NISSAN TEANA 2014 Service Manual

Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3821 of 4801

SE-72

< UNIT DISASSEMBLY AND ASSEMBLY >

REAR SEAT

REAR SEATBACK ASSEMBLY (RH) - WITHOUT REMOVABLE HEADREST

Disassembly

1. Remove the rear seatback assembly (RH). Refer to SE-36, "Removal and Installation - Seat Assembly".

2. Remove the armrest assembly. Refer to SE-38, "Removal and Installation - Armrest Assembly"

.

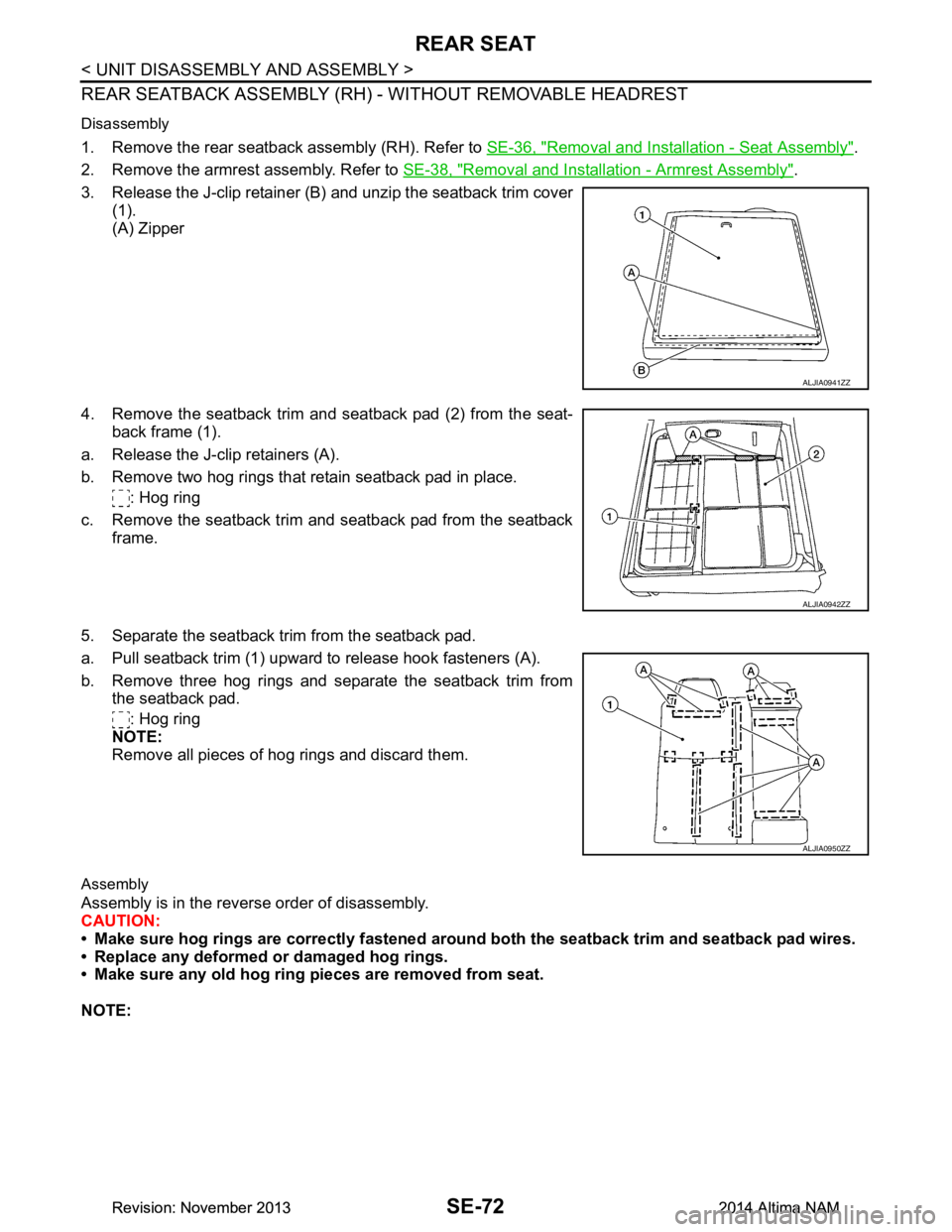

3. Release the J-clip retainer (B) and unzip the seatback trim cover (1).

(A) Zipper

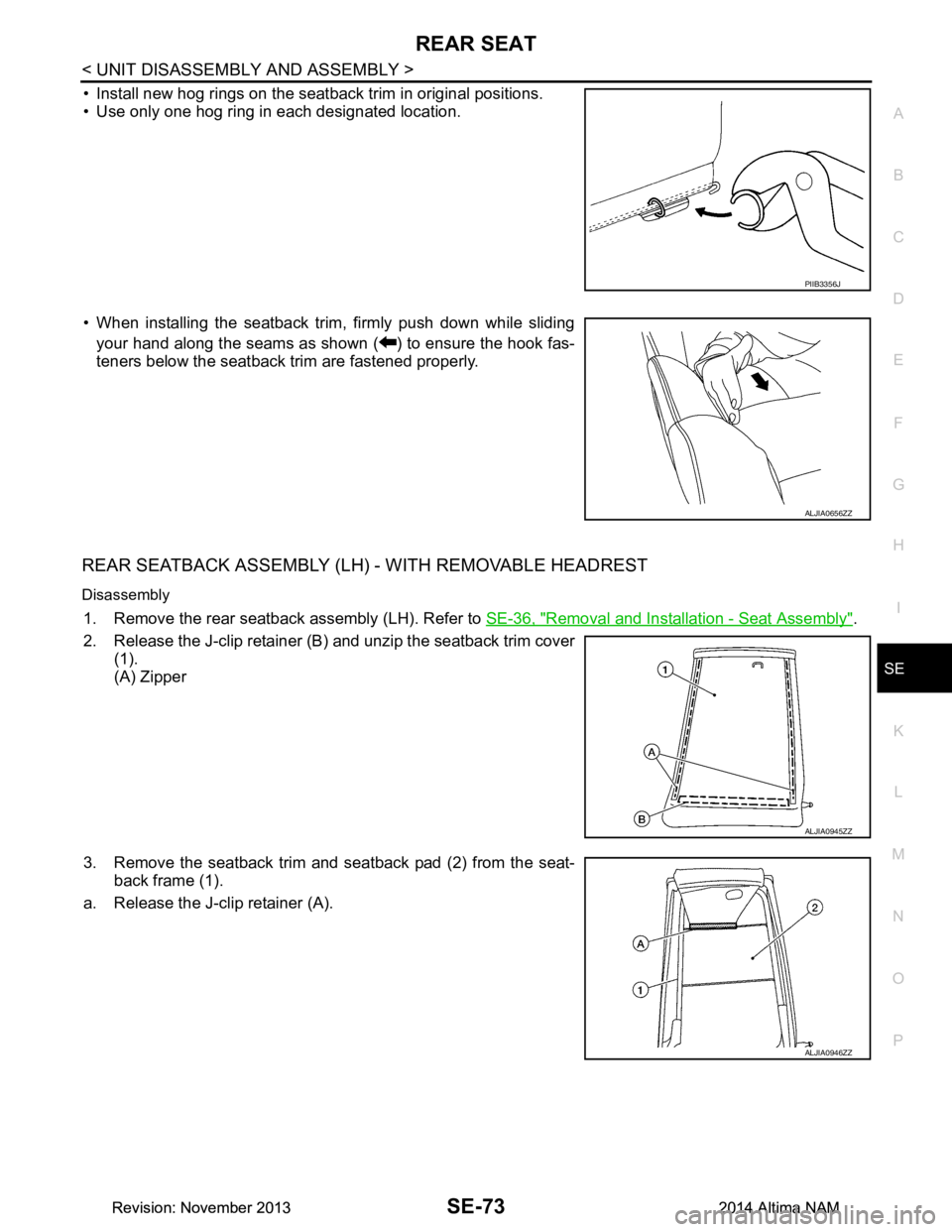

4. Remove the seatback trim and s eatback pad (2) from the seat-

back frame (1).

a. Release the J-clip retainers (A).

b. Remove two hog rings that retain seatback pad in place. : Hog ring

c. Remove the seatback trim and seatback pad from the seatback frame.

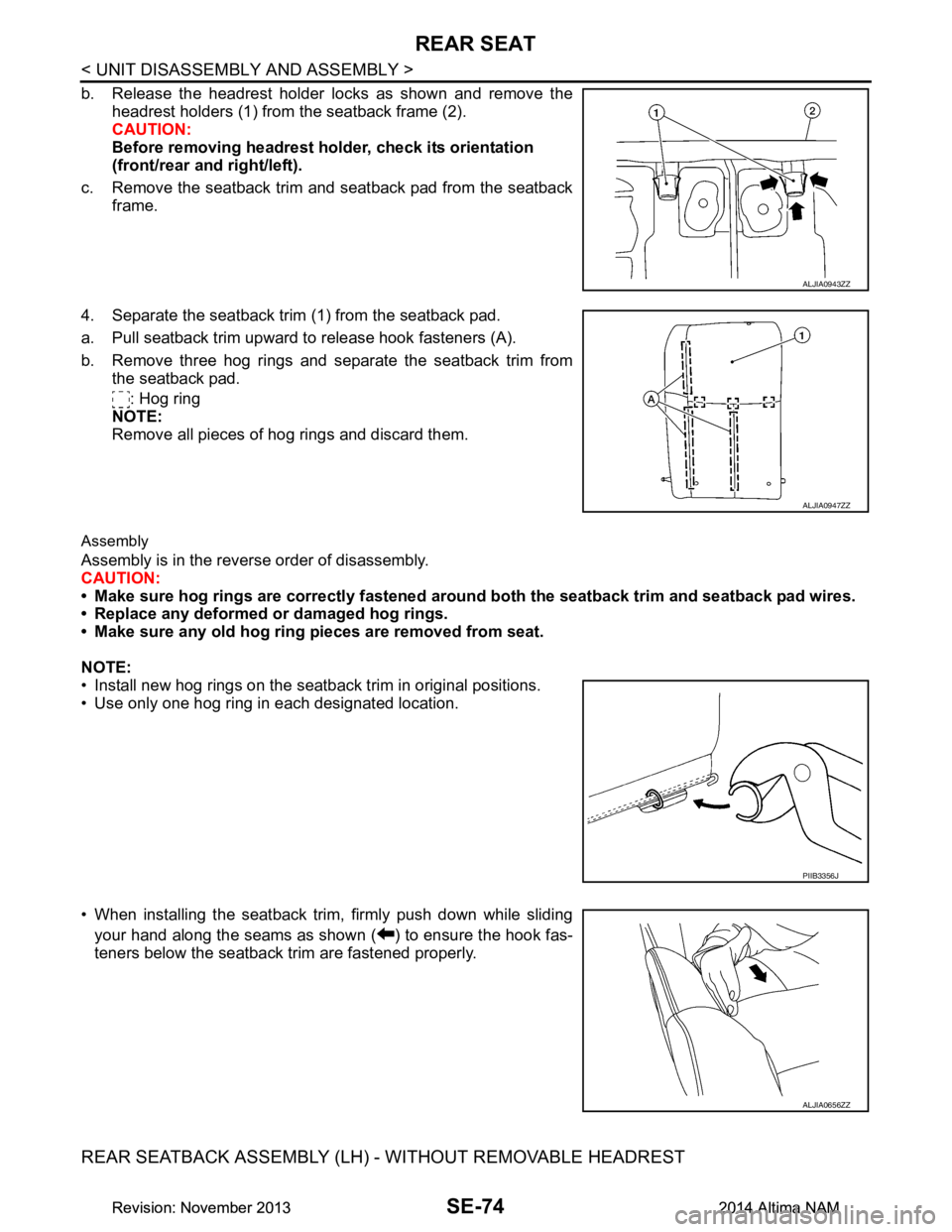

5. Separate the seatback trim from the seatback pad.

a. Pull seatback trim (1) upward to release hook fasteners (A).

b. Remove three hog rings and separate the seatback trim from the seatback pad.

: Hog ring

NOTE:

Remove all pieces of hog rings and discard them.

Assembly

Assembly is in the reverse order of disassembly.

CAUTION:

• Make sure hog rings are correctly fastened ar ound both the seatback trim and seatback pad wires.

• Replace any deformed or damaged hog rings.

• Make sure any old hog ring pieces are removed from seat.

NOTE:

ALJIA0941ZZ

ALJIA0942ZZ

ALJIA0950ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3822 of 4801

REAR SEATSE-73

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D E

F

G H

I

K L

M A

B

SE

N

O P

• Install new hog rings on the seatback trim in original positions.

• Use only one hog ring in each designated location.

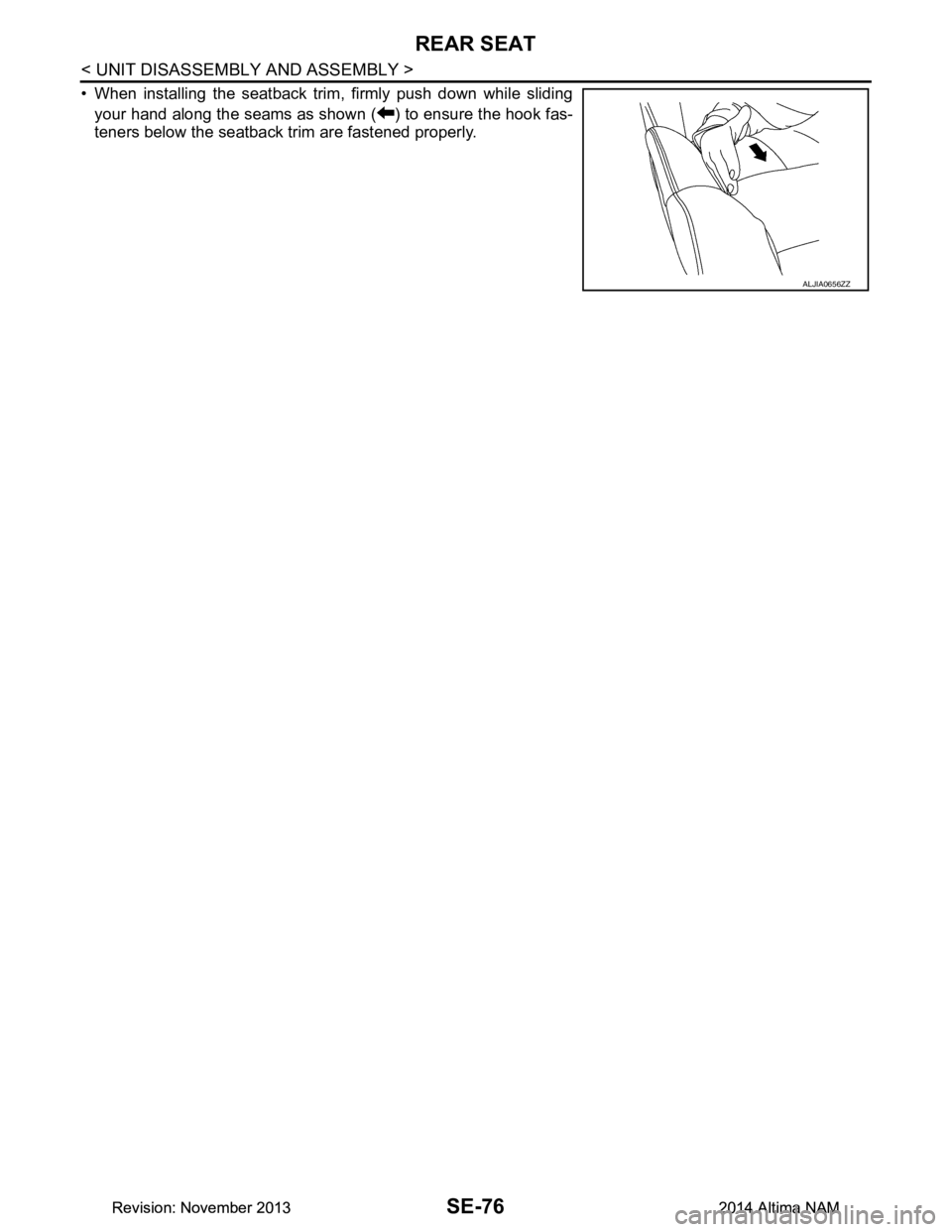

• When installing the seatback trim, firmly push down while sliding

your hand along the seams as shown ( ) to ensure the hook fas-

teners below the seatback trim are fastened properly.

REAR SEATBACK ASSEMBLY (LH) - WITH REMOVABLE HEADREST

Disassembly

1. Remove the rear seatback assembly (LH). Refer to SE-36, "Removal and Installation - Seat Assembly".

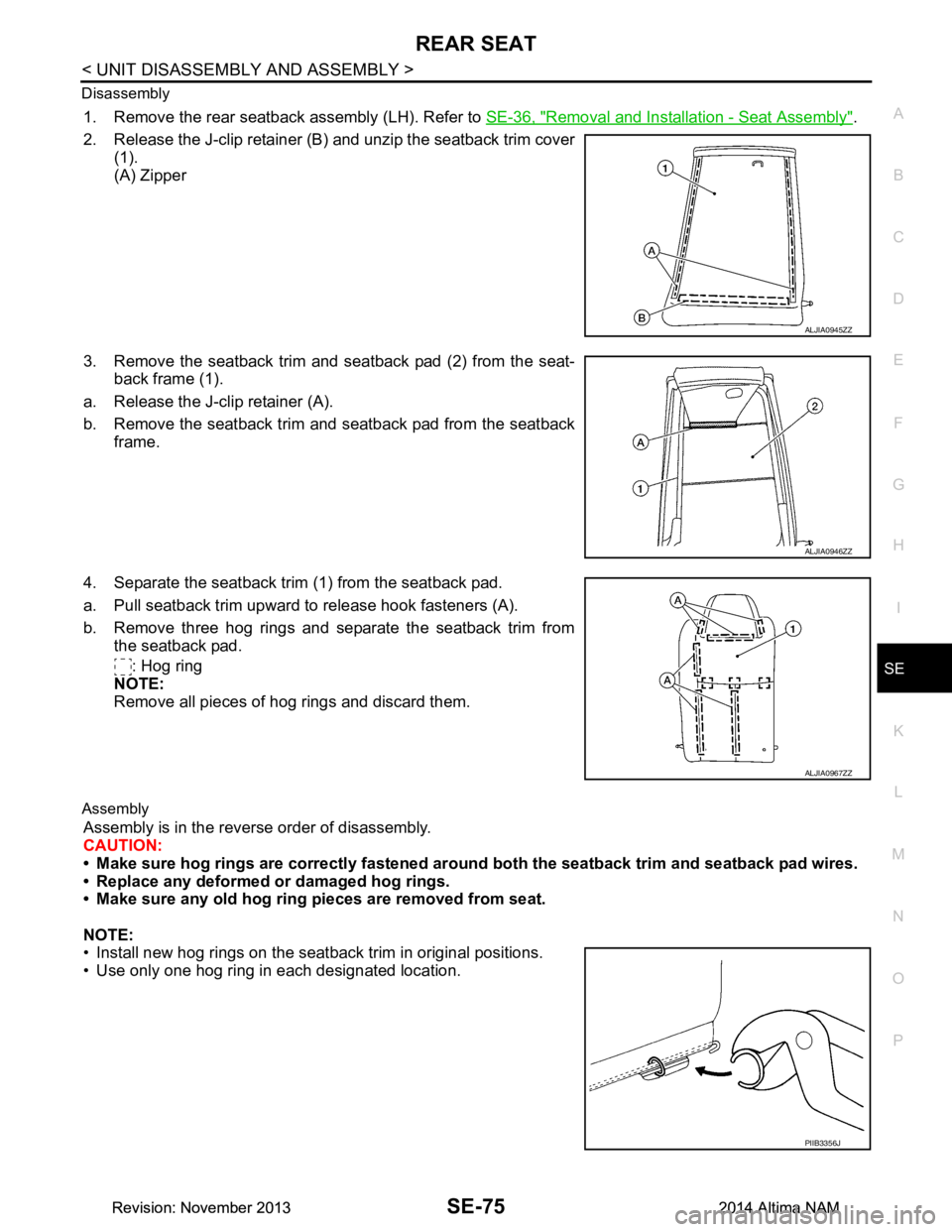

2. Release the J-clip retainer (B) and unzip the seatback trim cover (1).

(A) Zipper

3. Remove the seatback trim and seatback pad (2) from the seat- back frame (1).

a. Release the J-clip retainer (A).

PIIB3356J

ALJIA0656ZZ

ALJIA0945ZZ

ALJIA0946ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3823 of 4801

SE-74

< UNIT DISASSEMBLY AND ASSEMBLY >

REAR SEAT

b. Release the headrest holder locks as shown and remove theheadrest holders (1) from the seatback frame (2).

CAUTION:

Before removing headrest holder, check its orientation

(front/rear and right/left).

c. Remove the seatback trim and seatback pad from the seatback frame.

4. Separate the seatback trim (1) from the seatback pad.

a. Pull seatback trim upward to release hook fasteners (A).

b. Remove three hog rings and separate the seatback trim from the seatback pad.

: Hog ring

NOTE:

Remove all pieces of hog rings and discard them.

Assembly

Assembly is in the reverse order of disassembly.

CAUTION:

• Make sure hog rings are correctly fastened ar ound both the seatback trim and seatback pad wires.

• Replace any deformed or damaged hog rings.

• Make sure any old hog ring pieces are removed from seat.

NOTE:

• Install new hog rings on the seatback trim in original positions.

• Use only one hog ring in each designated location.

• When installing the seatback trim, firmly push down while sliding

your hand along the seams as shown ( ) to ensure the hook fas-

teners below the seatback trim are fastened properly.

REAR SEATBACK ASSEMBLY (LH) - WITHOUT REMOVABLE HEADREST

ALJIA0943ZZ

ALJIA0947ZZ

PIIB3356J

ALJIA0656ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3824 of 4801

REAR SEATSE-75

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D E

F

G H

I

K L

M A

B

SE

N

O P

Disassembly

1. Remove the rear seatback assembly (LH). Refer to

SE-36, "Removal and Installation - Seat Assembly".

2. Release the J-clip retainer (B) and unzip the seatback trim cover (1).

(A) Zipper

3. Remove the seatback trim and seatback pad (2) from the seat- back frame (1).

a. Release the J-clip retainer (A).

b. Remove the seatback trim and seatback pad from the seatback frame.

4. Separate the seatback trim (1) from the seatback pad.

a. Pull seatback trim upward to release hook fasteners (A).

b. Remove three hog rings and separate the seatback trim from the seatback pad.

: Hog ring

NOTE:

Remove all pieces of hog rings and discard them.

Assembly

Assembly is in the reverse order of disassembly.

CAUTION:

• Make sure hog rings are correctly fastened ar ound both the seatback trim and seatback pad wires.

• Replace any deformed or damaged hog rings.

• Make sure any old hog ring pieces are removed from seat.

NOTE:

• Install new hog rings on the seatback trim in original positions.

• Use only one hog ring in each designated location.

ALJIA0945ZZ

ALJIA0946ZZ

ALJIA0967ZZ

PIIB3356J

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3825 of 4801

SE-76

< UNIT DISASSEMBLY AND ASSEMBLY >

REAR SEAT

• When installing the seatback trim, firmly push down while slidingyour hand along the seams as shown ( ) to ensure the hook fas-

teners below the seatback trim are fastened properly.

ALJIA0656ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3826 of 4801

SEC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D E

F

G H

I

J

L

M

SECTION SEC

A

B

SEC

N

O P

CONTENTS

SECURITY CONTROL SYSTEM

PRECAUTION ................ ...............................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................8

CVT Shift Selector (Park Position Switch) ................8

BCM ..........................................................................8

ECM ..........................................................................8

IPDM E/R ..................................................................9

NATS Antenna Amp. .................................................9

TCM ..........................................................................9

Combination Meter ....................................................9

Door Switch ...............................................................9

Outside Key Antenna ................................................9

Hood Switch ..............................................................9

Inside Key Antenna ...................................................9

Remote Keyless Entry Receiver ...............................9

Intelligent Key ............................................................9

Push-button Ignition Switch .....................................10

Security Indicator Lamp ...................................... ....10

Starter Control Relay ...............................................10

Starter Relay ...........................................................10

Stop Lamp Switch ...................................................10

Transmission Range Switch ....................................10

Vehicle Information Display .....................................10

SYSTEM .............................................................11

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION ............................................................. ....

11

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION : System Diagram ............................ ....

11

INTELLIGENT KEY SYSTEM/ENGINE START

FUNCTION : System Description ........................ ....

11

NISSAN VEHICLE IMMOBILIZER SYSTEM-NATS ....13

NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS : System Diagram ..................................... ....

14

NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS : System Description ................................. ....

14

VEHICLE SECURITY SYSTEM .................................16

VEHICLE SECURITY SYSTEM : System Dia-

gram .................................................................... ....

16

VEHICLE SECURITY SYSTEM : System Descrip-

tion ....................................................................... ....

16

DIAGNOSIS SYSTEM (BCM) ...........................20

COMMON ITEM ..................................................... ....20

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) ................................................. ....

20

INTELLIGENT KEY ................................................ ....21

INTELLIGENT KEY : CONSULT Function (BCM -

INTELLIGENT KEY) ........... .....................................

21

THEFT ALM ........................................................... ....24

THEFT ALM : CONSULT Function (BCM - THEFT

ALM) .................................................................... ....

24

IMMU ...................................................................... ....25

IMMU : CONSULT Function (BCM - IMMU) ............25

DIAGNOSIS SYSTEM (IPDM E/R) ...................26

CONSULT Function (IPDM E/R) .............................26

ECU DIAGNOSIS INFORMATION ..............28

ECM, IPDM E/R, BCM .......................................28

List of ECU Reference ......................................... ....28

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3827 of 4801

SEC-2

WIRING DIAGRAM .....................................29

ENGINE START FUNCTION .......................... ...29

Wiring Diagram .................................................... ...29

NISSAN VEHICLE IMMOBILIZER SYSTEM-

NATS ............................................................... ...

40

Wiring Diagram .................................................... ...40

VEHICLE SECURITY SYSTEM .........................50

Wiring Diagram .................................................... ...50

BASIC INSPECTION ...................................63

DIAGNOSIS AND REPAIR WORK FLOW ..... ...63

Work Flow ............................................................ ...63

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ............................................. ...

66

ECM ........................................................................ ...66

ECM : Description ...................................................66

ECM : Work Procedure ...........................................66

BCM ........................................................................ ...66

BCM : Description ...................................................66

BCM : Work Procedure ...........................................66

DTC/CIRCUIT DIAGNOSIS ...................... ...68

P1610 LOCK MODE ....................................... ...68

Description ........................................................... ...68

DTC Logic ...............................................................68

Diagnosis Procedure ..............................................68

P1611 ID DISCORD, IMMU-ECM ......................69

DTC Logic ............................................................ ...69

Diagnosis Procedure ..............................................69

P1612 CHAIN OF ECM-IMMU ...........................70

DTC Logic ............................................................ ...70

Diagnosis Procedure ..............................................70

P1614 CHAIN OF IMMU-KEY ...........................71

DTC Logic ............................................................ ...71

Diagnosis Procedure ..............................................71

B210B STARTER CONTROL RELAY ..............73

DTC Logic ............................................................ ...73

Diagnosis Procedure ..............................................73

B210C STARTER CONTROL RELAY ..............74

DTC Logic ............................................................ ...74

Diagnosis Procedure ..............................................74

B210D STARTER RELAY .................................76

DTC Logic ............................................................ ...76

Diagnosis Procedure ..............................................76

B210E STARTER RELAY .................................78

DTC Logic ............................................................ ...78

Diagnosis Procedure ..............................................78

B210F TRANSMISSION RANGE SWITCH .......80

Description ........................................................... ...80

DTC Logic ...............................................................80

Diagnosis Procedure ...............................................80

B2110 TRANSMISSION RANGE SWITCH .......82

Description ........................................................... ...82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

B2190 NATS ANTENNA AMP. .........................84

Description ........................................................... ...84

DTC Logic ...............................................................84

Diagnosis Procedure ...............................................84

B2191 DIFFERENCE OF KEY ..........................86

Description ........................................................... ...86

DTC Logic ...............................................................86

Diagnosis Procedure ...............................................86

B2192 ID DISCORD, IMMU-ECM ......................87

DTC Logic ............................................................ ...87

Diagnosis Procedure ...............................................87

B2193 CHAIN OF ECM-IMMU ..........................88

DTC Logic ............................................................ ...88

Diagnosis Procedure ...............................................88

B2195 ANTI-SCANNING ...................................89

DTC Logic ............................................................ ...89

Diagnosis Procedure ...............................................89

B2196 DONGLE UNIT .......................................90

Description ........................................................... ...90

DTC Logic ...............................................................90

Diagnosis Procedure ...............................................90

B2198 NATS ANTENNA AMP. .........................92

DTC Logic ............................................................ ...92

Diagnosis Procedure ...............................................92

B2555 STOP LAMP ...........................................94

DTC Logic ............................................................ ...94

Diagnosis Procedure ...............................................94

Component Inspection ............................................96

B2556 PUSH-BUTTON IGNITION SWITCH .....97

DTC Logic ............................................................ ...97

Diagnosis Procedure ...............................................97

Component Inspection ............................................98

B2557 VEHICLE SPEED ...................................99

DTC Logic ............................................................ ...99

Diagnosis Procedure ...............................................99

B2560 STARTER CONTROL RELAY ..............100

Description ........................................................... .100

DTC Logic .............................................................100

Diagnosis Procedure .............................................100

B2601 SHIFT POSITION ..................................101

DTC Logic ............................................................ .101

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3828 of 4801

SEC-3

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

Diagnosis Procedure ...........................................

..

101

Component Inspection ..........................................103

B2602 SHIFT POSITION ..................................104

DTC Logic ........................................................... ..104

Diagnosis Procedure .............................................104

Component Inspection ..........................................105

B2603 SHIFT POSITION ..................................106

DTC Logic ........................................................... ..106

Diagnosis Procedure .............................................106

Component Inspection ..........................................109

B2604 SHIFT POSITION ..................................110

DTC Logic ........................................................... ..110

Diagnosis Procedure .............................................110

B2605 SHIFT POSITION ..................................113

DTC Logic ........................................................... ..113

Diagnosis Procedure .............................................113

B2608 STARTER RELAY ................................116

DTC Logic ........................................................... ..116

Diagnosis Procedure .............................................116

B2617 STARTER RELAY CIRCUIT .................118

Description .......................................................... ..118

DTC Logic .............................................................118

Diagnosis Procedure .............................................118

B261E VEHICLE TYPE .................................. ..120

Description .......................................................... ..120

DTC Logic .............................................................120

Diagnosis Procedure .............................................120

POWER SUPPLY AND GROUND CIRCUIT ....122

Diagnosis Procedure ........................................... ..122

POWER SUPPLY AND GROUND CIRCUIT ....123

Diagnosis Procedure ........................................... ..123

HEADLAMP FUNCTION ..................................124

Component Function Check ................................ ..124

Diagnosis Procedure .............................................124

HOOD SWITCH ................................................125

Component Function Check .............................. ..125

Diagnosis Procedure ............................................125

Component Inspection ..........................................126

SECURITY INDICATOR LAMP ........................127

Component Function Check .............................. ..127

Diagnosis Procedure ........................................... ..127

SYMPTOM DIAGNOSIS ............................129

ENGINE DOES NOT START WHEN INTELLI-

GENT KEY IS INSIDE OF VEHICLE ..............

129

Description ........................................................... ..129

Diagnosis Procedure .............................................129

SECURITY INDICATOR LAMP DOES NOT

TURN ON OR BL INK ......................................

130

Description ........................................................... ..130

Diagnosis Procedure .............................................130

VEHICLE SECURITY SYSTEM CANNOT BE

SET ..................................................................

131

INTELLIGENT KEY ................................................ ..131

INTELLIGENT KEY : Description ..........................131

INTELLIGENT KEY : Diagnos is Procedure ...........131

DOOR REQUEST SWITCH ................................... ..131

DOOR REQUEST SWITCH : Description .............131

DOOR REQUEST SWITCH : Diagnosis Proce-

dure ..................................................................... ..

131

DOOR KEY CYLINDER ......................................... ..132

DOOR KEY CYLINDER : Description ...................132

DOOR KEY CYLINDER : Diagnosis Procedure .. ..132

VEHICLE SECURITY ALARM DOES NOT

ACTIVATE .......................................................

133

Description ........................................................... ..133

Diagnosis Procedure .............................................133

PANIC ALARM FUNCTION DOES NOT OP-

ERATE .............................................................

134

Description ........................................................... ..134

Diagnosis Procedure .............................................134

REMOVAL AND INSTALLATION .............135

NATS ANTENNA AMP. ..................................135

Exploded View ..................................................... ..135

Removal and Installation .......................................135

PUSH BUTTON IGNITION SWITCH ...............136

Exploded View .......................................................136

Removal and Installation .......................................136

IMMOBILIZER CONTROL MODULE ..............137

Removal and Installation .......................................137

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3829 of 4801

SEC-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000009951563

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000009461062

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a s hop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3830 of 4801

PREPARATIONSEC-5

< PREPARATION >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000009461063

The actual shapes of the tools may differ from those illustrated here.

Tool number

(TechMate No.)

Tool name Description

—

(J-46534)

Trim Tool Set Removing trim components

AWJIA0483ZZ

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM