Pressure NISSAN TEANA 2014 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2014, Model line: TEANA, Model: NISSAN TEANA 2014Pages: 4801, PDF Size: 51.2 MB

Page 3388 of 4801

![NISSAN TEANA 2014 Service Manual

PCS

DIAGNOSIS SYSTEM (BCM)PCS-39

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D E

F

G H

I

J

K L

B

A

O P

N

INTELLIGENT KEY

INTELLIGENT KEY : CONSULT Func

tion (BCM - INTELLIGENT KEY)INFOID:0 NISSAN TEANA 2014 Service Manual

PCS

DIAGNOSIS SYSTEM (BCM)PCS-39

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D E

F

G H

I

J

K L

B

A

O P

N

INTELLIGENT KEY

INTELLIGENT KEY : CONSULT Func

tion (BCM - INTELLIGENT KEY)INFOID:0](/img/5/57390/w960_57390-3387.png)

PCS

DIAGNOSIS SYSTEM (BCM)PCS-39

< SYSTEM DESCRIPTION > [POWER DISTRIBUTION SYSTEM]

C

D E

F

G H

I

J

K L

B

A

O P

N

INTELLIGENT KEY

INTELLIGENT KEY : CONSULT Func

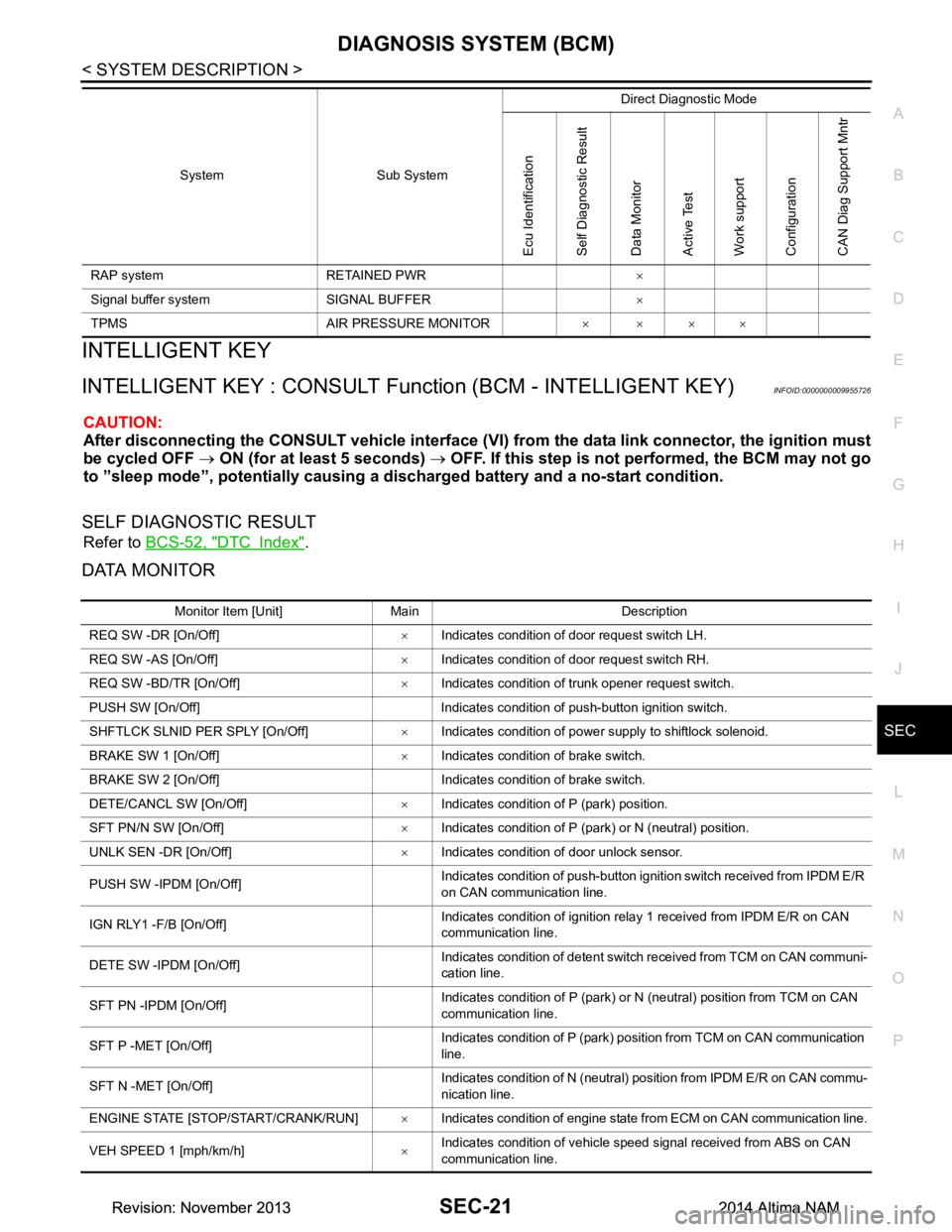

tion (BCM - INTELLIGENT KEY)INFOID:0000000009941331

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentiall y causing a discharged battery and a no-start condition.

SELF DIAGNOSTIC RESULT

Refer to BCS-52, "DTC Index".

DATA MONITOR

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

System Sub System

Direct Diagnostic Mode

Ecu Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN Diag Support Mntr

Monitor Item [Unit] Main Description

REQ SW -DR [On/Off] ×Indicates condition of door request switch LH.

REQ SW -AS [On/Off] ×Indicates condition of door request switch RH.

REQ SW -BD/TR [On/Off] ×Indicates condition of trunk opener request switch.

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

SHFTLCK SLNID PER SPLY [On/Off] ×Indicates condition of power supply to shiftlock solenoid.

BRAKE SW 1 [On/Off] ×Indicates condition of brake switch.

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW [On/Off] ×Indicates condition of P (park) position.

SFT PN/N SW [On/Off] ×Indicates condition of P (park) or N (neutral) position.

UNLK SEN -DR [On/Off] ×Indicates condition of door unlock sensor.

PUSH SW -IPDM [On/Off] Indicates condition of push-button ignition switch received from IPDM E/R

on CAN communication line.

IGN RLY1 -F/B [On/Off] Indicates condition of ignition relay 1 received from IPDM E/R on CAN

communication line.

DETE SW -IPDM [On/Off] Indicates condition of detent switch received from TCM on CAN communi-

cation line.

SFT PN -IPDM [On/Off] Indicates condition of P (park) or N (neutral) position from TCM on CAN

communication line.

SFT P -MET [On/Off] Indicates condition of P (park) position from TCM on CAN communication

line.

SFT N -MET [On/Off] Indicates condition of N (neutral) position from IPDM E/R on CAN commu-

nication line.

ENGINE STATE [STOP/START/CRANK/RUN] ×Indicates condition of engine state from ECM on CAN communication line.

VEH SPEED 1 [mph/km/h] ×Indicates condition of vehicle speed signal received from ABS on CAN

communication line.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3479 of 4801

PG

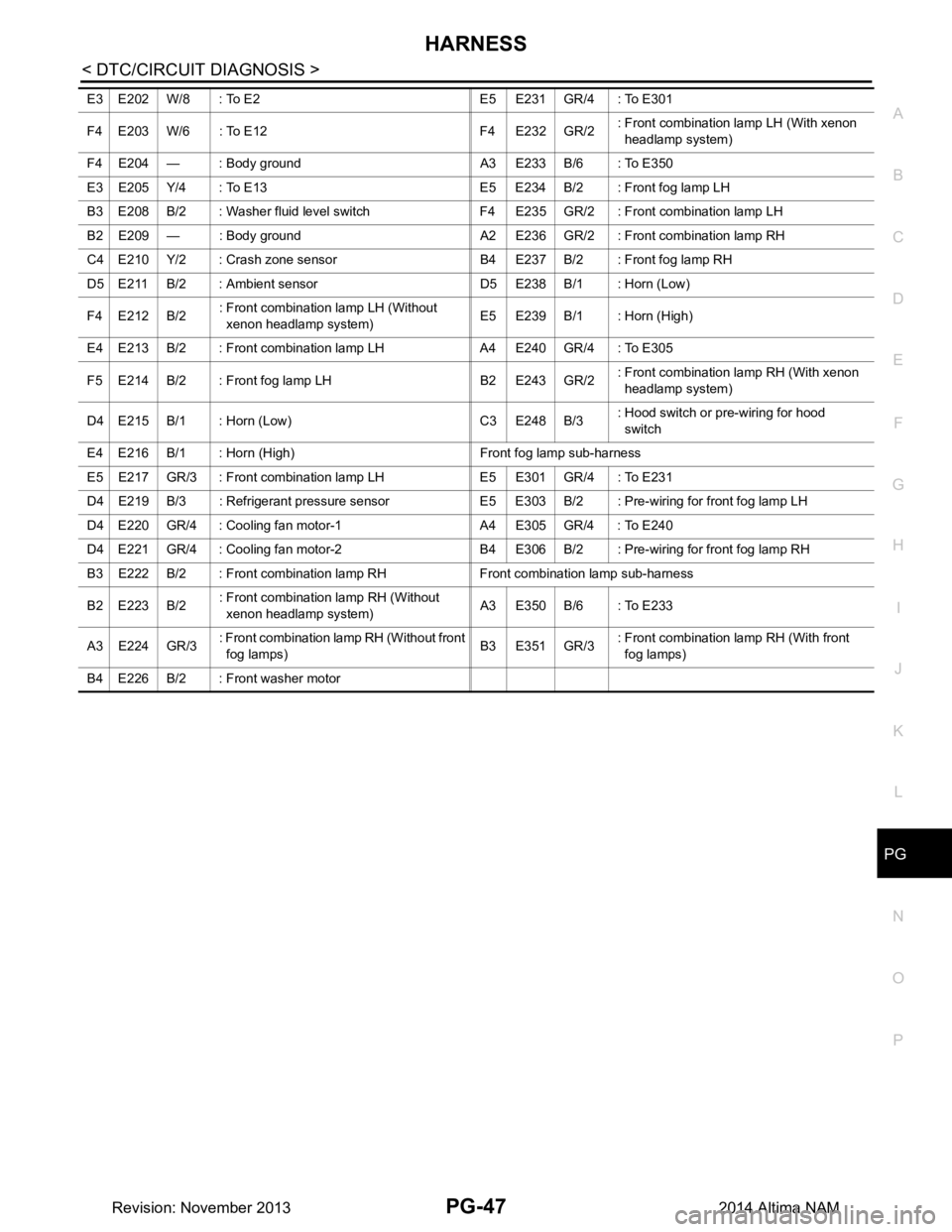

HARNESSPG-47

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B

A

O P

N

E3 E202 W/8 : To E2 E5 E231 GR/4 : To E301

F4 E203 W/6 : To E12 F4 E232 GR/2 : Front combination lamp LH (With xenon

headlamp system)

F4 E204 — : Body ground A3 E233 B/6 : To E350

E3 E205 Y/4 : To E13 E5 E234 B/2 : Front fog lamp LH

B3 E208 B/2 : Washer fluid level switch F4 E235 GR/2 : Front combination lamp LH

B2 E209 — : Body ground A2 E236 GR/2 : Front combination lamp RH

C4 E210 Y/2 : Crash zone sensor B4 E237 B/2 : Front fog lamp RH

D5 E211 B/2 : Ambient sensor D5 E238 B/1 : Horn (Low)

F4 E212 B/2 : Front combination lamp LH (Without

xenon headlamp system) E5 E239 B/1 : Horn (High)

E4 E213 B/2 : Front combination lamp LH A4 E240 GR/4 : To E305

F5 E214 B/2 : Front fog lamp LH B2 E243 GR/2 : Front combination lamp RH (With xenon

headlamp system)

D4 E215 B/1 : Horn (Low) C3 E248 B/3 : Hood switch or pre-wiring for hood

switch

E4 E216 B/1 : Horn (High) Front fog lamp sub-harness

E5 E217 GR/3 : Front combination lamp LH E5 E301 GR/4 : To E231

D4 E219 B/3 : Refrigerant pressure sensor E5 E303 B/2 : Pre-wiring for front fog lamp LH

D4 E220 GR/4 : Cooling fan motor-1 A4 E305 GR/4 : To E240

D4 E221 GR/4 : Cooling fan motor-2 B4 E306 B/2 : Pre-wiring for front fog lamp RH

B3 E222 B/2 : Front combination lamp RH Front combination lamp sub-harness

B2 E223 B/2 : Front combination lamp RH (Without

xenon headlamp system) A3 E350 B/6 : To E233

A 3 E 2 2 4 G R / 3 : Front combination lamp RH (Without front

fog lamps) B3 E351 GR/3

: Front combination lamp RH (With front

fog lamps)

B4 E226 B/2 : Front washer motor

Revision: November 20132014 Altima NAM

Page 3481 of 4801

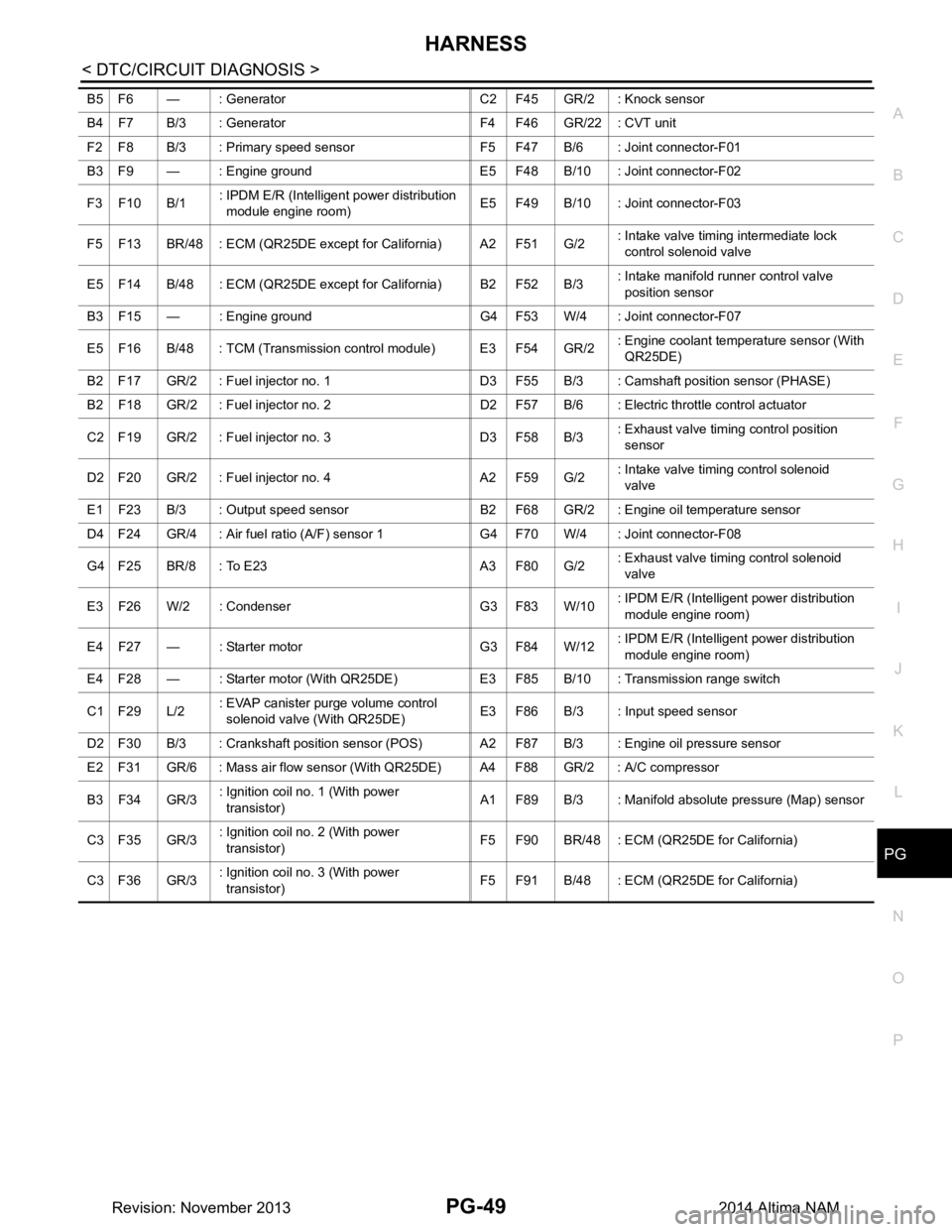

PG

HARNESSPG-49

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B

A

O P

N

B5 F6 — : Generator C2 F45 GR/2 : Knock sensor

B4 F7 B/3 : Generator F4 F46 GR/22 : CVT unit

F2 F8 B/3 : Primary speed sensor F5 F47 B/6 : Joint connector-F01

B3 F9 — : Engine ground E5 F48 B/10 : Joint connector-F02

F 3 F 1 0 B / 1 : IPDM E/R (Intelligent power distribution

module engine room) E5 F49 B/10 : Joint connector-F03

F 5 F 1 3 B R / 4 8 : E C M ( Q R 2 5 D E e x c e p t f o r C a l i f o r n i a ) A 2 F 5 1 G / 2 : Intake valve timing intermediate lock

control solenoid valve

E5 F14 B/48 : ECM (QR25DE except for California) B2 F52 B/3 : Intake manifold runner control valve

position sensor

B3 F15 — : Engine ground G4 F53 W/4 : Joint connector-F07

E5 F16 B/48 : TCM (Transmission control module) E3 F54 GR/2 : Engine coolant temperature sensor (With

QR25DE)

B2 F17 GR/2 : Fuel injector no. 1 D3 F55 B/3 : Camshaft position sensor (PHASE)

B2 F18 GR/2 : Fuel injector no. 2 D2 F57 B/6 : Electric throttle control actuator

C 2 F 1 9 G R / 2 : F u e l i n j e c t o r n o . 3 D 3 F 5 8 B / 3 : Exhaust valve timing control position

sensor

D 2 F 2 0 G R / 2 : F u e l i n j e c t o r n o . 4 A 2 F 5 9 G / 2 : Intake valve timing control solenoid

valve

E1 F23 B/3 : Output speed sensor B2 F68 GR/2 : Engine oil temperature sensor

D4 F24 GR/4 : Air fuel ratio (A/F) sensor 1 G4 F70 W/4 : Joint connector-F08

G 4 F 2 5 B R / 8 : To E 2 3 A 3 F 8 0 G / 2 : Exhaust valve timing control solenoid

valve

E 3 F 2 6 W / 2 : C o n d e n s e r G 3 F 8 3 W / 1 0 : IPDM E/R (Intelligent power distribution

module engine room)

E 4 F 2 7 — : S t a r t e r m o t o r G 3 F 8 4 W / 1 2 : IPDM E/R (Intelligent power distribution

module engine room)

E4 F28 — : Starter motor (With QR25DE) E3 F85 B/10 : Transmission range switch

C 1 F 2 9 L / 2 : EVAP canister purge volume control

solenoid valve (With QR25DE) E3 F86 B/3 : Input speed sensor

D2 F30 B/3 : Crankshaft position sensor (POS) A2 F87 B/3 : Engine oil pressure sensor

E2 F31 GR/6 : Mass air flow sensor (With QR25DE) A4 F88 GR/2 : A/C compressor

B 3 F 3 4 G R / 3 : Ignition coil no. 1 (With power

transistor) A1 F89 B/3 : Manifold absolute pressure (Map) sensor

C 3 F 3 5 G R / 3 : Ignition coil no. 2 (With power

transistor) F5 F90 BR/48 : ECM (QR25DE for California)

C 3 F 3 6 G R / 3 : Ignition coil no. 3 (With power

transistor) F5 F91 B/48 : ECM (QR25DE for California)

Revision: November 20132014 Altima NAM

Page 3483 of 4801

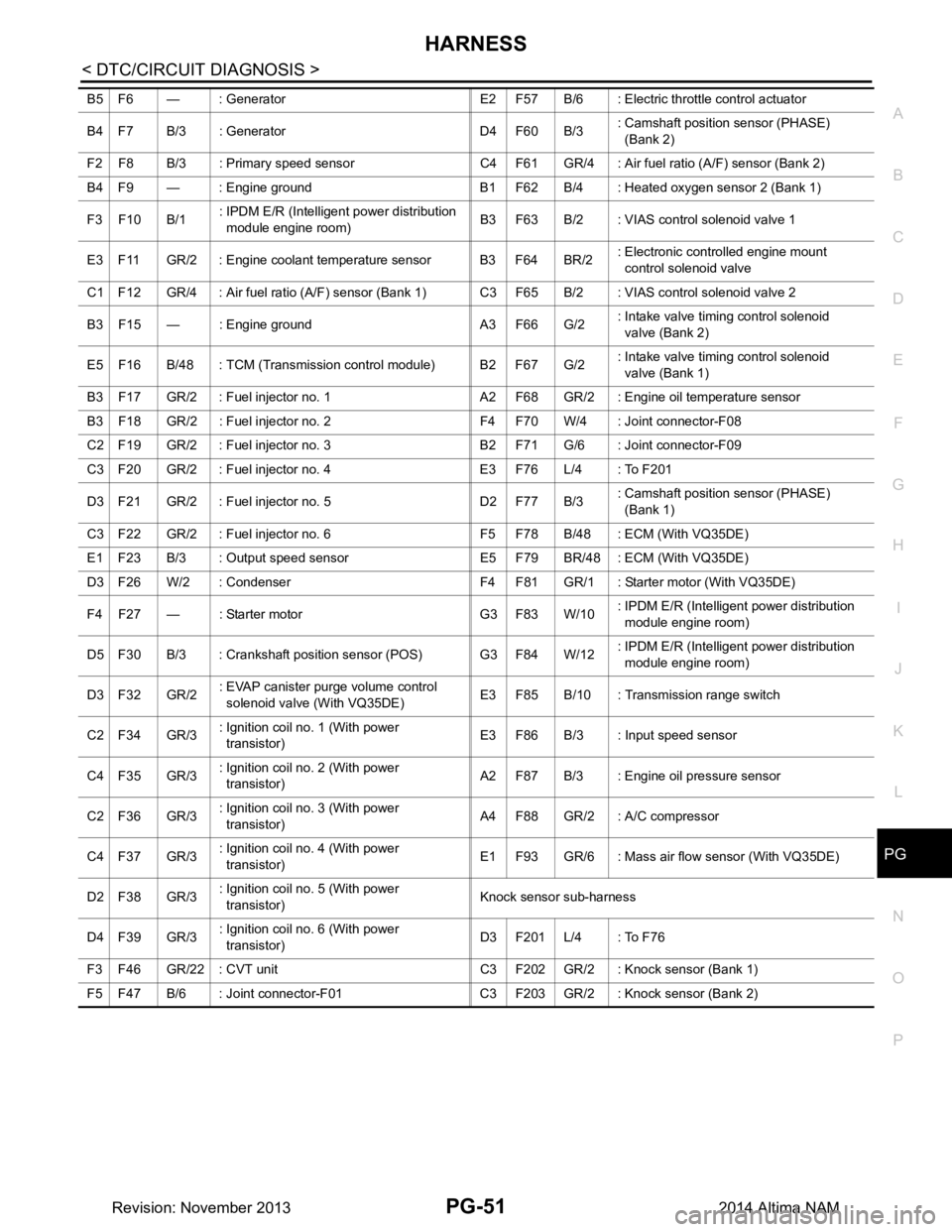

PG

HARNESSPG-51

< DTC/CIRCUIT DIAGNOSIS >

C

D E

F

G H

I

J

K L

B

A

O P

N

B5 F6 — : Generator E2 F57 B/6 : Electric throttle control actuator

B 4 F 7 B / 3 : G e n e r a t o r D 4 F 6 0 B / 3 : Camshaft position sensor (PHASE)

(Bank 2)

F2 F8 B/3 : Primary speed sensor C4 F61 GR/4 : Air fuel ratio (A/F) sensor (Bank 2)

B4 F9 — : Engine ground B1 F62 B/4 : Heated oxygen sensor 2 (Bank 1)

F 3 F 1 0 B / 1 : IPDM E/R (Intelligent power distribution

module engine room) B3 F63 B/2 : VIAS

control solenoid valve 1

E3 F11 GR/2 : Engine coolant temperature sensor B3 F64 BR/2 : Electronic controlled engine mount

control solenoid valve

C1 F12 GR/4 : Air fuel ratio (A/F) sensor (Ban k 1) C3 F65 B/2 : VIAS control solenoid valve 2

B 3 F 1 5 — : E n g i n e g r o u n d A 3 F 6 6 G / 2 : Intake valve timing control solenoid

valve (Bank 2)

E5 F16 B/48 : TCM (Transmission control module) B2 F67 G/2 : Intake valve timing control solenoid

valve (Bank 1)

B3 F17 GR/2 : Fuel injector no. 1 A2 F68 GR/2 : Engine oil temperature sensor

B3 F18 GR/2 : Fuel injector no. 2 F4 F70 W/4 : Joint connector-F08

C2 F19 GR/2 : Fuel injector no. 3 B2 F71 G/6 : Joint connector-F09

C3 F20 GR/2 : Fuel injector no. 4 E3 F76 L/4 : To F201

D 3 F 2 1 G R / 2 : F u e l i n j e c t o r n o . 5 D 2 F 7 7 B / 3 : Camshaft position sensor (PHASE)

(Bank 1)

C3 F22 GR/2 : Fuel injector no. 6 F5 F78 B/48 : ECM (With VQ35DE)

E1 F23 B/3 : Output speed sensor E5 F79 BR/48 : ECM (With VQ35DE)

D3 F26 W/2 : Condenser F4 F81 GR/1 : Starter motor (With VQ35DE)

F 4 F 2 7 — : S t a r t e r m o t o r G 3 F 8 3 W / 1 0 : IPDM E/R (Intelligent power distribution

module engine room)

D5 F30 B/3 : Crankshaft position sensor (POS) G3 F84 W/12 : IPDM E/R (Intelligent power distribution

module engine room)

D 3 F 3 2 G R / 2 : EVAP canister purge volume control

solenoid valve (With VQ35DE) E3 F85 B/10 : Transmission range switch

C 2 F 3 4 G R / 3 : Ignition coil no. 1 (With power

transistor) E3 F86 B/3 : Input speed sensor

C 4 F 3 5 G R / 3 : Ignition coil no. 2 (With power

transistor) A2 F87 B/3 : Engine oil pressure sensor

C 2 F 3 6 G R / 3 : Ignition coil no. 3 (With power

transistor) A 4 F 8 8 G R / 2 : A / C c o m p r e s s o r

C 4 F 3 7 G R / 3 : Ignition coil no. 4 (With power

transistor) E1 F93 GR/6 : Mass air flow sensor (With VQ35DE)

D 2 F 3 8 G R / 3 : Ignition coil no. 5 (With power

transistor) Knock sensor sub-harness

D 4 F 3 9 G R / 3 : Ignition coil no. 6 (With power

transistor) D 3 F 2 0 1 L / 4 : T o F 7 6

F3 F46 GR/22 : CVT unit C3 F202 GR/2 : Knock sensor (Bank 1)

F5 F47 B/6 : Joint connector-F01 C3 F203 GR/2 : Knock sensor (Bank 2)

Revision: November 20132014 Altima NAM

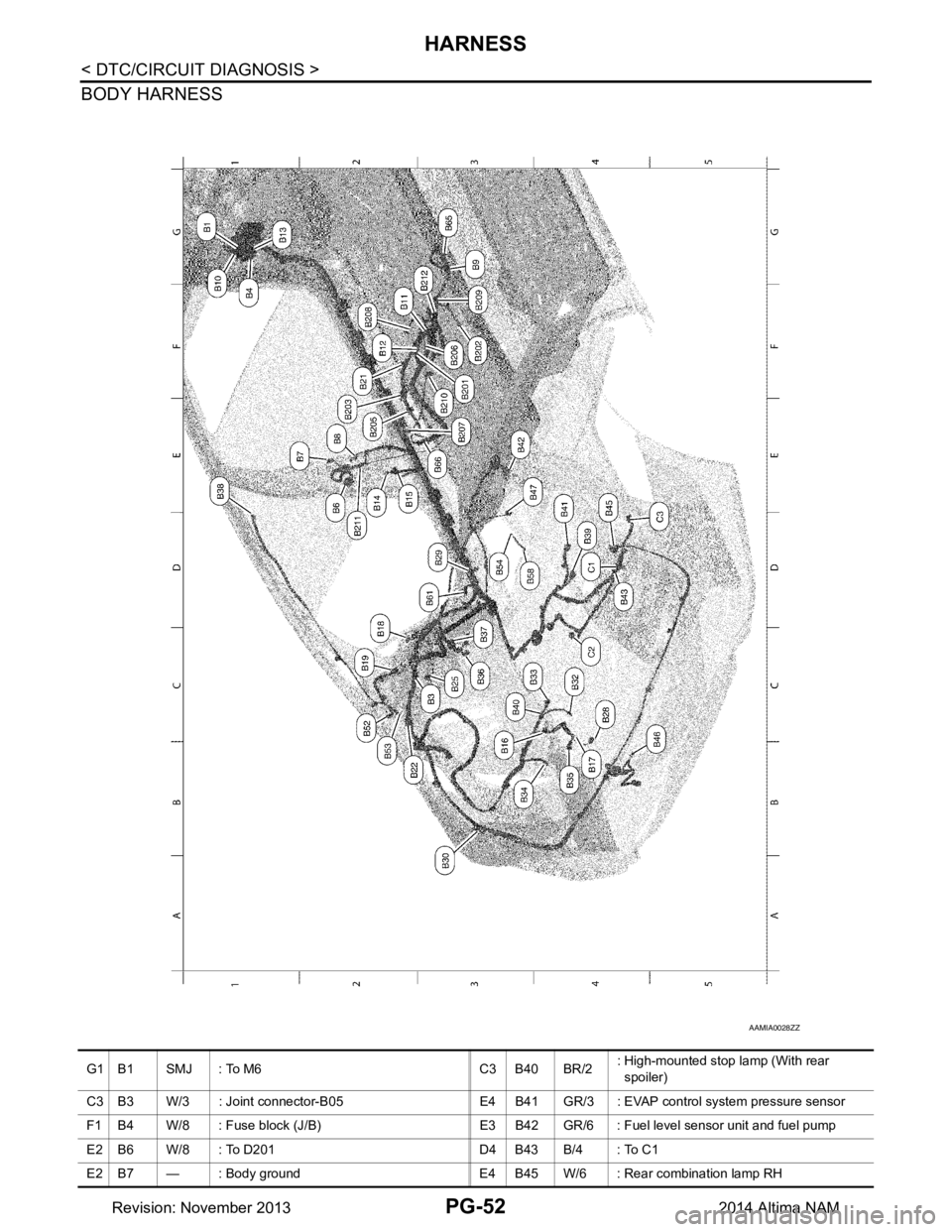

Page 3484 of 4801

PG-52

< DTC/CIRCUIT DIAGNOSIS >

HARNESS

BODY HARNESS

AAMIA0028ZZ

G1 B1 SMJ : To M6 C3 B40 BR/2: High-mounted stop lamp (With rear

spoiler)

C3 B3 W/3 : Joint connector-B05 E4 B41 GR/3 : EVAP control system pressure sensor

F1 B4 W/8 : Fuse block (J/B) E3 B42 GR/6 : Fuel level sensor unit and fuel pump

E2 B6 W/8 : To D201 D4 B43 B/4 : To C1

E2 B7 — : Body ground E4 B45 W/6 : Rear combination lamp RH

Revision: November 20132014 Altima NAM

Page 3521 of 4801

![NISSAN TEANA 2014 Service Manual

PWC-14

< SYSTEM DESCRIPTION >[LH FRONT ONLY ANTI-PINCH]

DIAGNOSIS SYSTEM (BCM)

RETAINED PWR

RETAINED PWR : CONSULT Function (BCM - RETAINED PWR)INFOID:0000000009955264

CAUTION:

After disconnecting t NISSAN TEANA 2014 Service Manual

PWC-14

< SYSTEM DESCRIPTION >[LH FRONT ONLY ANTI-PINCH]

DIAGNOSIS SYSTEM (BCM)

RETAINED PWR

RETAINED PWR : CONSULT Function (BCM - RETAINED PWR)INFOID:0000000009955264

CAUTION:

After disconnecting t](/img/5/57390/w960_57390-3520.png)

PWC-14

< SYSTEM DESCRIPTION >[LH FRONT ONLY ANTI-PINCH]

DIAGNOSIS SYSTEM (BCM)

RETAINED PWR

RETAINED PWR : CONSULT Function (BCM - RETAINED PWR)INFOID:0000000009955264

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and a no-start condition.

DATA MONITOR

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

System Sub System

Direct Diagnostic Mode

Ecu Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN Diag Support Mntr

Monitor Item [Unit] Description

DOOR SW-DR [On/Off] Indicates condition of front door switch LH.

DOOR SW-AS [On/Off] Indicates condition of front door switch RH.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3583 of 4801

![NISSAN TEANA 2014 Service Manual

PWC-76

< SYSTEM DESCRIPTION >[LH & RH FRONT ANTI-PINCH]

DIAGNOSIS SYSTEM (BCM)

RETAINED PWR

RETAINED PWR : CONSULT Function (BCM - RETAINED PWR)INFOID:0000000009955267

CAUTION:

After disconnecting t NISSAN TEANA 2014 Service Manual

PWC-76

< SYSTEM DESCRIPTION >[LH & RH FRONT ANTI-PINCH]

DIAGNOSIS SYSTEM (BCM)

RETAINED PWR

RETAINED PWR : CONSULT Function (BCM - RETAINED PWR)INFOID:0000000009955267

CAUTION:

After disconnecting t](/img/5/57390/w960_57390-3582.png)

PWC-76

< SYSTEM DESCRIPTION >[LH & RH FRONT ANTI-PINCH]

DIAGNOSIS SYSTEM (BCM)

RETAINED PWR

RETAINED PWR : CONSULT Function (BCM - RETAINED PWR)INFOID:0000000009955267

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentially causing a di scharged battery and a no-start condition.

DATA MONITOR

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

System Sub System

Direct Diagnostic Mode

Ecu Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN Diag Support Mntr

Monitor Item [Unit] Description

DOOR SW-DR [On/Off] Indicates condition of front door switch LH.

DOOR SW-AS [On/Off] Indicates condition of front door switch RH.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3846 of 4801

DIAGNOSIS SYSTEM (BCM)SEC-21

< SYSTEM DESCRIPTION >

C

D E

F

G H

I

J

L

M A

B

SEC

N

O P

INTELLIGENT KEY

INTELLIGENT KEY : CONSULT Func tion (BCM - INTELLIGENT KEY)INFOID:0000000009955726

CAUTION:

After disconnecting the CONSULT vehicle interface (VI) from the data link connector, the ignition must

be cycled OFF → ON (for at least 5 seconds) → OFF. If this step is not performed, the BCM may not go

to ”sleep mode”, potentiall y causing a discharged battery and a no-start condition.

SELF DIAGNOSTIC RESULT

Refer to BCS-52, "DTC Index".

DATA MONITOR

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ×

TPMS AIR PRESSURE MONITOR ××××

System Sub System

Direct Diagnostic Mode

Ecu Identification

Self Diagnostic Result

Data Monitor

Active Test

Work support

Configuration

CAN Diag Support Mntr

Monitor Item [Unit] Main Description

REQ SW -DR [On/Off] ×Indicates condition of door request switch LH.

REQ SW -AS [On/Off] ×Indicates condition of door request switch RH.

REQ SW -BD/TR [On/Off] ×Indicates condition of trunk opener request switch.

PUSH SW [On/Off] Indicates condition of push-button ignition switch.

SHFTLCK SLNID PER SPLY [On/Off] ×Indicates condition of power supply to shiftlock solenoid.

BRAKE SW 1 [On/Off] ×Indicates condition of brake switch.

BRAKE SW 2 [On/Off] Indicates condition of brake switch.

DETE/CANCL SW [On/Off] ×Indicates condition of P (park) position.

SFT PN/N SW [On/Off] ×Indicates condition of P (park) or N (neutral) position.

UNLK SEN -DR [On/Off] ×Indicates condition of door unlock sensor.

PUSH SW -IPDM [On/Off] Indicates condition of push-button ignition switch received from IPDM E/R

on CAN communication line.

IGN RLY1 -F/B [On/Off] Indicates condition of ignition relay 1 received from IPDM E/R on CAN

communication line.

DETE SW -IPDM [On/Off] Indicates condition of detent switch received from TCM on CAN communi-

cation line.

SFT PN -IPDM [On/Off] Indicates condition of P (park) or N (neutral) position from TCM on CAN

communication line.

SFT P -MET [On/Off] Indicates condition of P (park) position from TCM on CAN communication

line.

SFT N -MET [On/Off] Indicates condition of N (neutral) position from IPDM E/R on CAN commu-

nication line.

ENGINE STATE [STOP/START/CRANK/RUN] ×Indicates condition of engine state from ECM on CAN communication line.

VEH SPEED 1 [mph/km/h] ×Indicates condition of vehicle speed signal received from ABS on CAN

communication line.

Revision: November 20132014 Altima NAMRevision: November 20132014 Altima NAM

Page 3968 of 4801

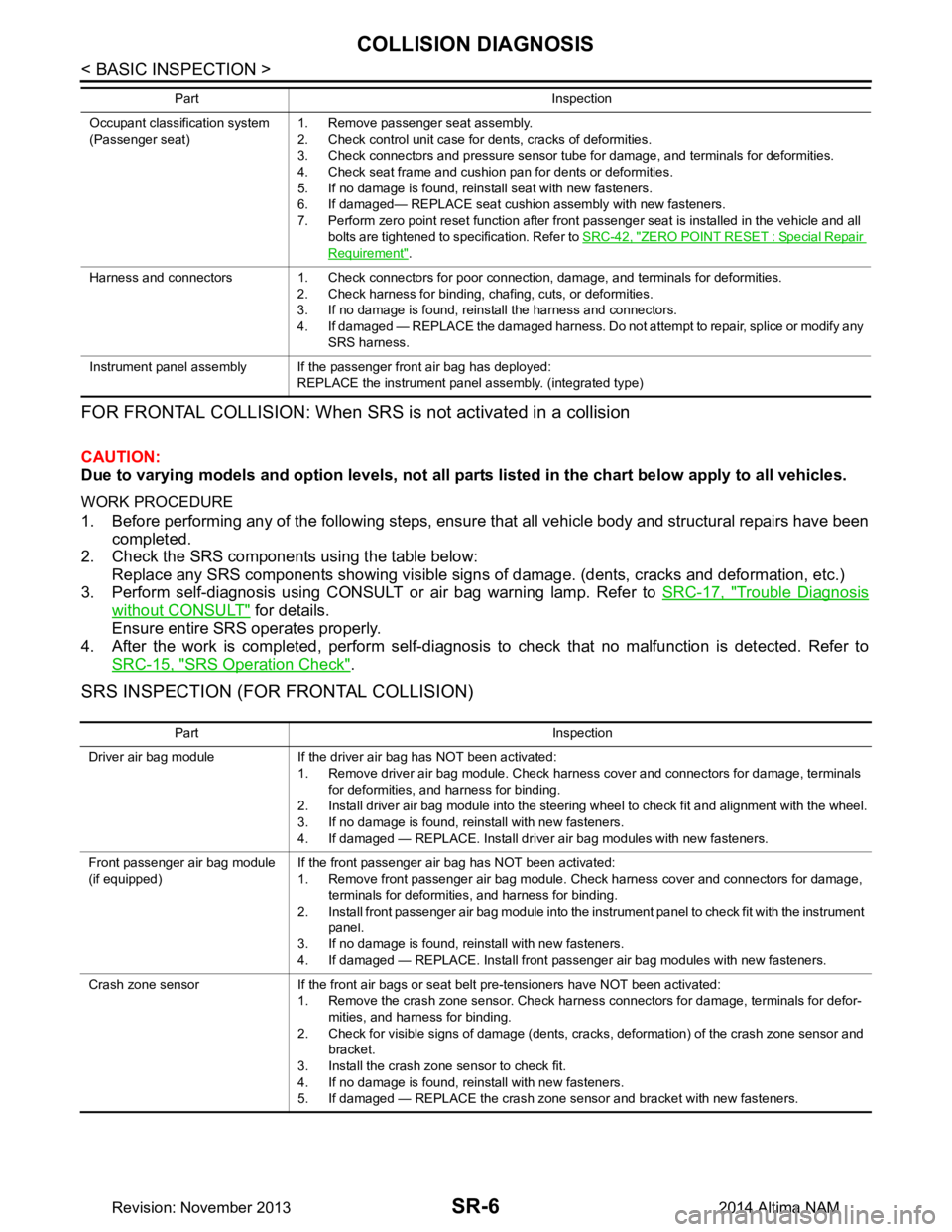

SR-6

< BASIC INSPECTION >

COLLISION DIAGNOSIS

FOR FRONTAL COLLISION: When SRS is not activated in a collision

CAUTION:

Due to varying models and option levels, not all part s listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Check the SRS components using the table below:

Replace any SRS components showing visible signs of damage. (dents, cracks and deformation, etc.)

3. Perform self-diagnosis using CONSULT or air bag warning lamp. Refer to SRC-17, "Trouble Diagnosis

without CONSULT" for details.

Ensure entire SRS operates properly.

4. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-15, "SRS Operation Check"

.

SRS INSPECTION (FOR FRONTAL COLLISION)

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged— REPLACE seat cushion assembly with new fasteners.

7. Perform zero point reset function after front passenger seat is installed in the vehicle and all bolts are tightened to specification. Refer to SRC-42, "ZERO POINT RESET : Special Repair

Requirement".

Harness and connectors 1. Check connectors for poor connection, damage, and terminals for deformities. 2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged — REPLACE the damaged harness. Do not attempt to repair, splice or modify any SRS harness.

Instrument panel assembly If the passenger front air bag has deployed: REPLACE the instrument panel assembly. (integrated type)

Part Inspection

Part Inspection

Driver air bag module If the driver air bag has NOT been activated: 1. Remove driver air bag module. Check harness cover and connectors for damage, terminals for deformities, and harness for binding.

2. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged — REPLACE. Install driver air bag modules with new fasteners.

Front passenger air bag module

(if equipped) If the front passenger air bag has NOT been activated:

1. Remove front passenger air bag module. Check harness cover and connectors for damage, terminals for deformities, and harness for binding.

2. Install front passenger air bag module into the instrument panel to check fit with the instrument panel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged — REPLACE. Install front passenger air bag modules with new fasteners.

Crash zone sensor If the front air bags or seat belt pre-tensioners have NOT been activated: 1. Remove the crash zone sensor. Check harness connectors for damage, terminals for defor-mities, and harness for binding.

2. Check for visible signs of damage (dents, cracks, deformation) of the crash zone sensor and bracket.

3. Install the crash zone sensor to check fit.

4. If no damage is found, reinstall with new fasteners.

5. If damaged — REPLACE the crash zone sensor and bracket with new fasteners.

Revision: November 20132014 Altima NAM

Page 3969 of 4801

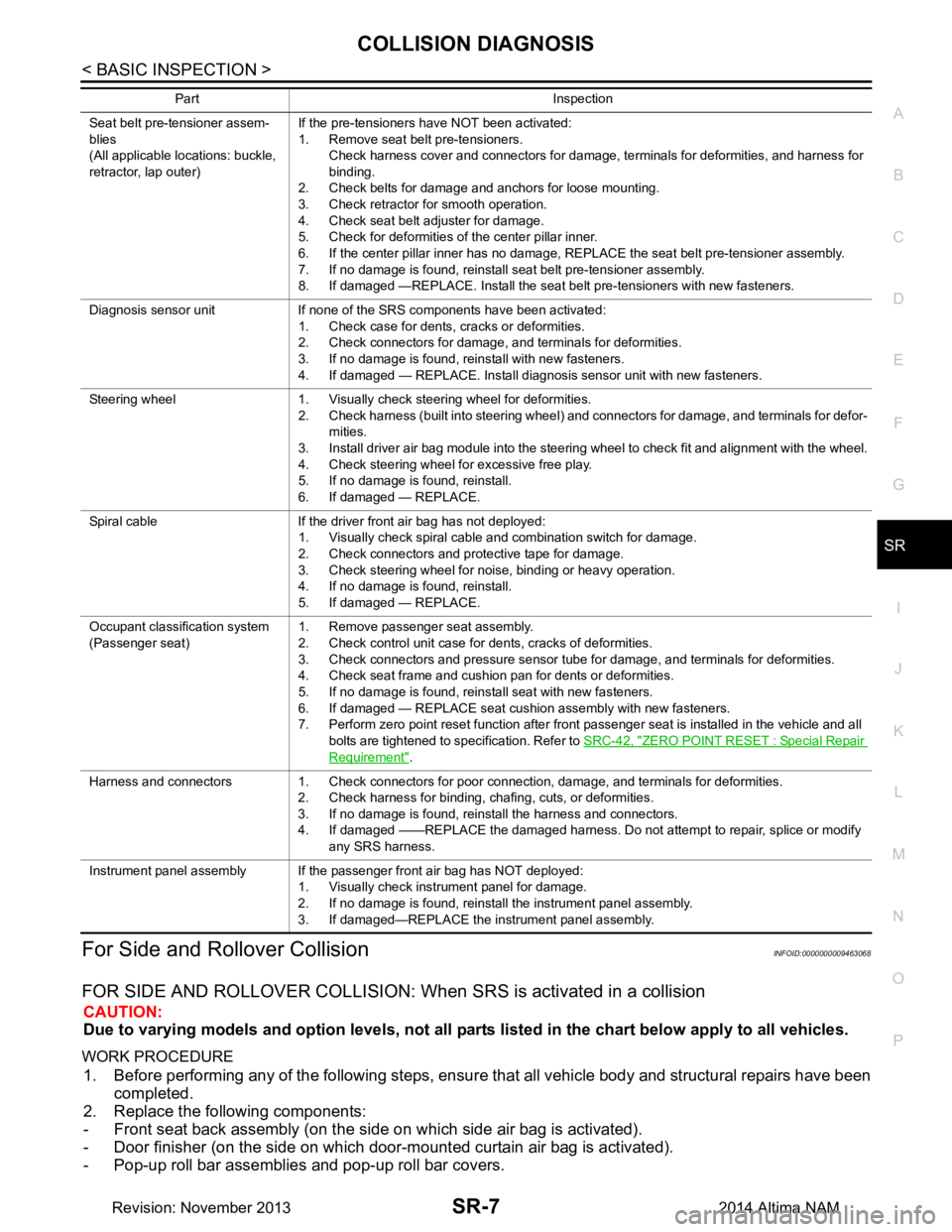

COLLISION DIAGNOSISSR-7

< BASIC INSPECTION >

C

D E

F

G

I

J

K L

M A

B

SR

N

O P

For Side and Rollover CollisionINFOID:0000000009463068

FOR SIDE AND ROLLOVER COLLISION: When SRS is activated in a collision

CAUTION:

Due to varying models and option levels, not all parts listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Replace the following components:

- Front seat back assembly (on the side on which side air bag is activated).

- Door finisher (on the side on which door-mounted curtain air bag is activated).

- Pop-up roll bar assemblies and pop-up roll bar covers.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If the pre-tensioners have NOT been activated:

1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities, and harness for

binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. Check seat belt adjuster for damage.

5. Check for deformities of the center pillar inner.

6. If the center pillar inner has no damage, REPLACE the seat belt pre-tensioner assembly.

7. If no damage is found, reinstall seat belt pre-tensioner assembly.

8. If damaged —REPLACE. Install the seat belt pre-tensioners with new fasteners.

Diagnosis sensor unit If none of the SRS components have been activated: 1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged — REPLACE. Install diagnosis sensor unit with new fasteners.

Steering wheel 1. Visually check steering wheel for deformities. 2. Check harness (built into steering wheel) and connectors for damage, and terminals for defor-mities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged — REPLACE.

Spiral cable If the driver front air bag has not deployed: 1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged — REPLACE.

Occupant classification system

(Passenger seat) 1. Remove passenger seat assembly.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged — REPLACE seat cushion assembly with new fasteners.

7. Perform zero point reset function after front passenger seat is installed in the vehicle and all

bolts are tightened to specification. Refer to SRC-42, "ZERO POINT RESET : Special Repair

Requirement".

Harness and connectors 1. Check connectors for poor connection, damage, and terminals for deformities. 2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged ——REPLACE the damaged harness. Do not attempt to repair, splice or modify any SRS harness.

Instrument panel assembly If the passenger front air bag has NOT deployed: 1. Visually check instrument panel for damage.

2. If no damage is found, reinstall the instrument panel assembly.

3. If damaged—REPLACE the instrument panel assembly.

Part Inspection

Revision: November 20132014 Altima NAM