Switch"

Parking brake switchBRC-11, "Parking Brake Switch"

ABS warning lamp

BRC-12, "VDC/TCS/ABS : System Description"

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

ECM Transmits the following signals to ABS actuator and electric unit (control unit) via CAN

communication.

• Accelerator pedal position signal

• Engine speed signal

• Target throttle position signal

TCM Transmits the current gear position signal

to ABS actuator and electric unit (control

unit) via CAN communication.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 156 of 4801

![NISSAN TEANA 2014 User Guide

BRC-10

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

COMPONENT PARTS

Suction Valve 1, Suction Valve 2

Supplies the brake fluid from master cylinder to t

he pump, when VDC function and TCS function are activate NISSAN TEANA 2014 User Guide

BRC-10

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

COMPONENT PARTS

Suction Valve 1, Suction Valve 2

Supplies the brake fluid from master cylinder to t

he pump, when VDC function and TCS function are activate](/img/5/57390/w960_57390-155.png)

BRC-10

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

COMPONENT PARTS

Suction Valve 1, Suction Valve 2

Supplies the brake fluid from master cylinder to t

he pump, when VDC function and TCS function are activated.

Return Check Valve

Returns the brake fluid from brake caliper and wheel cy linder to master cylinder by bypassing orifice of each

valve when brake is released.

Reservoir

Temporarily reserves the brake fluid drained from brake caliper, so that pressure efficiently decreases when

decreasing pressure of brake caliper and wheel cylinder.

Yaw rate/side/decel G sensor

Calculates the following information that affects the vehicle, and transmits a signal to ABS actuator and elec-

tric unit (control unit) via communication lines.

• Vehicle rotation angular velocity (yaw rate signal)

• Vehicle lateral acceleration (side G signal) and longitudinal acceleration (decel G signal)

Pressure Sensor

Detects the brake fluid pressure and transmits signal to ABS actuator and electric unit (control unit).

Wheel Sensor and Sensor RotorINFOID:0000000009463744

NOTE:

• Wheel sensor of front wheel is installed on steering knuckle.

• Sensor rotor of front wheel is integrated in wheel hub assembly.

• Wheel sensor of rear wheel is installed on back plate of rear brake.

• Sensor rotor of rear wheel is installed on rear brake drum.

• Never measure resistance and voltage value using a tester because sensor is active sensor.

• Downsize and weight reduction is aimed. IC for detection portion and magnet for sensor rotor are adopted.

• Power supply is supplied to detection portion so that magnetic field line is read. Magnetic field that is detected is converted to current

signal.

• When sensor rotor rotates, magnetic field changes. Magnetic field change is converted to current signals (rectangular wave) and is

transmitted to ABS actuator and el ectric unit (control unit). Change

of magnetic field is proportional to wheel speed.

Stop Lamp SwitchINFOID:0000000009463745

Detects the operation status of brake pedal and transmits converted electric signal to ABS actuator and elec-

tric unit (control unit).

Steering Angle SensorINFOID:0000000009463746

Detects the following information and transmits steering angl e signal to ABS actuator and electric unit (control

unit) via CAN communication.

• Steering wheel rotation amount

• Steering wheel rotation angular velocity

• Steering wheel rotation direction

Brake Fluid Level SwitchINFOID:0000000009463747

Detects the brake fluid level in reservoir tank and transmi ts converted electric signal from combination meter to

ABS actuator and electric unit (control unit) via CAN communication.

Vacuum SensorINFOID:0000000009463748

Detects the vacuum in brake booster and transmits conver ted electric signal to ABS actuator and electric unit

(control unit).

JPFIC0131GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 158 of 4801

![NISSAN TEANA 2014 User Guide

BRC-12

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

SYSTEM

SYSTEM

VDC/TCS/ABS

VDC/TCS/ABS : System DiagramINFOID:0000000009463751

VDC/TCS/ABS : System DescriptionINFOID:0000000009463752

• The system switche NISSAN TEANA 2014 User Guide

BRC-12

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

SYSTEM

SYSTEM

VDC/TCS/ABS

VDC/TCS/ABS : System DiagramINFOID:0000000009463751

VDC/TCS/ABS : System DescriptionINFOID:0000000009463752

• The system switche](/img/5/57390/w960_57390-157.png)

BRC-12

< SYSTEM DESCRIPTION >[VDC/TCS/ABS]

SYSTEM

SYSTEM

VDC/TCS/ABS

VDC/TCS/ABS : System DiagramINFOID:0000000009463751

VDC/TCS/ABS : System DescriptionINFOID:0000000009463752

• The system switches fluid pressure of each brake caliper to increase, to hold, or to decrease according to

signals from control unit in ABS actuator and electric unit (control unit). This control system is applied to

VDC, TCS, ABS and EBD functions.

• Fail-safe function is available for each function and is activated by each function when system malfunction

occurs.

INPUT SIGNAL AND OUTPUT SIGNAL

Major signal transmission between each unit via communication lines is shown in the following table.

ALFIA0294GB

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 159 of 4801

![NISSAN TEANA 2014 User Guide

SYSTEMBRC-13

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VALVE OPERATION (VDC AND TCS FUNCTIONS)

The control unit built in the ABS actuator and electric unit (control un NISSAN TEANA 2014 User Guide

SYSTEMBRC-13

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VALVE OPERATION (VDC AND TCS FUNCTIONS)

The control unit built in the ABS actuator and electric unit (control un](/img/5/57390/w960_57390-158.png)

SYSTEMBRC-13

< SYSTEM DESCRIPTION > [VDC/TCS/ABS]

C

D E

G H

I

J

K L

M A

B

BRC

N

O P

VALVE OPERATION (VDC AND TCS FUNCTIONS)

The control unit built in the ABS actuator and electric unit (control unit) controls fluid pressure of the brake cal-

ipers by operating each valve.

VDC and TCS Functions are Operating (Pressure Increases)

Component Signal description

Steering angle sensor Transmits the steering an

gle sensor signal to ABS actuator an d electric unit (control unit) via

CAN communication.

ECM Transmits the following signals to ABS actuator and electric unit (control unit) via CAN commu-

nication.

• Accelerator pedal position signal

• Engine speed signal

• Target throttle position signal

TCM Transmits the current gear positi

on signal to ABS actuator and electric unit (control unit) via

CAN communication.

Combination meter Transmits the following signals to ABS actuator and electric unit (control unit) via CAN commu-

nication.

• Brake fluid level switch signal

• Parking brake switch signal

Receives the foll owing signals from ABS actuator and elec tric unit (control unit) via CAN com-

munication.

• ABS warning lamp signal

• Brake warning lamp signal

• VDC OFF indicator lamp signal

• SLIP indicator lamp signal

ALFIA0309GB

Name Not activated Pressure increases

Cut valve 1 Power supply is not supplied (open) Power supply is supplied (close)

Cut valve 2 Power supply is not supplied (open) Power supply is supplied (close)

Suction valve 1 Power supply is not supplied (close) Power supply is supplied (open)

Suction valve 2 Power supply is not supplied (close) Power supply is supplied (open)

ABS IN valve Power supp ly is not supplied (open) Power supp ly is not supplied (open)

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM